THERMOROSSI BOSKY CHEF Fiori, BOSKY CHEF-F Fiori, BOSKY CHEF Vintage, BOSKY CHEF-F Vintage Installation, User & Service Manual

1

THERMOROSSI

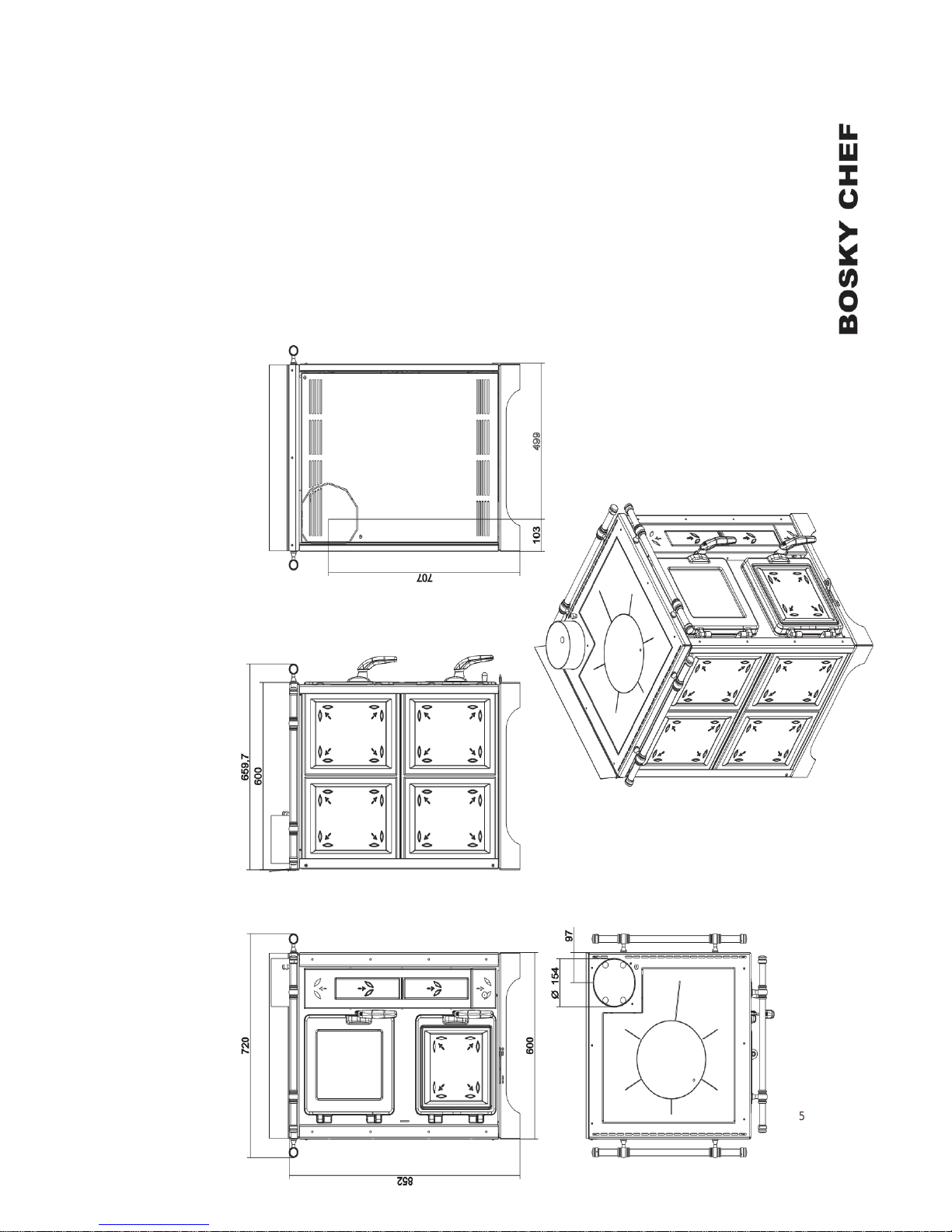

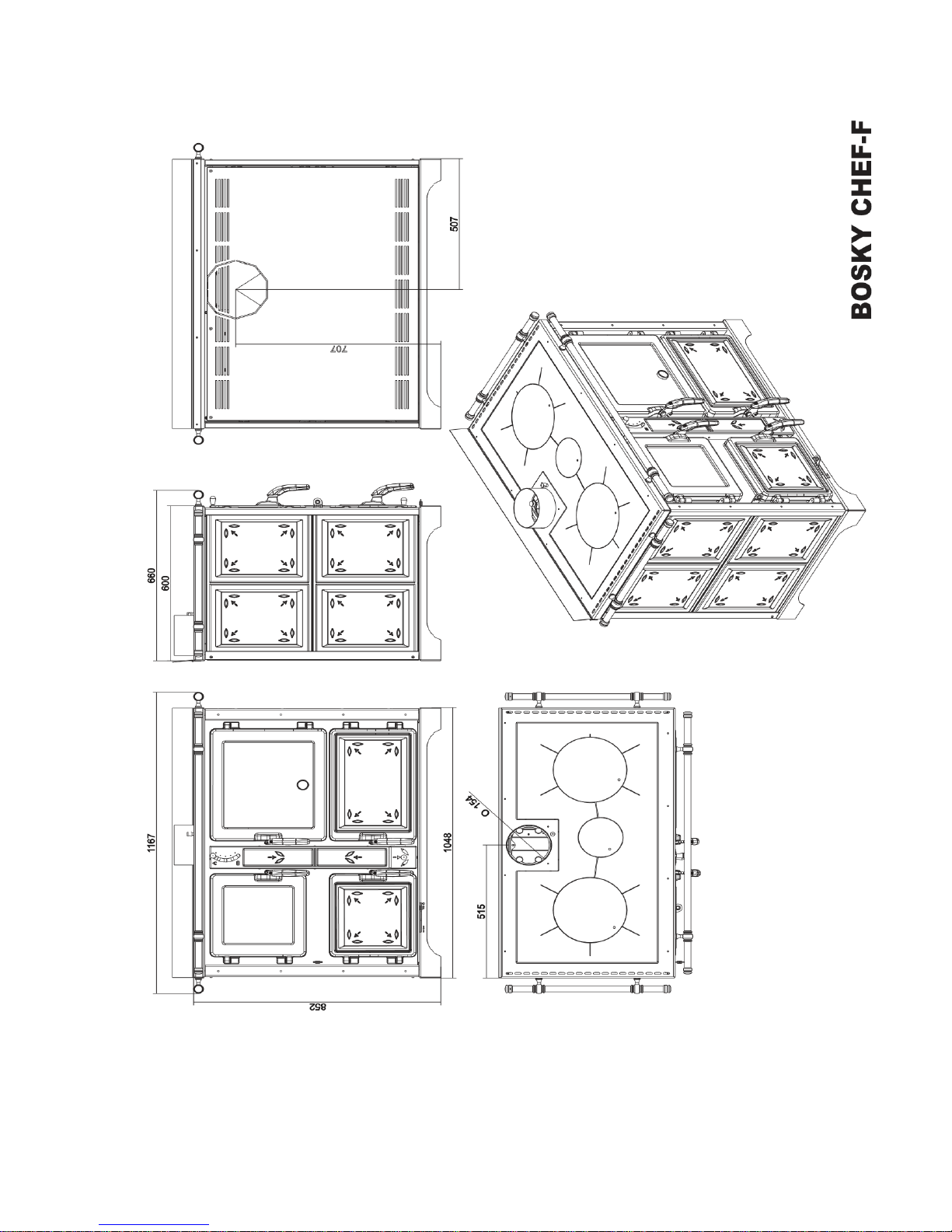

CHEF, CHEF F

INSTALLATION, USER &

SERVICE MANUAL

VER 1 10/2015

THERMOROSSI UK, BLYTH ROAD, HARWORTH, DONCASTER UK DN11 8NE -

tel. (0044) 1302742520 fax 01302 750573

EMAIL - technical@thermorossi.co.uk

www.thermorossi.co.uk

2

C O N T E N T S

DECLARATION OF CONFORMITY

1. INTRODUCTION ...................................................................................................................................

