Page 1

HEATING TECHNOLOGY AND INNOVATION

36011 Arsiero (VI) ITALY - V ia Grumolo, 4 - www .thermorossi.com

INST ALLATION, USE AND MAINTENANCE GUIDE

ECOTHERM 5000

Page 2

pg. 2

C O N T E N T SC O N T E N T S

C O N T E N T SC O N T E N T S

C O N T E N T S

DECLARATION OF CONFORMITY

1. INTRODUCTION .................................................................................................................................................................................

1.1 General guidelines .............................................................................................................................................................

1.2 Safety guidelines ................................................................................................................................................................

1.3 Standards and recommendations .....................................................................................................................................

1.4 Transportation and storage................................................................................................................................................

2. TECHNICAL CHARACTERISTICS ....................................................................................................................................................

3. GENERAL DESCRIPTION..................................................................................................................................................................

3.1 Operating technology .........................................................................................................................................................

3.2 Pellets .................................................................................................................................................................................

3.3 The feedbox ........................................................................................................................................................................

4. INSTALLATION ..................................................................................................................................................................................

4.1 Heater location ...................................................................................................................................................................

4.1.1 Installation of metalcolor casing .......................................................................................................................................

4.1.2 Installation of ceramic casing ...........................................................................................................................................

5 . DESCRIPTION OF CONTROLS .....................................................................................................................................................

5.1 Description of control panel and heater rear panel..............................................................................................................

5.2 Day and time setting .............................................................................................................................................................

5.3 ON/OFF Programming. ........................................................................................................................................................

5.4 Operating level setting .........................................................................................................................................................

6 . USE OF THE HEATER ...........................................................................................................................................................................

6.1 Switching on the heater ......................................................................................................................................................

6.2 Adjusting the heater’s combustion ...................................................................................................................................

6.3 Infrared remote control. .....................................................................................................................................................

6.4 Operation of white thermocomfort handheld radio control (optional) ..............................................................................

6.5 Filter ....................................................................................................................................................................................

6.6 Channelling .........................................................................................................................................................................

7 . ADDITIONAL ROOM TEMPERATURE THERMOSTAT (not supplied) ADDITIONAL CHRONOTHERMOSTAT (not supplied)

7.1 Operating with the additional room temperature thermostat (not supplied ) ..................................................................

7.2 Operating with the additional chronothermostat (not supplied) ......................................................................................

8. CLEANING AND MAINTENANCE ..................................................................................................................................................

8.1 Foreword .............................................................................................................................................................................

8.2 Cleaning and maintaining the heater ................................................................................................................................

8.3 Charging the battery of the handheld radio control. .........................................................................................................

8.4 Replacing the battery in the remote control .....................................................................................................................

8.5 Replacing the buffer battery of the control panel .............................................................................................................

9. SMOKE EXHAUST PIPE.....................................................................................................................................................................

9.1 Ventilation of the rooms .....................................................................................................................................................

9.2 Smoke outlet .......................................................................................................................................................................

10. ALARMS ............................................................................................................................................................................................

11. ELECTRICAL WIRING .....................................................................................................................................................................

12. INFORMATION FOR THE SKILLED TECHNICIAN.............................................................................................................................

12.1 Main components and their operation ...............................................................................................................................

12.2 Useful advice for installation and operation .....................................................................................................................

12.3 Troubleshooting cause-solution ........................................................................................................................................

13 SPARE PARTS ..................................................................................................................................................................................

Page 3

pg. 3

THERMOROSSI S.p.A.

Via Grumolo. 4

36011 ARSIERO

tel. 0445.741310

fax 0445.741657

"CE" DECLARA TION OF CONFORMITY

In accordance with the following directives:

European Directive 73/23/EEC and its amending directive 93/68/EEC

89/336/EEC and its amending directives 93/68/EEC

92/31/EEC

93/97/EEC

Thermorossi S.p.A., Via Grumolo 4 - ARSIERO (VI), declares that the heaters of the ECOTHERM series have been designed and manufactured

in compliance with the safety requirements of the standards for EC marking.

This declaration refers to the entire range of the specified series.

Ecotherm 5000 complies with EN 14785: 2006.

ARSIERO, 3 May 2010 THERMOROSSI S.p.A.

11

11

1

INTRODUCTIONINTRODUCTION

INTRODUCTIONINTRODUCTION

INTRODUCTION

1.11.1

1.11.1

1.1

GENERAL GUIDELINESGENERAL GUIDELINES

GENERAL GUIDELINESGENERAL GUIDELINES

GENERAL GUIDELINES

This installation, use and maintenance guide is an integral and essential part of the product and must be kept by the user . Before commencing with

the installation, use and maintenance of the product, carefully read all the instructions contained in this booklet. At the time of installation of the

appliance all local regulations, including those that refer to national and European regulations, must be observed. The Manufacturer recommends

carrying out all the maintenance operations described in this manual.

This appliance must only be used as intended by the manufacturer. Any other use is considered incorrect and therefore hazardous; consequently,

the user shall be totally liable for the product if used improperly. Installation, maintenance and repairs must be carried out by personnel with

professional qualifications and in compliance with current regulatory standards and in accordance with the instructions of the manufacturer of

the appliance. Use only original spare parts.

Incorrect installation or poor maintenance could injure or damage people, animals or things; in this case the manufacturer shall be relieved of all

responsibility. Before commencing any cleaning or maintenance operation ensure that the appliance has been disconnected from the mains

power supply by means of the main system switch or some other disconnecting device installed upstream from the appliance. The product must

be installed in locations suitable for fire-fighting and furnished with all the services (power and outlets) which the appliance requires for a correct

and safe operation. Any repairs or actions carried out on any systems, components or internal parts of the appliance, or on any of the

accessories supplied with it, that are not specifically authorised by Thermorossi s.p.a, will automatically void the warranty and the manufacturer's

responsibility, pursuant to D.P.R. 224 of 24/05/1988, art. 6/b.Use only original Thermorossi spare parts. If the appliance is sold or transferred to

another user ensure that the guide is handed over with it.

Thermorossi S.p.A. maintains the author’s rights on these service instructions.

The information in this booklet may not be reproduced or given to third parties or used for competitive purposes without the appropriate

authorization.

1.2 SAFETY GUIDELINES1.2 SAFETY GUIDELINES

1.2 SAFETY GUIDELINES1.2 SAFETY GUIDELINES

1.2 SAFETY GUIDELINES

PERSONAL INJURY

This safety symbol identifies important messages throughout the manual. Read the information marked by this symbol

carefully as non-observance of this message can cause serious injury to persons using the heater.

DAMAGE TO PROPERTY

This safety symbol identifies messages or instructions that are fundamental for the heater and system to function well. To

avoid serious damage to the heater adhere strictly to these instructions.

INFORMATION

This symbol indicates important instructions for good functioning of the heater. If this information is not correctly observed, the

performance of the heater and/or system will not be satisfactory.

Page 4

pg. 4

22

22

2

TECHNICAL CHARATECHNICAL CHARA

TECHNICAL CHARATECHNICAL CHARA

TECHNICAL CHARA

CTERISTICS *CTERISTICS *

CTERISTICS *CTERISTICS *

CTERISTICS *

1.41.4

1.41.4

1.4

TRANSPORTRANSPOR

TRANSPORTRANSPOR

TRANSPOR

TT

TT

T

AA

AA

A

TION TION

TION TION

TION

AND STAND ST

AND STAND ST

AND ST

ORAORA

ORAORA

ORA

GEGE

GEGE

GE

TRANSPORTATION AND HANDLING

The heater body must always be in a vertical position when handled and exclusively by means of trolleys. Take special care to protect the

electric panel, the glass, the ceramics and all the fragile parts from mechanical impact which could damage them and their correct

functioning.

STORAGE

The heater must be stored in a humid-free environment and sheltered from the weather; do not place the heater directly on the floor. The

Company denies all responsibility for damage caused to wood floors or floors made from any other material. It is inadvisable to store the

heater for long periods of time.

* All the data are based on the appliance fuelled with Austrian standard ÖNORM M 7135 typeapproved pellets.

1.31.3

1.31.3

1.3

STST

STST

ST

ANDAND

ANDAND

AND

ARDS ARDS

ARDS ARDS

ARDS

AND RECOMMENDAND RECOMMEND

AND RECOMMENDAND RECOMMEND

AND RECOMMEND

AA

AA

A

TIONSTIONS

TIONSTIONS

TIONS

NORMATIVE REFERENCES :national and international standards used as reference guides in the following manual for the design, industrialization

and production of the products:

- European directive 73/23/EEC - Standard CEI 61/50 - European directive 93/68/EEC

- Standard CEI EN 60204 - European directive 89/336/EEC - Standard CEI 64-8 (IEC 364)

- European directive EN 14785: 2006

RECOMMENDATIONS

Before using the appliance, carefully read every section of this instruction manual as knowledge of the information and the regulations contained

in it are essential for a correct use of the appliance.

The entire operation concerning the connection of the electric panel must be carried out by expert personnel; no responsibility will be accepted

for damages, even to third parties, if the instructions for installation, use and maintenance of the appliance are not followed scrupulously.

Modifications made to the appliance by the user or on his behalf, must be considered to be under his complete responsibility. The user is

responsible for all the operations required for the installation and maintenance of the appliance before and during its use.

GENERAL WARNINGS

Caution: the appliance must be connected to a system provided with a PE conductor (in compliance with the specifications of 73/23/EEC, 93/

98/EEC, concerning low voltage equipment).

Before installing the appliance check the efficiency of the earth circuit of the power supply system. Caution: the power supply line must have

a section which is suitable for the power of the equipment. The cable section must in any case be no less than 1.5 mm². The appliance must be

powered with a voltage of 220/240 V and 50 Hz. Voltage variations which exceed 10% of the nominal value can cause poor functioning or

damage the electrical device. Position the appliance so that the electric power plug is easily accessible. Voltage variations less than 10% of the

nominal value can cause lighting and use problems. Apply a current regulator. Ensure that a suitable differential switch is installed upstream from

the equipment.

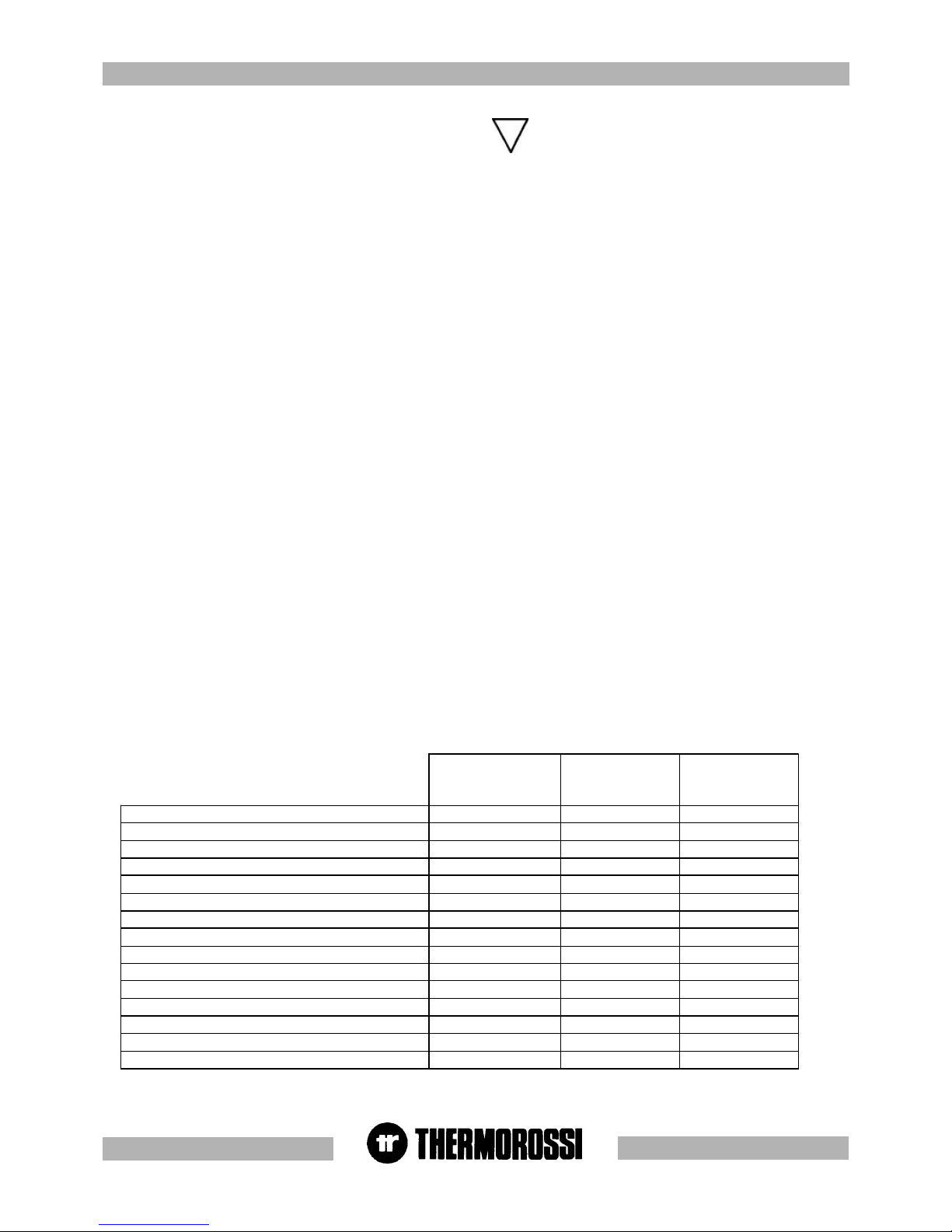

Ecotherm 5000

Easy

Ecotherm 5000

Metalcolor

Ecotherm 5000

Ceramic

element

Height (mm) 973 973 973

Depth (mm) 529 529 529

Length (mm) 460 460 460

Weight (Kg) 128 132 153

Rated power (Kw) 9,2 9,2 9,2

Reduced rated power (Kw) 2,5 2,5 2,5

Consumption min/max (Kg/h) 0,7 – 2,3 0,7 – 2,3 0,7 – 2,3

Smoke outlet tube D. (mm) 80 80 80

Min. draught at rated power (Pa) 12 12 12

Hopper capacity (Kg) ~ 14,5 ~ 14,5 ~ 14,5

Average smoke temp. at rated power (° C) 180 180 180

Smoke flow at rated power (g/sec) 5,5 5,5 5,5

Electricity 220 V 50 HZ 220 V 50 HZ 220 V 50 HZ

Max electrical consumption 1,17 A – 270 W 1,17 A – 270 W 1,17 A – 270 W

Min electrical consumption 0,34 A – 70 W ,34 A – 70 W ,34 A – 70 W

Page 5

pg. 5

251

460

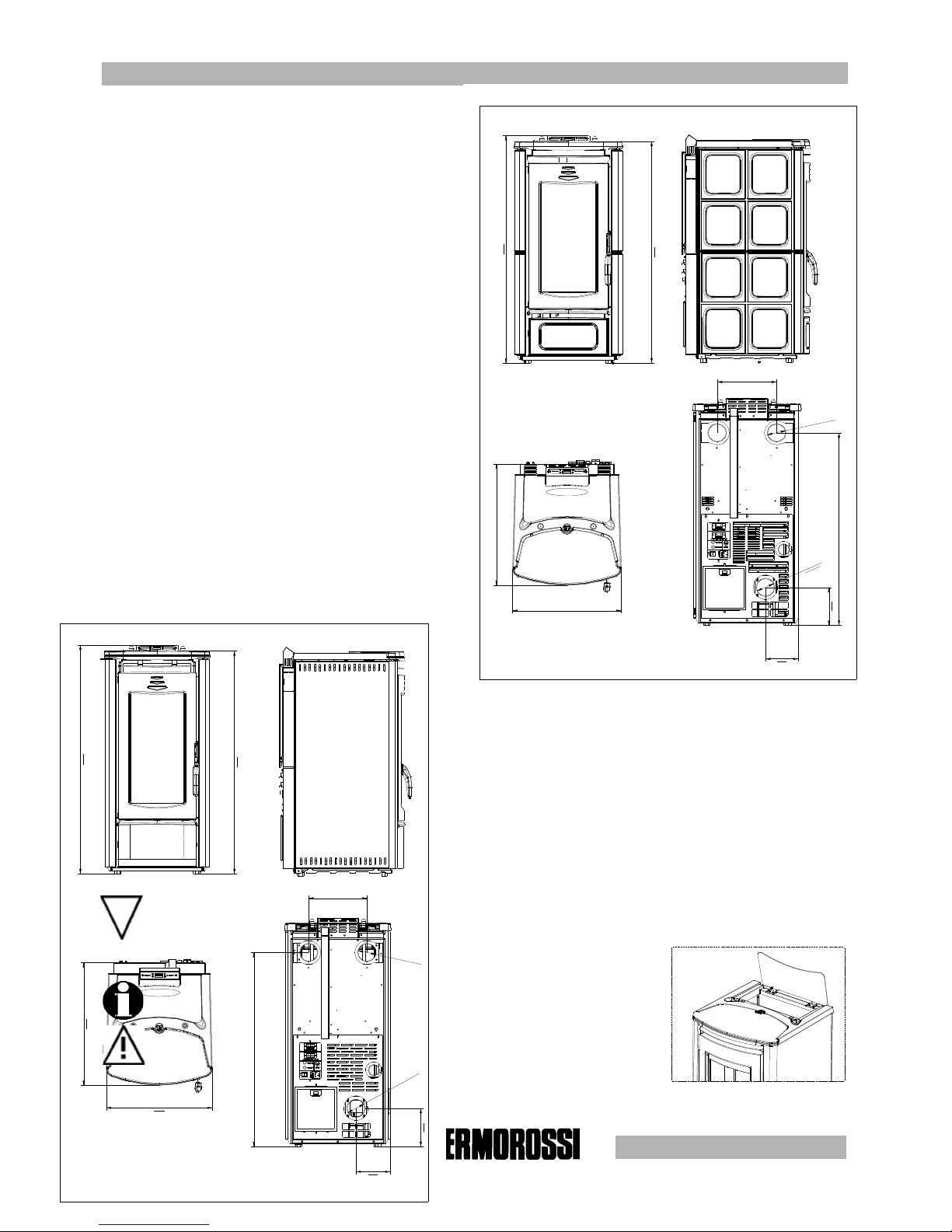

ECOTHERM 5000 EASY (in questo modello non è presente

la ceramica inferiore)

ECOTHERM 5000 METALCOLOR

529

165

152

838

O

8

0

O

8

0

973

955

460

ECOTHERM 5000 CERAMICA

529

152

O

8

0

165

838

O

8

0

973

955

251

33

33

3

GENERAL DESCRIPTIONGENERAL DESCRIPTION

GENERAL DESCRIPTIONGENERAL DESCRIPTION

GENERAL DESCRIPTION

3.13.1

3.13.1

3.1

OPERAOPERA

OPERAOPERA

OPERA

TING TING

TING TING

TING

TECHNOLTECHNOL

TECHNOLTECHNOL

TECHNOL

OGYOGY

OGYOGY

OGY

•Your heater has been built to fully satisfy all your heating and practical requirements. Top-grade components and functions managed with

microprocessor technology guarantee high reliability and optimal performance.

3.23.2

3.23.2

3.2

PELLETSPELLETS

PELLETSPELLETS

PELLETS

•The appliance is fuelled by pellets, that is, cylinders of compressed sawdust; this will make it possible for you to enjoy to the full the heat of the

flame without having to manually stoke the combustion.

The pellets are cylinders of compressed sawdust having a 6 mm diameter and a maximum length of 15 mm.

They have a maximum moisture content of 8%; a thermal value 4000/4500 Kcal/Kg and a density of approx. 620-630 Kg/m³.

The use of fuel which does not comply with the description given above immediately voids the heater warranty. Do

not use the appliance as an incinerator, at the risk of voiding the warranty.

3.33.3

3.33.3

3.3

THE FEEDBOTHE FEEDBO

THE FEEDBOTHE FEEDBO

THE FEEDBO

XX

XX

X

The feedbox is situated in the top part of the heater. The maximum load capacity of the tank is

approximately 14,5 Kg, but varies according to the specific weight of the pellets. The

manufacturer recommends emptying the hopper and vacuuming the screw feeder

zone once a month and during the summer period. Take special care when loading

the hopper as the screw feeder at its base is in motion.

