Page 1

MIKROTHERM® 825

MT825-A, controller

user´s manual

MT825A 11/09 Rev.7/Soft.4.3

THERMOPROZESS s.r.o.

Riegrova 2668/6c

370 01 České Budějovice

Czech Republic

Tel.: +420 387 313 182

Fax: +420 385 340 947

E-Mail: info@thermoprozess.cz

http://www.thermoprozess.cz

Page 2

2

If there is any default of the device could cause a damage,

the equipment with the controller must be fitted with the

independent protection unit (thermal cut-out/limiter).

Page 3

User part

3

1 Introduction

MIKROTHERM® MT825-A is ¼ DIN temperature/process controller with 1 input for

measurement, 1 input/output for controlling and 5 outputs ( thi first is for control, the second

is for alarm/signal, the event output 3,4,5).

• Buying a new controller, see the chapter Installation and configuration of controller.

• If you have the device installed from the producer of device, see the chapter Final User.

Final User

If you are a final user, you will get the device in the customised operation and you can view

and change only the parameters, you need for your own work. There is a special part for you

in manual – User Part.

If you are a new user of the device, focus on the following chapters:

• Basic terms, it is explained the key functions, modes of controller, info ans error

massages.. In the whole manual you will be referred to the terms expalined in this chapter.

• User level, in this level you can scroll through mode of controller, edit programmes, start,

stop and end programmes…

• If you want to create programme profile, you will find the information in chapter

ProF, creations of programme profiles. Programme profile means to create the structure

of programme (1.step – rate at set temperature, 2.step soak at this temperature…) and

only some parameters can be made accesible. The result is that during editing programmes

you will set just a few chosen parameters ( final temperature of 1.step, time of 2.step)

• Tips for operation and troubleshooting you will find in the chapter Tipps..

Installation and configuration of controller

For installation and controller configuration is determined configuration and service part of

manual.

It is assumed that you know basic operation of device described in the chapter Basic terms

and you are authorised for installation and you know how to set up the device.

• Information on installation of device you will find in chapter Installation.

• Wiring is described in chapter Power wiring..

• For further information on operation see chapter Configuration level and Tips for

configuration.. For service worker it is convenient to find out options in chapter Service

level. After the operation of device it is recommended to write down parameter values in

table on page 53 There is a blank table for writting of programmes on the same page.

• You will find the information on editing, starting and ending of programmes, viewing and

setting of parameters, etc.., in operation part of the manual.

Important:

The description of serial communications is not stated in this manual. It is stated in the

manual for the devices fitted with communications board.

Page 4

User part

4

2 Basic terms

The controller cna be used for control of temperature or other quantity (for simple description

the temperature will be used) according to set profile. To avoid problems in operation of

device the user must be able to manage its operation.

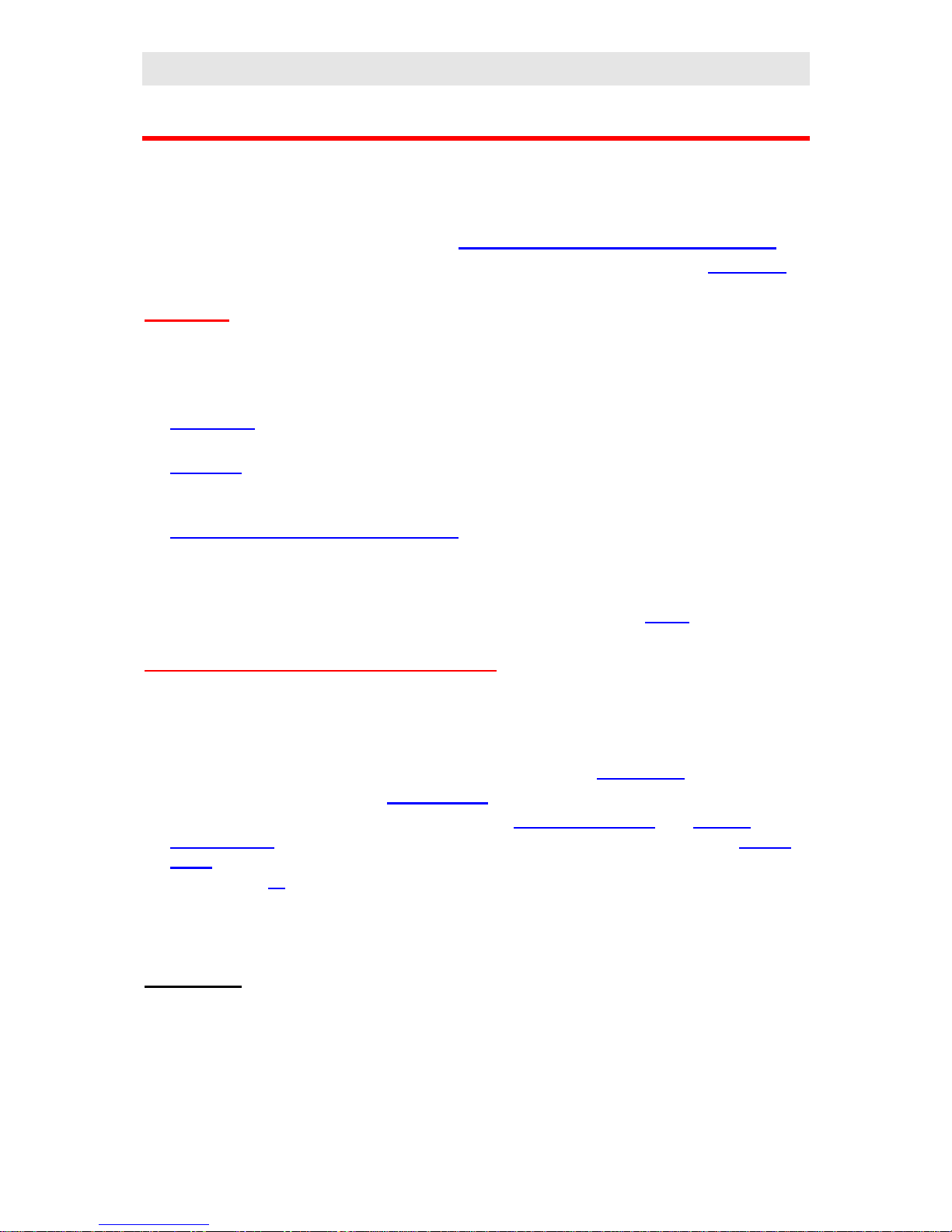

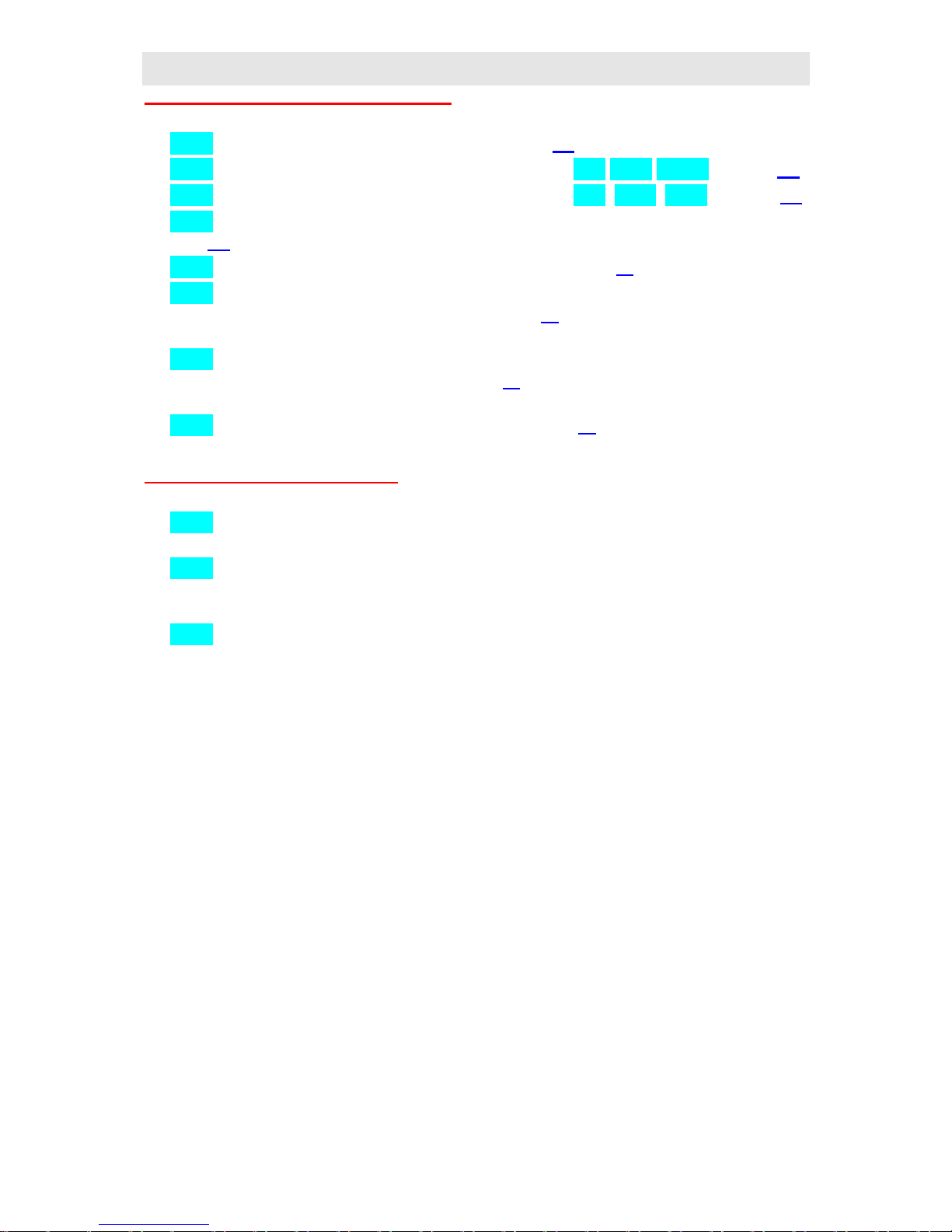

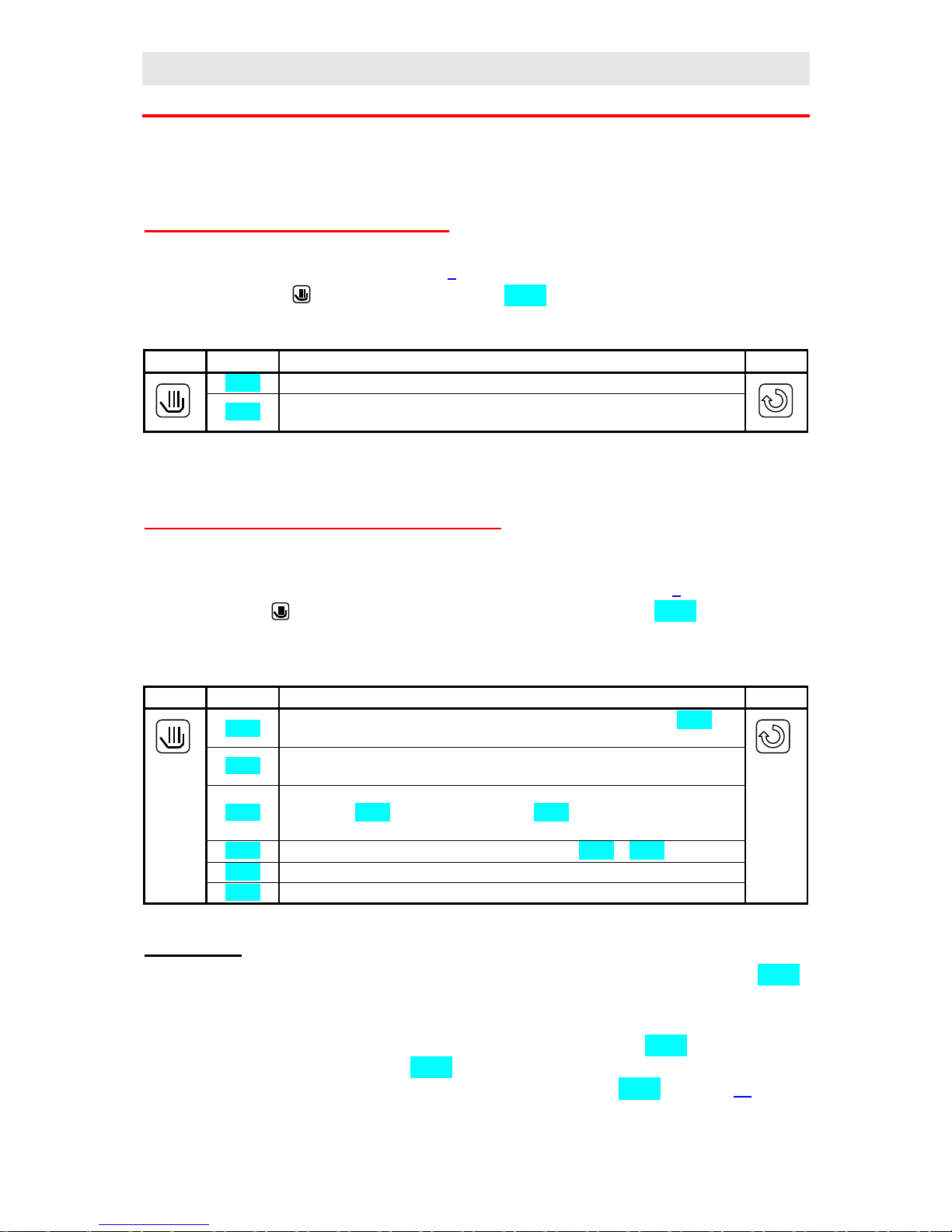

2.1 Operation and description of the controller

Before you start, it is necessary to explain the principals for control.On the front panel board

you can see 2 displays, 3 control lights and 4 keys. The device is set and configured via menu.

The features of keys and displays is shown on the following pictures:

The tables for menu and descriptions of parameters are in the following chapters.

Lower display

Upper display

•

Indicates actual process value

• at setting it shows parameter

value

•

Indicates set point value

• At setting shows type of

parameter

Indicates the state of

controller output

Indicates alarm/signal

output

Diode MODE indicates

mode of device

functions of indicators

Lower display

Upper display

Short-term press:

• listing in menu

• confirm of set values

• return from menu at start /

end

Long-term press -3 seconds):

• editing of programme

Short-term press:

• Starting, ending programme

Long-term press:

• Setting of programme and

time for starting programme

by the lock

decreasing of set

value

increasing of set value

Press 2 keys together (for 3 seconds)

to change levels from lower to higher

levels (user, configuration, service)

key functiones

Page 5

User part

5

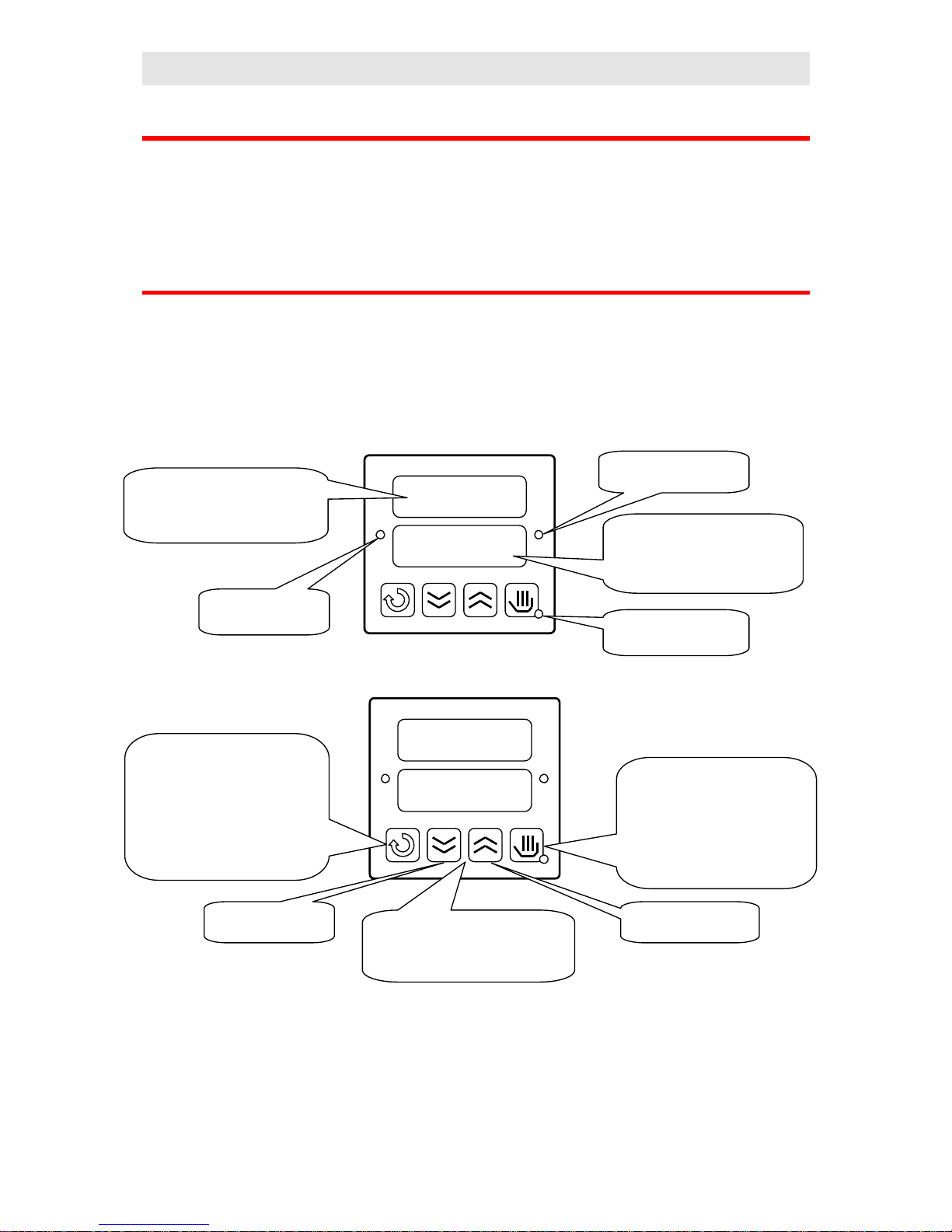

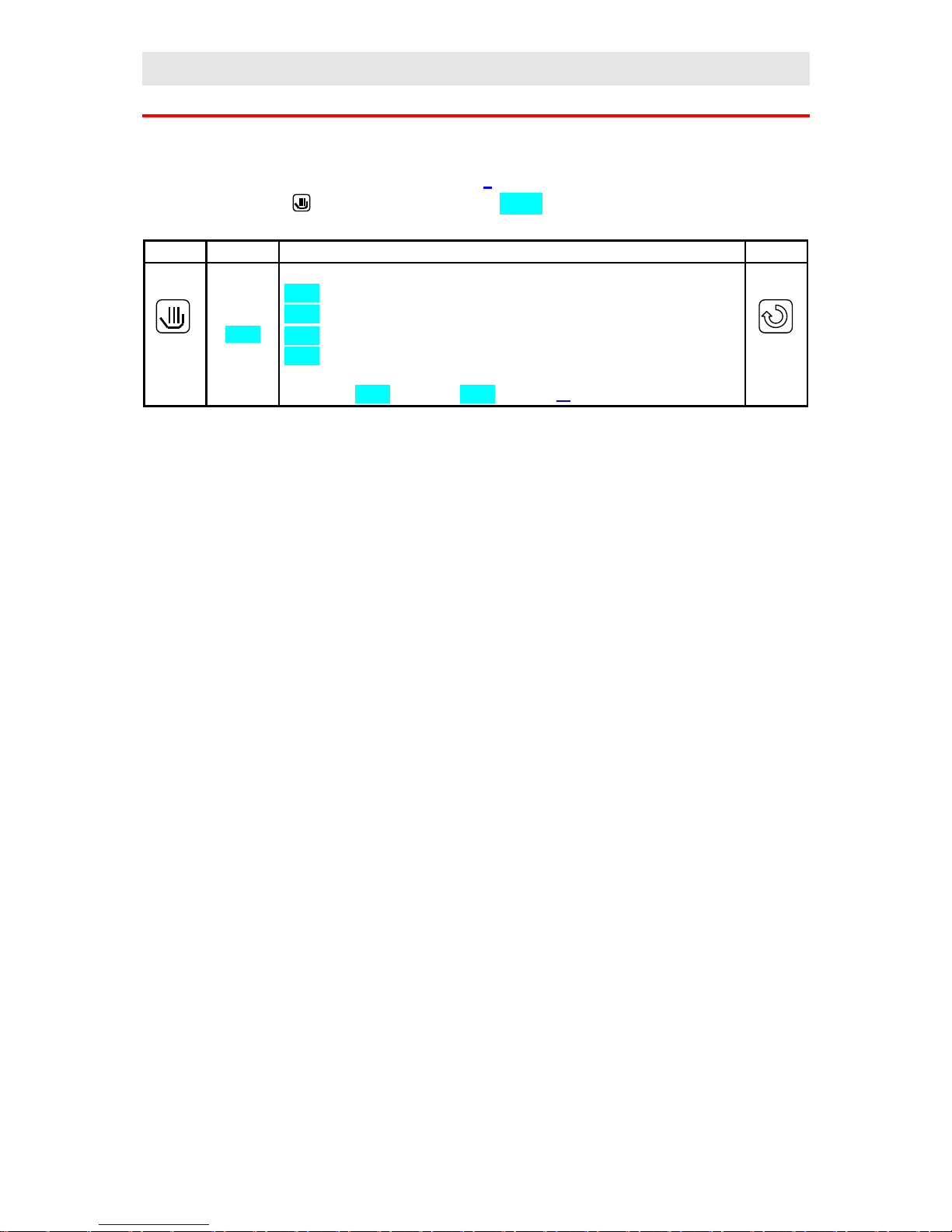

Settings parameters

In the user part the setting of parameters is described in the table of this format:

Confirm Display Procedure Return

• Confirm, indicates the key, with which you go through menu and confirm set parameters

• Display, show the data displayed on lover display

• Procedure, meaning of parameter and procedure how ti set it

• Return, return to basic mode without editing the parameter

Important:

• Parameters are selected with arrow keys

• If the parameter is not confirmed by the key stated in column Confirm, it is not set

• Returning to basic mode by the key Return, then the parameter is not set

• During automatic return to basic mode the parameter is not set. The controller returns to

basic mode automatically if no key is pressed for 60 seconds and automatic return is

allowed (in konfiguration level, menu SYS, parameter Aret=on)

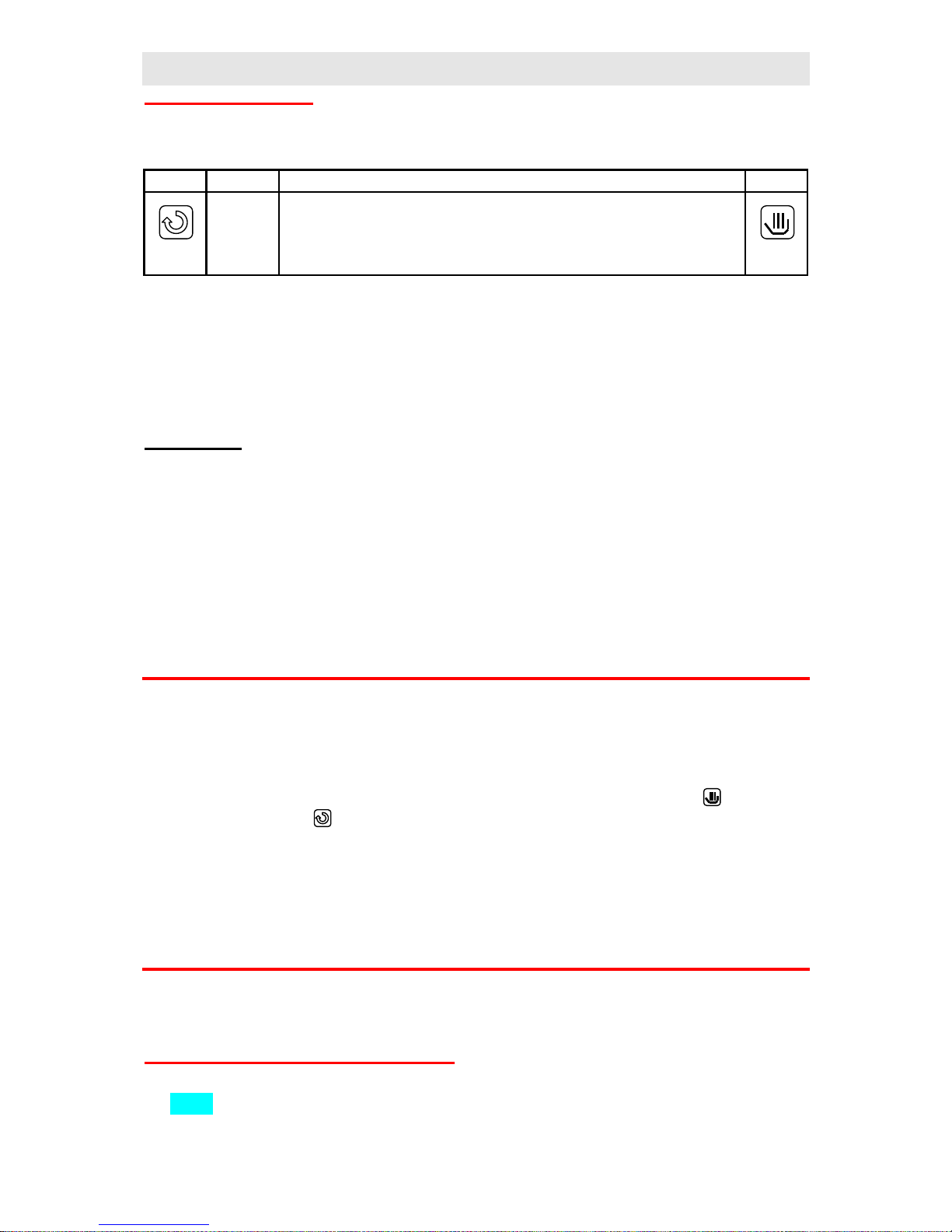

2.2 Modes of controller

Mode of controller is indicated by diode MODE, see page 4. The 3 following modes will be

often used in the description of controller.

• Basic, diode MODE is not lit, controller output is OFF or ON/OFF control switches

output depending on set value. If you set parameters you return by pressing to basic

mode or by pressing if you edit the start/end of programme.

• Running a programme, diode MODE is lit, the controller runs by programme

• Setting, diode MODE blinks, parameters are set.

2.3 Information and error messages

Information and error massages are indicated only in basic mode.

Information messages, upper display

• ---- … error of input sensor or input is not set.

Page 6

User part

6

Information messages, lower display

• PCLK … starting a programme by the clock, see page 15..

• Aut1 … automatic setting/autottuning of PID parametrs Pb1 It1 dE1, see page 26.

• Aut2 … automatic setting/autottuning of PID parametrs Pb2, It2, dE2, see page 26.

• Gsd … guaranteed soak deviation GSD, process value leaves the defined Soak Band,

page 22.

• trun … indicates time-limited running of controller, see page 27.

• hoLd … indicates mode of controller during programme running after the supply voltage

interruption or after setting from keyboard, see page 22. The programme is interrupted

and the last set value is retained.

• Abrt … indicates mode of controller during programme running after supply voltage

interruption or after setting keyboard, see page 22. The programme is interrupted and

controller output is switched OFF.

• hISt … indicates the browsing on data history, see page 25.

Error messages, lower display

• Err0 … error in EPROM. Switch the controller OFF and ON again. If the problem

persists, contact your supplier.

• Err1 … error in EEPROM, configuration and operation parameters. The troubleshooting

error (restart of parameters and subsequent configuration) can be made only by

experienced user. If the trouble persists, contact your supplier.

• Err3 … error in A/D converter. It can be caused by electrical impulse at input, too low

temperature and excessive humidity…. Switch the controller OFF and ON again. If the

problem persists, contact your supplier.

Page 7

User part

7

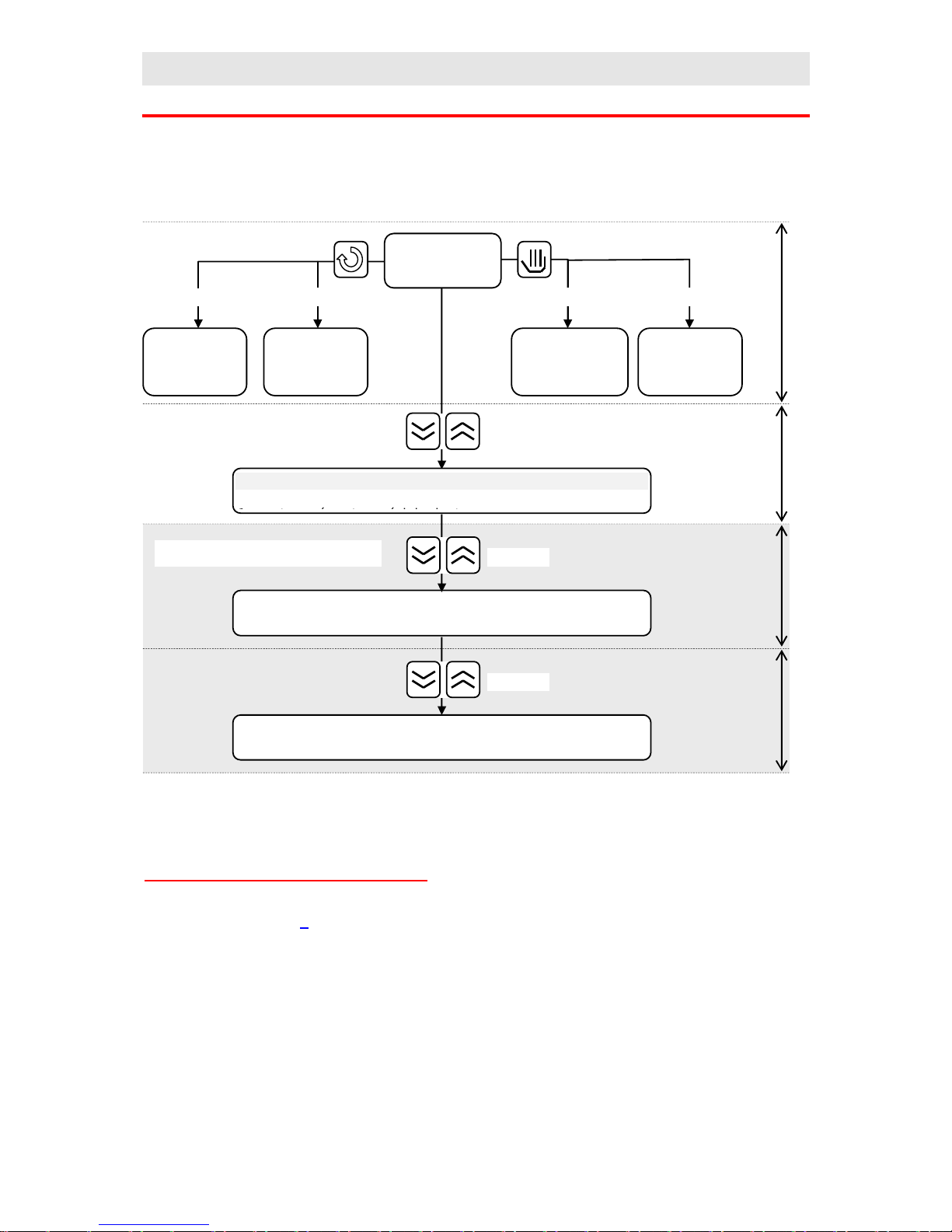

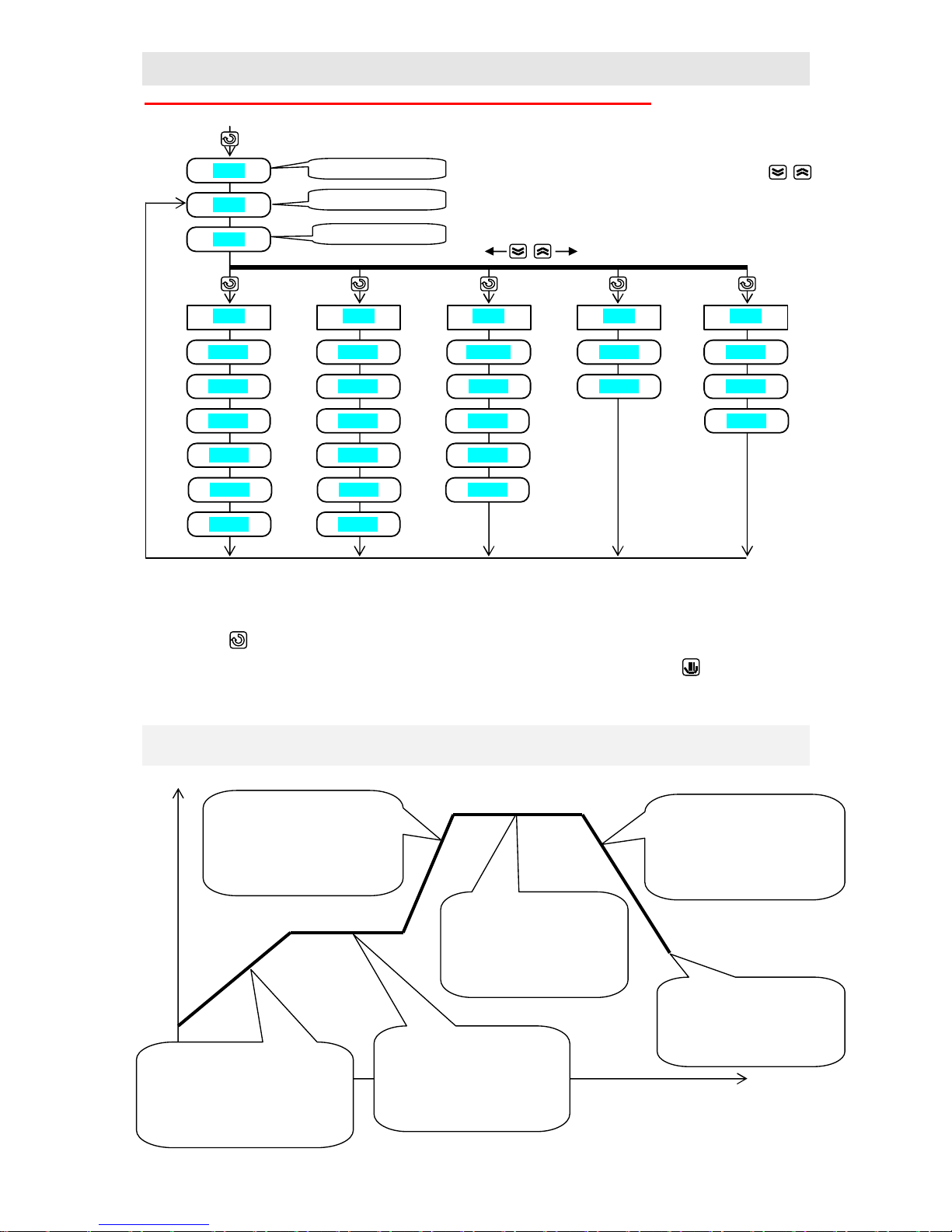

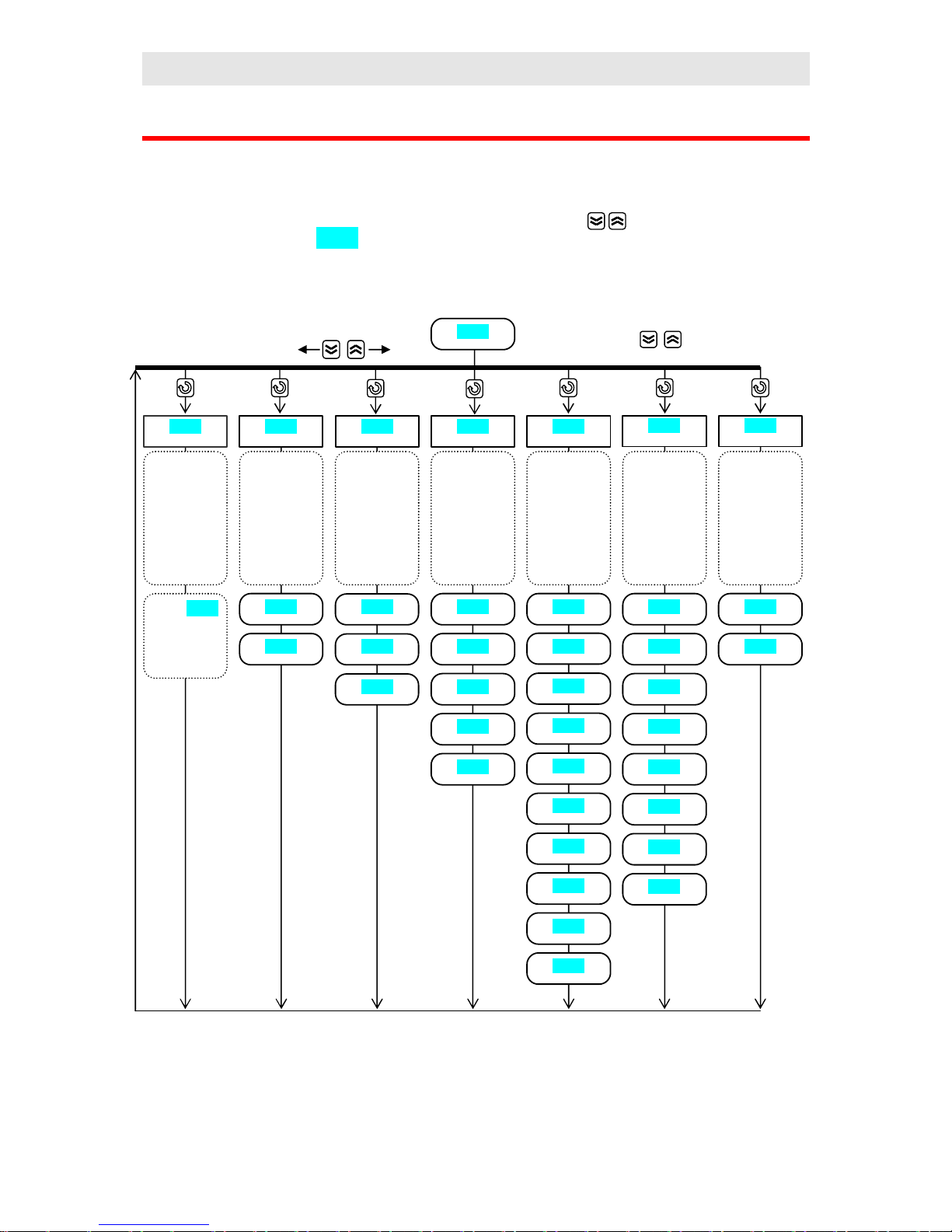

2.4 Overview of levels, menu

Total overview of programme levels and menu is shown below. The entry to menu is

indicated by the keys, long-term press is approximately 3 seconds.

Using of single menus and levels:

• User menu enables the quickest acces for user. The list of parameters in menu can be

selected, see page 8

• Programme menu is used for editing and viewing programmes.

• Start and end of programme, in this menu you can start, interrupt and end up

programme via keyboard.

• Starting programme by the internal clock, setting of programme number and time of

start.

• Operation level is accesible for user after setting of all necessary parameters. Most of

menu in user level can be inhibited (denied) to user.

• Configuration level is intended for configuration of device. In this level you can set most

of parameters of operation level. It is recommended to lock the menu after setting.

• Service level provides you with parameters for servicing.

Basic mode

User menu

Programme

menu

Start, interupt

and end

programme

Starting

programme

by clock

Short press Short press Long press

Long press

Operation level

Configuration level

Service level

Long press

Long press

Long press

User level

Operation

level

Configuration

level

Service level

Only for experienced user

Page 8

User part

8

3 User level

In this level you can access promptly to most common parameters. It consists of the following

menus:

• User menu, enables access to most applicable parameters of device. Their specification

and sequence can be set.

• Programme menu is intended for editing, monitoring and reading programmes.

• Start, interruption and end of a programme.

• Starting a programmme by the internal clock.

3.1 User menu

In user menu you can set and view the parameters of the controller. You can choose and set

the list of parameters and their sequence that will be in user menu.

• The controller is in basic MODE or in running a programme, see page 5. Upper display

indicates process value, lower display indicates set point value.

• By pressing key you can scroll through user menu.

Important:

• The tables shows parameters that can be accesible in user menu. Each parameter in this

menu can be permitted or not for the operator and the operator has only important

parameters available.

• The sequence of parameters is optional and can be set.

Page 9

User part

9

Confirm Display Procedure Return

trun

Work of controller is time limited. See details on page 27.

hISt

Reading of measured values from history. If you like to read measured/process values,

set YES and confirm. Upper display indicates process value, lower one time in format

hour.minute. Scroll through values with arrow keys.

Prog

On display appears number of actual programme in running.

StEP

On display appears actual step of programme.

EnSP

On display appears final set point value of actual step

trEM

Time to the end of actual step in format hours.minutes, if time is longer than 99 hours

then only in format hours.

CLK

Menu for setting real time clock.

• YEAr … set actual year

• Mon … set actual month

• dAY … set actual day

• hour … set current hour

• Min … set current minute

Pcnt

Shows instantaneous power in %

Ptot

Shows total power consumed in kWh

PPGM

Shows consumed power during the last programme in kWh

o2oF

Switch OFF permanent alarm/ signalling by setting YES and confirm..

Ent1

Indicates the state of event output 1 ( oFF, on). The output can be set by

arrowkeys only if programme does not run.

Ent2

Indicates the state of event output 2 ( oFF, on). The output can be set by

arrowkeys only if programme does not run.

Ent3

Indicates the state of event output 3 ( oFF, on). The output can be set by

arrowkeys only if programme does not run..

Aut

Sarting ( on), stopping ( oFF) of autotuning/automatic setting of PID parameters.

CAL1

Calibration of sensor. Set value is added to process value.

hPEr

Period for measured values storing (hISt) in minutes

hSto

Condition for data storing:

• oFF, storing is turned OFF

• ProG, storing is executed only if programmme runs

• ALSG, storing is executed only at alarm/signalling

• Cont, storing is executed constantly

PPEr

Period of printing in minutes

PSto

Condition for printing

• oFF, printing is turned OFF

• ProG, printing is executed only if programme runs

• ALSG, printing is executed only at alarm/signalling

• Cont, printing is executed constantly

Page 10

User part

10

3.2 Programme menu

In controller 30 user programmes can be stored numbered with 1 up to 30 and another 4

Steady fixed set programmes labelled FP1 – FP4, see page 23

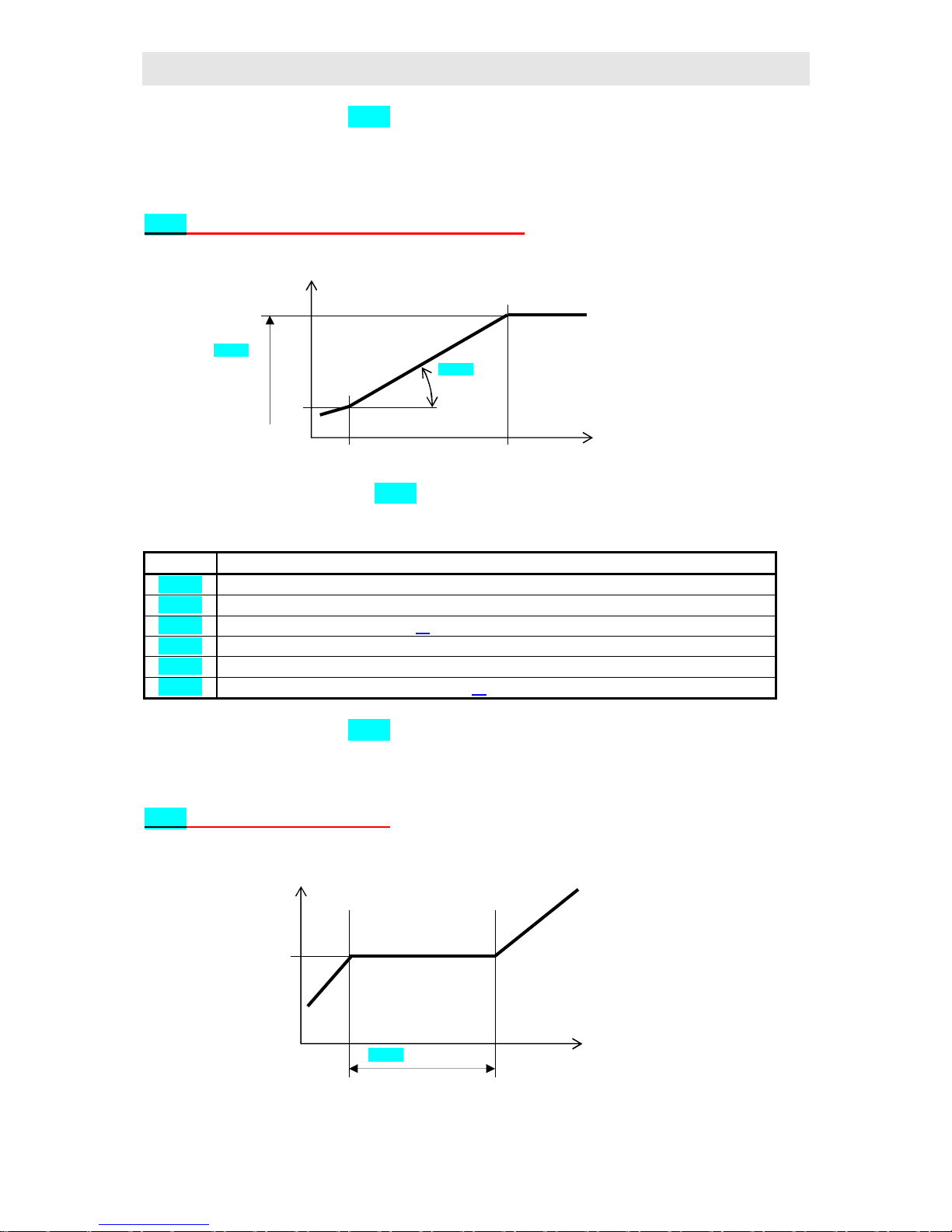

Each programmme consists of steps (max. 15). Types of steps are illustrated in the picture.

Each step is defined with parameters appearing on lower display in format AA.xx, where AA

means type of step and xx number of step. For example SP.11 means set point value of 11.

Step. Types of steps follows:

StPt, ramp rate up or down of set point value

Summary of parameters of step StPt

Dispaly Meaning

SP.xx

Final set point value.

tI.xx

Time needy for reaching set point value, is stated in format hour.minutes.

E1.xx

State of event output 1, see page 23

E2.xx

State of the event output 2.

E3.xx

State of the event output 3.

Gd.xx

Guaranteed soak deviation GSD, see page 22

Setpoint

value

temperatur

tim

Rate up or down StPt, rAtE

In real defined time:

• StPt, is defined by final temperature and

time needy for reaching final temperature.

• rAtE, ramp up or down is defined by final

temperature and ramp rate in (unit/hour)

SoAK

Set point value is not changed during the

step. Is setting soak time.

JuMP

Enables jump at:

-Another step in the

programmme that runs

-Another step of other

programme oothotherpr

End

Ends of programme

SP.xx

(°C)

tI.xx

(hour.min)

Set point

value

time

Page 11

User part

11

Initial set point value in step StPt in the same as the final set point value of preceding

(former) step. In case of starting a programmme the initial set point value is equal to the

process value.

Time for step is max. 99 hours 59 minutes.

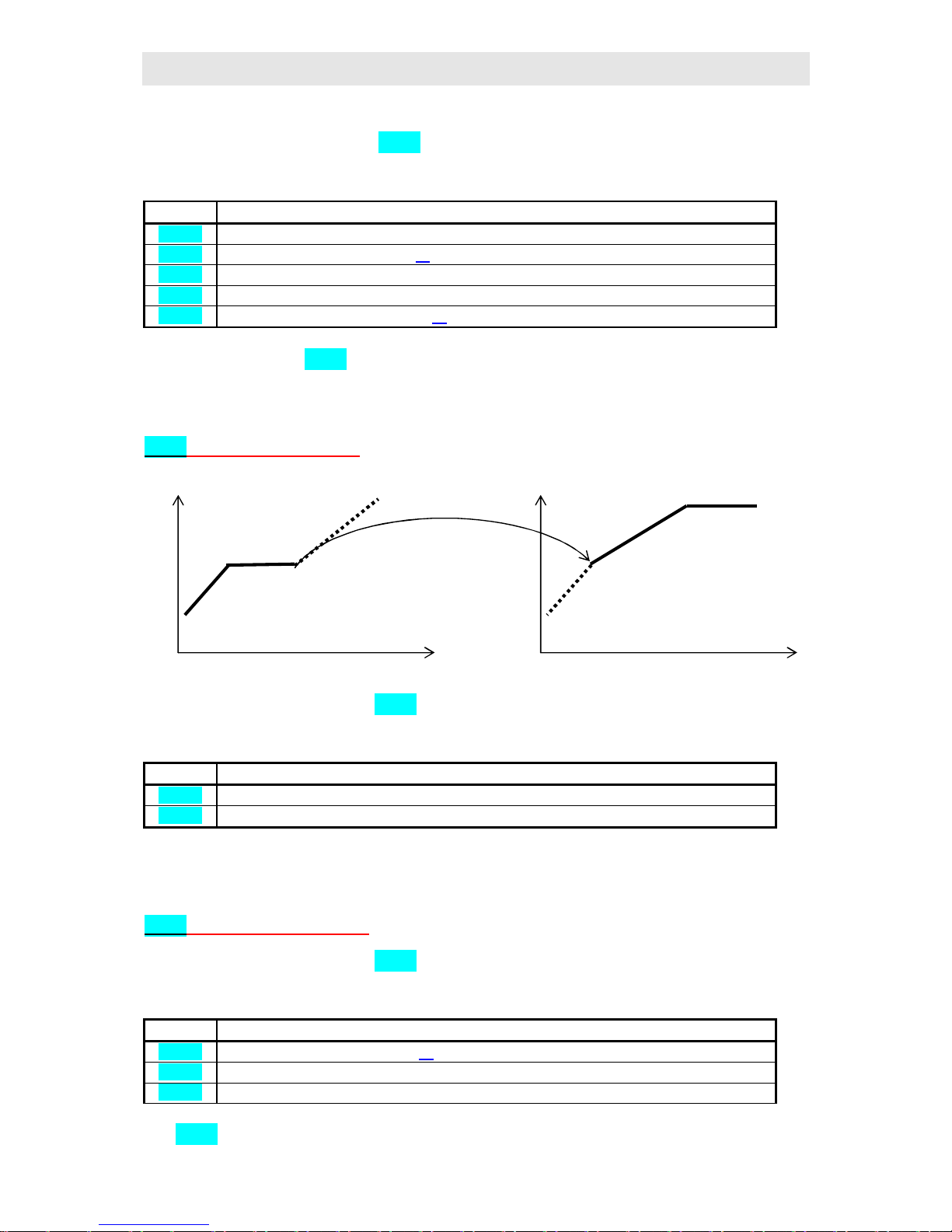

rAtE, ramp rate up or down of set point value

Summary of parameters of step rAtE

Display meaning

SP.xx

Final set point value

rt.xx

Speed of rate to set point value is stated in format °C/hour

E1.xx

State of event output 1, see page 23.

E2.xx

State of event output 2

E3.xx

State of event output 3

Gd.xx

Guaranteed soak deviation GSD, see page 22

Initial set point value in step rAtE is the same as the final set point value of preceding /

former step. In case of starting a programme the initial set point value is equal to the process

value. Duration of step is not limited.

SoAK, soak on set point value

SP.xx

(°C)

rt.xx

(°C/hour.)

Set point

value

time

tI.xx (hour.min)

Set point value

time

Page 12

User part

12

Summary of parameters of step SoAK

Display Meaning

tI.xx

Time of soak is stated in format hour.minutes

E1.xx

State of event output 1, see page 23.

E2.xx

State of event output 2.

E3.xx

State of event output 3.

Gd.xx

Guaranted soak deviation, see page 22

Set point value in step SoAK is the same as the final set point value of preceding (former)

step. In case of starting programme the set point value is equal to the process value.

Time for step is maximum 99 hours 59 minutes.

JuMP, jump in programme

Summary of parameters of step JuMP

Display Meaning

JP.xx

The number of programme to be jumped at.

JS.xx

The number of step to be jumped at.

If you create endless programme loop (jump at the same place), the programme will be ended

up.

End, ending a programme

Summary of parameters of step End

Display Meaning

E1.xx

State of event output 1, see page 23.

E2.xx

State of event output 2.

E3.xx

State of event output 3.

Step End ends up the programme and sets event outputs.

set point

value

time

set point

value

time

Page 13

User part

13

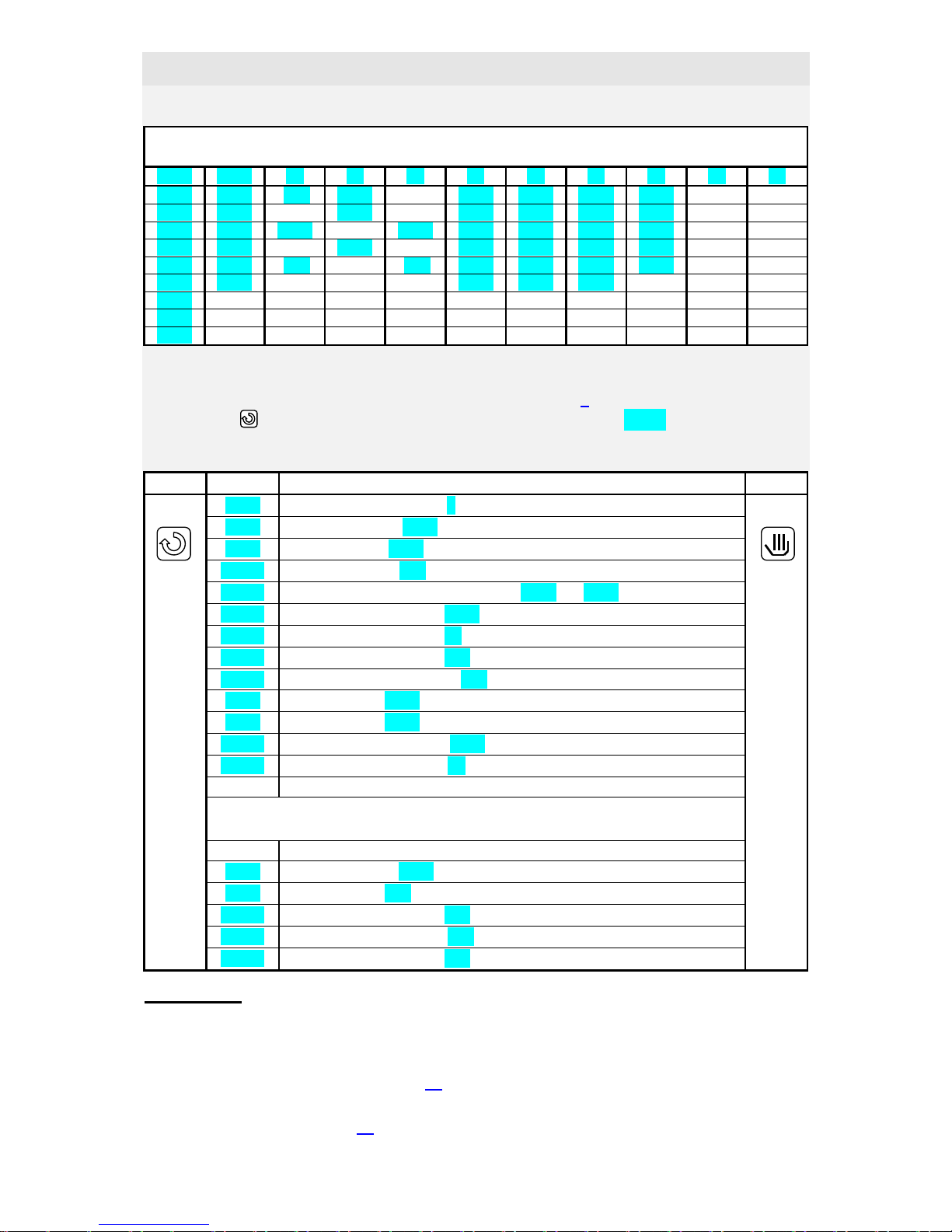

Complete menu for editing a programme is ilustrated below:

• To enter menu editing and reading a programme from basic MODE press for more than 3

sec. key .

• To return from menu for editing a programme to basic MODE press key .

Example:

Now you are able to edit your own programme as you know all the types of steps. The

following example clarifies editing a programme. This profile you like to edit on position 5.

set value

point

time

Step 1

• ramp rate at set point value

200°C in 2 hours 30 min.

• event outputs see table

• guaranted soak deviation is OFF

Step 2

• soak 1 hour. 20 min .

• event outputs see table.

• GSD turn ON on start

Step 3

• ramp at set point value

1050°C rate 250°C/hour.

• event outputs see table.

• guaranted soak deviation is

Step 4

• soak 2 hour 10 min .

• event output see table

• guaranted soak deviation

is ON in whole period

Step 5

• ramp down at set point value

150°C at rate 150°C/hour

• event output see table

• GSD is OFF

Step 6

• ending a programme

• event outputs see the table

ProG

StEP

tYPE

StPt

SP.xx

tI.xx

E1.xx

Gd.xx

rAtE

SP.xx

rt.xx

E1.xx

Gd.xx

SoAK

tI.xx

E1.xx

Gd.xx

JuMP

JP.xx

JS.xx

End

E1.xx

set number of programme

set number of step

set type of step

E2.xx

E3.xx

E2.xx

E3.xx E2.xx

E3.xx

E2.xx

E3.xx

Page 14

User part

14

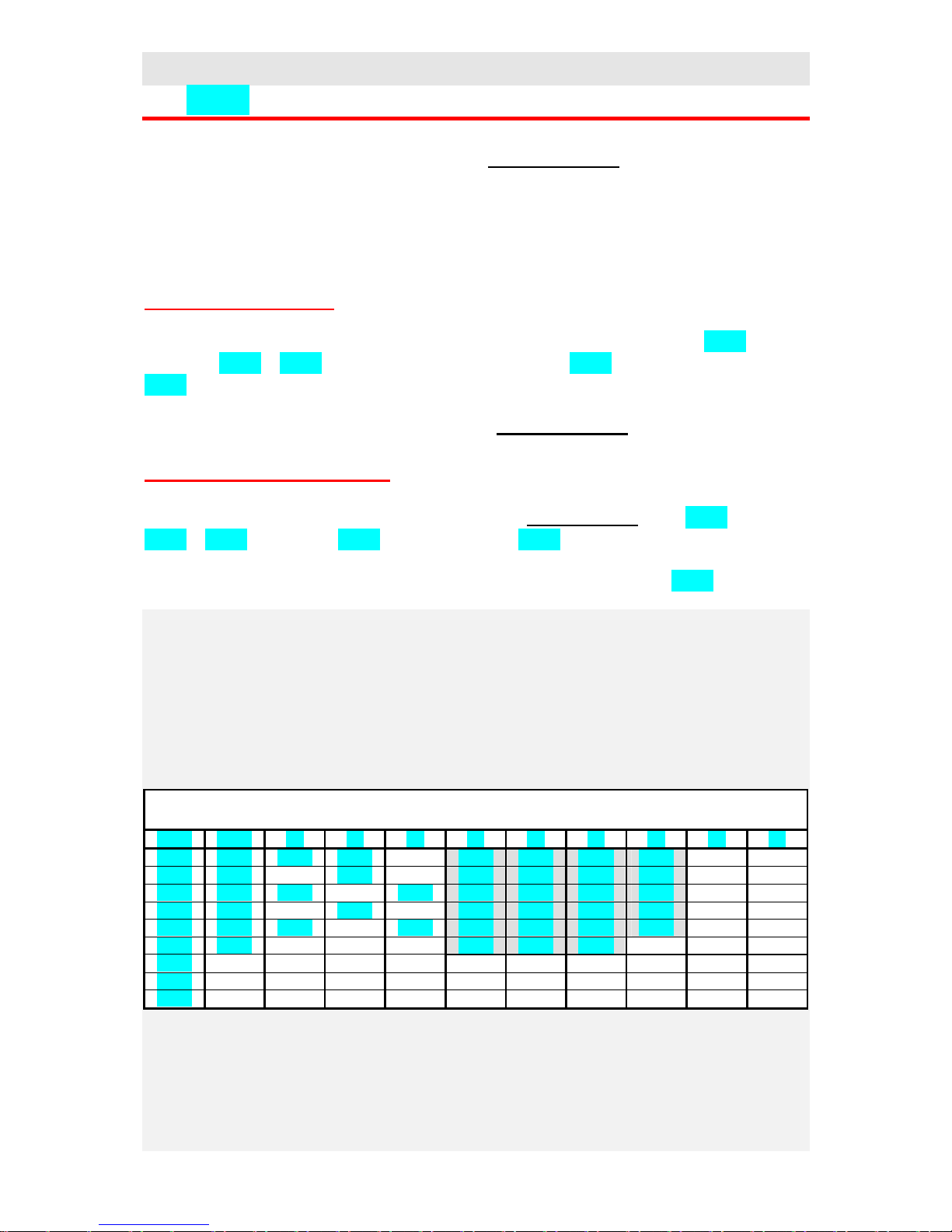

You can write down the profile to table:

Progr: 5

StEP tYPE SP TI rt E1 E2 E3 Gd JP JS

1 StPt 200 2.30

oFF on oFF oFF

2 SoAK

1.20

on on oFF Strt

3 rAtE 1050

250 on on On oFF

4 SoAK

2.10

on oFF oFF on

5 rAtE 150

150 oFF oFF oFF oFF

6 End

oFF oFF oFF

7

8

9

Now edit the programme to the memory of controller:

• Controller is in basic MODE or in a programme, see page 5

• Press key for more then 3 seconds. On lower display appears ProG, and then you can

proceed acc. the table below:

Confirm Display Procedure Return

Prog

Number of programme, set 5

Step

Number of step, set 1

tYPE

Type of step, set StPt

SP. 1

Set point value, set 200

tI. 1

Time needy for reaching set point value SP 1, set 2.30

E1. 1

State of event output 3, set oFF

E2. 1

State of event output 2, set on

E3. 1

State of event output 3, set oFF

Gd. 1

Guaranted soak deviation, set oFF

StEP

Type of step, set 2

tYPE

Type of step, set SoAK

TI. 2

Time to the end of soak, set 1.20

E1. 2

State of event output 1, set on

Proceed in editing another parameters in the same way up to step 6

StEP

Number of step,set 6

tYPE

Type of step, set End

E1. 6

State of event output 1, set oFF

E2. 6

State of event output 2, set oFF

E3. 6

State of event output 3, set oFF

Important:

• You need not always set all steps, which is time consuming and tiresome in most cases. In

that case you can create your own profile of programme (some parameters can be set

permanently, they will not be displayed). You will find all necessary information how to

make a programme profile on page 18.

• If you edit the same or similar programmes with different parameters, you can easily copy

the programmes, see page 19.

Page 15

User part

15

3.3 Starting a programme

The programme can be started up by the command of operator with keyboard or can be

automatically started up by the internal real time clok.

Starting a programme with keyboard

• Controller is in basic MODE, see page 5.

• Press shortly key . On lower display appears ProG, another procedure see table:

Confirm Display Procedure Return

ProG

Set number of programme you wish to start up.

StEP

Set step from wich you like to start programme. If it is not configured, the

programme starts up from step 1.

Starting a programme by the internal clock

You can select the programme that will be started up by the clock after time setting.

• The controller is in basic MODE or running in a programme, see page 5.

• Press the key for more then 3 seconds. On lower display appears PCLK, then proceed

acc. to the table:

Confirm Display Procedure Return

PCLK

Set number of programme you wish to start up by clock. If you set oFF,

automatic start is not alloved.

SCLK

Set step from wich you like to start programme. If it is not configured, the

programme starts up from step 1.

Mon

Set month of start of programme. If you don´t liketo set month and day of

starting, set oFF. In that case parameter dAY is not displayed and

programme starts every day.

dAY

Set day of starting. It is not displayed, if setting is Mon = oFF.

hour

Set hour of starting a programme.

Min

Set minute of starting a programme.

Important:

• If you set the automatic starting a programme by the clock, on lower display blinks PCLK

in basic menu.

• You can not set the automatic starting a programme if another programme runs.

• If the programme starting up by the clock is shorter than parameter tdEL, it can be started

many times in a series. Parameter tdEL means time duration in minutes in which you can

start programme. You will find it in configuration level, menu Prun, see page 37.

Page 16

User part

16

3.4 To hold, to continue with and to end a programme

You can hold or end a programme or you can continue with it:

• The controller is in a programme, see page 5..

• Press shortly key , on lower display appears ProG, then proceed acc. to table:

Confirm Display Procedure Return

ProG

Set the state of the controller:

Cont … programme continues

hoLd … programme is held and the controller retains the last set point value

Abrt … programme is held and the control output is turned OFF.

End … programme is ended up

Not all options can e offered. Setting can be performed in configuration

level, menu Prun, parameter StoP, see page 37.

Page 17

User part

17

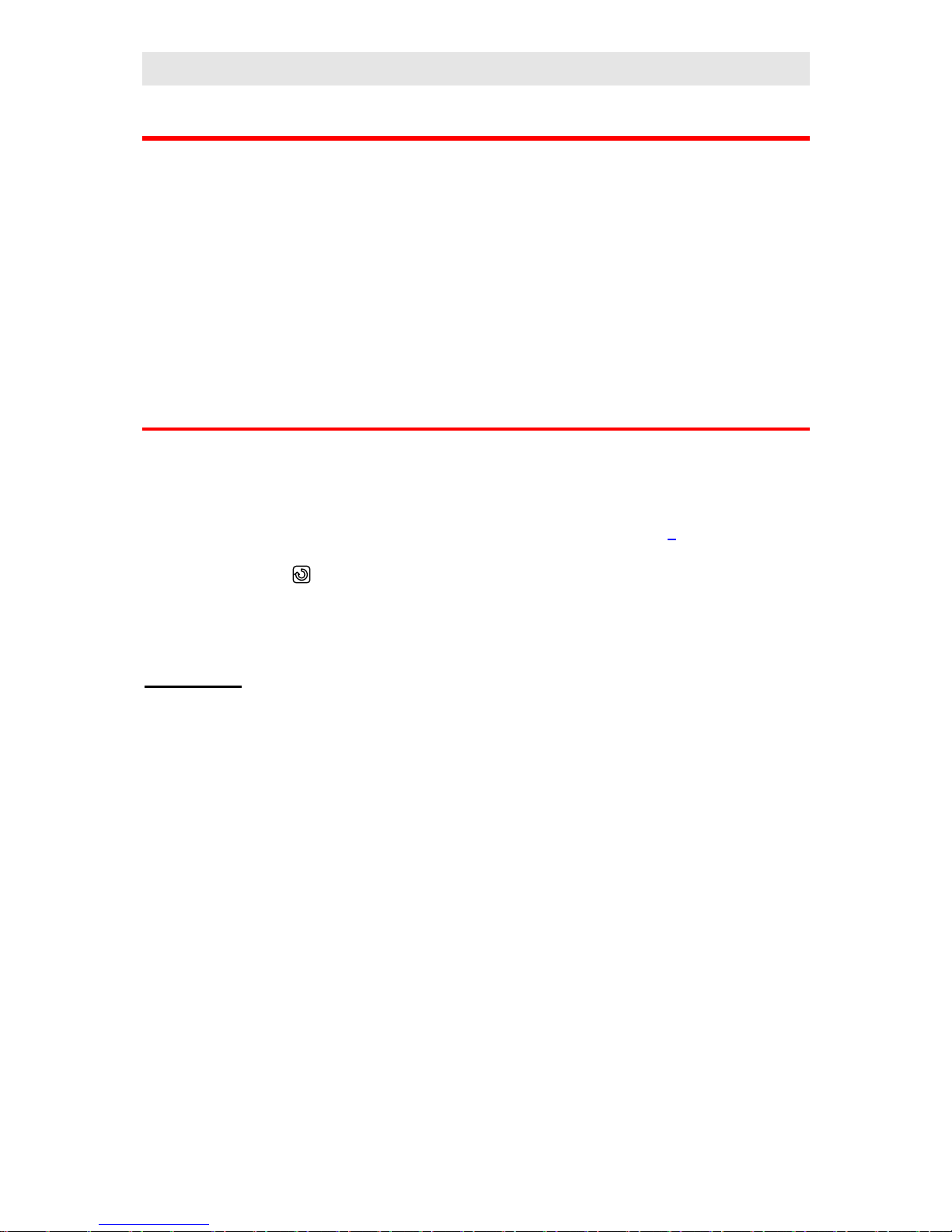

4 Operation level

In this level you can set parameters which are available to user.

To enter the menu from basic MODE press for 3 seconds key

On lower display blinks oPEr, set requested menu on upper display. Not all menus are

accesible.

oPEr

Editing of

programme.

profiles,

creating

programme

profiles

ProF

Menu

ProF

see below

FroM

Copying

programme

profiles

PCPY

to

Monitoring

actual power

and

consumed

energy

MonI

PCnt

Ptot

PPGM

Setting

internal time

clock

CLK YEAr

Mon

dAY

hour

Min

Start up

autotuningu,

state event

output, period

data history

…

GLbL

o2oF

Ent1

Aut

CAL1

hPEr

hSto

PPEr

PSto

Setting PID

parameters of

first output

out1

Pb1

It1

dE1

Pb2

It2

dE2

Ct1

hYS1

Setting

alarm/signal

limits of

second output

out2

o2Lo

o2hI

Ent2

Ent3

Set value parameters with

arrow keys

Page 18

User part

18

4.1 ProF, creations of programme profiles

If you edit a programme, as described in chapter Programme menu, you must go through and

edit all steps. But you can have a programmme, where you need to change only a few

parameters.Then it is convenient to create a programme profile.

Before the explanation how to create a profile it is necesarry to clear up 2 terms, full and

shortened edit of programme.

Full edit of programme

To create a profile you will set full edit of programme in operation level, menu ProF,

parameter EdIt = FuLL. Editing a programme parameters StEp (number of step) and

tYPE (type of step) are displayed. When create programme profile some parameters can be

firmly set. and tey are not displayed during editing. The procedure for editing a programme

cerresponds to procedure described in the chapter Programme menu.

Shortened edit of programme

To create a profile set shortened edit of programme in operation level, menu ProF, parameter

EdIt = Shot. Parameters StEp (number of step) a tYPE (type of step) are not displayed

when you edit. It is possible to view and set only accesible parameters of programme. The

best thing how to see shortened edit is to view some of fixed programmes ( FP1, …).

Example – how to create a programme profile:

You want to create profile of programme no. 5 for shortened edit.

First work out the table of programme and highlight the parameters to be hidden (grey in the

table), ie. they are set just right at creating a profile:

Prog: 5

StEP tYPE SP tI rt E1 E2 E3 Gd JP JS

1 StPt 200 2.30

oFF on oFF oFF

2 SoAK

1.20

on on oFF Strt

3 rAtE 1050

250 on on On oFF

4 SoAK

2.10

on oFF oFF on

5 rAtE 150

150 oFF oFF oFF oFF

6 End

oFF oFF oFF

7

8

9

Page 19

User part

19

Now start editing a programme profile:

Confirm Display Procedure Return

Prog

Number of programme, set 5

Edit

Full/ shortened edit of programme. Set shortened edit Shot

Step

Number of step, set 1

tYPE

Type of step, set StPt

SP. 1

Editing is allowed. This parameter is accesible, set EdIt

SP. 1

Set point value, set 200

tI. 1

Editing is allowed, set EdIt

tI. 1

Time needy for reaching set point value SP 1, set 2.30

Et. 1

If the parameters are not accesible you can allow the editing of all event

outputs, set SEt

E1. 1

State of event output 1, set oFF

E2. 1

State of event output 2, set on

E3. 1

State of event output 3, set oFF

Gd. 1

For editing to be allowed, set SEt

Gd. 1

Guaranteed soak deviation to be turned OFF, set oFF

StEP

Number of step, set 2

tYPE

Type of step, set SoAK

tI. 2

For editing to be allowed, set EdIt

tI. 2

Time to the end of soak, set 1.20

Et. 2

You can allow the editing of all event outputs by setting SEt

E1. 2

State of event output 1, set on

Proceed in editing another parameters in the same way up to step 6

StEP

Number of step, set 6

tYPE

Type of step, set End

Et. 6

For the permission ef editing of all event outputs, set SEt

E1. 6

State of event output 1, set oFF

E2. 6

State of event output 2, set oFF

E3. 6

State of event output 3, set oFF

To return to basic menu press the key

You can view the outcome in Programme menu.

4.2 PCPY, how to copy programmes

You can make your editing programmes easy with this menu. If the programmes are the same

or similar, you can create one programme that can be copied to the positions of another

programmes. Those programmes can be changed by your request.

You can also use steady fixed set programmes fo copying (FP 1, FP 2, …)

When you copy proceed as follows:

Confirm Display Procedure Return

FroM

The number of the source programme, ie. where it will be copied from..

Range: 1 to 30, FP 1, FP 2, FP 3, FP 4.

to

The number of the destined programme, ie. where it will be copied to.

Range: 1 to 30.

Page 20

User part

20

4.3 MonI, monitoring of power and consumption

In menu you cand find out the actual supplied power and the consumption of electrical energy.

Confirm Display Procedure Return

PCnt

Actual supplied power in %.

Ptot

Total consumption in kWh. After reaching value 9999 the counter is reset and

starts counting from 0.

PPGM

Energy consumption in kWh for one firing. When in programme the counter

is set to 0 and counting of consumption starts from 0.

4.4 CLK, how to set the time clock

In this menu you can set the real time clock. The clock is not equipped with automatic changeover

from standard time to daylight saving time and back in turn.

Confirm Display Procedure Return

YEAr

Set actual year

Mon

Set actual month

dAY

Set actual day

hour

Set actual hour

Min

Set actual minute

4.5 glBl, global parameters

In this menu there are the parameters taht can not be inserted elsewhere or any menu is not created for

this parameters.

Confirm Display Procedure Return

o2oF

Turn OFF constant alarm/signalling by setting YES and confirm

Ent1

Appears the state of event output 1 ( oFF, on). The output can be set with arrow

keys if programme does not run.

Ent2

Appears the state of event output 2 ( oFF, on). The output can be set with arrow

keys if programme does not run.

Ent3

Appears the state of event output 3 ( oFF, on). The output can be set with arrow

keys if programme does not run.

Aut

Starting ( on), stopping ( oFF) the automatic optimalization of PID parameters –

autotuning.

CAL1

Calibration of sensor. Set value is added to process value.

Range: -999 to 999 °C.

hPEr

The period of data storing of measured process values(hISt) in minutes.

Range: 1 to 120 minutes.

hSto

Condition for data storing of measured process values ( data history)

• oFF, data storing is turned OFF

• ProG, storing is executed only if programme runs

• ALSG, storing is executed only alarm / signalling

• Cont, storing is executed constantly

PPEr

The period for priting protocol on printer in minutes.

Range: 1 to 120 minutes.

PSto

Condition for priting:

• oFF, printing is turned OFF

• ProG, printing is executed only if programme runs

• ALSG, printing is executed only if programme runs

• Cont, printing is executed constantly

Page 21

User part

21

4.6 out1, setting parameters of control output

Menu is intended for manual setting of PID parameters or for improving parameters with

regard to offset of controlling.

Confirm Display Procedure Return

Pb1

Proportional band, 1.set of parameters

Range: 1 to 2499 °C.

It1

Integral value, 1.set of parameters

Range: oFF, 0.1 to 99.9 minutes

dE1

Derivative value, 1. set of parameters

Range: oFF, 0.01 to 9.99 minutes.

Pb2

Proportional band, 2. set of parameters

Range: 1 to 2499 °C.

It2

Integral value, 2. set of parameters

Range: oFF, 0.1 to 99.9 minutes

dE2

Derivative value, 2. set of parameters

Range: oFF, 0.01 to 9.99 minutes

Ct1

Time cycle

Range: 1 to 250 seconds for ot1 = ht, CL, 5 to 250 seconds for

ot1 = ht2, CL2.

hYS1

Hysteresis, this parameter is set only for ON/OFF control..

Range: 1 to 249 °C.

Parameters Pb1, It1, dE1 / Pb2, It2, dE2 are switched over depending on set

point value.

Temperature for switching over is set in configuration level, menu SYS parameter PID2. If

the process value is lower than PID2, parameters Pb1, It1, dE1 take efect, if the

process value is higher than PID2 parameters Pb2, It2, dE2 take effect.

4.7 out2, alarm set points / signal set points

Alarm / signal set points take action when the process temperature leaves a defined range or

deviation from set point value is higher, see page 48.

Confirm Display Procedure Return

o2Lo

Low alarm / signal set points

Range:

• -499 to o2hI °C for ot2 = ALPr, SGPr

• -999 to 0 °C for ot2 = ALdE, SGdE.

o2hI

High alarm / siganl set points

Range:

• o2Lo to 2499 °C for ot2 = ALPr, SGPr

• 0 to 999 °C for ot2 = ALdE, SGdE.

Page 22

User part

22

5 Tips

In this chapter the tips for operating and setting of the controller and the troubleshooting some

problems are described for an operator.

5.1 Running of programme, option for operation

Running a programme is indicated by diode MODE (lit). On lower display appears set point value, on

upper display appears process value.

The operation options for setting and viewing the parameters, alter. state of controller are:

• Setting and viewing the parameters in user menu.

• Editing and viewing a programme. If you change parameters of the programme that is just

running, current running step is not changed. The new parameters are accepted only in the

following step..

• Setting automatic start up of a programme by the clock.

• Entry to operation menu, setting and viewing the parameters in menu.

• Interruption and ending of programme.

5.2 State Hold, Abort

Hold and Abort are states for interruption of programme than can be caused:

• By the interruption of supply voltage, see page 24.

• By the interruption of programme via keyboard, see page 16

In state Hold (on lower display blinks hoLd) the controller retains the last set point value. The

programme can be ended up by the operator or can continue, see page 16

In state Abort (on lower display blinks Abrt) the controller switches OFF control output. The

programme can be ended up by the operator or can continue, see page 16

5.3 Guaranteed Soak Devition - GSD

GSD limits the Soak Band about the set point value in which the set point value must be maintained.

If the process value leaves the defined Soak Band, counting down is paused..

You can use this for furnace where rapid ramp rate and soak is required. The function GSD will ensure

that the counting down of time for soak start after reaching the set point value in the function GSD is

defined for each step separately and it can be selected as follows:

• oFF, it is turned OFF for the step

• Strt, it is only turned ON at the beginning of the step

• on, it is turned ON within the whole . The width of GSD range can be set in

configuration level, menu Prun, parameter GSd

set point

value

time

Range

GSD

GSD

Page 23

User part

23

5.4 Event outputs

If the controller is fitted with event outputs, the states of the outputs can be

programmed( oFF ... turned OFF, on … turned ON). The state is set when editing a

programme in parameters E1. , E2. , E3. .

Viewing and possible setting of the event outputs is the following:

• When running a programme it is posible to view the states of event outputs with help of

parameters Ent1, Ent2, Ent3, setting can not be changed.

• When a programme does not run, you can view and set the states of event outputs via

parameters Ent1, Ent2, Ent3.

• Parameters Ent1, Ent2, Ent3 can be present in user menu or in operation level, menu

GLbL.

5.5 Fixed programmes

There are 4 steady fixed programmes stored in the controller´s memory. You can:

• view and use the programmes like model for editing your own profiles.

• Copy them to the position of vacant programmes (1 to 30) and then modify them by your

wish.

• Start them up, if your profile of programme fits.

Programmes are allocated behind the programme no. 30.

Programme FP1

Programme FP2

set point

value

time

160 °C

30°C/hour

20 min.

•

Event outputs are turned OFF

• Type of function GSD Strt

turnedON at beginning of 2.

step.

set point

value

time

1050 °C

360°C/hou

30 min.

•

Event outputs are turned OFF

• Type of function GSD Strt

turnedON at beginning of step

2. and 3.

200 °C

100°C/hour

Page 24

User part

24

Programme FP3

Programme FP4

5.6 Interruption of supply voltage

With this controller you can set the max. duration of the supply voltage interruption where the

programme still resumes / continues. If the duration of interruption is longer than this setting

of max. duration, it is possible to choose the following response of the controller:

• Resumes / continues in programme (Cont).

• Switches the control output ON/OFF at the last set point value, the possibility of resuming

in programme after operator´s action (hoLd).

• Switches OFF the control output, the possibility of resuming in programme after

operator‘s action (Abrt).

set point

value

time

1100 °C

•

Event outputs are turned OFF

• Type of function GSD Strt

turnedON at beginning of step

2. and 4..

360°C/hou

30 min.

200 °C

100°C/hour

30 min.

set point

value

time

800 °C

•

Event outputs are turned OFF

• Type of function GSD Strt

turnedON at beginning of step

2, 4, 6.

360°C/hou

30 min.

200 °C

100°C/hour

30 min.

180°C/hou

20 min.

1100 °C

Page 25

User part

25

Parameters for the definition of response to the supply voltage interruption:

• tCon, the permittrd duration of the interruption. Time is set in minutes.

• Pout, the response to the longer interruption of the supply voltage

The both parameters are palced in configuration level, menu Prun., see page 37.

5.7 Data history

The controller is fitted with the function for data storing of measured values. By the

configuration the controller can store 200 data in basic model or 5000 data in model with

expanded memory. If the memory is full, the oldest data are writen over with the newer ones..

Each stored record consist of the following items:

• measured process value

• month, day, hour and minute of record

How to read stored data – 2 ways:

• you can read stored data on display of controller in user menu, submenu hISt, (it must

be set accesible in configuration level). when you enter submenu (on lower display

appears hISt, on upper display set YES and confirm ) on upper display there is

measured process value indicated and time in format hour. minute appears on lower

display. Month and day can not be read on display. You can scroll between records with

arrow keys.

• the transfer of parameters via series communications. You will find out the necessary

informations in the manual describing communication.

Data storing can be set by these parameters:

• hPER, period of data storing in minutes.

• hSto, condition of storing. Data will be stored constantly, hSto = Cont, if alarm /

signal is active, hSto = ALSG, if programme runs, hSto = ProG, or data storing is not

set, hSto = oFF.

Both parameters are allocated in operation level, menu glBl, see page 20 or they can be set

accessible in user menu.

set point

value

time

device resumes in

programme

Permitted duration of

supply interruption

longer interruption

• resumes in programm

• the last set point value

• switches OFF output

Page 26

User part

26

5.8 Printing of measurement protocols on the printer

If the controller is fitted with series communications RS 232, the printer series input port can

be connected to the port/output of communications. The format of printing of measurement

protocol is illustrated below. The heading with the date is printed every day in 00.00 clock or

when the controller is turned ON. The set point and process value is always printed without

decimal point.

Parameters for printing of the measurement protocol:

• Prot = Prnt, setting of communications for control of printer. parameter is in

configuration level, menu CoM.

• PPER, period of printing in minutes

• PSto, condition for printing. Data will be printed constantly, PSto = Cont, data printing

if alarm or signal is active, PSto = ALSG, data printing if programme runs, PSto =

ProG, or printing is not allowed, PSto = oFF.

Both parameters are allocated in operation level, menu glBl, see page 20 or they can be

accesible in user menu.

5.9 Autotuning – automatic setting of PID parameters

The controller is fitted with the function that sets automatically PID parameters.

Procedure of starting autotuning:

• The controller must switch the control output, it means the control output must not be

turned OFF (in basic MODE there must not be on lower display oFF).

• Automatic optimalization you can start with parameter Aut = on. You will find

parameter in operation level, menu GlbL or you can set it accesible in user menu.

• The controller explores the characteristics of system from switching ON/OFF on the

output and determines optimal PID parameters. It can cause an overshoot.

• On lower disply blinks Aut1 or Aut2 depending on which set of PID parameters is set.

************************

DATE: 20.08.1999

************************

time: sp: c:

15:47 852 850

15:57 860 859

16:07 868 868

16:17 876 877

16:27 884

884

16:37 892 892

16:47 900 901

16:57 900 900

17:07 oFF 889

17:17 oFF 852

Page 27

User part

27

Important:

• Autotuning can not take effect in ON/OFF control, ie. ot1 = ht2 or CL2.

• Autotune set point value for autotuning is set by actual process value, by actual set point

value and by parameter AtSP. It is calculated this way:

autotune set poin value = actual process value + (actual set point value -

actual process value) x AtSP / 100.

• Parameters Pb1 , It1 , dE1 are set, if actual set point value is lower than parameter

PId2 when both sets of PID parameters are used(ALGo = PID2).

• Parameters Pb2 , It2 , dE2 are set, if actual set point value is higher than parameter

PId2.

Parameters AtSP, ALGo a PID2 are in configuration level, menu SYS, see page 37.

5.10 Time-limited work of the controller and its unlocking

You can set time-limited work of controllers for reason of servicing, etc. This state is

indicated in basic MODE by blinking trun. After elapsing the permitted time the starting

programmes is not allowed.

You can read the time to the end for working of the controller in parameter StoP, see the

following table.

You can unlock this time-limited work of the controller by sending in for the service worker

or via the folloeing procedure.

• The controller is in basic MODE or in a programme, see page 5 . If the time-limited work

of the controller is set. There is parameter trun on the first place in user menu.

• Now press shortly key and go on acc. to the table.

Confirm Display

Procedure Return

trun

Set YES, after you confirm you vill get to submenu for reading of the

remain time of work of contreoller and unlocking of controller.

StoP

The remaining time for work is in hours. After this time has elapsed you can

not start a programme. The time of work of the controller is defined by the

time of switching ON of the control output.

PASS

Set password for unlocking the controller. The password is entered in 4 steps,

each position separately. Set 1. position, confirm, set 2. position,....

trun

Time of work of the controller in hours. For unlocking, set oFF.

Page 28

Configuration and service part

28

6 Installation

The controleer is designed to be mounted to the panel cutout. Slide the controller into the

cutout and fix with 2 flanges, that are supplied with the controller. The installation requires

the access to the back of the panel.

Mounting dimmensions

• Width x heigh x overall lenght: 96 x 96 x 160 mm (including terminalboard).

• Behind panel lenght: 153 mm (including terminalboard).

• Cutout in the panel: 91 x 91 mm.

• Thickness of panel: 1,5 to 10 mm.

Mounting

• Make the panel cutout 91 x 91 mm.

• Slide the controller into the panel cutout.

• Insert the flanges for holding into the holes upward and downward or on both sides of the

controller.

• Tighten the screw firmly on the flanges.

• The controller is installed, then its wiring follows, see page 29

Page 29

Configuration and service part

29

7 Power wiring

To avoid potential electric shock, use safety practices laid down by national standards

when wiring and connecting this unit to a power source. Failure to do so could result in

such damage, and / or injury. The wiring must be done only by the authorised person.

Supply voltage

Before you connect the unit to a supply power source, check the level of supply voltage.

Thermocouple input

The input impedance of thermocouple input is 20 MOhm.

RTD input Pt100

2 or 3 wire connection of RTD platinum sensor

1

2

3

4

5

6

12

11 10 9 8 7 18 17 16 15 14 13

Fuse

200 mA

230VAC

50Hz

Fuse

1 A

12-16V

AC/DC

1

2

3

4

5

6

-

+

1

2

3

4

5

6

1

2

3

4

5

6

Page 30

Configuration and service part

30

Process input – voltage or current

The input impedance for voltage is 10 kOhms, current 5 Ohms.

Analog (Retransmit) output

The output current of analog signal has the range 0 to 20 or 4 to 20 mA. Max. impedance of

load is 100 Ohms.

Communication

Communications is isolated / ungrounded.

The control output 1

Open collector / DC voltageis intended to switch solid state relays SSR, the output is not

galvanic isolated.

1

2

3

4

5

6

-

+ U

voltage

1

2

3

4

5

6

current

-

+ I

1

2

3

4

5

6

TxD

RS 232

RxD

Com

1

2

3

4

5

6

T-/R-

EIA 485

T+/R+

Com

12

11 10 9 8 7 18 17 16 15 14 13

mechanical relay

230VAC/5

A or

30VDC/5A

12

11 10 9 8 7 18 17 16 15 14 13

+

-

DC voltage output

max. 30

mA,

voltage in

open state

appr. 10V.

1

2

3

4

5

6

I -

I +

I

Page 31

Configuration and service part

31

The voltage as well as current output is isolated/ungrounded.

The output 2, alarm / signal

The event output 3, 4, 5

12

11 10 9 8 7 18 17 16 15 14 13

+

-

voltage output

load

min.

1kOhm

U

12

11 10 9 8 7 18 17 16 15 14 13

+

-

current output

load max.

500Ohms

I

12

11 10 9 8 7 18 17 16 15 14 13

230Vac/5A

or

30VDC/5A

12

11 10 9 8 7 18 17 16 15 14 13

output 3

output 4

output 5

common contact

230VAC/2A

or 30VDC/2A

Page 32

Configuration and service part

32

8 Putting into operation

The initial set-up can be done only by the qualified and authorised person.

The wrong set-up can cause serious damage.

When you power the controller up, you must enter the most necessary data to the controller

for its problem-free operation:

• type of sensor, position of decimal point

• scale for measured/process valuesappearing on display for process input

• operational range of set point value

• set-up for the control output

8.1 Guidelines

Let´s suppose that the controller is installed in the panel and you have just power it up for the

first time. Parameters of initial operation are the following:

• In1 , set input sensor. The descriptionof this parameter see on page 34.

• dEC1, set the decimal point. The description of this parameter see on page 34.

• rL1 , rh1 , parameters for setting of scale for process inputs. These are not displayed

for thermal inputs. The description of these parameters see on page 34.

• SP1L, SP1h, the limit for set point range. The description of these parameters see on

page 36.

• ot1 , setting of the control output. The description of this parameter see on page 35.

The futher information regarding the input setting is found on page 44, regarding the output

setting on page 45.

Important:

• All the parameters that were set in the initial operation can be later changed configuration

level.

• Another option of the configuration are in the chapter Tips for configuration on page 44.

• If you set more controllers, inform yourselves upon user configuration from your supplier.

The brief description is on page 52

Page 33

Configuration and service part

33

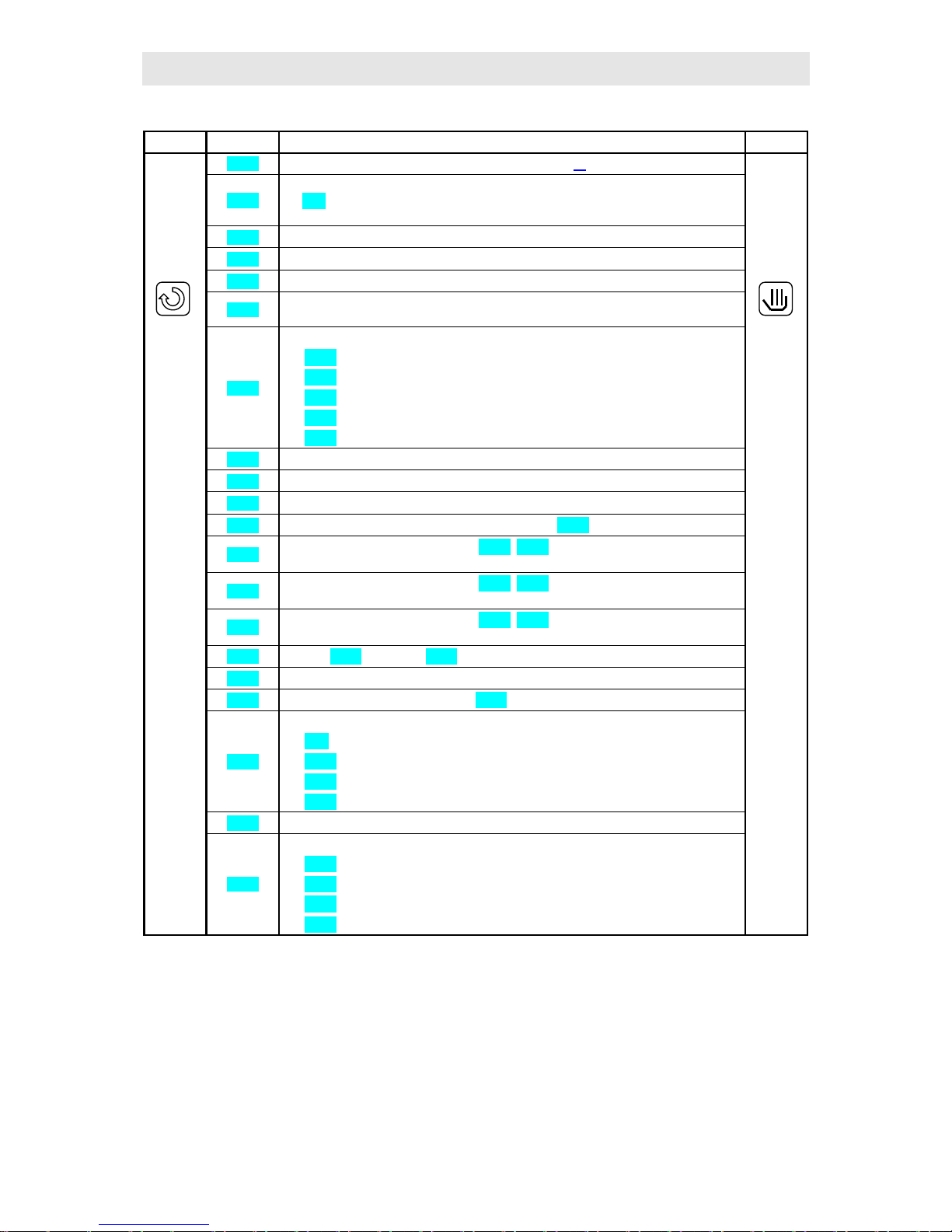

9 Configuration level

The configuration level is intended for basic setting of controller. In this level the control

output is turned OFF and alarm, signal and event output is deactivated.

The enter configuration level from operation level press for 3 seconds keys

To return from the configuration level press the key .

PASS

setting of the

input of the

controller

InP1

ot1

setting of the

control

output

out1

PLd1

setting of

alarm/signal

output

out2

ot2

Lat2

SIL2

setting of

analog

(retransmit)

output

rtMt

Aout

setting of

communicati

ons

CoM

bAud

setting of

parameters

for setpoint

value

StPt

SP1L

dEC1

rL1

rh1

Ftr1

SPL1

Plu1

o2Sd

hYS2

ProC

rtrL

rtrh

rtPL

rtPh

Prot

Addr

In1

SP1h

SLEP

Set

setting of

system

parameters

SYS GSd

setting of

parameters

start, run and

end of

programme

Prun

setting of

parameters

operation

menu

oPEr

SP1

CAL1

hPEr

dE1

setting of

user menu

uSEr

StP1

setting of

locks

LoC SP1

ALGo

Pid2

AtSP

Aret

hSto

PPEr

Pb2

It2

dE2

ct1

hYS1

StP2

StP3

PoW

ProF

PCPY

tCon

Pout

Strt

Stop

tdEL

PSto

Pb1

It1

o2Lo

o2hI

StP4

StP5

StP6

StP7

StP8

GLbL

ot1

ot2

Set

PASS

Page 34

Configuration and service part

34

The entry to configuration level can be locked by password, see page 39. In this case the

parameter PASS appears first (the requirement of password). If you do not write the right

password, the entry to configuration level is inhibited.

9.1 InP1, setting of input

Display Meaning

In1

Setting of input sensor.

Thermocouple input:

• no … input is not set

• J … thermocouple J, range -200 to 900°C

• K … thermocouple K, range -200 to 1360°C

• t … thermocouple T, range -200 to 400°C

• n … thermocouple N, range -200 to 1300°C

• E … thermocouple E, range -200 to 700°C

• r … thermocouple R, range 0 to1760°C

• S … thermocouple S, range 0 to 1760°C

• b … thermocouple B, range 300 to 1820°C

• C … thermocouple C, range 0 to 2320°C

• d … thermocouple D, range 0 to 2320°C

RTD input:

• no … input is not set

• rtd … sensor Pt100, range -200 to 800°C

Process input:

• no … input is not set

• 0-20 … 0 – 20 mA, range -499 to 2499 units

• 4-20 … 4 – 20 mA, range -499 to 2499 units

• 0-5 … 0 – 5 V, range -499 to 2499 units

• 1-5 … 1 – 5 V, range -499 to 2499 units

• 0-10 … 0 – 10 V, range -499 to 2499 units

dEC1

Setting of decimal point for the showing on display.

Thermocouple and RTD input.

• 0 … without decimal point

• 0.0 … one decimal figure

Process input:

• 0 … without decimal point

• 0.0 … one decimal figure

• 0.00 … two decimal figures

rL1

Together with parameter rh1 sets the scale of the process ranges for showing of values on

display.

Range: -499 to rh1 .

rh1

Together with parameter rL1 sets the scale of the process ranges for showing of values on

display.

Range: rL1 to 2499.

Ftr1

Set filter time constant for input signal. The more value is set, the more influence the filter has, see

page 44.

Range: oFF, 0.1 to 60.0 seconds

Page 35

Configuration and service part

35

9.2 out1, control output

Display Meaning

ot1

Function of the control output:

• ht … switches ON/OFF the heating, PID controlling

• CL … switches ON/OFF the cooling, PID controlling

• ht2 … switches ON/OFF the heating, 2-state (ON/OFF) controlling

• CL2 … switches On/OFF the cooling, 2-state (ON/OFF) controlling

PLd1

Output power limit within range low when set point value is below, set in %.

Range: 0 to 100 %.

SPL1

Setting the power limit set point between low range and high range for the power limit.

Range: -499 to 2499 °C.

Plu1

Output power limit within range high when set point value higher, set in %.

Range: 0 to 100 %.

9.3 out2, alarm, signal output

Display Meaning

ot2

Function of alarm / signal output:

• no … output is not actived

• ALPr … alarm defined by the absolute value

• ALdE … alarm defined by the deviation from the set point value

• SGPr … signalling defined by the absolute value

• SGdE … signalling defined by the deviation from the set point

Lat2

Setting alarm / signal latching (a latched alarm remains active after the alarm condition passed):

• oFF … temporary alarm / signalling

• on … permanent / latched alarm / signalling

SIL2

Alarm / signal silencing after the switching ON of the controller:

• oFF … the function is turned ON

• on … the function is turned OFF

o2Sd

The selection of active limits for alarm / signalling:

• LohI … is active low and high limit

• hI … is active high limit

• Lo … is active low limit

hYS2

The hysteresis of switching for alarm / signal output.

Range: 1 to 249 °C.

Page 36

Configuration and service part

36

9.4 rtMt, analog output

Display Meaning

Aout

Value transmitted by the analog output:

• PrC … process value (upper display)

• StPt … set point value (lower display)

• PCnt … power of the control output in %

ProC

Output analog signal:

• 0-20 … 0 to 20mA

• 4-20 … 4 to 20mA

rtrL

Together with parameter rtrh sets the scale of the transmitted process or set point value.

Range: -499 to 2499 °C.

rtrh

Together with parameter rtrL sets the scale of the transmitted process or set point value.

Range: -499 to 2499 °C.

rtPL

Together with parameter rtPh sets the scale of the transmitted output power.

Range: 0.0 to 100.0 %.

rtPh

Together with parameter rtPL sets the scale of the transmitted output power

Range: 0.0 to 100.0 %.

9.5 CoM, communications

Display Meaning

bAud

Baudrate of the communications is set to 9600Bd.

Prot

Protocol of communications:

• Mod … MODBUS, protocol used for the communication PC with the controller

• M-S … the controller M transmits set point value, the other controllers under M‘s control

receive it (system Master - Slave)

• Prnt … the controller transmits information for the printer. It is used for writing of

measurement protocol.

Addr

Address of the controller. It appears when Prot = Mod.

9.6 StPt, features of set point value

Display Meaning

SP1L

The limit of low range set point value.

Range: -499 to SP1h °C.

SP1h

The limit of high range for set point value.

Range: SP1L to 2499 °C.

SLEP

The state of the controller, if the programme does not run:

• oFF … the controller does not switch the control output

• SP … the controller switches ON/OFF the output to set point value SP1

Page 37

Configuration and service part

37

9.7 SYS, system parameters

Display Meaning

PoW

Power of system under control in kW. This parameter is used for the calculation of consumed

energy.

Range: 0.0 to 999.0 kW.

ALGo

Algorithm of PID controlling:

• PID … one set of PID parameters is used.

• PID2 … both sets of PID parameters are used

PId2

The limits between PID1 and PID2.

Range: -499 to 2499 °C.

AtSP

Setting of helping Auto-tune set point value for autotuning of PID parameters. This parameter is a

percentage of the process value and normal set point value.

Range: 0 to 100 %.

ArEt

How to allow the automatic return from open menu:

• oFF … automatic return is not allowed.

• on … automatic return from open menu after 1 minute of key inactivity.

9.8 Prun, programme parameters

Display Meaning

GSd

Setting the soak Band for GSD function about set point value vhen programme runs.

Range: 1 to 999 °C.

TCon

Maximum duration of the supply voltage interruption in minutes. If the interruption is shorter than

Tcon, the programme continues, if it is longer, the response to the interruption is set by parameter

Pout. When you set oFF this function is not active.

Range: oFF, 1 to 999 minute.

Pout

The response to the supply voltage interruption. It takes effect after the duration Tcon elapsed.

• Cont … the programme continues in run

• hoLd … the programme is held and the controller retains the last set point value.

• Abrt … the programme is interrupted and the control output is turned OFF.

Strt

Setting the options for a programme:

• ProG … you can set only the programme that starts with the first step

• PrSt … you can set a programme as well as a step

StoP

Setting the options for editing or interrupting a programme:

• C E … Continue,End

• Ch E … Continue , Hold (soak on set point value), End

• C AE … Continue, Abort (the control output is turned OFF), End

• ChAE … Continue , Hold (soak on set point value), Abort (the control output is turned OFF),

End

tdEL

Setting the delay of automatic start of programme in set real time (and date), when in this moment

the programme can not be started (for example if the device is turned OFF or if there is a supply

voltage interruption). Time delay is set in minutes.

Range: 1 to 99 minutes.

Page 38

Configuration and service part

38

9.9 oPEr, setting parameters in operation level

The parameters of operation level are accessible in configuration level for easier setting of the

controller (there is no need to switch over between operation and configuration level).

Display Meaning

SP1

Set point value SP1. It takes effect when SLEP = SP

CAL1

hPEr

hSto

PPEr

Psto

Pb1

It1

dE1

Pb2

It2

dE2

ct1

hYS1

o2Lo

o2Hi

Parameters are described in the chapter Operation level

9.10 uSEr, setting of user menu

Displej Význam

StP1

the parameter thet is placed on 1. position of user menu:

• no … there is no parameter

• hISt … enables the acces to submenu hISt

• run … enables the acces to the parameters Prog, SteP, EnSP, trEM, that indicate the state of

programme course

• CLK … enables the acces to submenu for setting of real time clock.

• PCnt … the actual supplied power in percentage %

• Ptot … the total consumption of energy in kWh

• PPGM … the energy consumption in kWh for 1.....

• o2oF … the function for permanent turning, alarm / signal OFF

• Ent1 … displaying / controlling 1.event output

• Ent2 … displaying / controlling 2.event output

• Ent3 … displaying / controlling 3.event output

• Aut … starting / ending automatic optimalization / autotuning of PID parameters

• CAL1 … the calibration of sensor

• hPEr … the period of data storing of measured values

• hSto … the condition for data storing (data history)

• PPEr … the period of printing

• PSto … the condition for printing

StP2

Parmeter thet is placed on 2. position of user menu. The list is the same as in StP1

StP3

Parmeter thet is placed on 3. position of user menu. The list is the same as in StP1

StP4

Parmeter thet is placed on 4. position of user menu. The list is the same as in StP1

StP5

Parmeter thet is placed on 5. position of user menu. The list is the same as in StP1

StP6

Parmeter thet is placed on 6. position of user menu. The list is the same as in StP1

StP7

Parmeter thet is placed on 7. position of user menu. The list is the same as in StP1

StP8

Parmeter thet is placed on 8. position of user menu. The list is the same as in StP1

Page 39

Configuration and service part

39

9.11 LoC, lock

Display Meaning

SP1

The lock for set point value SP1. The controller switches the control output to set point value SP1,

if a programme does not run and the control ON / OFF to SP1 is allowed(SLEP = SP), see page

36 :

• oFF … the change of set point value is allowed

• on … the change of set point value is not allowed

ProF

The lock for menu ProF in operation level:

• oFF … menu ProF is accessible

• on … menu ProF is not accessible.

PCPY

The lock for menu PCPY in operation level:

• oFF … menu PCPY is accessible

• on … menu PCPY is not accessible

GLbL

The lock for menu GLbL in operation level:

• oFF … menu GLbL is accessible

• on … menu GLbL is not accessible

ot1

The lock for menu ot1 in operation menu:

• oFF … menu ot1 is accessible

• on … menu ot1 is not accessible

ot2

The lock for menu ot2 in operation level:

• oFF … menu ot2 is accessible

• on … menu ot2 is not accessible

SEt

The lock for configuration level:

• oFF … configuration level SEt is accessible without password

• on … configuration level SEt is accessible with password

PASS

The password for the entry to configuration level.

Range: 0 to 9999.

Page 40

Configuration and service part

40

10 Service level

This level is intended for servicing.

You can get to service level from configuration level by pressing keys for 3 seconds.

To return from service level press the key .

SErV

Extended

configuration

menu

ASEt

System

parameters

SYS SoFt

Ptot

CLrP

ttot

CLrt

trun

PASS

Diagnostics

of inputs and

outputs

dIAG

AMb

tC

rtd

Pr I

Pr u

Editing of initial

or user

parameters

rSt rSt

Setting of 3.

event/alarm/

signal output

out3

IEt1

o3hI

tSG3

Setting of 4.

event/alarm/

signal output

out4

Setting of 5.

event/alarm/

signal output

out5

System

parameters

SYS

Setting of

locks

LOC IEt2

o4hI

tSG4

ot4

IEt3

o5hI

tSG5

ot5

dt

ProG

ot3

Limitation

output power

of control

output

out1

u1

SPu2

u2

SPu1

u3

SPu4

SPu3

u4

Page 41

Configuration and service part

41

10.1 ASEt, extended configuration menu

out1, limitation the output power of control output

Display Meaning

SPu1

The decide level for setting output power u1.

Range -499 to SPu2 °C.

u1

The maximal output power by a temperature SPu1.

Range: 0 to 100 %.

SPu2

The decide level for setting output power u2.

Range SPu1 to SPu3 °C.

u2

The maximal output power by a temperature SPu2.

Range: 0 to 100 %.

SPu3

The decide level for setting output power u3.

Range SPu2 to SPu4 °C.

u3

The maximal output power by a temperature SPu3.

Range: 0 to 100 %.

SPu4

The decide level for setting output power u4.

Range SPu3 to 2499 °C.

u4

The maximal output power by a temperature SPu4.

Range: 0 to 100 %.

out3, setting of output 3

Display Meaning

ot3

Setting of the function of output 3:

• Ent1 … event 1 defined by programme

• ALPr … alarm defined by the absolute value

• SGPr … signalling defined by the deviation from the absolute value

• SGA … signalling of the programme running

• Sgb … signalling of ending a programme

IEt1

The state of event output 1 when a prgramme is interrupted:

• hold … the event output 1 remains in the unchanged state

• oFF … the event output 1 is turned OFF

• on … the event output 1 is turned ON

Parameter is only displayed if the output is set as event one.

o3hI

High limit for alarm / signalling

Range: -499 to 2499 °C.

Parameter is only displayed, if the output is set as alarm or signal.

TSG3

Setting the time of signalling at the end of programme.

Range: 1 to 200 seconds.

Parameter is only displayed, if the output is set for signalling of the end of programme.

Page 42

Configuration and service part

42

out4, setting of output 4

Display Meaning

ot4

Setting of the function of output 4:

• Ent2 … event 2 defined by programme

• ALPr … alarm defined by the absolute value

• SGPr … signalling defined by the deviation from the absolute value

• SGA … signalling of the programme running

• Sgb … signalling of ending a programme

IEt2

The state of event output 2 when a prgramme is interrupted:

• hold … the event output 2 remains in the unchanged state

• oFF … the event output 2 is turned OFF.

• on … the event output 2 is turned ON

Parameter is only displayed, if the output is set as alarm or signal.

o4hI

High limit for alarm / signalling

Range: -499 to 2499 °C.

Parameter is only displayed, if the output is set as alarm or signal.

TSG4

Setting the time of signalling at the end of programme.

Range: 1 to 200 seconds.

Parameter is only displayed, if the output is set for signalling of the end of programme.

out5, setting of output 5

Display Meaning

ot5

Setting of the function of output 5:

• Ent3 … event 3 defined by programme

• ALPr … alarm defined by the absolute value

• SGPr … signalling defined by the deviation from the absolute value

• SGA … signalling of the programme running

• Sgb … signalling of ending a programme

IEt3

The state of event output 3 when a prgramme is interrupted:

• hold … the event output 3 remains in the unchanged state

• oFF … the event output 3 is turned OFF.

• on … the event output 3 is turned ON

Parameter is only displayed, if the output is set as alarm or signal.

o5hI

High limit for alarm / signalling

Range: -499 to 2499 °C.

Parameter is only displayed, if the output is set as alarm or signal.

TSG5

Setting the time of signalling at the end of programme.

Range: 1 to 200 seconds.

Parameter is only displayed, if the output is set for signalling of the end of programme.

SYS, systém parameters

Display Meaning

dt

Makes the derivative factor more accurate. The more value is set, the more damped the derivative

factor is.

Range: 1.0 to 100.0 seconds.

Page 43

Configuration and service part

43

LoC, setting of the locks

Display Meaning

ProG

The lock for editing a programme:

• oFF … menu for editing a programme is accessible.

• on … menu for editing a programme is not accessible.

10.2 SYS, systémové parametry

Display Meaning

SoFt

Number of software version.

Ptot

Total consumption in kWh. After reaching 9999 the counter is reset and starts counting from 0.

CLrP

Reseting of the counter Ptot. By setting YES and confirm the counter is reset Ptot.

ttot

Total time of the control output in hours. Simply it can be said that it is the time of switching ON

of the control output.

CLrt

Resets the counter ttot. By setting YES and confirm the counter is reset ttot.

trun

Sets the time for the operation of the controller in hours. After the time has elapsed (time indicated

by ttot) it is not allowed to start a programme. When you set oFF this function is not active.

PASS

Pasword for cancelling the time limit work for controller in user level. Consist of 4 figures.

10.3 dIAG, diagnostics of inputs and outputs

Display Meaning

AMb

Actual ambient temperature.

tC

Measured voltage, thermocouple input. Range 60mV.

rtd

Measured resistance, resistance input. Range 350 Ohms.

Pr I

Measured current, process input. Range 20mA.

Pr u

Measured voltage, process input. Range 10V.

10.4 rSt, editing of initial or user parameters

Display Meaning

rSt

rSt

rSt

rSt

Editing of initial or user parameters is the significant action to controller‘s setting. First it must be

confirmed 4x setting YES, and then the selection of initiation follows.

rSt

The selection of initiation:

• no … no setting of initiation.

• ConF … initial configuration (operation, configuration and service level).

• ProG … initiation of programmes.

• All … iniciation of configuration and programmes. After this step the restart of the

controller happens .

Page 44

Configuration and service part

44

11 Tips for configuration

In this chapter the tips for setting the device will be presented.

11.1 Measurement

The right selection the instalation, the wiring and location of sensor in the equipment and the

corresponding setting of parameters of the controller have the essential importance for the

correct function.

Configuration parameters of input for measurement are in configuration level, menu InP1.

Setting of input sensor

Set the corresponding input sensor in parameter In1 . You will find the survey of input

sensors in the chapter Technical parameters see page 54.

You can set the position of decimal point by parameter dEC1. You can set the displaying

without decimal point or with 1 decimal figure for thermal sensors, and for process sensors

you can set without decimal point, with 1 decimal figure or with 2 decimal figures.

You can set the limit set point value in configuration level, menu StPt, parameters SP1L a

SP1h, see page 36.

Important:

• Thermocouple and RTD inputs have the detection of improperly wired sensor. When the

sensor is open or broken, the control output is turned OFF, the alarm output is activated,

the signal output is deactivated...

• Process inputs do not have the detection of improperly wired sensor

Input filter

If the process value is distored by interference, you can use digital filter. The more the filter

factor is Ftr1, the more the filter smooths the input signal.When Ftr1 = oFF the filter is

turned OFF.

process

value

without

filter

time

with filter

time

Page 45

Configuration and service part

45

Measurement range of process inputs

In configuration level, menu InP1, with the parameters rL1 , rh1 a dEC1 you can

deliminate the measurement range of the process inputs.

Exmple of setting of process input:

You want to display the input signal 4 to 20 mA in the range 6.0 to 24.0.

Set dEC1 = 0.0, rL1 = 6.0 a rh1 = 24.0. The distribution between values 6.0

and 24.0 will be linear.

11.2 Control, the control output

You can select in the controller ON/OFF(2 state) or PID controlling for heating or cooling. If

PID controlling, you can use autotuning function for finding optimal PID parameters, see

page 26 and the power limit function, see page 47.

Parameters for configuration of the control output are in configuration level, menu out1.

ON / OFF control

ON / OFF control is selected by setting ot1 = ht2 (heating control) or CL2 (cooling

control). It is used for less exacting application. It is not possible to achieve zero hysteresis

value on principle. The process value rises and drops about set point value in the

characteristic way.

Displayed

process

value

input signal 4 mA

20 mA

6.0 24.0

Process

value

time

set poin value

hysteresi

The state of

the control

value

time

ON

OFF

Page 46

Configuration and service part

46

PID control

PID control is selected by setting ot1 = ht (heating) or CL (cooling). It provides the precise

control. For the correct function of the controller, however, it is necessary to set properly PID

parameters. Autotuning for setting of PID parameters is described on page 26.

PID parameters have the following meaning:

• Pb proportional band, is set in measured units. It is the band about the set point value in wich

the controller keeps the temperature.

• It integral factor, in minutes. Integral factor compensates the loss of system. A low integral

value causes a fast integrating factor.

• dE derivative factor, in minutes. Derivative responses to fast changes and tries to react against

them. The more value is, the more derivative factor reacts.

If the control output is 2 state (ON/OFF) (relay or SSR), the power (given in %) transferred to the

output with called pulse width modulation. In each time cycle (parameter Ct1 , that is in operation

level, menu out1) the control output is switched ON once and once OFF. The more power is

neccessary, the wider the width of switching is. The output responses are ilustrated in the third part of

the drawing.

Example of pulse width modulation of the output: