Page 1

MIKROTHERM® 825

MT825-A,

Communications

MT825A/C 11/09 Rev.3/Soft.4

THERMOPROZESS s.r.o.

Riegrova 2668/6c

370 01 České Budějovice

tel.: +420 387 313 182

fax : +420 385 340 947

e-mail: info@thermoprozess.cz

internet : www.thermoprozess.cz

THERMOPROZESS

Page 2

Communications

2

1 Scope of communications

Communication line enhances usability of the controller from autonomous controller to the

one which performs the tasks in a system. Basic feasibilities are described in the 5 following

articles:

• Reading data from the controller, Prot = Mod. Enables to acquire data (SP values,

process values, ..) for PC, their visual data processing and storing. The form for showing

and presenting depends on the features of the visual program used.

• Configuration of controller, Prot = Mod. In graphic environment of PC you can

easily configure and set parameters that are transferred to PC by one command. The

configuration via PC can be used for example for more sophisticated setting of controllers

or for setting of production line by the technology procedures stored in PC.

• The controllers configured in system Master – Slave, Prot = SGnL. The controller

MT825A - MASTER retransmits set point value and the SLAVE - controllers (MT600)

receive this value and process it. In comparison with analog retransmit the MASTERSLAVE system has the advantage in galvanic isolation of controllers and the precision of

transferring of STP value in 1 decimal point.

• Cascade controlling, Prot = SGnL. Used in process with long lag times between the

energy source and process measured value.

• Printing protocols of measurement, Prot = Prnt. Time, process and set point values

are shown on a printed copy, the format is illustrated below.

************************

DATE: 20.08.1999

************************

time: sp: c:

15:47 852 850

15:57 860 859

16:07 868 868

16:17 876 877

16:27 884 884

16:37 892 892

16:47 900 901

16:57 900 900

17:07 oFF 889

17:17 oFF 852

Page 3

Communications

3

2 Communication interfaces

The controllers can be equipped with communication interface RS 232 or EIA 485.

The baudrate of the communication is permanently set at 9600 Bd, the data bits is 8,

no parity, 1 stopbit.