1.1 General guidelines...................................................................................................................................

1.2 Safety guidelines .....................................................................................................................................

1.3 Standards and recommendations ...................................................................................................

1.4 Transport and storage .............................................................................................................................

2. TECHNICAL CHARACTERISTICS .........................................................................................................

3. GENERAL DESCRIPTION.........................................................................................................

3.1 Operating principle ..........................................................................................................................

3.2 Wood fuel............................................................................................................................................

4. INSTALLATION ......................................................................................................................................

4.1 Locating your cooker. ...........................................................................................................

4.2 ............................................................................................................

4.3 Installation of casing for Chef & Chef F. .................................................................

5. OPERATION ..........................................................................................................................................

5.1 Description of parts and main controls of the chef & chef F ...........................................

5.2 Lighting and starting the cookers ............................................................................................................

5.3 Operation of the cookers .......................................................................................................................

5.4 How to use the oven in cookers

6. CLEANING AND MAINTENANCE .........................................................................................................

6.1 General cleaning.....................................................................................................................................

6.2 Ash ............................................................................................................................................

6.3 How to clean the hot plate ....................................................................................................................

Recommendations ............................................................................................................................

7. Flue…………………….......................................................................................................................

7.1 General. ............................................................................................................................................

7.2 Essential requirements for the chimney cap ...................................................................................

7.3 Ventilation of the rooms ................................................................................................................

7.4 Connection with the flue outlet...............................................................................................................

8. TROUBLESHOOTING .....................................................................................................

9. Problems, causes and remedies for chef, chef F cookers .......................................................

10. SPARE PARTS ......................................................................................................................................

3

DICHIARAZIONE DI CONFORMITA'

DECLARATION OF CONFORMITY

La THERMOROSSI S.P.A., VIA GRUMOLO N° 4 36011 ARSIERO (VI), sotto la sua esclusiva

responsabilità DICHIARA che l’apparecchiatura descritta in appresso: DECLARES that the product:

Descrizione

Description

Cucina a legna

Wood Cooker

Marchio

Trademark

THERMOROSSI

S.P.A.

DICHIARAZIONE DI PRESTAZIONE

DECLARATION OF PERFORMANCE

Dichiarazione di prestazione in accordo con il Regolamento (UE)

EN.12815-2001 Declaration of performance according to Regulation

(EU) EN.12815-2001/A1.2004

Modelli Models

CHEF, CHEF F

Ultime due cifre dell’anno in cui è affissa la marcatura CE 11

Last two figures of the year of the CE marking

Luogo Arsiero

Place

Data 8 Novembre 2011

Date

Firma

Sign

THERMOROSSI S.p.A.

4

1 INTRODUCTION

1.1 GENERAL GUIDELINES

This installation, use and maintenance guide is an integral and essential part of the product and must

be kept by the user. Before commencing with the installation, use and maintenance of the product,

carefully read all the instructions contained in this booklet. This appliance must only be used as

intended by the manufacturer. Any other use is considered incorrect and therefore hazardous;

consequently, the user shall be totally liable for the product if used improperly.

Installation, maintenance and repairs must be carried out by personnel with professional qualifications

and in compliance with current regulatory standards and in accordance with the instructions of the

manufacturer of the appliance. Use only original spare parts. Incorrect installation or poor

maintenance could injure or damage people, animals or things; in this case the manufacturer shall be

relieved of all responsibility. Before commencing any cleaning or maintenance operation ensure that

the appliance has been disconnected from the mains power supply by means of the main system

switch or some other disconnecting device installed upstream from the appliance. The product must

be installed in locations suitable for fire-fighting and furnished with all the services (power and outlets)

which the appliance requires for a correct and safe operation. If the appliance is sold or transferred to

another user ensure that the guide is handed over with it.

Thermorossi S.p.A. maintains the author’s rights on these service instructions. The information in this

booklet may not be reproduced or given to third parties or used for competitive purposes without the

appropriate authorization.

