Page 1

TriPlus RSH

Robotic Sample Handling

Hardware Manual

P/N 31709640 Ninth Edition December 2015

Page 2

© 2015 Thermo Fisher Scientific Inc. All rights reserved.

TriPlus RSH, TRACE 1300, TRACE 1310, TRACE GC Ultra, and FOCUS GC are trademarks of Thermo

Fisher Scientific Inc., and its subsidiaries.

Published by Thermo Fisher Scientific S.p.A., Strada Rivoltana 20090 Rodano-Milan, Italy

Tel: +39 02 95059303; Fax: +39 02 95059388

Thermo Fisher Scientific Inc. provides this document to its customers with a product purchase to use in the

product operation. This document is copyright protected and any reproduction of the whole or any part of this

document is strictly prohibited, except with the written authorization of Thermo Fisher Scientific Inc.

The contents of this document are subject to change without notice. All technical information in this

document is for reference purposes only. System configurations and specifications in this document supersede

all previous information received by the purchaser.

Thermo Fisher Scientific Inc. makes no representations that this document is complete, accurate or errorfree and assumes no responsibility and will not be liable for any errors, omissions, damage or loss that might

result from any use of this document, even if the information in the document is followed properly.

This document is not part of any sales contract between Thermo Fisher Scientific Inc. and a purchaser. This

document shall in no way govern or modify any Terms and Conditions of Sale, which Terms and Conditions of

Sale shall govern all conflicting information between the two documents.

Release history:

First edition, released September 2011 “Original Instructions”

Second edition, October 2011; Third edition, March 2012; Fourth edition, September 2012; Fifth edition,

March 2013; Sixth edition, October 2013; Seventh edition, June 2014; Eighth Edition, February 2015; Ninth

Edition, December 2015

For Research Use Only. Not for use in diagnostic procedures.

Page 3

TriPlus RSH Hardware Manual, PN 31709640, Ninth Edition

Reader’s Survey

fold

fold

Strongly

Agree

Agree Neutral Disagree

Strongly

Disagree

The manual is well organized. 1 2 3 4 5

The manual is clearly written. 1 2 3 4 5

The manual contains all the info rmation I need. 1 2 3 4 5

The instructions are easy to follow. 1 2 3 4 5

The instructions are complete. 1 2 3 4 5

The technical information is easy to understand. 1 2 3 4 5

Examples of operation are clear and useful. 1 2 3 4 5

The figures are helpful. 1 2 3 4 5

I was able to operate the system using this manual. 1 2 3 4 5

If not, please comment below. Attach additional sheets if necessary.

__________________________________________________________ __________________________________________________________________

__________________________________________________________ __________________________________________________________________

__________________________________________________________ __________________________________________________________________

__________________________________________________________ __________________________________________________________________

__________________________________________________________ __________________________________________________________________

__________________________________________________________ __________________________________________________________________

__________________________________________________________ __________________________________________________________________

__________________________________________________________ __________________________________________________________________

__________________________________________________________ __________________________________________________________________

Customer Registration Card

Register now…and receive all the privileges associated with being a Thermo Fisher Scientific product user including customer

support, application reports, and technical reports.

MY ORGANIZATION IS: (Check only one) MY PRIMARY APPLICATION IS: (Check only one)

❏ Commercial (for profit) lab ❏ Analytical

❏ Government lab ❏ Biomedical

❏ Hospital/Clinic ❏ Clinical/Toxicology

❏ Industrial lab ❏ Energy

❏ Research Institute ❏ Environmental

❏ University/College ❏ Food/Agricultural

❏ Veterinary ❏ Forensic/Toxicology

❏ Other______________________ ❏ Pharmaceutical

❏ Research/Education

MY PRIMARY JOB FUNCTION IS: (Check only one)

❏ Administration

❏ Lab management

❏ Operator

❏ Other______________________

❏ Other______________________

Name __________________________________________________Title__________________________________________________________________

Company __________________________________________________ __________________________________________________________________

Address ___________________________________________________ __________________________________________________________________

City/State _________________ ___________________ _____Postal Code____________________ ______________________________________________

Country ___________________________________________________ __________________________________________________________________

Telephone_______________________________________________ Ext. __________________________________________________________________

Serial Number __________________________________ Date purchased __________________________________________________________________

Fold and mail or e-mail to:

Editor, Technical Publications

Thermo Fisher Scientific S.p.A.

Strada Rivoltana km 4

20090 Rodano (MI)

Italy

Editor, Technical Publications

Thermo Fisher Scientific SID GC-GC/MS

2215 Grand Avenue Parkway

Austin TX 78728-3812

Unites States of America

Page 4

Page 5

Declaration

Manufacturer: Thermo Fisher Scientific

Thermo Fisher Scientific is the manufacturer of the instrument described in this manual and, as such, is responsible

for the instrument safety, reliability and performance only if:

•installation

•re-calibration

•changes and repairs

have been carried out by authorized personnel and if:

• the local installation complies with local law regulations

• the instrument is used according to the instructions provided and if its operation is only entrusted to qualified

trained personnel

Thermo Fisher Scientific is not liable for any damages derived from the non-compliance with the aforementioned

recommendations.

Thermo Fisher Scientific S.p.A.

Strada Rivoltana, 20090 Rodano - Milan - Italy — Tel: +39 02 950591 - Fax: +39 02 9505276

Regulatory Compliance

Thermo Fisher Scientific performs complete testing and evaluation of its products to ensure full compliance with

applicable domestic and international regulations.

Thermo Fisher Scientific declares, under sole responsibility, that the product as originally delivered complies with

the requirements of the following applicable European Directives and carries the CE marking accordingly:

• Low Voltage Directive:2006/95/EC

• EMC Directive:2004/108/EC

• Machinery Directive: 2006/42/EC

… and conforms with the following product standards:

Safety

This device complies with:

• IEC61010-1:2010 3rd Edition | IEC/EN 61010-1 3rd Edition

• ANSI/UL 61010-1:2004 2nd Edition | CAN/CSA C22.2 No. 61010-1:2004 2nd Edition.

• EN 61010-2-010:2003 | EN 61010-2-051:2003 | EN 61010-2-081:2001+A1:2003 | EN 61010-2 101:2003

Electromagnetic Compatibility

This device complies with:

• IEC 61326-1:2nd Edition | EN 61326-1:2013 | CISPR 11:5th Edition

• EN 61000-6-2:2005 | IEC 61000-6-2:2nd Edition| IEC 61000-6-3:2nd Edition am1 | EN 61000-6-3:2007 +

A1:2011

• Conducted Emission, Subpart B. FCC part 15, §15.107(a) and §15.109(a)

Laser Class 1

The selected Class 1 Laser for the TriPlus RSH module Barcode Reader complies with the following regulations:

Page 6

• 21 CFR1040.10 and 1040.11 except for deviations pursuant to Laser Notice No. 50, dated July 26, 2001

• EN60825-1:1994 + A1:2002 + A2:2001

• IEC60825-1:1993 + A1:1997 + A2:2001

FCC Compliance Statement

THIS DEVICE COMPLIES WITH PART 15 OF THE FCC RULES. OPERATION IS SUBJECT TO THE

FOLLOWING TWO CONDITIONS: (1) THIS DEVICE MAY NOT CAUSE HARMFUL

INTERFERENCE, AND (2) THIS DEVICE MUST ACCEPT ANY INTERFERENCE RECEIVED,

INCLUDING INTERFERENCE THAT MAY CAUSE UNDESIRED OPERATION.

CAUTION Read and understand the various precautionary notes, signs, and symbols contained

inside this manual pertaining to the safe use and operation of this product before using the device.

Notice on Lifting and Handling of

Thermo Scientific Instruments

For your safety, and in compliance with international regulations, the physical handling of this Thermo Fisher

Scientific instrument requires a team effort to lift and/or move the instrument. This instrument is too heavy and/

or bulky for one person alone to handle safely.

Notice on the Proper Use of

Thermo Scientific Instruments

In compliance with international regulations: Use of this instrument in a manner not specified by Thermo Fisher

Scientific could impair any protection provided by the instrument.

Notice on the Susceptibility

to Electromagnetic Transmissions

Do not use radio frequency transmitters, such as mobile phones, in close proximity to the instrument.

Page 7

WEEE Compliance

This product is required to comply with the European Union’s Waste Electrical & Electronic Equipment (WEEE) Directive

2012/19/EU. It is marked with the following symbol:

Thermo Fisher Scientific has contracted with one or more recycling or disposal companies in each European Union (EU)

Member State, and these companies should dispose of or recycle this product. See www.thermoscientific.com/rohsweee

further information on Thermo Fisher Scientific’s compliance with these Directives and the recyclers in your country.

for

WEEE Konformität

Dieses Produkt muss die EU Waste Electrical & Electronic Equipment (WEEE) Richtlinie 2012/19/EU erfüllen. Das Produkt

ist durch folgendes Symbol gekennzeichnet:

Thermo Fisher Scientific hat Vereinbarungen mit Verwertungs-/Entsorgungsfirmen in allen EU-Mitgliedsstaaten getroffen,

damit dieses Produkt durch diese Firmen wiederverwertet oder entsorgt werden kann. Mehr Information über die Einhaltung

dieser Anweisungen durch Thermo Fisher Scientific, über die Verwerter, und weitere Hinweise, die nützlich sind, um die

Produkte zu identifizieren, die unter diese RoHS Anweisung fallen, finden sie unter www.thermoscientific.com/rohsweee

.

