Page 1

Page 2

Page

2

Installation, use and maintenance guide

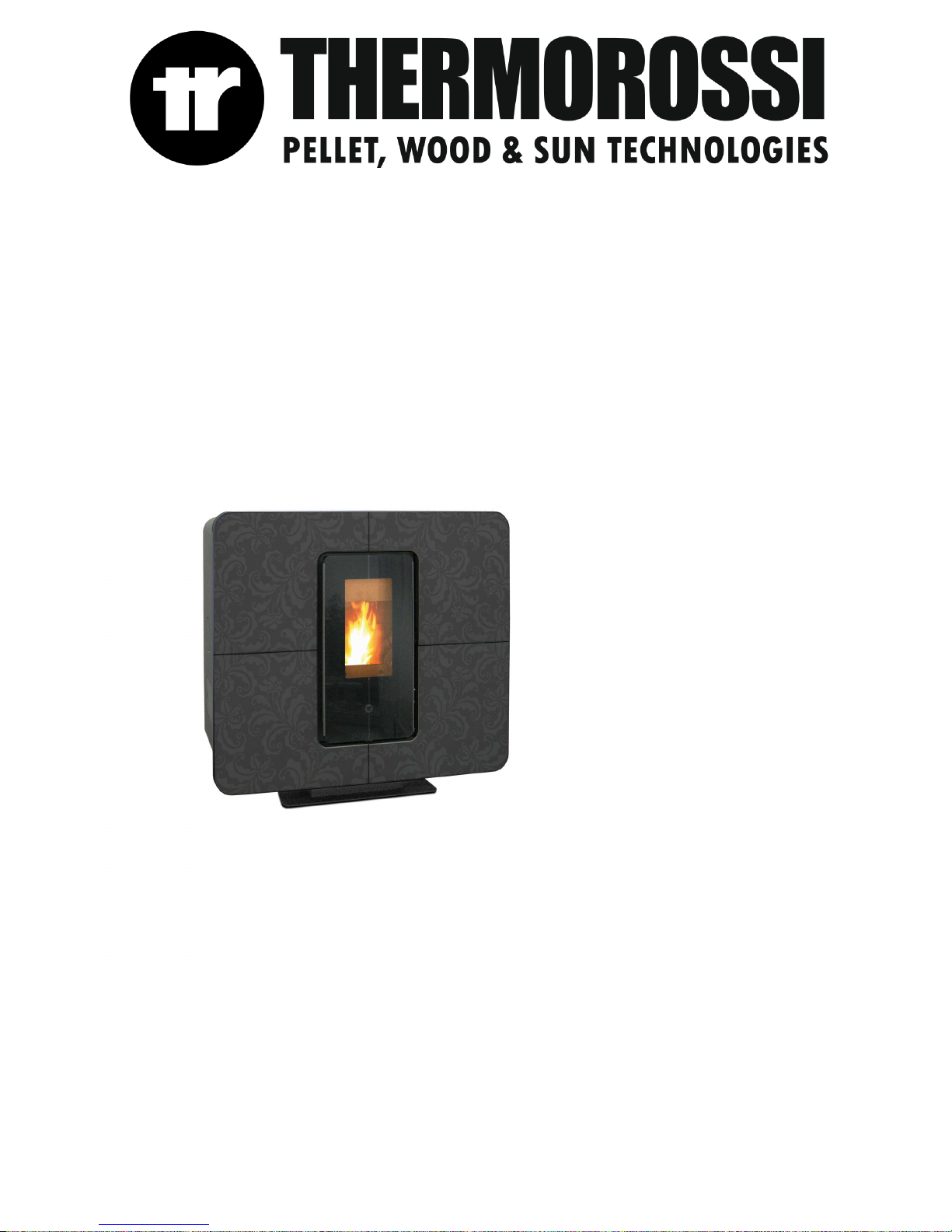

SlimQuadro Idra 14

INDEX

1 - INTRODUCTION .................................................................................................................................. 7

1.1 GENERAL GUIDELINES .................................................................................................................................. 7

1.2 SAFETY GUIDELINES ..................................................................................................................................... 7

1.2.2 GENERAL WARNINGS ............................................................................................................................................................ 8

1.3 TRANSPORTATION AND STORAGE .............................................................................................................. 8

2 – TECHNICAL CHARACTERISTICS* .................................................................................................... 9

3 – GENERAL DESCRIPTION .................................................................................................................11

3.1 OPERATING TECHNOLOGY ......................................................................................................................... 11

3.2 THE PELLET ................................................................................................................................................... 11

3.3 THE FEEDBOX ............................................................................................................................................... 11

3.4 MAIN COMPONENTS OF THE APPLIANCE ................................................................................................. 12

4 - INSTALLATION ..................................................................................................................................13

4.1 APPLIANCE LOCATION ................................................................................................................................. 13

4.2 UNPACKING THE APPLIANCE ..................................................................................................................... 13

4.3 GLUING THE GLASS PANES TO THE FRONT PANEL ............................................................................... 14

4.4 REMOUNTING THE FRONT PANEL ............................................................................................................. 14

4.5 HANDLE .......................................................................................................................................................... 15

4.6 WALL MOUNT INSTALLATION ...................................................................................................................... 15

5 –HYDRAULIC CONNECTION ...............................................................................................................17

5.1 HYDRAULIC DIAGRAM .................................................................................................................................. 17

5.1.1 GUIDELINES FOR PLANTS WITH ZONE VALVES ................................................................................................................ 18

5.2 HYDRAULIC DIAGRAM WITH HEATING ONLY ........................................................................................... 19

5.3 EXAMPLE OF HYDRAULIC DIAGRAM WITH INTERSPACED BOILER COILS OR BOILER COILS .......... 20

5.4 EXAMPLE OF HYDRAULIC DIAGRAM WITH BOILER COILS AND HEATING SYSTEM ........................... 21

5.5 HYDRAULIC DIAGRAM WITH THERMOCELL (OR THERMOPUFFER) + ADDITIONAL THERMOPUFFER +

HIGH TEMPERATURE HEATING AND LOW TEMPERATURE HEATING. ................................................ 22

5.6 INSTRUCTIONS FOR EXECUTING THE HYDRAULIC SYSTEM CLOSED EXPANSION TANK ................ 23

6 – USE OF THE APPLIANCE .................................................................................................................24

6.1 DESCRIPTION OF THE CONTROL PANEL .................................................................................................. 24

6.2 DESCRIPTION OF THE POWER PANEL ...................................................................................................... 26

6.3 DATE/TIME: SETTING THE DATE AND TIME .............................................................................................. 26

6.4 CHRONO: ON/OFF PROGRAMMING ............................................................................................................ 26

6.5 LEVEL: OPERATING LEVEL SETTING ......................................................................................................... 29

6.6 THERMOCONTROL: CONTROLLING A PUFFER ........................................................................................ 29

6.7 ACS SUMMER: ACTIVATION OF THE BOILER TUBE CONTROL FROM A CHRONO COMMAND .......... 31

6.8 T.AMBIENT: CONTROLLING THE ROOM TEMPERATURE ........................................................................ 32

6.9 THERMO ACS: CONTROLLING A CONFIGURED BOILER TUBE IN A SYSTEM ...................................... 33

6.10 OPERATION OF THE GENERATOR ........................................................................................................... 35

6.10.1 DESCRIPTION OF THE OPERATING STAGES ................................................................................................................... 35

6.10.2 SETTING RANGE ................................................................................................................................................................. 36

6.10.3 AUTOMATIC CYCLE ............................................................................................................................................................ 36

6.10.4 MANUAL OPERATING CYCLE ............................................................................................................................................. 37

6.11 SWITCHING ON THE APPLIANCE .............................................................................................................. 37

6.12 SWITCHING OFF THE APPLIANCE ............................................................................................................ 37

Page 3

Page

3

Installation, use and maintenance guide

SlimQuadro Idra 14

7 ADDITIONAL ROOM TEMPERATURE THERMOSTAT / ADDITIONAL CHRONOTHERMOSTAT (not

supplied) ................................................................................................................................................. 38

7.1 OPERATING WITH THE ADDITIONAL ROOM TEMPERATURE THERMOSTAT (NOT SUPPLIED ) ....... 38

7.2 OPERATING WITH THE ADDITIONAL CHRONOTHERMOSTAT (NOT SUPPLIED) .................................. 38

8 CLEANING AND MAINTENANCE ........................................................................................................ 40

9 – SMOKE DISCHARGE TUBE AND VENTILATION OF THE ROOMS ................................................ 42

9.1 FOREWORD ................................................................................................................................................... 42

9.2 ROOM VENTILATION .................................................................................................................................... 42

9.2.1 VENTILATION FROM ADJOINING ROOMS ........................................................................................................................... 42

9.2.2 SINGLE OR MULTIPLE VENTILATION DUCTING ................................................................................................................. 42

9.3 SMOKE OUTLET ............................................................................................................................................ 43

9.3.1 CHIMNEY TYPES ................................................................................................................................................................... 43

9.3.2 FLUE OUTLET / FLUE SYSTEM COMPONENTS .................................................................................................................. 43

9.3.3 CONTROLS PRIOR TO INSTALLING THE APPLIANCE ........................................................................................................ 44

10 – ALARMS .......................................................................................................................................... 46

11 - ELECTRICAL WIRING ..................................................................................................................... 47

12 - INFORMATION FOR THE SKILLED TECHNICIAN .......................................................................... 48

12.1 MAIN COMPONENTS AND THEIR POSITION ........................................................................................... 48

12.2 GUIDELINES FOR CORRECT INSTALLATION .......................................................................................... 48

12.3 TROUBLESHOOTING CAUSE / SOLUTION ................................................................................ 50

13 SPARE PARTS ................................................................................................................................... 52

13.1 SPARE PARTS (part 1/3) ............................................................................................................................. 52

13.2 SPARE PARTS (part 2/3) ............................................................................................................................. 53

13.3 SPARE PARTS (part 3/3) ............................................................................................................................. 54

13.4 KEYS ............................................................................................................................................................. 55

Page 4

Page

4

Installation, use and maintenance guide

SlimQuadro Idra 14

DICHIARAZIONE DI CONFORMITA'

DECLARATION OF CONFORMITY

La THERMOROSSI S.P.A., VIA GRUMOLO N° 4 36011 ARSIERO (VI), sotto la sua esclusiva responsabilità

DICHIARA che l’apparecchiatura descritta in appresso:

DECLARES that the product:

Descrizione

Description

Stufa a pellet

Pellet stove

Marchio

Trademark

THERMOROSSI S.P.A.

Modello

Model

SLIMQUADRO IDRA 14

è conforme alle disposizioni legislative che traspongono le seguenti Direttive:

• 2004/108/CE (Direttiva EMC)

• 2006/95/CE (Direttiva Bassa Tensione)

• 2011/65/EU (Direttiva RoHS 2)

is in accordance with the following Directives:

• 2004/108/EC Directive (EMC Directive)

• 2006/95/EC Directive (Low Voltage Directive)

• 2011/65/EU Directive (RoHS 2)

e che sono state applicate tutte le norme e/o specifiche tecniche di seguito indicate

and that all the following standards have been applied

EN 55014-1 EN 60335-1 EN 50581

EN 61000-3-2 EN 60335-2-102 EN 62233

EN 61000-3-3

Ultime due cifre dell’anno in cui è affissa la marcatura CE 14

Last two figures of the year of the CE marking

Luogo Arsiero

Place

Data 13/05/2014

Date

Firma

Sign.