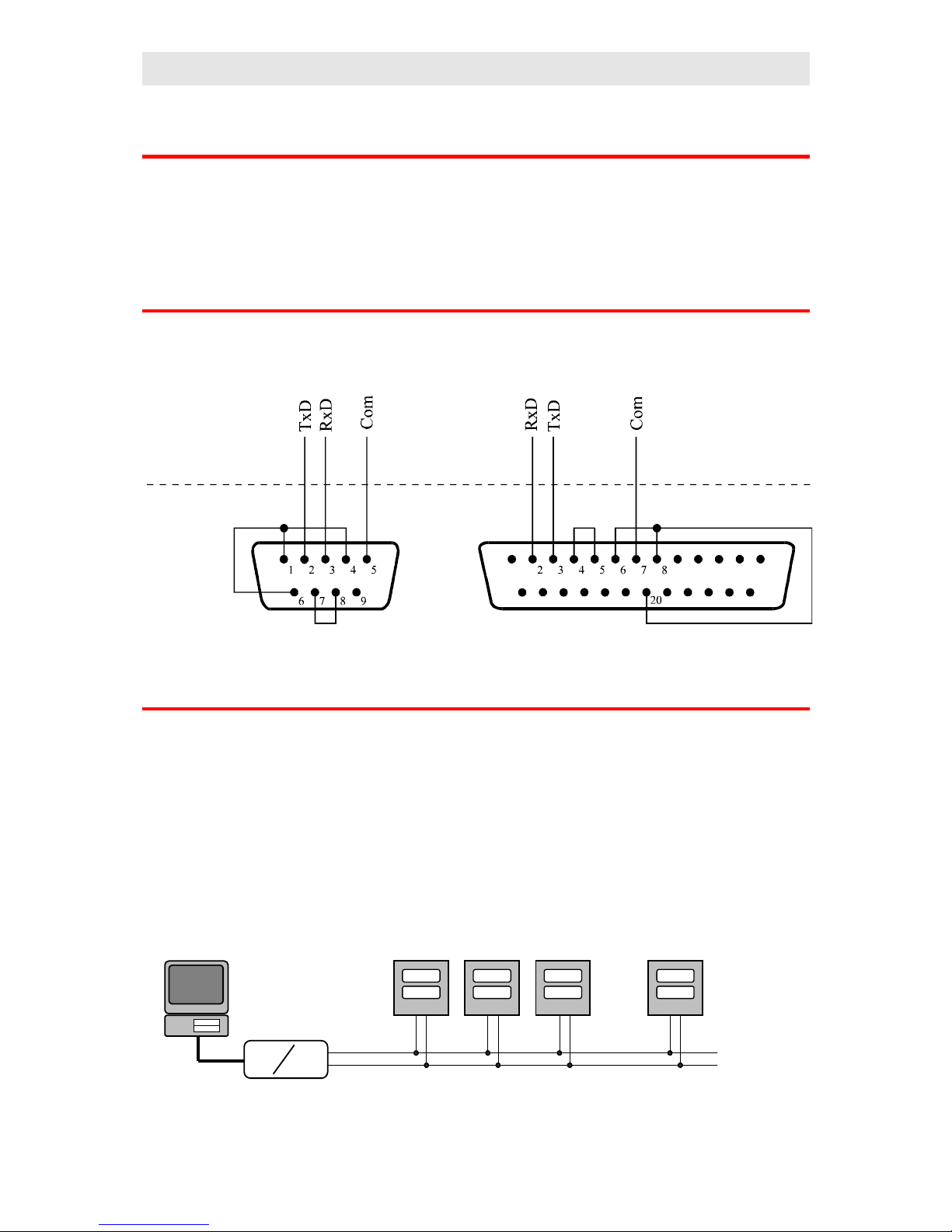

2.1 Interface RS 232

The interface RS 232 is intended for the link of 1 PC with 1 controller. Maximum network

length can be 12 meters. The wiring of standard connectors DB-9 and DB-25 on the side of

PC is illustrated in the following picture.

2.2 Interface EIA 485

The interface EIA 485 is suitable for industrial environment. The local network with this

interface can link as many as 32 controllers with PC up to the distance 1200 meters. When

repeaters are used more controllers can be linked at longer distance. In basic wiring there

must be an appropriate converter or PC card for transferring of interface RS 232 to EIA 485 at

the side of PC.

If controllers work in the environment with low interference, the communication line can be

carried out with twisted pair cable. The simplest wiring of communication line illustrates the

following picture.

RS 232

EIA 485

Side of controller

Side of PC

Page 4

Communications

4

3 Protocol MODBUS

The communication protocol MODBUS is intended for creating networks of type „Master –

Slave“, when „Master“ is PC, „Slave“ are always controllers. Its characteristic is simple, but

reliable structure with these features:

• Defined length of transmitted commands.

• Identification of the terminal equipment with the address (for MT825 address 1 to 250).

• The back confirmation of each command.

• The report is secured with CRC code.

• The transfer of error reports.

3.1 General structure of protocol

Address of

controller

Command

Address of register and/or data CRC

1 byte 1 byte n bytes 2 bytes

The commands for MT825:

• Read – 03H or 04H

• Write to 1 register – 06H

• Back inquiry – 08H

3.2 Operation - read

This operation enables reading as many as 32 registers in a row one after another. If register is

not defined the controller returns the value – 32000, if the register is not active

the controller returns the value –32001.

