THERMOROSSI DORICA METALCOLOR, DORICA MAIOLICA, DORICA PLUS METALCOLOR, DORICA PLUS MAIOLICA Installation, Use And Maintenance Manual

Page 1

Page 2

Page 2

manutenzione

INDEX

“EC” DECLARATION OF CONFORMITY................................................................................................. 0

1 - INTRODUCTION .................................................................................................................................. 0

1. 1 GENERAL GUIDELINES .................................................................................................................................0

1.2 SAFETY GUIDELINES .....................................................................................................................................0

1.2.1. RECOMMENDATIONS............................................................................................................................................................0

1.2.2 GENERAL GUIDELINES...........................................................................................................................................................0

1.3 TRANSPORTATION AND STORAGE..............................................................................................................0

2 – TECHNICAL CHARACTERISTICS*.................................................................................................... 0

3 – GENERAL DESCRIPTION.................................................................................................................. 0

3.1 OPERATING TECHNOLOGY...........................................................................................................................0

3.2 PELLETS...........................................................................................................................................................0

3.3 THE FEEDBOX.................................................................................................................................................0

4 - INSTALLATION ................................................................................................................................... 0

4.1 POSITIONING OF THE APPLIANCE...............................................................................................................0

4.2 UNPACKING THE APPLIANCE ......................................................................................................................0

4.3 UNPACKING THE MAJOLICA CASING AND THE METALCOLOR CASING................................................. 0

4.4 MOUNTING MAJOLICA CASING DORICA DORICA PLUS ...........................................................................0

4.5 MOUNTING METALCOLOR CASING DORICA DORICA PLUS .....................................................................0

4.6 CONNECTING THE APPLIANCE TO THE FLUE OUTLET.............................................................................0

4.7 HANDLE............................................................................................................................................................0

5 – DESCRIPTIONS OF CONTROLS ....................................................................................................... 0

5.1 DESCRIPTION OF CONTROL PANEL AND REAR PANEL ...........................................................................0

5.1 DESCRIPTION OF THE CONTROL PANEL................................................................................................................................0

5.1.2 APPLIANCE REAR PANEL.......................................................................................................................................................0

5.2 DAY AND TIME SETTING................................................................................................................................0

5.3 ON/OFF PROGRAMMING...............................................................................................................................0

5.3.1 ON-OFF PROGRAMMING DISPLAY........................................................................................................................................0

5.4 OPERATING LEVEL SETTING ........................................................................................................................0

6 – USE OF THE APPLIANCE.................................................................................................................. 0

6.1 SWITCHING ON THE APPLIANCE..................................................................................................................0

6.2 ADJUSTING COMBUSTION AND VENTILATION...........................................................................................0

6.3 INFRARED REMOTE CONTROL.....................................................................................................................0

6.4 OPERATION OF THE WHITE HANDHELD RADIO CONTROL THERMOCOMFORT (OPTIONAL) ............. 0

6.4.1 INDICATORS OF THE HANDHELD RADIO CONTROL............................................................................................................0

6.4.3 CARE AND MAINTENANCE OF THE RADIO CONTROL.........................................................................................................0

6.5 FILTER..............................................................................................................................................................0

6.6 CHANNELLING (DORICA PLUS ONLY)..........................................................................................................0

7 - ADDITIONAL ROOM TEMPERATURE THERMOSTAT (not supplied).............................................. 0

ADDITIONAL CHRONOTHERMOSTAT - MODEM (not supplied ).......................................................... 0

7.1 OPERATING WITH THE ADDITIONAL ROOM TEMPERATURE THERMOSTAT (not supplied) .................. 0

7.2 OPERATING WITH THE ADDITIONAL CHRONOTHERMOSTAT (not supplied)........................................... 0

Page 3

Page 3

manutenzione

8 - CLEANING AND MAINTENANCE........................................................................................................0

8.1 FOREWORD.....................................................................................................................................................0

8.2 CLEANING AND MAINTAINING THE APPLIANCE......................................................................................... 0

8.3 CHARGING THE BATTERY OF THE WHITE THERMOCOMFORT HANDHELD RADIO CONTROL (optional)

.........................................................................................................................................................................0

8.4 BATTERY REPLACEMENT FOR INFRARED REMOTE CONTROL.............................................................. 0

8.5 REPLACING THE BUFFER BATTERY OF THE CONTROL PANEL ..............................................................0

9.1 FOREWORD.....................................................................................................................................................0

9.2 ROOM VENTILATION ......................................................................................................................................0

9.2.2 VENTILATION OF THE ADJACENT ROOMS........................................................................................................................... 0

9.2.1 SINGLE OR MULTIPLE VENTILATION DUCTING................................................................................................................... 0

9.3 SMOKE OUTLET.............................................................................................................................................. 0

9.3.1 CHIMNEY TYPES..................................................................................................................................................................... 0

9.3.2 FLUE OUTLET / FLUE SYSTEM COMPONENTS................................................................................................................... 0

10 – ALARMS............................................................................................................................................0

11 - ELECTRICAL WIRING .......................................................................................................................0

12 - INFORMATION FOR THE SKILLED TECHNICIAN............................................................................ 0

12.1 MAIN COMPONENTS AND THEIR OPERATION ......................................................................................... 0

12.2 REQUIREMENTS NECESSARY FOR CORRECT INSTALLATION AND OPERATION .............................. 0

12.3 TROUBLESHOOTING CAUSE-SOLUTION................................................................................................... 0

13 - SPARE PARTS...................................................................................................................................0

13.1 SPARE PARTS DORICA PAG. 1/5 ...............................................................................................................0

13.2 SPARE PARTS DORICA PAG. 2/5 ...............................................................................................................0

13.3 SPARE PARTS DORICA PAG. 3/5 ...............................................................................................................0

13.5 SPARE PARTS DORICA PAG. 5/5 ...............................................................................................................0

13.6 SPARE PARTS DORICA PLUS PAG. 1/5...................................................................................................... 0

13.7 SPARE PARTS DORICA PLUS PAG. 2/5...................................................................................................... 0

13.8 SPARE PARTS DORICA PLUS PAG. 3/5...................................................................................................... 0

13.9 SPARE PARTS DORICA PLUS PAG. 4/5...................................................................................................... 0

13.10 SPARE PARTS DORICA PLUS PAG. 5/5.................................................................................................... 0

Page 4

Page 4

manutenzione

Page 5

Page 5

manutenzione

“EC” DECLARATION OF CONFORMITY

Page 6

Page 6

manutenzione

1 - INTRODUCTION

1. 1 GENERAL GUIDELINES

This installation, use and maintenance guide is an integral and essential part of the product and must be kept by the user. Before

commencing with the installation, use and maintenance of the product, carefully read all the instructions contained in this booklet.

All local, national and European regulations regarding the installation and use of the appliance must be met. The Manufacturer

recommends carrying out all the maintenance operations described in this manual.

This appliance must only be used as intended by the manufacturer. Any other use is considered incorrect and therefore hazardous;

consequently, the user shall be totally liable for the product if used improperly. Installation, maintenance and repairs must be carried

out by professionally qualified personnel, professionally certified according to Decree no. 37 of 22 January 2008 and in compliance

with current regulations and in accordance with the instructions provided by the manufacturer of the appliance. In case of repairs

only original spare parts supplied by the manufacturer must be used. Incorrect installation or poor maintenance could injure or

damage people, animals or things; in this case the manufacturer shall be relieved of all responsibility. Before beginning any

cleaning or maintenance operation switch off the appliance, turn the switch installed at the back of the appliance to the OFF position

and disconnect the plug from the electrical power socket. The product must be installed in locations suitable for fire-fighting and

furnished with all the services (power and outlets) which the appliance requires for a correct and safe operation. Any repairs or

actions carried out on any systems, components or internal parts of the appliance, or on any of the accessories supplied with it, that

are not specifically authorised by Thermorossi S.p.A. will automatically void the warranty and the manufacturer's responsibility,

pursuant to D.P.R. 224 of 24/05/1988, art. 6/b. Keep this manual in a safe place that is easily accessible to all users: if the manual

is lost or deteriorated contact the manufacturer for a replacement copy. If the appliance is sold or transferred to another user ensure

that the guide is handed over with it. If this manual is lost and/or damaged it is mandatory to ask the manufacturer for a replacement

copy.

Thermorossi S.p.A. retains copyright on these service instructions. These instructions may not be reproduced or communicated to

third parties or used in any other way without the necessary authorisation.

1.2 SAFETY GUIDELINES

PERSONAL INJURY

This safety symbol identifies important messages throughout the manual. Read the information

marked by this symbol carefully as non-observance of this message can cause serious injury to

persons using the appliance.

DAMAGE TO PROPERTY

This safety symbol identifies messages or instructions that are fundamental for the appliance and

system to function well. To avoid serious damage to the appliance adhere strictly to these

instructions.

INFORMATION

This symbol indicates important instructions for good functioning of the appliance. If this information

is not correctly observed, the performance of the appliance will not be satisfactory.

NORMATIVE REFERENCES :

complies with the legislative provisions transposing the following Directives:

2004/108/CE (EMC Directive)

2006/95/CE (Low voltage directive)

89/106/CEE (Construction Products Directive) and subsequent amendments

and that all the standards and/or technical specifications listed below were applied

EN 55014-1 EN 55014-2 EN 61000-3-2 EN 61000-3-3 EN 60335-1 EN 60335-2-102 EN 62233 EN 14785

1.2.1. RECOMMENDATIONS

Before using the appliance, carefully read every section of this instruction manual as knowledge of the information

and the regulations contained in it are essential for a correct use of the appliance.

The entire operation concerning the connection of the electric panel must be carried out by expert personnel; no

responsibility will be accepted for damages, even to third parties, if the instructions for installation, use and

maintenance of the appliance are not followed scrupulously. Modifications made to the appliance by the user or on

his behalf, must be considered to be under his complete responsibility. The user is responsible for all the operations

required for the maintenance of the appliance before and during its use.

Page 7

Page 7

manutenzione

1.2.2 GENERAL GUIDELINES

Caution: the appliance must be connected to a system provided with a PE conductor (in compliance with the

specifications of 73/23/EEC, 93/98/EEC, concerning low voltage equipment).

Before installing the appliance check the efficiency of the earth circuit of the power supply system.

Caution: the power supply line must have a section which is suitable for the power of the equipment. The cable section must in any

case be no less than 1.5 mm². The appliance requires powering with a voltage of 220-240 V and 50 Hz. Voltage variations greater

than 10% of the nominal value can cause irregular operation or damage the electrical device. Position the appliance so that the

electric power plug is easily accessible. Ensure that a suitable differential switch is installed upstream from the equipment.

Your appliance has obtained the CE marking and has been made to run for 1 hour to check that it functions correctly.

The product must not be used by children, by persons with physical or mental impairments, by persons who are not familiar with the

instructions for use and maintenance of the product (the instructions are found in this booklet).

CAUTION: Before each use make sure that the burner is clean and positioned correctly in its lodging, check that the ash pans are

clean and shut tight and check that the firebox door is locked.

WARNING: the door must always remain shut tight when the appliance is operating. It is strictly forbidden to open the door while

the appliance is in operation. While the appliance is in operation the smoke exhaust pipes and the appliance itself can reach

extremely high temperatures: do not touch them! Do not expose your body to hot air for long, do not overheat the room in which the

appliance is installed, as these actions could cause health problems. Do not expose plants or animals directly to the hot air flow as

this could have noxious effects on them. It is strictly forbidden to use any type of fuel (liquid, solid...) to light the appliance: the

appliance must light up automatically as designed and described in this installation, use and maintenance booklet; in this regard, it

is strictly prohibited to pour pellets (or other material) directly into the brazier. Do not place non-heat resistant or inflammable or

combustible objects in the vicinity of the appliance: keep them at a suitable distance. Do not place wet clothing to dry on the

appliance. When using a clothes horse, keep at a suitable distance. It is strictly prohibited to disconnect the appliance from the

electrical power mains.