Conformité DEEE

Ce produit doit être conforme à la directive européenne (2012/19/EU) des Déchets d'Equipements Electriques et

Electroniques (DEEE). Il est marqué par le symbole suivant:

Thermo Fisher Scientific s'est associé avec une ou plusieurs compagnies de recyclage dans chaque état membre de l’union

européenne et ce produit devrait être collecté ou recyclé par celles-ci. Davantage d'informations sur la conformité de Thermo

Fisher Scientific à ces directives, les recycleurs dans votre pays et les informations sur les produits Thermo Fisher Scientific qui

peuvent aider la détection des substances sujettes à la directive RoHS sont disponibles sur www.thermoscientific.com/rohsweee

.

Page 8

Conformità RAEE

Questo prodotto è marcato con il seguente simbolo in conformità alla direttiva europea 2012/19/EU (RAEE) sui rifiuti di

apparecchiature elettriche ed elettroniche:

Thermo Fisher Scientific si è accordata con una o più società di riciclaggio in ciascun Stato Membro della Unione Europea

(EU), e queste società dovranno smaltire o riciclare questo prodotto. Per maggiori informazioni vedere il sito

www.thermoscientific.com/rohsweee

.

Conformidad RAEE

Este producto es marcado con el siguiente símbolo en conformidad a la Directiva 2012/19/EU de la Unión Europea sobre los

residuos de aparatos eléctricos y electrónicos:

Thermo Fisher Scientific ha contratado una o más empresas de reciclo para tratar residuos en cada Estado Miembro de la

Unión Europea, y estas empresas deberían reciclar o eliminar este producto. Referirse a www.thermoscientific.com/rohsweee

para una mayor información sobre la conformidad de Thermo Fisher Scientific con estas Directivas y para las empresas de

reciclaje en su país.

IMPORTANT

The symbol indicates the product must not be disposed of with the normal household wastes. Correct disposal of

this product prevents any potentially negative impact on the environmental and human health that could arise

from any inappropriate handling of the product itself.

WEEE and RoHS rules, while laid down at European level, are put into national law at national level. When exporting to Europe, it is essential to comply with national law in each relevant country. The EU law simply serves

as a template for national laws, which may differ considerably.

Each EU Member State has own regulations regarding the application of these directives. Please refer to the

regulations in force in your country.

Page 9

C

Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

About Your System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiv

Power Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiv

Contacting Us . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiv

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

Safety Alerts and Important Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Special Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Safety Symbols and Signal Words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Instrument Markings and Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

Safety Information and Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xviii

General Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xviii

Electrical Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

Laser Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

Other Hazards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xxi

Working with Toxic or other Harmful Compounds . . . . . . . . . . . . . . . . . . xxii

Biological Hazards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xxiii

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xxiii

Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xxiv

Chapter 1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operating and Environmental Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Sound Pressure Level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Hardware and Software Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

TriPlus RSH System Software Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 2 Installation of the TriPlus RSH System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Installation Quick Reference Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Unpacking the Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installing the TriPlus RSH Supports on the GC . . . . . . . . . . . . . . . . . . . . . . . . 13

Placing the TriPlus RSH on the Supports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Installation of the TriPlus RSH System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Installing the TriPlus RSH Head. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Thermo Scientific TriPlus RSH Hardware Manual ix

Page 10

Contents

Installing the Handheld Controller and Safety Guard . . . . . . . . . . . . . . . . . . . . 27

Installing the Purge Gas Pressure Regulator. . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Installing the Tool Stations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Installing the Wash Stations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Installing a Tray Holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Installing an Agitator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Installing a Vortexer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Installing a MHE Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Installing a SPME Conditioning Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Installing a Barcode Reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Installing a Liquid Cooled Tray Holder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Installing a Temperature Controlled Drawer . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Installing an OC Injector Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Inserting a LS Syringe into the LS Tool. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Inserting a HS Syringe into the HS Tool. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Installing the SPME Fiber Protector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Inserting a SPME Fiber Holder into the SPME Tool . . . . . . . . . . . . . . . . . . . . 59

Managing an ITEX Syringe and Trap Assemble . . . . . . . . . . . . . . . . . . . . . . . . 61

Connecting the Power Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Combining the TriPlus RSH to Other Devices . . . . . . . . . . . . . . . . . . . . . . . . . 68

Establishing Communication with the Computer . . . . . . . . . . . . . . . . . . . . . . . 74

Chapter 3 TriPlus RSH Defining Object Positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

Definitions of Teaching, Referencing, and Calibration . . . . . . . . . . . . . . . . . . . 82

Slot Positions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Definition of Row and Column . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Definition of Vial or Well Position Pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Definition of Inclination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

TriPlus RSH Modules Teaching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Teaching TR Station Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Teaching ATC Station Position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Teaching Standard Wash Station Position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Teaching Large Volume Wash Station Position. . . . . . . . . . . . . . . . . . . . . . . . . 91

Teaching Solvents Station Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Teaching Fast Wash Station Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Teaching Tray Holder Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Teaching GC Injector Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Teaching Agitator Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Teaching Vortexer Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Teaching MHE Station Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Teaching SPME Conditioning Station Position . . . . . . . . . . . . . . . . . . . . . . . . 97

Teaching a Barcode Reader Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Teaching Liquid Cooled Tray Holder Position . . . . . . . . . . . . . . . . . . . . . . . . . 99

Teaching Temperature Controlled Drawer Position . . . . . . . . . . . . . . . . . . . . 100

TriPlus RSH Tool Referencing and Calibration . . . . . . . . . . . . . . . . . . . . . . . 101

x TriPlus RSH Hardware Manual Thermo Scientific

Page 11

Contents

Modules Teaching Step-by-Step Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Chapter 4 TriPlus RSH Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

The RSH Firmware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Create Diagnostic Backup File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Create Configuration Backup File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Restore Backup File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Update and Downgrade Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Update the RSH Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Downgrade the RSH Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Chapter 5 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .129

Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Preventative Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Working with Hazardous Material and Decontamination . . . . . . . . . . . . . . . . 132

Sampler Removal from the GC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Emptying of the Waste Container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

External Cleaning of the Sampler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Cleaning the interior of the Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Cleaning of the LS/HS Syringe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Cleaning the ITEX Trap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Maintaining a Fast Wash Station. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Maintaining an Agitator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Maintaining a Vortexer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Maintaining a MHE Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Maintaining a SPME Conditioning Station. . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Maintaining a Barcode Reader. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Maintaining a Liquid Cooler Tray Holder. . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Maintaining a Temperature Controlled Drawer . . . . . . . . . . . . . . . . . . . . . . . 137

Maintaining a OC Injector Actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Chapter 6 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .139

General Points Related to TriPlus RSH. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

RSH Firmware Related Points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

LAN Communication Problems using Direct Connection . . . . . . . . . . . . . . . 144

LAN Communication Problems within Corporate Network . . . . . . . . . . . . . . 145

LAN Communication Problems Related to Network Interface Card (NIC) . . 146

Troubleshooting Check for LAN Communication . . . . . . . . . . . . . . . . . . . . . 148

System Status LED at Status Bar or at X-Axis Side Cover . . . . . . . . . . . . . . . . 149

LED Status at Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Manually Removing a Tool from the Head . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Fast Wash Station Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Agitator Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Vortexer Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Thermo Scientific TriPlus RSH Hardware Manual xi

Page 12

Contents

MHE Station Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

SPME Conditioning Station Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . 157

Barcode Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Liquid Cooled Tray Holder Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . 159

Temperature Controlled Drawer Troubleshooting . . . . . . . . . . . . . . . . . . . . . 159

OC Injector Actuator Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

xii TriPlus RSH Hardware Manual Thermo Scientific

Page 13

P

Preface

This manual details informations for installing, defining object, interfacing, maintaining, and

troubleshooting the TriPlus RSH.

This manual is organized as follows:

• Chapter 1, “Specifications,” provides general specifications of the TriPlus RSH.

• Chapter 2, “Installation of the TriPlus RSH System,” provides informations for installing

the TriPlus RSH System.

• Chapter 3, “TriPlus RSH Defining Object Positions,” provides the instructions for

defining the teaching position of he TriPlus RSH modules, the referencing position and

the calibration of the tools. The definition of these terms, and the Row and Column

sample positions, are also explained.

• Chapter 4, “TriPlus RSH Firmware,” provides instructions for creating, copying, and

restoring backup files, and for upgrading and downgrading the Control Software.

• Chapter 5, “Maintenance,” provides guidelines for maintaining the TriPlus RSH and its

modules.

• Chapter 6, “Troubleshooting,” gives a quick overview of possible causes and

recommended actions which can be taken to eliminate an erratic behavior.

Thermo Scientific TriPlus RSH Hardware Manual xiii

Page 14

Preface

About Your System

About Your System

Thermo Fisher Scientific systems operate safely and reliably under carefully controlled

environmental conditions. If the equipment is used in a manner not specified by the

manufacturer, the protections provided by the equipment may be impaired. If you maintain a

system outside the specifications listed in this guide, failures of many types, including personal

injury or death, may occur. The repair of instrument failures caused by operation in a manner

not specified by the manufacturer is specifically excluded from the Standard Warranty and

service contract coverage.

