THERMOROSSI ECOTHERM H20 14, ECOTHERM H2O 25, ECOTHERM COMPACT 25 Installation, Use And Maintenance Manual

Page 1

pg. I

INSTALLATION, USE AND MAINTENANCE GUIDE

ECOTHERM H20 14 - COMPACT 14

HEATING TECHNOLOGY AND INNOVATION

Page 2

pg. II

C O N T E N T SC O N T E N T S

C O N T E N T SC O N T E N T S

C O N T E N T S

1. INTRODUCTION ...........................................................................................................................................................................................................

1.1 General guidelines ........................................................................................................................................................................................

1.2 Safety guidelines..........................................................................................................................................................................................

1.3 Standards and recommendations ..................................................................................................................................................................

1.4 Transportation and storage...........................................................................................................................................................................

2. TECHNICAL CHARACTERISTICS ............................................................................................................................................................................

2.1 Technical dat a ..............................................................................................................................................................................................

3. GENERAL DESCRIPTION...........................................................................................................................................................................................

3.1 Operating technology ...................................................................................................................................................................................

3.2 Pellets ..........................................................................................................................................................................................................

3.3 The feedbox .................................................................................................................................................................................................

3.4 Main components of heater mod. h2o and boiler mod. Compact ...................................................................................................................

4. INSTALLA TION ..............................................................................................................................................................................................................

4.1 Heater / boiler location .................................................................................................................................................................................

4.2 Mounting boiler / heater casing...................................................................................................................................................................

4.2.1 How to mount H2O 14 heater casing............................................................................................................................................................

4.2.3 How to mount Compact boiler casing............................................................................................................................................................

4.2.4 How to install the additional hopper (optional) with Compact boiler..............................................................................................................

4.2.5 Fastening additional hopper (optional) to Compact boiler .............................................................................................................................

4.3 Hydraulic drawing for heater H2O / Compact ...............................................................................................................................................

4.4 Example of hydraulic drawing for H2O / Compact only heating ....................................................................................................................

4.5 Example of hydraulic drawing H2O / Compact with interspaced boiler coils or boiler coils. ........................................................................

4.6 Example of hydraulic drawing H2O / Compact with boiler coils and use of Thermocontrol (optional) ...........................................................

4.7 Example of hydraulic drawing for H2O / Compact with "Kit for the production of instant domestic hot water " (optional)............................

4.8 Example of hydraulic drawing H2O / Compact + Thermocell (or Thermopuffer) + additional Thermopuffer + High temperature heating and

low temperature heating ...............................................................................................................................................................................

4.9 Instructions for executing the hydraulic system closed expansion tank.

5. USE OF THE HEATER / BOILER ...............................................................................................................................................................................

5.1 Description of control panel

5.2 Description of rear panel ..............................................................................................................................................................................

5.3 Day and time setting.....................................................................................................................................................................................

5.4 Chronothermostat: ON/OFF programming .....................................................................................................................................................

5.5 Language selection ......................................................................................................................................................................................

5.6 Operating level setting .................................................................................................................................................................................

5.7 Water pressure in the generator...................................................................................................................................................................

5.8 Action temperature setting "Sensor 1 Thermocell" and " Sensor 2 Thermocell " as indicated in the hydraulic drawing para. 4.8 .................

5.9 Domestic hot water production .....................................................................................................................................................................

5.10 Information about how the generator works .................................................................................................................................................

5.11 Boiler water pressure control. ......................................................................................................................................................................

5.12 Switching on the heater H2O / boiler Compact.............................................................................................................................................

5.13 Adjusting the combustion of the heater H2O / boiler Compact. ....................................................................................................................

5.14 Switching off the heater H2O / boiler Compact. ...........................................................................................................................................

6. ADDITIONAL ROOM TEMPERA TURE THERMOST A T AND ADDITIONAL CHRONOTHERMOST AT (NOT SUPPLIED)

6.1 Operating with the additional room temperature thermostat (not supplied )

6.2 Operating with the additional chronothermostat (not supplied) ....................................................................................................................

7. CLEANING AND MAINTENANCE..................................................................................................................................................................................

7.1 Foreword ......................................................................................................................................................................................................

7.2 Cleaning and maintenance of heater H2O / boiler Compact ..........................................................................................................................

8. SMOKE DISCHARGE TUBE AND COMBUSTION AIR INT AKE...................................................................................................................................

8.1 Ventilation of the rooms ................................................................................................................................................................................

8.2 Combustion air intake ...................................................................................................................................................................................

8.3 Smoke outlet .................................................................................................................................................................................................

9. ALARMS .....................................................................................................................................................................................................................

10. ELECTRICAL WIRING .................................................................................................................................................................................................

11. INFORMATION FOR THE SKILLED TECHNICIAN......................................................................................................................................................

11.1 Main components and their operation...........................................................................................................................................................

11.2 Useful advice for installation and operation .................................................................................................................................................

11.3 Troubleshooting cause - solution..................................................................................................................................................................

12. SPARE P ARTS ................................................................................................................................................................................................................

Page 3

pg. III

THERMOROSSI S.p.A.

Via Grumolo. 4

36011 ARSIERO

tel. 0445.741310

fax 0445.741657

"CE" DECLARATION OF CONFORMITY

In accordance with the following directives:

European Directive 73/23/EEC and its amending directive 93/68/EEC

89/336/EEC and its amending directives 93/68/EEC

92/31/EEC

93/97/EEC

EN 14785 : 2006

EN 303-5 : 1999

Thermorossi S.p.A., Via Grumolo 4 - ARSIERO (VI), declares that the heater H2O and the boiler Compact have been designed and manufactured

in compliance with the safety requirements of the standards for EC marking.

This declaration refers to the entire range of the specified series.

The reference standard for the H2O 14 IS EN 14785 :2006

The reference standard for the Compact 14 is EN 303-5

ARSIERO , 3 June 2010

THERMOROSSI S.p.A.

Page 4

pg. IV

11

11

1

INTRODUCTIONINTRODUCTION

INTRODUCTIONINTRODUCTION

INTRODUCTION

1.11.1

1.11.1

1.1

GENERAL GUIDELINESGENERAL GUIDELINES

GENERAL GUIDELINESGENERAL GUIDELINES

GENERAL GUIDELINES

This installation, use and maintenance guide is an integral and essential part of the product and must be kept by the user . Before commencing with

the installation, use and maintenance of the product, carefully read all the instructions contained in this booklet. At the time of installation of the

appliance all local regulations, including those that refer to national and European regulations, must be observed. The Manufacturer recommends

carrying out all the maintenance operations described in this manual.

This appliance must only be used as intended by the manufacturer. Any other use is considered incorrect and therefore hazardous; consequently,

the user shall be totally liable for the product if used improperly. Installation, maintenance and repairs must be carried out by personnel with

professional qualifications and in compliance with current regulatory standards and in accordance with the instructions of the manufacturer of

the appliance. Use only original spare parts.

Incorrect installation or poor maintenance could injure or damage people, animals or things; in this case the manufacturer shall be relieved of all

responsibility. Before commencing any cleaning or maintenance operation ensure that the appliance has been disconnected from the mains

power supply by means of the main system switch or some other disconnecting device installed upstream from the appliance. The product must

be installed in locations suitable for fire-fighting and furnished with all the services (power and outlets) which the appliance requires for a correct

and safe operation. Any repairs or actions carried out on any systems, components or internal parts of the appliance, or on any of the

accessories supplied with it, that are not specifically authorised by Thermorossi s.p.a, will automatically void the warranty and the manufacturer's

responsibility, pursuant to D.P.R.Use only original Thermorossi spare parts. If the appliance is sold or transferred to another user ensure that the

guide is handed over with it.

Thermorossi S.p.A. maintains the author’s rights on these service instructions.

The information in this booklet may not be reproduced or given to third parties or used for competitive purposes without the appropriate

authorization.

1.2 SAFETY GUIDELINES1.2 SAFETY GUIDELINES

1.2 SAFETY GUIDELINES1.2 SAFETY GUIDELINES

1.2 SAFETY GUIDELINES

PERSONAL INJURY

This safety symbol identifies important messages throughout the manual. Read the information marked by this symbol carefully as nonobservance of this message can cause serious injury to persons using the heater/boiler.

DAMAGE TO PROPERTY

This safety symbol identifies messages or instructions that are fundamental for the heater/boiler and system to function well. Failure

to observe these symbols could result in serious damage to the heater/boiler and system.

INFORMATION

This safety symbol signals instructions that are important for the good operation of the heater / boiler or heating system. The appliances

will not function correctly if the instructions are not observed correctly.

1.31.3

1.31.3

1.3

STST

STST

ST

ANDAND

ANDAND

AND

ARDS ARDS

ARDS ARDS

ARDS

AND RECOMMENDAND RECOMMEND

AND RECOMMENDAND RECOMMEND

AND RECOMMEND

AA

AA

A

TIONSTIONS

TIONSTIONS

TIONS

NORMATIVE REFERENCES :national and international standards used as reference guides in the following manual for the design,

industrialization and production of the products:

- European directive 73/23/EEC- Standard CEI 61/50 EN 303-5 : 1999

- European directive 93/68/EEC- Standard CEI EN 60204 EN 14785 : 2006

- European Directive 89/336/EEC- Standard CEI 64-8 (IEC 364)

RECOMMENDATIONS

Before using the appliance, carefully read every section of this instruction manual as knowledge of the information and the regulations

contained in it are essential for a correct use of the appliance.

The entire operation concerning the connection of the electric panel must be carried out by expert personnel; no responsibility will be

accepted for damages, even to third parties, if the instructions for installation, use and maintenance of the appliance are not followed

scrupulously. Modifications made to the appliance by the user or on his behalf, must be considered to be under his complete

responsibility. The user is responsible for all the operations required for the installation and maintenance of the appliance before and

during its use.

GENERAL WARNINGS

Caution: the appliance must be connected to a system provided with a PE conductor (in compliance with the specifications of 73/23/

EEC, 93/98/EEC, concerning low voltage equipment).

Before installing the appliance check the efficiency of the earth circuit of the power supply system.

Caution: the power supply line must have a section which is suitable for the power of the equipment. The cable section must in any

case be no less than 1.5 mm². The appliance must be powered with a voltage of 220/240 V and 50 Hz. Voltage variations which exceed

10% of the nominal value can cause poor functioning or damage the electrical device. Position the appliance so that the electric power

plug is easily accessible. Voltage variations less than 10% of the nominal value can cause lighting and use problems. Apply a current

regulator.

Ensure that a suitable differential switch is installed upstream from the equipment.

1.41.4

1.41.4

1.4

TRANSPORTRANSPOR

TRANSPORTRANSPOR

TRANSPOR

TT

TT

T

AA

AA

A

TION TION

TION TION

TION

AND STAND ST

AND STAND ST

AND ST

ORAORA

ORAORA

ORA

GEGE

GEGE

GE

TRANSPORTATION AND HANDLING The boiler body must always be in a vertical position when handled and exclusively by means of

trolleys. Take special care to protect the electric panel, the glass, the ceramics and all the fragile parts from mechanical impact which could

damage them and their correct functioning.

STORAGE : The heater / boiler must be stored in a humid-free environment and sheltered from the weather; do not place the heater / boiler

directly on the floor. The Company denies all responsibility for damage caused to wood floors or floors made from any other material. It is

inadvisable to store the heater / boiler for long periods of time.

Caution: it is mandatory to earth the heater / boiler. If this instruction is not observed serious damage, which is not

covered by warranty, will result to the body of the heater / boiler. Have an electrician check the earthing. there

must be no electric potential (volts) between the earth of the generator and the actual earth of the plant. To prevent

electrochemical corrosion of the boiler body do not use galvanised pipes and fittings.Dedicated ground wires must

be used to ground all other materials.

