THERMOROSSI BellaVista R silent, BellaVista R plus Installation, Use And Maintenance Manual

Page 1

Page 2

Page

1

Installation, use and maintenance guide

BellaVista™ R Silent - BellaVista™ R Plus

Page 3

Page

2

Manuale d'installazione, uso e manutenzione guide

BellaVista™ R Silent - BellaVista™ R Plus

INDEX

1 - INTRODUCTION .................................................................................................................................. 9

1.1 GENERAL GUIDELINES .................................................................................................................................. 9

1.2 SAFETY GUIDELINES ..................................................................................................................................... 9

1.3 RECOMMENDATIONS ..................................................................................................................................... 9

1.4 GENERAL GUIDELINES .................................................................................................................................. 9

1.5 TRANSPORTATION AND STORAGE ............................................................................................................ 10

1.6 GUIDELINES FOR CORRECT DISPOSAL OF THE PRODUCT ................................................................... 10

2 – TECHNICAL CHARACTERISTICS.....................................................................................................11

3 – GENERAL DESCRIPTION .................................................................................................................12

3.1 OPERATING TECHNOLOGY ......................................................................................................................... 12

3.2 THE PELLET ................................................................................................................................................... 12

3.3 PELLET REFUELLING .................................................................................................................................. 12

4 - INSTALLATION ..................................................................................................................................13

4.1 APPLIANCE LOCATION ................................................................................................................................. 13

4.2 UNPACKING THE APPLIANCE ..................................................................................................................... 13

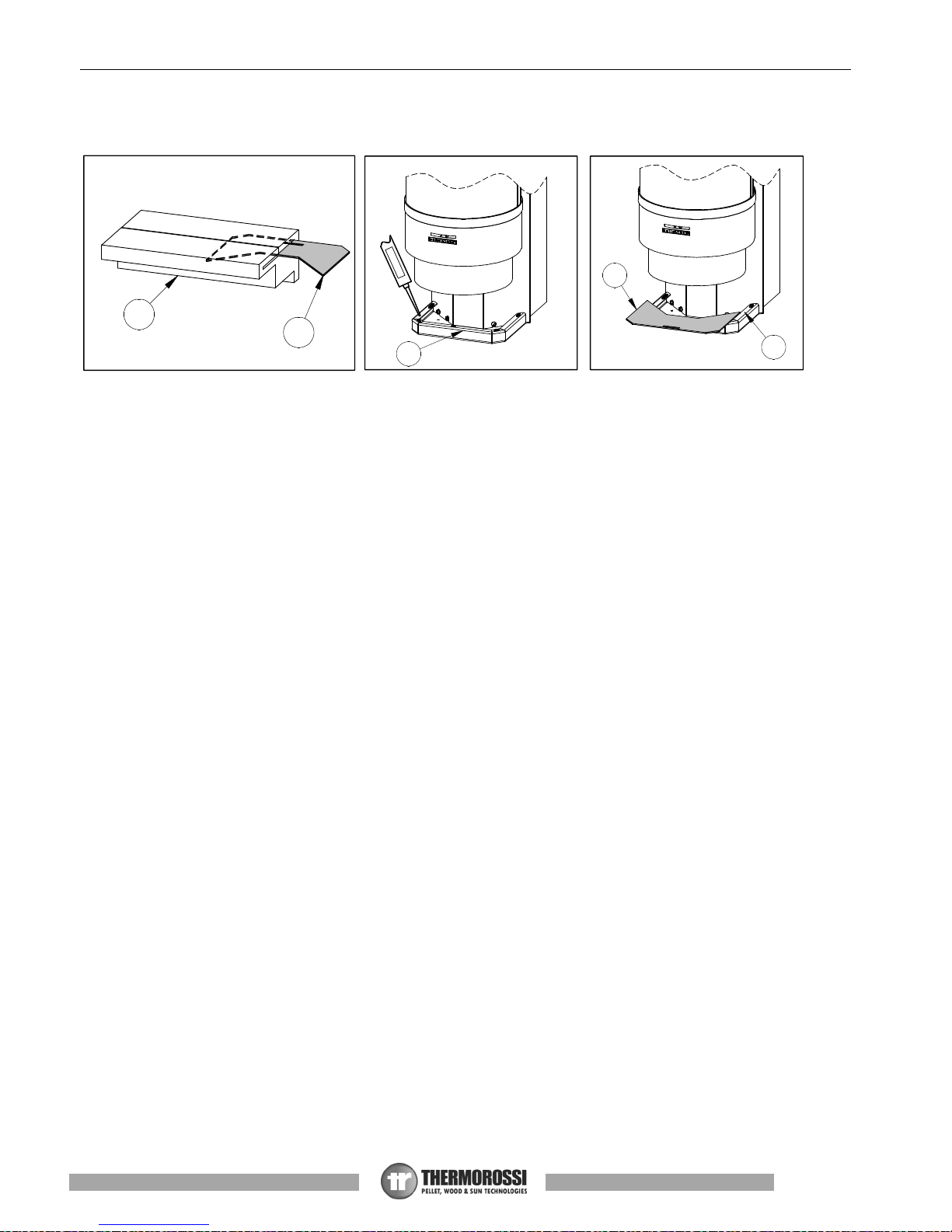

4.3 INSTALLATION OF GLASS ON BASE........................................................................................................... 14

4.4 RELOCATION OF THE CONTROL PANEL ................................................................................................... 15

4.5 INSTALLATION OF AIRBOX 3 VENTILATION KIT (OPTIONAL) .................................................................. 16

4.6 HANDLE .......................................................................................................................................................... 17

4.7 OPENING THE SLIDING DOOR OF THE COMBUSTION CHAMBER ......................................................... 18

4.8 DRAWING COMBUSTION AIR FROM OUTSIDE .......................................................................................... 18

5 – DESCRIPTION OF THE CONTROLS .................................................................................................19

5.1 DESCRIPTION OF THE CONTROL PANEL .................................................................................................. 19

5.2 DESCRIPTION OF THE POWER PANEL ...................................................................................................... 20

5.3 DATE/TIME: SETTING THE DATE AND TIME .............................................................................................. 21

5.4 CHRONO: ON/OFF PROGRAMMING ............................................................................................................ 21

5.5 LEVEL: OPERATING LEVEL SETTING ......................................................................................................... 23

5.6 THERMOCOMFORT: CONNECTION WITH THE HANDHELD CONTROL (OPTIONAL) ............................ 24

6 - OPERATION OF THE HANDHELD CONTROL THERMOCOMFORT (OPTIONAL) ...........25

6.1 INDICATORS OF THE HANDHELD CONTROL ............................................................................................ 25

6.2 USE OF THE HANDHELD CONTROL ........................................................................................................... 26

6.3 TRANSMISSION CODES SETTINGS ............................................................................................................ 27

6.4 CARE AND MAINTENANCE OF THE HANDHELD CONTROL..................................................................... 27

7 – USE OF THE APPLIANCE ............................................................................................................28

7.1 DESCRIPTION OF THE OPERATING STAGES ........................................................................................... 28

7.2 SWITCHING ON THE STOVE ........................................................................................................................ 28

7.3 COMBUSTION AND VENTILATION ADJUSTMENTS ................................................................................... 28

7.4 INFRARED REMOTE CONTROL ................................................................................................................... 28

7.5 CHANNELLING ............................................................................................................................................... 29

7.6 SWITCHING OFF THE APPLIANCE .............................................................................................................. 29

8 – ROOM TEMPERATURE THERMOSTAT / CHRONOTHERMOSTAT (optional) ................30

8.1 OPERATING WITH THE ADDITIONAL ROOM TEMPERATURE THERMOSTAT (not supplied) ................ 31

8.2 OPERATING WITH THE ADDITIONAL CHRONOTHERMOSTAT (not supplied) ......................................... 31

Page 4

Page

3

Installation, use and maintenance guide

BellaVista™ R Silent - BellaVista™ R Plus

9 - CLEANING AND MAINTENANCE ...................................................................................................... 32

9.1 FOREWORD ................................................................................................................................................... 32

9.2 CLEANING AND MAINTAINING THE APPLIANCE ....................................................................................... 32

9.3 AIR FILTER ..................................................................................................................................................... 34

9.4 CHARGING THE BATTERY OF THE THERMOCOMFORT HANDHELD CONTROL (optional) .................. 34

9.5 BATTERY REPLACEMENT FOR INFRARED REMOTE CONTROL ............................................................ 35

9.6 REPLACING THE BUFFER BATTERY OF THE CONTROL PANEL ............................................................ 35

10 – SMOKE DISCHARGE TUBE AND VENTILATION OF THE ROOMS .............................................. 36

10.1 FOREWORD ................................................................................................................................................. 36

10.2 ROOM VENTILATION .................................................................................................................................. 36

10.2.1 VENTILATION FROM ADJOINING ROOMS ......................................................................................................................... 36

10.3 SMOKE OUTLET .......................................................................................................................................... 36

10.3.1 CHIMNEY TYPES ................................................................................................................................................................. 36

10.3.2 FLUE OUTLET / FLUE SYSTEM COMPONENTS ................................................................................................................ 37

10.3.3 CONTROLS PRIOR TO INSTALLING THE APPLIANCE ...................................................................................................... 38

11 – ALARMS .......................................................................................................................................... 39

12 - ELECTRICAL WIRING ..................................................................................................................... 40

13 - INFORMATION FOR THE SKILLED TECHNICIAN .......................................................................... 41

13.1 MAIN COMPONENTS AND THEIR OPERATION .................................................................................... 41

13.2 PRESCRIPTIONS FOR CORRECT OPERATION ....................................................................................... 41

13.3 TROUBLESHOOTING CAUSES-SOLUTION .............................................................................................. 42

14 – SPARE PARTS ................................................................................................................................ 44

14.1 SPARE PARTS 1/6 ....................................................................................................................................... 44

14.2 SPARE PARTS 2/6 ....................................................................................................................................... 44

14.3 SPARE PARTS 3/6 ....................................................................................................................................... 45

14.4 SPARE PARTS 4/6 ....................................................................................................................................... 45

14.5 SPARE PARTS 5/6 ....................................................................................................................................... 46

14.6 SPARE PARTS 6/6 ....................................................................................................................................... 46

Page 5

Page

4

Manuale d'installazione, uso e manutenzione guide

BellaVista™ R Silent - BellaVista™ R Plus

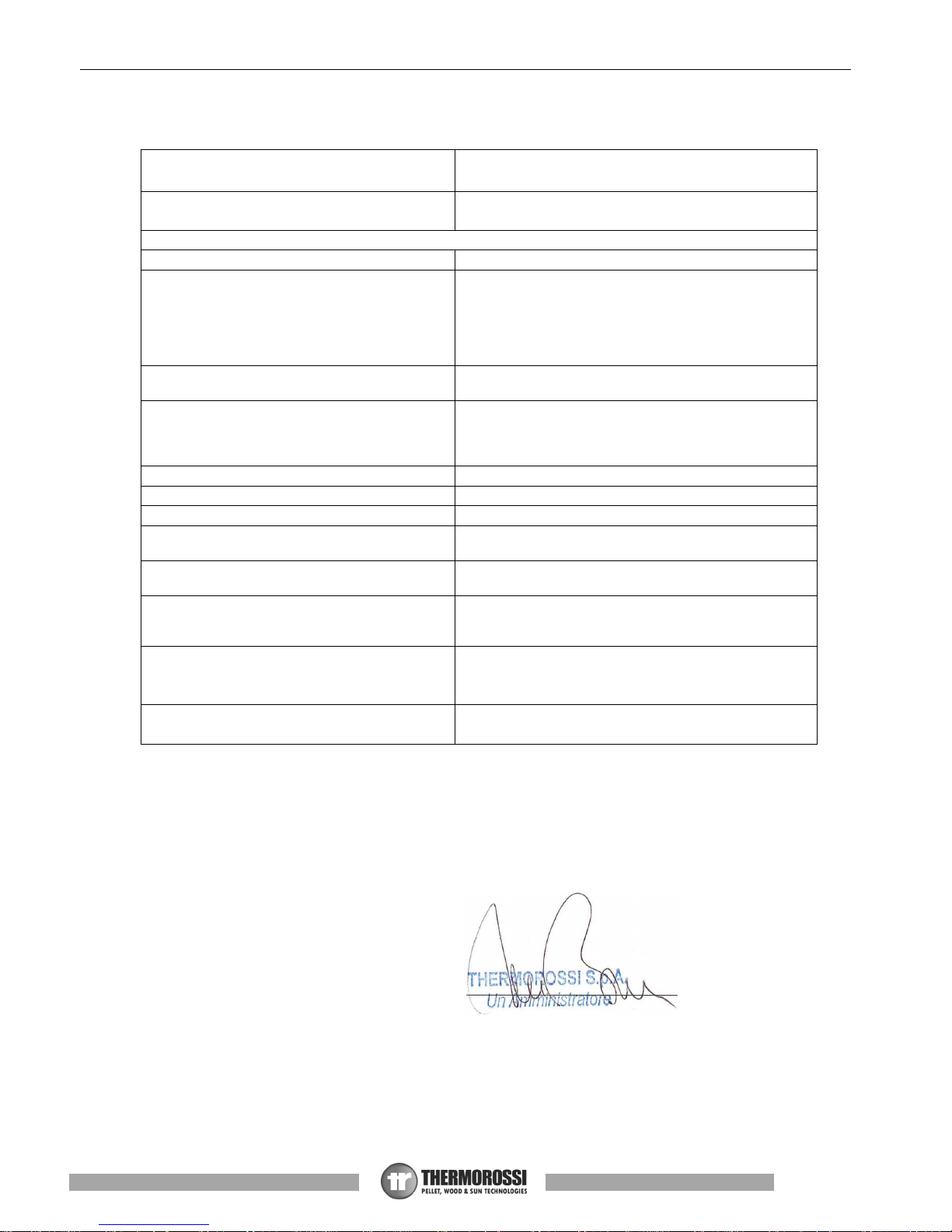

EU Declaration of Conformity (DoC)

Dichiarazione di Conformità UE (DoC)

Company name:

Azienda:

THERMOROSSI S.P.A.

Postal address:

Indirizzo:

VIA GRUMOLO, N° 4

Postcode and city:

Codice postale e città:

36011 ARSIERO (VI)

Telephone number:

Numero di telefono:

0445/741310

E-mail address:

Indirizzo e-mail:

INFO@THERMOROSSI.IT

declare that the DoC is issued under our sole responsibility and belongs to the following product:

dichiara che la dichiarazione viene rilasciata sotto la propria responsabilità e si riferisce al seguente prodotto:

Apparatus model / Product:

Descrizione prodotto:

Stufa a pellet

Pellet stove

Trademark:

Marchio

THERMOROSSI S.P.A.

Model/Type:

Modello/Tipo:

BellaVista™ R Silent

BellaVista™ R Plus

Date/Batch / Serial number:

Data/Numero di serie / di lotto:

L'oggetto della dichiarazione di cui sopra è conforme alla pertinente normativa di armonizzazione dell'Unione:

The object of the declaration described above is in conformity with the relevant Union harmonisation legislation:

•

Direttiva 2014/30/UE, EMCD

•

Direttiva 2014/35/UE, LVD

•

Direttiva 2011/65/UE, RoHS

•

2014/30/EU Directive, EMCD

•

2014/35/EU Directive, LVD

•

2011/65/EU Directive, RoHS

Sono state applicate le seguenti norme armonizzate e/o specifiche tecniche:

The following harmonised standards and/or technical specifications hav been applied:

EN 55014-1

EN 55014-2

EN 61000-3-2

EN 61000-3-3

EN 60335-1

EN 60335-2-102

EN 62233

EN 50581

EN 14785 tests carried out by the notified laboratory Kiwa Cermet Italia S.p.a (N.B. 0476) Viale Venezia, 45 31020

San Vendemiano (TV).

Arsiero, 16/03/2017

Firma/Sign.

Page 6

Page

5

Installation, use and maintenance guide

BellaVista™ R Silent - BellaVista™ R Plus

Dichiarazione di Prestazione

Declaration of Performance

Dichiarazione di prestazione in accordo con il Regolamento (UE) 305/2011

Declaration of performance according to Regulation (EU) 305/2011

N° 70

1

Codice di identificazione unico del prodotto-tipo:

Unique identification code of the product type:

BELLAVISTA™ R SILENT, apparecchio per il riscaldamento domestico, senza acqua,

alimentato a pellet di legno

BELLAVISTA™ R SILENT, residential space heating appliance without water fired by wood

pellets

EN 14785:2006

2

Numero di tipo, lotto, serie o qualsiasi altro elemento che consenta l'identificazione del prodotto

da costruzione ai sensi dell'articolo 11, paragrafo 4:

Type, batch or serial number or any other element allowing identification of the construction

product as required under Article 11( 4):

BELLAVISTA™ R SILENT

3

Uso o usi previsti del prodotto da costruzione, conformemente alla relativa specifica tecnica

armonizzata, come previsto dal fabbricante:

Intended use or uses of the construction product, in accordance with the applicable harmonised

technical specification, as foreseen by the manufacturer:

Apparecchio per il riscaldamento domestico, senza acqua, alimentato a pellet di legno

Residential space heating appliance without water fired by wood pellets

4

Nome, denominazione commerciale registrata o marchio registrato e indirizzo del fabbricante ai

sensi dell'articolo 11, paragrafo 5:

Name, registered trade name or registered trade mark and contact address of the manufacturer

as required pursuant Article 11( 5):

THERMOROSSI S.P.A. Via Grumolo, n° 4 36011 Arsiero (Vicenza)

5

Sistema o sistemi di valutazione e verifica della costanza della prestazione del prodotto da

costruzione di cui all'allegato V:

System or systems of assessment and verification of constancy of performance of the

construction product as set out in Annex V:

Sistema 3 e 4 / System 3 and 4

6

Nel caso di una dichiarazione di prestazione relativa ad un prodotto da costruzione che rientra

nell'ambito di applicazione di una norma armonizzata:

In case of the declaration of performance concerning a construction product covered by a

harmonised standard:

L' organismo notificato KIWA CERMET ITALIA S.p.a. N° 0476 ha determinato il prodottotipo in base a prove di tipo secondo il sistema 3 ed ha rilasciato il rapporto di prova 2001795

The notified laboratory KIWA CERMET ITALIA S.p.a. N° 0476 performed the determination

of the product type on the basis of type testing under system 3 and issued test report 2001795