Power Rating

Tr iP l us RSH

• 100/240 Vac +/-10%; 50/60 Hz; 5 A max; 200 VA (400 VA when two Power Modules

are required).

Detailed instrument specifications are in the Product Specification or Product Brochure.

Contacting Us

Thermo Fisher Scientific provides comprehensive technical assistance worldwide and is

dedicated to the quality of our customer relationships and services.

Use http://www.thermoscientific.com address for products information.address for products

information.

Use http://www.gc-gcms-customersupport.com/WebPage/Share/Default.aspx address to

contact your local Thermo Fisher Scientific office or affiliate GC-GC/MS Customer Support.

Related Documentation

In addition to this guide, Thermo Scientific provides the following documents for the TriPlus

RSH.

• TriPlus RSH Safety Guide, PN 31709600

• TriPlus RSH Preinstallation Requirements Guide, PN 31709610

• TriPlus RSH User Guide, PN 31709620

• Tri Pl us R SH Ha rdwar e Ma nu al , PN 31709640

To suggest ways we can improve the documentation, follow this link to complete our

documentation survey.

xiv TriPlus RSH Hardware Manual Thermo Scientific

Page 15

Safety Alerts and Important Information

Make sure you follow the precautionary notices presented in this manual. The safety and

other special notices appear in boxes.

Special Notices

Notices includes the following:

IMPORTANT Highlights information necessary to prevent damage to software, loss of

data, or invalid test results; or might contain information that is critical for optimal

performance of the system.

Note Emphasizes important information about a task.

Tip Helpful information that can make a task easier.

Preface

Safety Alerts and Important Information

Safety Symbols and Signal Words

All safety symbols are followed by WARNING or CAUTION, which indicates the degree of risk

for personal injury, instrument damage, or both. Cautions and warnings are following by a

descriptor, such as BURN HAZARD. A WARNING is intended to prevent improper actions that

could cause personal injury. Whereas, a CAUTION is intended to prevent improper actions

that might cause personal injury, instrument damage, or both. You can find the following

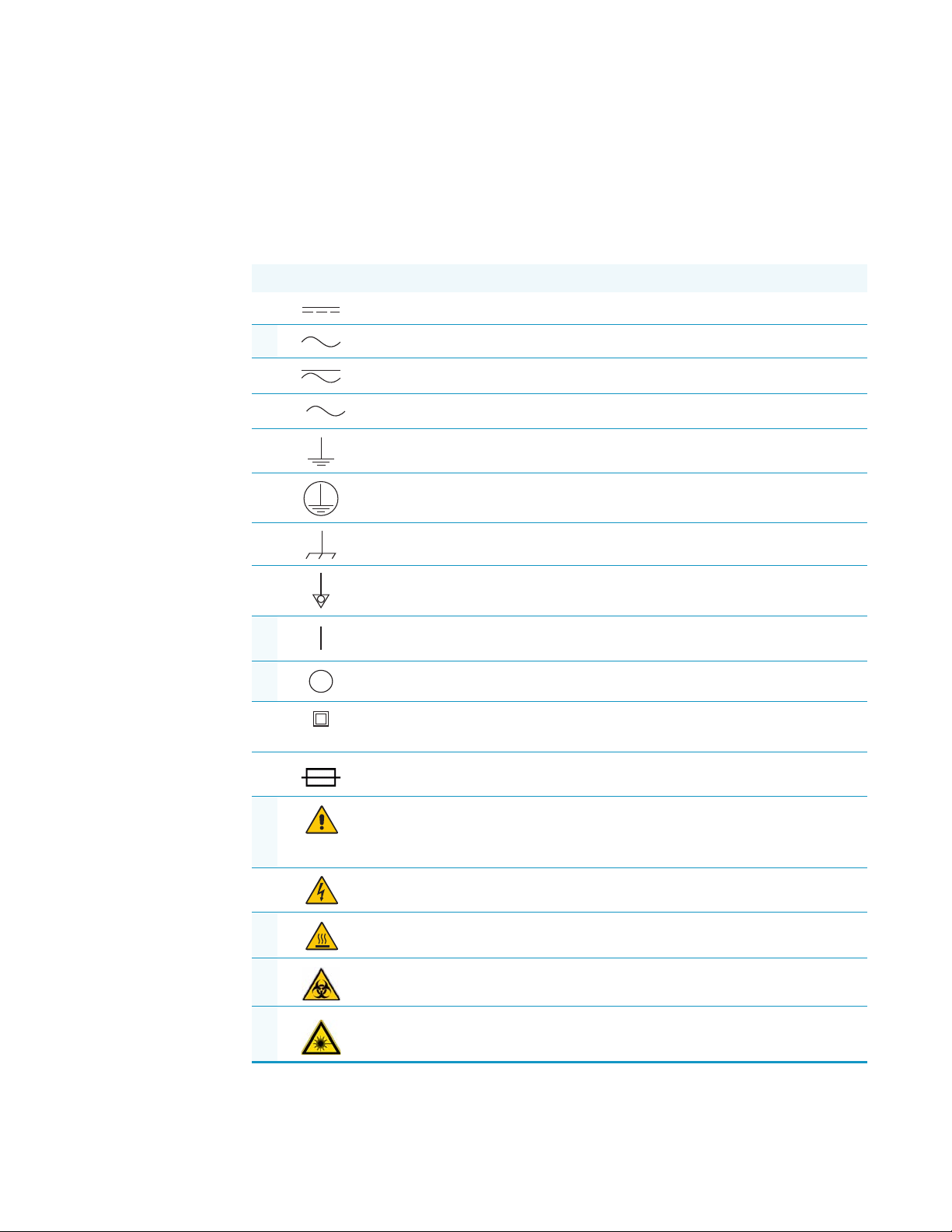

safety symbols on your instrument, or in this guide:

Symbol Descriptor

BIOHAZARD: Indicates that a biohazard will, could, or might occur.

BURN HAZARD: Alerts you to the presence of a hot surface that could or might

cause burn injuries.

ELECTRICAL SHOCK HAZARD: Indicates that an electrical shock could or

might occur.

FIRE HAZARD: Indicates a risk of fire or flammability could or might occur.

EXPLOSION HAZARD. Indicates an explosion hazard. This symbol indicates

this risk could or might cause physical injury.

FLAMMABLE GAS HAZARD. Alerts you to gases that are compressed,

liquefied or dissolved under pressure and can ignite on contact with an

ignition source. This symbol indicates this risk could or might cause physical

injury.

Thermo Scientific TriPlus RSH Hardware Manual xv

Page 16

Preface

Safety Alerts and Important Information

GLOVES REQUIRED: Indicates that you must wear gloves when performing a

task or physical injury could or might occur.

CLOTHING REQUIRED. Indicates that you should wear a work clothing when

performing a task or else physical injury could or might occur.

BOOTS REQUIRED. Indicates that you must wear boots when performing a

task or else physical injury could or might occur.

MATERIAL AND EYE HAZARD. Indicates you must wear eye protection when

performing a task.

HAND AND CHEMICAL HAZARD: Indicates that chemical damage or physical

injury could or might occur.

HARMFUL. Indicates that the presence of harmful material will, could, or

might occur.

INSTRUMENT DAMAGE: Indicates that damage to the instrument or

component might occur. This damage might not be covered under the

standard warranty.

LIFTING HAZARD. Indicates that a physical injury could or might occur if two

or more people do not lift an object.

MATERIAL AND EYE HAZARD: Indicates that eye damage could or might

occur.

READ MANUAL: Alerts you to carefully read your instrument’s

documentation to ensure your safety and the instrument’s operational ability.

Failing to carefully read the documentation could or might put you at risk for a

physical injury.

TOXIC SUBSTANCES HAZARD: Indicates that exposure to a toxic substance

could occur and that exposure could or might cause personal injury or death.

LASER HAZARD. Indicates that exposure to a laser beam will, could, or might

cause personal injury.

RADIOACTIVE HAZARD. Indicates that the presence of radioactive material

could or might occur.

For the prevention of personal injury, this general warning symbol precedes

the WARNING safety alert word and meets the ISO 3864-2 standard. In the

vocabulary of ANSI Z535 signs, this symbol indicates a possible personal

injury hazard exists if the instrument is improperly used or if unsafe actions

occur. This symbol and another appropriate safety symbol alerts you to an

imminent or potential hazard that could cause personal injury.

xvi TriPlus RSH Hardware Manual Thermo Scientific

Page 17

Instrument Markings and Symbols

3

Ta b le 1 explains the symbols used on Thermo Fisher Scientific instruments. Only a few of

them are used on the TriPlus RSH. See the asterisk.

Table 1 . Instrument Marking and Symbols (Sheet 1 of 2)

Symbol Description

Direct Current

* Alternating Current

Both direct and alternating current

Three-phase alternating current

Earth (ground) terminal

Protective conductor terminal

Preface

Instrument Markings and Symbols

Frame or chassis terminal

Equipotentiality

* On (Supply)

* Off (Supply)

Equipment protected throughout by DOUBLE INSULATION or

REINFORCED INSULATION (Equivalent to Class II of IEC 536)

Fuse

* Instruction manual symbol affixed to product. Indicates that the you must

refer to the manual for specific WARNING or CAUTION information to

avoid personal injury or damage to the product.