Warning: do not wet the appliance and do not touch the electrical parts with wet hands. Never vacuum hot ash: this

could damage the vacuum device. All the cleaning operations described in this manual must be carried out when the

appliance is cold.

Caution! Warning for Swiss users

Refer to the local cantonal regulations imposed by the Fire Department (Mandatory signalling and safety distances )

and the Note concerning installation of heaters issued by the Association of Cantonal Fire Agencies (VKF - AEAI).

1.3 TRANSPORTATION AND STORAGE

TRANSPORTATION AND HANDLING

The appliance must always be in a vertical position when handled and exclusively by means of trolleys. Take special care to protect

the electric panel, the glass, and all the fragile parts from mechanical impact which could damage them and their correct

functioning.

STORAGE

The appliance must be stored in a humid-free environment and sheltered from the weather; do not place the appliance directly on

the floor. The Company denies all responsibility for damage caused to wood floors or floors made from any other material.

It is inadvisable to store the appliance for long periods of time.

Page 8

Page 8

manutenzione

2 – TECHNICAL CHARACTERISTICS*

DORICA

METALCOLOR

DORICA

MAIOLICA

DORICA PLUS

METALCOLOR

DORICA PLUS

MAIOLICA

Height (mm) 1114 1114 1114 1114

Depth (mm) 665 665 665 665

Length (mm) 560 560 560 560

Weight (Kg) 132 142 132 142

Firebox power Min. / Max. (KW) 2.98 / 10.2 2.98 / 10.2 2.98 / 10.2 2.98 / 10.2

Rated power Min. / Max. (KW) 2.5 / 9.2 2.5 / 9.2 2.5 / 9.2 2.5 / 9.2

Min/max consumption (Kg/h) 0.70/2.3 0.70/2.3 0.70/2.3 0.70/2.3

Ø smoke exhaust pipe (mm) 80 80 80 80

Min. draught at rated power (Pa) 12 12 12 12

Min. draught at reduced power (Pa) 10 10 10 10

Tank capacity (Kg) approx. 19 approx. 19 approx. 15 approx. 15

Average smoke temperature at rated power

(°C)

180 180 180 180

Average smoke temperature at reduced power

(°C)

Not detected Not detected Not detected Not detected

Smoke flow at rated power (g/sec) 5.5 5.5 5.5 5.5

Smoke flow at reduced power (g/ sec) Not detected Not detected Not detected Not detected

Efficiency at rated power (%) 90.2 90.2 90.2 90.2

Efficiency at reduced power (%) 84.2 84.2 84.2 84.2

CO concentration in exhaust gas with 13% O2

at rated power (mg/M3)

188 188 188 188

CO concentration in exhaust gas with 13% O2

at rated power (mg/M3)

Not detected Not detected Not detected Not detected

Power supply voltage and frequency 220 V 50 HZ 220 V 50 HZ 220 V 50 HZ 220 V 50 HZ

Max electrical consumption 1.17A - 270W 1.17A - 270W 1.17A - 270W 1.17A - 270W

Min electrical consumption 0.34A - 70W 0.34A - 70W 0.34A - 70W 0.34A - 70W

Room heating capacity cubic metres 210** 210** 210** 210**

* All the data are based on the appliance fuelled with Austrian standard ÖNORM M 7135 type-approved pellets.

** It is important to take into consideration the fact that the heatable volume is greatly influenced by the insulation of the

house (energy class of the building) and by the position of the appliance in the planimetry of the house, therefore the

indicated values may vary, even significantly.

560

1114

665

644

202

O

8

0

193

1114

381

186

O

50

DORICA

Page 9

Page 9

manutenzione

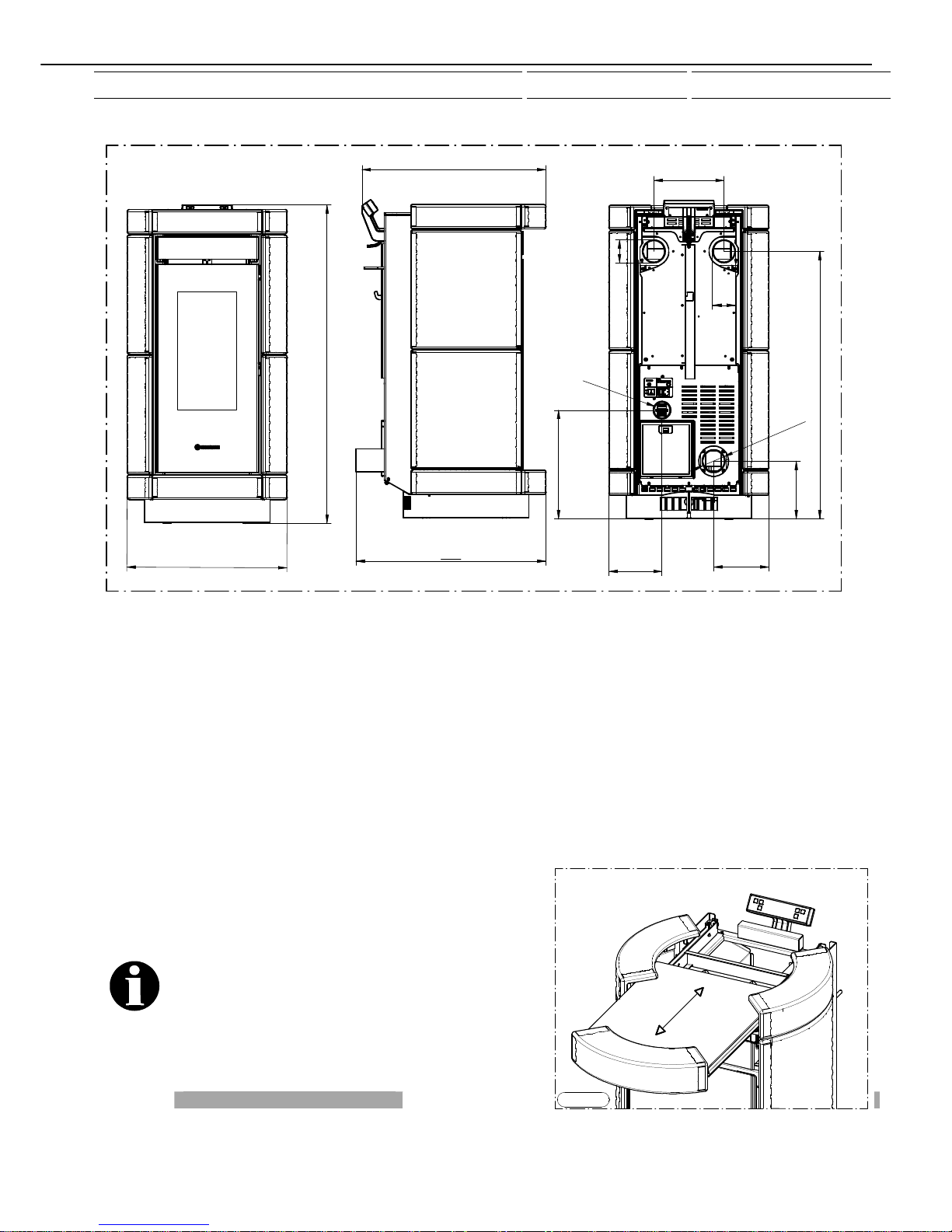

1114

644

665

5

6

0

202

193

O

8

0

381

186

O

50

937

245

80

O

80

O

DORICA PLUS

3 – GENERAL DESCRIPTION

3.1 OPERATING TECHNOLOGY

Your appliance has been built to fully satisfy all your heating and practical requirements. Top-grade components and functions

managed with microprocessor technology guarantee high reliability and optimal performance.

3.2 PELLETS

The appliance is fuelled by pellets, that is, cylinders of compressed sawdust; this allows you to fully enjoy the heat of the flame

without having to manually stoke the combustion.

The pellets have a 6 mm diameter and a maximum length of 15 mm. They have a maximum moisture content of 8%; thermal value

4000/4500 Kcal/Kg and density of 620-630 Kg/m³, less than 0.7% ash content.

It is strictly forbidden to use any pellet type other than that specified above. The use of fuel that does not comply with the

above specifications not only immediately invalidates the warranty for the appliance but can also create dangerous

situations. Do not use the appliance as an incinerator, at the risk of

voiding the warranty.

3.3 THE FEEDBOX

The feedbox is situated in the top part of the appliance. The

load capacity specified in the technical data can vary

according to the specific weight of the pellets.

Take special care when loading the tank as the screw

feeder at its base is in motion. Take care when topping up

with fuel as the loading area can get very hot.

Only pellets that comply with the specifications listed above

must be fed into the tank;

Figura 1

Page 10

Page 10

manutenzione

Never insert foreign objects into the tank. To access the feedbox firstly remove the tank cover as illustrated in Figure

1.

Caution: it is very important to use the supplied glove when removing the cover as the ceramic can be extremely hot.

Attention: when loading the pellets into the tank take care not to drop any in the inner parts of the appliance, as this

could cause live flames inside the appliance. The manufacturer recommends emptying the tank and vacuuming the

screw feeder zone once a month and during the summer period. The appliance is designed to run on pellet fuel. Use

of other combustible materials in the tank and/or combustion chamber is strictly prohibited.

4 - INSTALLATION

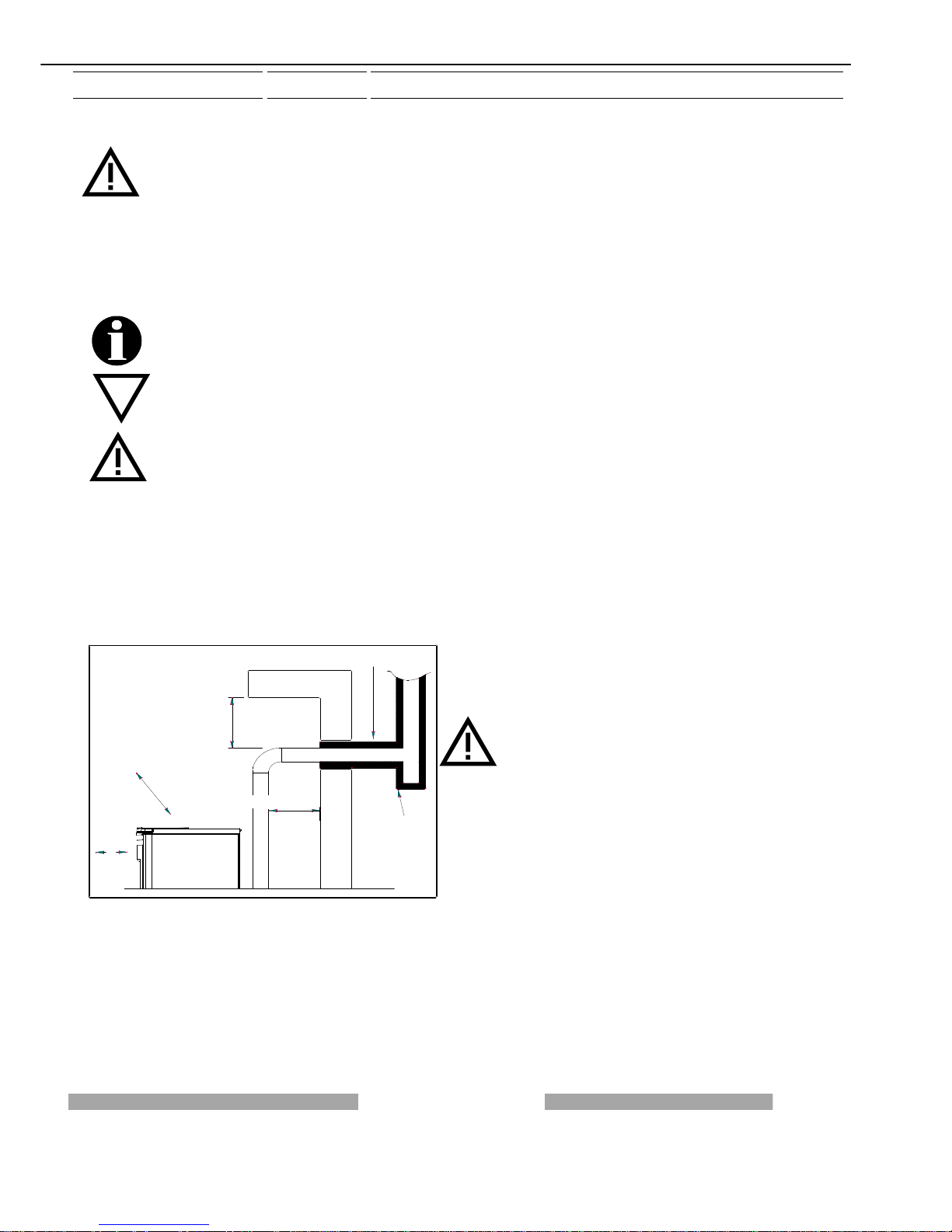

4.1 POSITIONING OF THE APPLIANCE

Follow the general guidelines set out in paragraph 1.1 to the letter. Keep in mind that the flooring of the room in which

the appliance is to be installed must withstand the combined weight of the appliance and the pellets contained in the

tank.