Page 5

Page

5

Installation, use and maintenance guide

SlimQuadro Idra 14

DICHIARAZIONE DI PRESTAZIONE

DECLARATION OF PERFORMANCE

Dichiarazione di prestazione in accordo con il Regolamento (UE) 305/2011

Declaration of performance according to Regulation (EU) 305/2011

N° 54

1

Codice di identificazione unico del prodotto-tipo:

Unique identification code of the product type:

SLIMQUADRO IDRA 14, apparecchio per il riscaldamento domestico, con acqua, alimentato a

pellet di legno

SLIMQUADRO IDRA 14, residential space heating appliance with water fired by wood pellets

EN 14785:2006

2

Numero di tipo, lotto , serie o qualsiasi altro elemento che consenta l'identificazione del prodotto da

costruzione ai sensi dell'articolo 11, paragrafo 4:

Type, batch or serial number or any other element allowing identification of the construction

product as required under Article 11( 4):

SLIMQUADRO IDRA 14

3

Uso o usi previsti del prodotto da costruzione, conformemente alla relativa specifica tecnica

armonizzata, come previsto dal fabbricante:

Intended use or uses of the construction product, in accordance with the applicable harmonised

technical specification, as foreseen by the manufacturer:

Apparecchio per il riscaldamento domestico, con acqua, alimentato a pellet di legno

Residential space heating appliance with water fired by wood pellets

4

Nome, denominazione commerciale registrata o marchio registrato e indirizzo del fabbricante ai

sensi dell'articolo 11, paragrafo 5:

Name, registered trade name or registered trade mark and contact address of the manufacturer as

required pursuant Article 11( 5):

THERMOROSSI S.P.A. Via Grumolo, n° 4 36011 Arsiero (VI)

5

Sistema o sistemi di valutazione e verifica della costanza della prestazione del prodotto da

costruzione di cui all'allegato V:

System or systems of assessment and verification of constancy of performance of the construction

product as set out in Annex V:

Sistema 3 e 4 / System 3 and 4

6

Nel caso di una dichiarazione di prestazione relativa ad un prodotto da costruzione che rientra

nell'ambito di applicazione di una norma armonizzata:

In case of the declaration of performance concerning a construction product covered by a

harmonised standard:

L' organismo notificato TÜV Rheinland Energie und Umwelt GmbH N° 2456 ha determinato il

prodotto-tipo in base a prove di tipo secondo il sistema 3 ed ha rilasciato il rapporto di prova

K10852013T1

The notified laboratory TÜV Rheinland Energie und Umwelt GmbH N° 2456 performed the

determination of the product type on the basis of type testing under system 3 and issued test report

K10852013T1

Page 6

Page

6

Installation, use and maintenance guide

SlimQuadro Idra 14

7

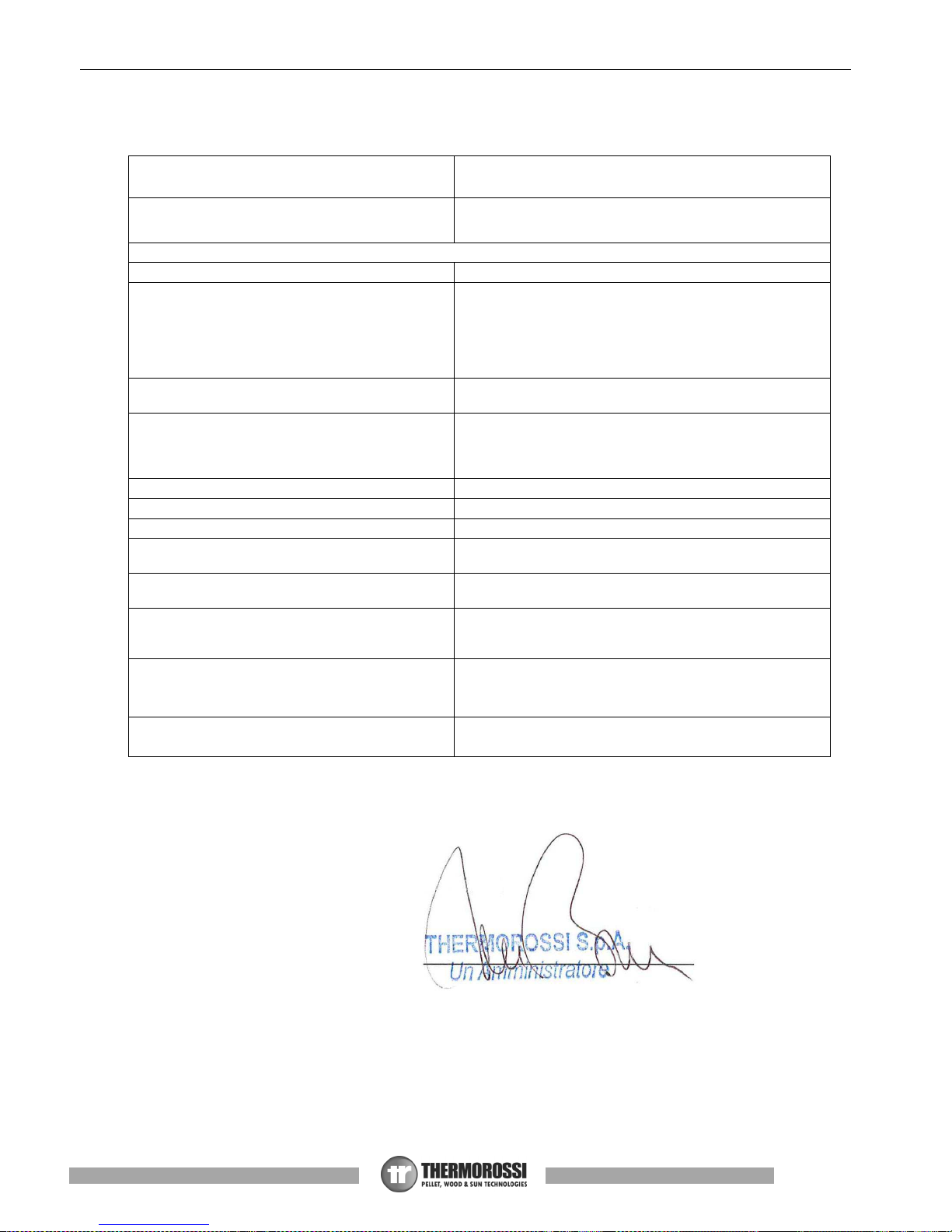

Prestazione dichiarata / Declared performance

Specifica tecnica armonizzata:

Harmonized technical specification:

EN 14785:2006

Caratteristiche Essenziali

Essential characteristics

Prestazione / Performance

Sicurezza antincendio / Fire safety

Reazione al fuoco / Reaction to fire A1

Distanza da materiali combustibili

Distance to combustible materials

Minime distanze / Minimum distances (mm):

posteriore / rear = 200

lati / sides = 200

frontale / front = 800

soffitto / ceiling = pavimento / floor = -

Rischio di fuoriuscita di braci incandescenti

Risk of burning fuel falling out

Passa / Pass

Emissione di prodotti della combustione

Emission of combustion products

CO 61,5 mg/m3 Alla potenza termica nominale / Nominal heat

output

CO 143,7 mg/m3 Alla potenza termica ridotta / Reduced heat

output

Temperatura superficiale / Surface temperature

Passa / Pass

Sicurezza elettrica / Electrical safety

Passa / Pass

Pulizia / Cleanability

Passa / Pass

Pressione massima di esercizio

Maximum operating pressure

2,5 bar

Temperatura fumi a potenza termica nominale

Flue gas temperature at nominal heat output

T 124°C

Resistenza meccanica (per sopportare un camino/una

canna fumaria)

Mechanical resistance (to carry a chimney/flue)

NPD {Nessuna Prestazione Determinata}

Potenza termica nominale / Nominal heat output 13,33 kW

Potenza termica resa in ambiente / Room heating output 1,46 kW

Potenza termica ceduta all’acqua / Water heating output 11,87 kW

Rendimento

Efficiency

93,27 % Alla potenza termica nominale / Nominal heat output

95,48 % Alla potenza termica ridotta / Reduced heat output

8

La prestazione del prodotto di cui ai punti 1 e 2 è conforme alla prestazione dichiarata di cui al

punto 7. Si rilascia la presente dichiarazione di prestazione sotto la responsabilità esclusiva del

fabbricante di cui al punto 4

The performance of the product identified in points 1 and 2 is in conformity with the declared

performance in point 7. This declaration of performance is issued under the sole responsibility of

the manufacturer identified in point 4

Firmato a nome e per conto del fabbricante da

(nome e funzione)

Signed for and on behalf of the manufacturer

(name and title)

Luogo/Place Data/Date

Arsiero 13/05/2014

Page 7

Page

7

Installation, use and maintenance guide

SlimQuadro Idra 14

1 - INTRODUCTION

1.1 GENERAL GUIDELINES

This installation, use and maintenance guide is an integral and essential part of the product and must be kept by the user. Before

commencing with the installation, use and maintenance of the product, carefully read this guide. All local, national and European

regulations regarding the installation and use of the appliance must be met. The Manufacturer recommends carrying out all the

maintenance operations described in this manual.

This appliance must only be used as intended by the manufacturer. Any other use is considered incorrect and therefore hazardous;

consequently, the user shall be totally liable for the product if used improperly. Installation, maintenance and repairs must be carried

out by professionally qualified personnel, certified according to Decree no. 37 of 22 January 2008 and in compliance with current

regulations. In case of repairs only original spare parts supplied by the manufacturer must be used. Incorrect installation or poor

maintenance can injure or damage people, animals or things; in this case the manufacturer shall be relieved of all responsibility.

Before beginning any cleaning or maintenance operation switch off the appliance by means of the 0/I switch located on the power

panel and disconnect the plug from the electrical power socket. The product must be installed in locations suitable for fire-fighting

and furnished with all the services (power and outlets) which the appliance requires for a correct and safe operation. Any repairs or

actions carried out on any systems, components or internal parts of the appliance, or on any of the accessories supplied with it, that

are not specifically authorised by Thermorossi S.p.A, will automatically void the warranty and the manufacturer's responsibility,

pursuant to Italian Decree no. 224 of the President of the Republic of 24/05/1988, art. 6/b.

It is recommended to keep this manual in a safe place that is easily accessible to all users; if the manual is lost or deteriorated

contact the manufacturer for a replacement copy. If the appliance is sold or transferred to another user ensure that the manual is

handed over with it.

Thermorossi S.p.A. retains copyright on this manual. These instructions may not be reproduced or communicated to third parties or

used in any other way without the necessary authorisation.

1.2 SAFETY GUIDELINES

PERSONAL INJURY

This safet y symbol identifies important messages throughout the manual. Read the information

marked by this symbol carefully as non-observance of this message can cause serious injury to

persons using the appliance.

DAM AGE TO PROPERTY

This safety symbol identifies messages or instructions that are fundamental for the generator to

function well. To avoid serious damage to the appliance adhere strictly to these instructions.

INFORMATION

This symbol indicates important instructions for good functioning of the generator. If this information

is not correctly observed, the performance of the appliance will not be satisfactory.

1.2.1 RECOMMENDATIONS

Before using the appliance, carefully read every section of this installation, use and maintenance guide as knowledge

of the information and the regulations contained in it are essential for a correct use of the appliance.

The entire operation concerning the connection of the electric panel must be carried out by expert personnel; no

responsibility will be accepted for damages, even to third parties, if the instructions for installation, use and

maintenance of the appliance are not followed scrupulously. Modifications made to the appliance by the user or on

his behalf, must be considered to be under his complete responsibility. The user is responsible for all the operations

required for the maintenance of the appliance before and during its use.

Page 8

Page

8

Installation, use and maintenance guide

SlimQuadro Idra 14

1.2.2 GENERAL WARNINGS

Attention: the appliance must be connected to a system provided with a PE conductor (in compliance with the

specifications of 2006/95/EC, concerning low voltage equipment).Before installing the appliance check the efficiency

of the earth circuit of the power supply system.

Attention: the power supply line must have a section which is suitable for the power of the equipment. The cable section must in any

case be no less than 1.5 mm². The appliance requires powering with a voltage of 230V and 50 Hz. Voltage variations greater than

10% of the nominal value can cause irregular operation or damage the electrical device.

Position the appliance so that the electric power outlet in the room is easily accessible. Ensure that a suitable differential switch is

installed upstream from the equipment.

Your appliance has obtained the CE marking and has been made to run for 1 hour to check that it functions correctly.

The product must not be used by children, by persons with physical or mental impairments, by persons who are not familiar with the

instructions for use and maintenance of the product (the instructions are found in this booklet).

ATTENTION: Before every use make sure that the burner is clean, and check that the ash pan is clean, check that the firebox door

is closed.

ATTENTION: the door must always remain shut tight when the stove is operating. It is strictly forbidden to open the door while the

appliance is in operation. While the appliance is in operation the smoke exhaust pipes and some parts of the appliance itself can

reach extremely high temperatures: do not touch them! Do not expose your body to hot air for long, do not overheat the room in

which the appliance is installed, as these actions could cause health problems. Do not expose plants or animals directly to the hot

air flow as this could have noxious effects on them. It is strictly prohibited to use any type of fuel (liquid, solid...) to light up the

appliance: lighting must occur automatically as intended and described in this installation, use and maintenance booklet;

consequently, it is also strictly forbidden to feed pellets (or any other material) into the brazier. Do not place non-heat resistant or

inflammable or combustible objects in the vicinity of the appliance: keep them at a suitable distance. Do not place wet clothing to

dry on the appliance. When using a clothes horse, keep at a suitable distance. It is strictly prohibited to disconnect the appliance

from the electrical power mains.

Warning: do not wet the appliance and do not touch the electrical parts with wet hands. Never vacuum hot ash: this

could damage the vacuum device. All the cleaning operations described in this manual must be carried out when the

appliance is cold.

Attention! Warning for Swiss users

Refer to the local cantonal regulations imposed by the Fire Department (Mandatory signalling and safety distances )

and the Note concerning installation of heaters issued by the Association of Cantonal Fire Agencies (VKF - AEAI).

ATTENTION: it is mandatory to earth the appliance. If this instruction is not observed serious damage, which is not

covered by warranty, will result to the body of the appliance. Have an electrician check the earthing. There must be

no electric potential (Volt) between the earth of the generator and the actual earth of the plant. To avoid

electrochemical corrosion of the appliance’s body when wet it is prohibited to use galvanised pipes or fittings.

Dedicated ground wires must be used to ground all other materials.