Caution, risk of electric shock

* Caution, hot surface

* Caution, biohazard

* Caution, Laser beam

Thermo Scientific TriPlus RSH Hardware Manual xvii

Page 18

Preface

Safety Information and Warnings

Table 1 . Instrument Marking and Symbols (Sheet 2 of 2)

Symbol Description

* Symbol in compliance to the Directive 2012/19/EU on Waste Electrical

and Electronic Equipment (WEEE) placed on the European market after

August, 13, 2005.

Safety Information and Warnings

This safety guide raises awareness of potential safety issues and general points for

consideration for Thermo Fisher Scientific representatives during installation, and repair of

the TriPlus RSH, or parts of it (following the life cycle principle), as well as for the end user

TriPlus RSH in the lab during the learning phase, and in routine work.

IMPORTANT Read this section first before operating the TriPlus RSH.

General Considerations

• Before a unit is put to use, consult the TriPlus RSH User Guide and related documents

under all circumstances.

• Changes or modifications to this unit not expressly approved by the party responsible for

compliance, could void your’s authority to operate the equipment.

• Be aware that if the equipment is used in a manner not specified by the manufacturer, the

protective and safety features of the equipment might be impaired.

• The repair of instrument failures caused by operation in a manner not specified by the

manufacturer is expressly excluded from the standard warranty and service contract

coverage.

• When for technical reasons it is necessary to work on instrument parts which might

involve a potential hazard (moving parts, components under voltage, and so on.) contact

the Thermo Fisher Scientific authorized representative. In general, this type of situation

arises when access to the parts is only possible using a tool. When you perform a

maintenance operation, you must have received proper training to carry out that specific

task.

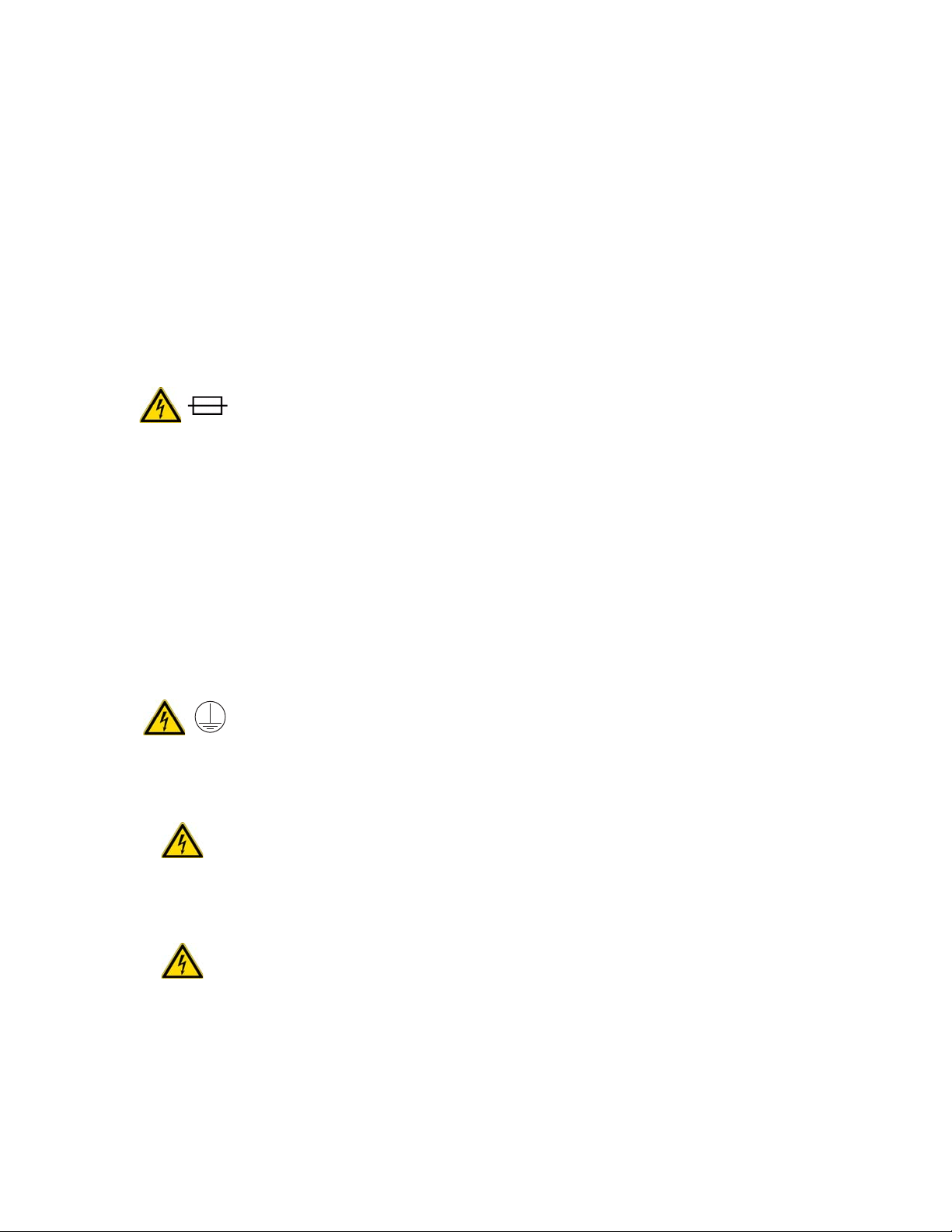

Electrical Hazards

Every analytical instrument has specific hazards. Be sure to read and comply with the

following pre-cautions. They ensure the safe and long-term use of your TriPlus RSH.

xviii TriPlus RSH Hardware Manual Thermo Scientific

Page 19

Preface

Safety Information and Warnings

The installation over-voltage category is Level II. The Level II category pertains to equipment

receiving its electrical power from the local level, such as an electrical wall outlet.

Connect the TriPlus RSH only to instruments complying with IEC 61010 safety regulations.

The power line and the connections between the TriPlus RSH and other instruments, used in

the configuration setup of the total analytical system, must maintain good electrical

grounding. Poor grounding represents a danger for the operator, and might seriously affect the

performance of the instrument.

Do not connect the TriPlus RSH to power lines that supply devices of a heavy duty nature,

such as motors, refrigerators and other devices that can generate electrical disturbances.

Use only fuses of the type and current rating specified. Do not use repaired fuses, and do not

short-circuit the fuse holder. The supplied power cord must be inserted into a power outlet

with a protective earth (ground) contact. When using an extension cord, make sure that the

cord also has an earth contact.

If the supplied power cord does not fit the local electrical socket and a replacement or adapter

has to be purchased locally, make sure that only a certified power cord is used. Any power cord

used must be certified by the appropriate local authorities.

Pay attention not to leave any cable connecting the TriPlus RSH and the chromatographic

system, or the power cord close to heated zone, such as the injector or detector heating blocks,

or the GC hot air vents.

Always replace any cable showing signs of damage with another one provided by the

manufacturer. Safety regulations must be respected.

Do not change the external or internal grounding connections. Tampering with or

disconnecting these connections could endanger you and damage the TriPlus RSH. The

instrument is properly grounded in accordance with these regulations when shipped. To

ensure safe operation, you do not must make any changes to the electrical connections or the

instrument's chassis.

Do not turn the instrument on if you suspect that it has incurred any type of electrical

damage. Instead, disconnect the power cord and contact a Thermo Fisher Scientific

representative for a product evaluation. Do not attempt to use the instrument until it has been

evaluated. Electrical damage might have occurred if the TriPlus RSH shows visible signs of

damage, exposure to any liquids or has been transported under severe stress.

Damage can also result if the instrument is stored for prolonged periods under unfavorable

conditions: for example, subjected to heat, moisture, and so on. Ensure that the power

supply/controller unit is always placed in a clean and dry position. Avoid any liquid spills in

the vicinity.

Thermo Scientific TriPlus RSH Hardware Manual xix

Page 20

Preface

Safety Information and Warnings

Before attempting any type of maintenance work, always disconnect the power cords from the

power supply(ies) if optional devices are installed. Capacitors inside the instrument might still

be charged also if the instrument is turned off.

To avoid damaging electrical parts, do not disconnect an electrical assembly while power is

applied to the TriPlus RSH. After the power is turned off, wait approximately 30 seconds

before you disconnect an assembly.

The instrument includes a number of integrated circuits. These circuits might be damaged if

exposed to excessive line voltage fluctuations, power surges or electrostatic charges, or both.

Never try to repair or replace any components of the instrument without the assistance of a

Thermo Fisher Scientific representative. There are no operator-serviceable or replaceable parts

inside the power supply(ies) or in the TriPlus RSH. If a power supply is not functioning,

contact a Thermo Fisher Scientific representative.

The power supplies for the TriPlus RSH, the Temperature Controlled Drawer have the

symbols I/O on the label for the power switch to indicate ON/OFF. If a Temperature

Controlled Drawer is installed in combination with a TriPlus RSH, a second power supply is

active in the complete system. Turning OFF the two power supplies, or pulling the two power

cords in an emergency, stop the entire TriPlus RSH.