Key

Ecotherm 5000 Easy The lower ceramic panel

is not included in this model

Ecotherm 5000 Ceramic

LEGENDA

Ecotherm 5000 Easy (In questo modello non è

presente la ceramica inferiore)

Ecotherm 5000 Ceramica

Page 6

pg. 6

44

44

4

INSTINST

INSTINST

INST

ALLAALLA

ALLAALLA

ALLA

TIONTION

TIONTION

TION

4.14.1

4.14.1

4.1

HEAHEA

HEAHEA

HEA

TER LTER L

TER LTER L

TER L

OCAOCA

OCAOCA

OCA

TIONTION

TIONTION

TION

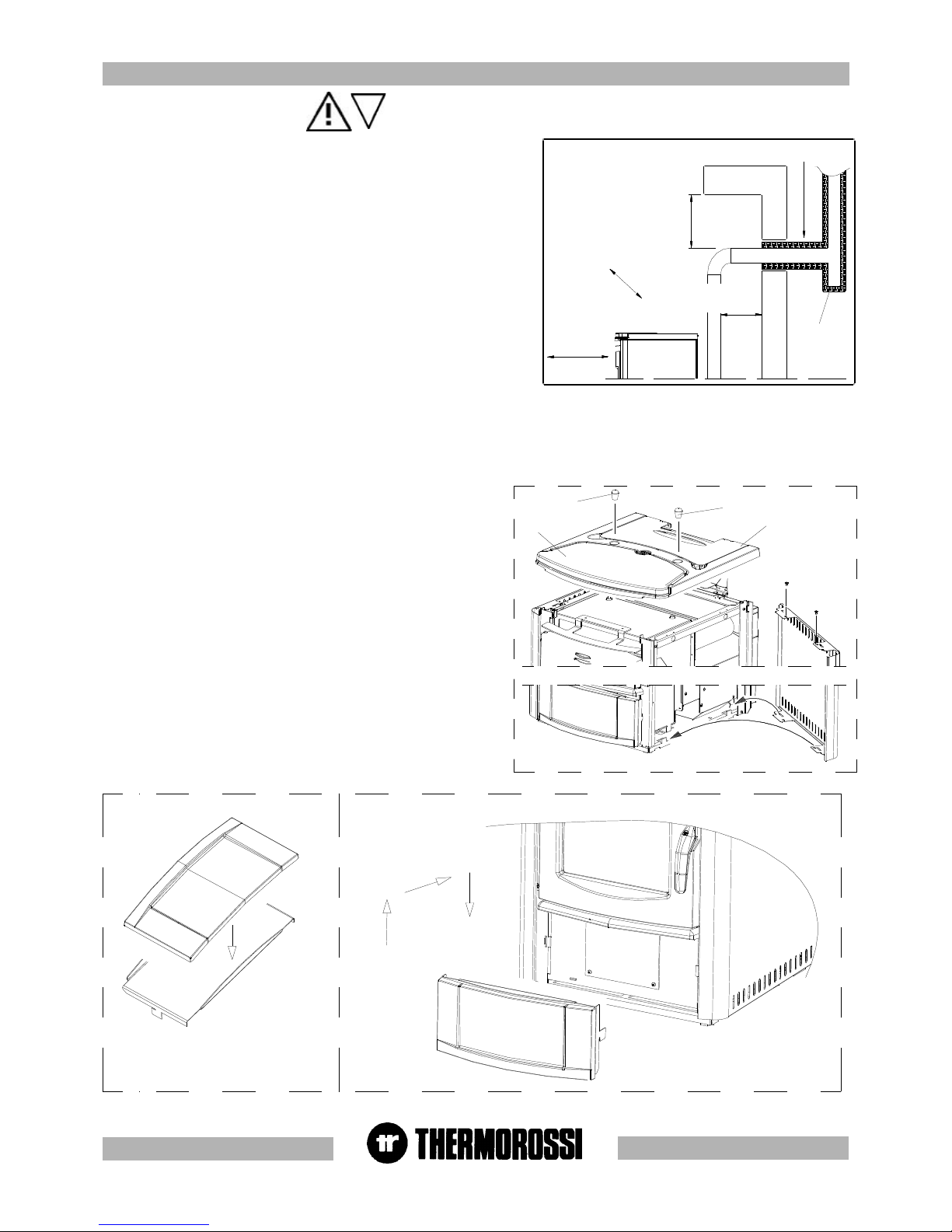

CAUTION : Always use trolleys to move the appliance and the appliance must

always be in a vertical position. Follow the general guidelines set out in paragraph

1.1 to the letter. Keep in mind that the flooring of the room in which the heater is to

be installed must withstand the combined weight of the appliance and the pellets

contained in the tank.

CAUTION: The room in which the appliance will operate must be adequately ventilated

(minimum air intake 1300 m3/h). The appliance must be positioned at a minimum

safe distance from walls and furnishings. This distance will have to be increased

considerably if the objects surrounding the appliance are inflammable

(matchboarding, furniture, curtains, picture frames, sofas, etc...). The recommended

minimum distances are illustrated in the drawing below on the right. Installation in

the vicinity of heat-sensitive materials is only permitted if suitable insulating protection

is placed between the object and the appliance (ref. Uni 10683). Adjust the mounting

feet to obtain a slight gap between heater and flooring to ensure that the heater is

not resting directly on the floor. It is advisable to interpose a floor protector plate

between the heater and the floor if the latter is made of wood or other combustible

material.

4.1.14.1.1

4.1.14.1.1

4.1.1

INST INST

INST INST

INST

ALLAALLA

ALLAALLA

ALLA

TION OF METTION OF MET

TION OF METTION OF MET

TION OF MET

ALAL

ALAL

AL

COLCOL

COLCOL

COL

OR CASINGOR CASING

OR CASINGOR CASING

OR CASING

Once the heater has been positioned the next step is to install the side panels

and the top ceramic panel as shown in the image below on the left. Carry out

the following operations:

- Unscrew and remove the 2 knobs (H).

- Remove the cover (I).

- Now insert the side panel (M)'; position the bottom holes on the folds in the

base and fix the 2 top screws (Figure 1).

- Next remount the complete cover (I) and the top ceramic panel (L) and

screw back on the 2 knobs (H) removed earlier.

- Fix the lower front ceramic panel to its support with the silicone provided;

degrease and clean the ceramic panel support before gluing the parts to

ensure optimal adhesion. Leave the ceramic panel in the position illustrated in

Figure 2 and wait 24 hours before handling it.

- Next fasten the lower ceramic panel to the heater following the instructions

in Figure 3 .

Remember that the heater must be completely cooled down before the side

panel can be cleaned with a soft cloth and water.

The casing on the easy model is factory-mounted before delivery .

450 mm SE MATERIALE COMBUSTIBILE

450 mm SE MATERIALE COMBUSTIBILE

ISOLANTE TERMICO

2

0

0

m

m

S

E

M

A

T

E

R

I

A

L

E

C

O

M

B

U

S

T

I

B

I

L

E

200 mm SE MATERIALE

COMBUSTIBILE

Tee ispezionabile

H

H

I

L

M

Figura 1

Figura 2

Figura 3

Key

200 / 450 mm if combustible material

Heat insulating material

Inspectable Tee element

Figure

LEGENDA

200 / 450 mm se materiale combustibile

Isolante termico

Tee ispezionabile

Figura

Page 7

pg. 7

4.1.24.1.2

4.1.24.1.2

4.1.2

MOUNTING CERAMIC CASING MOUNTING CERAMIC CASING

MOUNTING CERAMIC CASING MOUNTING CERAMIC CASING

MOUNTING CERAMIC CASING

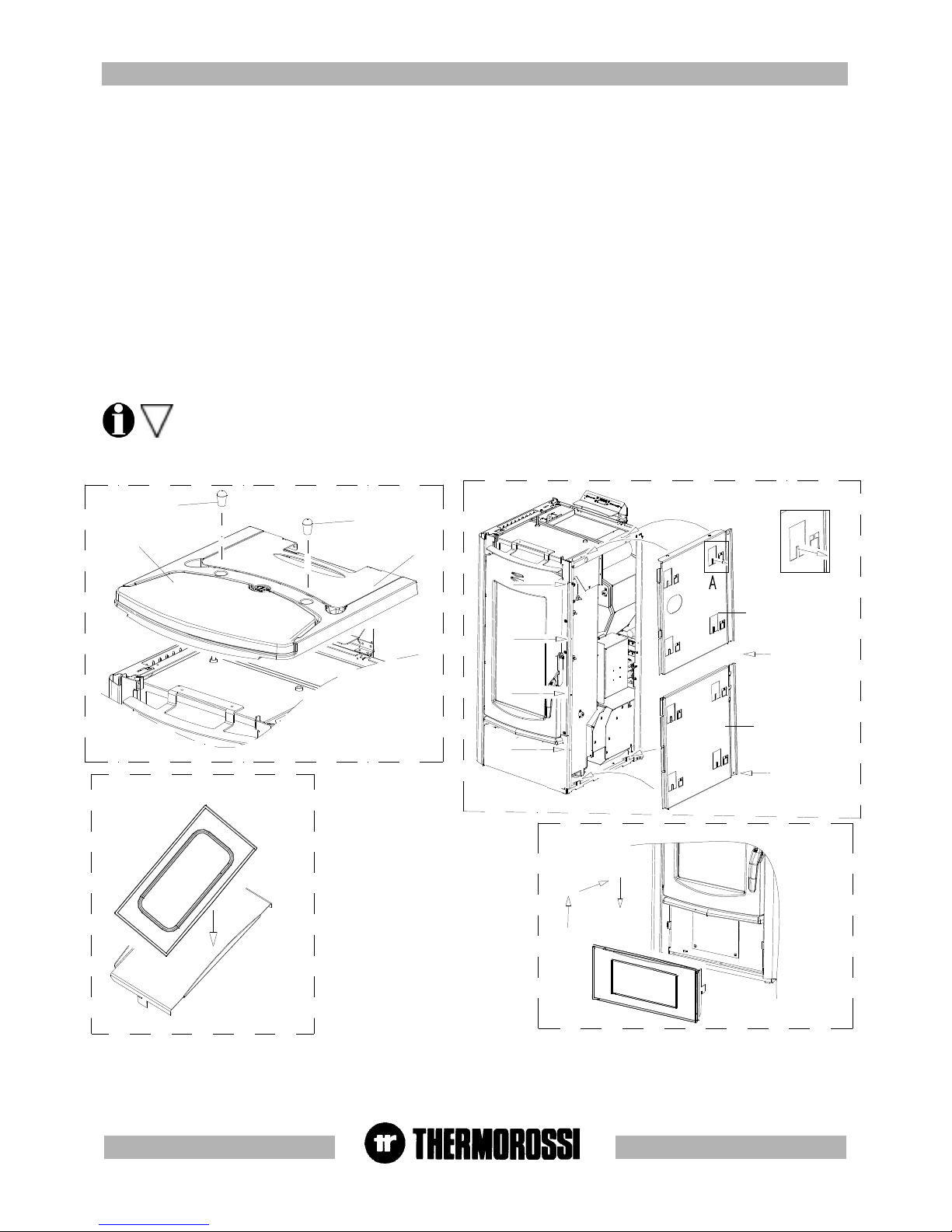

The next step, after positioning the heater, is to mount the ceramic casing as illustrated in the figures below.

Carry out the following operations:

- Unscrew the 2 knobs and remove the top cast iron cover.

- Mount the right ceramic panel supports (figure 2) following the procedure set out below:

Undo screws A and B and remove them momentarily. Fix support SID by firstly inserting the bottom folds on the seat of the heater base, next

re-insert and fasten screws A and B. Undo screws C and B and remove them momentarily. Fix support SSD then re-insert and fasten screws

C and D. Next screw in screws E and F provided. Screw in screws G and H provided.

Bend the tabs slightly (indicated in detail A of Figure 2) outwards from the heater. Next fix the side ceramics to the supports by securing them

to the bent tabs.

Next mount the left ceramic panel supports using the same procedure as described above for the right ceramic panel supports (Figure 2).

Next attach the side ceramic panels to the supports.

- Fix the lower front ceramic panel to its support (Figure 3) with the silicone provided; degrease and clean the ceramic panel support before gluing

the parts to ensure optimal adhesion. Leave the ceramic panel in the position illustrated in Figure 3 and wait 24 hours before handling it.

- Next fasten the lower ceramic panel to the heater following the instructions set out in Figure 4.

- Lastly position the top ceramic panel (Figure 1) and screw in the 2 knobs removed earlier.

Special care must be taken when handling and mounting the ceramics in order to prevent breakages that are not covered by

warranty. Small imperfections on the surfaces of the ceramics such as: dimples, shivering and slight colour variations are

normal characteristics of handcrafted ceramics which make each piece unique.

H

H

I

L

DETTAGLIO A

Figura 2

A

B

C

D

F

E

G

H

SID

SSD

Figura

1

3

Figura

4

Figura

Key

Detail A

Figure

LEGENDA

Dettaglio A

Figura

Page 8

pg. 8

55

55

5 DESCRIPTIONS OF CONTROLS

5.15.1

5.15.1

5.1

DESCRIPTION OF CONTRDESCRIPTION OF CONTR

DESCRIPTION OF CONTRDESCRIPTION OF CONTR

DESCRIPTION OF CONTR

OL POL P

OL POL P

OL P

ANEL ANEL

ANEL ANEL

ANEL

AND HEAAND HEA

AND HEAAND HEA

AND HEA

TER REAR PTER REAR P

TER REAR PTER REAR P

TER REAR P

ANELANEL

ANELANEL

ANEL

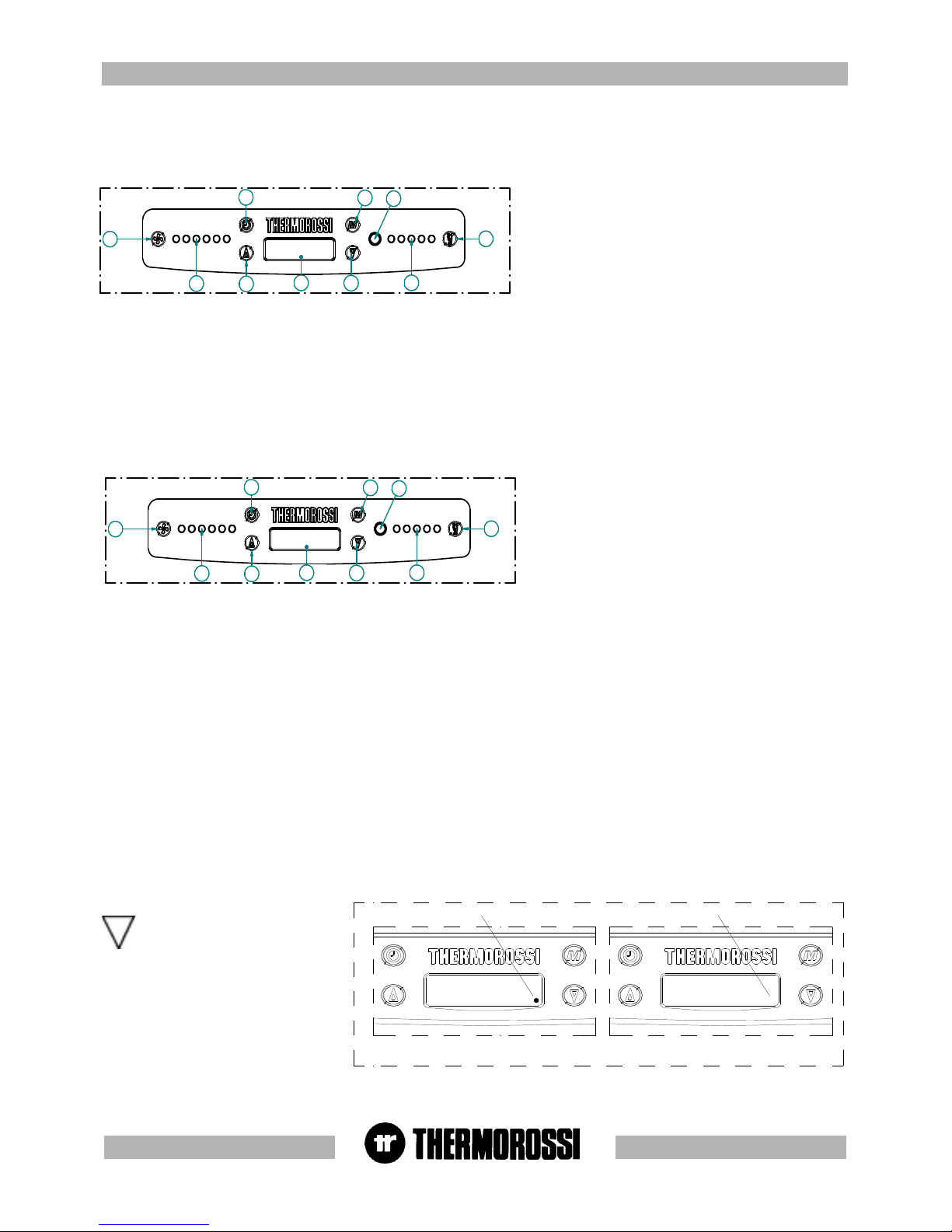

5.1.1 DESCRIPTION OF THE CONTROL PANEL

There are two main control pushbuttons marked with the ventilation symbol (2) and the symbol of the flame (1).The flame pushbutton (1) sets

the power of the heater with 5 levels available which are activated as the 5 leds light up in sequence (10). The off cycle is activated when

all power leds are turned off. Key (2) controls the ventilation of the heater. It is activated when the heater body reaches a temperature over

42 °C. The fan can be set to any of speed levels (9): when the heater is on the ventilation cannot be switched off .

5.1.2 BACK PANEL OF THE HEATER

A description of the functions of the buttons and LEDs on the back panel of the

heater:

(11) Main switch 0-1

(12) Heater electrical power outlet 220-240V 50 Hz.

(13) Overtemperature thermostat button cap.

In the event of overtemperature this safety thermostat stops the loading of

pellets. When it is activated LED 15 comes on. To restart the heater you

need to wait until it cools down, then verify the cause for the overheating,

remove the cause, unscrew the protective cap and press the button (13) .

(14) Feed motor test indicator light. When the pellet screw feeder is set in

motion the light must come on.

(15) Reset thermostat tripped indicator light. This LED comes on when

the reset thermostat is activated.

(16) Power outlet for additional chronothermostat connection.

(additional chronothermostat not supplied )

(17) Power outlet for additional room temperature thermostat

connection. (additional room temperature thermostat not supplied)

All controls and indicators are presented here below :

(1) Insert on/off and flame adjustment button . When you press this button the appliance (10) switches to Start / ON / OFF.

Up to 5 leds (10) are activated when pressed repeatedly.

(2) Ventilation setting button . Press this button to set the desired level of ventilation: up to a maximum of 6 speeds are available,

indicated by the lighting of the corresponding leds (9).

(3) (4) Auxiliary setting keys.

Keys (3) and (4) are operating keys necessary when on-off cycles are programmed, for operative levels, clock setting, etc..

5) Programming Enable / Disable keys.

(6) “MENU” selection button To access the main menu press the button marked with 6. Press button 6 repeatedly to scroll the

adjustment, setting and programming windows.

(7) Display

(8) Infrared sensor for remote control

(9) Ventilation level leds .

(10) Combustion level leds

1

2

3

4

5

6

7

8

9

10

11

13

14

15

16

17

12

Key

Room temperature thermostat

Chronothermostat - modem

Motor. LED

Reset LED

Reset

LEGENDA

Termostato ambiente

Cronotermostato - modem

Spia motor.

Spia riarmo

Riarmo

Page 9

pg. 9

5.2 D5.2 D

5.2 D5.2 D

5.2 D

AA

AA

A

Y Y

Y Y

Y

AND AND

AND AND

AND

TIME SETTINGTIME SETTING

TIME SETTINGTIME SETTING

TIME SETTING

The heater must be fed with the rear switch in position "1". Display (7) may show the inscriptions On , OFF or Start.