1.3 TRANSPORTATION AND STORAGE

TRANSPORTATION AND HANDLING

The appliance body must always be in a vertical position when handled and exclusively by means of trolleys. Take special care to

protect the electric panel, the glass, and all the fragile parts from mechanical impact which could damage them and their correct

functioning.

STORAGE

The appliance must be stored in a humid-free environment and sheltered from the weather; avoid placing the appliance directly on

the ground. The Company denies all responsibility for damage caused to wood floors or floors made from any other material.

It is inadvisable to store the product for long periods of time.

Page 9

Page

9

Installation, use and maintenance guide

SlimQuadro Idra 14

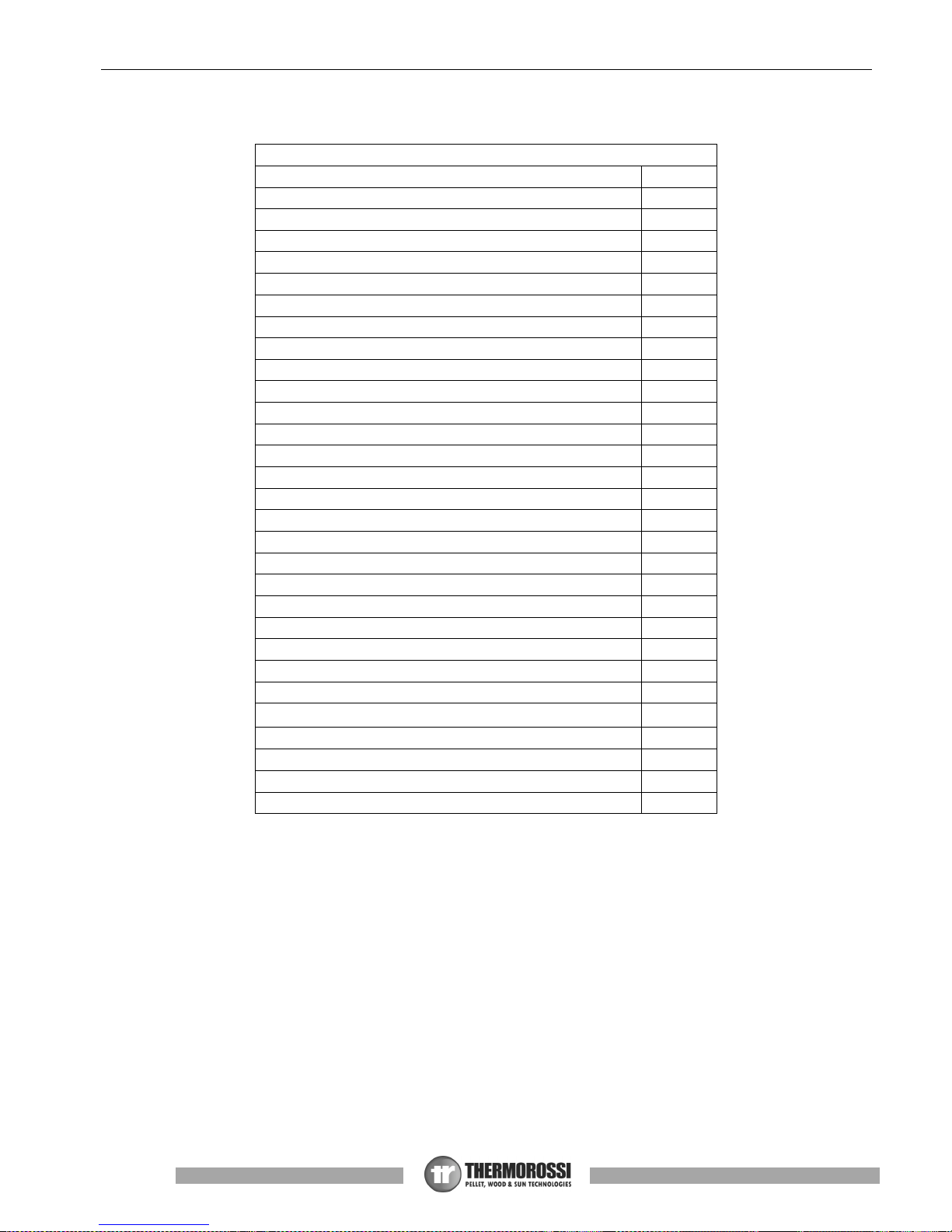

2 – TECHNICAL CHARACTERISTICS*

SLIMQUADRO IDRA 14

Height (mm) 991

Depth (mm) 315

Width (mm) 1109

Empty weight of the appliance (Kg) 164

Firebox power Min. / Max. (KW) 4.89 / 14.29

Rated power Min. / Max. (KW) 4.67 / 13.33

Power output to the room Min. / Max. (kW) 0.60 / 1.46

Min/Max consumption (Kg/ h) 1.1 / 3.1

Ø smoke exhaust pipe (mm) 80

Min. draught at rated power (Pa) 10

Min. draught at reduced power (Pa) 10

Tank capacity (Kg) 18.1

Water content (l) 21.5

Operating pressure (bar) 1.5

Max. operating pressure (bar) 2.5

Average smoke temperature at rated power (°C) 124

Average smoke temperature at reduced power (°C) 68

Max delivery water temperature (°C) 80

Min water return temperature (°C) 55

Smoke flow at rated power (Kg/sec) 9.6

Smoke flow at reduced power (Kg/sec) 5.5

Efficiency at rated power (%) 93.27

Efficiency at reduced power (%) 95.48

CO concentration in exhaust gas with 13% O2 at rated power (mg/m³) 61.5

CO concentration in exhaust gas with 13% O2 at reduced power (mg/m³) 143.7

Power supply voltage and frequency

230 V - 50

Hz

Max. electrical consumption (W) 340

Minimum electrical consumption (W) 90

Electrical consumption in standby (W) 4.8

Heatable volume (m3)** 360

* All the data are based on the appliance fuelled with EN 14961 standard type-approved pellets.

** Important: take into consideration the fact that the heatable volume is greatly influenced by the insulation of the house,

i.e. the energy class of the building and by the position of the appliance in the planimetry of the house. The indicated

values, therefore, can vary considerably.

Page 10

Page

10

Installation, use and maintenance guide

SlimQuadro Idra 14

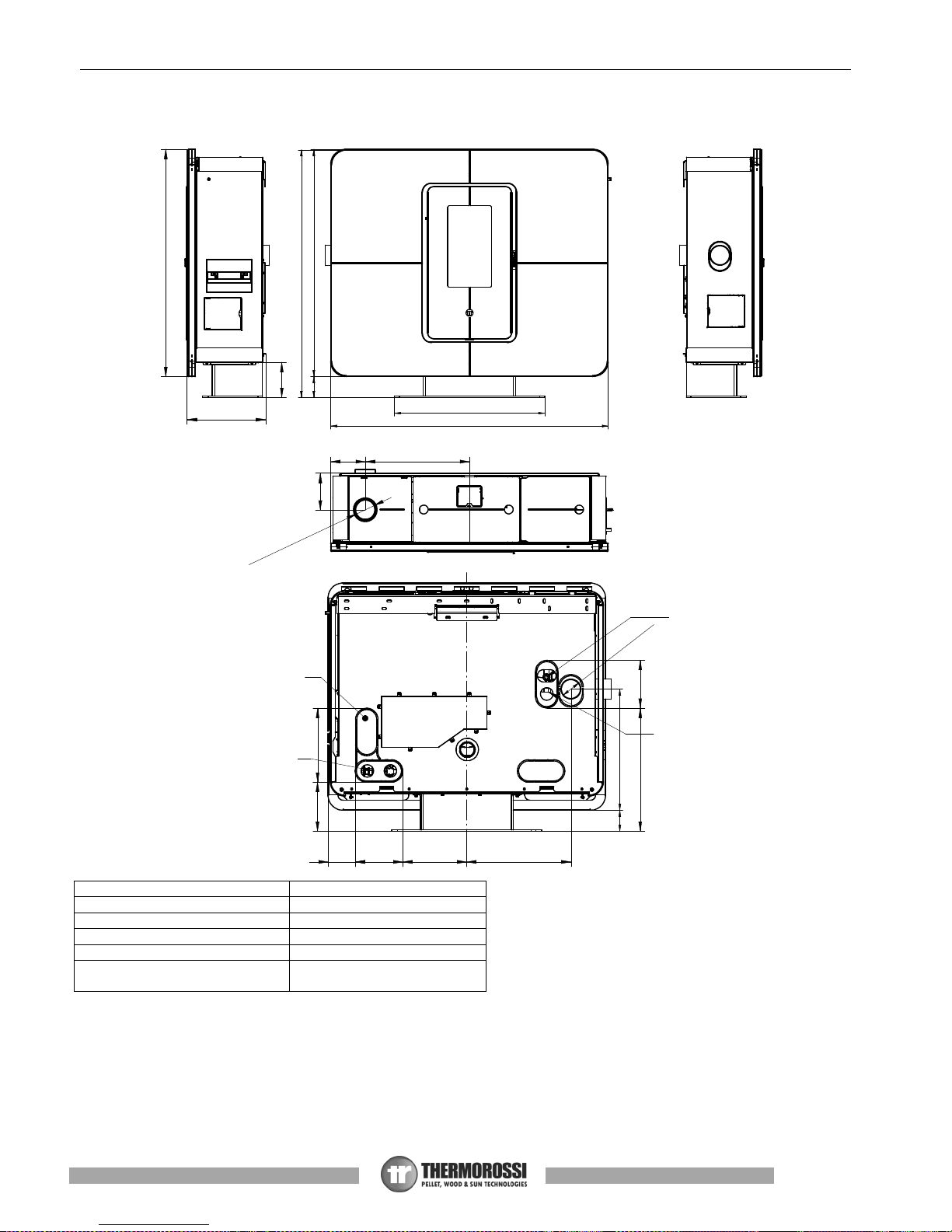

Legenda

Key

FUMI SMOKE

VALVOLA SICUREZZA 1/2'’ F. SAFETY VALVE 1/2'’ F.

RITORNO 3/4 ‘’F RETURN 3/4 ‘’F

MANDATA 3/4 ‘’F DELIVERY 3/4 ‘’F

CARICO

SCARICO 3/4” M

INLET

OUTLET 3/4” M

O

8

0

-

F

U

M

I

48484

90884

600

1109

989

416

MANDATA

3/4" F

VALVOLA

SICUREZZA

1/2" F

RITORNO

3/4" F

CARICO

SCARICO

3/4" M

295195

256189110

492 190

908

140

314

138 416

146.5

O

8

0

-

F

U

M

I

Page 11

Page

11

Installation, use and maintenance guide

SlimQuadro Idra 14

3 – GENERAL DESCRIPTION

3.1 OPERATING TECHNOLOGY

Your appliance has been built to fully satisfy all your heating and practical requirements. Top-grade components and functions

managed with microprocessor technology guarantee high reliability and optimal performance.

3.2 THE PELLET

The appliance is fuelled by pellets, that is, cylinders of compressed sawdust; it his allows you to fully enjoy the heat of the flame

without having to manually stoke the combustion.

The pellets have a 6 mm diameter and a maximum length of 15 mm. They have a maximum moisture content of 8%; thermal value

4000/4500 Kcal/Kg and density of approx. 620-630 Kg/m³.

It is strictly forbidden to use any pellet type other than that specified above. The use of fuel that does not comply with the

above specifications not only immediately invalidates the warranty for the appliance but can also create dangerous

situations. Do not use the appliance as an incinerator, at the risk of voiding the warranty.