It is important that the power supply(ies) is in a location where the power ON/OFF switch is

accessible and easy to operate, and where it is possible to unplug the AC power cord from the

power supply/wall outlet in case of emergency.

Laser Safety Information

Safety Warning for Laser Class 1 Product.

WARNING The installed Laser device is a Class 1 Laser Product.

Class 1 Laser devices are not considered to be hazardous when used for their intended

purpose. The following statement is required to comply with US and international

regulations.

CAUTION Use of controls, adjustments or performance of procedures other than those

specified herein might result in hazardous laser light exposures.

The selected Class 1 Laser for the TriPlus RSH module Barcode Reader complies with the

following regulations:

• 21 CFR1040.10 and 1040.11 except for deviations pursuant to Laser Notice No. 50,

dated July 26, 2001

xx TriPlus RSH Hardware Manual Thermo Scientific

Page 21

Other Hazards

Preface

Safety Information and Warnings

• EN60825-1:1994 + A1:2002 + A2:2001

• IEC60825-1:1993 + A1:1997 + A2:2001

The software contains a built-in safety time limit such that the laser scanning mechanism

cannot be operated in AIM mode for more than 5 continuous seconds.

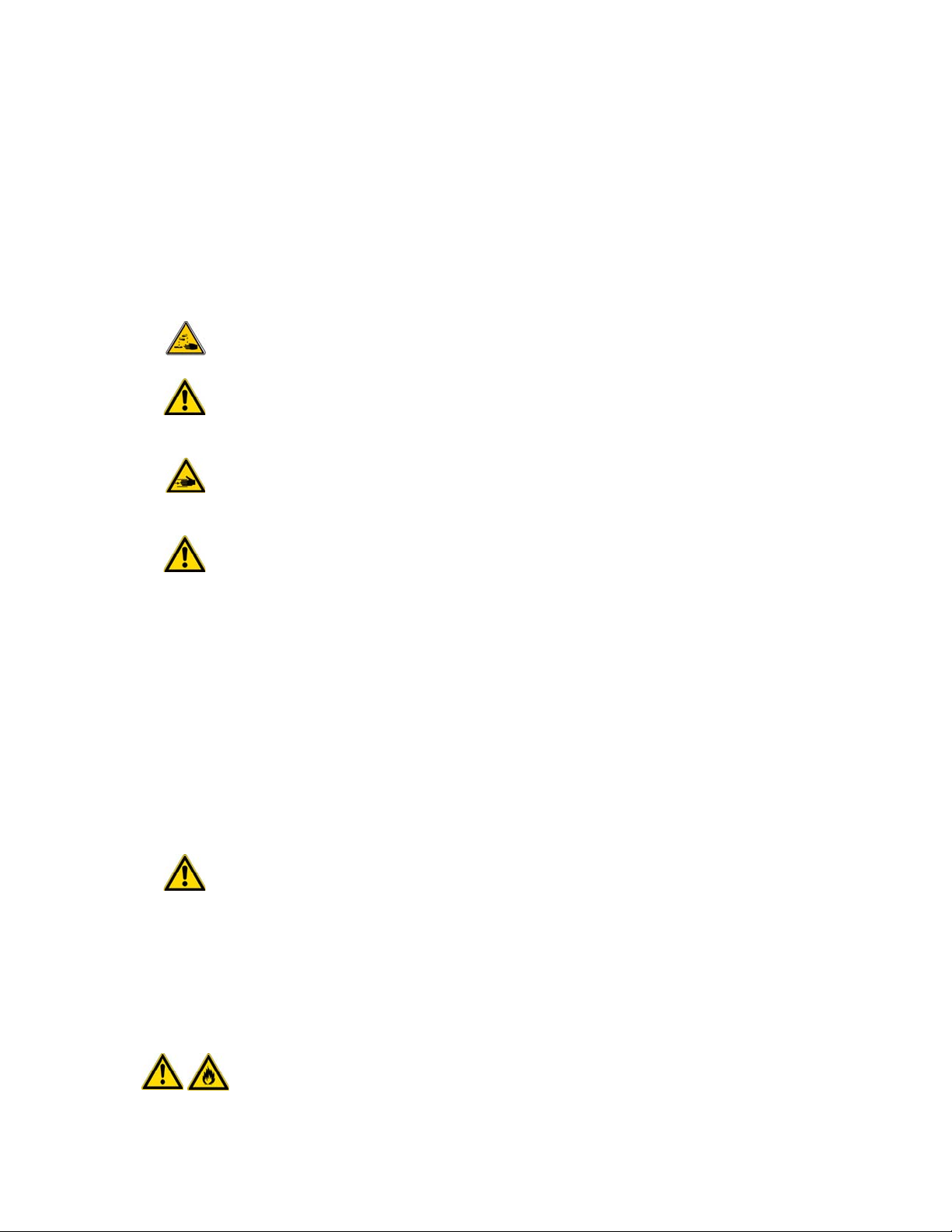

To avoid injury and possible infection through contamination during TriPlus RSH operation,

keep your hands away from the syringe.

Do not operate the TriPlus RSH without the safety guard. The safety guard must be installed

for safe operation. Do not place any objects inside the area of the safety guard. Keep away

from the area around the safety guard during operation of the TriPlus RSH.

Danger of crushing to fingers and hands. To avoid injury keep your hands away from moving

parts during operation. Turn off the power to the TriPlus RSH if you must reach inside a

mechanically powered system with moving parts.

To avoid injury, observe safe laboratory practice when handling solvents, changing tubing, or

operating the TriPlus RSH. Know the physical and chemical properties of the solvents you

use. See the MSDS (Material Safety Data Sheets) from the manufacturer of the solvents being

used.

When using the TriPlus RSH, follow the generally accepted procedures for quality control

and method development.

When using the TriPlus RSH in the field of chromatographic analysis, if a change is observed

in the retention of a particular compound, in the resolution between two compounds, or in

the peak shape, immediately determine the reasons for the changes. Do not rely on the

separation results until you determine the cause of a change.

Do not operate on the instrument components that form part of the work area of the TriPlus

RSH when it is in motion.

Use caution when working with any polymer tubing under pressure:

• Always wear eye protection when near pressurized polymer tubing.

• Do not use polymer tubing that has been severely stressed or kinked.

• Do not use polymer tubing, in particular no PEEK or Tefzel tubing when using

tetrahydrofuran (THF), dimethylsulfoxide (DMSO), chlorinated organic solvents,

concentrated mineral acids such as nitric, phosphoric or sulfuric acids, or any related

compounds.

Do not use vials without a sealing cap, or microtiter or deepwell plates without a plate seal.

Vapor phase from organic solvents can be hazardous and flammable. Acidic vapor phase can

cause corrosion to critical mechanical parts.

Thermo Scientific TriPlus RSH Hardware Manual xxi

Page 22

Preface

Safety Information and Warnings

When sample vials have to undergo heating and agitation, it is important to consider the glass

quality. Use high quality glass only. Remember that depending on the application conditions,

high pressure can build up in the vial. Whenever a temperature greater than 60 °C is applied,

consider the vapor pressure of the solvent used to ensure that no excessive pressure builds up.

This is important when using a temperature above 100°C and especially at the maximum

temperature of 200 °C. Be aware that solid materials can also contain volatile compounds

such as water (humidity) which could cause build-up of excess vapor pressure.

Do not reuse headspace vials. During the process of washing the vial, micro-cracks can form

which will weaken the glass wall and increase the chances of the vial breaking.

In case of a single fault situation where the temperature control of the Agitator fails, there is

the potential danger that the device will heat up in an uncontrolled manner until it reaches

the cut-off temperature of the over temperature fuse, in this case, 240 °C. Based on this single

fault scenario, when working with flammable solvents, ensure that the solvent used has a flash

point which is 25 °C higher than the maximum potential temperature (240 °C) of the

Agitator.

When filling-up a standard reservoir or replacing a solvent such as a washing solvent, remove

the solvent reservoir bottle from the system to avoid a possible spill over the instrument.

Depending on the physical, chemical or hazardous properties of the solvent, use the

appropriate protective measures for handling.

Working with Toxic or other Harmful Compounds

WARNING Before using hazardous substances (toxic, harmful, and so on), please read the

hazard indications and information reported in the applicable Material Safety Data Sheet

(MSDS). Use personal protective equipment according to the safety requirements.

Before using dangerous substances (toxic, harmful, and so on) read the hazard indications and

information reported in the Material Safety Data Sheet (MSDS) supplied by the

manufacturer, referring to the relevant CAS (Chemical Abstract Service) number. The TriPlus

RSH requires the use of several chemical products with different hazard characteristics, which

are present in vials and syringes. Before using these substances or replacing the syringe, please

read the hazard indications and information reported in the MSDS supplied by the

manufacturer referring to the relevant CAS number.

When preparing the samples, please refer to local regulations for the ventilation conditions of

the work room.

All waste materials must be collected and eliminated in compliance with the local regulations

and directives in the country where the instrument is used.

xxii TriPlus RSH Hardware Manual Thermo Scientific

Page 23

Biological Hazards

Preface

Safety Information and Warnings

In laboratories where samples with potential biological hazards are handled, you must label

any equipment or parts thereof which might become contaminated with biohazardous

material. The appropriate warning labels are included with the shipment of the instrument.