Command:

Address of

controller

03H Address of 1. read register Number of read registers CRC

1 byte 1 byte

2 bytes (1. byte higher) 2 bytes (1. byte higher) 2 bytes

Response:

Address of

controller

03H Number of

bytes

1. read register … The last read register CRC

1 byte 1 byte 1 byte 2 bytes (1. byte

higher)

2 bytes (1. byte higher) 2 bytes

Example: reading of register 100 (64H, set point value), controller

at the address 12 (0CH)

Command: 0C 03 00 64 00 01 C4 C8

Response: 0C 03 02 01 C8 95 83

Page 5

Communications

5

3.3 Operation - write (06H)

This operation enables writing a value to 1 register of controller:

Command:

Address of

controller

06H Address of register Data CRC

1 byte 1 byte 2 bytes (1. byte higher) 2 bytes (1. byte higher) 2 bytes

Response if the command is performed (is identical with the command):

Address of

controller

06H Address of register Data CRC

1 byte 1 byte 2 bytes (1. byte higher) 2 bytes (1. byte higher) 2 bytes

Example: writing to register 100 (64H, set point value), controller at the address

12 (0CH)

Command: 0C 06 00 64 01 C8 C9 0E

Response: 0C 06 00 64 01 C8 C9 0E

Response, error report:

Address of

controller

Command +

80H

Error reports CRC

1 byte 1 byte 1 byte 2 bytes

Error reports:

• 01 – error of command entered, error in CRC.

• 02 – register does not exist or is intended only for reading.

• 03 – data are beyond the limits.

• 04 – writing to register failed (e.g. error of hardware, too high interference …)

Example: error of the register entered

Command: 0C 01 00 64 04 20 7F D0

Response: 0C 81 01 10 53

Example: error, the register does not exist

Command: 0C 06 00 69 04 20 5B D3

Response: 0C 86 02 52 62

Example: error, data beyond the limits

Command: 0C 06 00 64 4E 20 FD 70

Response: 0C 86 03 93 A2

3.4 Operation - back inquiry:

This operation is only intended for the detection of the controller at the relevant address.

Page 6

Communications

6

Command:

Address of

controller

08H Data CRC

1 byte 1 byte 4 bytes 2 bytes

Response:

Address of

controller

08H Data CRC

1 byte 1 byte 4 bytes 2 bytes

Example: back inquiry, controller at the address 12 (0CH)