Page 5

pg. V

22

22

2

TECHNICAL CHARACTERISTICS *TECHNICAL CHARACTERISTICS *

TECHNICAL CHARACTERISTICS *TECHNICAL CHARACTERISTICS *

TECHNICAL CHARACTERISTICS *

2.12.1

2.12.1

2.1

TECHNICAL DTECHNICAL D

TECHNICAL DTECHNICAL D

TECHNICAL D

AA

AA

A

TT

TT

T

AA

AA

A

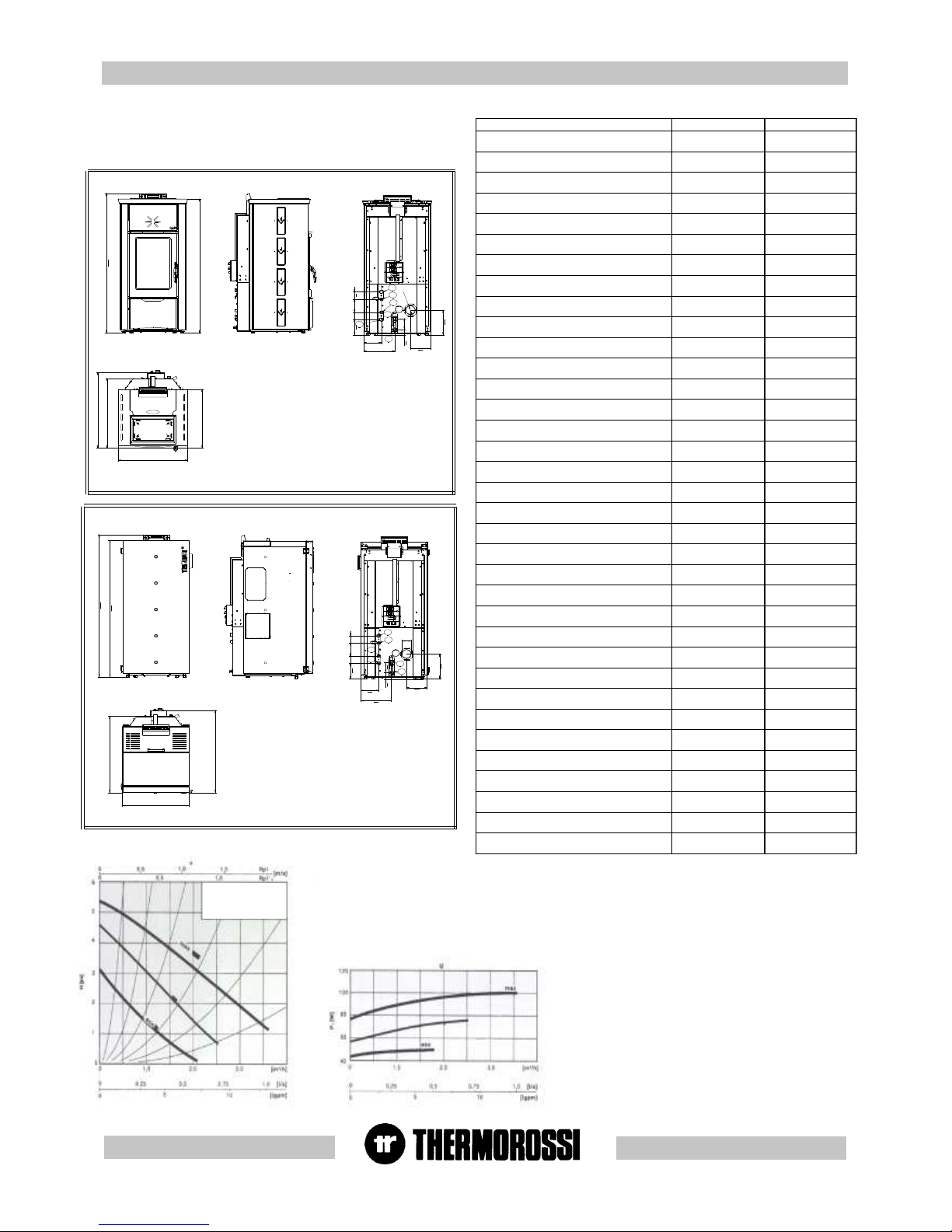

CHARACTERISTIC CURVES OF SINGLE-PHASE PUMP

41O2H 41O2H

41O2H

41O2H 41O2H 41tcapmoC 41tcapmoC

41tcapmoC

41tcapmoC 41tcapmoC

)mm(thgieH 2421

6621

)mm(htpeD 866

137

)mm(htgneL 765

065

)gK(thgieW 112

602

)wK(rewopdetarlatoT 6,21

6,01

)wK(rewopdetardecuderlatoT 7,4

5,4

)wK()retaw(rewopdetarlatoT 1,01

1,01

)wK()moor(rewopdetarlatoT 5,2

5,0

)retaw(rewopdetardecuderlatoT

)wK(

8,3

3,4

)wK()moor(rewopdetardecuderlatoT 9,0

2,0

ssalcrelioB 3

3

)h/gK(xam/nimnoitpmusnoC 8,2/9,0

5,2/9,0

)C°(erutarepmetgnitarepoxaM 37

37

)C°(erutarepmetnruter.niM 55

55

)mm(.DebutteltuoekomS 08

08

)aP(rewopdetartathguard.niM 01

01

)gK(yticapacreppoH 34

34

)l(tnetnocretaW 63

63

)rab(erusserpgnitarepO 1

1

)rab(erusserpgnitarepo.xaM 3

3

rewopdetarta.pmetekomsegarevA

)C°(

531

041

rewopdecuderta.pmetekomsegarevA

)C°(

18

68

detartaetarwolfekomS

)ces/gK(rewop

700,0

600,0

rewopdecudertaetarwolfekomS

)ces/gK(

8400,0

7400,0

)rabm(edisretaw-daolfossoL 3,0

3,0

yticirtcelE ZH05V022

ZH05V022

noitpmusnoclacirtcelexaM W253-A6,1

W253-A6,1

noitpmusnoclacirtceleegarevA W051-A7,0

W051-A7,0

nrutertnalpgnitaehA "4/3

"4/3

teltuo/telnireliobF "4/3

"4/3

evlavytefasE "2/1

"2/1

ebutyreviledtnalpgnitaehD "4/3

"4/3

)lanoitpo(telniretawdloccitsemodB "2/1

"2/1

)lanoitpo(teltuoretawtohcitsemodC "2/1

"2/1

emulovxamretawtohcitsemod

)lanoitpo(

*3.4.xorppa

nim/l

*3.4.xorppa

nim/l

CHARACTERISTIC

CURVES OF SINGLEPHASE PUMP

C

D

E

F

A- ritorno riscaldamento 3/4"

B- entrata acqua fredda sanitaria 1/2"

C- Uscita acqua calda sanitaria 1/2"

D- Mandata riscaldamento 3/4"

E- Valvola di sicurezza 1/2"

F - Carico -Scarico caldaia 3/4"

A

B

1214

1266

731

678

560

222

162

O 80

9460

142

259

148

65 116 65

A - Heating plant return 3/4''

B - Domestic cold water inlet 1/2''

C - Domestic hot water outlet 1/2''

D - Heating plant delivery tube 3/4''

E - Safety valve 1/2''

F - Boiler inlet/outlet 3/4''

F - Carico -Scarico caldaia 3/4"

E- Valvola di sicurezza 1/2"

D- Mandata riscaldamento 3/4"

C- Uscita acqua calda sanitaria 1/2"

B- entrata acqua fredda sanitaria 1/2"

A- ritorno riscaldamento 3/4"

1191

1242

567

521

616

668

148

249

142

42

162

222

F

H2O 14

65

11665

D

O

8

0

C

94

E

B

A

A - Heating plant return 3/4''

B - Domestic cold water inlet 1/2''

C - Domestic hot water outlet 1/2''

D - Heating plant delivery tube 3/4''

E - Safety valve 1/2''

F - Boiler inlet/outlet 3/4''

* The volume of domestic hot water refers to max

combustion power and temperature of water

flowing into the heat exchanger at 20 °C and water

flowing out of the heat exchanger at 60 °C.

* All the data are based on the appliance fuelled with Austrian standard ÖNORM M 7135 type-approved pellets.

Page 6

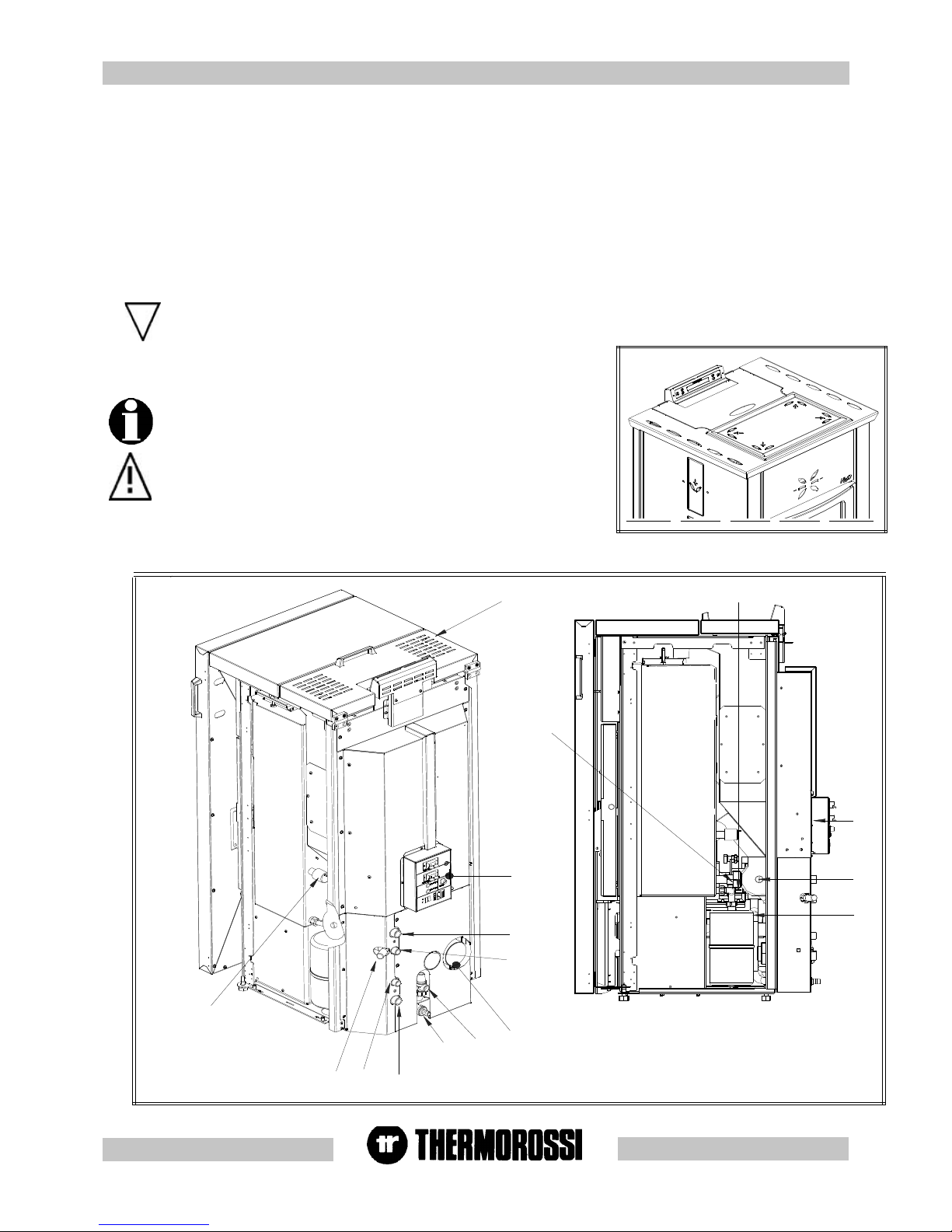

pg. VI

M

F

G

E

N

C

D

B

A

I

H

AD

O

Q

P

AD

33

33

3

GENERAL DESCRIPTIONGENERAL DESCRIPTION

GENERAL DESCRIPTIONGENERAL DESCRIPTION

GENERAL DESCRIPTION

3.13.1

3.13.1

3.1

OPERAOPERA

OPERAOPERA

OPERA

TING TING

TING TING

TING

TECHNOLTECHNOL

TECHNOLTECHNOL

TECHNOL

OGYOGY

OGYOGY

OGY

•Your heater / boiler has been constructed to satisfy in full all your heating and practical needs. Top-grade components and functions

managed with microprocessor technology guarantee high reliability and optimal performance.

3.23.2

3.23.2

3.2

PELLETSPELLETS

PELLETSPELLETS

PELLETS

•The appliance is fuelled by pellets, that is, cylinders of compressed sawdust; this will make it possible for you to enjoy to the full the flame without

having to manually stoke the combustion.

•The pellets are cylinders of compressed sawdust having a 6 mm diameter and a maximum length of 15 mm.

They have a maximum moisture content of 8%, a thermal value of 4000/4500 Kcal/Kg and a density of approx. 620-630 Kg/m³.

The use of fuel which does not comply with the description given above immediately voids the heater / boiler

warranty. Do not use the appliance as an incinerator, at the risk of voiding the warranty.

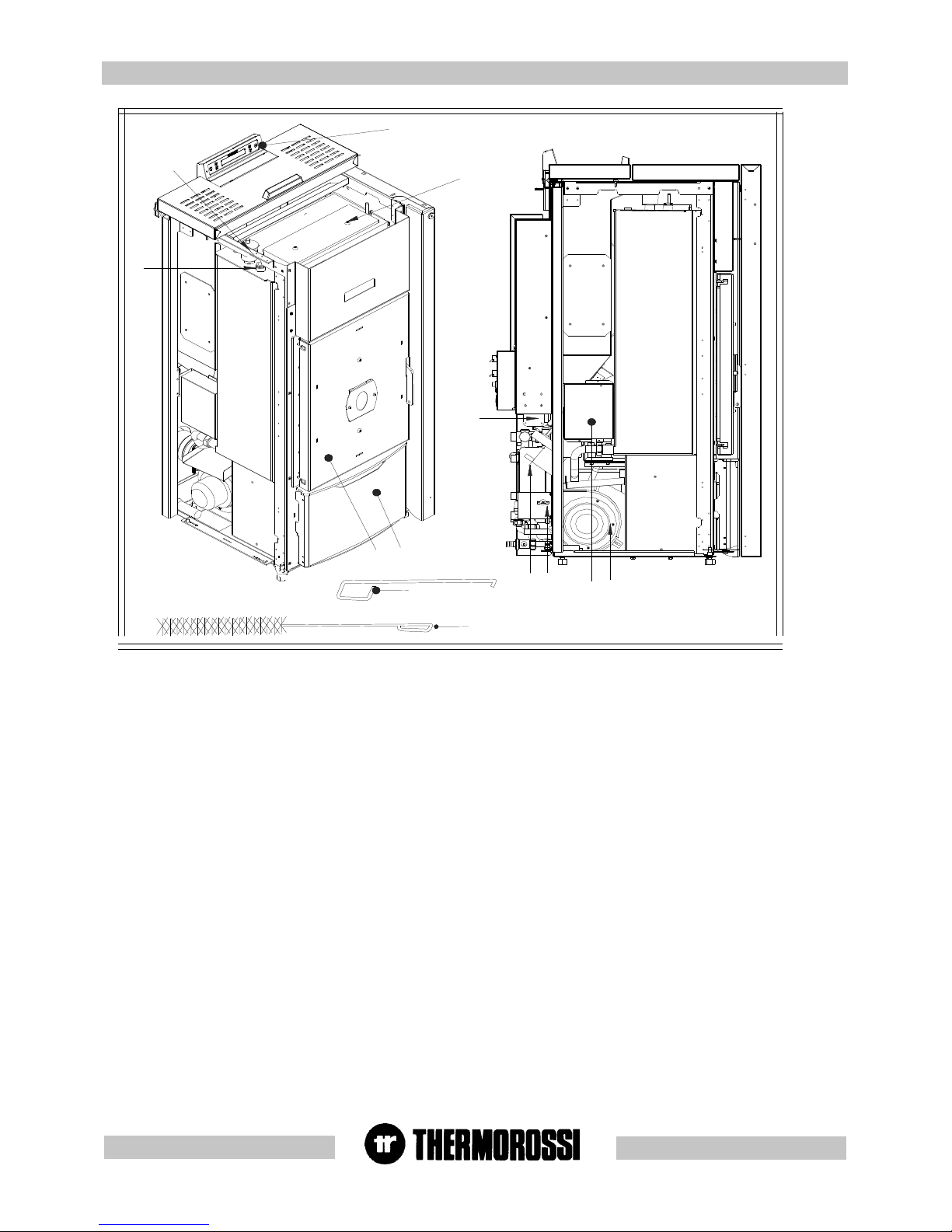

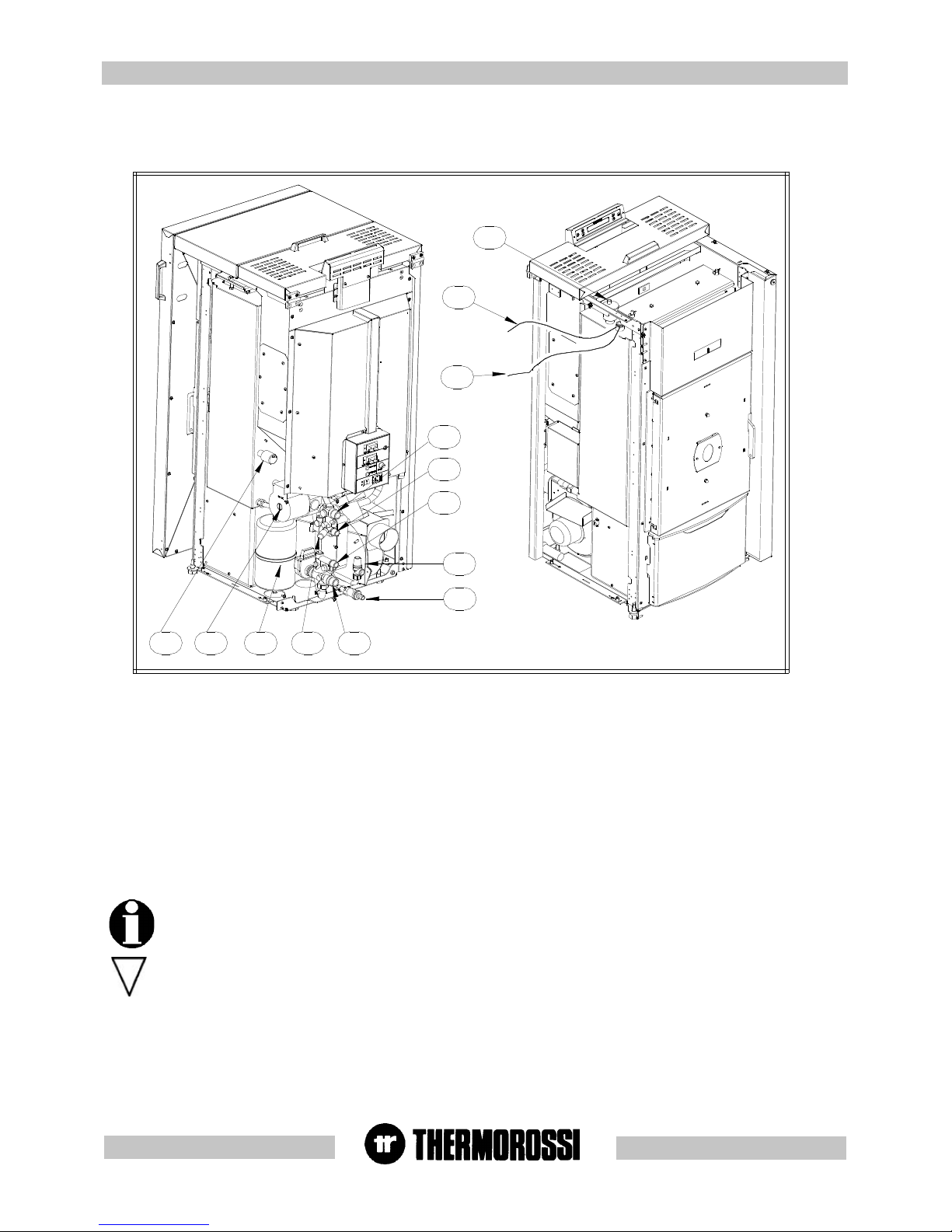

3.43.4

3.43.4

3.4

MAIN COMPONENTS OF HEAMAIN COMPONENTS OF HEA

MAIN COMPONENTS OF HEAMAIN COMPONENTS OF HEA

MAIN COMPONENTS OF HEA

TER MODTER MOD

TER MODTER MOD

TER MOD

..

..

.

H2O H2O

H2O H2O

H2O

AND BOILER MODAND BOILER MOD

AND BOILER MODAND BOILER MOD

AND BOILER MOD

..

..

.

COMP COMP

COMP COMP

COMP

AA

AA

A

CTCT

CTCT

CT

3.33.3

3.33.3

3.3

THE FEEDBOTHE FEEDBO

THE FEEDBOTHE FEEDBO

THE FEEDBO

XX

XX

X

The feedbox is situated in the top part of the heater / boiler.

The maximum load capacity of the tank is approximately 43 Kg, but varies

according to the specific weight of the pellets.

The manufacturer recommends emptying the hopper and vacuuming

the screw feeder zone once a month and during the summer period.

Take special care when loading the hopper as the screw feeder at its

base is in motion.

Page 7

pg. VII

Z

U

AA

AC

R

V

T

S

X

Y

AF

W

AB

A : Heating plant return

B : Domestic cold water inlet 1/2''. (only with

Domestic Water Kit - optional -)

C : Domestic hot water outlet 1/2''. (only with

Domestic Water Kit - optional -)

D : Heating plant delivery tube 3/4".

E : Safety valve 3 bar 1/2".

F : Boiler Inlet - Outlet 3/4".

G : Smoke exhaust pipe

H : Safety thermostat 100° C.

I : Pellet hopper.

M : Pressure transducer.

N : System inlet (only with Domestic Water

Kit - optional - )

O : Expansion tank 2.5 l for protection of the

boiler only.

P : System circulating pump.

Q : Back panel of heater.

R : Thermostat 42°C.

S : Smoke suction unit

T : Electronic power board.

U : Cleaning brush

V : Pellet loading motor.

W : Tube bundle inspection cover.

X : Automatic relief valve.

Y : Pocket for heating system PTC sensor

and thermostat bulb 100°C reset.

Z : Burner.

AA: Ash pan.

AB: Control panel.

AC: Riddling tool.

AD: Spark plug.

AF: Smoke side pressure switch.

Page 8

pg. VIII

44

44

4

INSTINST

INSTINST

INST

ALLAALLA

ALLAALLA

ALLA

TIONTION

TIONTION

TION

4.14.1

4.14.1

4.1

HEAHEA

HEAHEA

HEA

TER / BOILER LTER / BOILER L

TER / BOILER LTER / BOILER L

TER / BOILER L

OCAOCA

OCAOCA

OCA

TIONTION

TIONTION

TION

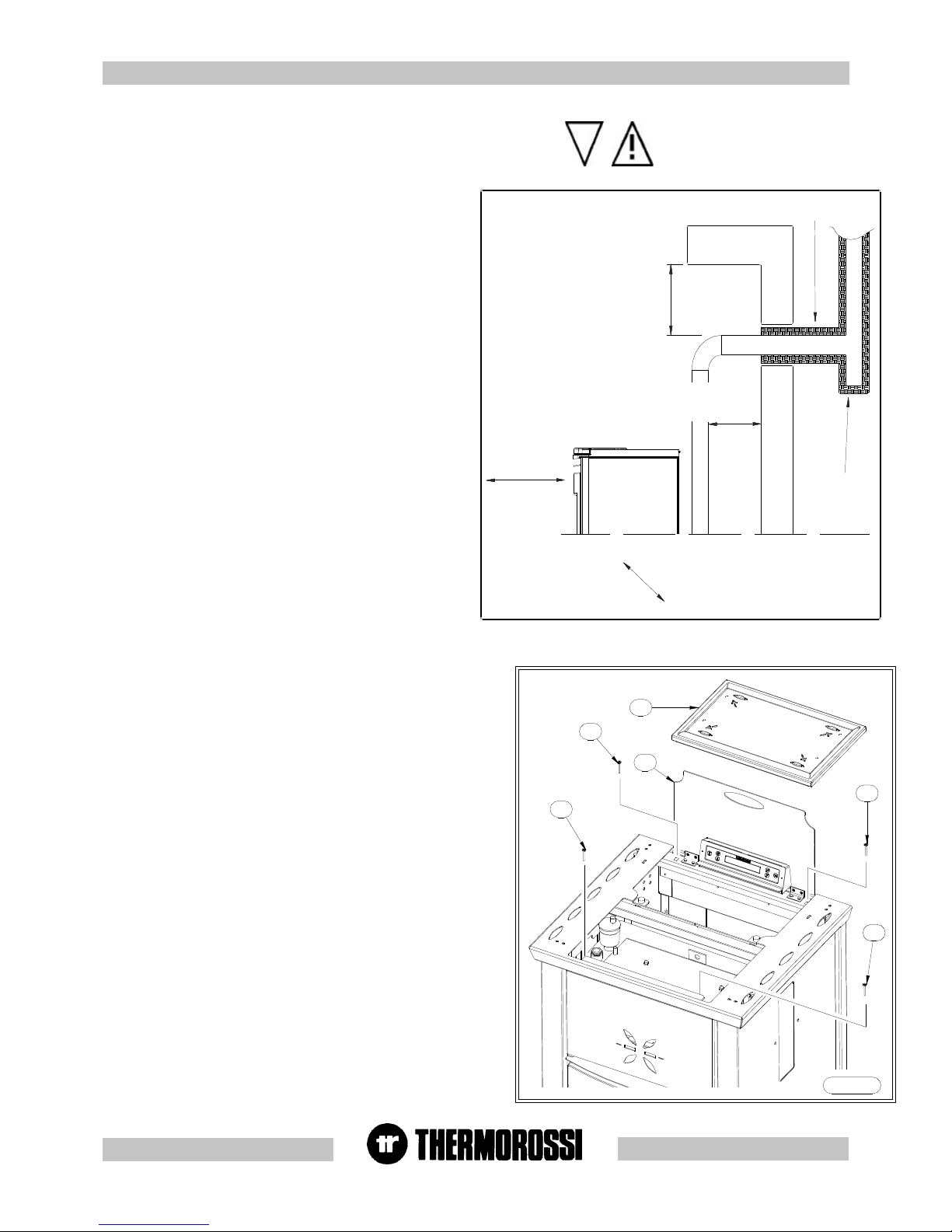

CAUTION: Always use trolleys to move the appliance and the appliance

must always be in a vertical position. The casing for the H2O is packed

separately . On the contrary, to unpack the Compact, once the wood

crate has been removed, remove the casing (in reverse order as set

out in par.4.2.3). Remove the screw at the base of the heater / boiler

and remove the base from the bottom pallet.

Follow the general guidelines set out in paragraph 1.1 to the letter.

Above all ensure that the flooring of the room where the heater / boiler

will be installed is capable of bearing the weight of the appliance plus

the weight of the water contained in it and the weight of the pellets in

the hopper.

CAUTION: The room in which the appliance will operate must be

adequately ventilated (minimum air intake for an air flow of 1300 m3/h).

The heater / boiler must be positioned at a minimum safe distance

from walls and furnishings. This distance will have to be increased

considerably if the objects surrounding the appliance are

inflammable (matchboarding, furniture, curtains, picture frames,

sofas, etc...). The recommended minimum distances are illustrated

in the drawing below on the right. Installation in the vicinity of heatsensitive materials is only permitted if suitable insulating protection is

provided for ( ref. Uni 10683).

4.2.14.2.1

4.2.14.2.1

4.2.1

HOHO

HOHO

HO

W W

W W

W

TT

TT

T

O MOUNT H2O 14 HEAO MOUNT H2O 14 HEA

O MOUNT H2O 14 HEAO MOUNT H2O 14 HEA

O MOUNT H2O 14 HEA

TER CASINGTER CASING

TER CASINGTER CASING

TER CASING

200 mm SE MATERIALE COMBUSTIBILE

200 mm SE MATERIALE

COMBUSTIBILE

450 mm SE MATERIALE COMBUSTIBILE

450 mm SE MATERIALE COMBUSTIBILE

Tee ispezionabile

ISOLANTE TERMICO

After positioning and levelling the heater by raising or lowering the mounting

feet, connecting it to the heating system and to the electrical system, the next

step is to mount the casing as shown in the image:

Carry out the steps described below as illustrated in figures 1,2,3:

- Open the pellets feed cover and remove the screws (C) (Figure 1).

- Remove the complete cover (B) (Figure 1).

- Next undo the first 2 screws (L) then remove the side panels (I) (Figure 2).

- Next fix the ceramic tiles on the side (G) as shown in Figure 3.

Take care not to over-tighten the nuts (F) as this could cause the tile to

break<>; this type of damage is not covered by warranty.

- After fixing the 4 ceramics proceed to mount the side panel (I) (Figure 2).

-Reassemble the complete cover (B) by fixing it with the screws (C) then

place the ceramics (A).

4.24.2

4.24.2

4.2

MOUNTING HEAMOUNTING HEA

MOUNTING HEAMOUNTING HEA

MOUNTING HEA

TERTER

TERTER

TER

/ BOILER/ BOILER

/ BOILER/ BOILER

/ BOILER

CASINGCASING

CASINGCASING

CASING

..

..

.

C

C

A

B

C

Figura 1

C

Key

200 / 450 mm if

combustible material

Heat insulating material

Inspectable Tee

element

Figure

LEGENDA

200 / 450 mm se materiale

combustibile

Isolante termico

Tee ispezionabile

Figura

Page 9

pg. IX

Figura 2

L

I

L

Figura 3

H

F

F

F

E

G

F

E

D

D

CP

F

T

P

M

C

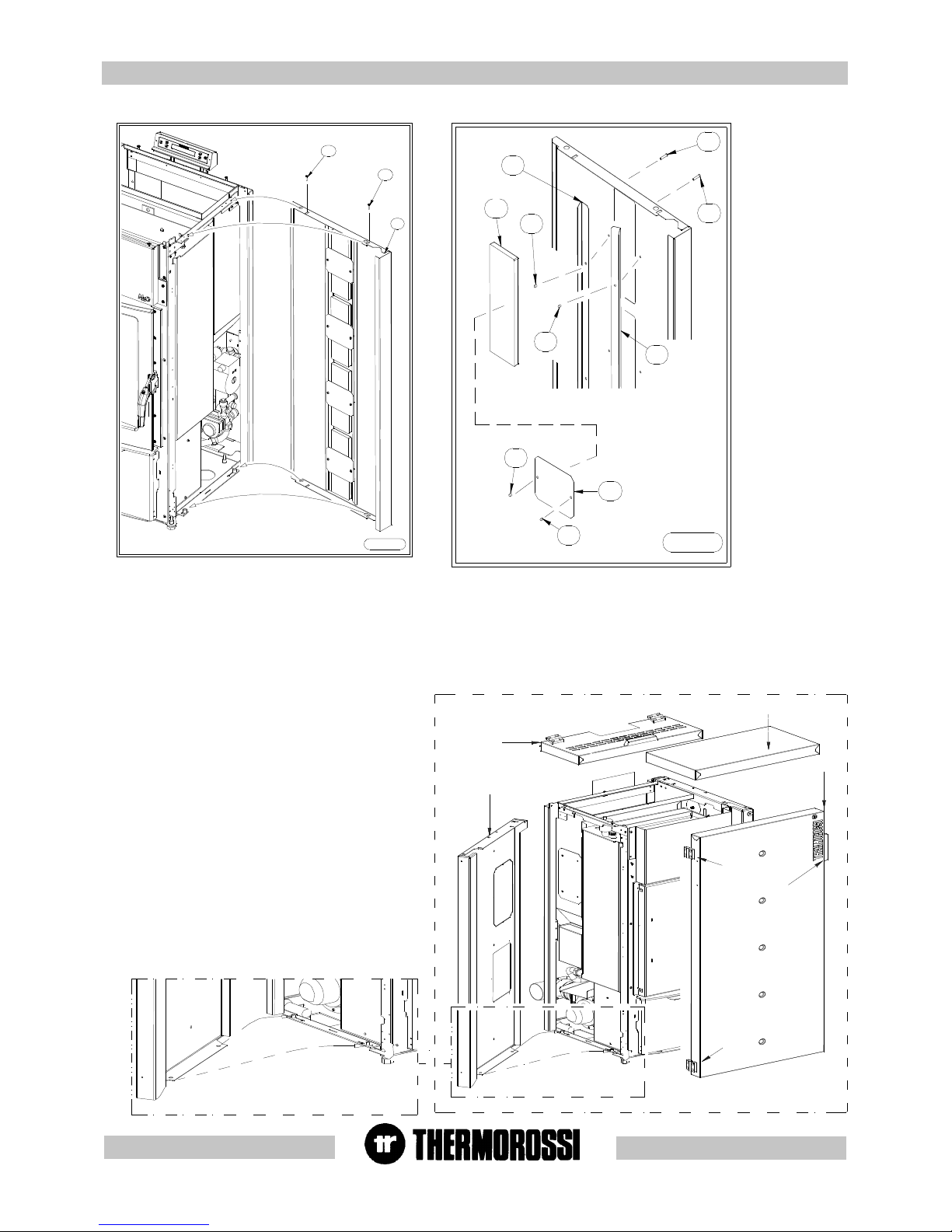

- Firstly remove the protective film from the casing.

- Next mount the 2 side panels (F) by inserting the 2 holes of the

bottom fold on the pins of the base and fastening the 2 top

screws with a screwdriver.

- Fasten the front cover (C) by fitting it onto the side panels.

- Fasten the door (P) to the left side with the special hinges and

screws provided.

- Lastly fit the back cover (CP) on the front cover (C) and

fasten the hinges with the screws provided.

If you prefer the door (P) can be mounted with the handle on the

left and the hinges on the right. Simply remove the handle (M)

from the door and fix it to the holes on the left side of the door,

remove the hinges (T) and fix them to the right side of the door.

Similarly, remove the magnet from the right side of the door and

mount it on the left side of the door.

After positioning and levelling the boiler by raising or lowering the mounting feet, connecting it to the heating system and to the electrical system

(see para. 4.4, 4.5, 4.6, 4.7, 4.8 and 4.9 ),proceed to mount the casing as illustrated:

4.2.34.2.3

4.2.34.2.3

4.2.3

HO HO

HO HO

HO

W W

W W

W

TT

TT

T

O MOUNT O MOUNT

O MOUNT O MOUNT

O MOUNT

THE COMPTHE COMP

THE COMPTHE COMP

THE COMP

AA

AA

A

CT BOILER CASINGCT BOILER CASING

CT BOILER CASINGCT BOILER CASING

CT BOILER CASING

Page 10

pg. X

VITE TC+ 4,8X13 (2 pz.)

G

VITE TC+ 4 ,8X 13 (2 pz.)

F

H

VITE TC+ 4,8X13

(2 pz.)

E

VITE TC+ 4,8X13 (2 pz.)

D

VITE TC+ 4,8X13 (4 pz.)

A

B

VITE TC+ 4,8X13 (4 pz.)

VITE TC+ 4,8X13 (2 pz.)

VITE TSP+ 8X50

+ DADO (4 pz.)

C

B1

H

F

I

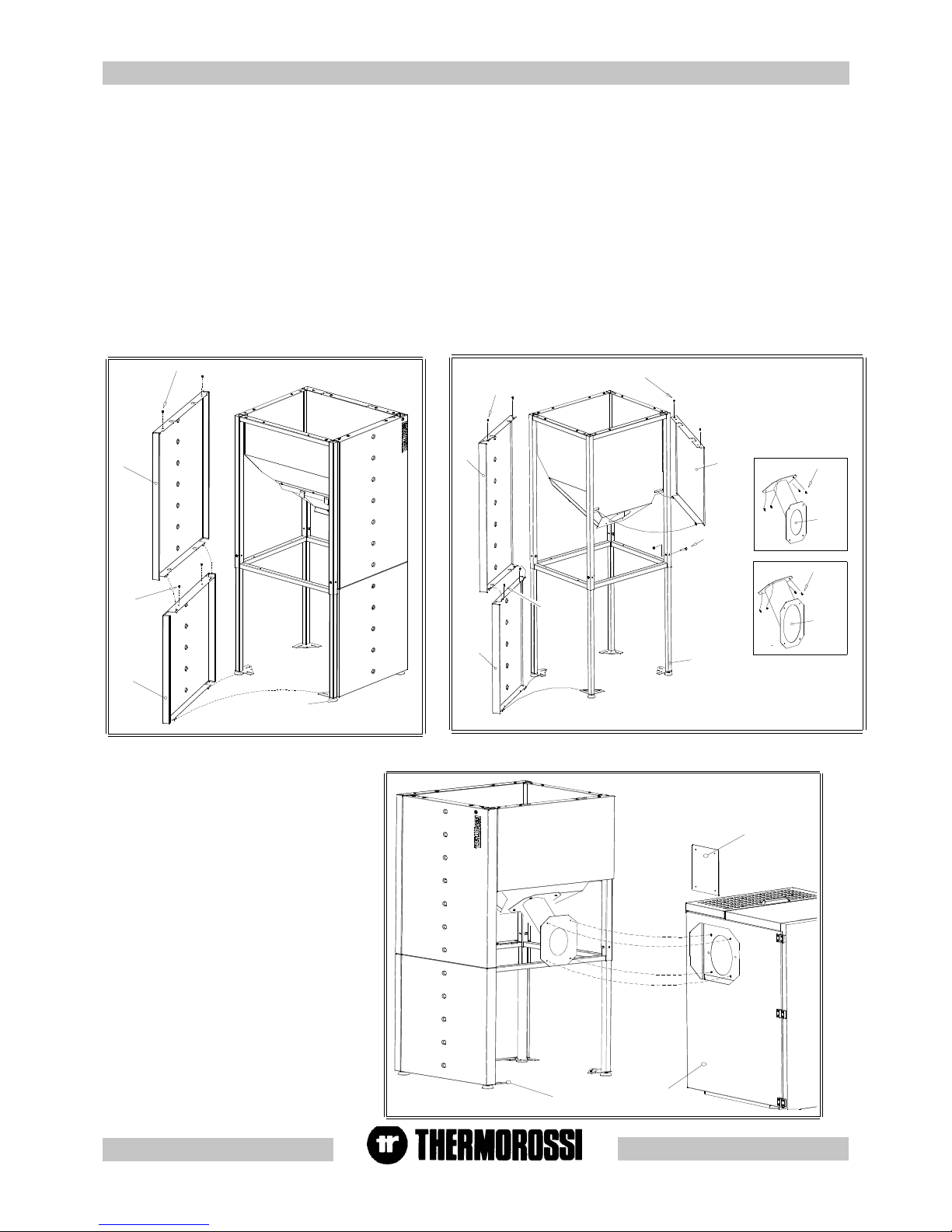

After having mounted the additional hopper

fasten the hopper to the boiler:

- Remove the octagonal portion of precut

sheet metal from the side (F) of the boiler

- Remove the cap (I) from the hopper by

undoing the screws fastened to it.

- Move the additional tank up against the

boiler by adjusting the mounting feet (H)

until the assembly is satisfactory.

- Fasten the assembly using the screws

previously removed from the cap (I).

4.2.54.2.5

4.2.54.2.5

4.2.5

HO HO

HO HO

HO

W W

W W

W

TT

TT

T

O FO F

O FO F

O F

ASTEN ASTEN

ASTEN ASTEN

ASTEN

THE THE

THE THE

THE

ADDITIONADDITION

ADDITIONADDITION

ADDITION

AL HOPPER (OPTIONAL HOPPER (OPTION

AL HOPPER (OPTIONAL HOPPER (OPTION

AL HOPPER (OPTION

AL) AL)

AL) AL)

AL)

TT

TT

T

O COMPO COMP

O COMPO COMP

O COMP

AA

AA

A

CT BOILER.CT BOILER.

CT BOILER.CT BOILER.

CT BOILER.

To increase the boiler's autonomy of operation it is possible to install one or two additional hoppers at the sides of the boiler. Each additional hopper

can hold up to 100 Kg of pellets.

Firstly unpack the hopper then assemble it as follows:

- Fasten the 4 telescopic legs (A) using the screws provided (screws TSP+ 8x50).

- Fasten the pellet chute (attention: use chute B1) to the hopper using the screws provided (screws TC+4.8x13).

- Mount the panel (C) by inserting the bottom folds on the holes of the hopper, and then securing it using the screws provided (screws

TC+4.8x13).

- Similarly fasten the panel (E) using the screws provided (screws TC+4.8x13).

- Then mount the panel (D) by lining up the lower rectangular holes on the panel folds (E) and fastening them using the screws provided (screws

TC+4.8x13).

- The panels (D) and (E) can be mounted either to the right or to the left of the pellet chute (B1); if mounted on the right the additional hopper will

have to be mounted to the right of the boiler. .

- Fix the panel (G) by firstly inserting the holes on the bottom on the mounting feet then securing them with the screws provided (screws

TC+4.8x13).

- Next mount the panel (F) by inserting the bottom folds on the holes in the panel (G).

4.2.44.2.4

4.2.44.2.4

4.2.4

HO HO

HO HO

HO

W W

W W

W

TT

TT

T

O INSTO INST

O INSTO INST

O INST

ALL ALL

ALL ALL

ALL

ADDITIONADDITION

ADDITIONADDITION

ADDITION

AL HOPPER (OPTIONAL HOPPER (OPTION

AL HOPPER (OPTIONAL HOPPER (OPTION

AL HOPPER (OPTION

AL) AL)

AL) AL)

AL)

WITH COMPWITH COMP

WITH COMPWITH COMP

WITH COMP

AA

AA

A

CT BOILER.CT BOILER.

CT BOILER.CT BOILER.

CT BOILER.

Key

SCREW

NUT

LEGENDA

Vite

Dado

Page 11

pg. XI

A : Heating plant return

C : Domestic hot water outlet 1/2''. (only

with Domestic Water Kit - optional -)

E : Safety valve 3 bar 1/2".

H : Safety thermostat 100° C.

M : Pressure transducer.

O : Expansion tank 2.5 l for protection of

the boiler only.

X : Automatic relief valve.

4.34.3

4.34.3

4.3

HYDRA HYDRA

HYDRA HYDRA

HYDRA

ULIC DRAULIC DRA

ULIC DRAULIC DRA

ULIC DRA

WING FOR HEAWING FOR HEA

WING FOR HEAWING FOR HEA

WING FOR HEA

TER HTER H

TER HTER H

TER H

22

22

2

O / COMPO / COMP

O / COMPO / COMP

O / COMP

AA

AA

A

CTCT

CTCT

CT

CAUTION: FOR THE DELIVERY , RETURN, MAKE-UP AND DISCHARGE CONNECTIONS USE FLEXIBLE TUBES HA VING A LENGTH

OF AT LEAST 70 CM TO FACILITATE MOVING THE APPLIANCE FOR MAINTENANCE.

CAUTION: A CONNECTION MUST BE MADE BETWEEN THE SAFETY V AL VE AND THE OUTLET TO PREVENT DAMAGING

MATERIALS SURROUNDING THE BOILER/HEA TER WHEN THE V AL VE IS ACTIVA TED.

(SEE PAR. 4.4 - 4.5 - 4.6 - 4.7 - 4.8 - 4.9).

F

PM O N D

B

E

C

1

A

X

H

B : Domestic cold water inlet 1/2''. (only with

Domestic Water Kit - optional -)

D : Heating plant delivery tube 3/4".

F : Boiler Inlet - Outlet 3/4". (only with

Domestic Water Kit - optional -)

N : System Inlet

P : System circulating pump.

1 : Boiler sensor

Page 12

pg. XII

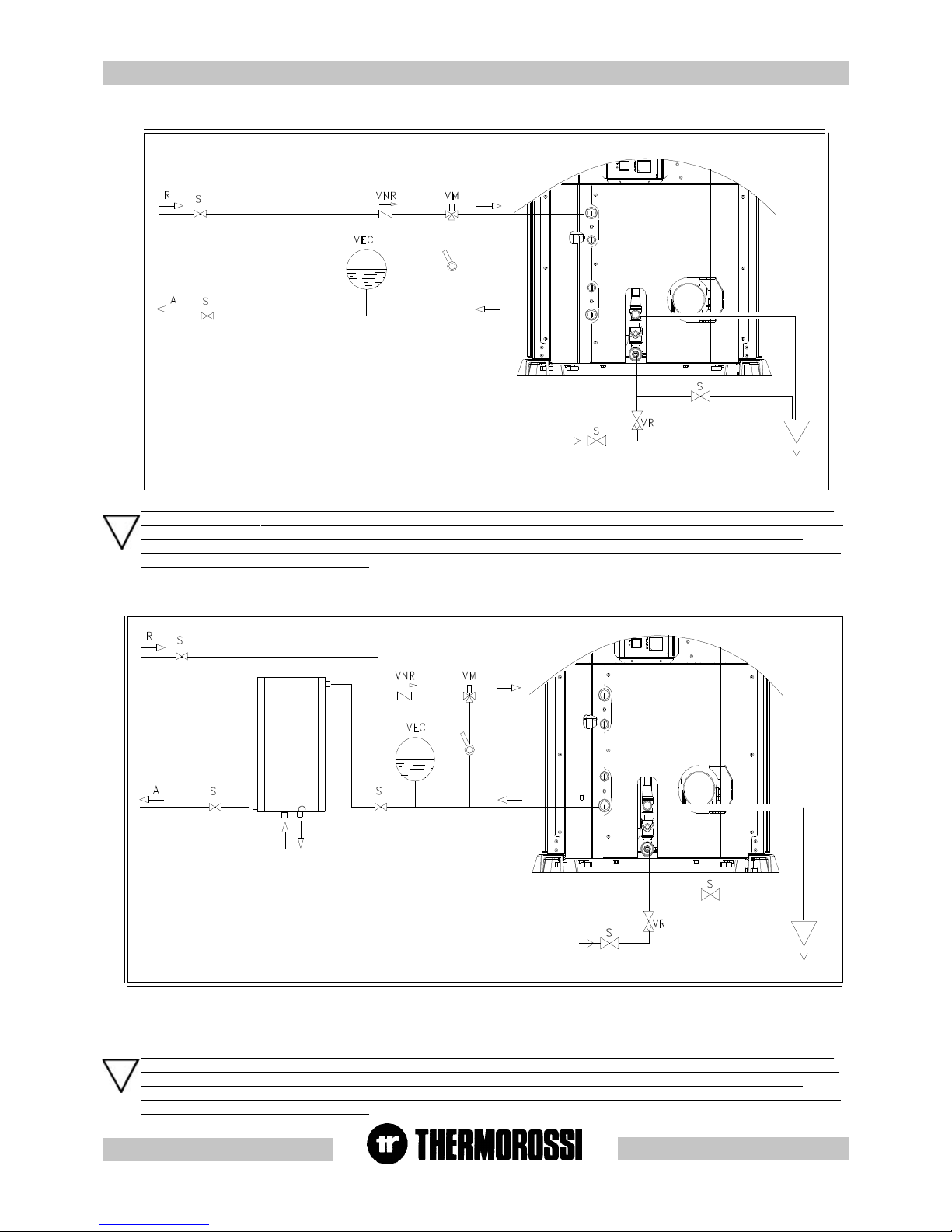

4.4 EXAMPLE OF HYDRA4.4 EXAMPLE OF HYDRA

4.4 EXAMPLE OF HYDRA4.4 EXAMPLE OF HYDRA

4.4 EXAMPLE OF HYDRA

ULIC DRAULIC DRA

ULIC DRAULIC DRA

ULIC DRA

WING FOR HWING FOR H

WING FOR HWING FOR H

WING FOR H

22

22

2

O / COMPO / COMP

O / COMPO / COMP

O / COMP

AA

AA

A

CT ONLCT ONL

CT ONLCT ONL

CT ONL

Y HEAY HEA

Y HEAY HEA

Y HEA

TINGTING

TINGTING

TING

4.5 EXAMPLE OF HYDRA4.5 EXAMPLE OF HYDRA

4.5 EXAMPLE OF HYDRA4.5 EXAMPLE OF HYDRA

4.5 EXAMPLE OF HYDRA

ULIC DRAULIC DRA

ULIC DRAULIC DRA

ULIC DRA

WING HWING H

WING HWING H

WING H

22

22

2

0 / COMPACT WITH INTERSPACED BOILER COILS OR BOILER COILS

Caution: it is mandatory to earth the heater / boiler. If this instruction is not observed serious damage, which is not

covered by warranty, will result to the body of the heater / boiler.Have an electrician check the earthing. There must

be no electric potential (volts) between the earth of the generator and the actual earth of the plant. To prevent

electrochemical corrosion of the boiler body do not use galvanised pipes and fittings. Dedicated ground wires must

be used to ground all other materials.

Caution: it is mandatory to earth the heater / boiler. If this instruction is not observed serious damage, which is not

covered by warranty, will result to the body of the heater / boiler. Have an electrician check the earthing. There must

be no electric potential (volts) between the earth of the generator and the actual earth of the plant. To prevent

electrochemical corrosion of the boiler body do not use galvanised pipes and fittings. Dedicated ground wires must

be used to ground all other materials.

A : andata impianto riscaldamento

R : ritorno impianto riscaldamento

S : saracinesca

VNR : valvola di non ritorno

VEC : vaso di espansione chiuso per protezione impianto

VR : valvola riduttrice di pressione

VM : valvola miscelatrice termostatica punto fisso 55°c

VSP: valvola saracinesca (da parzializzare in funzione

delle perdite di carico dell'impianto).

CAUTION : The water temperature in the boiler tubes in this case is not adjustable and depends on the systems's delivery temperature, that

is the boiler temperature setting. The boiler tubes can be installed on the water return circuit. Moreover, the Manufacturer recommends

installing a water softener in the domestic hot water system in order to prevent the formation of limescale deposits in the boiler tubes which

could compromise their functionality.

A : andata impianto riscaldamento

R : ritorno impianto riscaldamento

S : saracinesca

VNR : valvola di non ritorno

VEC : vaso di espansione chiuso per protezione impianto

VR : valvola riduttrice di pressione

VM : valvola miscelatrice termostatica punto fisso 55°c.

VSP: valvola saracinesca (da parzializzare in funzione

delle perdite di carico dell'impianto)

A: heating plant delivery

R: heating plant return

S: gate valve

VNR: nonreturn valve

VEC: closed expansion tank for plant protection

VR: reducing valve

VM: thermostatic mixing valve, fixed point 55°C

VSP: gate valve (throttle according to pressure drop in the system)

DAR: From water mains for make-up

SC: discharge

DAR

SC

A: heating plant delivery

R: heating plant return

S: gate valve

VNR: nonreturn valve

VEC: closed expansion tank for plant protection

VR: reducing valve

VM: thermostatic mixing valve, fixed point 55°C

VSP: gate valve (throttle according to pressure drop in the system)

DAR: From water mains for make-up

SC: discharge

BAI: Interspaced boiler coils or boiler coils

DAR

SC

BAI

Page 13

pg. XIII

4.6.14.6.1

4.6.14.6.1

4.6.1

TT

TT

T

herher

herher

her

mocontrmocontr

mocontrmocontr

mocontr

ol electrical connection wol electrical connection w

ol electrical connection wol electrical connection w

ol electrical connection w

herher

herher

her

e the H2O 14 / COMPe the H2O 14 / COMP

e the H2O 14 / COMPe the H2O 14 / COMP

e the H2O 14 / COMP

AA

AA

A

CT 14 boiler is inteCT 14 boiler is inte

CT 14 boiler is inteCT 14 boiler is inte

CT 14 boiler is inte

gg

gg

g

rr

rr

r

aa

aa

a

tedted

tedted

ted

in a plumbing system with boiler coils.in a plumbing system with boiler coils.

in a plumbing system with boiler coils.in a plumbing system with boiler coils.

in a plumbing system with boiler coils.

The following is a description of the electric wiring for Thermocontrol and H2O 14 / Compact 14: through this electrical

connection, the shut off action by Thermocontrol automatically switches the diverter valve and also switches off the boiler: if the

system Chronothermostat requires more heat the boiler does not switch off until it has satisfied the heating requirements of the

room. The connections to the diverter valve and system chronothermostat are shown in the diagram and in the following photos.

CAUTION: in order to prevent too many boiler start ups, with consequent reduction in the electrical heater lifetime, the

manufacturer highly recommends using a chronothermostat with a thermal hysteresis of at least 2°C.

" CRONOTERMOSTATO - MODEM " sul pannello posteriore

ON / OFF ECOTHERM (da collegare al connettore

termica minima di 2°C).

Cronotermostato (con isteresi

posteriore

Pannello

Valvola deviatrice

220 V 50 Hz

N F

220 V 50 Hz

Alimentazione

N F

Thermocontrol

Caution: it is mandatory to earth the heater / boiler. If this instruction is not observed serious damage, which is not

covered by warranty, will result to the body of the heater / boiler. Have an electrician check the earthing. There

must be no electric potential (volts) between the earth of the generator and the actual earth of the plant. To prevent

electrochemical corrosion of the boiler body do not use galvanised pipes and fittings. Dedicated ground wires

must be used to ground all other materials.

In order to guarantee correct absorption of the heat produced by the generator is it is advisable to use a boiler tube with volume and heat

exchange capacity suitable for the power of the generator.

See key page XLIV

TB : termostato bollitore

VR : valvola riduttrice di pressione

VM : valvola miscelatrice termostatica punto fisso 55°c.

VDEV3V : valvola deviatrice 3 vie

THER : thermocontrol

A : andata impianto riscaldamento

R : ritorno impianto riscaldamento

S : saracinesca

VNR : valvola di non ritorno

VEC : vaso di espansione chiuso per protezione impianto

VSP : valvola saracinesca ( da parzializzare in funzione

delle perdite di carico dell'impianto).

DAR

SC

CCI

CCT

A: heating plant delivery

R: heating plant return

S: gate valve

VNR: nonreturn valve

VEC: closed expansion tank for plant protection

VSP: gate valve (throttle according to pressure drop in

the system)

VR: reducing valve

TB: reducing valve

VM: thermostatic mixing valve, fixed point

55°C

VDEV3V: Three-way diverting valve

THER: Thermocontrol

CCI: system chronothermostat contact

CCT: Chronothermostat modem contact

DAR: From water mains for make-up

SC: discharge

4.64.6

4.64.6

4.6

EXAMPLE OF HYDRAEXAMPLE OF HYDRA

EXAMPLE OF HYDRAEXAMPLE OF HYDRA

EXAMPLE OF HYDRA

ULIC DRAULIC DRA

ULIC DRAULIC DRA

ULIC DRA

WING HWING H

WING HWING H

WING H

22

22

2

0/COMP0/COMP

0/COMP0/COMP

0/COMP

AA

AA

A

CT CT

CT CT

CT

WITH BOILER COILS WITH BOILER COILS

WITH BOILER COILS WITH BOILER COILS

WITH BOILER COILS

AND USE OF AND USE OF

AND USE OF AND USE OF

AND USE OF

THERMOCONTRTHERMOCONTR

THERMOCONTRTHERMOCONTR

THERMOCONTR

OLOL

OLOL

OL

(OPTIONAL)(OPTIONAL)

(OPTIONAL)(OPTIONAL)

(OPTIONAL)

Page 14

pg. XIV

4.74.7

4.74.7

4.7

EXAMPLE OF HYDRAEXAMPLE OF HYDRA

EXAMPLE OF HYDRAEXAMPLE OF HYDRA

EXAMPLE OF HYDRA

ULIC DRAULIC DRA

ULIC DRAULIC DRA

ULIC DRA

WING FOR H20 /COMPWING FOR H20 /COMP

WING FOR H20 /COMPWING FOR H20 /COMP

WING FOR H20 /COMP

AA

AA

A

CT CT

CT CT

CT

WITH "KIT FOR WITH "KIT FOR

WITH "KIT FOR WITH "KIT FOR

WITH "KIT FOR

THE PRTHE PR

THE PRTHE PR

THE PR

ODUCTIONODUCTION

ODUCTIONODUCTION

ODUCTION

OF INSTOF INST

OF INSTOF INST

OF INST

ANT DOMESTIC HOANT DOMESTIC HO

ANT DOMESTIC HOANT DOMESTIC HO

ANT DOMESTIC HO

T T

T T

T

WW

WW

W

AA

AA

A

TER TER

TER TER

TER

" (OPTIONAL).

The diverting valve switches the water to the plate heat exchanger of the "Domestic hot water production kit " when the flow switch detects

the passage of water towards the usage point and when the boiler temperature exceeds 61° C. When there is a request for hot water the

boiler operates at maximum steady state power level. See also paragraph 5.9.

Ecotherm

ON - OFF

CAUTION: it is mandatory to earth the heater / boiler. If this instruction is not observed serious damage, which is not

covered by warranty, will result to the body of the heater / boiler. Have an electrician check the earthing. There must

be no electric potential (volts) between the earth of the generator and the actual earth of the plant. To prevent

electrochemical corrosion of the boiler body do not use galvanised pipes and fittings. Dedicated ground wires must

be used to ground all other materials.

Rubinetto di carico impianto riscaldamento

A : andata impianto riscaldamento VNR : valvola di non ritorno

R : ritorno impianto riscaldamento VEC : vaso di espansione

S : saracinesca chiuso per protezione impianto

VR : valvola riduttrice di pressione VM : valvola miscelatrice termostatica punto fisso 55°c.

VSP : valvola saracinesca (da parzializzare in funzione delle perdite di carico dell'impianto).

A: heating plant delivery

R: heating plant return

S: gate valve

VR: reducing valve

VSP: gate valve (throttle according to pressure drop in

the system)

VNR: nonreturn valve

VEC: closed expansion tank for plant

protection

VM: thermostatic mixing valve, fixed point

55°C

See key page XLIV

Page 15

pg. XV

CAUTION: CONNECT , AS INDICATED, THE CONNECT ORS SUPPLIED WITH THE KIT FOR THE PRODUCTION OF

INSTANT DOMESTIC HOT WATER . THIS OPERATION MUST BE CARRIED OUT WITH THE ' " MAIN SWITCH 0-1

" INSTALLED AT THE BACK IN POSITION " 0 ".

FLUSSOSTATO

TUBO MANDATA

RISCALDAMENTO

COLLARE FERMATUBO

COMPLETO DI VITE

VALVOLA DEVIATRICE

GUARNIZIONE

CAVO VALVOLA

DEVIATRICE

CORPO RITORNO

I

M

P

I

A

N

T

O

R

I

S

C

A

L

D

A

M

E

N

T

O

SCAMBIATORE

A PIASTRE

GUARNIZIONE

CORPO MANDATA

R

U

B

I

N

E

T

T

O

C

A

R

I

C

O

VITE

VITE

CAVO FLUSSOSTATO

The heater H2O / boiler Compact can be supplied with a

" Kit for the production of instant domestic hot water" (see par. 4.7) . When

a tap is turned on, the " flow switch" commands the " diverting valve" to

convey the hot water from the boiler to the plate heat exchanger . The

temperature of the domestic hot water obtained in this way is roughly 10° 15° lower than the temperature in the boiler as indicated on the handheld

radio control and in any case within the limits indicated in par. 2.

Hot water is not available when the boiler is switched off. When

the boiler switched on, upon a request for hot water, it operates at

the maximum steady state level of combustion: the diverting valve

only conveys the water to the plate heat exchanger if the temperature in the boiler is above 61°.

The manufacturer recommends installing a water softener to ensure an

optimal life of the plate heat exchanger (see par. 4.7). It is also advisable to

regularly clean and check the plate heat exchanger.

The Kit for the production of instant domestic hot water comprises:

4.7.1 MOUNTING 4.7.1 MOUNTING

4.7.1 MOUNTING 4.7.1 MOUNTING

4.7.1 MOUNTING

THE KIT FOR THE KIT FOR

THE KIT FOR THE KIT FOR

THE KIT FOR

THE PRTHE PR

THE PRTHE PR

THE PR

ODUCTION OF INSTODUCTION OF INST

ODUCTION OF INSTODUCTION OF INST

ODUCTION OF INST

ANT DOMESTIC HOANT DOMESTIC HO

ANT DOMESTIC HOANT DOMESTIC HO

ANT DOMESTIC HO

T T

T T

T

WW

WW

W

AA

AA

A

TER (OPTIONTER (OPTION

TER (OPTIONTER (OPTION

TER (OPTION

AL)AL)

AL)AL)

AL)

RETRO INFERIORE

RISCALDAMENTO ( TIPO 1 )

FERMATUBO

VITI DI MONTAGGIO

GRUPPO COMPLETO

GUARNIZIONE

PREMONTATO.

VITE

VITE

VITE

COLLARE

DI SCARICO

RUBINETTO

RISCALDAMENTO ( TIPO 2 )

GRUPPO COMPLETO

PREMONTATO

TUBO MANDATA

COMPLETO PREMONTATO

SUPPORTO GRUPPO

GHIERA

TUBO MANDATA

GUARNIZIONE

VITE

VITE

VITE

VITE

VITE

VITE

Installation of the " Kit for the production of instant domestic hot water"

must be made as indicated below:

- Empty the boiler completely by acting on the "drain tap" and empty or shut

off the system.

-Remove the ring nut from the "delivery tube to heating system (type 1)".

-Remove, by acting on the indicated screws, the "bottom back plate" and

the "complete preassembled unit support".

-Next remove the "delivery tube to heating system (type 1) " fastened to the

boiler.

-Fasten the " locking band " as indicated.

-Fasten the " delivery tube to heating system (type 2) " with the

corresponding gasket.

-Connect the " complete preassembled unit" to the " delivery tube to heating

system and to the circulating pump of the boiler with the corresponding

gaskets.

-Next fasten the "preassembled unit support" with the corresponding

screws.

-Firmly fasten the "complete preassembled unit" with the "screws for

mounting the complete preassembled unit " to the "complete preassembled

unit support".

-Lastly fasten the "bottom back plate".

-Then make the hydraulic connections between the heater / boiler and the

system and fill up with water.

4.7.24.7.2

4.7.24.7.2

4.7.2

HYDRAHYDRA

HYDRAHYDRA

HYDRA

ULIC INSTULIC INST

ULIC INSTULIC INST

ULIC INST

ALLAALLA

ALLAALLA

ALLA

TION FOR " KIT FOR TION FOR " KIT FOR

TION FOR " KIT FOR TION FOR " KIT FOR

TION FOR " KIT FOR

THETHE

THETHE

THE

PRPR

PRPR

PR

ODUCTION OF INSTODUCTION OF INST

ODUCTION OF INSTODUCTION OF INST

ODUCTION OF INST

ANT DOMESTIC HOANT DOMESTIC HO

ANT DOMESTIC HOANT DOMESTIC HO

ANT DOMESTIC HO

T T

T T

T

WW

WW

W

AA

AA

A

TER TER

TER TER

TER

"

CAUTION: CHECK CAREFULL Y THA T THE "HEA TING SYSTEM WA TER INLET TAP" IS CLOSED BEFORE MAKING THE

HYDRAULIC CONNECTIONS BETWEEN THE BOILER AND SYSTEM.

- 1 Complete Unit, preassembled,

consisting of a plate heat

exchanger, heating system inlet

tap, diverting valve, flow switch,

brass delivery body, brass return

body.

-1 complete locking band .

4.7.3 ELECTRICAL INST4.7.3 ELECTRICAL INST

4.7.3 ELECTRICAL INST4.7.3 ELECTRICAL INST

4.7.3 ELECTRICAL INST

ALLAALLA

ALLAALLA

ALLA

TION FOR " KIT FOR TION FOR " KIT FOR

TION FOR " KIT FOR TION FOR " KIT FOR

TION FOR " KIT FOR

THE PRTHE PR

THE PRTHE PR

THE PR

ODUCTION OF INSTODUCTION OF INST

ODUCTION OF INSTODUCTION OF INST

ODUCTION OF INST

ANT DOMESTIC HOANT DOMESTIC HO

ANT DOMESTIC HOANT DOMESTIC HO

ANT DOMESTIC HO

TT

TT

T

WW

WW

W

AA

AA

A

TER TER

TER TER

TER

"

- 2 Gaskets.

- 1 Hot water delivery tube to the

heating system.

- 1 Flow switch cable.

- 1 Diverting valve cable.

-2 screws for fastening the unit.

See key page XLIV

Page 16

pg. XVI

FLUSSOSTATO

CONNESSIONE

VALVOLA DEVIATRICE

CONNESSIONE

CAUTION: CONNECT THE FLOW SWITCH CABLE TAKING CARE TO ASSEMBLE IT AS ILLUSTRATED IN THE IMAGE:

CONNECTIONS THAT ARE DIFFERENT TO THOSE INDICATED WILL LEAD TO BREAKAGE OF THE FLOW SWITCH

BOARD (DAMAGE NOT COVERED BY THE WARRANTY).

See key page XLIV

See key page XLIV

Page 17

pg. XVII

Valvola miscelatrice 3 vie termostatica 55°c

Valvola saracinesca (da parzializzare in

funzione delle perdite di carico dell'impianto

Tubi di collegamento accumuli

Vaso di espansione chiuso

Attenzione : chiudere tutti i fori

non usati del puffer

Sonda 2

Sonda 1

Thermopuffer aggiuntivo

punto fisso.

Mandata caldaia

non usati del puffer

Attenzione : chiudere tutti i fori

Riscaldamento pavimento

Radiatori

Ritorno caldaia

Valvola a 3 vie

Thermocell o Thermopuffer

Circolatore

Valvola di non ritorno

Valvola 3 vie manuale

Saracinesca

4.84.8

4.84.8

4.8

SCHEMASCHEMA

SCHEMASCHEMA

SCHEMA

TIC DRATIC DRA

TIC DRATIC DRA

TIC DRA

WING OF WING OF

WING OF WING OF

WING OF

TYPICAL HYDRATYPICAL HYDRA

TYPICAL HYDRATYPICAL HYDRA

TYPICAL HYDRA

ULIC CIRULIC CIR

ULIC CIRULIC CIR

ULIC CIR

CUIT FOR H20 / COMPCUIT FOR H20 / COMP

CUIT FOR H20 / COMPCUIT FOR H20 / COMP

CUIT FOR H20 / COMP

AA

AA

A

CT +CT +

CT +CT +

CT +

THERMOCELL (OR THERMOCELL (OR

THERMOCELL (OR THERMOCELL (OR

THERMOCELL (OR

THERMOPUFFER) + THERMOPUFFER) +

THERMOPUFFER) + THERMOPUFFER) +

THERMOPUFFER) +

ADDITIONADDITION

ADDITIONADDITION

ADDITION

AL AL

AL AL

AL

THERMOPUFFER + HIGH THERMOPUFFER + HIGH

THERMOPUFFER + HIGH THERMOPUFFER + HIGH

THERMOPUFFER + HIGH

TEMPERATEMPERA

TEMPERATEMPERA

TEMPERA

TU-TU-

TU-TU-

TU-

RE HEARE HEA

RE HEARE HEA

RE HEA

TING TING

TING TING

TING

AND LAND L

AND LAND L

AND L

OO

OO

O

W W

W W

W

TEMPERATEMPERA

TEMPERATEMPERA

TEMPERA

TURE HEATURE HEA

TURE HEATURE HEA

TURE HEA

TINGTING

TINGTING

TING

CAUTION: The system operating pressure must always be above the expansion tank preload: If the operating pressure of the system is

2 bar, the expansion tank must be preloaded to 1.5 bar.

CAUTION: The Thermocell must also be connected only to 220V - 50Hz power supply"; the adjustments of Sensor 1 and Sensor 2 must

be controlled by the heater / boiler and not by the Thermocell electric panel.

For this purpose connect 2 thermocouples (optional code no. 60010695) to the cable clamps of Sensor 1 and Sensor 2" of

the heater / boiler.

CAUTION: Sensor S1 must be set at 65°C (over 65°C it switches off the boiler ). Sensor S2 must be set at 4045°C (under 40 - 45°C it

switches on the boiler).

CAUTION: it is mandatory to earth the heater / boiler. If this instruction is not observed serious damage, which is

not covered by warranty, will result to the body of the heater / boiler. Have an electrician check the earthing.

There must be no electric potential (volts) between the earth of the generator and the actual earth of the plant. To

prevent electrochemical corrosion of the boiler body do not use galvanised pipes and fittings. Dedicated ground

wires must be used to ground all other materials.

See key page

XLIV

Page 18

pg. XVIII

The safety valve must be connected to the highest part of the heat generator or the outlet tube, next to the generator. The length of the section

of tube between the generator fitting and the safety valve must not be more than one metre. There must be no cocks that can cut off the tube

connecting the safety valve to the heat generator and the section must not be less than the inlet section of the safety valve or the sum of the inlet

sections if there are several valves that head a single tube, at any point whatsoever along its length. The outlet tube of the safety valve must be

installed in such a way that it does not prevent the normal functioning of the valves and will not cause injury to persons ; the outlet must be located

as close as possible to the safety valve and be accessible and visible. The diameter of the outlet tube must not in any case be less than the

diameter of the safety valve outlet fitting. The outlet fitting diameter is the minimum internal diameter of the valve outlet upstream from any existing

internal threading. The valve discharge pressure, equal to the calibration pressure and increased by the overpressure, must not exceed the

maximum working pressure of the heat generator. The designer must ensure that the maximum pressure existing at every point of the system

does not exceed the maximum working pressure of each of its components. The discharge capacity of the safety valve must be calculated

according to the prescriptions set out in UNI 10412/2. The diameter of the minimum net cross section of the valve inlet must in any case be not

less than 15 mm. The maximum working pressure of the closed expansion tank must not be less than the calibration pressure of the

safety valve, plus the specific overpressure of the valve itself, with any difference in height between the tank and the valve taken into

account,and the pressure generated by the functioning of the pump. The capacity of the expansion tank or tanks is evaluated according to the

overall capacity of the plant as per the design. The closed expansion tanks must comply with current regulations governing pressure appliances

in terms of design, construction, conformity assessment and utilization.

The rated volume of the closed expansion tank must be sized in relation to the expansion volume of the water in the

system.

The heat generator must be connected directly to the plant's expansion tank or group of expansion tanks with a tube having an internal

diameter no less than 18 mm. The connecting tube, which may consist of plant parts, must not be fitted with any shutoff cocks or have reduced

sections. One three-way on-off valve may be installed for connecting the tank to the atmosphere for maintenance operations. This device must

be protected against accidental manoeuvres. The connecting tube must be fitted in such a way that no scaling or deposit points are created. If

several heat generators power a single system or secondary circuit, each heat generator must be connected directly to the system's expansion

tank or group of expansion tanks sized overall for the total volume of water contained in the same plant or independent circuit. When it is

necessary to separate the single heat generator from the expansion tank or group of expansion tanks, then a three-way tap having the same

characteristics as those listed above must be installed on the tube that connects the generator to the expansion tank, in order to ensure that the

generator is in any case connected either with the expansion tank or with the atmosphere in every position. The expansion tanks, connecting

tubes, the vent and smoke exhaust pipes must be protected against freezing in areas where this could occur. The solution adopted for this

purpose must be described in the project. Given that the circulation of the water in the heat generator must be maintained in any system and in

all operating conditions within the limits prescribed by the supplier of the generator, in closed expansion tank heating systems, in which the

circulation of the water is assured by means of an electric pump, the pump stopping must not cause, in any operating condition, the temperature

to rise above the limit prescribed in these instructions.

The previous chapter does not replace UNI 10412/2 to which it makes reference . The qualified installer must in any case be

fully aware of this standard and its amending versions.