CAUTION: The appliance must be installed in a room with adequate ventilation. The appliance must be positioned at

a minimum safe distance from walls and furnishings. If inflammable items are positioned near the appliance

(matchboarding, furniture, curtains, wall hangings, sofas, etc...), this gap must be increased considerably. The

recommended minimum distances are illustrated in Figure 1. If the flooring is made of wood or any other combustible

material, it is recommended to install a fireproof floor protector plate between the appliance and the floor. Installation

in the vicinity of heat-sensitive materials is only permitted if suitable insulating and fireproof protection is placed

between the object and the appliance (ref. Uni 10683). Failure to observe this instruction will immediately invalidate

the warranty.

The installer must issue a certificate of conformity for the installation which includes the design plans and the

following documents:

a) Report containing the type of materials utilised.

b) Project as defined in Article 5 of Ministerial Decree n° 37 22 January 2008.

c) Drawing of the finished installation.

d) References to existing partial or previous declarations of conformity (e.g. electrical wiring).

e) Copy of the certificate of recognition of the professional technical qualifications.

These documents must, by law, be kept together with the

use and maintenance guide. The customer is responsible

for verifying, directly or indirectly, that the installation has

been carried out to perfection in accordance with relevant

regulations in force. Do not install the appliance in

unsuitable rooms such as bedrooms, bathrooms, garages

and/or lock-ups. It is forbidden to place the appliance in

environments with an explosive atmosphere.

ATTENTION , the stove is not simply a household

appliance: if the instructions set out in this booklet are not

followed and/or if installation of the appliance is not

executed perfectly and/or the provisions in force are not

strictly complied with dangerous conditions could arise for

both objects and persons.

LEGENDA KEY

Figura 1 Figure 1

ISOLANTE TERMICO HEAT INSULATING MATERIAL

T ispezionabile Inspectable Tee element

200/450 mm se materiale combustibile 200/450 mm if the material is combustible

200 mm se materiale combustibile

450 mm se materiale combustibile

ISOLANTE TERMICO

2

0

0

m

m

s

e

m

a

t

e

r

i

a

l

e

c

o

m

b

u

s

t

i

b

i

l

e

450 mm se materiale combustibile

T ispezionabile

Figura 1

Page 11

Page 11

manutenzione

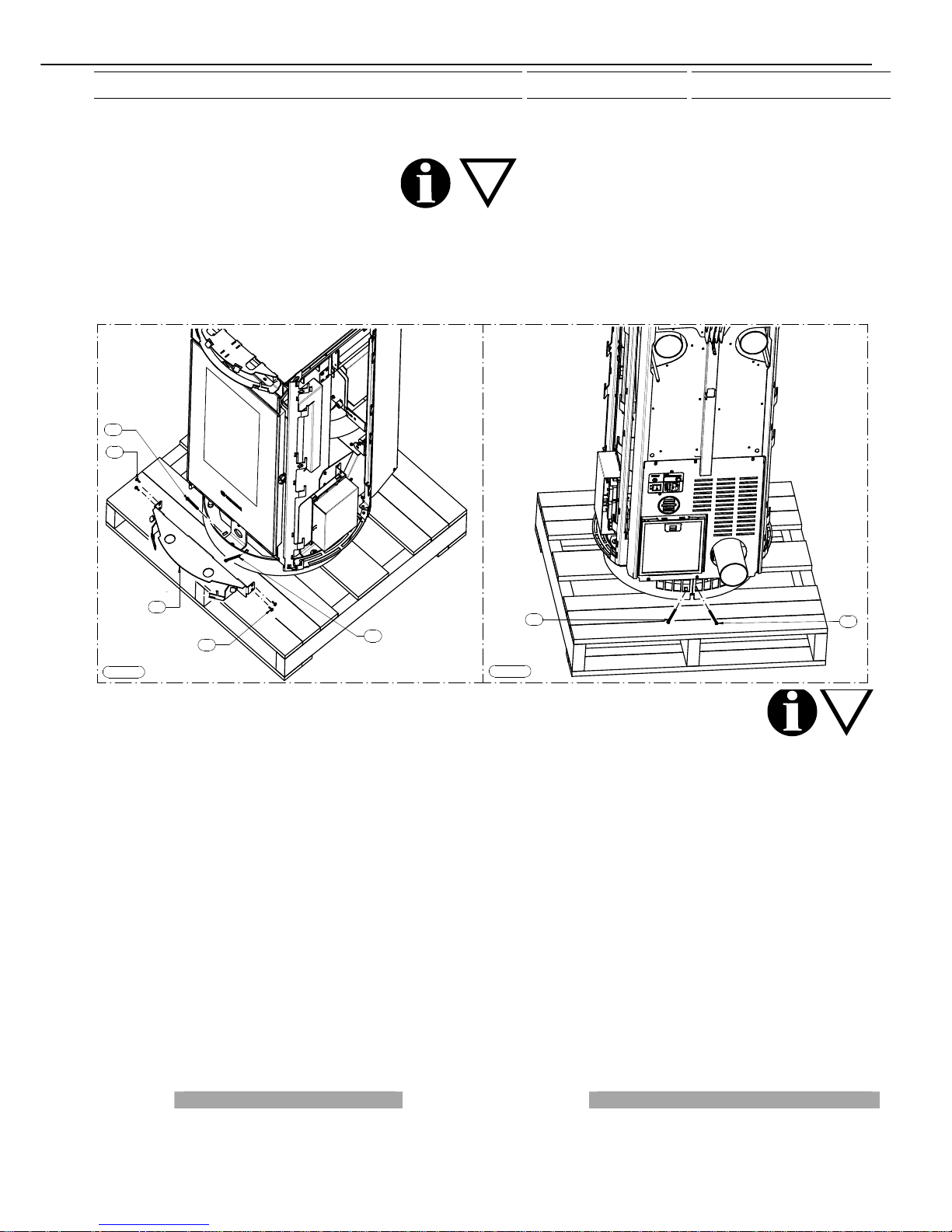

4.2 UNPACKING THE APPLIANCE

To unpack the appliance remove the packaging cover and sides, undo the 4 screws C that fix the appliance to the pallet. To remove

the 2 screws C indicated in Figure 1 firstly remove the bracket A by undoing the screws B. Next undo the last 2 screws C as

illustrated in Figure 2.

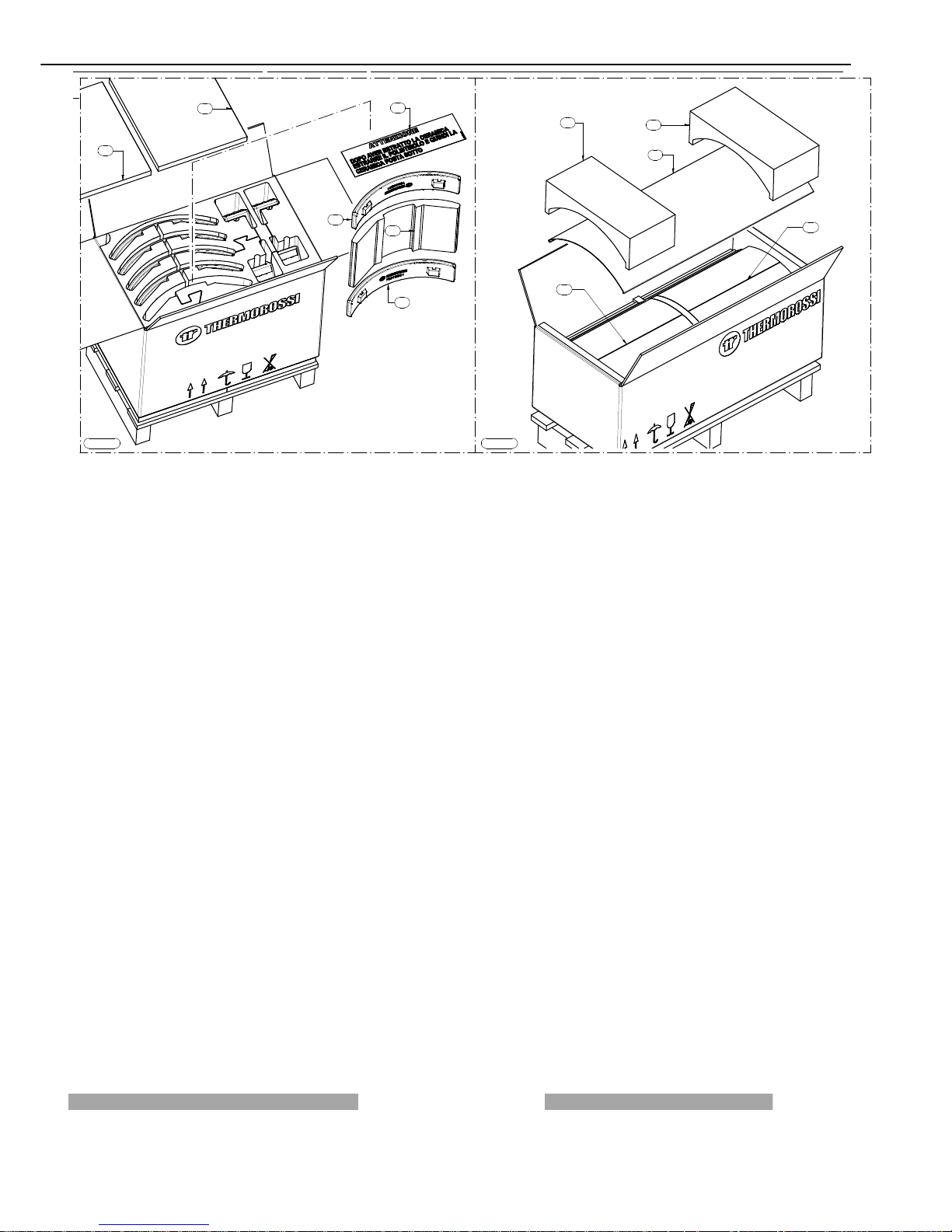

4.3 UNPACKING THE MAJOLICA CASING AND THE METALCOLOR CASING

To unpack the majolica casing follow the instructions illustrated in Figure 1; firstly open the box and remove the 2 polystyrene

elements A, then, with extreme care, remove each of the ceramic elements: once you have removed the ceramic indicated with the

letter C remove the polystyrene element D followed by the ceramic E.

To unpack the metalcolor casing follow the instructions illustrated in Figure 2; firstly open the box and remove the 2 polystyrene

elements E and remove the side panel F. Proceed to remove the polystyrene elements G which enclose 3 ceramics. Lastly remove

the second side panel F. Caution: the painted casings are delicate and must be handled with extreme care. Wear soft cotton

gloves. Clean with soft microfibre cloths for delicate surfaces such as lenses, glasses, monitors...

