Page 1

TABULAR DATA SHEET

MAC-220

ECN 5287-MA 121005

Outdoor Split System Heat Pump 1.5 Thru 5 Tons

MODELS: THJD18* THRU 60

13 SEER – R-410A, 1 PHASE

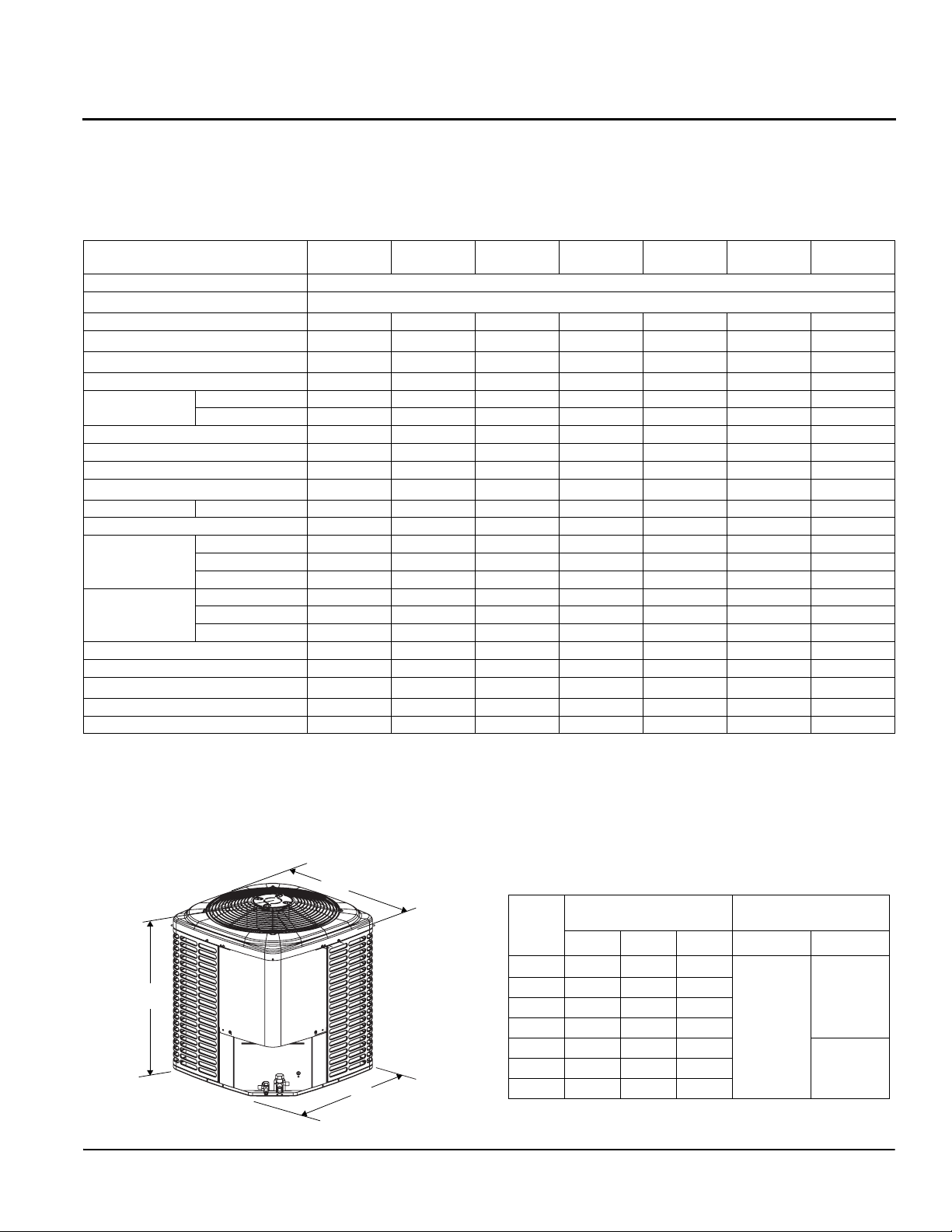

Physical and Electrical Data

MODEL

Unit Supply Voltage 208-230V, 1 60Hz

Normal Voltage Range

Minimum Circuit Ampacity 11.9 11.2 14.1 19.7 20.9 25.6 34.9

Max. Overcurrent Device Amps

Min. Overcurrent Device Amps

Compressor Type Scroll Recip Recip Recip Recip Recip Scroll

Compressor

Amps

Crankcase Heater No Yes Yes Yes Yes Yes No

Factory External Discharge Muffler Yes No No No No No Yes

Factory External Check Valve NoNoNoNoNoNoNo

HS Kit Required with TXV

Fan Motor Amps Rated Load 0.70 0.80 0.80 1.3 1.3 1.3 1.3

Fan Diameter Inches 24 24 24 24 24 24 24

Fan Motor

Coil

Liquid Line Set OD (Field Installed) 3/8 3/8 3/8 3/8 3/8 3/8 3/8

Vapor Line Set OD (Field Installed) 3/4 3/4 3/4 3/4 7/8 7/8 7/8

Unit Charge (Lbs. - Oz.)

Charge Per Foot, Oz. 0.62 0.62 0.62 0.62 0.67 0.67 0.67

Operating Weight Lbs. 172 194 206 218 218 285 284

* These models are shipped with a Hard Start Kit installed at the factory.

1. Rated in accordance with ANSI/AHRI Standard 110-2002, utilization range “A”.

2. Dual element fuses or HACR circuit breaker. Maximum allowable overcurrent protection.

3. Dual element fuses or HACR circuit breaker. Minimum recommended overcurrent protection.

4. See Hard Start Kit Accessory Installation Manual for Hard Start Kit part number for each model.

5. The Unit Charge is correct for the outdoor unit, matched indoor coil, and 15 feet of refrigerant tubing. For tubing lengths other than 15 feet, add

or subtract the amount of refrigerant, using the difference in length multiplied by the per foot value.

A

1

2

3

Rated Load 9.0 8.3 10.6 14.7 15.7 19.4 26.9

Locked Rotor 48.0 43.0 54.0 74.0 88.0 88.0 135.0

4

Rated HP 1/10 1/8 1/8 1/4 1/4 1/4 1/4

Nominal RPM 825 1075 1075 850 850 850 850

Nominal CFM 2000 2900 3000 3800 3800 3600 3600

Face Area Sq. Ft. 15.7 18.3 21.0 23.6 23.6 23.6 23.6

Rows Deep 1 1 1 1 1 2 2

Fin / Inches 22 22 22 22 22 18 18

5

THJD18

S41S3

20 15 20 30 35 45 60

15 15 15 20 25 30 35

No Ye s Yes Ye s Ye s Ye s* N o

6 - 6 9 - 6 9 - 0 10 - 0 9 - 10 14 - 12 13 - 13

C

B

THJD24

S41S4

THJD30

S41S4

All dimensions are in inches. They are subject to change without notice.

Certified dimensions will be provided upon request.

Unit

Model

18 28

24 32 34 34

30 36 34 34

36 40 34 34

42 40 34 34

60 40 34 34

1. Including Fan Guard.

THJD36

S41S4

187 to 252

Dimensions

1

A

THJD42

S41S4

(Inches)

B C Liquid Vapor

34 34

THJD48

S41S4

Refrigerant Connection

Service Valve Size

3/8”

THJD60

S41S4

3/4”

7/8”48 40 34 34

Thermo Products, LLC

Page 2

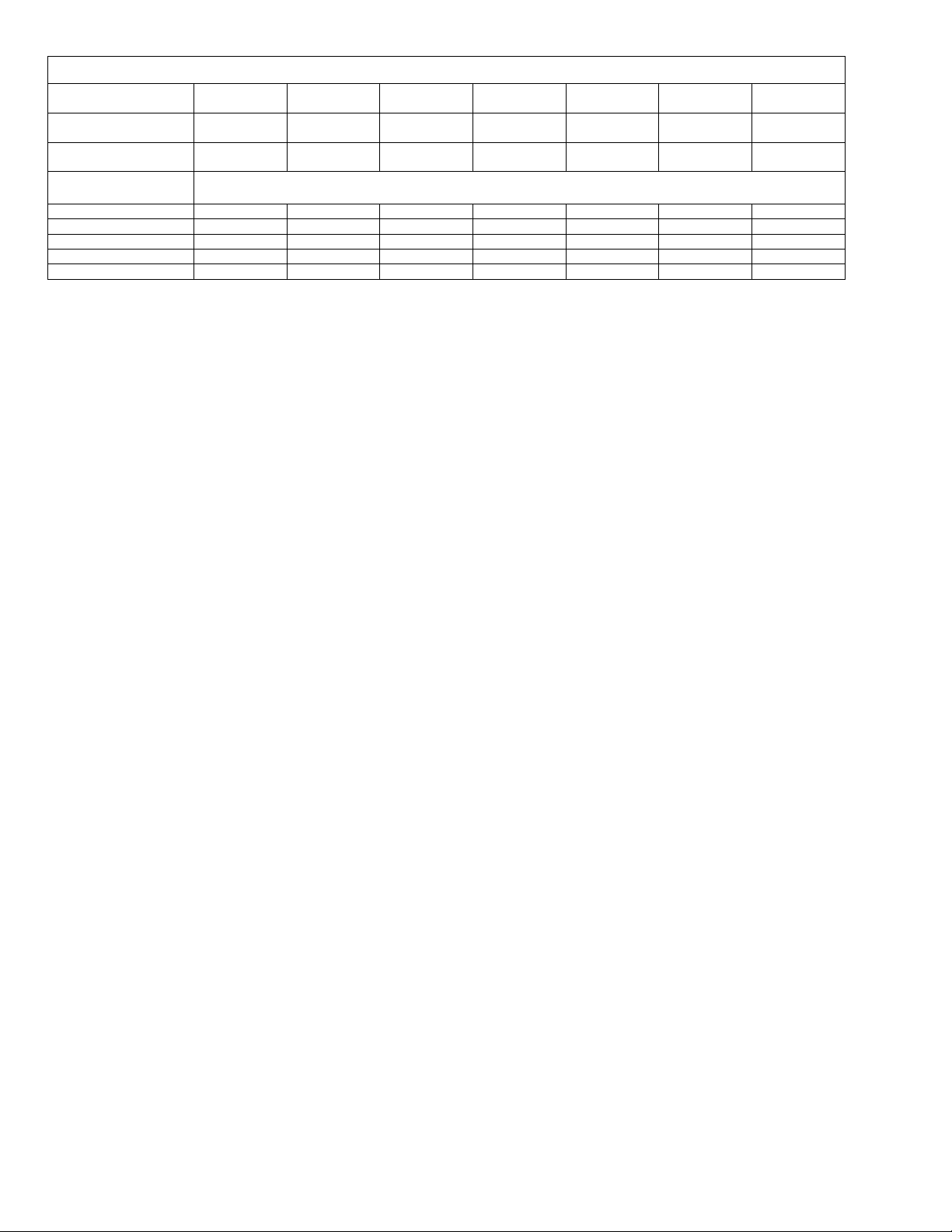

System Charge for Various Matched Systems

Thermo Products, LLC

5235 West State Road 10

North Judson, IN 46366

www.thermopride.com

Copyright © 2012 by Johnson Controls, Inc. All rights reserved.

Outdoor Unit

Required Orifice or

1

TXV

Factory Charge,

lbs-oz

Indoor Unit

2,3

Additional Charge, oz

THJD18

S41S3

.051/4F1 .054/4G1 .063/4G1 .071/4H1 .075/4H1 4J1 4K1

6 – 6 9 – 6 9 – 0 10 – 0 9 – 10 14 – 2 13 - 13

THJD24

S41S4

THJD30

S41S4

THJD36

S41S4

THJD42

S41S4

THJD48

S41S4

THJD60

S41S4

FC/MC/PC/UC18 .051/TXV+0 -- -- -- -- -- -FC/MC/PC/UC35 -- .059/TXV+0 .063/TXV+0 -- -- -- -FC/MC/PC/UC43 -- .059/TXV+23 .063/TXV+25 .071/TXV+6 -- -- -FC/MC/PC/UC60 -- -- -- -- .075/TXV+0 TXV_0 -FC/PC/62 -- -- -- -- -- TXV+25 TXV+0

Footnotes:

1. For applications requiring a TXV use S1-1TVM*** series kit.

2. Systems matched with furnaces or air handlers not equipped with blower-off delays may require blower Time Delay Kit S1-2FD06700224.

3. PC coils cannot be used in downflow or horizontal applications. FC coils cannot be sued in horizontal applications.

Procedures:

1. Unit factory charge listed on the unit nameplate includes refrigerant for the outdoor unit, the smallest matched indoor unit, and 15 feet of

interconnecting line tubing.

2. Verify the TXV or orifice and additional charge required for specific matched indoor unit in the system using the above table.

3. Add additional charge for the amount of interconnecting line tubing greater than 15 feet at the rate specified in Physical and Electrical Data

table.

4. For indoor matches requiring additional charge, the refrigerant needs to be weighed in for specific matched indoor unit and line set lengths.

5. Permanently mark the unit nameplate with the total system charge. Total system charge = base charge as shipped plus charge adder for

matched indoor unit and charge adder for line set.

Loading...

Loading...