1.2 SAFETY GUIDELINES

PERSONAL INJURY

This safety symbol identifies important messages throughout the manual. When you come across this

symbol, read the following message carefully. Users of the cooker must adhere strictly to

the instructions to avoid serious injury.

DAMAGE TO PROPERTY

This safety symbol identifies messages or instructions that are essential for the correct

operation of the cooker and heating system. These guidelines must be observed to avoid

serious damage to both the cooker and the heating system.

INFORMATION

This safety symbol instructions are important for the good operation of the cooker/heating

system. The appliances will not function correctly if the instructions are not observed correctly.

1.3 STANDARDS AND RECOMMENDATIONS

•Normative references: national and international standards used as reference guides for the

design, industrialization and production of the products indicated in this manual

– European Directive 73/23/EEC – standard CEI 61/50

- European Directive 93/68/EEC – standard CEI EN 60204 – European Directive

89/336/EEC – standard CEI64-8 (IEC364) EN 12815 : 2001 , EN 12815 : 2001 / A1:2004

– RECOMMENDATIONS:

Before using the appliance, carefully read every section of this instruction manual as knowledge of

the information and the regulations contained in it are essential for a correct use of the appliance.

The entire operation concerning the connection of the electric panel must be carried out by expert

personnel; no responsibility will be accepted for damages, even to third parties, if the instructions for

installation, use and maintenance of the appliance are not followed scrupulously.

Modifications made to the appliance by the user or on his behalf, must be considered to be under his

complete responsibility.The user is responsible for all the operations required for the installation and

maintenance of the appliance before and during its use.

1.4 TRANSPORT AND STORAGEPackaging The products are packaged in a

wooden crateTransport and handling The cooker must be kept in a vertical position and moved

exclusively by means of trolleys; take particular care not to damage the glass components.Storage

The cooker must be stored in humid free environments sheltered from the weather; it is inadvisable to

store the cooker directly on the floor. Thought must be given to the flooring as damage cannot be

responsible to Thermorossi.