Command: 0C 08 0A 14 1E 28 AB 74

Response: 0C 08 0A 14 1E 28 AB 74

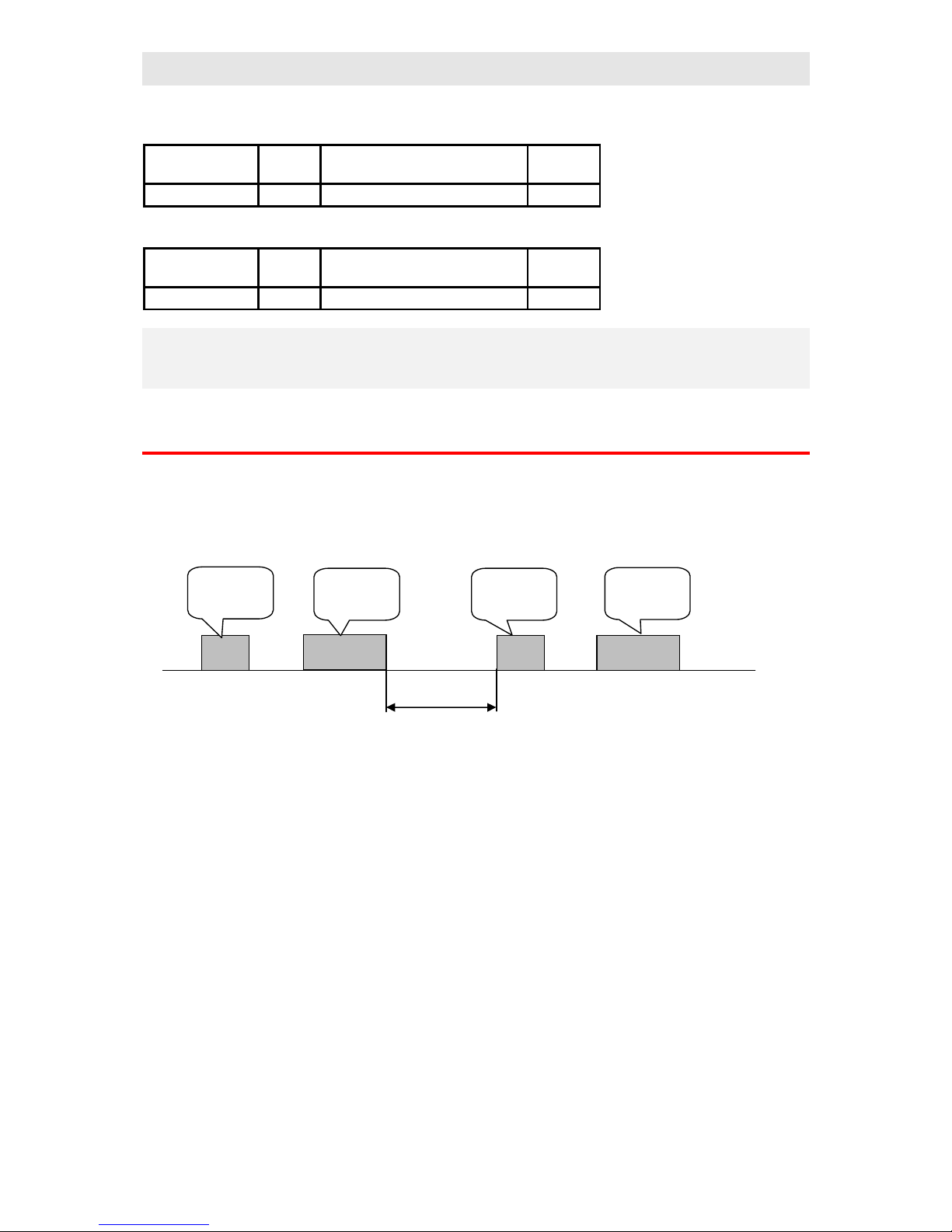

3.5 Timing of communication line

If there is more than 1 controller on the line (only line EIA 485) it is necessary to observe the

timing shown in the following picture.

The time interval (pause between ending of receiving and transmitting of another command)

must be more or equal to 50ms. In opposite case the data collision might appear.

time

Transmitting

command

Receiving

response

Transmitting of

another

command

Receiving

response

Interval >= 50 ms

Page 7

Communications

7

4 Overview of registers

The table comprises the total overview of registers that are accessible for communication line.

The meaning of particular parameters is the following:

• Display … if you set the relevant parameter via keyboard, on lower display appears

writing stated in the column display.

• Address … address of register. The access for register is shown after the address,

r … read only, r/w … read as well as write.

• Range … range of register values.

• Initiation … initial value at first power-up or after restart.

• Decimal point … determines the number of decimal points that are to be displayed.

The conversion shows the following table.

Decimal point Value entered with

communication line

Display reading Note

0 1800 Factory setting, no decimal point

1 180.0 Factory setting, 1 decimal point

2 18.00 Factory setting, 2 decimal point

dEC1 (0) 180 By par. dEC1 (no dec. point), input tc, rtd

dEC1 (1) 1800 180.0 By par. dEC1 (1 dec. point), input tc, rtd

dEC1 (0) 180 By par. dEC1 (no dec. point), input process

dEC1 (1) 18.0 By par. dEC1 (1 dec. point), input process

dEC1 (2) 1.80 By par. dEC1 (2 dec. points), input process

dEC1 (3) 0.180 By par. dEC1 (3 dec. points), input process

• Note … the meaning of register is mostly stated

System registers

Display Address Range Initiation Dec. point

Note

SoFt

0 r Software version

1 r 0 … 2kB

1 … 32kB

Embedded memory RAM for

datalogger

2 r 0 … tc

1 … rtd

2 … proc

Measuring input

3 r 0 … none

1 … retransmit

2 … communication

Control input, output

4 r 0 … SSD

1 … relay

2 … process

Control output

5 r 0 … none

1 … relay

Alarm / signal output

6 r 0 … none

1 … 1 relay

2 … 2 relay

3 … 3 relay

Event output

Page 8

Communications

8

Display Address Range Initiation Dec. point

Note

Aut

12 r/w 0 … oFF

1 … on

0 Start on, stop oFF

automatic setting of PID

parameters

50 r Process value

upper display

dEC1

If sensor is not set, the controller

returns the value –22000.

If the bad sensor is detected

the controller returns the value –

22001.

51 r Ambient temperature 1 The controller returns only

process/measured value for

thermocouple input

60 r Actual set point value

lower display

dEC1

If SP value is OFF oFF,

the controller returns the value -

22000

70 r PID controlling:

0 to 1000

ON/OFF controlling:

0 … switched OFF

1 … switched ON

1

Control output.

Power at % for PID controlling

State of the output for ON/OFF

controlling

71 r 0 … switched OFF

1 … switched ON

Alarm/ signal output

72 r 0 … switched OFF

1 … switched ON

Event output 1

73 r 0 … switched OFF

1 … switched ON

Event output 2

74 r 0 … switched OFF

1 … switched ON

Event output 3

80 r 0 to 9999 0 Total time of the control output

in hours.

81 r 0 to 9999 0 Total consumption of energy

in kWh. After reaching 9999 the

counter is reset and starts from 0.

82 r 0 to 9999 0 Total consumption in kWh for 1

firing. When program is released

the counter is reset and counting

of the consumption starts from 0.

Page 9

Communications

9

Operation level

Display Address Range Initiation Dec. point

Note

100 r/w SP1L to SP1h Set point value, reading appears

on lower display

Pb1

110 r/w 10 to 24990 200

dEC1

Proportional band

It1

111 r/w 0 to 999

0 … oFF

100 1 Integrative value

dE1

112 r/w 0 to 999

0 … oFF

24 2 Derivative value

Pb2

113 r/w 10 to 24990 200

dEC1

Proportional band

It2

114 r/w 0 to 999

0 … oFF

100 1 Integrative value

dE2

115 r/w 0 to 999

0 … oFF

24 2 Derivative value

Ct1

116 r/w 1 to 250 for ot1 =

ht, Cl

5 to 250 for ot1 =

ht2, Cl2

1

15

0 Time cycle

hYS1

117 r/w 10 to 2490 20

dEC1

Hysteresis for switching

ON/OFF of the control output

CAL1

120 r/w -9990 to 9990 0

dEC1

Calibration of measuring input

o2Lo

130 r/w -4990 to o2hI for ALPr,

SGPr

-9990 to 0 pro AldE,

SGdE

-4990

-990

dEC1

Low alarm / signal set points

o2hI

131 r/w o2Lo to 24990 pro

AlPr, SGPr

0 to 9990 pro AldE,

SGdE

24990

990

dEC1

High alarm / signal set points

hPEr

140 r/w 1 … 120 10 0 Period of data storing in minutes

hSto

141 r/w 0 … oFF

1 … ProG

2 … AlSG

3 … Cont

1 Condition for data storing

PPEr

142 r/w 1 to 120 10 0 Period for printing protocol on

the printer in minutes

PSto

143 r/w 0 … oFF

1 … ProG

2 … AlSG

3 … Cont

1 Condition for printing

Page 10

Communications

10

Configuration level

Display Address Range Initiation Dec. point

Note

In1

200 r/w Thermocouple input:

0 … no

1 … J

2 … K

3 … t

4 … n

5 … E

6 … r

7 … S

8 … b

9 … C

10 … d

RTD input:

0 … no

1 … rtd

Process input:

0 … no

1 … 0-20

2 … 4-20

3 … 0-5

4 … 1-5

5 … 0-10

0 Setting of the input sensor

dEC1

201 r/w tc and rtd input:

0 … 0

1 … 0.0

Process input

0 … 0

1 … 0.0

2 … 0.00

rL1

202 r/w -4990 to rh1 -4990

dEC1

Low range of process input

rh1

203 r/w RL1 to 24990 24990

dEC1

High range of process input

Ftr1

204 r/w 0 to 600

0 … oFF

10 1 Input filter

ot1

210 r/w 0 … ht

1 … CL

2 … ht2

3 … CL2

0 for SSD

and proc

2 pro relay

Setting of the control output

PLd1

211 r/w 0 to 100 100 0 Output power limit below SPL1

SPL1

212 r/w -4990 to 24990 250

dEC1

SP value for power limit function

PLu1

213 r/w 0 to 100 100 0 Output power limit above SPL1

Page 11

Communications

11

Display Address Range Initiation Dec. point

Note

ot2

220 r/w 0 … no

1 … ALPr

2 … AldE

3 … SGPr

4 … SGdE

0 Setting of alarm / signal output

Lat2

221 r/w 0 … oFF

1 … on

0 Latching of alarm / signaling

SIL2

222 r/w 0 … oFF

1 … on

0 Silencing of alarm / signaling

o2Sd

223 r/w 0 … LohI

1 … hI

2 … Lo

0 Active limits for alarm /

signaling

hYS2

224 r/w 10 to 2490 20

dEC1

Hysteresis of switching for alarm

/ signal output

SP1L

240 r/w -4990 to SP1h 0

dEC1

The limit of low range for SP

SP1h

241 r/w SP1L to 24990 1000

dEC1

The limit of high range for SP

SLEP

242 r/w 0 … oFF

1 … SP

0 The state of the controller,

if the program does not run

GSD

250 r/w 10 to 9990 100

dEC1

Guaranteed soak deviation

tCon

251 r/w 0 to 999

0 … oFF

0 0 Maximum duration of the

interruption in minutes for

continuing in program

Pout

252 r/w 0 … Cont

1 … hoLd

2 … Abrt

0 Response to the supply voltage

interruption. It takes effect after

the duration Tcon elapsed.

Strt

253 r/w 0 … ProG

1 … PrSt

0 Setting of options

for starting a program

StoP

254 r/w 0 … C E

1 … Ch E

2 … C AE

3 … ChAE

Setting of options for ending up

or interrupting a program

tdEL

255 r/w 1 to 99 10 Time delay for automatic start-up

of program in minutes

PoW

260 r/w 0 to 9990 0 1 Power of system in kWh

ALGo

261 r/w 0 … PID

1 … PID2

0 Alghoritmus of PID controlling

PID2

262 r/w -4990 to 24990 250

dEC1

The limit between PID1 and

PID2

AtSP

263 r/w 0 to 100 75 0 Helping auto/tune set point value

for autotunning in %

ArEt

264 r/w 0 … oFF

1 … on

1 Automatic return from open

menu

Page 12

Communications

12

Display Address Range Initiation Dec. point

Note

StP1

270 r/w 0 … no

1 … hISt

2 … run

3 … CLK

4 … PCnt

5 … Ptot

6 … PPGM

7 … o2oF

8 … Ent1

9 … Ent2

10 … Ent3

11 … Aut

12 … CAL1

13 … hPEr

14 … hSto

15 … PPEr

16 … PSto

1 1st position of user menu

StP2

271 r/w The same as StP1 2 2nd position of user menu

StP3

272 r/w The same as StP1 0 3rd position of user menu

StP4

273 r/w The same as StP1 0 4th position of user menu

StP5

274 r/w The same as StP1 0 5th position of user menu

StP6

275 r/w The same as StP1 0 6th position of user menu

StP7

276 r/w The same as StP1 0 7th position of user menu

StP8

277 r/w The same as StP1 0 8th position of user menu

SP1

280 r/w 0 … oFF

1 … on

0 The lock for set point value SP1

ProF

281 r/w 0 … oFF

1 … on

0 The lock for menu ProF in

operation level

PCPY

282 r/w 0 … oFF

1 … on

0 The lock for menu PCPY in

operation level

GLbL

283 r/w 0 … oFF

1 … on

0 The lock for menu GLbL in

operation level

out1

284 r/w 0 … oFF

1 … on

0 The lock for menu ot1 in

operation level

out2

285 r/w 0 … oFF

1 … on

0 The lock for menu ot2 in

operation level

Set

286 r/w 0 … oFF

1 … on

0 The lock for configuration level

PASS

287 r/w 0 to 9999 1000 0 The password for the entry to

configuration level

Page 13

Communications

13

Extended configuration menu

Display Address Range Initiation Dec. point

Note

ot3

300 r/w 0 … Ent1

1 … ALPr

2 … SGPr

3 … SGA

4 … SGb

0 Setting of the function for

the output 3

IEt1

301 r/w 0 … hold

1 … oFF

2 … on

0 State of the event output 1 when

a program is interrupted

o3hI

302 r/w -4990 to 24990 24990

dEC1

High limit for alarm / signaling

tSG3

303 r/w 1 to 200 10 0 Setting of time of signaling at

the end of program

ot4

310 r/w 0 … Ent2

1 … ALPr

2 … SGPr

3 … SGA

4 … SGb

0 Setting of the function for

the output 4

IEt2

311 r/w 0 … hold

1 … oFF

2 … on

0 State of the event output 2

when a program is interrupted

o4hI

312 r/w -4990 to 24990 24990

dEC1

High limit for alarm / signaling

tSG4

313 r/w 1 to 200 10 0 Setting of time of signaling at

the end of program

ot5

320 r/w 0 … Ent3

1 … ALPr

2 … SGPr

3 … SGA

4 … SGb

0 Setting of the function for

the output 5

IEt3

321 r/w 0 … hold

1 … oFF

2 … on

0 State of the event output 3

when a program is interrupted

o5hI

322 r/w -4990 to 24990 24990

dEC1

High limit for alarm / signaling

tSG5

323 r/w 1 to 200 10 0 Setting of time of signaling at

the end of program

dt

330 r/w 10 to 1000 23 1 Character of derivative factor

ProG

340 r/w 0 … oFF

1 … on

0 The lock for editing a program

Page 14

Communications

14

Editing a program

Display Address Range Initiation Dec. point

Note

Prog

1400 r/w 1 to 30 1 0 Program for editing

StEP

1401 r/w 1 to 15 1 0 Step to be edited

tyPE

1410 r/w 0 … End

1 … StPt

2 … rAtE

3 … SoAK

4 … JuMP

0 Type of step

SP

1411 r/w -4990 to 24990 250

dEC1

Set point value

tI

1412 r/w 0 to 5999 10 0 Time of step in minutes

rt

1413 r/w 10 to 30000 1000

dEC1

Ramp rate up/down in K/hour

JP

1414 r/w 1 to 34 1 0 Jump, number of program

JS

1415 r/w 1 to 15 1 0 Jump, number of step

E1

1416 r/w 0 … oFF

1 … on

0 The event output 1

E2

1417 r/w 0 … oFF

1 … on

0 The event output 2

E3

1418 r/w 0 … oFF

1 … on

0 The event output 3

Gd

1419 r/w 0 … oFF

1 … on

2 … Strt

1 Guaranteed soak deviation

If the parameters of the same program and step are edited currently from the keyboard as well

as from communication line, the values transferred from communication are not accepted.

Starting, holding, interrupting a program

Display Address Range Initiation Dec. point

Note

ProG

1200 r/w 1 to 34 1 0 Program you wish

StEP

1201 r/w 1 to 15 1 0 Step you wish

1210 r/w 0 … no action

1 … start of program

0 Executive command. Program

and step are defined at the

address 1200 and 1201

End

1211 r/w 0 … no action

1 … interruption of

program

0 Executive command

hoLd

1212 r/w 0 … no action

1 … state - hold

0 Executive command

Abrt

1213 r/w 0 … no action

1 … state - abort

0 Executive command

Cont

1214 r/w 0 … no action

1 … program continues

0 Executive command

Page 15

Communications

15

Starting a program by the internal clock

Display Address Range Initiation Dec. point

Note

PCLK

1220 r/w 0 to 34

0 … oFF

0 0 Set number of program you wish

to start up

SCLK

1221 r/w 1 to 15 1 0 Set step from which you like to

start

Mon

1222 r/w 0 to 12

0 … oFF

0 0 Month

dAY

1223 r/w 1 to 31 1 0 Day

hour

1224 r/w 0 to 23 0 0 Hour

Min

1225 r/w 0 to 59 0 0 Minute

Editing of the state of the controller

Display Address Range Initiation Dec. point

Note

1250 r 0 … the program

does not run

1 … program runs

2 … state - hold

3 … state - abort

State of the controller

ProG

1251 r 1 to 34 Actual program that runs

StEP

1252 r 1 to 15 Actual step that runs

EnSP

1253 r Final set point value

trEM

1254 r Time to the end of step, hours

trEM

1255 r Time to the end of step, minutes

How to set the time clock

Display Address Range Initiation Dec. point

Note

YEAr

500 r/w 0 to 99 0 0 Year

Mon

501 r/w 1 to 12 1 0 Month

DAY

502 r/w 1 to 31 1 0 Day

hour

503 r/w 0 to 23 0 0 Hour

MIn

504 r/w 0 to 59 0 0 Minute

Page 16

Communications

16

Reading of measured values, deleting memory

Display Address Range Initiation Dec. point

Note

1300 r/w 0 to 199 pro RAM 2kB

0 to 4999 pro RAM 32kB

0 0 Setting of position for reading

data. 0 sets the newest value,

199/4999 sets the oldest one

1301 r

dEC1

Process value at the position

defined by the address 1300.

If sensor is not set, controller

returns the value –22000. If there

is a error in sensor, controller

returns the value –22001.

1302 r 1 to 12 0 Month, position at the address

1300

1303 r 1 to 31 0 Day, position at the address 1300

1304 r 0 to 23 0 Hour, position at the address

1300

1305 r 0 to 59 0 Minute, position at the address

1300

1330 r/w 0 … no action

1 … deleting of memory

0 Deleting data in the memory of

the controller

Page 17

Communications

17

5 Index

1 Scope of communications........................................................................................................................2

2 Communication interfaces.......................................................................................................................3

2.1 Interface RS 232.............................................................................................................................3

2.2 Interface EIA 485...........................................................................................................................3

3 Protocol MODBUS.................................................................................................................................4

3.1 General structure of protocol...........................................................................................................4

3.2 Operation - reading.........................................................................................................................4

3.3 Operation - writing (06H)...............................................................................................................5

3.4 Operation - back inquiry:................................................................................................................5

3.5 Timing of communication line........................................................................................................6

4 Overview of registers...............................................................................................................................7

System registers.......................................................................................................................................7

Operation level........................................................................................................................................9

Configuration level................................................................................................................................10

Extended configuration menu................................................................................................................13

Editing a program..................................................................................................................................14

Starting, holding, interrupting a program................................................................................................14

Starting a program by the internal clock.................................................................................................15

Editing of the state of the controller.......................................................................................................15

How to set the time clock.......................................................................................................................15

Reading of measured values, deleting memory.......................................................................................16

5 Index.....................................................................................................................................................17

Loading...

Loading...