Page 7

Page

6

Manuale d'installazione, uso e manutenzione guide

BellaVista™ R Silent - BellaVista™ R Plus

7

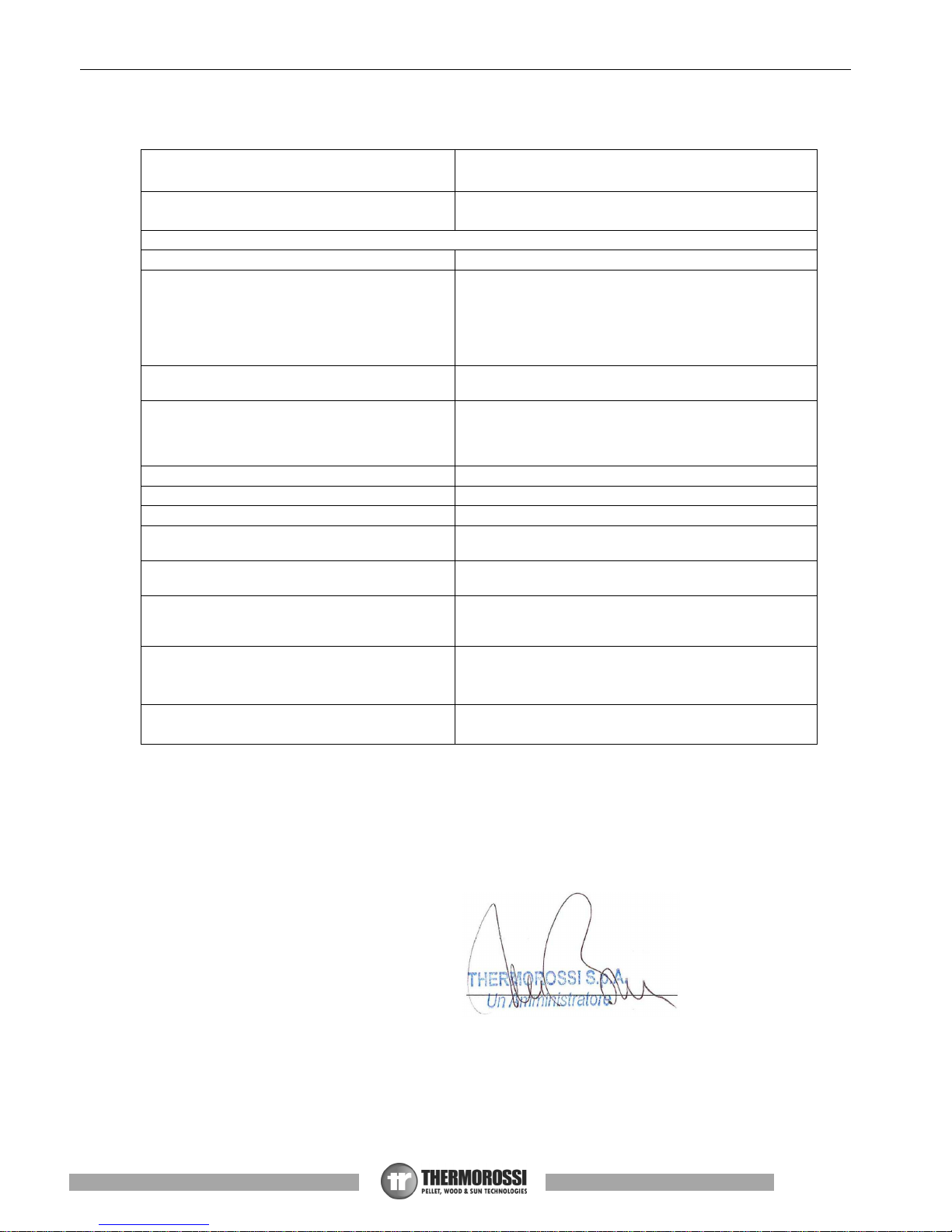

Prestazione dichiarata / Declared performance

Specifica tecnica armonizzata:

Harmonized technical specification:

EN 14785:2006

Caratteristiche Essenziali

Essential characteristics

Prestazione / Performance

Sicurezza antincendio / Fire safety

Reazione al fuoco / Reaction to fire A1

Distanza da materiali combustibili

Distance to combustible materials

Minime distanze / Minimum distances (mm):

posteriore / rear = 200

lati / sides = 400

frontale / front = 1,000

soffitto / ceiling = pavimento / floor = -

Rischio di fuoriuscita di braci incandescenti

Risk of burning fuel falling out

Passa / Pass

Emissione di prodotti della combustione

Emission of combustion products

CO 65.0 mg/m3 Alla potenza termica nominale / Nominal heat

output

CO 429.0 mg/m3 Alla potenza termica ridotta / Reduced heat

output

Temperatura superficiale / Surface temperature

Passa / Pass

Sicurezza elettrica / Electrical safety

Passa / Pass

Pulizia / Cleanability

Passa / Pass

Maximum working pressure

Maximum operating pressure

-- bar

Temperatura fumi a potenza termica nominale

Flue gas temperature at nominal heat output

T 187 °C

Resistenza meccanica (per sopportare un

camino/una canna fumaria)

Mechanical resistance(to carry a chimney/flue)

NPD {Nessuna Prestazione Determinata}

Potenza termica nominale / Nominal heat output 8.98 kW

Potenza termica resa in ambiente / Room heating output 8.98 kW

Potenza termica ceduta all’acqua / Water heating output - - kW

Rendimento

Efficiency

85.36 % Alla potenza termica nominale / Nominal heat output

85.26 % Alla potenza termica ridotta / Reduced heat output

8

La prestazione del prodotto di cui ai punti 1 e 2 è conforme alla prestazione dichiarata di cui al

punto 7. Si rilascia la presente dichiarazione di prestazione sotto la responsabilità esclusiva del

fabbricante di cui al punto 4

The performance of the product identified in points 1 and 2 is in conformity with the declared

performance in point 7. This declaration of performance is issued under the sole responsibility

of the manufacturer identified in point 4

Firmato a nome e per conto del fabbricante da

(nome e funzione)

Signed for and on behalf of the manufacturer

(name and title)

Luogo/Place Data/Date

Arsiero 16/03/2017

Page 8

Page

7

Installation, use and maintenance guide

BellaVista™ R Silent - BellaVista™ R Plus

Dichiarazione di Prestazione

Declaration of Performance

Dichiarazione di prestazione in accordo con il Regolamento (UE) 305/2011

Declaration of performance according to Regulation (EU) 305/2011

N° 70A

1

Codice di identificazione unico del prodotto-tipo:

Unique identification code of the product type:

BELLAVISTA™ R PLUS, apparecchio per il riscaldamento domestico, senza acqua,

alimentato a pellet di legno

BELLAVISTA™ R PLUS, residential space heating appliance without water fired by wood

pellets

EN 14785:2006

2

Numero di tipo, lotto, serie o qualsiasi altro elemento che consenta l'identificazione del prodotto

da costruzione ai sensi dell'articolo 11, paragrafo 4:

Type, batch or serial number or any other element allowing identification of the construction

product as required under Article 11( 4):

BELLAVISTA™ R PLUS

3

Uso o usi previsti del prodotto da costruzione, conformemente alla relativa specifica tecnica

armonizzata, come previsto dal fabbricante:

Intended use or uses of the construction product, in accordance with the applicable harmonised

technical specification, as foreseen by the manufacturer:

Apparecchio per il riscaldamento domestico, senza acqua, alimentato a pellet di legno

Residential space heating appliance without water fired by wood pellets

4

Nome, denominazione commerciale registrata o marchio registrato e indirizzo del fabbricante ai

sensi dell'articolo 11, paragrafo 5:

Name, registered trade name or registered trade mark and contact address of the manufacturer

as required pursuant Article 11( 5):

THERMOROSSI S.P.A. Via Grumolo, n° 4 36011 Arsiero (Vicenza)

5

Sistema o sistemi di valutazione e verifica della costanza della prestazione del prodotto da

costruzione di cui all'allegato V:

System or systems of assessment and verification of constancy of performance of the

construction product as set out in Annex V:

Sistema 3 e 4 / System 3 and 4

6

Nel caso di una dichiarazione di prestazione relativa ad un prodotto da costruzione che rientra

nell'ambito di applicazione di una norma armonizzata:

In case of the declaration of performance concerning a construction product covered by a

harmonised standard:

L' organismo notificato KIWA CERMET ITALIA S.p.a. N° 0476 ha determinato il prodottotipo in base a prove di tipo secondo il sistema 3 ed ha rilasciato il rapporto di prova 2001795

The notified laboratory KIWA CERMET ITALIA S.p.a. N° 0476 performed the determination

of the product type on the basis of type testing under system 3 and issued test report 2001795

Page 9

Page

8

Manuale d'installazione, uso e manutenzione guide

BellaVista™ R Silent - BellaVista™ R Plus

7

Prestazione dichiarata / Declared performance

Specifica tecnica armonizzata:

Harmonized technical specification:

EN 14785:2006

Caratteristiche Essenziali

Essential characteristics

Prestazione / Performance

Sicurezza antincendio / Fire safety

Reazione al fuoco / Reaction to fire A1

Distanza da materiali combustibili

Distance to combustible materials

Minime distanze / Minimum distances (mm):

posteriore / rear = 200

lati / sides = 400

frontale / front = 1,000

soffitto / ceiling = pavimento / floor = -

Rischio di fuoriuscita di braci incandescenti

Risk of burning fuel falling out

Passa / Pass

Emissione di prodotti della combustione

Emission of combustion products

CO 47.0 mg/m3 Alla potenza termica nominale / Nominal heat

output

CO 206.0 mg/m3 Alla potenza termica ridotta / Reduced heat

output

Temperatura superficiale / Surface temperature

Passa / Pass

Sicurezza elettrica / Electrical safety

Passa / Pass

Pulizia / Cleanability

Passa / Pass

Maximum working pressure

Maximum operating pressure

-- bar

Temperatura fumi a potenza termica nominale

Flue gas temperature at nominal heat output

T 151 °C

Resistenza meccanica (per sopportare un

camino/una canna fumaria)

Mechanical resistance(to carry a chimney/flue)

NPD {Nessuna Prestazione Determinata}

Potenza termica nominale / Nominal heat output 10.68 kW

Potenza termica resa in ambiente / Room heating output 10.68 kW

Potenza termica ceduta all’acqua / Water heating output - - kW

Rendimento

Efficiency

86.43 % Alla potenza termica nominale / Nominal heat output

87.90 % Alla potenza termica ridotta / Reduced heat output

8

La prestazione del prodotto di cui ai punti 1 e 2 è conforme alla prestazione dichiarata di cui al

punto 7. Si rilascia la presente dichiarazione di prestazione sotto la responsabilità esclusiva del

fabbricante di cui al punto 4

The performance of the product identified in points 1 and 2 is in conformity with the declared

performance in point 7. This declaration of performance is issued under the sole responsibility

of the manufacturer identified in point 4

Firmato a nome e per conto del fabbricante da

(nome e funzione)

Signed for and on behalf of the manufacturer

(name and title)

Luogo/Place Data/Date

Arsiero 16/03/2017

Page 10

Page

9

Installation, use and maintenance guide

BellaVista™ R Silent - BellaVista™ R Plus

1 - INTRODUCTION

1.1 GENERAL GUIDELINES

This installation, use and maintenance guide is an integral and essential part of the product and must be kept by the user. Before

commencing with the installation, use and maintenance of the product, carefully read this guide. All local, national and European

regulations regarding the installation and use of the appliance must be met. The Manufacturer recommends carrying out all the

maintenance operations described in this manual.

This appliance must only be used as intended by the manufacturer. Any other use is considered incorrect and therefore hazardous;

consequently, the user shall be totally liable for the product if used improperly. Installation, maintenance and repairs must be carried

out by professionally qualified personnel, certified according to Decree no. 37 of 22 January 2008 and in compliance with current

regulations. In case of repairs only original spare parts supplied by the manufacturer must be used. Incorrect installation or poor

maintenance can injure or damage people, animals or things; in this case the manufacturer shall be relieved of all responsibility.

Before beginning any cleaning or maintenance operation switch off the appliance by means of the 0/I main switch and disconnect

the plug from the electrical power socket. The product must be installed in suitable locations and furnished with all the services

(power and outlets) which the appliance requires for a correct and safe operation. Any repairs or actions carried out on any

systems, components or internal parts of the appliance, or on any of the accessories supplied with it, that are not specifically

authorised by Thermorossi S.p.A, will automatically void the warranty and the manufacturer's responsibility, pursuant to Italian

Decree no. 224 of the President of the Republic of 24/05/1988, art. 6/b.

It is recommended to keep this manual in a safe place that is easily accessible to all users; if the manual is lost or deteriorated

contact the manufacturer for a replacement copy. If the appliance is sold or transferred to another user ensure that the manual is

handed over with it. The images and figures featured in this manual are purely illustrative and may differ from the actual product.

Furthermore, Thermorossi reserves the right to apply changes to the content of this manual anytime and without notice.

Thermorossi S.p.A. retains copyright on this manual. These instructions may not be reproduced or communicated to third parties or

used in any other way without the necessary authorisation.

1.2 SAFETY GUIDELINES

PERSONAL INJURY

This safet y symbol identifies important messages throughout the manual. Read the information

marked by this symbol carefully as non-observance of this message can cause serious injury to

persons using the appliance.

DAM AGE TO PROPERTY

This safety symbol identifies messages or instructions that are fundamental for the appliance and

system to function well. To avoid serious damage to the appliance adhere strictly to these

instructions.

INFORMATION

This symbol indicates important instructions for good functioning of the appliance. If this information

is not correctly observed, the performance of the appliance will not be satisfactory.

1.3 RECOMMENDATIONS

Before using the appliance, carefully read every section of this installation, use and maintenance guide as knowledge

of the information and the regulations contained in it are essential for a correct use of the appliance.

The entire operation concerning the connection of the electric panel must be carried out by expert personnel; no

responsibility will be accepted for damages, even to third parties, if the instructions for installation, use and

maintenance of the appliance are not followed scrupulously. Modifications made to the appliance by the user or on

his behalf, must be considered to be under his complete responsibility. The user is responsible for all the operations

required for the maintenance of the appliance before and during its use.

1.4 GENERAL GUIDELINES

Attention: the appliance must be connected to a system provided with a PE conductor (in compliance with the

specifications concerning low voltage equipment). Before installing the appliance check the efficiency of the earth

circuit of the power supply system.

Attention: the power supply line must have a section which is suitable for the power of the equipment. The cable section must in any

case be no less than 1.5 mm². The appliance requires powering with a voltage of 230V and 50 Hz. Voltage variations greater than

10% of the nominal value can cause irregular operation or damage the electrical device. Position the appliance so that the electric

power outlet in the room is easily accessible. Ensure that a suitable differential switch is installed upstream from the equipment.

Position the power supply cable in order to prevent any contact of the latter with the smoke exhaust pipe or hot parts of the

appliance. If the power cord is damaged it must be replaced by the manufacturer or by an authorised technical assistance service in

order to avoid risks.

Your appliance has obtained the CE marking and has been made to run for 1 hour to check that it functions correctly.

The product must not be used by children under the age of 8 years, by persons with physical, mental or sensorial impairments, or

by persons who are not familiar with the instructions for use and maintenance of the product (the instructions are found in this

booklet). Children must not play with the appliance.

Page 11

Page

10

Manuale d'installazione, uso e manutenzione guide

BellaVista™ R Silent - BellaVista™ R Plus

ATTENTION: before any use, make sure the burner is thoroughly clean and check that the sliding door of the combustion chamber

is properly closed and air-tight.

ATTENTION: during operation, the sliding door of the combustion chamber must always remain properly closed. It is strictly

forbidden to open it while the appliance is in operation. During operation, the smoke exhaust pipes, glasses, handles and some

parts of the appliance may reach extremely high temperatures: be careful not to touch them and also educate children to be aware

of said risks. Do not expose your body to hot air for long, do not overheat the room in which the appliance is installed, as these

actions could cause health problems. Do not expose plants or animals directly to the hot air flow as this could have noxious effects

on them. It is strictly prohibited to use any type of fuel (liquid, solid...) to light up the appliance: lighting must occur automatically as

intended and described in this installation, use and maintenance booklet; consequently, it is also strictly forbidden to feed pellets (or

any other material) into the brazier. Do not place non-heat resistant or inflammable or combustible objects in the vicinity of the

appliance: keep them at a suitable distance. Do not place wet clothing to dry on the appliance. When using a clothes horse, keep at

a suitable distance. It is strictly prohibited to disconnect the appliance from the electrical power mains while it is in operation.

Warning: do not wet the appliance and do not touch the electrical parts with wet hands. Never vacuum hot ash: this

could damage the vacuum device. All the cleaning operations described in this manual must be carried out when the

appliance is cold and shut off.

Attention! Warning for Swiss users

Refer to the local cantonal regulations imposed by the Fire Department (Mandatory signalling and safety distances )

and the Note concerning installation of heaters issued by the Association of Cantonal Fire Agencies (VKF - AEAI).

ATTENTION: it is mandatory to earth the appliance. If this instruction is not observed serious damage, which is not

covered by warranty, will result to the body of the appliance. Have an electrician check the earthing. There must be

no electric potential (Volt) between the earth of the generator and the actual earth of the systerm.

1.5 TRANSPORTATION AND STORAGE

TRANSPORTATION AND HANDLING

The appliance body must always be in a vertical position when handled and exclusively by means of trolleys. Take special care to

protect all the fragile parts from mechanical impact which could damage them and their correct functioning.

STORAGE

The appliance must be stored in a humid-free environment and sheltered from the weather; avoid placing the appliance directly on

the ground. The Company denies all responsibility for damage caused to wood floors or floors made from any other material.

It is inadvisable to store the product for long periods of time.

1.6 GUIDELINES FOR CORRECT DISPOSAL OF THE PRODUCT

At the end of the product’s useful life it must be disposed of in compliance with applicable regulations and in respect of the

environment, not with urban waste. The product must be consigned to designated sorted waste collection centres for the disposal of

electronic waste authorised by the local municipal councils. Correct disposal not only helps safeguard the environment but it also

promotes recovery and recycling of the materials.

Page 12

Page

11

Installation, use and maintenance guide

BellaVista™ R Silent - BellaVista™ R Plus

2 – TECHNICAL CHARACTERISTICS

M.U.

BELLAVISTA™ R

SILENT

BELLAVISTA™ R

PLUS

Height mm 1,493 1,493

Depth mm 670 – 971 670 – 971

Width mm 485 485

Empty weight Kg 180 180

Firebox power (Min. / Max.)* kW 3.89 / 10.52 4.43 / 12.36

Rated power Min. / Max.* kW 3.31 / 8.98 3.89 / 10.68

Consumption (Min. / Max.)* Kg/h 0.83 / 2.24 0.94 / 2.63

Ø smoke exhaust pipe mm 100 100

Min. draught at rated power Pa 12 12

Min. draught at reduced power Pa 12 12

Tank capacity Kg 25 25

Average smoke temperature at rated power* °C 187 151

Average smoke temperature at reduced power* °C 109 93

Smoke flow at rated power* g/s 8.0 11.3

Smoke flow at reduced power* g/s 6.1 7.0

Efficiency at rated power* % 85.36 86.43

Efficiency at reduced power* % 85.26 87.90

CO emissions with 13% O2 at rated power* mg/m

3

65 47

CO emissions with 13% O2 at reduced power* mg/m

3

429 206

Power supply voltage and frequency V / Hz 230V 50Hz 230V 50Hz

Max electrical consumption A / W 1.40 - 320 1.40 - 320

Min electrical consumption A / W 0.27 - 60 0.31 - 70

Heatable volume** m3 240 285

* All the data are based on the appliance fuelled with standards UNI EN 14961-2 A1 and A2 type-approved pellets.

** It is important to take into consideration the fact that the heatable volume is greatly influenced by the insulation of the

house (energy class of the building) and by the position of the appliance in the planimetry of the house, therefore the

indicated values may vary, even significantly.

485

1493

971

670

140

O

8

0

1493

485

670

O

1

0

0

440

1349

O

5

0

475

Page 13

Page

12

Manuale d'installazione, uso e manutenzione guide

BellaVista™ R Silent - BellaVista™ R Plus

3 – GENERAL DESCRIPTION

3.1 OPERATING TECHNOLOGY

Your appliance has been built to fully satisfy all your heating and practical requirements. Top-grade components and functions

managed with microprocessor technology guarantee high reliability and optimal performance.

3.2 THE PELLET

The appliance is fuelled by pellets, that is, cylinders of compressed sawdust; it his allows you to fully enjoy the heat of the flame

without having to manually stoke the combustion.

The pellets have a 6 mm diameter and a length between 10 e 20 mm. They have a max moisture content of 8%; a thermal value of

4000/4500 Kcal/kg and density of 630-640 kg/m³. It must be approved according to UNI EN 14961-2 A1 A2.

It is strictly forbidden to use any pellet type other than that specified above. The use of fuel that does not comply with the

above specifications not only immediately invalidates the warranty for the appliance but can also create dangerous

situations. Do not use the appliance as an incinerator, at the risk of voiding the warranty.