5

6

7

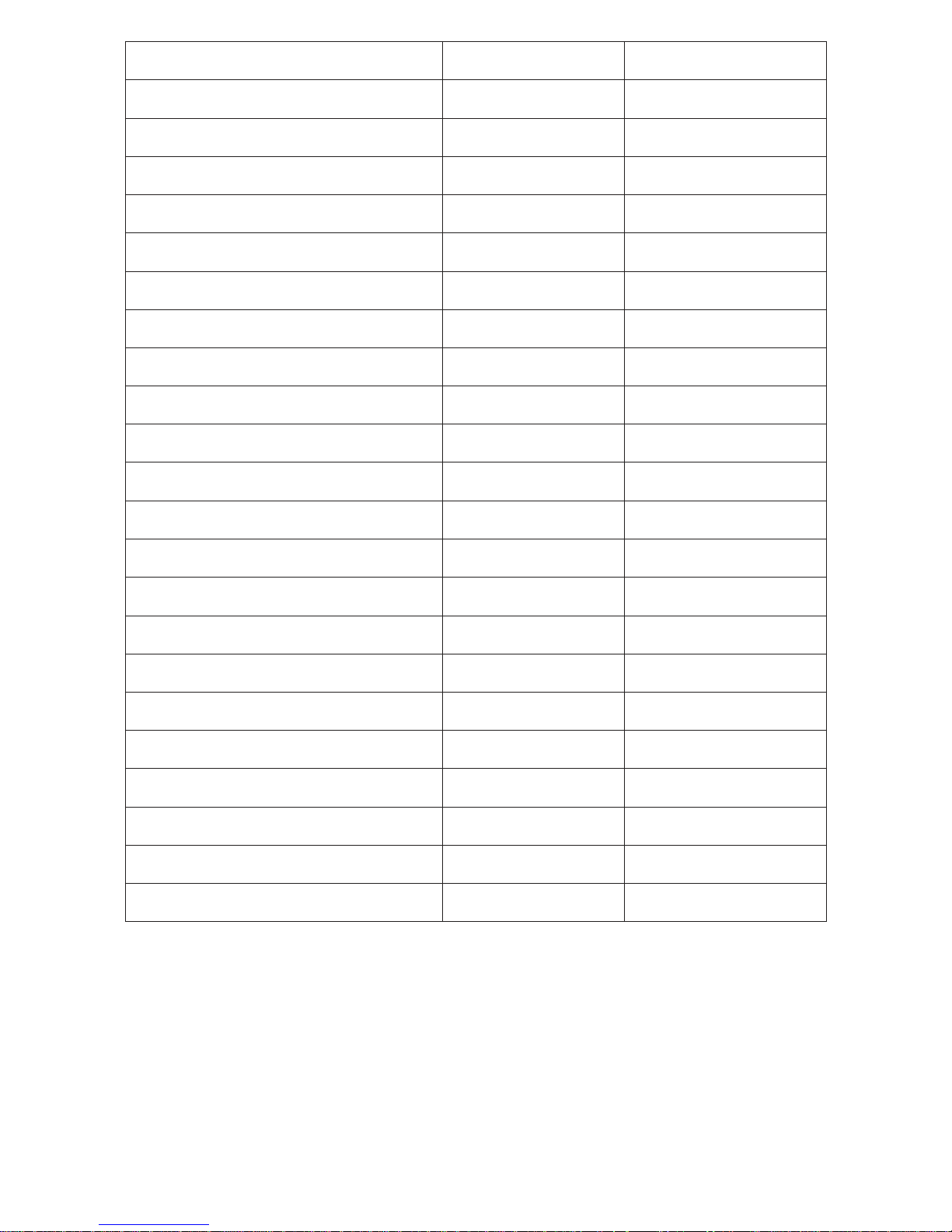

The performance values are from two beech logs totalling 3.7kg where the calorific value was 15.953

kj/kg with a moisture content of 9%. Using wood with different specifications to this will directly effect

performance, efficiency, ash formation, glass cleanliness and general dirtiness..

CHEF FIORI

CHEF F FIORI

HEIGHT (mm)

852

852

DEPTH ( mm)

667

667

WIDTH ( mm)

600

1048

WEIGHT ( Kg )

247

330

FLUE DIAMETER ( mm)

Ø150

Ø150

MINIMUM FLUE DRAUGHT (Pa)

12

12

MAXIMUM POWER (kW )

16.4

16.4

MAXIMUM POWER (Btu)

56000

56000

NOMINAL POWER (KW)

12

12

NOMINAL POWER (Btu)

41000

41000

EFFICIENCY %

73.4

73.4

EMISSIONS CO (mg/m³ AT 13% O )

939.6

939.6

TOP OVEN DEPTH mm

515

TOP OVEN WIDTH mm

340

TOP OVEN HEIGHT mm

320

TOP OVEN CAPACITY LT

56

BOTTOM OVEN DEPTH mm

530

BOTTOM OVEN WIDTH mm

350

BOTTOM OVEN HEIGHT mm

200

BOTTOM OVEN CAPACITY LT

37

MAXIMUM ALLOWED FUEL PER HOUR KG

3.7

3.7

HOTPLATE DIMENSIONS MM

480 x 480

930 x 480

8

The performance values are from two beech logs totalling 3.7kg where the calorific value was 15.953

kj/kg with a moisture content of 9%. Using wood with different specifications to this will directly effect

performance, efficiency, ash formation, glass cleanliness and general dirtiness..