It is your responsibility to label the relevant parts of the instrument.

When working with biohazardous materials, it is your responsibility to fulfill the following

mandatory requirements:

• Instructions on how to safely handle biohazardous material must be provided.

• Operators must be trained and made aware of the potential dangers.

• Personal protective equipment must be provided.

• Instructions must be provided on what to do in case operators are exposed to aerosols or

vapors during normal operation (within the intended use of the equipment) or in case of

single fault situations such as a broken vial.

The protective measures must consider potential contact with the skin, mouth, nose

(respiratory organs), and eyes.

Maintenance

• Instructions for decontamination and safe disposal of the relevant parts must be provided.

It is your responsibility to handle hazardous chemicals or biological compounds (including,

but not limited to, bacterial or viral samples and the associated waste), safely and in

accordance with international and local regulations.

Any external cleaning or maintenance must be performed with the TriPlus RSH turned off

and the power cord disconnected. Avoid using solvents and spraying on electrical parts. For

the removal of potentially dangerous substances (toxic, harmful, and so on) read the hazard

indications and information reported in the MSDS (Material Safety Data Sheet) supplied by

the manufacturer referring to the relevant CAS (Chemical Abstract Service) number. Use

proper protective gloves.

When working with hazardous materials such as radioactive, biologically hazardous material,

and so on, it is important to train all operators how to respond in case of spills or

contamination.

Depending on the class of hazardous material, the appropriate measures have to be taken

immediately. Therefore, the chemicals or solvents needed for decontamination have to be on

hand.

Any parts of the equipment which can potentially be contaminated, such as the sample vial

rack, syringe tool, wash module, and so on, must be cleaned regularly. The waste solvent from

cleaning and any hardware which requires to be disposed of has to be properly eliminated

with all the necessary precautions, abiding by national and international regulations.

Thermo Scientific TriPlus RSH Hardware Manual xxiii

Page 24

Preface

Safety Information and Warnings

Disposal

When preparing for decontamination, ensure that the solvent or chemical to be used will not

damage or react with the surface, dye (color) of the instrument, table or other nearby objects.

If in doubt, please contact your Thermo Fisher Scientific representative to verify the

compatibility of the type or composition of solvents with the TriPlus RSH.

Do not dispose of this equipment or parts thereof unsorted in municipal waste.

Follow local municipal waste regulations for proper disposal provisions to reduce

the environmental impact of waste electrical and electronic equipment (WEEE).

European Union customers: Call your local customer service representative responsible for the

TriPlus RSH for complimentary equipment pick-up and recycling.

WARNING The customer has to ensure that the TriPlus RSH has not been contaminated

by any hazardous chemical or biological compounds including (but not limited to)

bacteria or viruses.

Any part which had direct contact with the analytical sample must be identified and must

undergo an appropriate decontamination procedure prior to shipping for disposal.

Potentially dangerous components are: Syringes, Vials and Well Plates. Any critical parts

sent for disposal must be handled according to national laws for hazardous compounds.

The customer and the service engineer are fully responsible for enforcing these

requirements. Thermo Fisher Scientific will hold the representative, customer responsible,

or both, if these regulations are not observed.

xxiv TriPlus RSH Hardware Manual Thermo Scientific

Page 25

1

Specifications

This section provides general specifications of the TriPlus RSH.

Contents

• Electrical Specifications

• Physical Specifications

• Operating and Environmental Specifications

• Sound Pressure Level

• Hardware and Software Requirements

• TriPlus RSH System Software Requirements

Thermo Scientific TriPlus RSH Hardware Manual 1

Page 26

1

Specifications

Electrical Specifications

Electrical Specifications

The electrical specifications and the various protection classes are provided in Ta bl e 1 and

Ta b le 2 .

Table 1 . General Electrical Specifications

Parameter Requirements

Voltage 36 VDC

Current 3.2 A

Fuse T6.3 A/250 V

Table 2 . Handheld Controller Power Supply

Parameter Requirements

Input line voltage Grounded AC, 100 V to 240 V

Input line frequency 50/60 Hz

Input power 4 A

Output voltage 36 VDC

Output current 5.55 A (total for two Outlets)

• Protection Class I — Describes the insulating scheme used in the instrument to protect

the user from electrical shock. Class I identifies a single level of insulation between live

parts (wires) and exposed conductive parts (metal panels), in which the exposed

conductive parts are connected to a grounding system. In turn this grounding system is

connected to the third pin (ground pin) on the electrical power plug.

• Over Voltage Category II — Pertains to instruments that receive their electrical power

from a local level such as an electrical wall outlet.

• Pollution Degree 2 — Measure of pollution on electrical circuits that may produce a

reduction of the dielectric strength or surface resistivity. Degree 2 normally refers only to

non-conductive pollution.Occasionally, however, a temporary conductivity caused by

condensation is to be expected.

• Moisture Protection — Normal (IPXO) – PIXY means that there is NO Ingress

Protection against any type of dripping or sprayed water. The X is a place holder to

identify protection against dust, if applicable.

2 TriPlus RSH Hardware Manual Thermo Scientific

Page 27

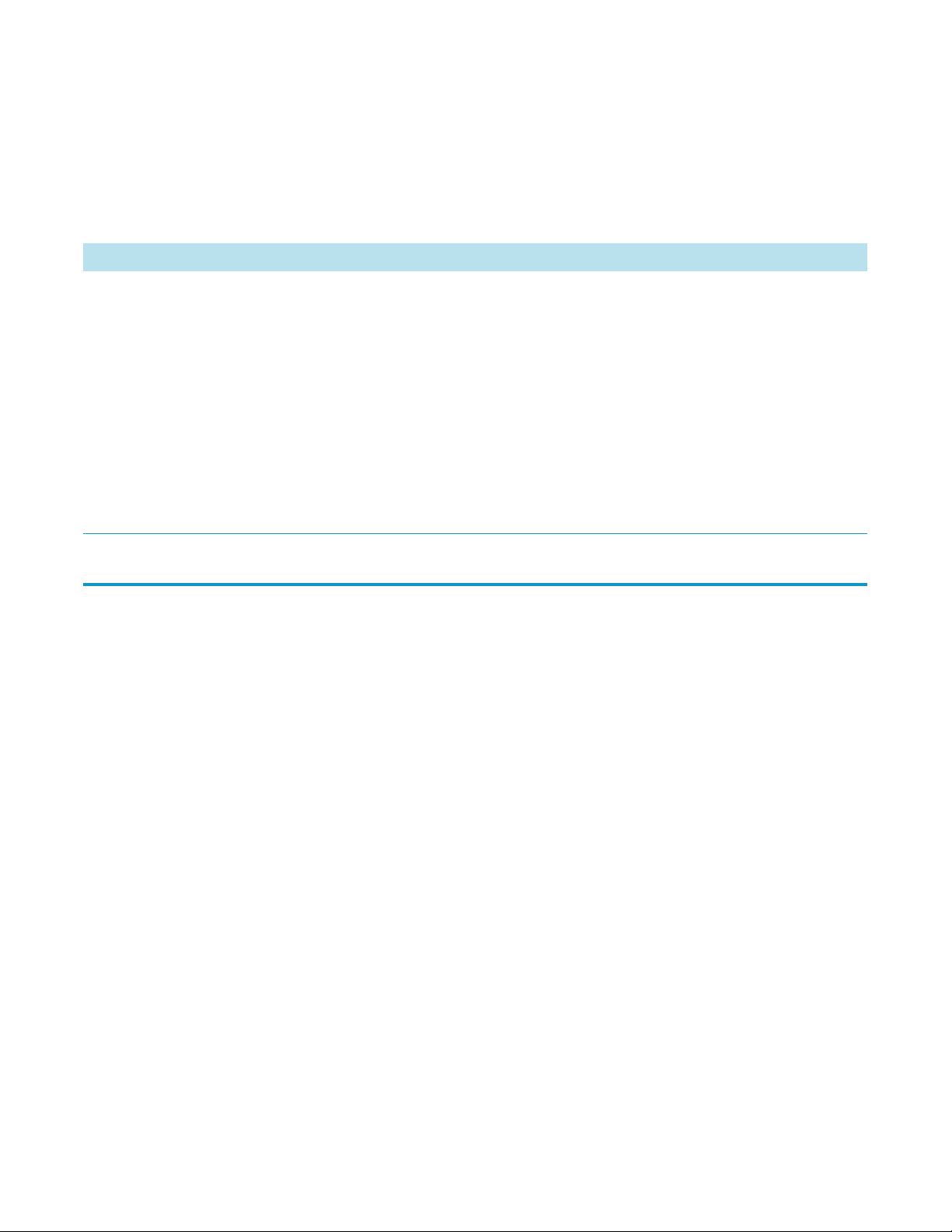

Physical Specifications

The physical specification for the TriPlus RSH with Standard are listed in Tab l e 3.