Figura 1

Figura 2

A

B

B

C

C

C

C

Page 12

Page 12

manutenzione

Figura 1

E

C

B

A

A

D

Figura 2

E

E

F

G

G

Page 13

Page 13

manutenzione

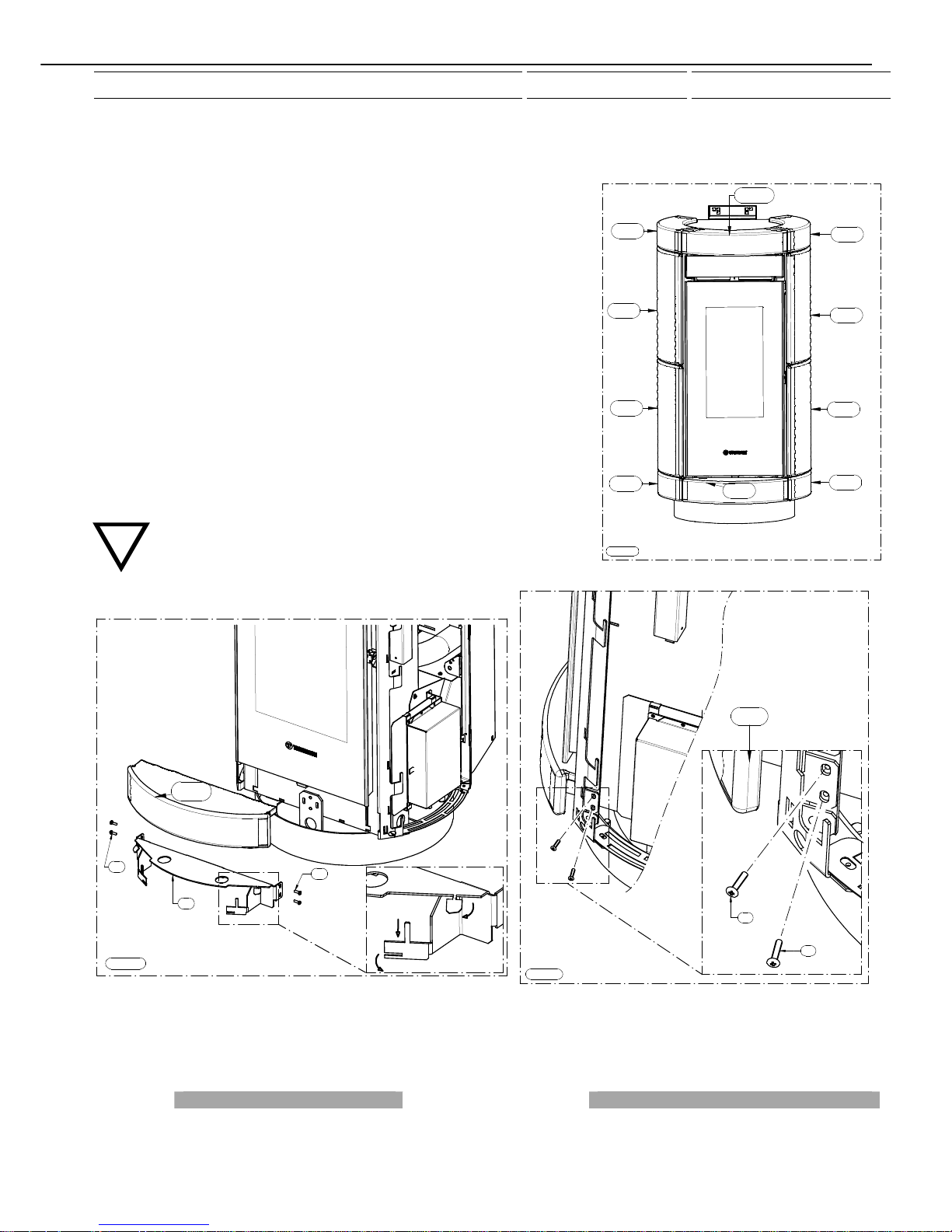

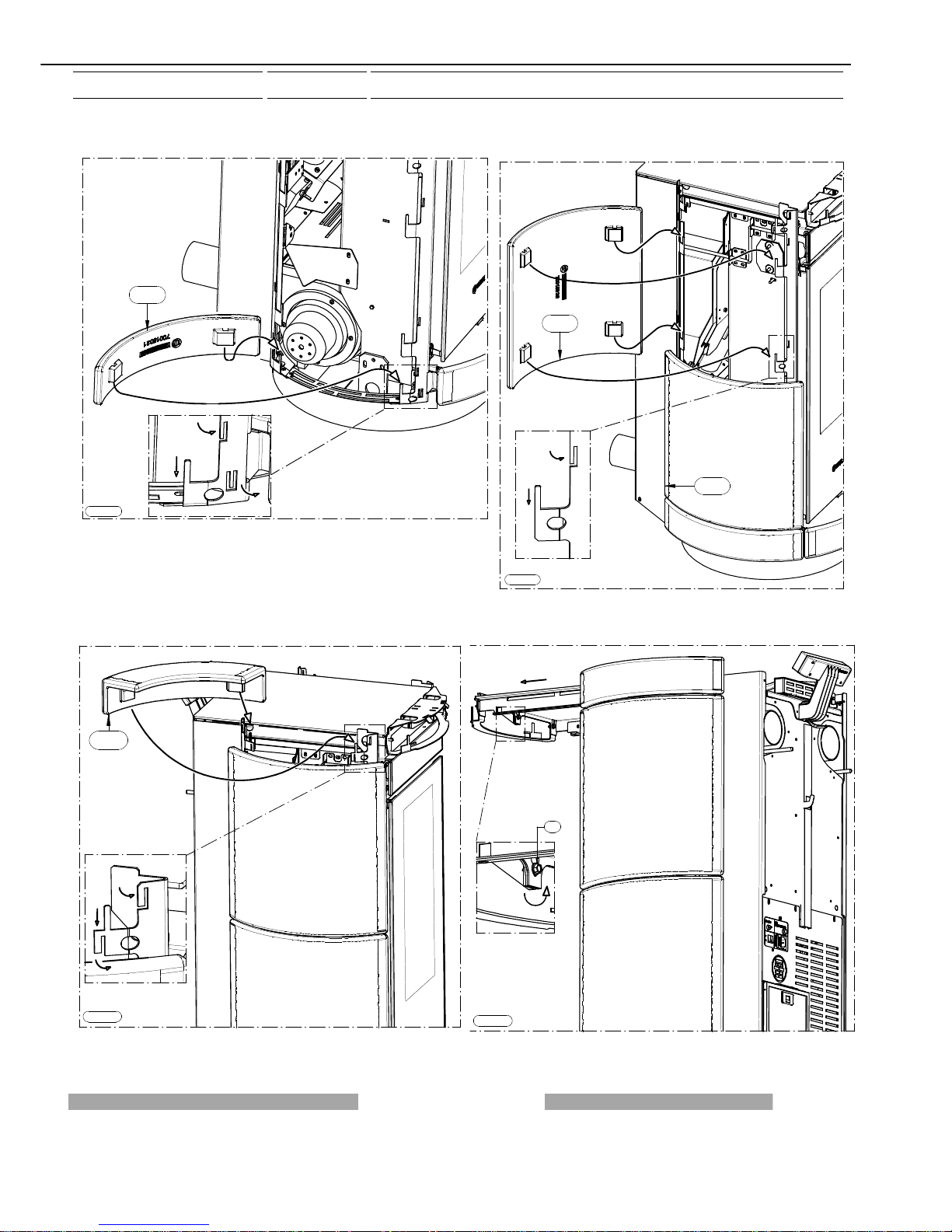

4.4 MOUNTING MAJOLICA CASING DORICA DORICA PLUS

Unpack the majolica casing and follow the instructions set out below:

- The majolica elements are numbered on the inner surface ( Figure 1).

- Firstly remove support B by acting on the screws A then insert the ceramic (1↑) in

the support; to make it integral with the support act on the indicated stops. Next fix

this assembled unit with the screws removed earlier (Figure 2 and Figure 3).

- Next mount the ceramic (2↑) as indicated in Figure 4, that is, by slightly bending

the stops until the ceramic is securely fastened.

- Then mount the ceramics (3↑) and (4↑) following the indications in Figure 5, that

is, by slightly bending the stops until the ceramic is securely fastened.

- Next mount the ceramic (5↑) following the indications in Figure 6, that is, by

slightly bending the tabs until the ceramic is securely fastened.

- Continue the procedure by mounting ceramics (6↑) (7↑) (8↑) and (9↑) using the

assembly logic described above (Figure 1).

- Lastly, mount the ceramic (10↑):

remove the tank cover as indicated in Figure 7 and slightly loosen, by one turn, the

3 screws indicated with the letter C. Next remove support D by lifting it and pulling

it outwards. Fix the ceramic (10↑) as indicated in Figure 8 using the same

procedure described above (it is mandatory to fix the ceramic securely to the

support D with black high temperature silicone sealant). Next fix this assembled

unit by tightening the screws C (see Figure 9).

It is recommended to use pliers to bend the tabs.

CAUTION, IMPORTANT: carefully adjust the ceramics particularly around

the handle area and verify that the handle does not touch the ceramic

when opening or closing the door.

2 ↑

1 ↑

3 ↑

4 ↑

5 ↑

6 ↑

7 ↑

8 ↑

9 ↑

10 ↑

Figura 1

Figura 2

A

B

1 ↑

A

Figura 3

A

1 ↑

A

Page 14

Page 14

manutenzione

Figura 4

2 ↑

Figura 7

C

Figura 6

5 ↑

Figura 5

3 ↑

4 ↑

Page 15

Page 15

manutenzione

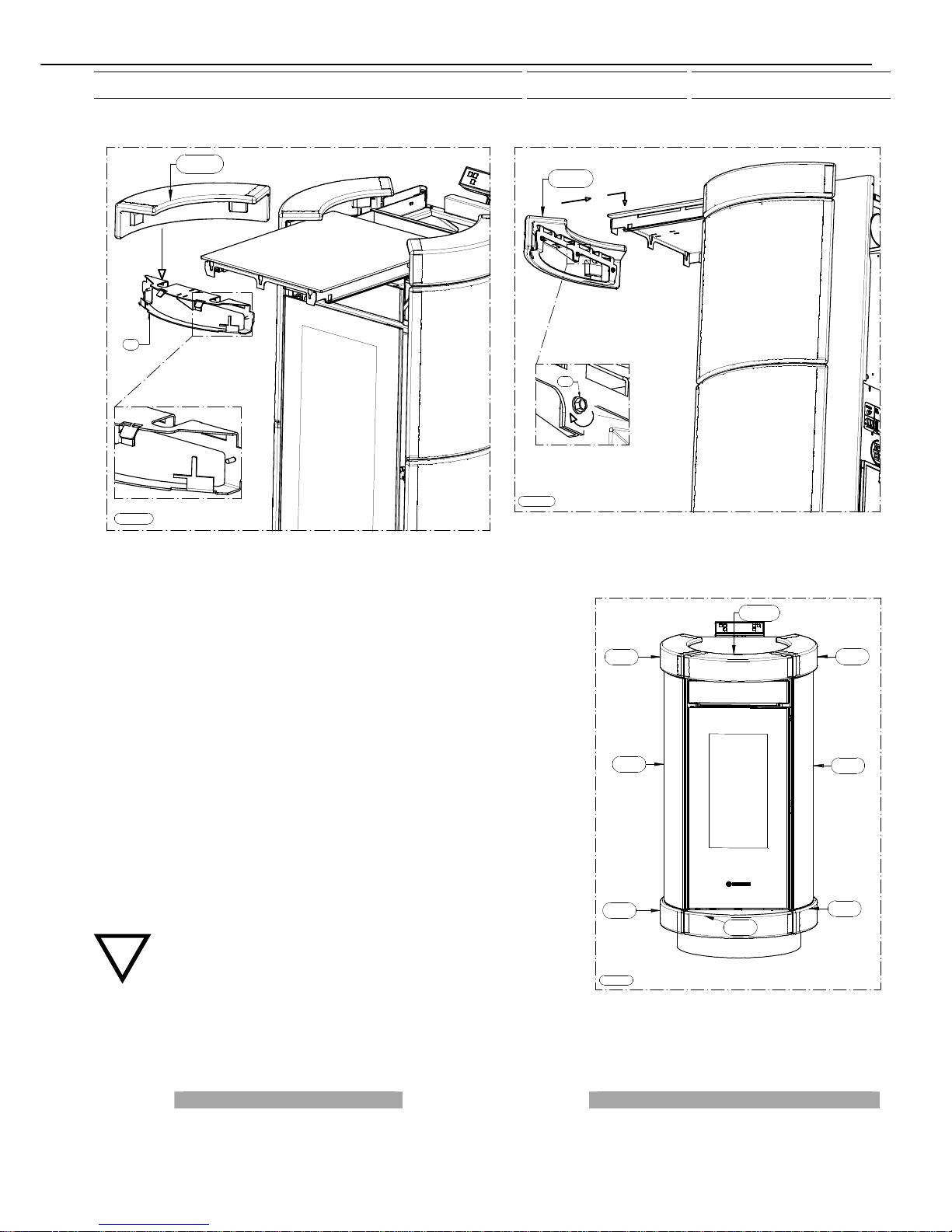

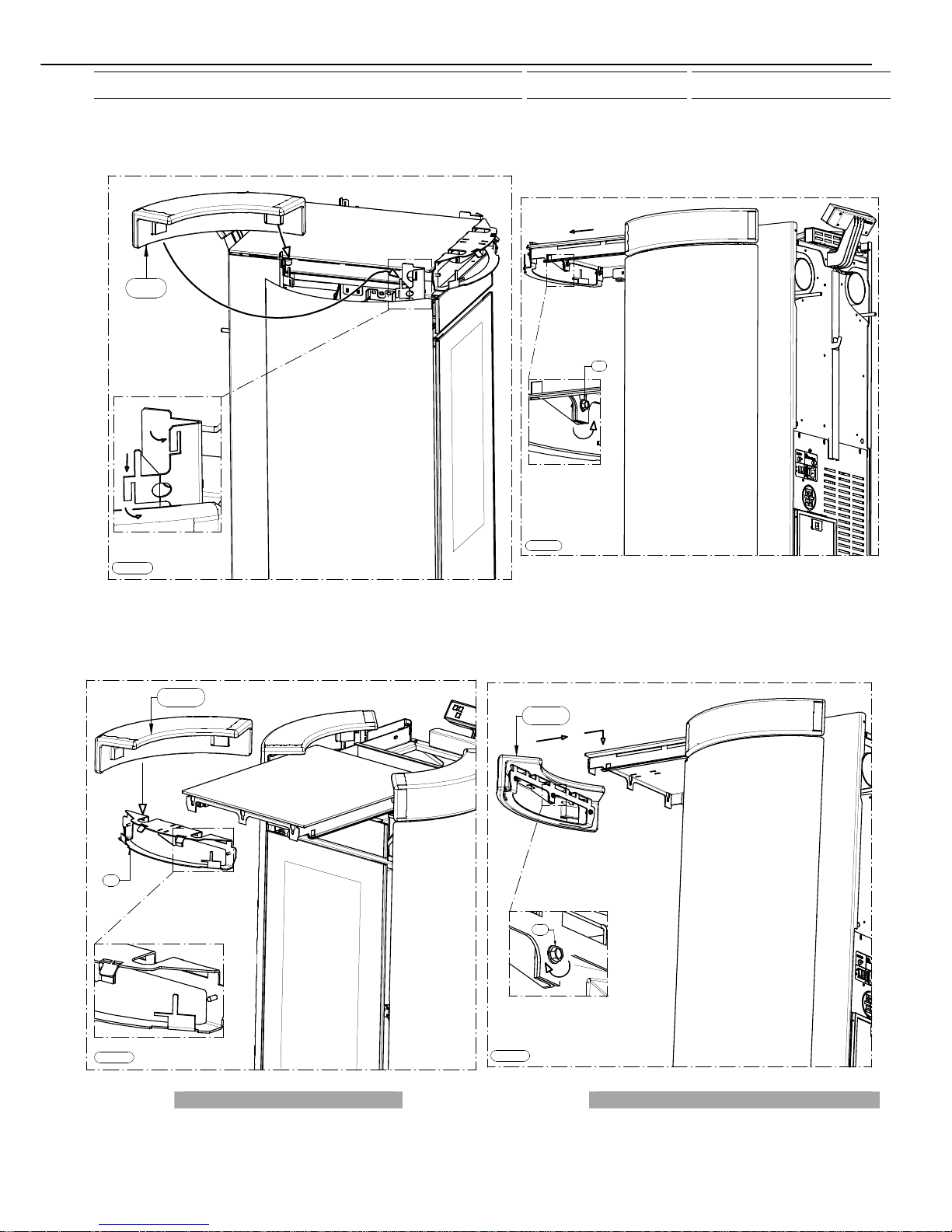

4.5 MOUNTING METALCOLOR CASING DORICA DORICA PLUS

Unpack the metalcolor casing and follow the instructions set out below:

- The majolica elements are numbered on the inner surface ( Figure 1).

- Firstly remove support B by acting on the screws A then insert the ceramic (1↑)

in the support; to make it integral with the support act on the indicated stops. Next

fix this assembled unit with the screws removed earlier (Figure 2 and Figure 3).

- Next mount the ceramic (2↑) as indicated in Figure 4, that is, by slightly bending

the stops until the ceramic is securely fastened.

- Then mount the metalcolor side panel (3↑) following the indications in Figure 5,

that is, by slightly bending the stops until the metalcolor side panel is securely

fastened.

- Next mount the ceramic (5↑) following the indications in Figure 6, that is, by

slightly bending the tabs until the ceramic is securely fastened.

- Continue the procedure by mounting ceramics (6↑), the metal side panel (7↑)

and the ceramic (9↑) (Figure 1).

- Lastly, mount the ceramic (10↑):

remove the tank cover as indicated in Figure 7 and slightly loosen, by one turn,

the 3 screws indicated with the letter C. Next remove support D, fix the ceramic

(10↑) as indicated in Figure 8 using the same procedure described above (it is

mandatory to fix the ceramic securely to the support D with black high

temperature silicone sealant). Next fix this assembled unit by tightening the

screws C (see Figure 9). It is recommended to use pliers to bend the tabs.

CAUTION, IMPORTANT: carefully adjust the ceramics particularly

around the handle area and verify that the handle does not touch the

ceramic when opening or closing the door.

2 ↑

1 ↑

3 ↑

5 ↑

6 ↑

7 ↑

9 ↑

10 ↑

Figura 1

Figura 9

C

10 ↑

Figura 8

D

10 ↑

Page 16

Page 16

manutenzione

Figura 2

A

B

1 ↑

A

Figura 3

A

1 ↑

A

Figura 4

2 ↑

Figura 5

3 ↑

Page 17

Page 17

manutenzione

Figura 8

D

10 ↑

Figura 9

C

10 ↑

Figura 6

5 ↑

Figura 7

C

Page 18

Page 18

manutenzione

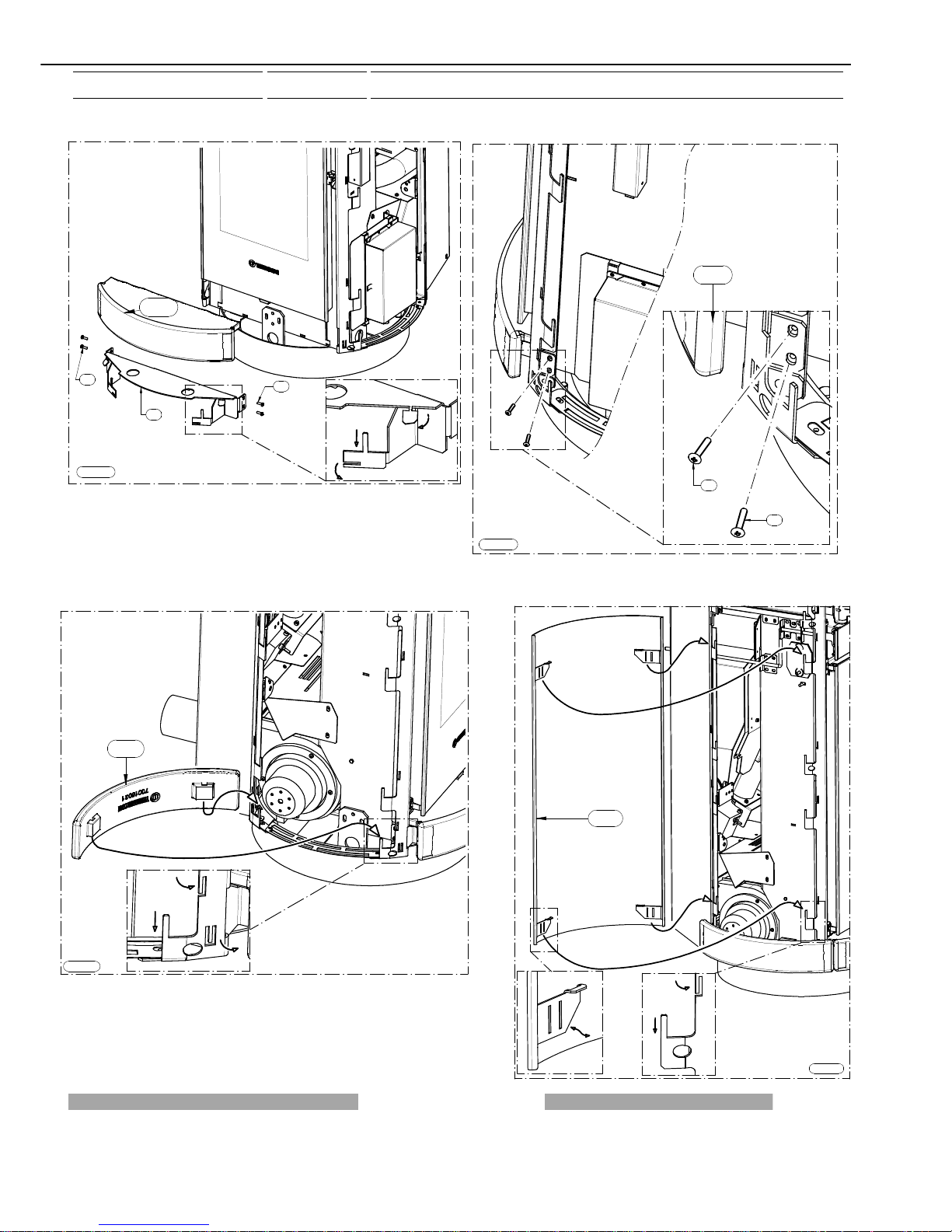

4.6 CONNECTING THE APPLIANCE TO THE FLUE OUTLET

Connection of the appliance to the flue outlet must be carried out in strict compliance with the instructions contained in

this booklet and particularly with those in Chapter 9.

The appliance is supplied with the control panel assembled symmetrically with the generator: the connection to the flue

outlet in this case must be carried out as indicated in figures 1, 2, 3. Pay particular attention when assembling the smoke outlet pipe

as it must be no less 15 mm from the control panel (Figure 2): if the pipe is positioned close to the panel it would certainly damage

the control panel (damage which is not covered by warranty).

Installed in this way the hot air can be channelled to the back using both vents.

Figura 2

Figura 1

1

5

Figura 3

Page 19

Page 19

manutenzione

If there is not sufficient depth the size can be reduced

to roughly 80 mm; follow the indications in figures 4, 5, 6,

7 and specifically:

- Remove the tank cover (Figure 4).

- Remove the 4 screws from the control panel (Figure 4).

- Shift the panel then fix with the screws removed earlier

(Figure 5).

- Pay particular attention when assembling the smoke

outlet pipe as it must be no less 10 mm from the control

panel (Figure 6): if the pipe is positioned close to the panel

it would certainly damage the control panel (damage which

is not covered by warranty). Installed in this way the hot air

can be channelled to the back using only the RH side vent.

It is strictly forbidden to use the LH side ducting.

Figura 4

Figura 5

Figura 6

10

Figura 7

Page 20

Page 20

manutenzione

14:30

WORK

Zona del display dove viene

visualizzato il giorno

corrente (per esempio 3 pallini = mercoledì).

Indicatore

livello

di ventilazione

Zona del display

visualizzati fasi di

funzionamento, ora....

dove vengono

"

Themocomfort On "

ovvero connesso

Indicatore

livello

di combustione

14:30

WORK

3

2

5

4

8

1

7

6

4.7 HANDLE

Your appliance is supplied with a handle for opening the firebox door; this tool must be used for opening the door to permit carrying

out cleaning operations (see paragraph 8). The handle, when not being used, can be stored at the back of the appliance on the

hook provided (see Figures 1 and 2).

5 – DESCRIPTIONS OF CONTROLS

There are two main control pushbuttons marked with the ventilation symbol (2) and the symbol of the flame (1). The flame

pushbutton (1) sets the power of the appliance with 5 levels available which are activated as the 5 bars light up in sequence on the

display (7). The off cycle is activated when all power bars are turned off. The fan button (2) controls the ventilation of the appliance.

It is activated when the smoke, detected by the smoke probe, reaches a temperature over 60°C.

The fan can be set to any of 6 speed levels displayed by the 6 bars progressively coming on on the display (7): when the appliance

is on the ventilation cannot be switched off.

5.1 DESCRIPTION OF CONTROL PANEL AND REAR PANEL

5.1 DESCRIPTION OF THE CONTROL PANEL

All controls and indicators are presented here below :

(1) Appliance on/off and flame adjustment button When you press this button

the appliance switches to START/WORK/ OFF

(appearing on the display 7). Press repeatedly to activate up to 5 bars on the

display (7)

(2) Ventilation setting button Press this button to set the desired level of

ventilation: up to a maximum of 6 speeds are available, indicated by the

lighting of the corresponding bars in the display (7). One bar is always lit

on the display even in OFF status.

(3) (4) Auxiliary setting buttons

Keys (3) and (4) are operating buttons necessary when on-off cycles are

programmed, for operative levels, clock setting, etc..

(5) Programming Enable / Disable / Chrono Reset buttons

(6) “MENU” selection button To access the main menu press the button

marked with 6. Press button 6 repeatedly to scroll the various windows:

date, programming setting,...

(7) Display

(8) Infrared remote control sensor

Figura 1

Figura 2

Page 21

Page 21

manutenzione

11

13

12

14

DAYS

DATA MON

2

3

5

4

7

6

1

8

00 : 00

LEGENDA KEY

Zona del display dove viene visualizzato il giorno corrente

(per esempio 3 pallini = mercoledì)

Display area in which the current day is displayed (for example,

3 dots = Wednesday)

Zona del display dove vengono visualizzati fasi di

funzionamento, ora,. . .

Display area in which the operation steps are displayed, time...

Indicatore livello di ventilazione Ventilation level indicator

"Thermocomfort On" ovvero connesso "Thermocomfort On" i.e. connected

Indicatore livello di combustione Combustion level indicator

Riarmo Reset

Spia motoriduttore Ratio motor led

5.1.2 APPLIANCE REAR PANEL

A description of the functions of the buttons and LEDs on the rear panel:

(11) Main switch 0-1

(12) Electrical power outlet 220-240V 50 Hz

(13) Overtemperature reset thermostat button cap

In the event of overtemperature this safety thermostat stops the loading of

pellets. To restart the appliance you need to wait until it cools down, then

verify the cause for the overheating, remove the cause, unscrew the

protective cap and press the button (13).

(14) Feed motor test indicator light When the pellet screw feeder is set

in motion the light must come on.

5.2 DAY AND TIME SETTING

The appliance must be energised and the rear switch in position "1". The

words START or WORK or OFF could be present on the display (7). To set the time and the day of the week carry out the

procedures described below. Press button (6) once;

the word DATA will appear on the display followed

by the words illustrated in the figure on the left. To

set the day press arrow button (3) and/or (4)

repeatedly until the desired day appears: (MON and

one dot for Monday -- TUE and two dots for Tuesday

-- WED and 3 dots for Wednesday -- THU and 4 dots

for Thursday -- FRI and 5 dots for Friday -- SAT and

6 dots for Saturday -- SUN and 7 dots for Sunday).

Then confirm the day by pressing the key (1). The 2

digits representing the hours will start flashing in the

display: it is possible to select the present hour using the arrow keys (3) and/or (4); the selection must be confirmed by pressing key

(1). The 2 digits indicating the minutes will start flashing: it is possible to select the present minutes using the arrow keys (3) and/or

(4), the selection must be confirmed by pressing the key (1). The day and time setting is now completed.

5.3 ON/OFF PROGRAMMING

The generator must be energised and the rear switch in position "1". The words START or WORK or OFF could be present on the

display (7).

DAYS

CRONO MON

3

2

5

4

8

1

7

6

DAYS

CRONO MON

3

2

5

4

8

1

7

6

00

: 00

ON

1

Page 22

Page 22

manutenzione

It is possible to carry out the weekly programming by setting up to 3 on/off cycles for each day from Monday to Sunday. To program

the appliance press button (6) twice until the word CRONO appears followed by the words illustrated in the figure above on the left.

Now you can begin programming the first day of the week - Monday - by pressing button (1). Press the arrow button (3) and/or (4)

to choose another day to be programmed, to confirm the selection press button (1) again. The words ON1 will appear on the display

followed by 2 blinking digits indicating the hours (figure above right). Press button (3) and/or (4) to enter the hour of the first cycle

start time. To confirm the selection press the button (1). The 2 digits indicating the minutes will start flashing. Press button (3)

and/or (4)to enter the minutes of the first cycle start time. To confirm the selection press the button (1). The first start up time for the

selected day has now been set. Then the inscription OFF1 will appear in the display and the two digits representing the hours will

turn on. When the (3) and/or (4) button is pressed the hour of the first off-cycle is entered.

To confirm the selection press the button (1). The 2 digits indicating the minutes will start flashing. By pressing the button (3) and/or

(4) the minutes for the first off-cycle will be entered. To confirm the selection press the button (1). This concludes the setting of the

first on-off cycle for the selected day. Later, it is possible to set the second on-off cycle (e.g. Monday) (shown with the display of

ON2 and OFF2) and the third Monday’s on-off cycle (shown with the display ON3 and OFF3). Next the display appears as

illustrated in the figure above on the left. Press the arrow button (3) and/or (4) to choose another day to be programmed, to confirm

the selection press button (1) again.

If you wish to copy all the on-off programs, for example the Monday settings, to the other days of the week, proceed as follows:

press button (6) until the word "CRONO" appears followed by the screen illustrated in the figure below on the left. Next press button

(2) and the display appears as illustrated in the figure below on the right: the program for Monday has been copied to Tuesday.

Press button (2) again to copy the program to Wednesday, Thursday ...

. In the programming menu if you wish, for example, to edit the programming for Sunday press button (3) and/or (4) to go to

Sunday and then press button (1). If the second on-off cycle is not required simply set the ON2 time as 00:00 and the OFF2 time as

00:00 .

The programming procedure ends when you confirm the last data entered by pressing button (6) or when you exit the programming

menu. During the START, WORK or OFF phases press button (5) to enable / disable the programming (Enabled = CR.ON appears

momentarily on the display together with the fixed presence of the chrono symbol on the right of the display (see figure below).

Disabled: message CR.OFF temporarily displayed and, at the same time, the chrono symbol on the right side of the display is not

present (see figure below): this function is useful if you wish to disable the established weekly program setting. Moreover, you can

reset, or delete, all the programmings by holding down (in OFF or START or WORK phase) button (5) for approximately 8 seconds;

the word "RESET CRONO" appears momentarily in order to indicate deletion of all the programmings previously set. With the

programming active, the operating conditions at the start-up (combustion power – ventilation speed) are the same as set-up before

the last off-cycle of the appliance: this is the case if the off-cycle has been done through the programming and not through a manual

action.

Manual shut down can only be carried out with the programming disabled. After shut down, by re-enabling the programming, at the

next start up controlled by the programming the appliance will be set at the first combustion power position and first ventilation

speed.

In the event of a programmed cycle on always ensure that the brazier is clean and seated correctly in its

lodging: failure to clean the brazier can reduce and/or affect the life of the spark plug as it would be

subjected to high temperatures due to poor cooling. When the programming is enabled (CR.ON appears

momentarily together with the fixed presence of the chrono symbol on the bottom of the display) any

additional chronothermostats (see para. 7.2) are disabled.

DAYS

CRONO MON

3

4

8

2

5

7

6

1

DAYS

CRONO TUE

Copy

3

4

8

2

5

7

6

1

Page 23

Page 23

manutenzione

3

4

8

2

5

7

6

1

LEVEL 1

WORK

14:30

14:30

WORK

Programmazione

abilitata

Programmazione

disabilitata

5.3.1 ON-OFF PROGRAMMING DISPLAY

To view the programmings press button (6) 5 times until the words "Show Chrono" appear.

After a few seconds the display appears as illustrated in the figure below on the left. Press button (3) repeatedly to scroll the

programmings for all the days of the week (see figure below on the right):

press button (6) to exit.

Caution: the on-off programmings cannot be modified from the "SHOW CRONO" menu, this menu is used only for

viewing the programs that have been entered and/or edited through the "CRONO" menu.

5.4 OPERATING LEVEL SETTING

The appliance must be energised and the rear switch in position

"1".

The words START or WORK or OFF could be present on the

display (7).

Your appliance is delivered with an excellent program installed

that favours combustion yield; the program is called

LEVEL 1. If you are using pellets with an out-of-standard

incidence of residues after combustion in the brazier, alternative

levels may be selected:

LEVEL 2: this program increases the smoke suction unit speed acceleration. (program Level 2 increases air delivery to the burner

which promotes the combustion of tightly compacted pellets: this program reduces combustion efficiency).

LEVEL 0: when using too long pellets and/or flue outlets with very high vacuum, over 2 Pascal. When operating at LEVEL 0 the

burner becomes dirty very easily. The pellet consumption value is not affected by the operating level settings. Select the required

level by acting as follows:

press button (6) three times until the word LEVEL appears on the display after which the level set will appear (LEVEL 1 or LEVEL 2

or LEVEL 0). In order to change the operating level as key (3) is kept pressed, press the key (4). By holding down button (3) and

pressing button (4) repeatedly the level changes in the following sequence: LEVEL 2 ... LEVEL 0 ... LEVEL 1.

DAYS 10:45

MON

3

4

8

2

5 7

6

1

DAYS 10:45

MON

3

4

8

2

5

7

6

1

ON

1 11:15

OFF 1

13:45

Programming enabled

Page 24

Page 24

manutenzione

If the change is made while the appliance is running the difference in the flame will be apparent. It is

mandatory to pay particular care when selecting the most appropriate operating cycle for your

installation. After the selection of the operating cycle a thorough cleaning of the brazier is mandatory.

For the entire procedure to be confirmed and to move back to the appliance status display, key (6) must

be repeatedly pressed.

6 – USE OF THE APPLIANCE

Your appliance has obtained the CE marking and has been made to run for 1 hour to check that it functions correctly. It has also

undergone numerous tests as detailed in the test check sheet supplied with the generator. The product must not be used by

children, by persons with physical or mental impairments, by persons who are not familiar with the instructions for use and

maintenance of the product (the instructions are found in this booklet). CAUTION: Before each use make sure that the burner is

clean and positioned correctly in its lodging, check that the ash pans are clean and shut tight and check that the firebox door is

locked. WARNING: the door must always remain shut tight when the appliance is operating. It is strictly forbidden to open the door

while the appliance is in operation. While the appliance is in operation the smoke exhaust pipes and the appliance can reach

extremely high temperatures: do not touch them! Do not expose your body to hot air for long, do not overheat the room in which the

appliance is installed, as these actions could cause health problems. Do not expose plants or animals directly to the hot air flow as

this could have noxious effects on them. It is strictly forbidden to use any type of fuel (liquid, solid...) to light the appliance:the

appliance must light up automatically as designed and described in this installation, use and maintenance booklet; in this regard, it

is strictly prohibited to pour pellets (or other material) directly into the brazier. Do not place non-heat resistant or inflammable or

combustible objects in the vicinity of the appliance: keep them at a suitable distance. Do not place wet clothing to dry on the

appliance.

When using a clothes horse, keep at a suitable distance. It is strictly prohibited to disconnect the appliance from the electrical

power mains while it is in operation.

6.1 SWITCHING ON THE APPLIANCE

Before using the appliance check that all the movable parts are in place; also remove any labels and stickers from the glass to

avoid having permanent traces remain on the surfaces. Always ensure that the brazier is clean and seated correctly in its lodging

(see para. 8).

Turn the switch installed on the back of the appliance to position "1" (= ON). Press button (1) to start the start up phase. When key

(1) is repeatedly pressed, the desired combustion level can be set and it will be active at the end of the ignition stage. The electrical

heater will start to overheat and after a few minutes the first lot of pellets will start dropping into the brazier. This occurs because the

screw feeder has to fill up because it is completely empty. The first time the appliance is started up the start up phase will have to

be carried out twice for this very reason.

CAUTION: The start up phase (the word START appearing on the display) continues until the word

START remains lit. Once this phase has ended the word WORK appears on the display. The fan will

begin operating as soon as the combustion smoke reaches a suitable temperature. During the work

stage it is then possible to adjust combustion and the ventilation:

The combustion can be adjusted by 5 bars through button (1)), the ventilation setting can be set on 6 levels indicated by the

sequential lighting up of the corresponding bars on the display (through button (2)).

To turn the appliance on it is necessary for the inscription OFF to be present on the display: if it is not present, the key (6) must be

repeatedly pressed until the inscription OFF appears.

6.2 ADJUSTING COMBUSTION AND VENTILATION

The heating capacity is adjusted by pressing key (1) or on the remote control provided. Act on this command to adjust the quantity

of pellets fed to the firebox. Maximum combustion power is achieved when all 5 leds are lit.

Caution: the room fan starts up as soon as the temperature of the combustion smoke reaches a suitable threshold. The

fan setting is expressed visually by means of 6 different positions represented by 6 bars:press button (2) repeatedly to

regulate it. A slight vibration of the appliance is quite normal when it is running. One bar is always present on the display

even in OFF status.

Page 25

Page 25

manutenzione

8 R

9 R

10 R

3 R

2 R

4 R

1 R

6 R

7 R

5 R

11 R

12 R

13 R

6.3 INFRARED REMOTE CONTROL

A practical infrared remote control is supplied with the appliance: adjust the ventilation level by means of the left button, whereas

use the right button to start the appliance, to adjust the power and combustion level and to switch off the appliance. If the appliance

is supplied with a white radio control (optional) the infrared control only works when the MANUAL setting is set on the white

handheld radio control.

6.4 OPERATION OF THE WHITE HANDHELD RADIO CONTROL THERMOCOMFORT (OPTIONAL)

INTRODUCTION

The thermocomfort handheld radio control is the instrument that allows you to optimise both consumption and functions. Keep in

mind that radio wave transmissions can be affected by the surrounding environment: the presence of thick walls can reduce the

transmission that normally extends to 6-7 metres.

Caution: to guarantee optimal data transmission it is advisable to always place the radio control in its support in a vertical

position.

The following operations must be carried out the first time the appliance is started up:

- Turn the switch (11R) to ON (see drawing below)

- Connect the radio control by means of the battery charger supplied to the power line (it must be recharged for at

least 5 days), as the rechargeable batteries could be partially or completely flat. The appliance must be energised

and the rear switch turned to position "1".

CAUTION: the Thermocomfort function is disabled when the remote control is OFF. To enable it, in the START,

WORK, OFF phases, repeatedly press button (6) on the appliance's control panel until the word

"THERMOCOMFORT" appears on the display (7) followed by the words Thermocomfort Off". To activate the

Thermocomfort function simply press the button (3) on the appliance's control panel: " Thermocomfort On". To

return to the original operating function simply press the button (6) again on the appliance's control panel. At the

end of the winter season it is mandatory to recharge the batteries and switch off the radio control completely, by

means of the switch situated inside the battery compartment, in order to preserve the life of the batteries. The

batteries are guaranteed for 6 months. When the batteries are exhausted dispose of them safely. It is normal for

the temperature sensor to detect temperatures which are slightly different to the real ones: variations caused by

the environment in which the radio control is positioned and by the tolerance of the thermostat.

6.4.1 INDICATORS OF THE HANDHELD RADIO CONTROL

(1R) Flame selection button

(2R) Ventilation selection button

(3R) (4R) Auxiliary buttons

(5R) “Room temperature detected by the radio control's sensor” indicator

(6R) “Ventilation” indicator

(7R) “Combustion” indicator

(8R) “Room temperature setting” indicator: this is the room temperature

that you wish to reach by means of buttons 3R and 4R.

(9R) Area of the display where the operating program is displayed.

(10R) Battery charge level

(11R) Switch 0-1 radio control power

(12R) Battery charger connection

(13R) Code selector and batteries compartment cover

The Thermocomfort radio control can be used with 4 different operating

programs:

- Manual (MANUAL appears in area (9R) of the display).

- Automatic 5 (AUTO 5 appears in area (9R) of the display).

- Automatic 3 (AUTO 3 appears in area (9R) of the display) .

Page 26

Page 26

manutenzione

- Economy (ECONOMY appears in area (9R) of the display). To change the operating program turn the switch (11R) to "1". Press

and hold down button (3R) until the set program begins to blink on the display (9R). Now release button (3R) and press button (3R)

and/or (4R) repeatedly until you select the desired operating program.

MANUAL program (the "Thermocomfort ON" symbol blinks on the display of the appliance)In the MANUAL program the room

temperature thermostat is disabled. Press button (1R) and the flame symbol blinks. Press button (3R) to reduce the combustion

level as signalled by the power bars lighting up in sequence, vice versa press button (4R) to increase the combustion level.

The combustion level changes every time buttons (3R) and (4R) are pressed. Press button (2R) and the ventilation symbol blinks.

Press button (3R) to decrease the combustion level, vice versa press button (4R) to increase the combustion level. The ventilation

level changes every time buttons (3R) and (4R) are pressed. Caution: it is possible that, due to radio interference or sending

commands too close together, the changes will not be implemented. When using this program the infrared remote control can also

be used. It is normal that in the manual cycle the ventilation is often set at the maximum speed in order to cool the appliance body

more effectively.

AUTO 5 program (the "Thermocomfort ON" symbol is steady on the display of the appliance) In program AUTO 5 the room

temperature thermostat is enabled. The remote control adjusts the ventilation and combustion automatically in relation to the target

room temperature set in display area (8R). The desired room temperature is displayed in area (8R). You can vary the desired room

temperature by simply pressing button (3R) and/or (4R) (variation indicated in area (8R)). The remote control will set the maximum

combustion and ventilation levels and modulate them both as the room temperature (5R) approaches the target temperature (8R).

When the target temperature (8R) in the room (5R) is reached, the combustion level will stabilise on a bar as will the ventilation

level. Caution: it is possible that, due to radio interference, the commands sent to the generator will not be implemented. When

using this program the infrared remote control cannot be used. Caution: the power and the ventilation depend on the preset value, if

the required temperature is too high or not reachable the appliance could operate at maximum power for long periods of time.

AUTO 3 program (the "Thermocomfort ON" symbol is steady on the display of the appliance) In program AUTO 3 the room

temperature thermostat is enabled. The remote control adjusts the ventilation and combustion automatically in relation to the target

room temperature set in display area (8R). The desired room temperature is displayed in area (8R).

You can vary the desired room temperature by simply pressing button (3R) and/or (4R) (variation indicated in area (8R)). The

remote control will set the combustion power at level 3 and the ventilation at level 4 and modulate them both as the room

temperature (5R) approaches the target temperature (8R). When the target temperature (8R) in the room (5R) is reached, the

combustion level will stabilise on a bar as will the ventilation level. Caution: it is possible that, due to radio interference, the

commands sent to the appliance will not be implemented. When using this program the infrared remote control cannot be used.

Caution: the power and the ventilation depend on the preset value, if the required temperature is too high or not reachable the

appliance could operate at maximum power for long periods of time.

ECONOMY program (the "Thermocomfort On" symbol is steady on the display of the appliance) In the ECONOMY program the

appliance always operates at the minimum combustion level and the minimum ventilation level. When using this program the

infrared remote control cannot be used.

CAUTION: THE APPLIANCE MUST ALWAYS BE STARTED UP AND SHUT DOWN FROM THE CONTROL PANEL OR

THROUGH PROGRAMMING.

6.4.2 TRANSMISSION CODES SETTINGS.

The appliance must be energised and the rear switch in position "1". The words START or WORK or OFF could be present on the

display (7).

If there are several appliances installed in rooms closely to each other it may be necessary to set different transmission codes as

this type of interference deactivates operation of the optional Thermocomfort radio control. To change the transmission codes

proceed as follows:

-Disable the Thermocomfort function. To disable it, in the START, WORK, OFF phases, repeatedly press button (6) on the

appliance's control panel until the word "THERMOCOMFORT" appears on the display (7) followed by the words "Thermocomfort

On". To deactivate the Thermocomfort function simply press the button (3): "Thermocomfort Off". To return to the original operating

function simply press the button (6) again.

-Switch off the Thermocomfort radio control by pressing the button (11R) on the device.

-To change the transmission codes, open the cover (13R) and act as indicated in the figure below.

-Next switch on the radio control by pressing the button (11R).

Page 27

Page 27

manutenzione

-Activate the Thermocomfort function. To enable it, in the START, WORK, OFF phases, repeatedly press button (6) on the

appliance's control panel until the word "THERMOCOMFORT" appears on the display (7) followed by the words Thermocomfort

Off". To activate the Thermocomfort function simply press the button (3): "Thermocomfort On". To return to the original operating

function simply press the button (6) again. The radio control may still not function even after having changed the transmission

codes. If this occurs change the codes once again using the procedure described above.

LEGENDA KEY

Selettore codici per radiocomando palmare gestito via

onde radio

Code selector for handheld radio control controlled by radio

waves

6.4.3 CARE AND MAINTENANCE OF THE RADIO CONTROL

The radio control has been designed and produced to the strictest standards and must be handled with great care. If you observe

the guidelines set out below, the radio control will provide a long trouble-free performance:

-Protect the radio control against humidity! Precipitation, humidity and liquids corrode the electronic circuits. If the radio control is

wet, disconnect it immediately from a power source, remove the battery, open it and allow it to dry at room temperature.

-Do not use or store the radio control in dusty or dirty environments. The dust/dirt

could damage the movable parts of the radio control.

-Do not store the radio control in very hot environments. High temperatures could

shorten the life of the electronic devices, damage the batteries and deform or even

melt plastic parts. -Do not store the radio control in cold environments. When it heats

up (when it returns to normal operating temperature), humidity could form inside it and

damage the electronic circuits.