CHEF VINTAGE

CHEF F VINTAGE

HEIGHT (mm)

852

852

DEPTH ( mm)

667

667

WIDTH ( mm)

680

1119

WEIGHT ( Kg )

251

332

FLUE DIAMETER ( mm)

Ø150

Ø150

MINIMUM FLUE DRAUGHT (Pa)

12

12

MAXIMUM POWER (kW )

16.4

16.4

MAXIMUM POWER (Btu)

56000

56000

NOMINAL POWER (KW)

12

12

NOMINAL POWER (Btu)

41000

41000

EFFICIENCY %

73.4

73.4

EMISSIONS CO (mg/m³ AT 13% O )

939.6

939.6

TOP OVEN DEPTH

515

TOP OVEN WIDTH

340

TOP OVEN HEIGHT

320

TOP OVEN CAPACITY LT

56

BOTTOM OVEN DEPTH

530

BOTTOM OVEN WIDTH

350

BOTTOM OVEN HEIGHT

200

BOTTOM OVEN CAPACITY LT

37

MAXIMUM ALLOWED FUEL PER HOUR KG

3.7

3.7

HOTPLATE DIMENSIONS MM

480 x 480

930 x 480

9

GENERAL DESCRIPTION

3.1 OPERATING PRINCIPLE

•Your cooker has been constructed to satisfy in full all your cooking needs.

3.2 THE FUEL

CORRECT use of appliance when using wood fuel

For anyone interested in wood burning, there is much to learn; in the following text you will find

guidance and information on the subject.

Before installing or using a wood burning appliance, carefully read the installation procedure or if you

are in any doubt as to the soundness of your chimney, call us and we will be pleased to advise you.

ALL WORK MUST COMPLY WITH CURRENT BUILDING REGULATIONS or local applicable

legislation.

1-1 GOOD WOODBURNING TECHNIQUE

If wood is burned at high temperatures a more complete combustion occurs, complete combustion

means that most of the volatile hydrocarbons locked in the wood are released in the form of heat

generally displayed as long yellow flame combustion.

The higher the combustion chamber temperature, the more complete the combustion process.

1-2 BAD WOOD BURNING technique

If wood is burned at low temperatures then very little is achieved and incomplete combustion occurs.

Incomplete combustion is typified by wood tar deposits all over the internals of the firebox, flue ways

and door glass.

The lower the combustion chamber temperature, the worse the combustion and the greater the build

up of wood tar.

In really bad cases, wood tar can drip from the appliance.

GOOD wood burning technique increases the efficiency of the burn process.

BAD wood burning technique decreases the efficiency of the burn process.

GOOD wood burning technique decreases your running costs.

BAD wood burning technique increases your running costs.

GOOD wood burning technique increases the life expectancy of the COOKER.

BAD wood burning technique decreases the life expectancy of the COOKER.

GOOD wood burning technique results in a clean appliance and chimney.

BAD wood burning technique results in a tar covered appliance and chimney.

Below is an example of tar build up that caused excessive damage when the chimney caught

fire – totally preventable!

10

1-3 loading and running the appliance

The fire is ignited in the usual way and air is automatically admitted through the air inlet flap controlled

by the relevant setting of the thermostat knob.

When the fire is established, build it up slowly by adding a small quantity of wood, take care not to

put too much wood on at once otherwise this will :-

Kill the fire.

Reduce the firebox temperature.

Create smoke.

Cause tarring.

Cause condensation.

When the combustion chamber is up to a high enough temperature, the wood oil starts to vaporise

from the wood, and creates long yellow flames.

Secondary air is drawn in to mix with these flames and this further improves the combustion.

As the wood fuel burns away it slowly decomposes leaving a light grey coloured ash.

As is the case with all fires, if it is allowed to die down too much, it will not be possible to recover it.

Try to keep topping the firebox up regularly but do not overload it so as to kill the temperature of it.

If you need to keep the appliance in for longer periods of time try topping it up with smokeless fuel

otherwise let it go out and re light it.

If your wood has a moisture content above 25%, it would an idea to mix it with expensive kiln dried

wood (which is normally sub 10% moisture) to make sure the average burning is well below 20%

moisture.

11

Do not burn general waste or various plastics, but above all never use gasoline or flammable liquids.

In the case of use of briquettes it is required to halve the fuel consumption.

2. ABOUT WOOD FUEL

2-1 Do I know how much wood I will need to burn?

Roughly 1 lb of wood equals 1Kw of energy; therefore if you need 10Kw of energy per hour you are

going to have to burn about 10 lbs of wood per hour.

Pine and Oak have different density therefore a tonne of Pine will take up substantially more volume

than a tonne of Oak.

If you work out how many Kilowatt hours are required to keep your property warm then you should be

able to work out the weight of wood required for a seasons heating.

2-2 Do I have a reliable and proven supplier of wood and do I know the cost?

Once you have established your seasons requirement you can order your supplies from a local wood

fuel supplier.

2-3 Do I know how to store the wood?

Before any wood is burnt, it should have a moisture content of no more that 20%.

This can be achieved by drying outdoors for 12 months and then under cover for the second 12

months assuming that the wood has been cut, split and stored in such a way as to allow adequate air

to circulate through the wood pile.

Ash is an exception to this rule as it can be cut early in the year and (providing it is stored correctly)

burned in the autumn.

2-4 equipment to help me get the best from my wood burning appliance

There are many factors which will affect the running of your wood burning appliance but the most

common problems are:-

WET WOOD

RUNNING THE APPLIANCE AT THE WRONG TEMPERATURE

INCORRECT INSTALATION

INCORRECT CHIMNEY

The main problem here is knowing

How do I know that the wood fuel is at the correct moisture content for burning?

How do I know if I am burning the wood at the correct temperature?

12

Two pieces of equipment will help here, a moisture meter will tell you what the moisture content of

your wood is and a stove top thermometer will tell you what temperature your appliance is running at.

Both of these are available from us.

COAL

Firstly and most importantly we must say that you cannot burn coal on any appliance in a

smoke controlled area unless the appliance is specially designed and approved according to

statutory requirements.

If you wish to burn ordinary house coal on a chef or chef F you need to know how to do it, and that the

chef or chef F has the necessary design features. Do not use petrocoke as this will damage the

appliance.

The main problems are nearly always caused by: Putting too much coal on a fire which is almost out and then opening the ash pan door to increase the

draw.

Running the appliance at too low a temperature causing the fire to smoulder continuously.

Not riddling the fire often enough so preventing the required amount of combustion air reaching the

fire

If you put masses of coal on a low fire and then open the bottom ash access door, the result will be

that the fire will produce too much smoke which cannot burn or which when it bursts into flames will

cause a small explosion in the firebox and also up the chimney, the latter being particularly

dangerous.

The name of the game is to keep your fire burning healthily. Build it up with small amounts regularly

rather than large amounts infrequently and use coal no smaller than doubles. Cobbles are better

because they allow plenty of air to get around the firebox.

When loading the fire with a fresh change of coal, if it is possible rake the hot or glowing embers to

the front of the firebox and pout the new coal to the back. In this way the new coal will burst into

flames more quickly and the bright embers will encourage the smoke to ignite quickly.

Slack, shale, singles or small fuel will simply stop air getting through and cause the sooting and

exploding problems, which are to be avoided. Regular riddling is of prime importance, as mentioned

earlier.

If you get it wrong - you will normally do it in the first week or month. In some cases the result can be

a blocked chimney in less than a week. The part of the chimney, which blocks up first, will be the pipe

connecting the cooker to the chimney. This pipe must be as near vertical as possible for coal burning.

Rear outlet flues or bends are to be avoided at all costs, according to building regulations the

minimum angle a flue pipe can run is 45 dg., although we think a minimum of 60 dg is better.

Regular cleaning of the appliance and the chimney is essential the frequency of such cleaning would

be established by experience but we would think once every 6 weeks would be adequate.

13

4 INSTALLATION

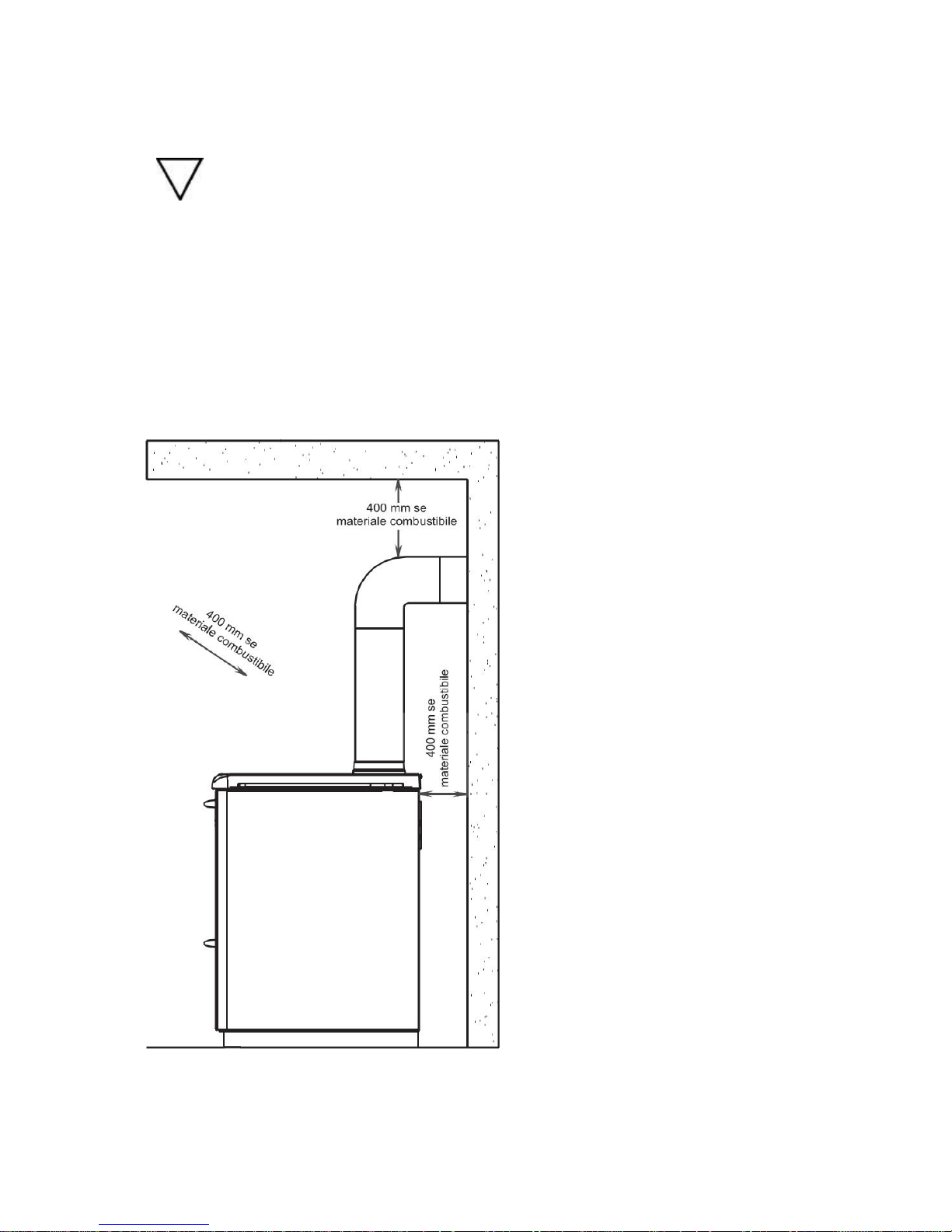

4.1 LOCATING THE COOKER

A vital aspect to consider is that the flooring of the room in which the cooker is installed

must be capable of bearing the weight of the cooker.

CAUTION: The room in which the cooker is installed must be adequately ventilated (1300 m3/h).

Ensure that there is always a minimum 75mm safety gap between the cooker and walls or

combustable materials. Inflammable items are positioned near the cooker (matchboarding,

furniture, curtains, wall hangings, sofas, etc...), this gap must be increased considerably. Adhere to

the recommended minimum distances illustrated in the drawing below. It is permissible to install the

heater near materials that are sensitive to heat as long as suitable insulating protection is placed

between the material and the heater (ref. UNI 10683).

For inset installations ensure that the top cast iron cornice is insulated from the surrounding

furnishings by means of lateral air spaces or compressed vermiculite insullation board

Loading...

Loading...