Table 3 . Space and Load Requirements

1

Specifications

Physical Specifications

Instrument

TriPlus RSH standard X axis 46

TriPlus RSH extended X-axis 46

TriPlus RSH standard X axis

Depth (Y-axis) Width (X-axis) Height (Z-axis) Mass

cm in. cm in. cm in. kg lbs

80

1

1

1

1

18

18

1

85 33.5 54 21.3 13.3

120.5 47 54 21.3 15.3

31.5 99

2

39

2

(Working Range)

TriPlus RSH extended X-axis

80

1

31.5 135

2

53

2

(Working Range)

1

About 20 cm (about 8-in.) of the orthogonal crossrail (Y-axis) are protruding the back of the GC.

2

Dimension of the entire working range including Handheld bracket

3

Dimension including the support legs [about 22 cm (8.7 in.) height]

4

Mass without accessories.

Operating and Environmental Specifications

These specifications are listed in Ta b le 4 .

53 (74)

53 (74)

3

3

20.9 (29)

20.9 (29)

3

3

4

29.3

4

33.7

25 55

27 60

4

4

Table 4 . Operating and Environmental Specifications

Parameter Requirements

Operating temperature range 5 °C to 40 °C (41 °F to 104 °F)

Non-operating temperature range (transport or storage conditions) -25 °C to +65 °C (-13 °F to + 149 °F)

Maximum relative humidity 80%, non-condensing

Work environment Indoor use

Altitude Up to 3000 m above sea level

Mains voltage variation ±10%

Bench space At least 30 cm (12 in.) at the back.

Access to power switches and power cords. Clean, level, and smooth surface.

Clean, level and smooth surface. Solid bench plate.

Vibration Negligible

Static electricity Negligible

Thermo Scientific TriPlus RSH Hardware Manual 3

Page 28

1

Specifications

Sound Pressure Level

Sound Pressure Level

The sound pressure level is listed in Ta b le 5 .

Table 5 . Sound Pressure Level

Parameter Requirements

Sound Pressure Level Measured value:

• TriPlus RSH (basic unit): 64 dBA

• TriPlus RSH with Agitator: 66 dBA

• TriPlus RSH with Vortexer without sample vial: 67

dBA

• TriPlus RSH with Vortexer with 20 ml sample vial

inserted: 78 dBA.

One meter from the equipment in the direction of

maximum sound pressure level.

According to UL 610107A-1, 1st Edition, clause 12.5. Limit < 85 dBA

dBA = A weighted sound pressure level

Hardware and Software Requirements

This section details the hardware and software requirements.

Computer Hardware Requirements

The computer hardware minimal requirements depends on the Microsoft Windows

Operating System and, if applicable, on the MS.NET Framework software used. See

recommendations from Microsoft.

It is also important to consider the minimum requirements for the operation of the

Chromatography Data System Software (CDS).

For operation of the TriPlus RSH, both an Ethernet (TCP/IP) and a USB communication

port are required. The computer in use must be equipped accordingly: LAN or Ethernet IEEE

802.3 Industry Standard 10/100 Base-T. The network interface of the TriPlus RSH supports

the Auto-MDI(X) protocol.

The USB Device/Client Type B communication port of the TriPlus RSH is currently not

activated.

4 TriPlus RSH Hardware Manual Thermo Scientific

Page 29

USB Stick (Memory Drive)

Use a commercially available standard USB memory stick with at least 100 MB memory size.

No special formatting of the drive (stick) is necessary; on the contrary only one partition must

be defined. If two partitions are defined, subsequent errors occur, and the access to the system

is denied.

Note Commercially available USB sticks with encrypting software installed, and secure

USB drives, typically have two partitions. This type of USB drive cannot be utilized in

combination with the TriPlus RSH system.

The following software types of the USB memory drive are compatible with the TriPlus RSH:

•FAT

•FAT32

• The software NTFS is NOT supported. If a USB Stick with this software is used, the stick

will not be recognized by the RSH Firmware.

1

Specifications

Hardware and Software Requirements

• Starting with Firmware version 1.5.0 a USB Stick with software version 3.0 can be

operated. With Firmware versions lower than 1.5.0, USB sticks can be operated with

software version 2.X.X only.

• It is recommended to adjust the Allocation Unit Size as large as possible. There is a

dependency observed between the Capacity Size and the size of the Allocation Unit.

Examples: USB Stick Capacity 4 GB with 4 MB Allocation Unit, or 16 GB Capacity

with 64 MB Allocation Units. These combinations are valid; however a 16 GB Capacity

with 8 MB Allocation Units is not working. The observed effect is that the USB Stick is

not recognized within the 10 seconds time limit.

Note The Recognition Time is time used from the moment the stick is connected to

the TriPlus RSH System until the USB symbol is displayed on the handheld controller

(terminal).

Recognition Time of the USB Stick is:

• Firmware version < 1.5.0:Time-out after 10 s.

• Firmware version ≥ 1.5.0: Time-out after 30 s.

PC Software Requirements

All the software functionality such as Backup, Restore, or Update for the RSH Firmware are

performed directly via USB interface using the USB stick. For these purposes, no specific

software on a PC is required.

Thermo Scientific TriPlus RSH Hardware Manual 5

Page 30

1

Specifications

Hardware and Software Requirements

For the operation of the TriPlus RSH with a Thermo Scientific Chromatography Data System

(CDS), for example: Chromeleon, Xcalibur, ChromQuest, or Chrom-Card, a software driver

is used. The specific requirements for operation of the integrated TriPlus RSH System in the

CDS are outlined by the supplier of the CDS software.

For the operation of the TriPlus RSH in combination with Sample Control, the software from

Microsoft MS.net framework version 4.0 (or higher) is required.

Configuring Windows for Firmware and for the CDS

When configuring the Windows Operating software for the TriPlus RSH, it is important to

note that the CDS to be used in conjunction with the TriPlus RSH might require specific

settings as well. These settings have to be matched for reliable operation of the analytical

system. See the corresponding sections in the installation manual of the specific CDS.

Firewall or Virus Scanner Settings

In order to reliably operate the TriPlus RSH and the selected Chromatography Data System

(CDS), it is necessary to turn OFF any third party Firewall or Virus Scanner software.

If for any reason a firewall must be activated; the TCP Ports 80, 64000, 64001, and 8194

must be unlocked.

Screen Savers

It is highly recommended NOT to use any Screen Savers.

Disabling Power Management

Depending on the Windows Operating System version and the default settings, the computer

may enter standby mode automatically after a specified time if no mouse or keyboard activity

is detected. Using this Power Save mode in the environment with laboratory instruments

where unattended operation day and night is expected, will likely result in loss of data,

interruptions of specific functions, or whole operations.

To disable Windows power management

1. Select the Windows Control Panel

2. Select System and Security

3. Select Power Options

4. From Power Plan select the menu item Put the Computer to sleep: Never

Note Depending on the Windows version, the path or wording may differ slightly.

The example given above is based on Windows 7.

6 TriPlus RSH Hardware Manual Thermo Scientific

Page 31

TriPlus RSH System Software Requirements

The TriPlus RSH Firmware is the collective term referring to all required software and data

that complement one another and make up the complete TriPlus RSH Firmware. It consist

mainly of:

•Operating System (OS)

• TriPlus RSH Application Software

• TriPlus RSH Configuration (persisted data)

•TriPlus RSH Device Firmware

When restoring a TriPlus RSH Configuration Backup, the software packages Tri Plus R SH

Application and TriPlus RSH Configuration are saved, under the file extension *.pac.

This file is always stored as an archive file.

The Operating System and TriPlus RSH device firmware are not stored in the configuration

backup.

1

Specifications

TriPlus RSH System Software Requirements

In case of a software update for the TriPlus RSH Firmware, a single archive file with the file

extension *.cont will be supplied.

The software supplied depends on the compatibility of all the software packages. In some

cases, only the TriPlus RSH device firmware is necessary to complete the update. All other

software packages remain untouched, and are compatible. If major changes are made to the

operating systems, could also be necessary to adapt both the TriPlus RSH Application, and

the TriPlus RSH Configuration software to provide full compatibility.

Note For detailed information see the Chapter 4, “TriPlus RSH Firmware.”

Thermo Scientific TriPlus RSH Hardware Manual 7

Page 32

Page 33

2

Installation of the TriPlus RSH System

This chapter provides informations for installing the TriPlus RSH System.

Contents

• Introduction

• Installation Quick Reference Guide

• Unpacking the Components

• Installing the TriPlus RSH Supports on the GC

• Placing the TriPlus RSH on the Supports

• Installation of the TriPlus RSH System

• Installing the TriPlus RSH Head

• Installing the Handheld Controller and Safety Guard

• Installing the Purge Gas Pressure Regulator

• Installing the Tool Stations

• Installing the Wash Stations

• Installing a Tray Holder

• Installing an Agitator

• Installing a Vortexer

• Installing a MHE Station

• Installing a SPME Conditioning Station

• Installing a Barcode Reader

• Installing a Liquid Cooled Tray Holder

• Installing a Temperature Controlled Drawer

• Installing an OC Injector Module

• Inserting a LS Syringe into the LS Tool

• Inserting a HS Syringe into the HS Tool

• Installing the SPME Fiber Protector

• Inserting a SPME Fiber Holder into the SPME Tool

• Managing an ITEX Syringe and Trap Assemble

• Connecting the Power Module

• Combining the TriPlus RSH to Other Devices

• Establishing Communication with the Computer

Thermo Scientific TriPlus RSH Hardware Manual 9

Page 34

2

Installation of the TriPlus RSH System

Introduction

Introduction

This chapter describes the installation of the TriPlus RSH and its modules. Referencing of the

TriPlus RSH and teaching of the various modules are described in Chapter 3, “TriPlus RSH

Defining Object Positions.”