4.9 INSTR4.9 INSTR

4.9 INSTR4.9 INSTR

4.9 INSTR

UCTIONS FOR EXECUTING UCTIONS FOR EXECUTING

UCTIONS FOR EXECUTING UCTIONS FOR EXECUTING

UCTIONS FOR EXECUTING

THE HYDRATHE HYDRA

THE HYDRATHE HYDRA

THE HYDRA

ULIC SYULIC SY

ULIC SYULIC SY

ULIC SY

STEM CLSTEM CL

STEM CLSTEM CL

STEM CL

OSED EXPOSED EXP

OSED EXPOSED EXP

OSED EXP

ANSION ANSION

ANSION ANSION

ANSION

TT

TT

T

ANK.ANK.

ANK.ANK.

ANK.

Systems with closed expansion tank, must be provided with :

a) safety valve b) thermal relief valve or thermal safety outlet (positive safety )

c) closed expansion tank d) circulating pump activation thermostat (included in the panel of the central heating cooker).

e) acoustic alarm activation thermostat f) acoustic alarm

g) pressure gauge thermometer h) circulation system

These devices must be installed on the generator's delivery tube, within not more than 1 metre from the machine.

4.8.1 CONNECTION OF SENSORS S1 4.8.1 CONNECTION OF SENSORS S1

4.8.1 CONNECTION OF SENSORS S1 4.8.1 CONNECTION OF SENSORS S1

4.8.1 CONNECTION OF SENSORS S1

AND S2 AND S2

AND S2 AND S2

AND S2

TT

TT

T

O O

O O

O

THE REAR PTHE REAR P

THE REAR PTHE REAR P

THE REAR P

ANEL OF ANEL OF

ANEL OF ANEL OF

ANEL OF

THE HEATHE HEA

THE HEATHE HEA

THE HEA

TER / BOILER.TER / BOILER.

TER / BOILER.TER / BOILER.

TER / BOILER.

Sensor S2 and sensor S1 must be connected to the dedicated clamps on the rear panel (see para. 5.2). To activate the detections of

Sensors S1 and S2 set THERMOCONTROL ON (see para. 5.8).

Page 19

pg. XIX

(1) Insert on/off and flame adjustment button . When you press this button the appliance (7) switches to START / OFF. Press

repeatedly to activate up to 5 bars and the AUTO indicator is activated (automatic).

START - start up phase: during this phase (lasts approx. 20 minutes ) the appliance is self-adjusted independently from the settings.

OFF - shut down phase. As soon as the OFF symbol appears the smoke suction unit operates for a certain amount of time before

placing the heater / boiler in stand-by mode.

The circulator pump begins operating as soon as the temperature in the boiler reaches 61°C.(symbol displayed)

The other boiler operating statuses appear in the display, that is, WORK..... STOP..... WAIT ON.... SUN OUT (para. 5.10)

(2) Button for setting water temperature in boiler. Press this button to set the temperature for the appliance to reach; The setting

range is between 65 °C and 73°C. This value is displayed in the area of the display next to the drop symbol. Press this button

repeatedly and the following numbers will appear on the display (7) 65 ..... 66 ............... 73 ...... 65.

The temperature detected by the thermocouple in the boiler is indicated after the symbol .

(3) (4) Auxiliary buttons for setting values (only useable within the Menus).

Press button (3) to lower the value. Press button (4) to raise the preset value.

(5) Programming Enable / Disable keys. Press this button to activate/deactivate the programming (presence/absence of the symbol on

the display (7)).

(6) “MENU” selection button To access the main menu press the indicated button. Press button 6 repeatedly to scroll the adjustment,

setting and programming windows (see next paragraphs).To return to the operating status simply continue to press the button (6)

repeatedly.

55

55

5

USE OF USE OF

USE OF USE OF

USE OF

THE HEATHE HEA

THE HEATHE HEA

THE HEA

TER / BOILERTER / BOILER

TER / BOILERTER / BOILER

TER / BOILER

The appliance, when operating, is hot to the touch and the glass in particular is extremely hot: take care not to touch hot parts.

4

5

1

3

17 : 15

7

WORK

Auto

68

62

6

2

5.15.1

5.15.1

5.1

DESCRIPTION OF DESCRIPTION OF

DESCRIPTION OF DESCRIPTION OF

DESCRIPTION OF

THE CONTRTHE CONTR

THE CONTRTHE CONTR

THE CONTR

OL POL P

OL POL P

OL P

ANELANEL

ANELANEL

ANEL

The control panel is managed by a microprocessor. The temperature detection system is controlled by a thermocouple. The large display

improves the appliance management by making read-outs and functions promptly available. The main feature of the panel is the all-automatic

management of the boiler. The controls and displays are described below.

Page 20

pg. XX

(7) Display various information are displayed here.

HEATER OFF

1 POWER LEVEL (The appliance remains always at this power level)

2 POWER LEVELS (The appliance remains always at ?????this power level)

3 POWER LEVEL (The appliance remains always at this power level)

4 POWER LEVELS (The appliance remains always at this power level)

5 POWER LEVELS (The appliance remains always at this power level)

AUTOMATIC (The appliance modulates the thermal power according to system demands)

(For further details see the following paragraph)

- Time

- indicates that the circulation pump is activated when the temperature exceeds 61°C.

- indicates the maximum boiler water temperature adjustable by means of button (2).

- indicates the boiler water temperature detected by the thermocouple.

When the button is pressed repeatedly the following words appear in sequence :

DATE .. to set the day of the week the hour and minutes.

CHRONO .. to set the chronothermostat.

LEVEL .. to vary the rotating speed of the smoke suction unit, the fuel consumption does not change.

THERMOCONTROL .. the operating temperature for Sensor S1 and Sensor S2 can be activated and set if the plumbing system is

fitted with Thermocell.

ITALIANO .. to select the language ( ITALIAN ... ENGLISH....)

To access the functions of each subwindow wait a few seconds then act as described in the following paragraphs.

Page 21

pg. XXI

5.25.2

5.25.2

5.2

DESCRIPTION OF DESCRIPTION OF

DESCRIPTION OF DESCRIPTION OF

DESCRIPTION OF

THE REAR PTHE REAR P

THE REAR PTHE REAR P

THE REAR P

ANELANEL

ANELANEL

ANEL

11

12

13

14

15

10

9

8

17

16

(8) Power outlet for additional room temperature connection.(see para.

6.1)

(additional room temperature thermostat not supplied ))

(9) Power outlet for additional chronothermostat connection.(see para.

6.2)

(additional chronothermostat not supplied )

(10) Loading motor test LED. The light must come on when the pellet screw

feeder starts.

(11) Reset thermostat tripped indicator light. This LED comes on when the

reset thermostat is activated.

(12) Main switch 0-1

(13) Electrical power outlet for heater / boiler 220-240V 50Hz.

(14) General fuse 3,15 A.

(15) Clamp for connecting Sensor 1 (see hydraulic drawing 4.8)

(16) Clamp for connecting Sensor 2 (see hydraulic drawing 4.8 )

(17) Overtemperature thermostat button cap.

In the event of overtemperature this safety thermostat stops the loading of pellets. When it is activated LED 11 comes on. To restart

the heater you have to wait until the water inside it cools down, then verify the cause for the overheating, remove the cause,

unscrew the protective cap and press the button.

5.3 D5.3 D

5.3 D5.3 D

5.3 D

AA

AA

A

Y Y

Y Y

Y

AND AND

AND AND

AND

TIME SETTINGTIME SETTING

TIME SETTINGTIME SETTING

TIME SETTING

The heater / boiler must be energised and the switch at the back turned to position "1".

To set the clock and the day of the week carry out the procedures described below. Press button (6) repeatedly until the word DATE

appears on the Display (7); wait a few seconds for the following indications to appear on the Display (7):

4

1

5

3

7

2

6

DAYS MON

00:

MON

00:00

MON

the figures relating to the minutes on the clock begin to blink. Press button (3) and/or (4) to

change the minutes. Press the button (2) to confirm. The day and time setting is now

completed : the operating status of the heater/boiler will now appear on the display.

The dot/s begins/begin to blink. Press button (3) and/or (4) to change the day of the week (

... TUE o o ... WED o o o ... THU o o o o ... FRI o o o o o ... SAT o o o o o o .. SUN o o

o o o o o ..). Press the button (2) to confirm. The following indications appear next on the

display:

the figures relating to the hours on the clock begin to blink. Press button (3) and/or (4) to

change the hours. P

ress the button (2) to confirm. The following indications appear next on the display:

Page 22

pg. XXII

5.4 CHR5.4 CHR

5.4 CHR5.4 CHR

5.4 CHR

ONOONO

ONOONO

ONO

THERMOSTTHERMOST

THERMOSTTHERMOST

THERMOST

AA

AA

A

TT

TT

T

::

::

:

ON/OFF PR ON/OFF PR

ON/OFF PR ON/OFF PR

ON/OFF PR

OGRAMMINGOGRAMMING

OGRAMMINGOGRAMMING

OGRAMMING

4

1

5

3

7

2

6

DAYS MON 00 : 00

ON 1

Press button (1) repeatedly to display the desired day in which to enter or change the programming.

Press the button (2) to confirm.The following indications appear next on the display:

DAYS MON

ON 1

00 : 00

the figures relating to the hours programming for the first startup (ON 1) begin to blink.

Press button (3) and/or (4) to change the hours. P

ress the button (2) to confirm.

The following indications appear next on the display:

DAYS MON

00 : 00

ON 1

the figures relating to the minutes programming for the first startup begin to blink (ON 1).

Press button (3) and/or (4) to change the minutes. P

ress the button (2) to confirm the value.

The following indications appear next on the display:

DAYS MON

00 : 00

OFF 1

now press button (2) once again and the figures relating to the hours programming for the first

shut off (OFF 1) begin to blink. Similarly, as described above, proceed to enter the hours and

minutes for the first shut off (OFF 1). Next proceed to program the other on - off cycles for

Monday and for the remaining days of the week .

In the event of a programmed cycle on always ensure that the brazier is clean:

failure to keep the brazier clean can reduce the life of the spark plug.

To exit programming simply press button (6): the operating status of the heater/boiler will now appear on the display. Press button (5), while

the heater/boiler is running, to enable or disable the programming function.

(when you press button (5) the words ON CHRONO or OFF CHRONO will appear on the display accompanied by the fixed presence or the

absence of the symbol).

The heater / boiler must be energised and the switch at the back turned to position "1".

It is possible to execute the weekly programming by setting up to 3 on-off cycles for each day from Monday to Sunday. To access the

programming mode press the button (6) repeatedly until the word CRONO appears: wait a few seconds for the following indications to

appear on the Display (7):

17 : 15

Simbolo presente : programmazione abilitata

WORK

60

65

WORK

17 : 15

60

65

Simbolo presente : programmazione disabilitata

Symbol displayed: programming enabled

No symbol: programming disabled

Page 23

pg. XXIII

5.6 OPERA5.6 OPERA

5.6 OPERA5.6 OPERA

5.6 OPERA

TING LEVEL SETTINGTING LEVEL SETTING

TING LEVEL SETTINGTING LEVEL SETTING

TING LEVEL SETTING

The heater / boiler must be energised and the switch at the back turned to position "1".

Your appliance is delivered with an excellent program installed that favours combustion yield; the program is called LEVEL 1.

If you are using pellets with a higher than normal incidence of residues after combustion in the brazier, alternative levels may be selected:

LEVEL 2 : this program increases the smoke suction unit speed acceleration.

LEVEL 0 : when using lightly-compressed pellets and/or flue outlets with very high vacuum, over 2 mm water column.

The pellet consumption value is not affected by the operating level settings.

Select the required level by acting as follows:

Press button (6) repeatedly until the word LEVEL appears on the display then after a few seconds the word LEVEL followed by the value

set on the heater / boiler (LEVEL 01 or LEVEL 02 or LEVEL 00). In order to change the operating level as key (4) is kept pressed, press

the key (3). Hold down button (4) once again and press button (3) to change the level.

To return to the boiler operating status simply press button (6) repeatedly until the operating status appears

The level selection can be made with the heater / boiler OFF or ON. If the change is made while the insert is running the

difference in the flame will be apparent. It is mandatory to pay particular care when selecting the most appropriate