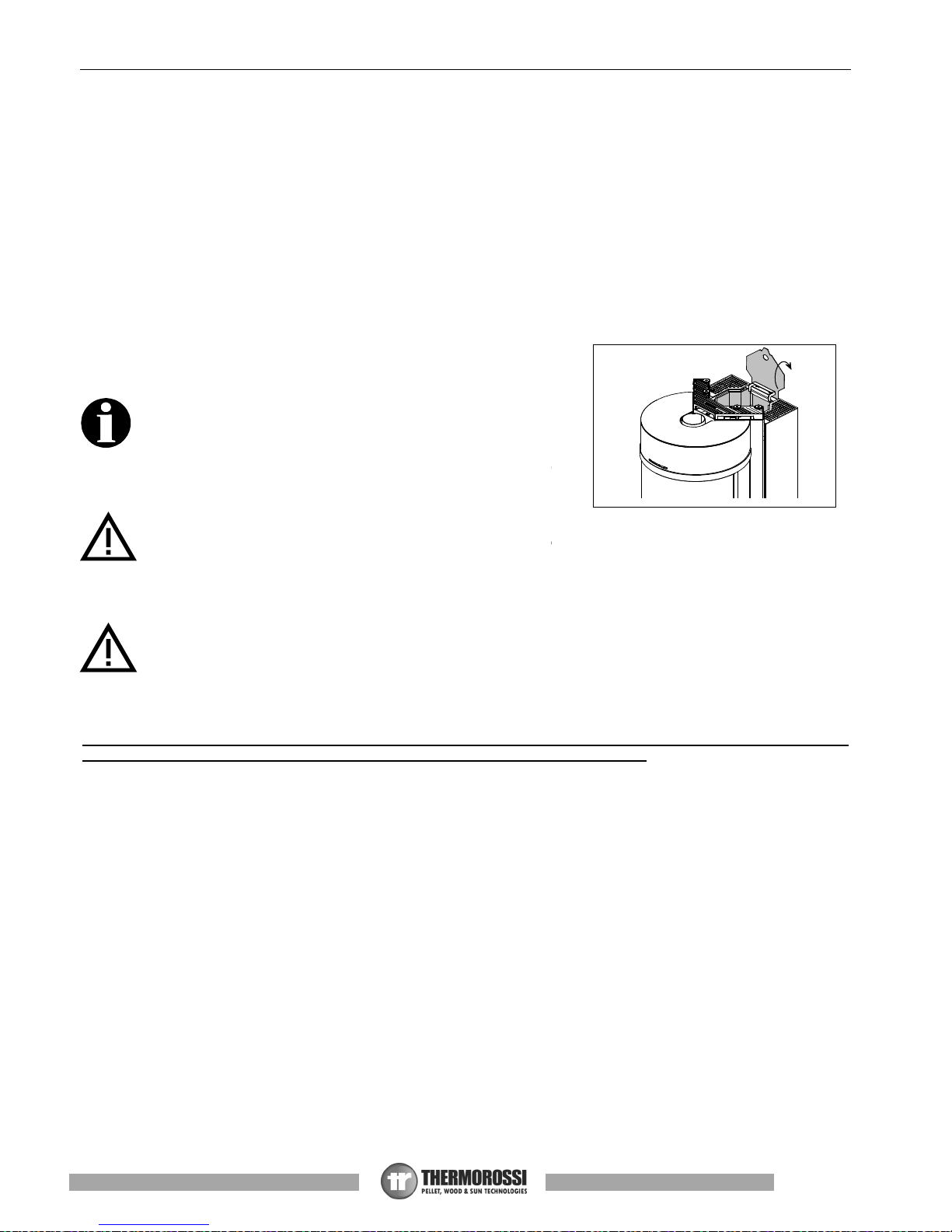

3.3 PELLET REFUELLING

The pellet feedbox is situated in the top part of the appliance. The load

capacity specified in the technical data can vary according to the specific

weight of the pellets.

Take special care when loading the tank as the screw feeder at its base is

in motion. Take care when topping up with fuel as the loading area can

get very hot.

ATTENTION: it is normal to find some pellets remaining in the tank even if

the stove shuts off because the pellets have run out.

Attention: when filling up the tank, take care not to drop any pellets into

the internal parts of the appliance, as, in extreme cases, this could generate live flames.

The manufacturer recommends emptying the tank and vacuuming the screw feeder zone once a month and during the

summer period. If the screw feeder can be seen when loading the pellet in the tank (pellet almost exhausted in the tank),

the appliance must be turned off, cooled down and the brazier must be cleaned. Do not switch off the appliance by

means of the main switch O/I on the power panel or by cutting off the power supply. Then restart the appliance.

Should you notice an excessive stagnation of flue gas in the combustion chamber, move away from the appliance

immediately. In particular move away from the glass sliding door of the combustion chamber. The excessive

concentration of unburned gases could create an explosion that could break the glass. Do not open the sliding door of

the combustion chamber for any reason and do not go near the appliance until said gases have been exhausted. Contact

a technical service centre to determine the causes. Do not switch off the appliance by means of the main switch O/I on

the power panel or by cutting off the power supply. Do not turn on the appliance for any reason whatsoever following an

event such as this.

Only pellets complying with the above specifications are to be loaded into the tank; in no case whatsoever must foreign

substances or objects be introduced into the tank, the brazier or any part of the generator.

Page 14

Page

13

Installation, use and maintenance guide

BellaVista™ R Silent - BellaVista™ R Plus

ATTENZIONE

Contiene vetro

E

A

B

C

C

D

D

E

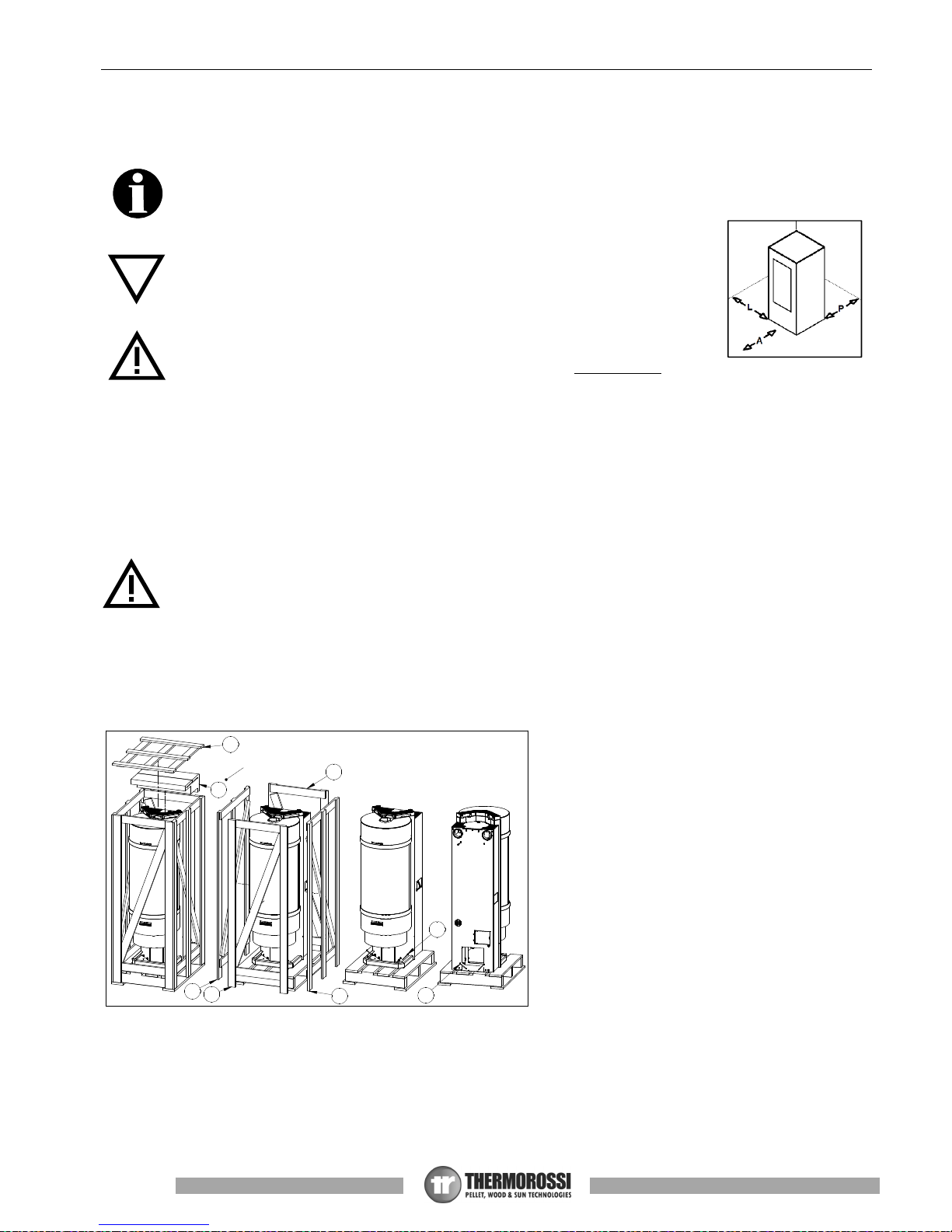

4 - INSTALLATION

4.1 APPLIANCE LOCATION

Follow the general guidelines set out in paragraph 1.1 to the letter. Keep in mind that the flooring of the room in which

the appliance is to be installed must withstand the combined weight of the appliance and the pellets contained in the

tank.

ATTENTION: The room where the appliance is installed must be well-ventilated and free

from humidity and salty air. A high level of humidity or saltiness in the room can lead to

the onset of rust or corrosion which will not be covered by warranty. The appliance must

be positioned at a minimum safe distance from walls and furnishings. If inflammable

materials are located in the vicinity of the appliance (e.g.: matchboarding, furniture,

curtains, pictures and paintings, sofas) it is mandatory to comply with the minimum

distances illustrated (see figure at right) Installation in the vicinity of heat-sensitive

materials is only permitted if suitable insulating and fireproof protection is placed

between the object and the appliance (ref. Uni 10683).

If the flooring is made of wood or any other combustible material, it is mandatory to install

a fireproof floor protector plate between the appliance and the floor. Failure to observe this

instruction will immediately invalidate the appliance warranty.

The installer must issue a certificate of conformity for the installation which includes the design plans and

the following documents:

a) Report containing the type of materials utilised.

b) Project as defined in Article 5 of Ministerial Decree n° 37 22 January 2008.

c) Drawing of the finished installation.

d) References to existing partial or previous declarations of conformity (e.g. electrical wiring).

e) Copy of the certificate of recognition of the professional technical qualifications.

These documents must, by law, be kept together with the use and maintenance booklet. The customer is responsible

for verifying, directly or indirectly, that the installation has been carried out to perfection in accordance with relevant

regulations in force. Do not install the appliance in unsuitable rooms such as bedrooms, bathrooms, garages and/or

lock-ups. It is forbidden to place the appliance in environments with an explosive atmosphere.

ATTENTION, the stove is not simply a household appliance: if the instructions set out in this booklet are not followed

and/or if installation of the appliance is not executed perfectly and/or the provisions in force are not strictly complied

with, dangerous conditions could arise for both objects and persons. It is the user’s responsibility to verify the presence,

in the room, of a vent necessary for supplying oxygen to the generator.

4.2 UNPACKING THE APPLIANCE

Proceed as follows to unpack the appliance:

1) Remove the top of the wooden crate (A).

2) Remove the box (B) very carefully and gently

since it contains extremely fragile material.

3) Remove the sides (C) of the wooden packaging.

4) Remove the sides (D) of the wooden packaging.

5) Remove the 4 screws (E).

6) Now remove the product from the pallet, making

sure not to damage it during handling.

A = 1,000 mm

L = 400 mm

P = 200 mm

Page 15

Page

14

Manuale d'installazione, uso e manutenzione guide

BellaVista™ R Silent - BellaVista™ R Plus

4.3 INSTALLATION OF GLASS ON BASE

1) Gently extract the glass (B) from the packaging (C)

2) Silicone-coat the surface of the base (A) using single-component, acetic silicone suitable for high temperatures (minimum

200°C, maximum 300°C).

3) Gently lay the glass (B) on the base (A), wait at least 24 hours before handling the product in order to let the silicone dry. If

the room temperature is lower than 18°, wait at least 48 hours until the silicone is completely dry.

B

C

S

I

L

I

C

O

N

E

A

A

B

Page 16

Page

15

Installation, use and maintenance guide

BellaVista™ R Silent - BellaVista™ R Plus

4.4 RELOCATION OF THE CONTROL PANEL

The product is supplied with the control panel on the right side; if needed, the control panel can be moved to the left side of the

appliance.

This operation must be exclusively performed by qualified professional staff, as set forth by Decree no. 37 of 22nd

January 2008 and applicable laws on the subject. Before performing said task, make sure the power supply cable is

disconnected from the electrical power socket.

Follow the procedures below to carry out this operation, referring to the images below:

1) Loosen the 2 Philips screws at the bottom (A) and the 3 Philips screws at the top (B).

2) Remove the rear panel (C), making sure not to scratch it.

3) Remove the metal sheet top (E) from the rear panel just removed (C), loosening the 3 Philips screws (D).

4) Mount the metal sheet top just removed (E) in the opposite side of the rear panel (C), so as to close the hole.

5) Loosen the 4 Philips screws (F) and remove the sheet protection of the control panel (G).

6) Loosen the two nuts (H) in order to remove the control panel (1) from the supporting bracket.

7) Secure the control panel (I) to the bracket (L), tightening the 2 nuts previously loosened.

8) Mount and secure the metal sheet protection (G) previously removed, fastening it with the 4 Philips screws (F).

9) At the end, mount the rear panel (C), securing it with the 3 screws (B) and two screws (A).

Pay particular attention during this operation, making sure the control panel's cable does not come into contact with

the hot or moving parts of the appliance. If said rule is not abided to, the cable may be damaged thus voiding the

warranty.

B

A

C

E

C

D

G

F

H

I

L

Page 17

Page

16

Manuale d'installazione, uso e manutenzione guide

BellaVista™ R Silent - BellaVista™ R Plus

A

I

H

G

C

H

I

G

D

E

C - sx

C - dx

4.5 INSTALLATION OF AIRBOX 3 VENTILATION KIT (OPTIONAL)

Airbox 3 ventilation kit can be installed on the appliance. By introducing this optional, the appliance will become Plus, therefore

ventilated and ductable. Once the kit is connected, all parameters required to transform the product from Silent to Plus will be preloaded automatically, with the possibility to change the fan's speed directly from the control display.

This operation must be exclusively performed by qualified professional staff, as set forth by Decree no. 37 of 22nd

January 2008 and applicable laws on the subject. Before performing said task, make sure the power supply cable is

disconnected from the electrical power socket.

Follow the procedures below to install Airbox 3 ventilation kit:

B

C

E

F

D

1) Unpack the ventilation kit

2) Remove the plug (A) from the appliance, pulling

downward

3) Introduce the condenser (B) in the specific hole,

fasten it with bolt (C) and couple connector (E) with

connector (F). At the end, push the fan inside until the

end-stop.

4) Remove the filter (G) and secure the fan at the top by

means of bolt (H) and washer (I).

Page 18

Page

17

Installation, use and maintenance guide

BellaVista™ R Silent - BellaVista™ R Plus

A

B

B

4.6 HANDLE

Your appliance is supplied with a handle (B) to open and close the sliding door of the combustion chamber and thus proceed with

maintenance operations. When not in use, the handle can be stowed on the back of the appliance if the hook provided is attached

to the stove. (A). (See figure).

A

B

C- dx

D

E

C - sx

5) Unscrew the 4 knobs (A) and remove the cast-iron top

(B), pulling it upward.

6) Insert deflectors (C – sx/LH) and (C – dx/RH). Open

the sliding door of the combustion chamber (for this

operation, refer to the specific chapter) and secure the

two deflectors with 4 screws (E) and 4 washers (D). Then

re-fit the cast

-

iron top (B).

Page 19

Page

18

Manuale d'installazione, uso e manutenzione guide

BellaVista™ R Silent - BellaVista™ R Plus

600

mm

4.7 OPENING THE SLIDING DOOR OF THE COMBUSTION CHAMBER

To open and close the sliding door of the combustion chamber, release the fastening hook (B) by acting on the suitable handle. In

the same way, release fastening hook (C) also by acting on the suitable handle. At the end of this operation, it is recommended to

remove the handle in order to avoid opening the door accidentally. Open the door only for cleaning operations and exclusively with

the appliance cooled off and disconnected from electric power.

4.8 DRAWING COMBUSTION AIR FROM OUTSIDE

The appliance is fitted with an intake to enable drawing in the combustion air directly from outside the building. Connect the air

intake on the appliance to the exterior of the building with suitable piping, capable of resisting high temperatures. The pipe’s length

must be maximum 600 mm.

ATTENTION: The suction duct must be protected with a grid and never be clogged. The protection grid, if installed,

must be inspected and cleaned on a monthly basis. Moreover, a suitable windbreak fitting must be installed in the

duct’s terminal.

A

D

A

B

C

D

Page 20

Page

19

Installation, use and maintenance guide

BellaVista™ R Silent - BellaVista™ R Plus

5 – DESCRIPTION OF THE CONTROLS

The appliance, when operating, could be hot to the touch, particularly the glass of the combustion chamber: take care

when handling the appliance components. Your appliance has obtained the CE marking and has been made to run for

at least one hour to check that it functions correctly. The product must not be used by children, by persons with physical

or mental impairments, by persons who are not familiar with the instructions for use and maintenance of the product

(the instructions are found in this use and maintenance booklet).

ATTENTION: before each use make sure that the burner is always very clean.

ATTENTION: during operation, the sliding door of the combustion chamber must always remain properly closed. It is

strictly forbidden to open the door while the appliance is in operation. While the appliance is in operation the smoke

exhaust pipes can reach extremely high temperatures: do not touch them! It is strictly prohibited to use any type of fuel

(liquid, solid...) other than pallet to light up the appliance: lighting must occur automatically as intended and described in

this installation, use and maintenance booklet; consequently, it is also strictly forbidden to feed pellets (or any other

material) into the brazier. Do not place non-heat resistant or inflammable or combustible objects in the vicinity of the

appliance: keep them at a suitable distance. Do not place wet clothing to dry on the appliance. When using a clothes

horse, keep at a suitable distance. It is strictly prohibited to disconnect the appliance from the electrical power mains

during normal operation.

5.1 DESCRIPTION OF THE CONTROL PANEL

The control panel is managed by a microprocessor. The control buttons and the various displays are described below.

The control buttons are:

Clock button

Press this button to activate / deactivate the programming.

Ventilation button (only in the PLUS version)

Press this button to set the desired level of ventilation: Six ventilation levels can be set on this stove. The fan starts

operating as soon as the temperature inside the stove body rises and the smoke thermocouple gives the signal.

The fan stops automatically when the stove body has cooled sufficiently. The fan cannot be disabled during

operation.

Flame button

Pressing this button when the appliance is off activates the START sequence, sets the power of combustion in the

WORK mode or shuts off the appliance by activating the OFF sequence.

Scroll buttons (only in the Menu)

Press MINUS key to lower the value. Press PLUS key to raise the preset value.

Menu button

Press this button to access the main menu. You can scroll the setting screens shown below, which will be

described in detail in the following paragraphs. To access the functions of each subwindow wait a few seconds.

Page 21

Page

20

Manuale d'installazione, uso e manutenzione guide

BellaVista™ R Silent - BellaVista™ R Plus

DATE/TIME This button is used to set the day of the week, the hour and minutes. (see para. 5.3)

CHRONO This button is used to set the programmed on and off sequences. (see para. 5.4)

LEVEL Is used to change the rotation speed of the smoke suction unit. (see para. 5.5)

THERMOCOMFORT This button is used to activate the connection with the optional handheld control. (see para. 5.6)

Display

The following information can appear on the display:

Displays the preset combustion power, and consequently the pellet consumption, by the number of bars that are

lit up around the flame symbol, using this logic:

One bar lit up: Minimum combustion power (and therefore with minimum pellet consumption)

Two bars lit: Second combustion power

Three bars lit: Third combustion power

Four bars lit: Fourth combustion power

Five bars lit up: Maximum combustion power (and therefore with maximum pellet consumption)

No bars lit up: The appliance is OFF

Only in the PLUS version it displays the preset ventilation power, and consequently the room fan speed, by

the number of bars that are lit up around the fan symbol, using this logic:

One bar lit: Minimum ventilation power

Two bars lit: Second ventilation power

Three bars lit: Third ventilation power

Four bars lit: Fourth ventilation power

Five bars lit: Fifth ventilation power

Six bars lit: Maximum ventilation power

Dashes appear along the top of the display, and each dash corresponds to one day of the week set by the user

(e.g. 1 corresponds to Monday, 2 corresponds to Tuesday… etc.).

The operating status of the appliance appears below these dashes, that is START, OFF or WORK. And the

current time set by the user appears below this word.

The presence in the display of the clock symbol indicates that the CHRONO programming has been enabled; if

this symbol does not appear it means that the CHRONO programming has been disabled. (see para. 5.4)

5.2 DESCRIPTION OF THE POWER PANEL

The components of the power panel present on the back of the

product are described below:

1) Electrical power outlet 220V-240V 50Hz

2) Main switch 0/I.

3) Test light for pellet feed motor.

The light comes on simultaneously with the activation of the pellet feed

motor.

4) Cap for reset thermostat button.

If the reset thermostat overheats stop the pellet feeder. The appliance

must cool down before you can restart the appliance. After verifying

and eliminating the causes of the event

undo the protective cap and press the button.

5) Protection fuse 3.15 A.

Legenda

Key

RIARMO RESET

SPIA MOTORIDUTTORE GEARMOTOR INDICATOR

3

4

2

1

5

SILENT version

PLUS version

Page 22

Page

21

Installation, use and maintenance guide

BellaVista™ R Silent - BellaVista™ R Plus

5.3 DATE/TIME: SETTING THE DATE AND TIME

The appliance must be energised and the I/0 switch in position “I".

The current date and time can be set using the DATE/TIME function.

To set the current time and date proceed as follows:

1) Press the Menu Button once to view the following screen:

2) After a few seconds the following screen will appear on the display:

3) Now press the Scroll Buttons to change the day of the week; each number corresponds to one day of the week (e.g. 1

corresponds to Monday, 2 corresponds to Tuesday, etc...). To confirm the selection of the day of the week press the Flame

Button.

Once confirmed, the selector shifts to the hour section while the selected day of the week remains framed:

4) Press the Scroll Buttons to change the hour. Once you have set the hour confirm the value by pressing the Flame Button.

Once confirmed, the selector shifts to the minutes section. Press the Scroll Buttons to set the minutes. Press the Flame

button to confirm.

Once confirmed, the date and time setting screen closes automatically and the initial screen returns to the display.

If you confirm the wrong value simply press the Menu Button several times to exit the box until the initial screen will appear, and

repeat the procedure described above.

5.4 CHRONO: ON/OFF PROGRAMMING

The appliance must be energised and the I/0 switch in position “I".

The CHRONO function allows you to set the weekly program by setting up to 3 on-off cycles at different times for every day from

Monday through to Sunday.

To set a program follow the procedure described below:

1) Press the Menu Button twice quickly to view the following screen:

After a few seconds the following screen will appear on the display:

2) Press the Scroll Buttons to select the day of the week on which you want to set the program. Each number corresponds to one

day of the week (e.g. 1 corresponds to Monday, 2 corresponds to Tuesday, etc...). To confirm the day of the week selected for

the programming press the Flame Button. The following screen will appear:

3) Now press the Scroll Buttons to select the hour at which you wish the appliance to start up automatically (ON1). Once the hour

has been set, confirm the value by pressing the Flame Button. When scrolling the ON1 values the OFF1 values will scroll as

well; this is to avoid setting a shut off time that is earlier than the start up time.

Once confirmed, the selector shifts to the minute section of ON1. Press the Scroll Buttons to set the minutes for the first start

up. Confirm the value by pressing the Flame Button.

4) Now press the Scroll Buttons to select the hour at which you wish the appliance to shut off automatically (OFF1). Once the

hour has been set, confirm the value by pressing the Flame Button.

Once confirmed, the selector shifts to the minute section of OFF1. Press the Scroll Buttons to set the minutes for the first shut

off. Confirm the value by pressing the Flame Button.

At this point the first ON/OFF cycle for the selected day has been set.

Page 23

Page

22

Manuale d'installazione, uso e manutenzione guide

BellaVista™ R Silent - BellaVista™ R Plus

The following screen will appear:

At this point if no further programming is required for that day go to point 5-A.

If, on the other hand, you wish to program a second ON/OFF cycle for that day go to point 5-B.

5-A) Press the Menu Button to exit the screen, in order to enable you to program the times for the ON/OFF cycles for the other

days of the week. In this case repeat the instructions from point 2 up to this paragraph.

5-B) Press the Scroll Buttons to select the hour at which you wish the appliance to start up automatically for the second time

(ON2). The start up time will be that set before OFF1; this is to avoid setting a second start up time that is earlier than the

preceeding shut off time. Once the hour has been set, confirm the value by pressing the Flame Button. When scrolling the

ON2 values the OFF2 values will scroll as well; this is to avoid setting a shut off time that is earlier than the start up time.

Once confirmed, the selector shifts to the minute section of ON2. Press the Scroll Buttons to set the minutes for the second

start up. Confirm the value by pressing the Flame Button.

Now press the Scroll Buttons to select the hour at which you wish the appliance to shut off automatically (OFF2). Once the

hour has been set, confirm the value by pressing the Flame Button.

Once confirmed, the selector shifts to the minute section of OFF2. Press the Scroll Buttons to set the minutes for the

second shut off. Confirm the value by pressing the Flame Button.

At this point the second ON/OFF cycle for the selected day has been set.

The following screen will appear:

At this point if no further programming is required for that day go to point 6-A.

If, on the other hand, you wish to program a third ON/OFF cycle for that day go to point 6-B.

6-A) Press the Menu Button to exit the screen, in order to enable you to program the times for the ON/OFF cycles for the other

days of the week. In this case repeat the instructions from point 2 up to this paragraph.

6-B) Press the Scroll Buttons to select the hour at which you wish the appliance to start up automatically for the third time (ON3).

The start up time will be that set before OFF2; this is to avoid setting a third start up time that is earlier than the preceeding

shut off time. Once you have set the hour confirm the value by pressing the Flame Button. When scrolling the ON3 values

the OFF3 values will scroll as well; this is to avoid setting a shut off time that is earlier than the start up time..

Once confirmed, the selector shifts to the minute section of ON3. Press the Scroll Buttons to set the minutes for the third

start up. Confirm the value by pressing the Flame Button.

Now press the Scroll Buttons to select the hour at which you wish the appliance to shut off automatically (OFF3). Once the

hour has been set, confirm the value by pressing the Flame Button. Once confirmed, the selector shifts to the minute

section of OFF3. Press the Scroll Buttons to set the minutes for the third shut off. Confirm the value by pressing the Flame

Button.

At this point the third and final ON/OFF cycle for the selected day has been set.

Alternatively, if you wish to copy the exact same programming for the ON/OFF cycles set for a particular day to the next day simply

press the Ventilation button.

For example: if I want to copy all the programmed ON/OFF cycles set for Monday to Tuesday the following screen will appear:

I press the Ventilation button once again to copy all the cycles programmed for Tuesday to Wednesday. The following screen will

appear:

Using the same logic we can copy the programmed cycles to the other days.

7) To conclude the programming operations simply press the Menu Button several times to exit the screen until the initial screen

will appear.

ATTENTION: The appliance ignores any ON or OFF command programmed with a value of 00:00.

Consequently if you do not wish to use an ON or OFF time setting simply set a value of 00:00. The appliance ignores

any ON or OFF command if the shut off time is set the same as or before the start up time.

Page 24

Page

23

Installation, use and maintenance guide

BellaVista™ R Silent - BellaVista™ R Plus

ATTENTION: In the event of a programmed cycle on always ensure that the brazier is clean. Failure to clean the

brazier can reduce and/or affect the life of the spark plug as it would be subjected to high temperatures due to poor

cooling. It is recommended to set ON/OFF cycles times lasting no less than 2 hours, in order to save energy and for

the proper operation of the appliance.

Enabling the programmed cycles:

Back in the initial screen, to enable the appliance to carry out the ON/OFF cycles as programmed it is necessary to press the Clock

Button.

The image of a clock will appear on the main screen:

The programmed cycles are now enabled.

When the programmed cycles are enabled (a clock symbol appears on the display) it will not be possible to

use an additional chronothermostat (see para. 8.2).

Disabling the programmed cycles:

To disable the appliance from carrying out the programmed ON/OFF cycles press the Clock Button once again.

On the display the clock symbol will disappear. This operation disables the weekly program that has been set by the user but does

not delete or reset the times.

Resetting the programmed cycles:

Moreover, it is possible to reset, in other words delete, all the programmed cycles entered by the user by holding down the Clock

Button in the initial screen for approx. five seconds.

The words CLEAR TIMERS will appear momentarily on the screen.

Do not release the button until the text CLEARED appears on the screen. Only the appearance of the words CLEARED

signal that the previously entered programmed cycles have been deleted. When the programmed cycles are active the

operating level at start up, that is the combustion power, will be the same level set before the last time the machine was

shut off: that is, only if it was a programmed shut off, not if the machine was shut off by means of a manual action.

Manual shut down can only be carried out with the programming disabled. If after a manual shut off the programmed

cycle re-enables, at the next programmed start up the appliance will be on the first combustion power level.

5.5 LEVEL: OPERATING LEVEL SETTING

The appliance must be energised and the I/0 switch in position “I".

Your appliance is delivered with an excellent program installed that favours combustion efficiency; the program is called LEVEL 1.

However, if you are using pellets with a higher than normal incidence of residues after combustion in the brazier, it is possible to

select alternative levels:

LEVEL 2 is an operating program that accelerates the speed of the smoke suction unit in proportion to all the combustion

power levels. This level must be set when the user notices a weak, high and very dark flame. Attention: this

modification does not authorise the use of below-standard pellets, or no vacuum in the flue outlet.

If using loosely compressed pellets, you could select:

LEVEL 0: is an operating program that decelerates the speed of the smoke suction unit when using loosely compressed

pellets and/or when the flue outlet has a very high vacuum, over 2 mm water column (20 Pascal).

The pellet consumption value remains unchanged regardless of the selected operating level. These variations will only change the

rotation of the smoke suction unit in the WORK stage, all the other stages will not undergo any changes.

Select the required Level by acting as follows:

1) Press the Menu Button three times quickly and the following box will appear:

Page 25

Page

24

Manuale d'installazione, uso e manutenzione guide

BellaVista™ R Silent - BellaVista™ R Plus

After a few seconds the following screen will appear on the display:

2) To change the operating level, hold down a Scroll Button while simultaneously pressing the other Scroll Button.

To set the desired level simply press the Menu Button several times until the initial screen will appear on the display.

The level selection can be made with the appliance OFF or ON. If the change is made while the appliance is running

the difference in the flame will be apparent. It is mandatory to pay particular care when selecting the most appropriate

operating cycle for your installation. After the selection of the operating cycle a thorough cleaning of the brazier is

mandatory.

5.6 THERMOCOMFORT: CONNECTION WITH THE HANDHELD CONTROL (OPTIONAL)

The appliance must be energised and the I/0 switch in position “I".

This function enables you to activate the connection of the appliance with the optional THERMOCOMFORT handheld control (See

Para. 6).

The THERMOCOMFORT function can be activated by proceeding as follows:

1) Press the Menu Button five times quickly until the following screen appears:

After a few seconds the following screen will appear on the display:

2) Press one of the two Scroll Buttons and the following screen will appear (Select ON to activate).

ATTENTION: It will only be possible to activate the THERMOCOMFORT function and select ON in the previous screen if the

appliance detects the handheld control signal. It is therefore recommended to ensure that the handheld control is energised and

within close vicinity of the appliance.

3) To confirm the activation of the THERMOCOMFORT function or to exit the screen simply press the Menu Button to return to the

initial screen.

The THERMOCOMFORT symbol will be present on the initial screen if the appliance is in the START or WORK stage:

The Thermocomfort function is automatically disabled when the appliance is OFF. It automatically reactivates at the next START

up.

To disable the THERMOCOMFORT function simply repeat operations 1 and 2, but this time select the OFF command. The

function will be disabled immediately.

Page 26

Page

25

Installation, use and maintenance guide

BellaVista™ R Silent - BellaVista™ R Plus

6 - OPERATION OF THE HANDHELD CONTROL THERMOCOMFORT (OPTIONAL)

The Thermocomfort handheld control is the instrument that allows you to optimise both consumption and functions.

If set in AUTO mode, the handheld control detects the room temperature where it is located and automatically manages the

modulation of the combustion power and the ventilation power (only in the PLUS version) of the appliance according to the target

temperature set by the user in the handheld control.

If set in MANUAL mode, the user can select both the ventilation power (only in the PLUS version) and the flame power.

6.1 INDICATORS OF THE HANDHELD CONTROL

1 Flame button

2 Ventilation button (only in the PLUS version)

3 DOWN key

4 UP key

5 Displays the room temperature detected by the handheld control sensor

6 Ventilation power indicator (only in the PLUS version)

7 Combustion power indicator

8 Target temperature indicator, use buttons 3 and 4 to change the value

9 Area of the display where the operating program is displayed

10 Battery charge level

11 Main switch 0-1 handheld control power supply

12 Battery charger connection

13 Code selector and batteries compartment cover

To switch on the handheld control, the following operations must be carried out:

1) Remove the battery cover and flick the main switch to ON, as illustrated in the figure below (This operation is only required

the first time you switch on the handheld control)

2) Flick the main switch upwards (11):

3) Connect the handheld control to the mains power supply by means of the supplied battery charger. The handheld control

must be recharged for at least 24 hours, as the rechargeable batteries could be partially or completely empty. Repeat the

same procedure every time the handheld control batteries discharge.

At the end of the winter season, in order to preserve the life of the batteries, it is mandatory to recharge the batteries and switch off

the handheld control completely by means of the switch located on the back (11). The batteries are guaranteed for 6 months. When

the batteries are exhausted dispose of them safely. It is normal for the temperature sensor to detect temperatures which are slightly

different to the real ones due to the thermostat tolerances.

Page 27

Page

26

Manuale d'installazione, uso e manutenzione guide

BellaVista™ R Silent - BellaVista™ R Plus

6.2 USE OF THE HANDHELD CONTROL

The Thermocomfort handheld control can be used with 4 different operating programs:

• MANUAL

• AUTO 5

• AUTO 3

• ECONOMY

To change an operating program hold down the DOWN arrow on the handheld control until the set program begins to flash. Now

release the DOWN arrow and quickly press the DOWN arrow (3) and/or UP arrow (4) to select the preferred operating program.

MANUAL

program

In the MANUAL program the room temperature thermostat of the handheld control is disabled. It will therefore be possible to

manually set both the ventilation power (only in the PLUS version) and the combustion power.

- To set or change the combustion power simply press the Flame Button (1), and the flame symbol on the screen will begin to

flash for several seconds. While it is flashing press the DOWN arrow (3) to reduce the combustion power, and on the display

you will see the bars disappear in sequence; vice versa to increase the combustion power, press the UP arrow (4).

The combustion level changes with each press of DOWN key (3) and UP key (4) .

- To set or modify the ventilation power (only in the PLUS version) simply press the Ventilation button (2), and the fan

symbol will begin to flash for a few seconds. While it is flashing press the Down arrow (3) to reduce the ventilation power, and

on the display you will see the bars disappear in sequence; vice versa to increase the ventilation power, press the Up arrow

(4).

The ventilation power changes with each press of DOWN key (3) and UP key (4).

Attention: it is possible that, due to radio interference or sending commands too close together, the changes will not

be implemented. With this program you can also use the infrared control supplied. It is normal that in the manual

cycle the room ventilation is often set at the maximum speed in order to cool the appliance body more effectively.

AUTO 5 program

In program AUTO 5 the room temperature thermostat is enabled. The handheld control adjusts the ventilation power (only in the

PLUS version) and power automatically in relation to the target room temperature set in handheld control display.

You can vary the desired room temperature by simply pressing DOWN key (3) and/or UP key (4).

The handheld control will set the maximum combustion and ventilation power (only in the PLUS version) and modulate them both

as the room temperature approaches the preset target temperature.

Once the target temperature has been achieved the combustion power and the ventilation power (only in the PLUS version) will

remain steady at the minimum value.

Attention: it is possible that, due to radio interference, the commands sent to the generator will not be implemented.

When using this program the infrared remote control supplied cannot be used.

Attention: the power and the ventilation depend on the preset target temperature, if the required temperature is too

high or not reachable the appliance could operate at maximum power for long periods of time.

AUTO 3 program

In program AUTO 3 the room temperature thermostat is enabled. The handheld control adjusts the ventilation power (only in the

PLUS version) and power automatically in relation to the target room temperature set in handheld control display.

You can vary the desired room temperature by simply pressing DOWN key (3) and/or UP key (4).

The handheld control will remain steady at the maximum value, level 3 for the combustion power and level 4 for the ventilation

power (only in the PLUS version), and lower the level as the room temperature approaches the preset target temperature.

Once the target temperature has been achieved the combustion power and the ventilation power (only in the PLUS version) will

remain steady at the minimum value.

Attention: it is possible that, due to radio interference, the commands sent to the appliance will not be implemented.

When using this program the infrared remote control supplied cannot be used. Caution: the power and the ventilation

depend on the preset value, if the required temperature is too high or not reachable the appliance could operate at

maximum power for long periods of time.

Page 28

Page

27

Installation, use and maintenance guide

BellaVista™ R Silent - BellaVista™ R Plus

ECONOMY program

In the ECONOMY program the appliance always operates at the minimum combustion power and the minimum ventilation power

(only in the PLUS version). When using this program the infrared remote control supplied cannot be used.

ATTENTION: THE THERMOCOMFORT HANDHELD CONTROL DOES NOT SWITCH THE APPLIANCE ON OR

OFF.

THE APPLIANCE MUST ALWAYS BE STARTED UP AND SHUT DOWN FROM THE CONTROL PANEL OR

THROUGH PROGRAMMING.

Keep in mind that radio wave transmissions can be affected by the surrounding environment: the presence of thick walls can reduce

the transmission that normally extends to 6-7 metres.

ATTENTION: to guarantee optimal data transmission it is advisable to always place the handheld control in its

support in a vertical position.

6.3 TRANSMISSION CODES SETTINGS

If there are several appliances installed in rooms closely to each other or in case of electromagnetic disturbances it may be

necessary to set different transmission codes as this type of interference deactivates operation of the optional Thermocomfort

handheld control.

To change the transmission codes proceed as follows:

The appliance must be energised and the main switch O/I in the "I" position.

1) Disable the Thermocomfort function (see para. 5.6)

2) Switch off the Thermocomfort handheld control using the main switch (11).

3) To change the transmission codes, open the battery cover and act as indicated in the figure below.

4) To change the frequency simply change the order of even only one of the four switches shown in the figure above.

5) Next switch on the handheld control by pressing the main switch (11).

6) Re-enable the THERMOCOMFORT function.

6.4 CARE AND MAINTENANCE OF THE HANDHELD CONTROL

The handheld control has been designed to the strictest standards and must be handled with great care.

If you observe the guidelines set out below, the handheld control will provide a long trouble-free performance:

• Protect the handheld control against precipitation, moisture, liquids and all those substances that could corrode the internal

electronic circuits. If the handheld control gets wet, remove it immediately from the battery charger if it is in the process of

charging, remove the battery and leave it open to dry at room temperature for as long as necessary.

• Do not use or store the handheld control in dusty or dirty environments. The dust/dirt could damage the movable parts of

the handheld control.

• Do not store the handheld control in very hot environments. High temperatures could shorten the life of the electronic