Who Performs the Installation

CAUTION The TriPlus RSH is installed by authorized Thermo Fisher Scientific technical

personnel, who will check its correct operation. For more details, please contact Thermo

Fisher Scientific local representatives. Should the instrument not be installed by Thermo

Fisher Scientific personnel, please strictly adhere to the following instructions.

Space Requirements

Provide enough space around the instrument on which the TriPlus RSH must be installed

making reference to the overall dimensions of the sampler described in the TriP lu s RS H

Preinstallation Requirements Guide.

WARNING Pay attention not to operate on the instrumental parts included in the work

area of the sampler when this is in movement.

Electrical Requirements

The power line and the connections between the instruments must maintain good electrical

grounding. Poor grounding represents a danger for the operator and may seriously affect the

instrument performance.

CAUTION Do not connect the TriPlus RSH to lines feeding devices of a heavy duty

nature, such as motors, UV lamps, refrigerators and other devices that can generate

disturbances.

Pay attention not to leave any cable connecting the sampling unit and the

chromatographic system or the power cord close to the GC hot air vents.

Connect the TriPlus RSH only to instruments complying with the IEC 61010 safety

regulations.

Sampler Supports

The TriPlus RSH is installed on the GC by using the two appropriate supports provided.

Every support has a bar provided with holes for the fixing on the GC, and a vertical support

leg provided with clamps for the correct hookup of the sampler.

10 TriPlus RSH Hardware Manual Thermo Scientific

Page 35

Material Required for the Installation

To install the TriPlus RSH, and its modules, the following material is required:

• T6 Torxhead screwdriver

• T10 Torxhead screwdriver

• T20 Torxhead screwdriver

• T25 Torxhead screwdriver

• Two flat wrenches

•Flat-head screwdriver

Installation Quick Reference Guide

Table 6 . Installation Quick Reference Guide (Sheet 1 of 2)

2

Installation of the TriPlus RSH System

Installation Quick Reference Guide

Step Action Reference

01 Prepare the working area and the GC System. See the relevant Preinstallation Requirements Guide for

the GC system and the TriPlus RSH.

02 Check if all components of the TriPlus RSH System are

delivered.

03 Install the TriPlus RSH supports on the GC See “Installing the TriPlus RSH Supports on the GC” on page 13

04 Install the TriPlus RSH on the GC. See “Placing the TriPlus RSH on the Supports” on page 19

05 Connect all the Active and Passive modules, to complete the

required system configuration.

06 Make all electrical connections, including for the Active

modules

07 Prepare the tool(-s). Insert the required syringe(-s). “Inserting a LS Syringe into the LS Tool” on page 53 or

08 Prepare the Computer with the required software: Follow the recommendations and specifications from Thermo

09 Connect the TriPlus RSH to the Network environment.

LAN cable provided with the system.

See “Unpacking the Components” on page 12

See “Installation of the TriPlus RSH System” on page 20

See “Installation of the TriPlus RSH System” on page 20

“Inserting a HS Syringe into the HS Tool” on page 55, or

“Inserting a SPME Fiber Holder into the SPME Tool” on page 59

“Managing an ITEX Syringe and Trap Assemble” on page 61

Fisher Scientific.

See the section Hardware and Software Requirements in

the TriPlus RSH User Guide.

See “Combining the TriPlus RSH to Other Devices” on page 68.

10 Power up the system See the section How to Start the TriPlus RSH in the Tr iP lu s

RSH User Guide.

11 When handheld controller is not part of the TriPlus RSH system:

Establish LAN Communication and Start the Virtual handheld

controller software under Xcalibur.

Thermo Scientific TriPlus RSH Hardware Manual 11

Follow the recommendations and specifications from Thermo

Fisher Scientific.

Page 36

2

Installation of the TriPlus RSH System

Unpacking the Components

Table 6 . Installation Quick Reference Guide (Sheet 2 of 2)

Step Action Reference

12 Check the RSH Firmware Version.

If the software version is lower than 1.4.0, perform an Update

procedure at the beginning of the installation. The minimum

software version should not be lower than 1.3.2.

13 Change the Access Level to Extended User See the section Access Level in the TriPlus RSH User Guide.

14 Press Options and select in the pull-up menu the item Setup |

Modules.

- Check availability of the Active modules.

- Add all required Passive modules.

- Check or add if necessary in following order:

Signal, Input/Output Interface, Chromatograph System

15 From the Start Screen select the required Tool, press Enter and

select menu item Needle Guide Type.

Note: The parameter Cap Type in the class Vial Type has to

correspond with the Tool Needle Guide Type.

Example:

Magnetic10/20 | Magnetic Cap.

Magnetic 2mL | Magnetic Cap

Foil Cutter | MTP Plates.

If Needle Guide Type is defined as Not Specified, a run is

prohibited also when the Cap Type is set No Cap or Non

Magnetic Cap.

Path from the Start Screen: Options | About. See the section

About Menu in the TriPlus RSH User Guide.

See “Update the RSH Firmware” on page 121.

See the chapter Setup Menu Item in the TriPlus RSH User

Guide.

Explanations for the different settings:

Not Specified: Prohibits the execution of a run.

Magnetic 2mL: Magnetic Transport for 2 mL vial

(large magnetic ring not installed).

Magn. 10/20 mL: Magnetic transport of 10 or 20 mL vials.

Large magnetic ring installed.

Foil Cutter: Foil Cutter for MicroTiter Plate foils installed.

16 Press Options and select in the pull-up menu the item Service |

Installation. Follow step-by-step the installation wizard.

17 Make a Backup file See the section Maintenance Menu Item- Backup in the

See the section Service Menu - Installation Item in the

TriPlus RSH User Guide.

TriPlus RSH User Guide and Chapter 4, “TriPlus RSH Firmware.”

Unpacking the Components

A TriPlus RSH is shipped into two boxes. Depending on the configuration and optional

modules, the entire system may be shipped in more than two boxes:

• The main box contains the TriPlus RSH base (X-,Y- axes assembly) and the standard

modules such as the TriPlus RSH Handheld Controller, Power Module, Tray Holders,

Trays, Wash Stations, and so on.

• The second box contains the TriPlus RSH Head (entire Z-axis). For shipping and

protective reasons, the inner mechanical part is separated from the cover.

12 TriPlus RSH Hardware Manual Thermo Scientific

Page 37

2

Installation of the TriPlus RSH System

Installing the TriPlus RSH Supports on the GC

To unpack the instrument

1. Open the boxes, remove the accessory boxes to compare the packing list, and check for

completeness of the shipment

2. Carefully lift the TriPlus RSH base and remove it from the box.

CAUTION This operation must be performed by TWO persons who must stand each on

one side of the X-axis and put their hands underneath it.

Hold the Y-axis in place while the assembly is being removed from the box. Set the

TriPlus RSH base assembly on a bench.

3. Unpack the remaining box that includes the TriPlus RSH Head. If applicable, unpack the

other boxes with any additional accessories included.

4. When placing the TriPlus RSH System onto a GC, make sure that no objects interfere

with the Y-axis, or the TriPlus RSH Head, throughout the entire potential range of

movement.

Installing the TriPlus RSH Supports on the GC

The TriPlus RSH supports are two vertical legs provided into a dedicated GC Mounting Kit.

To install the supports on your GC refer to the following procedures:

• “Installing the Supports on a Single GC” on page 14

• “Installing the Supports on a Double TRACE 1300/1310” on page 15

• “Installing the Supports on a TRACE 1300/1310 Coupled with a MS” on page 15

• “Installing the Supports on a Double TRACE GC Ultra” on page 15

• “Installing the Supports on a Double FOCUS GC” on page 16

• “Installing the Supports on a TRACE GC Ultra Coupled with a FOCUS GC” on

page 17

• “Installing the Supports on a Double TRACE GC Ultra Coupled with a MS” on page 18

• “Installing the Supports on a TRACE GC Ultra and on a FOCUS GC Coupled with a

MS” on page 18

Thermo Scientific TriPlus RSH Hardware Manual 13

Page 38

2

1

2

3

4

4

5

6

6

6

1 = Support Bar

2 = Support Leg

3 = Mounting clamps

4 = Support Leg Holes

5 = Leg Fixing Screws

6 = Support Bar Fixing Holes for the GC

Installation of the TriPlus RSH System

Installing the TriPlus RSH Supports on the GC

Sampler Supports Assembling

To assemble the sampler support

With reference to Figure 1, proceed as follows:

Figure 1. Support Assembling

.

1. Insert the provided fixing screw into each hole present on the support bar.

2. Place the support leg on the support bar paying attention that the fixing screw of the leg is

frontally turned.

3. Tighten the fixing screws.

Installing the Supports on a Single GC

To install the sampler supports on a GC

1. From the GC upper cover remove the plastic caps covering the corresponding fixing

holes.

2. Insert into each holes present on the support bar the provided fixing screw.