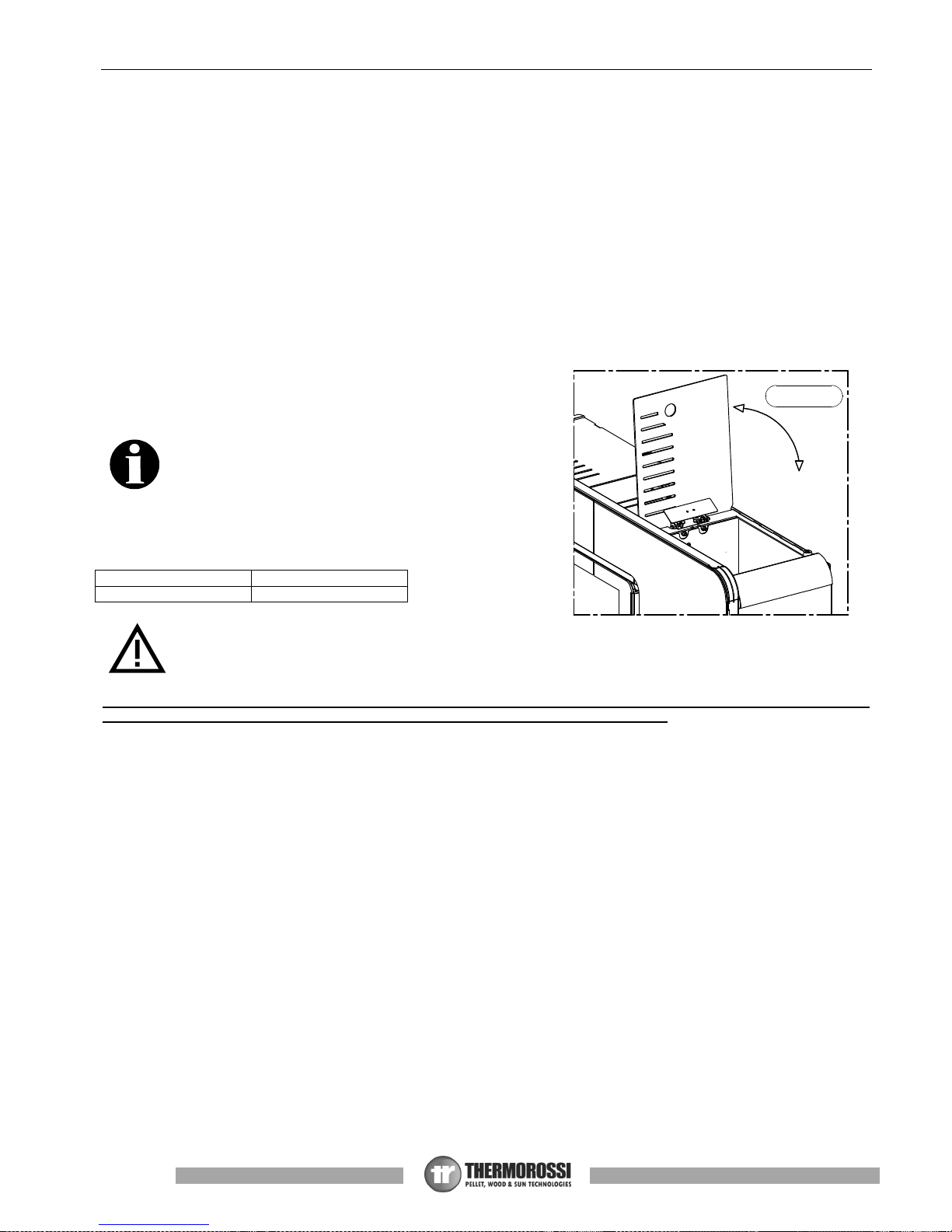

3.3 THE FEEDBOX

The feedbox is situated in the top part of the appliance (Figure

1). The load capacity specified in the technical data can vary

according to the specific weight of the pellets.

Take special care when loading the tank as the screw feeder at

its base is in motion. Take care when topping up with fuel as the

loading area can get very hot.

ATTENTION: it is normal to find some pellets remaining in the

tank even if the stove shuts off because the pellets have run

out.

Legenda

Key

Figura Figure

Attention: when filling up the tank, take care not to drop any pellets into the internal parts of the appliance, as, in

extreme cases, this could generate live flames.

The manufacturer recommends emptying the tank and vacuuming the screw feeder zone once a month and during

the summer period.

Only pellets complying with the above specifications are to be loaded into the tank; in no case whatsoever must foreign

substances or objects be introduced into the tank, the brazier or any part of the generator.

Figura 1

Page 12

Page

12

Installation, use and maintenance guide

SlimQuadro Idra 14

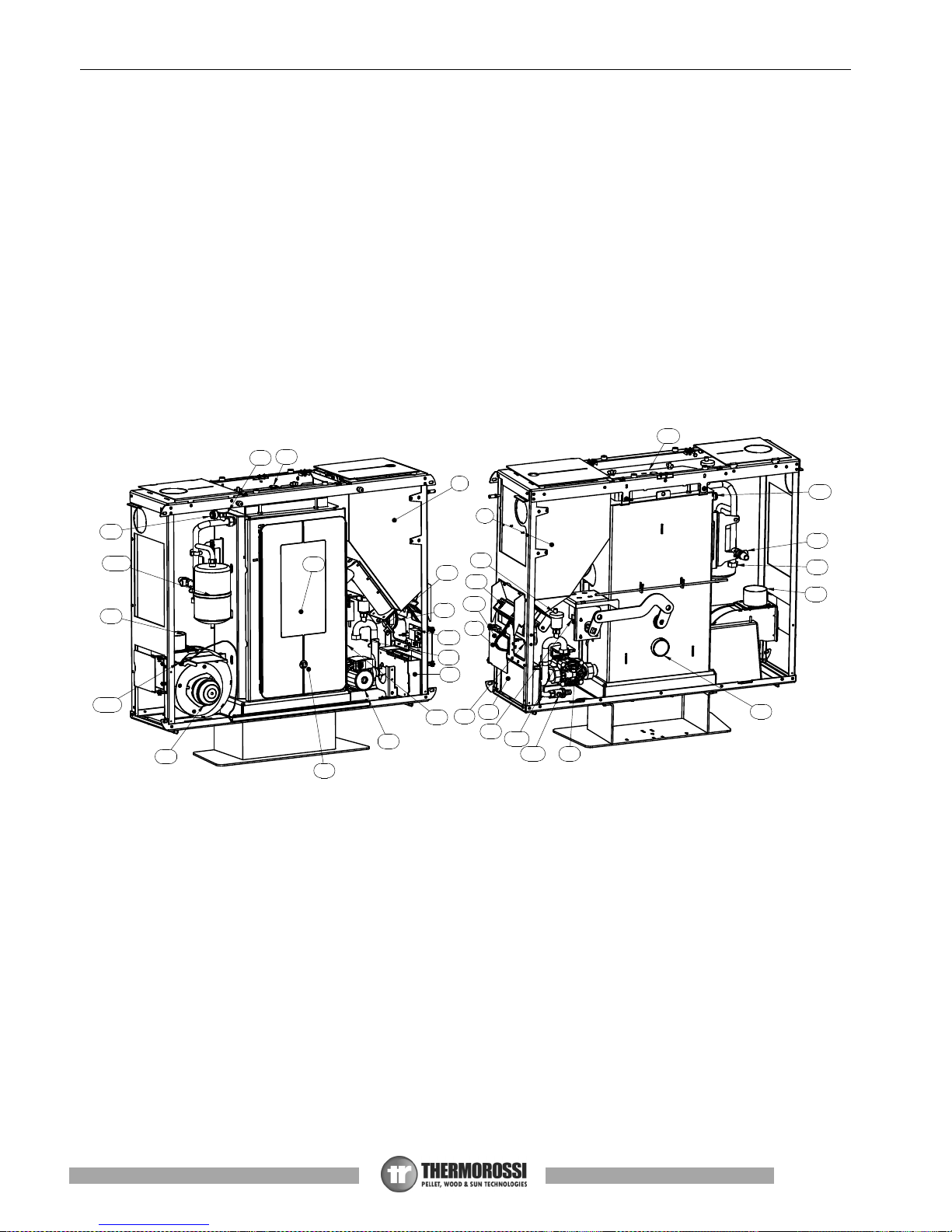

3.4 MAIN COMPONENTS OF THE APPLIANCE

A Burner cleaning motor

O

Pocket for heating system PTC sensor and

thermostat bulb 100°C reset

B System circulating pump

P Automatic relief valve

C Smoke suction unit

Q Tube bundle inspection cover

D Smoke exhaust pipe

R Control panel

E Combustion air exhaust tube

S Spiral tube scraper lever

F Smoke exhaust pressure switch

T Ash pan

G Safety thermostat 100°C

U Combustion chamber / Patented burner

H Pellet loading motor

W 3/4" fill/drain tap

I Pellet tank

X Y

Plant water return

1/2" pressure safety valve 3000 mbar

J Main switch

K Plant water delivery

AD Smoke temperature sensor

L Electronic power board

AC

Expansion tank 2 l for protection of the

appliance only

N Glow plug

A

B

B

C

D

D

E

F

F

H

G

I

I

G

J

K

L

L

N

O

O

P

P

Q

R

S

T

U

W

X

W

Y

AD

AC

Page 13

Page

13

Installation, use and maintenance guide

SlimQuadro Idra 14

4 - INSTALLATION

4.1 APPLIANCE LOCATION

Follow the general guidelines set out in paragraph 1.1 to the letter. Above all keep in mind that the flooring of the

room in which the stove is being installed must withstand the weight of the stove with the added weight of the pellet

load and the water contained in it.

ATTENTION: The appliance must be installed in a

room with adequate ventilation. The appliance must be

positioned at a minimum safe distance from walls and

furnishings. If inflammable items are positioned near

the appliance (matchboarding, furniture, curtains, wall

hangings, sofas, etc...), this gap must be increased

considerably. The recommended minimum distances

are illustrated in the drawing below on the right. If the

flooring is made of wood or any other combustible

material, it is recommended to install a fireproof floor

protector plate between the appliance and the floor.

Installation in the vicinity of heat-sensitive materials is

only permitted if suitable insulating and fireproof

protection is placed between the object and the

appliance (ref. Uni 10683). Failure to observe this

instruction will immediately invalidate the warranty.

The installer must issue a certificate of conformity for

the installation which includes the design plans and the

following documents:

a) Report containing the type of materials utilised.

b) Project as defined in Article 5 of Ministerial Decree n° 37 22 January 2008.

d) References to existing partial or previous declarations of conformity (e.g. electrical wiring).

e) Copy of the certificate of recognition of the professional technical qualifications.

These documents must, by law, be kept together with the use and maintenance booklet. The customer is responsible

for verifying, directly or indirectly, that the installation has been carried out to perfection in accordance with relevant

regulations in force. Do not install the appliance in unsuitable rooms such as bedrooms, bathrooms, garages and/or

lock-ups. It is forbidden to place the appliance in environments with an explosive atmosphere.

ATTENTION, the stove is not simply a household appliance: if the instructions set out in this booklet are not followed and/or if

installation of the appliance is not executed perfectly and/or the provisions in force are not strictly complied with, dangerous

conditions could arise for both objects and persons. It is the user’s responsibility to verify the presence, in the room, of a vent

necessary for supplying oxygen to the generator.

The installer must provide the final user with verbal instructions on the correct use of the appliance when the

appliance is set at work for the first time.

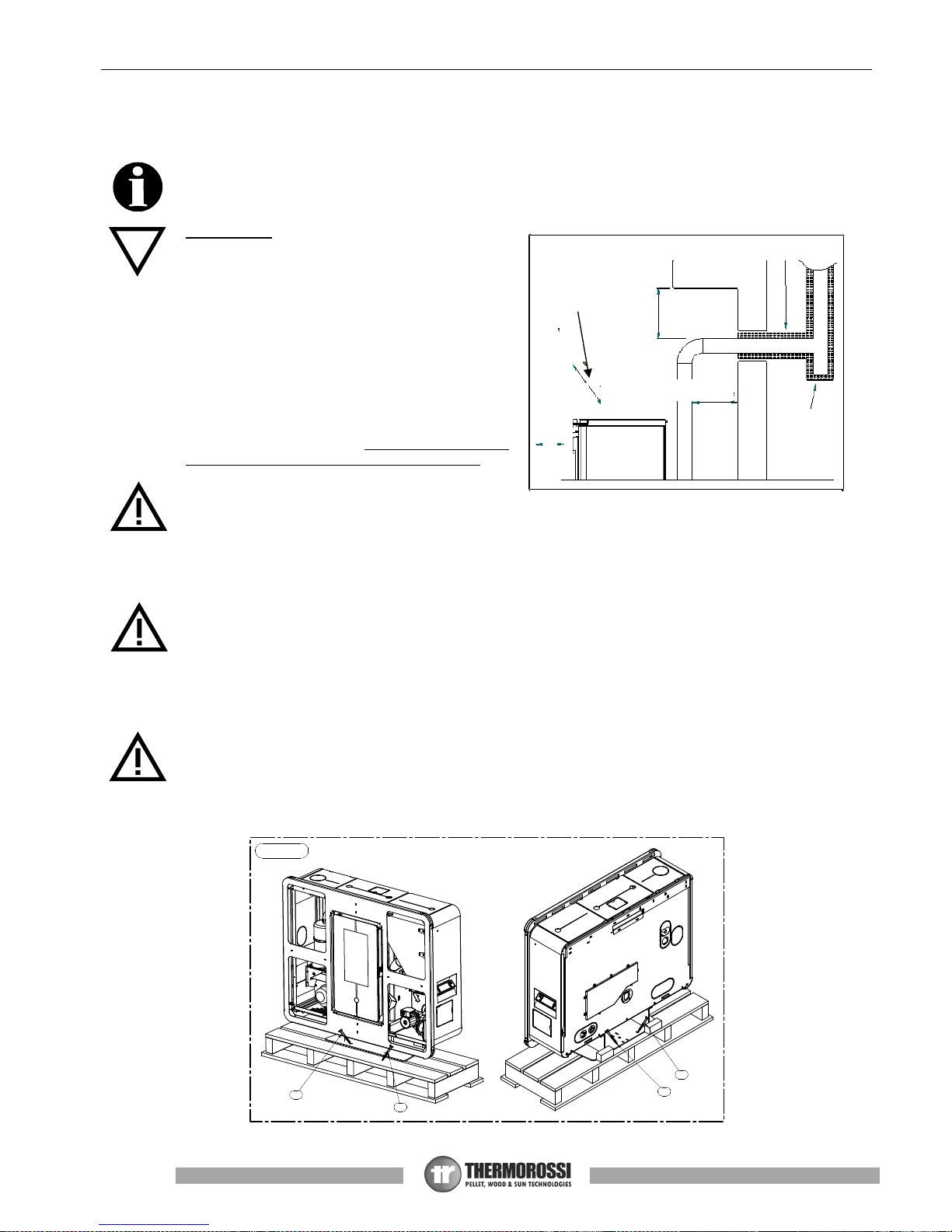

4.2 UNPACKING THE APPLIANCE

To unpack the appliance undo the screws C that fasten the base of the appliance to the pallet (Figure 1).