-Do not drop the radio control, do not hit or bump it and do not shake it. Actions such

as these could damage the internal circuits of the device.

-Do not use corrosive chemical substances, caustic solutions or detergents to clean

the radio control.

All the above guidelines apply equally to the radio control, the battery, the battery

charger, and all the accessories. The parts subject to wear (such as batteries,

keypads, lodging compartments, small compartment parts) are guaranteed for 6

months from the purchase date. The guarantee does not apply if the defect is caused

by non-conforming use and/or if the instructions and guidelines described above are

not observed to the letter. Devices or parts returned for replacement become the

property of Thermorossi. The presence of irregular black-blue lines on the display

(also present when de-energised and battery flat or missing) indicate that the glass screen of the display is damaged following a fall

or impact: in this case the breakage is not covered by the guarantee.

SELETTORE CODICI PER RADIOCOMANDO

PALMARE GESTITO VIA

ONDE RADIO

O

N

1

2

3

4

3

1

O

N

2

4

THERMOCOMFORT

3

5

4

7 6

Thermocomfort

On

11 R

12 R

13 R

A

Figura 1

Page 28

Page 28

manutenzione

6.5 FILTER

This practical device prevents the circulation of dust which is always present in household environments. The filter (marked by letter

A in the figure on the side) is installed at the back of the appliance (see figure 1 on the side). Clean frequently to ensure the

maximum availability of hot air when the appliance is operating (wash the filter

with cold water then dry thoroughly every 5 days).

6.6 CHANNELLING (DORICA PLUS ONLY)

To obtain an optimal flow of channelled hot air:

- Avoid narrow or reduced sections, sharp curves, downhill runs in the tubing.

- Reduce the horizontal runs as much as possible.

- Use pipes with smooth inner surfaces made of material capable of resisting

continuous temperatures of 150°C.

- Insulate pipes with mineral wool (resistant to at least 150°C).

If you follow the instructions given above it is possible to channel:

- up to 16 metres using 1 vent

- up to 8 metres using 2 vents

- up to 6 metres using 3 vents

- up to 4 metres using 4 vents

The appliance is supplied with both fittings already mounted. The air can be

ducted from the front or the back of the appliance by acting on the 2 levers

indicated in Figure 1 and Figure 2; to completely or partially channel the air to

the right rear pipe act on lever A (Figure 1), to completely or partially channel

the air to the left rear pipe act on lever B (Figure 2).

CAUTION: WHEN ONE OR BOTH DUCTING COLLARS ARE NOT BEING

USED TO CHANNEL THE AIR PUSH CHANNELLING LEVERS (A) AND (B)

TOWARDS THE FRONT OF THE APPLIANCE. IT IS MANDATORY

THEREFORE TO ENSURE THAT THERE ARE NO OBJECTS AND/OR

MATERIALS PRESENT AT THE BACK OF THE APPLIANCE THAT COULD

BE DAMAGED BY THE HEAT WHICH, IF THE CHANNELLING LEVER IS IN

THE INCORRECT POSITION (THAT IS POSITIONED TOWARDS THE BACK

OF THE APPLIANCE), WOULD DIRECT EXTREMELY HOT AIR

TOWARDS THEM. SEE INDICATIONS ON PARA. 4.1.

CAUTION: the channelling levers are extremely hot; it is mandatory to use the supplied glove.

A

Figura 1

B

Figura 2

Page 29

Page 29

manutenzione

7 - ADDITIONAL ROOM TEMPERATURE THERMOSTAT (not supplied)

ADDITIONAL CHRONOTHERMOSTAT - MODEM (not supplied )

The control panel ensures that your appliance is provided with all the required programming and temperature adjustment functions:

the appliance can be connected to an additional room temperature thermostat or to an additional chronothermostat:

---> for an additional room temperature thermostat connect terminals 7-8 directly to terminal bock CN7 on the board as illustrated in

Figure 1.

---> for the additional chronothermostat – modem connect terminals 9-10 directly to terminal bock CN7 on the board as illustrated in

Figure 1.

Contacts are defined as "CLEAN" contacts and they must never be fed with 220 V. It is strictly prohibited to supply any tension

whatsoever to the above-mentioned terminals as this would permanently damage the control board; such damage is not covered by

WARRANTY.

LEGENDA KEY

Cronotermostato (optional) Chronothermostat (optional)

(morsetti 9-10 Morsettiera CN7) (terminals 9-10 Terminal block CN7)

Termostato ambiente (optional)

Room thermostat (optional)

(morsetti 7-8 Morsettiera CN7)

(terminals 7-8 Terminal block CN7)

7.1 OPERATING WITH THE ADDITIONAL ROOM TEMPERATURE THERMOSTAT (not supplied)

An additional room temperature thermostat can be installed by connecting it to the board as indicated in Figure 1. The operating

principle is as follows:

-When the room temperature reaches the set temperature (only during the WORK phase) the thermostat closes the contact and the

appliance shifts to the minimum room fan speed and minimum combustion power. This condition is indicated on the display by the

blinking ventilation bar and combustion bar: the appliance ignores all commands transmitted to it. By using the room temperature

thermostat the appliance does not shut down, therefore electrical energy consumption is kept to the minimum and the appliance

has a longer life. -When the room temperature drops the thermostat opens the contact and the appliance returns to its original

position in terms of thermal power and ventilation. In this position the appliance can be started up automatically via the

programming.

CAUTION: Use N.O. (normally open) contacts for the connection to the additional room temperature thermostat.

The thermostat must have a thermal hysteresis that is not less than 2°C.

1

2

1

3

2

4

MORSETTIERA CN7

2

3

1

121011

9 78 6

( morsetti 9 - 10 Morsettiera CN7)

Cronotermostato (optional )

( morsetti 7-8 Morettiera CN7)

Termostato ambiente (optional )

245 3

1

8

5

6

7

10

9

Figura 1

Page 30

Page 30

manutenzione

7.2 OPERATING WITH THE ADDITIONAL CHRONOTHERMOSTAT (not supplied)

As an alternative to the room temperature thermostat, a chonothermostat can be installed by connecting it to the board as indicated

in Figure 1. Using this output when the chronothermostat contact closes the START cycle begins, whereas when the contact opens

the OFF cycle begins. The operating level at start up (combustion power - fan speed) is the same as the level used before the last

time the appliance shut down.

CAUTION: when using the chronothermostat program up to a maximum of 3 on-off cycles without setting the desired

target temperature or set it at the highest possible value for the chronothermostat.

At the end of the preset time the contact will open and perform the appliance shut down process. Similarly at the preset startup time

the contact will close and initiate the START cycle. The chronothermostat can be used to program start up and shut down times and

dates for the appliance. It is therefore possible to program a momentary shut down of the appliance according to the preset time.

Do not shut down the appliance according to the room temperature.

It is mandatory to deactivate the “Crono” symbol on the display (see para. 5.3) if an external chronothermostat is used.

CAUTION: The manufacturer denies all responsibility for the life of the electrical heater if subjected to excessive start ups.

It is recommended not to set the desired room temperature or to set it at the highest possible value for the

chronothermostat in order to avert this danger.

CAUTION: Use N.O. (normally open) contacts for the connection to the chronothermostat.

CAUTION: In the event of connections to the chronothermostat Thermorossi shall not be held responsible for the

appliance not starting up, smoke leaks, breakage of the lighting component. In the event of a programmed cycle on always

ensure that the brazier is clean and seated correctly in its lodging. A maximum of 3 on-off cycles per day are permitted.

The chronothermostat must have a thermal hysteresis that is not less than 2°C.

8 - CLEANING AND MAINTENANCE

8.1 FOREWORD

Before commencing any operation disconnect the appliance from the electric power outlet. Your pellet appliance needs

maintenance; it requires a few simple, basic but frequent control and general cleaning operations. This will guarantee

consistently smooth operation and optimal efficiency of the appliance. In the event of prolonged non-use of the product it

is mandatory to check for obstructions in the smoke channel and flue outlet before putting it back into use. It is

necessary to accurately follow the directions given below: otherwise severe damages may occur for the product, the

installation, objects and the people who use the generator. Failure to observe cleaning and maintenance instructions will

immediately void the warranty . Warning: do not wet the appliance and do not touch the electrical parts with wet hands.

Never vacuum hot ash: this could damage the vacuum device. All the cleaning operations described in this manual must

be carried out when the appliance is cold.

8.2 CLEANING AND MAINTAINING THE APPLIANCE

The cleaning and maintenance operations can be carried out by

the user.

EVERY DAY clean out all the combustion residues from the

brazier B and remount the brazier B and catalyst A correctly (figure

2, 2A, 2B). To open and close the door use the tool provided (see

para. 4.5). (Figure 2A shows a clean brazier) CAUTION: make

sure, before every start up, that the brazier is clean and if

necessary also thoroughly clean the burner with a suction unit. To

guarantee correct operation of the appliance, carefully clean the

area around the spark plug:this will guarantee the correct operation

of the appliance.

EVERY 3 DAYS lift and drop the tube scraper rods several times

(figure 1); to access the tube scraper rods you need to firstly

remove the tank cover.

EVERY 5 DAYS clean the room air filter located at the back of the

appliance (figure 6).

EVERY WEEK clean out all the ash from the ash pans V and V1

(figure 2B and figure 3): to access the compartment V simply lift

out the brazier B and the catalyst A.

EVERY 2 WEEKS clean the smoke exhaust "T" at the appliance

inlet .

EVERY MONTH inspect and clean the vents identified as "A1"

Figura 1

Page 31

Page 31

manutenzione

(figure 5). To access the vents open the door, remove the

ash pan and lift up the cover.

EVERY MONTH check that the smoke exhaust is free

from fly ash deposits, particularly in the initial sections.

EVERY MONTH vacuum the ash deposited on the

bottom of the tank (when the tank is empty).

EVERY 3 MONTHS clean the smoke channels and check

that they are airtight.

TWICE A YEAR clean the flue outlet and inspect the

smoke exhaust pipe for airtightness.

TWICE A YEAR remove the back of the combustion

chamber (figure 4A, 4B, 4C) to clean it by lifting and

rotating it outwards.

AT THE END OF THE WINTER SEASON OR

WHENEVER NECESSARY thoroughly clean the

appliance firebox, using brushes and vacuum cleaner.

A vacuum device simplifies the cleaning procedure. Use

a damp cloth or a scrunched up piece of newspaper,

dampened and rolled in the ash, to wipe the glass until it

is perfectly clean. Do not clean the glass while the

appliance is operating. The glass remains reasonably

clean if the catalyst - deviator blade is installed correctly

in the brazier as shown in figure 5A. The front profiles,

the glass elements and the casing must be cleaned,

when the appliance has cooled, with a special soft

microfibre cloth for delicate surfaces such as lenses,

glasses, monitors, etc..., and water. CAUTION: a daily

deposit of soot and combustion residues on the glass is

quite normal.

It is normal for the ash to fall to the floor when the door is

opened. CAUTION: after cleaning it is mandatory to

carefully check that the combustion chamber door is

firmly closed and airtight. CAUTION: the smoke channel

and flue outlet generator must be cleaned in accordance

with the specifications described above and use of

inflammable products is strictly forbidden: using

inflammable products can create dangerous situations.

Failure to carry out the necessary maintenance or if only

partial maintenance is carried out will affect the correct

functioning of the appliance. Any problems resulting from

total or partial lack of maintenance will immediately void

the warranty. CAUTION: if the appliance remains inactive

(not used for over a month) the appliance, the smoke

discharge tube and the flue outlet must be thoroughly

cleaned and checked for any possible obstructions (e.g.

birds nests) before restarting.

Figura 2

A

B

Figura 2 A

A

B

Page 32

Page 32

manutenzione

Figura 2 B

B

A

V

Figura 3

V1

Page 33

Page 33

manutenzione

Figura 4A

Figura 4 B

Page 34

Page 34

manutenzione