To set the time and the day of the week carry out the

procedures described below. Press once the key (6), and the

inscription HoUr will flash. After a few seconds the fixed

inscription days will appear. In order to ad just the day,

repeatedly press key (4) and/or (3) until the led turns on in

area (9) which corresponds to the present day; Monday is

indicated by the 1st led on, Tuesday is indicated by the 2nd led

on,....... Saturday is indicated by led (6) on, while Sunday

corresponds to all 8 leds being on. Then confirm the day by

pressing the key (1). The 2 digits representing the hours will start flashing in the display: it is possible to select the present hour using the

arrow keys (4) and/or (3); the selection must be confirmed by pressing key (1). The 2 digits indicating the minutes will start flashing: it is

possible to select the present minutes using the arrow keys (4) and/or (3), the selection must be confirmed by pressing the key (1). The

setting of the day and of the hour is now completed. For the entire procedure to be confirmed and to move back to the heater status display,

key (6) must be repeatedly pressed until the operating status is displayed: On , Off, or Start. :

5.3 ON/OFF PROGRAMMING.5.3 ON/OFF PROGRAMMING.

5.3 ON/OFF PROGRAMMING.5.3 ON/OFF PROGRAMMING.

5.3 ON/OFF PROGRAMMING.

The heater must be fed with the rear switch in position "1". Display (7) may show the inscriptions On , OFF or Start.

It is possible to carry out the weekly programming by setting up to 3 on/off cycles for each day from Monday to Sunday. To carry out the

programming, push button (6) must be pressed twice until

the inscription cr on is on.: in area (9) a led goes on (which

indicates that the first day of the week, Monday, is being

programmed). Inscription On1 will appear on the display,

and the 2 digits representing the hours will turn on. Press

button (3) and/or (4) to enter the hour of the first cycle start

time. To confirm the selection press the button (1). The two

digits representing the minutes will be turn on. Press button

(3) and/or (4) to enter the minutes of the first cycle start

time. For the selection to be confirmed press the key (1). The

first hour for the Monday on-cycle has been set. Then the inscription OFF1 will appear in the display and the two digits representing the

hours will turn on. When the (3) and/or (4) is pressed the hour of the first off-cycle is entered. To confirm the selection press the button (1).

The two digits representing the minutes will be turn on. By pressing the key (3) and/or (4) the minutes for the first off-cycle will be entered

To confirm the selection press the button (1). At this point the first on-off cycle for Monday has been entered. Later, it is possible to set the

Monday’s second on-off cycle (shown with the display of On2 and OFF2) and the third Monday’s on-off cycle (shown with the display On3

and OFF3) . Inside the programming menu, if for example the Wednesday’s programming is to be changed, go to the third green led by

pressing key(2): then it is possible to change the on-off programs for Wednesday, confirm the change by pressing the key (6). If the second

on-off cycle is not required simply set the ON2 time as 00:00 and the OFF2 time as 00:00 .

The programming procedure ends when you confirm the last data entered by pressing button (6) or when you exiting the programming menu.

Pressing pushbutton (5) programming is enabled/disabled (Enabled= message on cr temporarily displayed and, at the same time, a fixed

point is present on the right side at the bottom of the display. Disabled= message of cr temporarily displayed and, at the same time, the point

on the right side at the bottom of the display is not present.) : this function is useful if one wants to prevent the weekly established

programming. With the programming active, the operating conditions at the start-up (combustion power – ventilation speed) are the same as

set-up before the last off-cycle of the heater: this is the case if the off-cycle has been done through the programming and not through a

manual action. In case the off-cycle (if carried out while the heater cycle is being controlled by the programming) is activated manually, at the

next start up controlled by the programming the heater will be set at the 1st combustion power level and the 1st ventilation speed.

In order to display the present time and programmings, key (6) must be repeatedly pressed until the current time is

displayed. By pressing keys (3) and/or (4) all programming values will be displayed : to exit this condition, twice press the

key (6) .

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

Esempio di come si presenta il display

con la programmazione attivata.

Esempio di come si presenta il display

con la programmazione disattivata.

On

Presenza fissa punto

On

Assenza punto

Key

Point steady presence

Point absence

Example of how the display

appears with the programming

activated/deactivated.

LEGENDA

Presenza fissa punto

Assenza punto

Esempio di come si presenta il

display con la programmazione

attivata / disattivata

In the event of a programmed cycle

on always ensure that the brazier is

clean and seated correctly in its

lodging: failure to keep the brazier

clean can reduce the life of the

spark plug.

Page 10

pg. 10

5.4 OPERA5.4 OPERA

5.4 OPERA5.4 OPERA

5.4 OPERA

TING LEVEL SETTINGTING LEVEL SETTING

TING LEVEL SETTINGTING LEVEL SETTING

TING LEVEL SETTING

The heater must be fed with the rear switch in position "1". Display (7) may show the inscriptions On , OFF or Start. ".

Your appliance is delivered with an excellent program installed that favours combustion yield; the program is called P 1.

If you are using pellets with an out-of-standard incidence of residues after combustion in the brazier, alternative levels may be selected:

P 2 : this program increases the smoke suction unit speed acceleration.

(program P2 increases air delivery to the burner which promotes the combustion of tightly compacted pellets: this program reduces

combustion efficiency).

P 0 : when using too long pellets and/or flue outlets with very high vacuum, over 2 mm water column.

The pellet consumption value is not affected by the operating level settings.

Select the required level by acting as follows:

Repeatedly press three times the key (6) until the inscription LIV flashes on the display and, then, the corresponding level set on the heater

will show ( P1 o P2 o P0) In order to change the operating level as key (4) is kept pressed, press the key (3).

By holding down button (4) and pressing button (3) repeatedly the level changes in the following sequence: P2... ...P0 ... P1.

If the change is made while the insert is running the difference in the flame will be apparent. It is mandatory to pay

particular care when selecting the most appropriate operating cycle for your installation. After the selection of the

operating cycle a thorough cleaning of the brazier is mandatory.

For an overall confirmation and to return to the status display of the heater, repeatedly press the key (6) until the operating status is

displayed.

When the programming is enabled (temporary inscription on cr on the display and, at the same time, a fixed point is present on the

right side at the bottom of the display) any additional chronothermostat (see para. 7.2) is deactivated.

1

2

3

4

5

6

7

8

9

10

66

66

6

USE OF USE OF

USE OF USE OF

USE OF

THE HEATHE HEA

THE HEATHE HEA

THE HEA

TERTER

TERTER

TER

6.16.1

6.16.1

6.1

5.15.1

5.15.1

5.1

SWITSWIT

SWITSWIT

SWIT

CHING ON CHING ON

CHING ON CHING ON

CHING ON

THE HEATHE HEA

THE HEATHE HEA

THE HEA

TERTER

TERTER

TER

Before using the appliance check that all the movable parts are in place; also remove any labels and stickers from the glass to avoid having

permanent traces remain on the surfaces.

Turn the switch installed on the back of the heater to position "1" (= ON). Press button (1) to start the start up phase. When key (1) is

repeatedly pressed, the desired combustion level can be set and it will be active at the end of the ignition stage.

The electrical heater will start to overheat and after a few minutes the first lot of pellets will start dropping into the brazier. This occurs

because the screw feeder has to fill up because it is completely empty. The first time the heater is started up the start up phase will have to

be carried out twice for this very reason.

CAUTION : The start up phase (word Start appearing on the display) takes 20 minutes during which the heater ignores any

commands transmitted to it. After this time has elapsed the word ON appears on the display. The fan starts as soon as the heater

body exceeds 42°C. During the work stage it is then possible to adjust combustion and the ventilation:

Combustion is adjusted by 5 leds (through key (1)) , while the ventilation adjustment is distributed over 6 levels shown by the leds

that turn on in succession (through key (2)).

To turn the heater on it is necessary for the inscription OFF to be present on the display; if it is not present, the key (6) must be

repeatedly pressed until the inscription OFF appears.

The heating capacity is adjusted by pressing key (1) or on the remote control provided . Act on this command to adjust the quantity of pellets

fed to the firebox. Maximum combustion power is achieved when all 5 leds are lit.

Caution: The fan starts as soon as the heater body exceeds 42°C. The fan setting is expressed visually by means of 6 different

positions represented by 6 bars: press button (2) repeatedly to regulate it.

A slight vibration of the heater is quite normal when it is running.

6.2 HEA6.2 HEA

6.2 HEA6.2 HEA

6.2 HEA

TER COMBTER COMB

TER COMBTER COMB

TER COMB

USTION USTION

USTION USTION

USTION

AND AND

AND AND

AND

VENTILAVENTILA

VENTILAVENTILA

VENTILA

TION TION

TION TION

TION

ADJUSTMENTSADJUSTMENTS

ADJUSTMENTSADJUSTMENTS

ADJUSTMENTS

Page 11

pg. 11

A practical infrared remote control is supplied with the heater: press the left button to adjust the ventilation level, press the right button to

adjust the combustion level. If the heater is supplied with a white radio control (optional) the infrared control only works when the MANUAL

setting is set on the white handheld radio control.

6.3 INFRARED REMO6.3 INFRARED REMO

6.3 INFRARED REMO6.3 INFRARED REMO

6.3 INFRARED REMO

TE CONTRTE CONTR

TE CONTRTE CONTR

TE CONTR

OLOL

OLOL

OL

INTRODUCTION

The handheld radio control is the device that allows you to control Ecotherm in order to optimise consumption and its functions. Keep in mind

that radio wave transmissions can be affected by the surrounding environment: the presence of thick walls can reduce the transmission that

normally extends to 6-7 metres.

6.46.4

6.46.4

6.4

OPERAOPERA

OPERAOPERA

OPERA

TION OF TION OF

TION OF TION OF

TION OF

THE THE

THE THE

THE

WHITE HANDHELD RADIO CONTRWHITE HANDHELD RADIO CONTR

WHITE HANDHELD RADIO CONTRWHITE HANDHELD RADIO CONTR

WHITE HANDHELD RADIO CONTR

OL (OPTIONOL (OPTION

OL (OPTIONOL (OPTION

OL (OPTION

AL)AL)

AL)AL)

AL)

3

4

2

1

7

6

5

8

9

10

11

13

12

6.4.16.4.1

6.4.16.4.1

6.4.1

Indicators of the handheld radio controlIndicators of the handheld radio control

Indicators of the handheld radio controlIndicators of the handheld radio control

Indicators of the handheld radio control

(1) Flame adjustment button

(2) Ventilation adjustment button

(3) (4) Auxiliary keys.

(5) “Room temperature detected by the radio control's sensor” indicator .

(6) "Ventilation" indicator.

(7) " Combustion" indicator.

(8) “ Room temperature setting" indicator : this is the room temperature that you

wish to reach by means of buttons 3 and 4.

(9) Area of the display where the operating program is displayed.

(10) Battery charge level

(11) Switch 0-1 radio control power

(12) Battery charger connection.

(13) Code selector and Batteries compartment cover

The Thermocomfort radio control can be used with 4 different operating programs:

- Manual (MANUAL appears in area (9) of the display).

- Automatic 5 (AUTO 5 appears in area (9) of the display).

- Automatic 3 (AUTO 3 appears in area (9) of the display) .

- Economy (ECONOMY appears in area (9) of the display).

To change the operating program turn the switch (11) to "1". Press and hold down button (3) until the set program begins to blink on the

display (9). Now release button (3) and press button (3) and/or (4) repeatedly until you select the desired operating program.

Caution: to guarantee optimal data transmission it is advisable to always place the radio control in its support in a vertical

position.

The following operations must be carried out the first time the heater is started up :

- Turn the switch (11) to ON (see drawing below)

- Connect the radio control by means of the battery charger supplied to the power line, ( it must be recharged for

at least 5 days); as the rechargeable batteries could be partially or completely flat). Leave the radio control

connected at all times, by means of the battery charger, to the power supply line.

The heater must be energised and the switch turned to position "1".

At the end of the winter season it is mandatory to switch off the radio control completely, by means of the switch

situated inside the battery compartment, in order to preserve the life of the batteries. The batteries are

guaranteed for 6 months. When the batteries are exhausted dispose of them safely. It is normal for the tempera-

ture sensor to detect temperatures which are slightly different to the real ones: variations caused by the

environment in which the radio control is positioned.

MANUAL program

In the MANUAL program the room temperature thermostat is disabled. Press button (1) and the flame symbol begins to blink. Press button (3)

to decrease the combustion level by lighting up the bars sequentially, vice versa press button (4) to increase the combustion level. The

combustion level changes with each press of buttons (3) and (4).

Press button (2) and the ventilation symbol blinks. Press button (3) and the combustion level decreases,

vice versa press button (4) to increase the combustion level. The ventilation level changes with each press of buttons (3) and (4) . Caution:

it is possible that, due to radio interference or sending commands too close together, the changes will not be implemented. With this program

you can also use the infrared control supplied. It is normal that in the manual cycle the ventilation is often set at the maximum speed in order

to cool the heater body more effectively.

Page 12

pg. 12

ECONOMY program

In the ECONOMY program the heater always operates at the minimum combustion level and the minimum ventilation level. You cannot use the

infrared control with this program .

CAUTION: THE HEATER MUST ALWAYS BE SWITCHED ON AND OFF FROM THE CONTROL PANEL LOCATED ON THE HEATER.

FOR THE RADIO CONTROL TO WORK THERE MUST NOT BE AN ACTIVE PROGRAM SET ON THE CONTROL PANEL LOCATED

ON THE HEATER OR AN EXTERNAL ROOM TEMPERATURE THERMOSTAT OR AN EXTERNAL CHRONOTHERMOSTAT.

6.4.2 TRANSMISSION CODES SETTINGS.6.4.2 TRANSMISSION CODES SETTINGS.

6.4.2 TRANSMISSION CODES SETTINGS.6.4.2 TRANSMISSION CODES SETTINGS.

6.4.2 TRANSMISSION CODES SETTINGS.

Before beginning any maintenance operation ensure that the appliance is in the OFF phase and disconnect it from the electric power outlet.

If several heaters are installed in close locations it may be necessary to set different transmission codes. The change of code must be made

both on the motherboard inserted in the heater (see figure below left ), and in the radio control (see figure below left). Position the switch 0-1

(located on the back of the heater) on 0. To access the board you need to remove the heater's right side panel as described in the dedicated

paragraph and remove the board cover by undoing the two screws as indicated in the figure below on the right.

The codes must be identical, and for this purpose you could use the numbers marked on the microswitches as reference. Firstly set the new

code on the motherboard, next set the new code on the remote control and then switch the remote control on and off with the switch (11)

located on the back of the remote control.

AUTO 5 program

In program AUTO 5 the room temperature thermostat is enabled. The radio control adjusts the ventilation and the combustion automatically in

relation to the target room temperature set in display area (8). The desired room temperature appears in area (8). You can vary the desired

room temperature by simply pressing button (3) and/or (4) (variation indicated in area (8)). The remote control will set the maximum

combustion and ventilation levels and modulate them both as the room temperature (5) approaches the target temperature (8). When the

target temperature (8) in the room (5) is reached, the combustion level will stabilise on a bar as will the ventilation level. Caution: it is possible

that, due to radio interference, the commands sent to the heater will not be implemented. You cannot use the infrared control with this

program. Caution: the power and the ventilation depend on the preset value, if the required temperature is too high or not reachable the

heater could operate at maximum power for long periods of time.

PALMARE GESTITO VIA ONDE RADIO

SELETTORE CODICI PER RADIOCOMANDO

3

2

1

O

N

4

4

1

O

N

3

2

2

1

3

4

5

6

PER RADIOCOMANDO

SELETTORE CODICI

4

3

ON

2

1

4

3

ON

2

1

AUTO 3 program

In program AUTO 3 the room temperature thermostat is enabled . The remote control adjusts the ventilation and combustion automatically in

relation to the target room temperature set in display area (8). The desired room temperature is displayed in area (8). You can vary the

desired room temperature by simply pressing button (3) and/or (4) (variation indicated in area (8)). The remote control will set the

combustion power at level 3 and the ventilation at level 4 and modulate them both as the room temperature (5) approaches the target temperature (8). When the target temperature (8) in the room (5) the combustion level will stabilise on a bar as will the ventilation level. Caution: it is

possible that, due to radio interference, the commands sent to the heater are not acknowledged???implemented. You cannot use the infrared

control with this program . Caution: the power and the ventilation depend on the preset value, if the required temperature is too high or not

reachable the heater could operate at maximum power for long periods of time.

Caution: ensure correct and equivalent position of

the microswitches.

KEY

code selector for handheld radio control

radio wave-controlled code selector for

handheld radio control

LEGENDA

selettore codici per radiocomando

selettore codici per radiocomando

palmare gestito via onde radio

Page 13

pg. 13

6.4 CHANNELLING6.4 CHANNELLING

6.4 CHANNELLING6.4 CHANNELLING

6.4 CHANNELLING

To obtain an optimal flow of channelled hot air:

- Avoid narrow or reduced sections, sharp curves, downhill runs in the tubing.

- Reduce the horizontal runs as much as possible.

- Use pipes with smooth inner surfaces made of material capable of resisting

continuous temperatures of 150°C.

- Insulate pipes with mineral wool (resistant to at least 150°C).

If you follow the instructions given above it is possible to channel:

- up to 16 metres using 1 vent

- up to 16 metres using 2 vents

- up to 16 metres using 3 vents

- up to 16 metres using 4 vents

The heater is supplied with both fittings already mounted.

If you wish to channel the air with 1 vent only then you must (see figure 4) partially

undo the screw C1 using a suitable screwdriver, remove screws C2 and C3,

remove the pipe E and replace it with the cover D which you must fasten to the

heater (see figure 4). To start the air channelling act on lever A (figures 1 2 and 3).

To act on lever A firstly open the hopper compartment and, using the hook provided,

lift the lever and position it where necessary.

The A control is extremely hot. In order to prevent burns, it is

mandatory to use the tool provided to act on the control.

C2

Figura 4

D

E

C2

C1

(Posizioni intermedie)

Figura 2

Figura 1

(Tutta l'aria canalizzata)

A

Figura 3

(Nessuna canalizzazione)

A

A

6.4 FIL6.4 FIL

6.4 FIL6.4 FIL

6.4 FIL

TERTER

TERTER

TER

This practical device prevents the circulation of dust which is always present in

household environments. The filter is installed at the back of the heater (see figure on

the right). Clean frequently to ensure the maximum availability of hot air when the

heater is operating (wash the filter with cold water then dry thoroughly every 5

days).

6.4.3 CARE AND MAINTENANCE RADIO CONTROL6.4.3 CARE AND MAINTENANCE RADIO CONTROL

6.4.3 CARE AND MAINTENANCE RADIO CONTROL6.4.3 CARE AND MAINTENANCE RADIO CONTROL

6.4.3 CARE AND MAINTENANCE RADIO CONTROL

The radio control has been designed and produced to the strictest standards and must be handled with great care.

If you observe the guidelines set out below, the radio control will provide a long trouble-free performance:

-Protect the radio control against humidity! Precipitation, humidity and liquids corrode the electronic circuits. If the radio control is wet,

disconnect it immediately from a power source, remove the battery, open it and allow it to dry at room temperature.

-Do not use or store the radio control in dusty or dirty environments. The dust/dirt could damage the movable parts of the radio control.

-Do not store the radio control in very hot environments. High temperatures could shorten the life of the electronic devices, damage the

batteries and deform or even melt plastic parts. -Do not store the radio control in cold environments. When it heats up (when it returns to

normal operating temperature), humidity could form inside it and damage the electronic circuits.

-Do not drop the radio control, do not hit or bump it and do not shake it. Actions such as these could damage the internal circuits of the device.

-Do not use corrosive chemical substances, caustic solutions or detergents to clean the radio control.

All the above guidelines apply equally to the radio control, the battery, the battery charger, and all the accessories.

The parts subject to wear (such as batteries, keypads, lodging compartments, small compartment parts) are guaranteed for 6 months from the

purchase date. The guarantee does not apply if the defect is caused by non-conforming use and/or if the instructions and guidelines described

above are not observed to the letter. Non-conformities must be reported within two months of having identified them. Devices or parts returned

for replacement become the property of Thermorossi. The presence of irregular black-blue lines on the display (also present when deenergised and battery flat or missing) indicate that the glass screen of the display is damaged following a fall or impact: in this case the

breakage is not covered by the guarantee.

Key

Figure 1 (all the hot air is channelled )

Figure 2 (Intermediate positions)

Figure 3 (no channelling)

FIGURE 4

LEGENDA

Figura 1 (tutta l'aria canalizzata)

Figura 2 (Posizioni intermedie)

Figura 3 (nessuna canalizzazione)

Figura 4

Page 14

pg. 14

88

88

8

CLEANING AND MAINTENANCECLEANING AND MAINTENANCE

CLEANING AND MAINTENANCECLEANING AND MAINTENANCE

CLEANING AND MAINTENANCE

8.18.1

8.18.1

8.1

FOREWORDFOREWORD

FOREWORDFOREWORD

FOREWORD

Before commencing any operation disconnect the appliance from the electric power outlet. Your ECOTHERM pellet heater does not

require any special maintenance; simply adhere to the simple and basic but regular controls and general cleaning. This will guarantee

regular operation and optimal output at all times. If the product is unused for a prolonged period of time it is mandatory to inspect the

smoke channel and outlet to ensure that there are no obstructions before use. It is necessary to accurately follow the directions given

below: Otherwise severe damages may occur for the product, the installation, objects and the people who use the generator.

CAUTION: The manufacturer denies all responsibility for the life of the electrical heater if subjected to excessive start ups. The

manufacturer recommends setting a suitable room temperature value in the chronothermostat in order to prevent this possibility.

CAUTION: Use N.O. (normally open) contacts for the connection to the chronothermostat. Contact 1-3 of the chronothermostat

mod. "Perry".

CAUTION: In the event of connections to the chronothermostat Thermorossi shall not be held responsible for the insert not starting

up, smoke leaks, breakage of the lighting component. In the event of a programmed cycle on always ensure that the brazier is

clean and seated correctly in its lodging.

7 ADDITIONAL ROOM TEMPERATURE THERMOSTAT (not supplied)

ADDITIONAL CHRONOTHERMOSTAT (not supplied)

The control panel ensures that your heater is provided with all the required programming and temperature adjustment functions:

Two gland nuts are fitted to the back of the heater near the power point.

They refer to two operating modes:

à With the room temperature thermostat. à With the chronothermostat or modem.

Simply connect the additional room temperature thermostat to the gland nut on the heater marked

"Room Temperature Thermostat" or the additional chronothermostat to the gland nut on the heater marked "Chronothermostat - modem".

Use only contacts 1 and 2.

Contacts 1-2 are defined as "CLEAN" contacts and they must never be fed with 220 V. If the board is energised with 220V or

voltages exceeding 6 V the control board will be permanently damaged and will not be covered by the GUARANTEE.

7.1 OPERATING WITH THE ADDITIONAL ROOM TEMPERATURE THERMOSTAT (NOT SUPPLIED )

An additional room temperature thermostat can be installed by connecting it to the cable gland marked “THERMOSTAT” at the back of the

heater. The operating principle is as follows:

-When the room temperature reaches the set temperature (only during the RUNNING phase) the thermostat closes the contact and the heater

shifts to the minimum room fan speed and minimum combustion power. By using the room temperature thermostat the heater does not shut

down, therefore electrical energy consumption is kept to the minimum and the heater has a longer life.

-When the room temperature drops the thermostat opens the contact and the heater returns to its original position in terms of thermal power

and ventilation.

-In this position it is not possible to start up the heater automatically or shut it down automatically.

CAUTION: N.C. (normally closed) contacts must be used for the connection to the additional room temperature thermostat.

Contacts 1-2 of the chronothermostat mod. "Perry".

7.2 OPERATING WITH THE ADDITIONAL CHRONOTHERMOSTAT (NOT SUPPLIED )

As an alternative to the room temperature thermostat, a chonothermostat can be installed by connecting it to the cable gland marked

“CHRONOTHERMOSTAT” fitted to the back of the heater. Using this outlet when the chronothermostat contact closes the START cycle starts,

whereas when the contact opens the OFF cycle starts. The operating level at start up (combustion power - fan speed ) is the same as the

level used before the last time the heater shut down. This operation can also occur by adjusting its room temperature. Once the desired temperature set on the chronothermostat is reached the contact opens and executes the shut down cycle. Similarly when the room temperature

drops below the set temperature the contact closes and the START cycle starts. If an unsuitable room temperature value is selected the

heater will be subjected to continual ON-OFF cycles, consequently the increased number of start ups will result in greater consumption of

electrical energy. The chronothermostat can be used to program temperatures, times and dates for the ON-OFF cycles. It is therefore

possible to program a momentary shutting down of the heater according to the room temperature.

Page 15

pg. 15

8.28.2

8.28.2

8.2

CLEANING CLEANING

CLEANING CLEANING

CLEANING

AND MAINTAND MAINT

AND MAINTAND MAINT

AND MAINT

AINING AINING

AINING AINING

AINING

THE HEATHE HEA

THE HEATHE HEA

THE HEA

TERTER

TERTER

TER

• EVERY DAY remove all combustion residues from the brazier then remount the brazier and the catalyst (Figure 1 shows a clean brazier).

Caution: make sure, before every start up, that the brazier is clean and if necessary also thoroughly clean the burner with a suction unit.

Take particular care to clean the area near the spark plug : this will guarantee the correct operation of the appliance .

• EVERY 3 DAYS lift and drop the tube scraper rods several times (Figure 2)

• EVERY 5 DAYS clean the room air filter located at the back of the heater (Figure 11).

• EVERY WEEK empty the ash pan "V" of all residual ash (figure 9).

• EVERY WEEK vacuum the residual ash from the compartment "V1" under the brazier.To facilitate vacuuming remove the blade and brazier

(Figure 10).

• EVERY 2 WEEKS clean the smoke exhaust "T" at the heater inlet .

• EVERY MONTH undo the screws to inspect and clean vent A1 shown in Figure 5; to access this area remove the lower covering as

indicated in Figures 3 and 4. In the Easy model press the 2 side folds of the lower cover inwards to extract it.

• EVERY MONTH check that the smoke exhaust is free from fly ash deposits, particularly in the initial sections.

• EVERY MONTH vacuum the ash deposited on the bottom of the tank (when the tank is empty).

• AT THE END OF THE WINTER SEASON OR WHENEVER NECESSARY we recommend thoroughly cleaning the Ecotherm firebox, using

brushes and vacuum cleaner.

• TWICE A YEAR clean the smoke exhaust, including the flue outlet. clean the inside of the combustion chamber behind the tube bundle

(Figures 6,7,8). To access this area lift the shell (Figures 6 , 7) by rotating it as shown in Figure 8: now clean the area with a suction device.

A vacuum device simplifies the cleaning procedure. Use a damp cloth or a

scrunched up piece of newspaper, dampened and rolled in the ash, to wipe

the glass until it is perfectly clean. Do not clean the glass while the heater

is operating.

The glass remains reasonably clean if the catalyst - deviator blade is installed

correctly in the brazier as shown in figure 9. The insert must be completely

cooled down before the side panel can be cleaned with a soft cloth and

water.

Caution: A daily deposit of soot and combustion residues on the glass is

quite normal. It is normal for the ash to fall to the floor when the door is

opened.

Page 16

pg. 16

Page 17

pg. 17

Page 18

pg. 18

9.19.1

9.19.1

9.1

VENTILAVENTILA

VENTILAVENTILA

VENTILA

TION OF TION OF

TION OF TION OF

TION OF

THE RTHE R

THE RTHE R

THE R

OOMSOOMS

OOMSOOMS

OOMS

•The room where the heater is installed must have a good air flow to guarantee secondary air for the appliance for the combustion process and

for ventilation of the room. The natural air flow occurs directly through permanent apertures to the outside made in the walls of the room, or by

means of single or multiple ventilation ducting.

The ventilating air must come from outside and if possible, away from sources of pollution. Indirect ventilation is also allowed by taking in air from

rooms adjacent the one where the insert eater is installed taking into account all the warnings and limitations specified below.

•The apertures in the walls must comply with the following requirements:

- -have an unobstructed section of at least 6cm² for each Kw of installed thermal power, with a minimum limit of 100cm²;

- be made in such a way that the vent openings, both on the inside and outside of the wall, cannot be obstructed;

- be protected with grills or similar systems in order not to reduce the section described above;

- be situated at floor-level.

•The air flow can also be obtained from an adjacent room as long as:

- the adjacent room is equipped with direct ventilation in compliance with the points described above;

- in the room to be ventilated the installed appliances are only connected to one flue outlet;

- the adjacent room is not used as a bedroom or a common area of the building;

- the adjacent room is not a room with a fire hazard, such as storage sheds, garages, combustible material store rooms, etc...;

- the adjacent room does not become a vacuum compared to the room to be ventilated due to an opposite draught effect;

- the air flow from the adjacent room to the room to be ventilated is unobstructed through the permanent apertures having an overall net section

of no less than that indicated above. These apertures can be obtained by enlarging the space between the door and the floor.

This chapter is not intended to replace UNI 7129/92, UNI 10683 and EN 14785 standards to which it refers. The qualified

installer must in any case be fully aware of this standard and its amending versions.

8.48.4

8.48.4

8.4

BB

BB

B

AA

AA

A

TTERTTER

TTERTTER

TTER

Y REPLAY REPLA

Y REPLAY REPLA

Y REPLA

CEMENT FOR INFRARED REMOCEMENT FOR INFRARED REMO

CEMENT FOR INFRARED REMOCEMENT FOR INFRARED REMO

CEMENT FOR INFRARED REMO

TE CONTRTE CONTR

TE CONTRTE CONTR

TE CONTR

OL.OL.

OL.OL.

OL.

When the infrared remote control does not send out the transmission signal (led on), the battery must be replaced. Use a Phillips screwdriver

of proper size, to separate the half shells and replace the battery. The dead battery must be disposed of safely.

Inside the control panel there is a buffer battery type CR2032. When

hour and programming are not kept in storage , the battery must be

replaced using the 2 screws in the rear of the control panel. The

dead battery must be disposed of safely.

99

99

9

SMOKE DISCHARGE TUBESMOKE DISCHARGE TUBE

SMOKE DISCHARGE TUBESMOKE DISCHARGE TUBE

SMOKE DISCHARGE TUBE

Due to the frequent accidents caused by poor functioning of flue outlets installed in private dwellings, we have prepared the following

paragraph to assist the installer in his inspection of the parts concerned with eliminating the gases produced by combustion. The gases

must be discharged in compliance with UNI7129/92, UNI 10683 and EN14785. 2006. It is necessary to accurately follow the directions

given below: Otherwise severe damages may occur for the product, the installation, objects and the people who use the generator.

The battery charger must be connected to a 220-240V 50Hz power mains. To obtain a total recharge of the batteries they must be charged for

at least 5 days: lower charge times could reduce the duration and life of the batteries. Leave the radio control connected at all times, by means

of the battery charger, to the power supply line. It is completely normal for symbols and/or lines to appear haphazardly on the display while the

battery is being charged. The optimal battery autonomy is achieved after several battery charge / discharge cycles.If the radio control is not used

for more than one week it is mandatory to switch it off completely in order to preserve the life of the batteries. Turn the switch located in the

battery compartment to 1, that is, OFF.

The batteries are guaranteed for 6 months.

Caution: Use only the battery charger provided by Thermorossi. The use of any other type of battery charger will invalidate the product

warranty.

17

13

As soon as the battery symbol on the display begins to blink, as shown in the drawing, the battery

needs to be charged.While it is being charged and consequently while it is connected to the electrical

power mains the battery symbol blinks continuously even when the batteries of the radio control are

completely charged.

This operation is necessary as otherwise the communication between the heater and the radio control

could be cut off. The batteries of the handheld radio control require regular recharging in relation to the

amount of use made of it The duration of the battery charge is variable and depends on how often the

remote control is used. The batteries must be recharged using the supplied battery charger :

INPUT 100V-240V 50/60 Hz 0,3/A OUTPUT 5,5V 750 ma

8.38.3

8.38.3

8.3

CHARCHAR

CHARCHAR

CHAR

GING GING

GING GING

GING

THE BTHE B

THE BTHE B

THE B

AA

AA

A

TTERTTER

TTERTTER

TTER

Y OF Y OF

Y OF Y OF

Y OF

THE HANDHELD RADIO CONTRTHE HANDHELD RADIO CONTR

THE HANDHELD RADIO CONTRTHE HANDHELD RADIO CONTR

THE HANDHELD RADIO CONTR

OL (optio-OL (optio-

OL (optio-OL (optio-

OL (optio-

nal)nal)

nal)nal)

nal)

BATTERIA TAMPONE CR2032

Buffer battery CR2032

8.58.5

8.58.5

8.5

RR

RR

R

ee

ee

e

placing the bplacing the b

placing the bplacing the b

placing the b

ufuf

ufuf

uf

ff

ff

f

er baer ba

er baer ba

er ba

ttertter

ttertter

tter

yy

yy

y

ofof

ofof

of

the contr the contr

the contr the contr

the contr

ol panelol panel

ol panelol panel

ol panel

Page 19

pg. 19

9.29.2

9.29.2

9.2

SMOKE OUTLETSMOKE OUTLET

SMOKE OUTLETSMOKE OUTLET

SMOKE OUTLET

•The smoke exhaust shown in the following figures is the best solution to ensure the discharge of smoke even when the fan is

not operational, such as for example if there is an electrical power failure. A minimum drop of 1.5 metres is required between the

T terminal on the outside of the building and the outlet at the back of the appliance, to ensure that residual combustion smoke is

discharged in the case described above (Otherwise the residues would stagnate inside the firebox and be discharged out to the

free atmosphere).

The figures below illustrate the best solution for discharging the smoke out through the roof or into the flue outlet. If you opt to

discharge the smoke out through the roof it is important to operate as shown in the figure below on the left. Insert a union tee with

inspection cap, connecting brackets suitable for the height of the flue outlet, flashing that crosses the roof and chimney cap

to protect against bad weather conditions. If you decide to use a classic masonry outlet see the diagram below on

the right. A union tee with inspection cap and suitable supporting brackets are required. If the flue outlet

is too big we recommend inserting a stainless steel or porcelain-coated steel tube with a

diameter not exceeding 150mm. Seal area where the inlet and outlet part of the smoke exhaust

meets the wall. It is strictly forbidden to apply mesh to the end of the outlet tube , as

it could cause the heater to malfunction If the smoke tube is installed in a fixed position

it is advisable to provide inspection openings for clean-out purposes especially in the horizontal

sections. See the diagram. These openings are essential to allow for the removal of ash and

unburned products which tend to accumulate along the discharge path. The appliance

functions with the firebox in a vacuum, while the discharge of smoke to the flue

outlet has a slight pressure, consequently it is imperative to ensure that the

discharge system is hermetically sealed. The smoke discharge tube must be made from

suitable materials such as for example: porcelain-coated steel tubes, and the various fittings

sealed with red silicone (resistant to 350°C). The outer casing of the tube must be made with

insulating material (mineral wool, ceramic fiber) or use pre-insulated tubing.

In the event of a fire call the fire brigade immediately.

9.1.19.1.1

9.1.19.1.1

9.1.1

COMBCOMB

COMBCOMB

COMB

USTION USTION

USTION USTION

USTION

AIR INTAIR INT

AIR INTAIR INT

AIR INT

AKEAKE

AKEAKE

AKE

The air required for combustion is taken directly from the room in which the heater is installed. The room where it is installed must always be

adequately ventilated (1300 m3/h) .

CAUTION: The presence of extraction fans or similar appliances, if operating in the same room or space in which the heater

is installed, could cause problems for the correct operation of the heater.

KEY

Inspection

Slope 3-5%

Height more than 4m

Internal

External

Rain protection

Cover slab

Watertight steel sheet

It must be possible to inspect and remove all the smoke tube sections

for clean-out purposes. The appliance must always and only be installed

in a single flue outlet system dedicated exclusively to the appliance. If

the appliance is connected to a flue system that is non-compliant with

the standards the appliance could show signs of early damage due to an

anomalous continual overheating of the heater itself : in this case the

damaged parts will not be replaced under warranty.

LEGENDA

Ispezione

Pendenza 3-5%

Altezza superiore a 4m

Interno

Esterno

Protezione dalla pioggia

Lastra di copertura

Lamiera di acciaio a tenuta

stagna

Page 20

pg. 20

If another heater is installed in the vicinity of this heater then the

code selector in both the power board and the handheld radio

control (optional) will have to be reset; this is necessary to prevent

interferences with the operation of the two heaters. The code set

in out products is standard. If you wish to alter the transmission

code act on the selectors in the power board and the handheld

radio control, making sure that they are set identically (see dedicated

paragraph).

11A ELECTRICAL WIRING FOR MODEL11A ELECTRICAL WIRING FOR MODEL

11A ELECTRICAL WIRING FOR MODEL11A ELECTRICAL WIRING FOR MODEL

11A ELECTRICAL WIRING FOR MODEL

Ventilatore 1 A

MICROPROCESSORE

Fusibile 1A

2

ON

1

PRESSOSTATO

TERMOSTATO 95°C

TERMOSTATO 42°C

214

AMBIENTE

VENTILATORE

MANUALE

TERMOSTATO RIARMO

PELLETS

MOTORE CARICO

ASPIRATORE FUMI

Fusibile 3,15 A

Fusibile

220-240V

50 Hz

RESISTENZA

RADIOCOMANDO PALMARE

SCHEDINA RICEVITORE

412

1-4 Termostato Ambiente

1-2 Cronotermostato

Per i modelli ECOTHERM 3001 THERMOCOMFORT EASY,METALCOLOR,CERAMICA

SELETTORE CODICI

PER RADIOCOMANDO

3 4

ON

3 42

1

1010

1010

10

ALARMSALARMS

ALARMSALARMS

ALARMS

The heater is programmed to communicate 3 fundamental alarms. The alarms are listed below:

AL PE : is communicated when the temperature during the On mode drops below 42 °C.

This indicates that the heater is switching off due to lack of pellets.

AL AC : is communicated if after the start up phase the temperature does not rise above 42°C.

AL OP : this occurs when the smoke outlet is partially blocked.

In order to set the alarms to zero, the feed to the heater must be turned off and restored using switch 0-1 on the back of the heater.

SELETTORE CODICI PER RADIOCOMANDO

PALMARE GESTITO VIA ONDE RADIO

2

1

O

N

3

4

2

O

N

1

3

4

KEY

Radio wave-controlled code selector for

handheld radio control

Code selector for handheld radio

control

Thermostat 42°/95°C

Pressure switch

Room temperature thermostat

Chronothermostat

Handheld radio control receiver card

Heater

Smoke suction unit

Manual reset thermostat

Pellet feed motor

Room fan

Microprocessor

Fan fuse 1A

Fuse 1 A / 3,15 A

For models ECOTHERM3001,

THERMOCOMFORT, EASY,

METALCOLOR, CERAMIC

LEGENDA

Selettore codici per radiocomando

palmare gestito via onde radio

Selettore codici per radiocomando

Termostato 42°/95°C

Pressostato

Termostato ambiente

Cronotermostato

Schedina ricevitore radiocomando

palmare

Resistenza

Aspiratore fumi

Termostato riarmo manuale

Motore carico pellets

Ventilatore ambiente

Microprocessore

Fusibile ventilatore 1A

Fusibile 1 A / 3,15 A

Per i modelli ECOTHERM3001,

THERMOCOMFORT, EASY,

METALCOLOR, CERAMICA

Page 21

pg. 21

1212

1212

12

INFORMAINFORMA

INFORMAINFORMA

INFORMA

TION FOR TION FOR

TION FOR TION FOR

TION FOR

THE SKILLED THE SKILLED

THE SKILLED THE SKILLED

THE SKILLED

TECHNICIANTECHNICIAN

TECHNICIANTECHNICIAN

TECHNICIAN

12.1 MAIN COMPONENTS AND THEIR OPERATION

SMOKE PRESSURE SWITCH

This is a safety switch that stops the screw feeder motor whenever necessary. The main cause for the pressure switch tripping is a blocked

flue outlet or smoke exhaust pipe. Note that it is strictly forbidden to apply any kind of mesh screen to the end of the pipe. When the holes of the