C

C

C

C

Figura 1

HEAT INSULATING MATERIAL

Inspectable Tee

element

if the material is combustible

200 mm if the material is

combustible

200 mm if the

material is

combustible

Page 14

Page

14

Installation, use and maintenance guide

SlimQuadro Idra 14

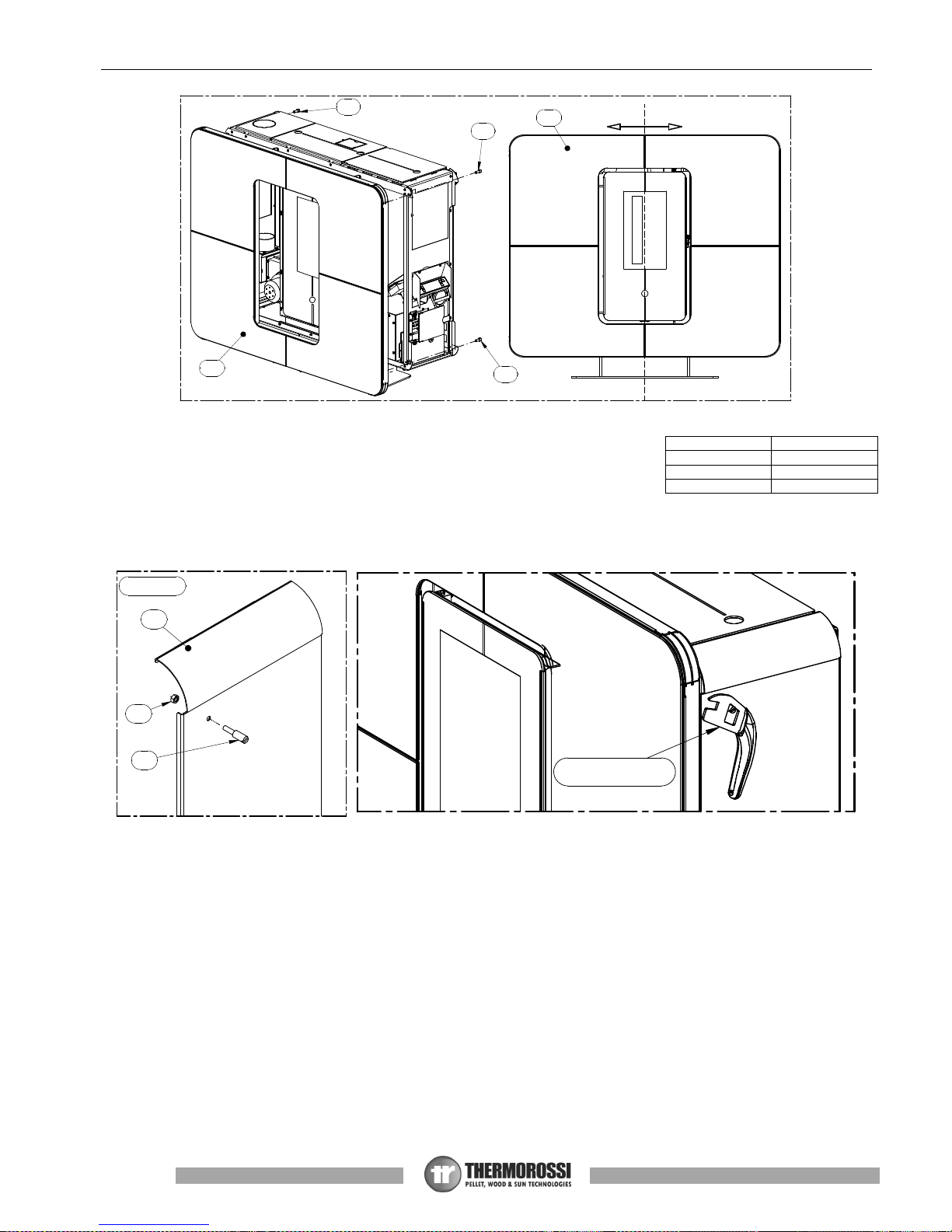

4.3 GLUING THE GLASS PANES TO THE FRONT

PANEL

After unpacking the glass panes of the casing,

disassemble the front panel as described below.

Prior to beginning any operation, lay a soft sheet

on the floor where you can place the front panel

after removing it from the appliance, in order to

prevent damaging the floor or scratching the paint

on the panel.

• Undo screws A and slide out the left protective

panel B

• Undo screws C and slide out the right protective

panel D

• Undo the two screws E that fix the right side of

the front panel

• Undo the two screws F that fix the left side of the

front panel

• Remove the front panel by detaching it from the

body of the appliance.

• Lay the front panel on the sheet on the floor.

To glue the panes to the front panel, firstly apply silicone to the surface of the panel as illustrated in Figure 1. Attention: as

highlighted in Detail C, do not apply silicone to the areas where the corners of the glass cross over. If applied here the silicone

could leak out and ruin the look of the product.

Position each glass pane by placing it in an inclined position and using the locators A indicated in Figure 1. When the edges of the

glass abut the locators A, delicately place the entire surface of the pane with the applied silicone and exert uniform pressure with

your hands over the whole surface, while making sure that the pane remains aligned in position. Repeat this procedure for all the

glass panes.

After checking that the panes are aligned with each other and with the front panel secure them in position by applying strips of

paper tape along the edges.

Wait at least 24h for the silicone to cure before handling the front panel. If the room temperature drops below 18°, wait at least 48

hours for the silicone to cure completely.

ATTENTION: Use mono-component acetic-reticulation silicone suitable for high temperatures (min. 200°C, max.

300°C) .

4.4 REMOUNTING THE FRONT PANEL

Once the appliance has been installed, the next step is to remount the front panel. Re-attach the front panel G to the body of the

appliance and lightly screw in the screws E (do not tighten). After checking that the front panel is aligned with the door (see the

alignment line in the drawing below) tighten the screws E. Complete the assembly of the heater.

Legenda

Key

Figura Figure

S

I

L

I

C

O

N

E

A

L

T

A

T

E

M

P

E

R

A

T

U

R

A

C

C

A

A

A

A

Figura 1

B

B

E

F

E

A

A

B

C

C

D

Page 15

Page

15

Installation, use and maintenance guide

SlimQuadro Idra 14

4.5 HANDLE

Your appliance is supplied with a handle for opening and closing the firebox door to facilitate

cleaning (see paragraph 8). The handle is also designed to be used for regulating the channelling flow rate. When not in use, the

handle can be stowed on the side of the appliance if the hook provided is attached to the stove. (see Figure 4).

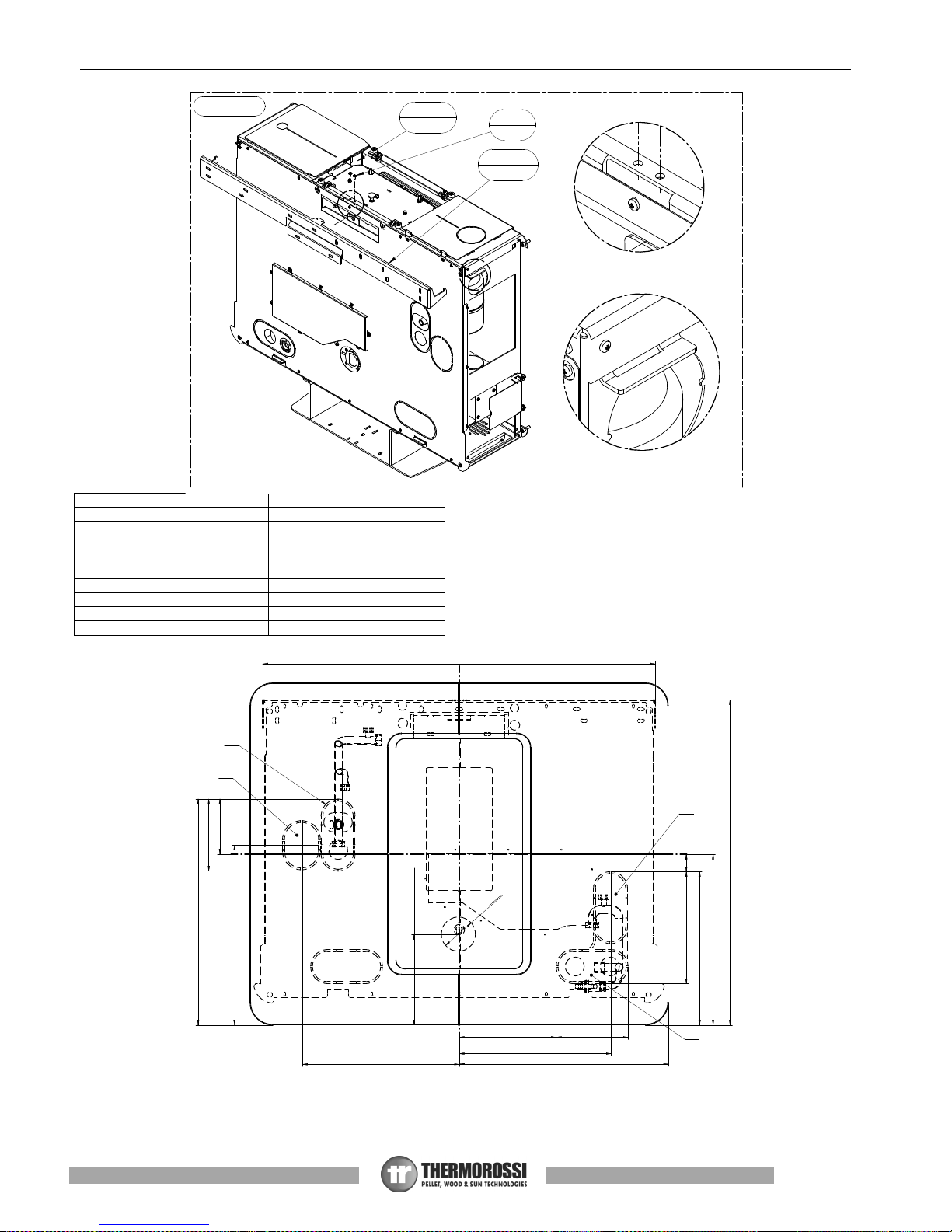

4.6 WALL MOUNT INSTALLATION

The appliance is supplied standard with a wall mount bracket.

To install the appliance on the wall firstly remove the left, right and front panels (see instructions in paragraph 4.3).

Remove the bracket A by undoing the two screws B which can be accessed by releasing the central cover of the compartment C.

For instructions on how to fasten the bracket to the wall refer to the drawing in Figure 8.

ALLINEAMENTO

E

G

G

E

E

Figura 4

1

3

2

MANIGLIA

Legenda

Key

Figura Figure

MANIGLIA HANDLE

ALLINEAMENTO ALIGNMENT

Page 16

Page

16

Installation, use and maintenance guide

SlimQuadro Idra 14

Legenda

Key

Figura Figure

Vano Compartment

Viti Screws

Staffa Bracket

DETTAGLIO DETAIL

MANDATA IMPIANTO PLANT DELIVERY

USCITA FUMI SMOKE OUTLET

RITORNO IMPIANTO PLANT RETURN

CARICO SCARICO IMPIANTO SYSTEM INLET OUTLET

A

DETTAGLIO D

Figura 7

Staffa

A

Viti

B

Vano

C

B

DETTAGLIO C

401

552

452

47295

256 190

145

596

405

475

414

190

858

1037

MANDATA

IMPIANTO

USCITA

FUMI

RITORNO

IMPIANTO

CARICO

SCARICO

IMPIANTO

O

6

0

240 - Presa aria

Page 17

Page

17

Installation, use and maintenance guide

SlimQuadro Idra 14

1

6

K

4

2

2

W

X

Y

3

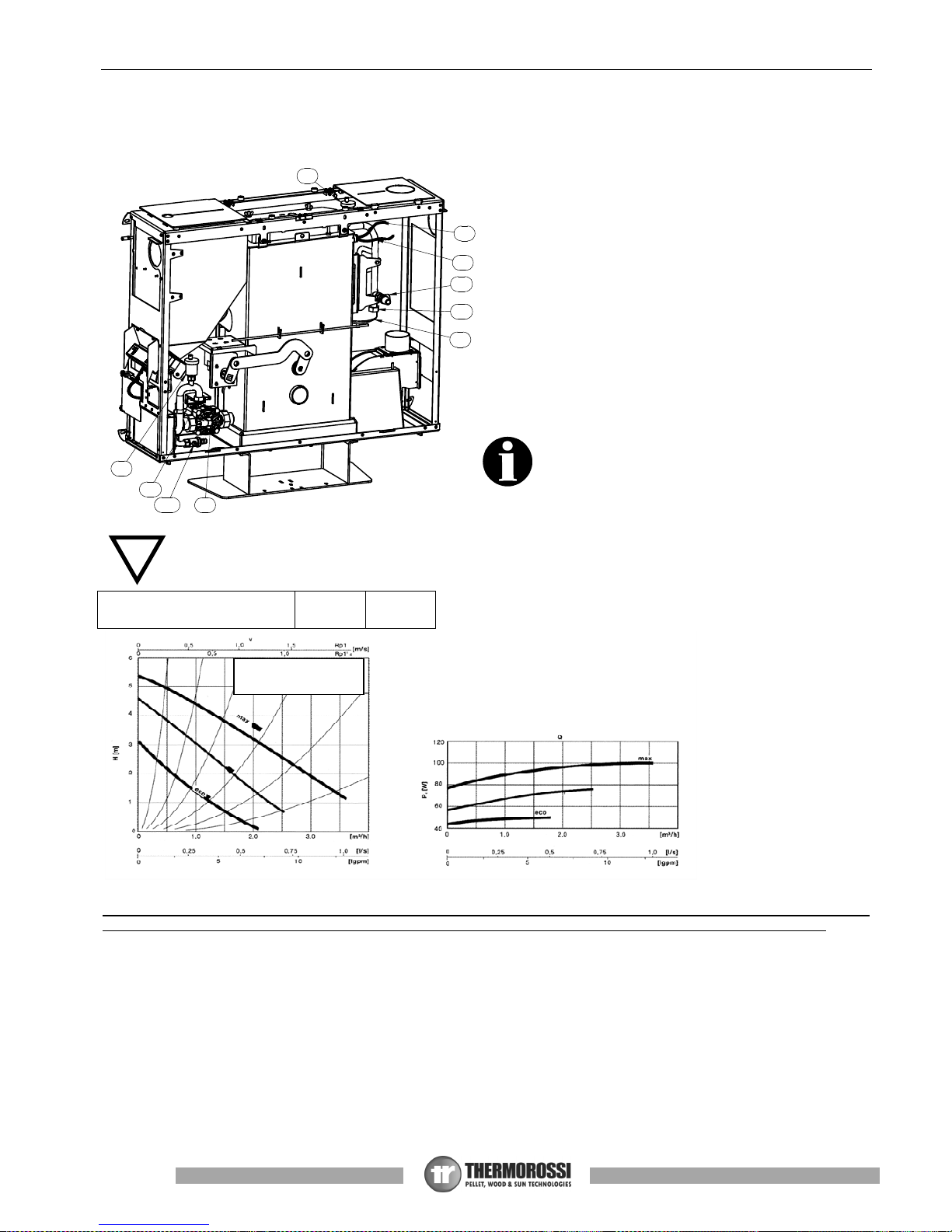

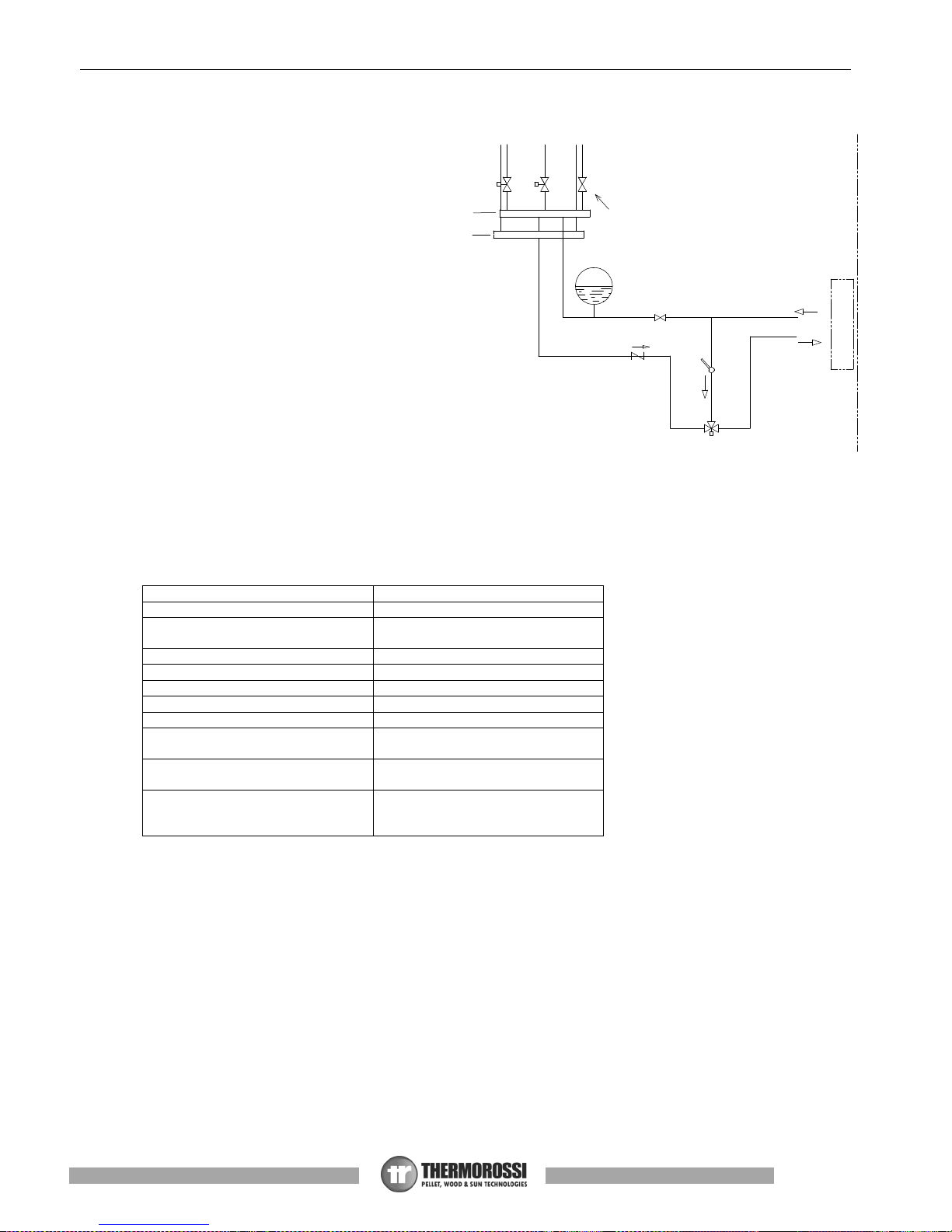

5 – HYDRAULIC CONNECTION

5.1 HYDRAULIC DIAGRAM

1 System circulating pump

2 Automatic relief valve

3 Sensor PTC appliance’s body

4 Thermostat bulb 100°C reset

6 Closed expansion tank

X Heating plant return

K Plant delivery

Y Safety valve 3 bar

W Plant drain and make-up gate valve

ATTENTION: FOR THE DELIVERY, RETURN, MAKEUP AND DISCHARGE CONNECTIONS USE FLEXIBLE

TUBES HAVING A LENGTH OF AT LEAST 70 CM TO

FACILITATE MOVING THE APPLIANCE FOR

MAINTENANCE.

ATTENTION: A CONNECTION MUST BE MADE BETWEEN THE SAFETY VALVE AND THE OUTLET TO

PREVENT DAMAGING MATERIALS SURROUNDING THE APPLIANCE WHEN THE VALVE IS ACTIVATED.

ATTENTION: To avoid continual startups and shut offs, the size of the plant must be such as to guarantee power

absorption that is not less than the power generated by the appliance running at minimum steady state power level.

Head loss with ∆t 20°C between

delivery and return - mbar

32.2 15.4

CHARACTERISTIC CURVES OF

SINGLE-PHASE PUMP

Page 18

Page

18

Installation, use and maintenance guide

SlimQuadro Idra 14

VNR

(z o n a c o n p iu ' a s so r b im en to )

Elettrova lvola s em p re ap e r t a

COLLETTORE

COLLETTORE

TA TA

VEC

TA

S

VM3VT

APPARECCHIO

VSP

A

R

A : andata impianto riscaldamento

R : ritorno impianto riscaldamento

S : saracinesca

VNR : valvola di non ritorno

VEC : vaso di espansione chiuso per protezione impianto

VM3VT : valvola miscelatrice 3 vie termostatica 55°c punto fisso

VSP : valvola saracinesca (da parzializzare in funzione delle

perdite

di carico dell'impianto

5.1.1 GUIDELINES FOR PLANTS WITH ZONE VALVES

Note: above 61°C, the generator pump is always

active as it is essential to dissipate the heat;

therefore the solenoid valve must be open for the

following reasons

:

• to prevent the generator from continually

starting up and shutting off caused by the

inevitable loss of heat to the header and/or due to

plant tubing.

• to prevent the generator from raising the water

temperature by just a few degrees each time it is

switched off then back on until it shuts down due

to exceeding the maximum threshold temperature

of 98°C (manually reset thermostat).

To adjust the ambient temperature in which the

valve opened, we recommend connecting the

room temperature thermostat to the

CHRONOTHERMOSTAT MODEM terminal (free

contact COM-NO see para. 7) that allows the

machine to be shut off via an external contact and

therefore also restarted.

This ensures that the generator only activates if

there is a real request for heat from the zone in which the chronothermostat is installed.

Several parallel-connected room temperature thermostats can be installed in the CHRONOTHERMOSTAT MODEM. This will

ensure that the zone requesting heat (contact closed) automatically activates the generator.

In the event of frequent startups and shut offs due to the heat produced by the generator not being absorbed, the manual reset

safety thermostat trips and blocks the generator.

N.B.: Use chronothermostats having at least 2°C hysterisis.

Legenda

Key

Collettore Header

Elettrovalvola sempre aperta

(zona con più assorbimento)

Solenoid valve always open

(zone with the most absorption)

Apparecchio Appliance

A: andata impianto riscaldamento A – heating plant delivery

R: ritorno impianto riscaldamento R – heating plant return

S: saracinesca S – gate valve

VNR: valvola di non ritorno VNR – nonreturn valve

VEC: vaso di espansione chiuso per

protezione impianto

VEC: closed expansion tank for

plant protection

VM3VT: valvola miscelatrice 3 vie

termostatica 55°C punto fisso

VM3VT: Three-way thermostatic

mixing valve 55°C, fixed point

VSP: valvola saracinesca (da

parzializzare in funzione delle

perdite di carico dell’impianto)

VSP: Gate valve (throttle according

to pressure drop in the system)

Page 19

Page

19

Installation, use and maintenance guide

SlimQuadro Idra 14

5.2 HYDRAULIC DIAGRAM WITH HEATING ONLY

Legenda

Key

Scarico Outlet

APPARECCHIO APPLIANCE

A: andata impianto riscaldamento A – heating plant delivery

R: ritorno impianto riscaldamento R – heating plant return

S: saracinesca S – gate valve

VNR: valvola di non ritorno VNR – nonreturn valve

VEC: vaso di espansione chiuso per protezione

impianto

VEC: closed expansion tank for plant protection

VR: valvola riduttrice di pressione VR: pressure reducing valve

VM3VT: valvola miscelatrice termostatica punto

fisso 55°C

VM3VT: thermostatic mixing valve, fixed point 55°C

VSP: valvola saracinesca (da parzializzare in

funzione delle perdite di carico dell’impianto)

VSP: Gate valve (throttle according to pressure

drop in the system)

Dall’acquedotto per reintegro From water mains for make-up

ATTENTION: it is mandatory to earth the generator. If this instruction is not observed serious damage, which

is not covered by warranty, will result to the body of the appliance. Have a skilled electrician check the

earthing. There must be no electric potential (Volt) between the generator earth and the plant’s real earth

(earth plate). To prevent electrochemical corrosion of the appliance body do not use galvanised pipes and

fittings. Other materials must be earthed with special earthing cables in order to obtain a unipotential

earthing system.

R

S

VNR

A

S

VEC

VM3 VT

per r e i n teg ro

Da ll 'a cq ue d otto

sca ric o

S

VR

VSP

APPARECCHIO

A

R

A : andata impianto riscaldamento

R : ritorno impianto riscaldamento

S : saracinesca

VNR : valvola di non ritorno

VEC : vaso di espansione chiuso per protezione impianto

VR : valvola riduttrice di pressione

VM3VT : valvola miscelatrice termostatica punto fisso

55°c.

VSP: valvola saracinesca (da parzializzare in funzione

delle perdite di carico dell'impianto)

Page 20

Page

20

Installation, use and maintenance guide

SlimQuadro Idra 14

5.3 EXAMPLE OF HYDRAULIC DIAGRAM WITH INTERSPACED BOILER COILS OR BOILER COILS

Legenda

Key

Scarico Outlet

APPARECCHIO APPLIANCE

Bollitore ad intercapedine o a serpentino Boiler tubes with interspacing or boiler coils

A: andata impianto riscaldamento A – heating plant delivery

R: ritorno impianto riscaldamento R – heating plant return

S: saracinesca S – gate valve

VNR: valvola di non ritorno VNR – nonreturn valve

VEC: vaso di espansione chiuso per protezione

impianto

VEC: closed expansion tank for plant protection

VR: valvola riduttrice di pressione VR: pressure reducing valve

VM3VT: valvola miscelatrice termostatica punto

fisso 55°C

VM3VT: thermostatic mixing valve, fixed point 55°C

VSP: valvola saracinesca (da parzializzare in

funzione delle perdite di carico dell’impianto)

VSP: Gate valve (throttle according to pressure

drop in the system)

Dall’acquedotto per reintegro From water mains for make-up

ATTENTION: The water temperature in the boiler tubes in this case is not adjustable and depends on the system's delivery

temperature, that is the temperature set in the generator. The boiler tubes can be installed on the water return circuit. It is

recommended to install a water softener in the domestic water system in order to maintain the boiler at its peak efficiency.

ATTENTION: it is mandatory to earth the generator. If this instruction is not observed serious damage, which

is not covered by warranty, will result to the body of the appliance. Have a skilled electrician check the

earthing. There must be no electric potential (Volt) between the generator earth and the plant’s real earth

(earth plate). To prevent electrochemical corrosion of the appliance body do not use galvanised pipes and

fittings. Other materials must be earthed with special earthing cables in order to obtain a unipotential

earthing system.

A : andata impianto riscaldamento

R : ritorno impianto riscaldamento

S : saracinesca

VNR : valvola di non ritorno

VEC : vaso di espansione chiuso per protezione impianto

VR : valvola riduttrice di pressione

VM3VT : valvola miscelatrice termostatica punto fisso 55°c

VSP: valvola saracinesca (da parzializzare in funzione

delle perdite di carico dell'impianto).

S

R

VNR

A

VEC

BOLLITORE AD

INTERCAPEDINE

S

S

O A SERPENTINO

per rein teg r o

Da ll' a c q u e d ott o

sca ric o

S

VR

VM3 VT

VSP

APPARECCHIO

A

R

Page 21

Page

21

Installation, use and maintenance guide

SlimQuadro Idra 14

5.4 EXAMPLE OF HYDRAULIC DIAGRAM WITH BOILER COILS AND HEATING SYSTEM

Legenda

Key

Contatto cronotermostato Chronothermostat contact

Impianto System

Contatto cronotermostato modem della caldaia Chronothermostat modem contact of the stove

SB ai pin 5 e 6 della morsettiera CN5 SB to pins 5 and 6 of the terminal block CN5

Alimentazione dalla morsettiera CN3 pin 5 (neutro), pin 7 (L1), pin 8

(L2)

Power supply from the terminal block CN3 pin 5 (neutral), pin 7 (L1),

pin 8 (L2)

Scarico Outlet

APPARECCHIO APPLIANCE

A: andata impianto riscaldamento A – heating plant delivery

R: ritorno impianto riscaldamento R – heating plant return

S: saracinesca S – gate valve

VNR: valvola di non ritorno VNR – nonreturn valve

VEC: vaso di espansione chiuso per protezione impianto VEC: closed expansion tank for plant protection

VSP: valvola saracinesca (da parzializzare in funzione delle perdite

di carico dell’impianto)

VSP: Gate valve (throttle according to pressure drop in the system)

SB: sonda acqua calda sanitaria SB: domestic hot water sensor

VR: valvola riduttrice di pressione VR: pressure reducing valve

VM3VT: valvola miscelatrice termostatica punto fisso 55°C VM3VT: thermostatic mixing valve, fixed point 55°C

VDEV3V: valvola deviatrice 3 vie alimentata in chiusura e anche in

apertura

VDEV3V: 3 way diverting valve powered at closure and also at

opening

Dall’acquedotto per reintegro From water mains for make-up

In order to guarantee correct absorption of the heat produced by the generator it is advisable to use a boiler tube with volume and

heat exchange capacity suitable for the power of the generator. The boiler tube must have a minimum capacity of 300l. In any case

the boiler tube must be capable of absorbing all the power that the generator is capable of delivering.

If this rule is not observed, the generator could raise the water temperature to such a point as to activate the safety limit thermostat

which stops the fuel from dropping into the burner and therefore forces the appliance to shut off.

The installer is required to install a valve that switches over to the system, powered by the stove’s control unit, which trips when the

boiler is thermally “satisfied ”. Consequently, the plant must be designed in such a way that the hot water produced by the generator

can reach the various rooms by acting on the zone valves.

ATTENTION: it is mandatory to earth the generator. If this instruction is not observed serious damage, which

is not covered by warranty, will result to the body of the appliance. Have a skilled electrician check the

earthing. There must be no electric potential (Volt) between the generator earth and the plant’s real earth

(earth plate). To prevent electrochemical corrosion of the appliance body do not use galvanised pipes and

fittings. Other materials must be earthed with special earthing cables in order to obtain a unipotential

earthing system.

S

R

S

VNR

S

VNR

S

A

VDEV3 V

VEC

VM3 VT

Co n t a t t o Cr o n o t e r m o s t a t o

Mo d e m d ella ca ld a ia

Co n t a t t o Cr o n oter m o st a t o

Im p i a n to

VSP

p er rein teg r o

Da l l' acq u ed otto

sca r i c o

S

VR

APPARECCHIO

A

R

A : andata impianto

riscaldamento

R : ritorno impianto riscaldamento

S : saracinesca

VNR : valvola di non ritorno

VEC : vaso di espansione chiuso per protezione

impianto

VSP : valvola saracinesca ( da parzializzare in

funzione

delle perdite di carico dell'impianto).

SB : sonda acqua calda sanitaria

VR : valvola riduttrice di pressione

VM3VT : valvola miscelatrice termostatica punto fisso 55°c.

VDEV3V : valvola deviatrice 3 vie alimentata in chiusura e anche in

apertura.

Alimentazione

dalla morsettiera CN3

pin 5 (neutro), pin 7 (L1) , pin 8 (L2)

SB ai pin 5 e 6 della

morsettiera CN5.

Page 22

Page

22

Installation, use and maintenance guide

SlimQuadro Idra 14

5.5 HYDRAULIC DIAGRAM WITH THERMOCELL (OR THERMOPUFFER) + ADDITIONAL THERMOPUFFER +

HIGH TEMPERATURE HEATING AND LOW TEMPERATURE HEATING.

Legenda

Key

Attenzione: chiudere tutti i fori non usati del puffer Note: close all the holes not used by the puffer

Radiatori Radiators

Riscaldamento pavimento Underfloor heating

Sonda PT 100 S1 ai pin 1 e 2 della morsettiera CN5 Temperature sensor PT 100 S1 to pins 1 and 2 of terminal block CN5

Sonda PT 100 S2 ai pin 3 e 4 della morsettiera CN5 Temperature sensor PT 100 S2 to pins 3 and 4 of terminal block CN5

Sonda PT 100 S2 (50°c – 55°c) Temperature sensor PT 100 S2 (50°C – 55°C)

Sonda PT 100 S1 (60°c – 65°c) Sensor PT 100 S1 (60°C – 65°C)

Tubi di collegamento accumuli Connection tubes to puffers

Thermopuffer aggiuntivo Additional Thermopuffer

Thermocell o Thermopuffer Thermocell or Thermopuffer

Apparecchio Appliance

A: andata impianto riscaldamento A – heating plant delivery

R: ritorno impianto riscaldamento R – heating plant return

S: saracinesca S – gate valve

VNR: valvola di non ritorno VNR – nonreturn valve

C: circolatore C: circulating pump

V3V: valvola a 3 vie V3V: three-way valve

V3VM: valvola 3 vie ad azionamento manuale V3VM: manual 3-way valve

VM3VT: valvola miscelatrice termostatica punto fisso 55°C VM3VT: thermostatic mixing valve, fixed point 55°C

VEC: Vaso di espansione chiuso per protezione impianto VEC: Closed expansion tank for plant protection

VSP: valvola saracinesca (da parzializzare in funzione

delle perdite di carico dell’impianto)

VSP: Gate valve (throttle according to pressure drop in the system)

ATTENTION: the preload pressure of the expansion tank must be greater than the plant pressure: for an expansion

tank preloaded to 2 bar the plant must be loaded to a pressure that does not exceed 1.5 bar.

ATTENTION: The Thermocell is only fitted with a connection to 230V - 50Hz power line; The settings of Sensor S1

and Sensor S2 must only be controlled by the appliance (See Par. 6.6) Connect the two sensors PT 100 (optional

code no. 60010695) to the terminals on the appliance’s "Sensor S1" and “Sensor S2" board. Sensor S2 must always

be positioned at the same height as the water delivery to the system.

ATTENTION: Sensor S1 must be set at a range of between 60°C and 65°C, sensor S2 must be set at a range of

between 50°C and 55°C. These settings are only approximate as the optimal setting is carried out by the Service

Centre on site during the initial testing of the stove, following the assessment of the system’s specific characteristics.

Attenzione : chiudere tutti i fori

non usati del puffer

Sonda PT100 S2

Sonda PT100 S1

non usati del puffer

Attenzione : chiudere tutti i fori

Riscaldamento pavimento

Radiatori

Thermopuffer aggiuntivo

Tubi di collegamento accumuli

Thermocell o Thermopuffer

(50°c - 55°c)

(60°c - 65°c)

Sonda PT 100 S1 ai pin 1 e 2

della morsettiera CN5

APPARECCHIO

A

R

Sonda PT 100 S2 ai pin 3 e 4

della morsettiera CN5

S

S

S

S

S

S

S

S

S

S

VSP

VM3 VT

VNR

VNR

VNR

VEC

V3 VM

V3 V

V3 V

C

C

A : andata impianto riscaldamento

R : ritorno impianto riscaldamento

S : saracinesca

VNR : valvola di non ritorno

VEC : vaso di espansione chiuso per protezione impianto

VSP : valvola saracinesca ( da parzializzare in funzione

delle perdite di carico dell'impianto).

C : circolatore

V3V : valvola 3 vie

V3VM : valvola 3 vie ad azionamento manuale

VM3VT : valvola miscelatrice termostatica punto fisso 55°c.

Page 23

Page

23

Installation, use and maintenance guide

SlimQuadro Idra 14

ATTENTION: it is mandatory to earth the generator. If this instruction is not observed serious damage, which

is not covered by warranty, will result to the body of the appliance. Have a skilled electrician check the

earthing. There must be no electric potential (Volt) between the generator earth and the plant’s real earth

(earth plate). To prevent electrochemical corrosion of the appliance body do not use galvanised pipes and

fittings. Other materials must be earthed with special earthing cables in order to obtain a unipotential

earthing system.

ATTENTION: Sensor S2 and sensor S1 must be connected to the dedicated clamps on the terminal block as indicated in the

diagram. To view the readings of Sensors S1 and S2 on the display it is necessary to activate the THERMOCONTROL function

(See. Para. 6.6).

5.6 INSTRUCTIONS FOR EXECUTING THE HYDRAULIC SYSTEM CLOSED EXPANSION TANK

To install the system with a closed expansion tank refer to the requirements laid down in EN 10412-2:2009 for appliances with

nominal heat output not exceeding 35 kW or in the Ministerial Decree Collection R edition 2009 for appliances with nominal heat

output exceeding 35kW.

The hydraulic system must be installed by qualified personnel who are familiar with the standards mentioned above and who have

the appropriate professional requirements to release the declaration of conformance in accordance with Ministerial Decree n° 37 of

22 January 2008.

The generator is already supplied with the following safety devices on board:

a) closed expansion tank for generator protection only*

b) ordinary safety valve 3 bar, not I.S.P.E.S.L. approved

c) an automatic reset temperature limiting device;

This is an automatic adjustment device that interrupts the fuel supply to the generator when the water reaches the

temperature setting. The system starts up again automatically when the water temperature drops below the preset value.

d) a manual reset temperature limiting safety device;

This is an automatic device that interrupts the fuel supply when the water reaches the maximum permissible temperature.

The fuel infeed will only restart when the water temperature drops below a preset value and after the device has been

reset manually.

e) circulation system.

The appliance is fitted with a circulating pump connected to the return pipes which is controlled directly by the

generator’s control board.

*

An additional closed expansion tank must be series-connected to the generator as protection for the system.

The nominal volume of the additional closed expansion tank must be sized in relation to the volume of expansion of the water

contained in the system. Thermorossi prescribes that the size of the additional closed expansion tank must be equal to 10% of the

water contained in the system.

The previous chapter does not replace the above standards to which it makes reference. The qualified installer must in

any case be fully aware of the above standards and their amending versions.

Page 24

Page

24

Installation, use and maintenance guide

SlimQuadro Idra 14

6 – USE OF THE APPLIANCE

The appliance, when operating, could be hot to the touch, particularly the door of the combustion chamber: take care

when handling the appliance components. Your appliance has obtained the CE marking and has been made to run for

at least one hour to check that it functions correctly. The product must not be used by children, by persons with

physical or mental impairments, by persons who are not familiar with the instructions for use and maintenance of the

product (the instructions are found in this use and maintenance booklet).

ATTENTION: Before each use make sure that the burner is clean.

ATTENTION: the door must always remain shut tight when the appliance is operating. It is strictly forbidden to open the

door while the appliance is in operation. While the appliance is in operation the smoke exhaust pipes can reach

extremely high temperatures: do not touch them! It is strictly prohibited to use any type of fuel (liquid, solid...) other than

pallet to light up the appliance: lighting must occur automatically as intended and described in this installation, use and

maintenance booklet; consequently, it is also strictly forbidden to feed pellets (or any other material) into the brazier. Do

not place non-heat resistant or inflammable or combustible objects in the vicinity of the appliance: keep them at a

suitable distance. Do not place wet clothing to dry on the appliance. When using a clothes horse, keep at a suitable

distance. It is strictly prohibited to disconnect the appliance from the electrical power mains during normal operation.

6.1 DESCRIPTION OF THE CONTROL PANEL

The control panel is managed by a microprocessor. The temperature detection system uses thermocouples. The large display

improves the appliance management by making read-outs and functions promptly available. The main feature of the panel is the allautomatic management of the appliance. The controls and the various displays are described below.

Flame button

Pressing this button when the appliance is off activates the

START

sequence (See Para. 6.10), sets the operating

power in the

WORK

mode (See Para. 6.10) or shuts off the appliance by activating the

OFF

sequence (See Para.

6.10).

Degrees Button

Press this button to set the target water temperature; the setting range is between 65 °C and 73 °C. This value is

displayed on the left side of the display next to the thermometer symbol.

Attention: the target temperature is only considered if the appliance is in AUTO mode (See Para. 6.10).

Scroll buttons (only in the Menu)

Press MINUS key to lower the value. Press PLUS key to raise the preset value.

Clock button

Press this button to activate / deactivate the programming. (See para. 6.4),

Menu button

Press this button to access the main menu. You can scroll the setting screens shown below, which will be described in

detail in the following paragraphs. To access the functions of each subwindow wait a few seconds.

DATE/TIME

This button is used to set the day of the week, the hour and minutes. (See para. 6.3)

CHRONO

This button is used to set the programmed on and off sequences. (See para. 6.4)

LEVEL

Is used to change the rotation speed of the smoke suction unit. (See para. 6.5)

THERMOCONTROL

Enables you to activate or deactivate the control of a puffer (if installed).

This screen only appears if the two optional sensors are connected to the appliance. (See para. 6.6)

ACS SUMMER

Enables you to activate or deactivate the dedicated control of a boiler (if installed) that produces

domestic hot water, thereby cutting off the system.

This screen only appears if the

optional sensor is connected to the appliance. (See para. 6.7)

T.AMBIENT

Enables you to control the ON/OFF cycles of the appliance according to the desired room temperature.

This screen only appears if the optional sensor is connected to the appliance (See para. 6.8)

Page 25

Page

25

Installation, use and maintenance guide

SlimQuadro Idra 14

THERMO ACS

Enables you to activate control of a boiler (if installed) for domestic hot water assigning absolute priority

to the boiler requirements before replenishing the system.

This screen only appears if the optional sensor is connected to the appliance (See para. 6.9)

Display

The following information can appear on the display:

The appliance is in the OFF stage (See para. 6.9).

1° MANUAL OPERATING POWER

2° MANUAL OPERATING POWER

3° MANUAL OPERATING POWER

4° MANUAL OPERATING POWER

5° MANUAL OPERATING POWER

In this mode the user can choose to run the appliance from the minimum power (therefore with the minimum pellet consumption) to

the maximum power (therefore with the maximum pellet consumption). In this case the appliance always runs at the set power

without any modulation in accordance with the target temperature.

AUTOMATIC LEVEL

The appliance modulates the the operating power automatically based on the target temperature set by the user. (See para. 6.10),

Indicates the temperature of the domestic hot water boiler, if the optional sensor is connected. (See para. 6.7 or 6.9)

Indicates the temperature of Sensor S1 for control of a puffer, if the optional sensor is connected. (See Para. 6.6)

Indicates the temperature of Sensor S2 for control of a puffer, if the optional sensor is connected. (See Para. 6.6)

Indicates that the circulation pump is activated when the water temperature in the boiler exceeds 61°C.

Indicates the boiler water temperature detected by the thermocouple.

The thermometer icon, on the left of the display, indicates the target temperature for the water in the boiler, which can be

adjusted by the user by means of the

Degrees Button.

Indicates that the appliance has been switched on by the contact of an external chronothermostat. (See para. 7.2)

Indicates that the appliance has been connected to a puffer which is requesting heat. (See para. 6.6)

Indicates that the ON/OFF programming set through CHRONO has been enabled. (See para. 6.4)

Indicates the room temperature detected by the thermocouple, if connected. (See para. 6.8)

The thermometer icon, on the right of the display, indicates the target room temperature set by the user if the optional

sensor is connected. (See para. 6.8)

Page 26

Page

26

Installation, use and maintenance guide

SlimQuadro Idra 14

6.2 DESCRIPTION OF THE POWER PANEL

The components of the power panel are described below:

1) Electrical power outlet 220V-240V 50Hz

2) Main switch 0/I.

3) Test light for pellet feed motor.

The light comes on simultaneously with the activation of the pellet

feed motor.

4) Cap for reset thermostat button.

If the reset thermostat overheats stop the pellet feeder. The appliance

must cool down before you can restart the appliance. After verifying

and eliminating the causes of the event, undo the protective cap and

press the button.

5) Safety fuse.

6.3 DATE/TIME: SETTING THE DATE AND TIME

The appliance must be energised and the I/0 switch in position “I".

The current date and time can be set using the DATE/TIME function.

To set the current time and date proceed as follows:

1) Press the

Menu Button

once to view the following screen:

2) After a few seconds the following screen will appear on the display:

3) Now press the

Scroll Buttons

to change the day of the week; each number corresponds to one day of the week (e.g. 1

corresponds to Monday, 2 corresponds to Tuesday, etc...). To confirm the selected day of the week press the

Degrees Button

.

Once confirmed, the selector shifts to the hour section while the selected day of the week remains framed:

4) Press the

Scroll Buttons

to change the hour. Once you have set the hour confirm the value by pressing the

Degrees Button.

Once confirmed, the selector shifts to the minutes section. Press the

Scroll Buttons

to set the minutes. To confirm press the

Degrees Button

.

Once confirmed, the date and time setting screen closes automatically and the initial screen returns to the display.

If you confirm the wrong value simply press the

Menu Button

several times to exit the box until the initial screen will appear, and

repeat the procedure described above.

6.4 CHRONO: ON/OFF PROGRAMMING

The appliance must be energised and the I/0 switch in position “I".

The CHRONO function allows you to set the weekly program by setting up to 3 on-off cycles at different times for every day from

Monday through to Sunday.

To set a program follow the procedure described below:

1) Press the

Menu Button

twice quickly to view the following screen:

After a few seconds the following screen will appear on the display:

2) Press the

Scroll Buttons

to select the day of the week on which you want to set the program. Each number corresponds to one

day of the week (e.g. 1 corresponds to Monday, 2 corresponds to Tuesday, etc...). To confirm the selected day of the week for

the programming press the

Degrees Button

. The following screen will appear:

Legenda

Key

RIARMO RESET

SPIA MOTORIDUTTORE RATIO MOTOR

INDICATOR

3

4

2

1

5

Page 27

Page

27

Installation, use and maintenance guide

SlimQuadro Idra 14

3) Now press the

Scroll Buttons

to select the hour at which you wish the appliance to start up automatically (ON1). Once the hour

is set confirm the value by pressing the

Degrees Button.

When scrolling the ON1 values the OFF1 values will scroll as well; this

is to avoid setting a shut off time that is earlier than the start up time.

Once confirmed, the selector shifts to the minute section of ON1. Press the

Scroll Buttons

to set the minutes for the first start

up. Confirm by pressing the

Degrees Button

.

4) Now press the

Scroll Buttons

to select the hour at which you wish the appliance to shut off automatically (OFF1). Once the

hour has been set, confirm the value by pressing the

Degrees Button.

Once confirmed, the selector shifts to the minute section of OFF1. Press the

Scroll Buttons

to set the minutes for the first shut

off. Confirm by pressing the

Degrees Button

.

At this point the first ON/OFF cycle for the selected day has been set.

The following screen will appear:

At this point if no further programming is required for that day go to point 5-A.

If, on the other hand, you wish to program a second ON/OFF cycle for that day go to point 5-B.

5-A) Press the

Menu Button

to exit the screen, in order to enable you to program the times for the ON/OFF cycles for the other

days of the week. In this case repeat the instructions from point 2 up to this paragraph.

5-B) Press the

Scroll Buttons

to select the hour at which you wish the appliance to start up automatically for the second time

(ON2). The start up time will be that set before OFF1; this is to avoid setting a second start up time that is earlier than the

preceeding shut off time. Once the hour is set confirm the value by pressing the

Degrees Button.

When scrolling the ON2

values the OFF2 values will scroll as well; this is to avoid setting a shut off time that is earlier than the start up time.

Once confirmed, the selector shifts to the minute section of ON2. Press the

Scroll Buttons

to set the minutes for the second

start up. Confirm by pressing the

Degrees Button

.

Now press the

Scroll Buttons

to select the hour at which you wish the appliance to shut off automatically (OFF2). Once the

hour has been set, confirm the value by pressing the

Degrees Button.

Once confirmed, the selector shifts to the minute section of OFF2. Press the

Scroll Buttons

to set the minutes for the

second shut off. Confirm by pressing the

Degrees Button

At this point the second ON/OFF cycle for the selected day has been set.

The following screen will appear:

At this point if no further programming is required for that day go to point 6-A.

If, on the other hand, you wish to program a third ON/OFF cycle for that day go to point 6-B.

6-A) Press the

Menu Button

to exit the screen, in order to enable you to program the times for the ON/OFF cycles for the other

days of the week. In this case repeat the instructions from point 2 up to this paragraph.

6-B) Press the

Scroll Buttons

to select the hour at which you wish the appliance to start up automatically for the third time (ON3).

The start up time will be that set before OFF2; this is to avoid setting a third start up time that is earlier than the preceeding

shut off time. Once you have set the hour confirm the value by pressing the

Degrees Button.

When scrolling the ON3

values the OFF3 values will scroll as well; this is to avoid setting a shut off time that is earlier than the start up time..

Once confirmed, the selector shifts to the minute section of ON3. Press the

Scroll Buttons

to set the minutes for the third

start up. Confirm by pressing the

Degrees Button

.

Now press the

Scroll Buttons

to select the hour at which you wish the appliance to shut off automatically (OFF3). Once the

hour has been set, confirm the value by pressing the

Degrees Button.

Once confirmed, the selector shifts to the minute section of OFF3. Press the

Scroll Buttons

to set the minutes for the third

shut off. Confirm by pressing the

Degrees Button.

At this point the third and final ON/OFF cycle for the selected day has been set.

Alternatively, if you wish to copy the exact same programming for the ON/OFF cycles set for a particular day to the next day simply

press the

Flame button

.

For example: if I want to copy all the programmed ON/OFF cycles set for Monday to Tuesday the following screen will appear:

Press the

Flame button

once again to copy all the cycles programmed for Tuesday to Wednesday. The following screen will

appear:

Page 28

Page

28

Installation, use and maintenance guide

SlimQuadro Idra 14

Using the same logic we can copy the programmed cycles to the other days.

7) To conclude the programming operations simply press the

Menu Button

several times to exit the box until the initial screen will

appear.

ATTENTION: The appliance ignores any ON or OFF command programmed with a value of 00:00

.

Consequently if you do not wish to use an ON or OFF time setting simply set a value of

00:00

. The appliance ignores

any ON or OFF command if the shut off time is set the same as or before the start up time.

ATTENTION:

In the event of a programmed cycle on always ensure that the brazier is clean. Failure to clean the brazier can reduce

and/or affect the life of the spark plug as it would be subjected to high temperatures due to poor cooling. It is

recommended to set ON/OFF cycles times lasting no less than 2 hours, in order to save energy and for the proper

operation of the appliance.

.

Enabling the programmed cycles:

Back in the initial screen, to enable the appliance to carry out the ON/OFF cycles as programmed it is necessary to press the

Clock

Button

.

The image of a clock will appear on the main screen:

The programmed cycles are now enabled.

When the programmed cycles are enabled (a clock symbol appears on the display) it will not be possible to

use an additional chronothermostat (see Para. 7.2). The appliance will strictly follow the programmed ON/OFF

times. No request for heat by the system, a puffer or a domestic hot water boiler will be considered by the

appliance if it is outside the programmed time interval.

Disabling the programmed cycles:

To disable the appliance from carrying out the programmed ON/OFF cycles press the

Clock Button

once again.

On the display the clock symbol will disappear. This operation disables the weekly program that has been set by the user but does

not delete or reset the times.

Resetting the programmed cycles: