Page 1

INSTALLATION AND SERVICE MANUAL

MODELS:

PGT5-100, PGT11-125, PGT16-160,

PGL20-180, PGL33-250, PGL37-312, & PGL39-400

???? WARNING: IF YOU DO NOT FOLLOW THE SAFETY PRECAUTIONS BELOW AND IN THIS

MANUAL, A FIRE OR EXPLOSION MAY RESULT CAUSING PROPERTY DAMAGE, PERSONAL INJURY,

OR LOSS OF LIFE.

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS IN THE

VICINITY OF THIS OR ANY OTHER APPLIANCE.

WHAT TO DO IF YOU SMELL GAS:

• DO NOT TRY TO LIGHT ANY APPLIANCE.

• DO NOT TOUCH ANY ELECTRICAL SWITCH; DO NOT USE ANY PHONE IN YOUR BUILDING.

• LEAVE THE BUILDING IMMEDIATELY.

• IMMEDIATELY CALL YOUR GAS SUPPLIER FROM A NEIGHBOR’S PHONE. FOLLOW THE GAS

SUPPLIER’S INSTRUCTIONS.

• IF YOU CANNOT REACH YOUR GAS SUPPLIER; CALL THE FIRE DEPARTMENT.

INSTALLATION AND SERVICE MUST BE PERFORMED BY A QUALIFIED INSTALLER, SERVICE

AGENCY OR THE GAS SUPPLIER. (REFERRED TO IN THESE INSTRUCTIONS AS A QUALIFIED

HEATING CONTRACTOR).

PLEASE READ THESE INSTRUCTIONS PRIOR TO INSTALLATION, INITIAL FIRING, AND BEFORE

PERFORMING ANY SERVICE OR MAINTENANCE. THESE INSTRUCTIONS MUST BE LEFT WITH THE

HOMEOWNER AND SHOULD BE RETAINED FOR FUTURE REFERENCE BY QUALIFIED SERVICE

PERSONNEL.

THERMO PRODUCTS,LLC.

BOX 217

NORTH JUDSON, IN 46366

PHONE: (574) 896-2133

MG-807C

ECN 4403-MA MADE IN USA

Page 2

TABLE OF CONTENTS

SECTION

BEGINNING PAGE

WARNING AND INSTRUCTION LABELS 1

WARNINGS AND CAUTIONS 2

I. GENERAL INSTRUCTIONS 3

II. GENERAL INSTALLATION 3

A. CODES AND CLEARANCES 3

B. CONSTRUCTION MATERIALS 3

a. COMBUSTIBLE MATERIALS 3

b. NON-COMBUSTIBLE MATERIALS 3

C. FURNACE LOCATION, COMBUSTION AND MAKE-UP AIR 4

D. VENTING 5

E. VENT DAMPERS 7

F. CONDENSING IN CHIMNEY 7

G. REPLACING AN EXISTING FURNACE FROM A COMMON VENT 8

H. GENERAL GAS PIPING 8

I. INSTALLATION OF NATURAL GAS PIPING 9

J. INSTALLATION OF LP GAS PIPING 10

K. BURNER INSTALLATION 11

L. REQUIREMENTS AND SIZING OF DUCTWORK 15

M. FILTERS 18

a. PGT HORIZONTALS 18

b. PGL LOWBOYS 18

N. FAN AND LIMIT POSITION AND LOCATION 19

O. WIRING 20

III. STARTING THE UNIT 27

A. INITIAL START UP 27

B. BURNER COMBUSTION 27

C. ADJUSTMENT OF BTU INPUT RATE 27

D. FURNACE CHECK OUT PROCEDURE 29

IV. INSTALLER'S INSTRUCTIONS TO USER 29

V. DEALER MAINTENANCE 30

A. ELECTRICAL 30

B. CLEANING HEAT EXCHANGER 30

VI. TROUBLESHOOTING 31

VII. REPLACEMENT PARTS - PGT 32

EPLACEMENT PARTS - PGL 34

Page 3

All installations and services must be performed by qualified service personnel.

This page contains reproductions of the various warning and instruction labels placed on the Thermo Pride Power Gas

Furnaces. Please read and comply with the contents of these labels.

1

Page 4

All installations and services must be performed by qualified service personnel.

This page contains various warnings and cautions reproduced from the Power Gas Furnace Manual. Please read

and comply with the statements below

CAUTION: When installing the burner, it should be noted that the loose fill insulation and fiber chambers are made with

ceramic fibers. Currently, there are no known chronic health effects in humans associated with long term exposure to

ceramic fibers. The International Agency for Research on Cancer (IARC) based on its review of studies that injected

ceramic fiber into the abdomens of hamsters and rats have classified fibrous glass wool, mineral wool (both rock wool and

slag wool) and ceramic fiber as group 2B carcinogens. A group 2B agent is considered by IARC to have the possibility of

being carcinogenic to humans. IARC has also classified these fibrous materials as group 2A carcinogens when they have

undergone long term exposure to temperatures greater than 18000F. A group 2A agent is considered to have the probability

of being carcinogenic to humans. For these reasons, we suggest the use of a 3M 9900, 3M 8710 or equivalent mask when

working with any ceramic fiber products. For further information, contact the Manager of Customer Service for Rex Roto

Corporation at (517) 324-7533.

WARNING:

WARNING:

top opening.

WARNING:

fireplace chimney, lined with a metal liner is used to vent this appliance, the fireplace opening must be permanently sealed.

WARNING:

WARNING:

WARNING:

This should be done by qualified service personnel. If excessive gas escapes when purging the supply at the union, allow the

area to ventilate for at least 15 minutes before attempting to start the furnace. LP gas is especially dangerous because LP gas

is heavier then air allowing it to accumulate at floor level at a dangerous concentration.

WARNING:

WARNING:

WARNING:

transformer. If an electrical vent damper is used, a separate transformer and relay must be installed. Thermally actuated vent

dampers cannot be used with this power burner because the damper must be in the open position before the burner ignites.

WARNING:

below grade, contact your gas supplier for a gas detector.

This furnace is not to be used as a construction heater.

When common venting two appliances into a common vent, the smallest appliances must be vented into the

A Category 1 appliance must never be connected to a chimney that is servicing a solid fuel appliance. If a

The PG Series furnaces must not be installed with a manual or thermally actuated vent damper.

TURN OFF THE ELECTRICAL POWER to the furnace before attempting to change blower speed wiring.

For initial start-up, of the furnace after installation, it may be necessary to purge the air out of the gas line.

Heat exchanger paint will cure on initial firing creating an odor.

The heat exchanger must be cleaned by a qualified service technician.

The power gas burner has its own transformer and no other electrical equipment should be operated from this

Because of the potential of odorant fade, a gas leak may not be detected by smell. If this furnace is installed

.

2

Page 5

All installations and services must be performed by qualified service personnel.

I. GENERAL INSTRUCTIONS

These instructions must be read in their entirety before installing the furnace. It is the installer's responsibility to do the

following:

1. Inform and demonstrate to the user, the correct operation and maintenance of the appliance.

2. Inform the user of the hazards of flammable liquids and vapors and to remove such liquids and vapors from the vicinity of

the appliance.

II. GENERAL INSTALLATION

These furnaces are shipped with the power gas burner shipped separately. For parts shortage or damage, see the Dealer

Receiving and Freight Claim Procedure Section of the price guide. After installation, the furnace and duct system must be

adjusted to obtain a temperature rise of 50°F to 80°F through the furnace. The installation must conform with local codes or

in the absence of local codes with the National Fuel Gas Codes ANSI Z223.1 LATEST EDITION and to these instructions.

WARNING:

A. CODES AND CLEARANCES:

The following items must be considered when choosing the size and location of the furnace.

1. All local codes and/or regulations take precedence over the instructions in this manual and should be followed

accordingly. In the absence of local codes, installation must conform to these instructions, regulations of the National Fire

Protection Association, provisions of National Electrical Code (ANSI/NFPA70 LATEST EDITION), and the National Fuel

Gas Code (ANSI Z223.1 LATEST EDITION).

2. The BTU output capacity of the furnace proposed for installation should be based on a heat loss calculation made

according to the manuals provided by the Air Conditioning Contractors of America (ACCA) or ASHRAE.

3. The furnace installed is to be level in a central location with respect to outlet registers and should be located near the

chimney to minimize the numbers of elbows and the length of any horizontal run of connecting flue pipe which may be

required.

4. Definitions of "COMBUSTIBLE MATERIAL" and "NON-COMBUSTIBLE" as issued by

NFPA-Z11-1-3 is as follows:

B. CONSTRUCTION MATERIALS

a. COMBUSTIBLE MATERIAL:

Materials made of or surfaced with wood, compressed paper, plant fibers, plastics or other material that will ignite and burn

whether flameproof, fire retardant treated, or plastered.

b. NON-COMBUSTIBLE MATERIAL:

Material which will not ignite and burn; such materials consisting entirely of steel, iron, brick, concrete, slate, glass, plaster

or combination thereof.

This furnace is not to be used as a construction heater.

3

Page 6

All installations and services must be performed by qualified service personnel.

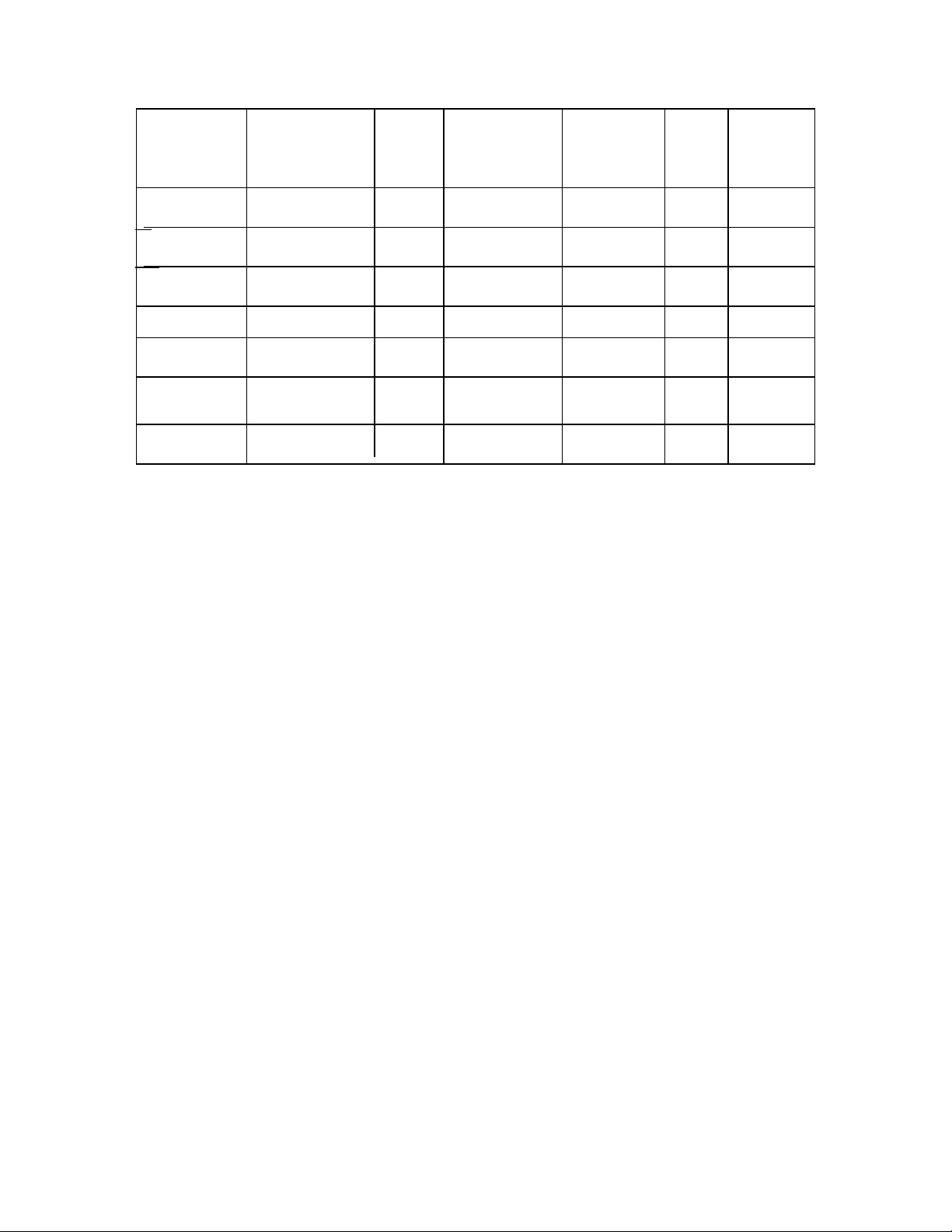

- MINIMUM CLEARANCES TO COMBUSTIBLE MATERIALS -

MODEL NO. FROM SIDES

OF FURNACE

PGT5-100

PGT11-125

PGT16-160

PGL20-180

PGL33-250

PGL37-312

PGL39-400

1 IN.

1 IN.

1 IN.

1 IN.

1 IN.

1 IN.

1 IN.

FRONT TOP & SIDES

OF PLENUM

24 IN.

24 IN.

24 IN.

24 IN.

24 IN.

24 IN.

24 IN.

1 IN.

1 IN.

1 IN.

1 IN.

1 IN.

1 IN.

1 IN.

FROM THE

FLUE OR

VENT

4 IN.

9 IN.

9 IN.

18 IN.

18 IN.

18 IN.

18 IN.

REAR BOTTOM

1 IN.

1 IN.

1 IN.

1 IN.

1 IN.

1 IN.

1 IN.

1 IN.

1 IN.

1 IN.

N/A

N/A

N/A

N/A

The minimum clearances are listed for fire protection. Clearance for servicing the front of the furnaces and to all points on

the furnace requiring access must be 24".

Equipment must be installed in accordance with regulations of the National Board of Fire Underwriters. Authorities

having jurisdiction should be consulted before installations are made.

C. FURNACE LOCATION AND COMBUSTION AIR

A furnace installed in a residential garage must be installed so the burners and ignition source are located higher than 18

inches above the floor. Also, the furnace must be located or protected to avoid physical damage by vehicles. The furnace

must be located on a dry surface. If the surface becomes wet or damp at times, the furnace should be supported above the

floor using a concrete base, bricks, patio blocks, etc.

The electrical components of this furnace should be protected against water or moisture.

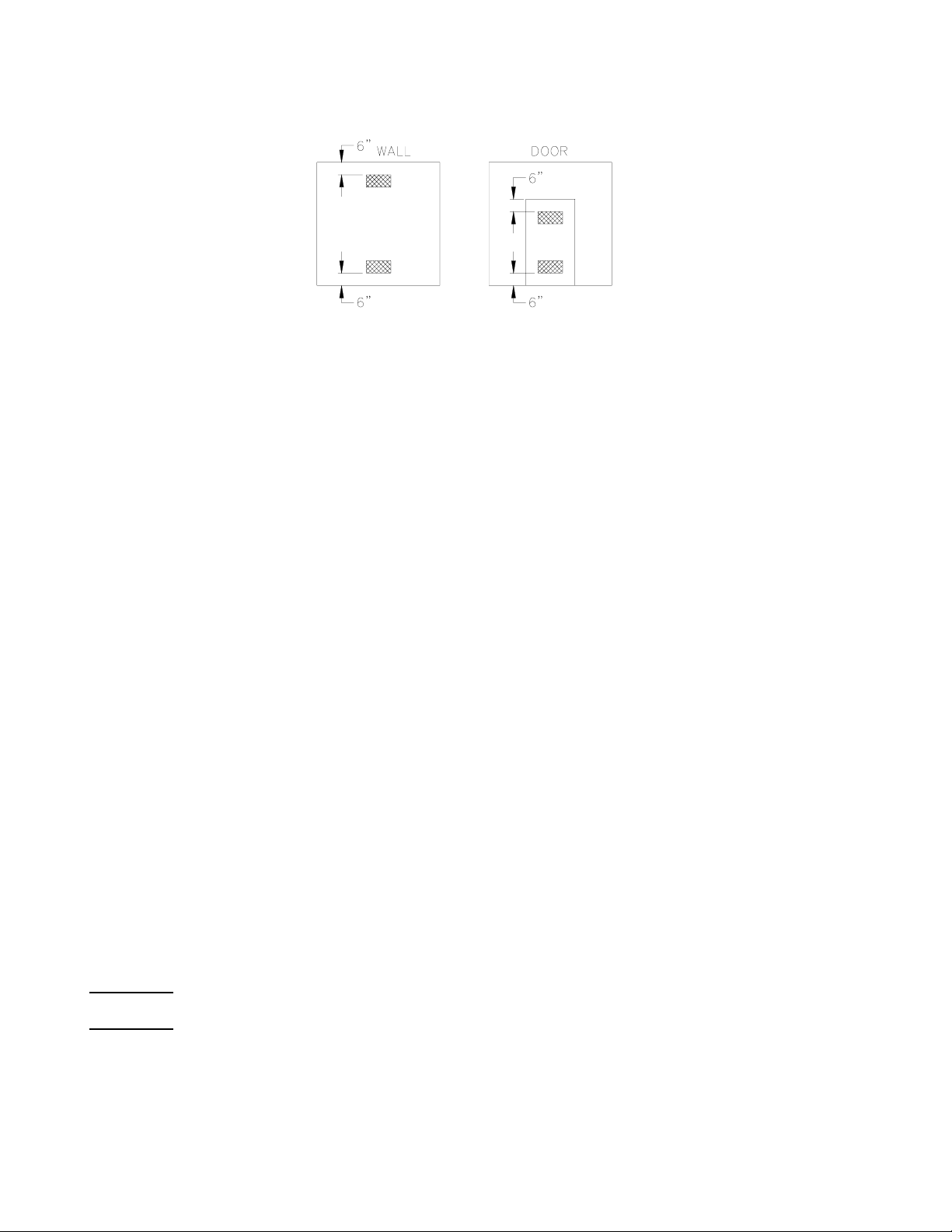

The area in which the furnace is located must have an adequate supply of air for combustion and draft. Open non-partitioned

basements, below grade utility room windows without storms or rooms with loose access doors will generally permit

adequate air infiltration. However, if the furnace is located in an area of the building with tight doors and windows, outside

ventilation or an opening into another room is recommended. This can be accomplished with two rectangular openings

located in a wall or door, one 6" from the ceiling or at the top of the door and one 6" from the floor or at the bottom of the

door each having a free area of not less than 1 square inch per 1,000 BTUH input but not less than 100 square inches total.

These openings must be free and unobstructed. Maintain a minimum 24" clearance to ventilation openings, which provide

combustion air to the furnace.

4

Page 7

All installations and services must be performed by qualified service personnel.

EXAMPLE: 100,000 BTUH input furnaces requires "two" openings of 100 square inches each. A minimum opening of

100 square inches is required regardless of the input.

If the building is tightly constructed and or has an exhaust fan(s) that creates a negative pressure, air for combustion and

ventilation must be supplied from the outdoors or from spaces freely communicating with the outdoors. When

communicating directly with the outdoors or with vertical ducts to the outdoors, two openings each having a minimum free

area of 1 square inch per 4,000 BTU of the input rating of all gas appliances in the area are required. When horizontal ducts

are used to communicate with the outdoors, the free area must be based on 2,000 BTUH per square inch of the total input

rating of all gas appliances in the area. The minimum dimension of an air duct must be at least 4 inches in diameter.

EXAMPLE: 100,000 BTU input furnace, 40,000 BTU input water heater and 30,000 BTU gas dryer would require two

openings of 42.5 square inches each if ducted vertically to the outdoors or 85 square inches each if horizontal ducts are

used.

MAKE-UP AIR

Today's emphasis on home insulation and tightness increases the problem of air supply to the furnace. Heavy insulation cuts

off infiltration of outside air, which previously replaces inside air removed by bathroom, kitchen and laundry vent fans and

air escaping up chimneys. This tightness can cause a negative pressure condition to develop within the home. For this

reason, it is recommended that in tightly constructed and insulated homes, make-up air be provided. This can be done with

Skuttle Mfg. Co. 200 Series make-up air control. This control installs quickly and easily on any warm air heating system and

delivers controlled, fresh air automatically during the winter and summer. This type control helps solve a negative pressure

problem in a structure.

D. VENTING:

NOTICE: A draft control (double acting (MG-1) or hood type) suitable for gas firing, certified by a nationally recognized

testing laboratory and acceptable to local codes must be installed according to the control manufacturer's instructions.

The PGT and PGL series furnaces must be vented in accordance with local codes and the National Fuel Gas Code (ANSIZ223.1 Latest Edition) Category 1 vent tables.

The vent connector must be galvanized or stainless steel metal pipe.

The following items are requirements:

1. Flue or vent connection materials must meet requirements of all applicable local codes and the National Fuel Gas Code

(ANSI-Z223.1 LATEST EDITION).

2. A PVC pipe is not an acceptable substitute for a chimney or a flue connector. A chimney with an internal construction of

stainless steel or some other material that will withstand the flue gas temperature of 500°F is required.

3. A type B venting system as well as some masonry systems are acceptable as described in the venting tables included in

the NFGC. These venting tables also include venting combinations, which apply to common venting arrangements of two

appliances.

WARNING:

opening.

WARNING:

fireplace chimney, lined with a metal liner is used to vent this appliance, the fireplace opening must be permanently sealed.

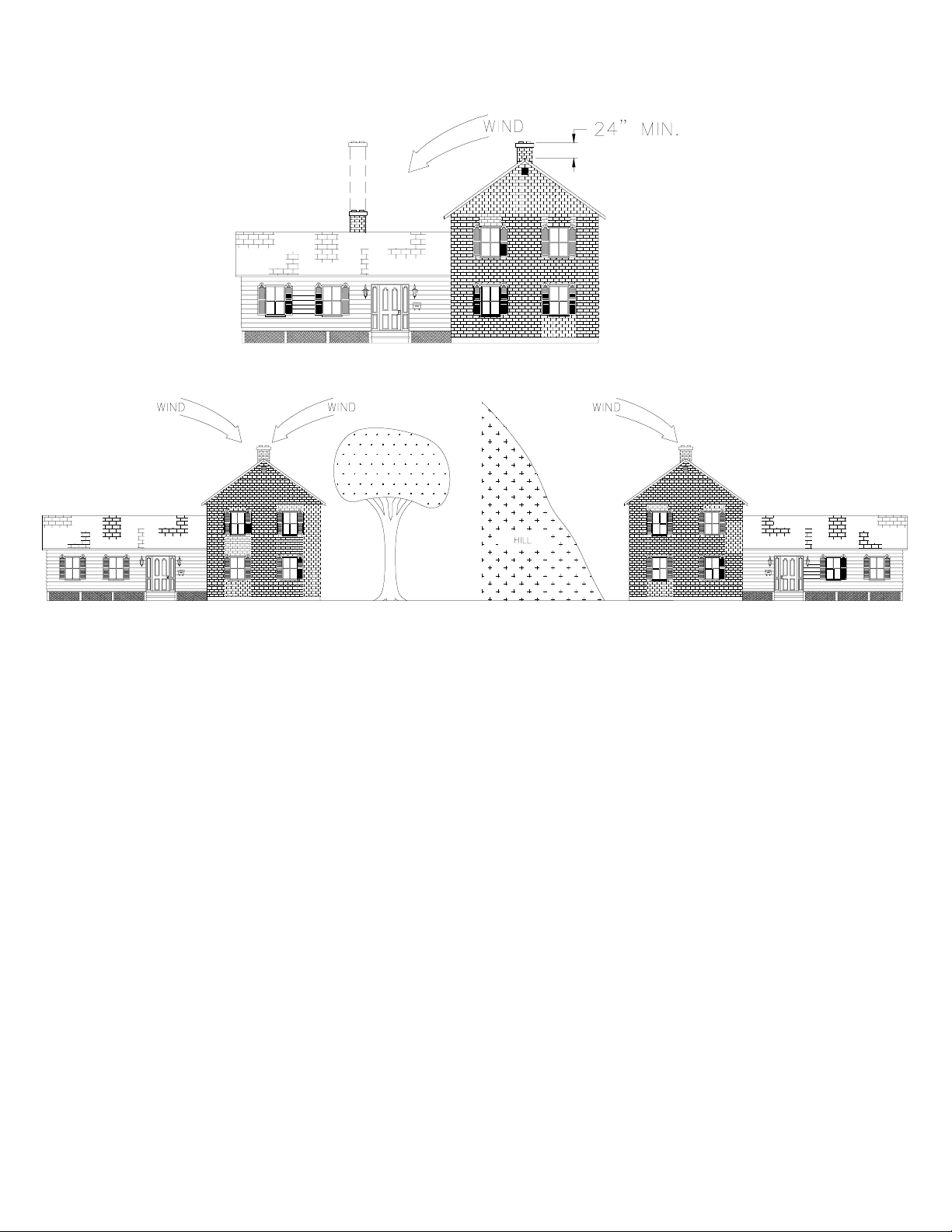

4. The chimney height is determined by the height of the surrounding trees, roof, buildings and terrain. The chimney should

extend 24" above any surrounding obstructions.

When common venting two appliances into a common vent, the smallest appliance must be vented into the top

A Category 1 appliance must never be connected to a chimney that is servicing a solid fuel appliance. If a

5

Page 8

All installations and services must be performed by qualified service personnel.

Trim or remove nearby trees that could interfere with chimney draft.

5. In cases where the chimney flue extends to the basement floor, the draft can usually be improved by filling the base of the

chimney with sand to within 12" of the flue pipe after relocating the cleanout cover.

6. All joints of the vent must be tightly sealed. The inside of the vent should be free of all obstructions.

7. All vents and vent connectors must fit tightly to avoid air leaks.

8. All vent connectors connecting the furnace to the vent must be rigidly supported with hangers and straps, in order to

prevent movement after installation. The vent connector must be supported every four feet for the design and weight of the

material used, to maintain clearances, and to prevent physical damage.

9. Vent connectors used in connecting the furnace to the vent cannot be channeled through floors, ceilings, and walls

without the proper protective construction. This construction must be in accordance with the requirements of the National

Fuel Gas Code (ANSI Z223.1 LATEST EDITION).

10. All single wall vent connectors connected to the PGT & PGL Series furnaces must have all seams and joints sealed with

high temperature pressure sensitive aluminum tape or silicone rubber sealant.

EXAMPLE:

1. High temperature aluminum tape, temperature rating of 400°F or more.

2. Dow Corning RTV-732 rubber sealant or equivalent.

Temperature rating of 450°F or more.

11. Vent connectors installed in or passing through an unheated space must be insulated with 1.0" thick foil faced fiberglass

or its equivalent to prevent condensate from forming in the connector or vent.

6

Page 9

All installations and services must be performed by qualified service personnel.

NOTE: If this furnace replaces an appliance with a vent that was originally installed in a common vent system serving other

appliances, the vent system is likely now too large to properly vent the remaining appliances only and must be modified

accordingly. Refer to Natural Fuel Gas Code Appendix G Category I vent tables for common venting a PG Series furnace

and another fan assisted or natural draft unit.

In order too common vent a PG Series furnace with a natural draft gas fired hot water heater; follow the recommendation of

the NFGC Category I venting tables.

If the NFGC venting tables do not apply to a specific common venting system then refer to the section on replacing an

existing furnace from a common vent in Section G of this manual.

NOTICE:

for the application and certified by a nationally recognized testing agency for use with gas fired warm air central furnaces.

NOTICE:

also meet the approval of the local authorities. See the draft control manufacturers instructions for installation.

Thermo Pride power gas units may be sidewall vented with a power sidewall venting system that is appropriate

An agency approved gas barometric control or draft diverter must be installed. The draft control device must

E. VENT DAMPERS

If a vent damper is installed, it must be certified by a nationally recognized testing agency. It must be an electromechanical type that opens completely before gas flows to the main burner and closes only after the gas valve has

shut off gas flow to the main burner.

WARNING:

F. CONDENSING IN THE CHIMNEY:

Due to the increasing efficiencies of our furnaces, more heat is being placed into the home instead of up the chimney.

This means that the stack temperature will be lowered which may result in condensing within the chimney under

certain conditions. The following is an explanation on why and what to do if condensing occurs.

Moisture occurs in flue gases when hydrogen is mixed with oxygen from the chemical reaction produced by

combustion. This mixture of hydrogen and oxygen produces water molecules.

The flue gas vapor may do one of two things as it escapes up the chimney:

1. Remain in a vapor state if the internal chimney wall temperature is above the dew point, or

2. Condense on the chimney walls if they are chilled below the dew point.

Condensing will always occur on chimney walls whose temperatures are below the dew point, but will evaporate

once the walls are warmer than the dew point. If the chimney walls do not reach the dew point during the cycle of the

furnace, the moisture may accumulate in large enough quantities to cause problems such as corrosion of the chimney

or corrosion of the heat exchanger.

This condensation most likely will not occur at the bottom of the chimney, because the flue gas is heating the

chimney walls as it rises and the bottom will be heated first. This heating of the walls will cause the flue gas

temperature to drop, which in turn may reduce the wall temperature below the dew point causing condensation to

appear on the upper part of the chimney first. This condensation may drip back as far as the flue pipe and heat

exchanger, where corrosion may occur if not treated.

To prevent condensation, it is necessary that the internal chimney wall temperature always be kept above the dew

point. The chimney may have to be lined with a flue liner if the temperature loss is too great for the furnace. A liner

will act as an insulator and reduce the flue gas temperature loss. Insulation may be added around the liner for further

The PG Series furnaces must not be installed with a manual or thermally actuated vent damper.

7

Page 10

All installations and services must be performed by qualified service personnel.

temperature stability. If the chimney is on the homes exterior and condensing occurs, the chimney may be insulated

around its exterior to help the flue hold its temperature. Also, check to see if the chimney is too large for the flue

gases to heat, if so reduce to proper size by lining. Be sure to use stainless steel liners such as types 430, 304 or for

the toughest corrosion resistant type 316. If the chimney is the correct size for the unit and condensing still occurs

then further insulating of the chimney must occur or the efficiency of the furnace may have to be reduced to raise the

chimney temperature.

More detailed information may be obtained from the current ASHRAE Equipment Handbook.

G. REPLACING AN EXISTING FURNACE FROM A COMMON VENT

When an existing furnace is removed from a common vent serving other appliances, the vent system is likely too

large to safely vent the remaining attached appliances. If only two appliances remain on the venting system, then the

system may be sized with the venting tables in the NFGC of this manual. If more than two appliances remain, then

the following steps shall be followed with each appliance remaining connected to the common venting system placed

in operation, while the other appliances remaining connected to the common venting system are not in operation.

a. Seal off any unused opening(s) in the common venting system.

b. Visually inspect the venting system for proper size and horizontal pitch and determine there is no blockage or

restriction, leakage, corrosion and other deficiencies which could cause an unsafe condition.

c. Insofar as is practical, close all building doors and windows and all doors between the space in which the

appliances remaining connected to the common venting system are located and other spaces of the building. Turn on

clothes dryers and any appliance not connected to the common venting system. Turn on any exhaust fans, such as

range hoods and bathroom exhausts, so they will operate at maximum speed. Do not operate a summer exhaust fan.

Close fireplace dampers.

d. Follow the lighting instructions. Place the appliance being inspected in operation. Adjust thermostat so appliance

will operate continuously.

e. Test for spillage at the draft hood relief opening after 5 minutes of main burner operation. Use the flame of a

match or candle or smoke from a cigarette, cigar or pipe.

f. After it has been determined that each appliance remaining connected to the common venting system properly

vents when tested as outlined above, return doors, windows, exhaust fans, fireplace dampers and any other gasburning appliance to their previous conditions of use.

g. If the improper venting is observed on any of the appliances during the above testing, the common vent system

must be corrected. Follow the steps outlined in the National Fuel Gas Code, NFPA 54/ANSI Z223.1-LATEST

EDITION to resize the vent system. The National Fuel Gas Code may be obtained by writing the American Gas

Association Laboratories, 8501 East Pleasant Valley Road, Cleveland, OH 44131 or the National Fire Protection

Association, Battery march Park, Quincy, MA 02269.

H. GENERAL GAS PIPING

WARNING:

installed below grade, contact your gas supplier for a gas detector.

All gas piping and testing must be performed by a qualified installer or service person. The installation must comply

with local codes, these instructions and The National Fuel Gas Code NFPA54/ANSI Z223.1-LATEST EDITION.

Because of the potential of odorant fade, a gas leak may not be detected by smell. If this furnace is

8

Page 11

All installations and services must be performed by qualified service personnel.

Piping from the natural gas meter to the furnace shall be in accord with requirements of the local

utility. Piping from the LP tank to the furnace must follow the recommendations of the gas supplier.

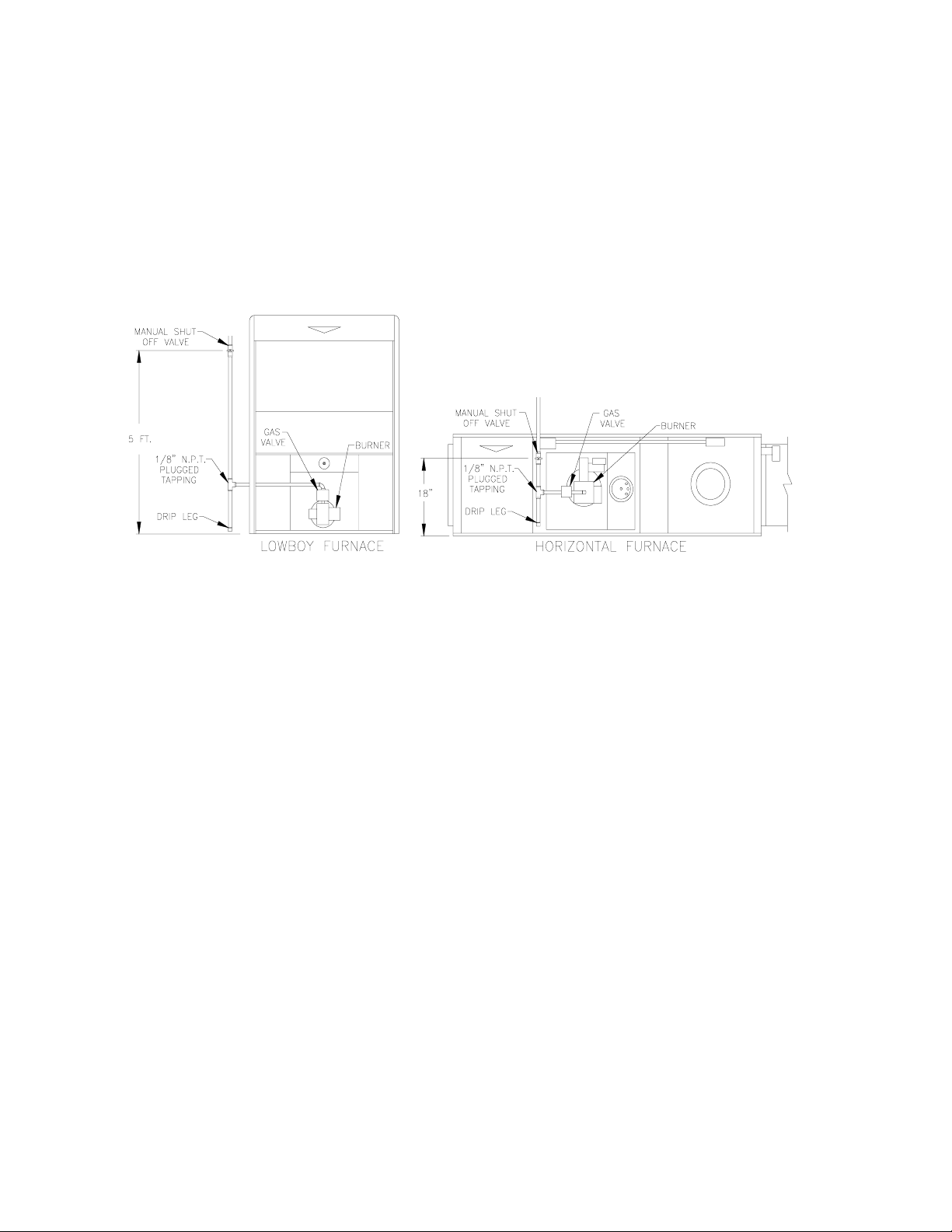

1. A readily accessible, certified manual shut off valve with a non-displaceable rotor member should be installed

within six feet of the gas equipment it serves. A union or flanged connection shall be provided downstream from the

manual valve to permit removal of controls. A 1/8" N.P.T. plugged tapping, that is accessible for connecting a test

gage, must be installed immediately upstream of the gas connection to the furnace. Unions must be of a ground joint

type or flanged-joint using a gasket resistant to LPG. Pipe dope or tape certified to be resistant to the action of

liquified petroleum gases should be used on all threaded joints.

2. A drip leg must be used on both LP and natural gas installations prior to the furnace to trap oil, condensate and

other impurities which might otherwise lodge in the gas valve or plug the burner orifice. When there is excessive

condensation between the gas meter and the furnace, a drip leg shall be provided at the outlet of the gas meter.

Failure to install a drip leg may void the limited warranty on the furnace.

NOTE: All gas piping must be leak tested using a soap and water solution (if the gas is turned on) following the

procedure outline in this section (caution must be taken not to wet electronic components). A final test for gas

leakage must be made after purging the gas line. This test must be conducted with the unit operating and should

include the furnace piping and gas valve. Never use an open flame to check for a gas leak.

IMPORTANT: Care must be taken not to wet electronic components during leak test. Wetting the primary ignition

module may damage its circuitry and cause a hazardous situation. If wetting occurs, dry moisture from all leads,

terminals, and electronic components using a hair dryer or similar means or wait at least 24 hours for the circuit to

fully dry before energizing the burner circuit.

The furnace and its individual gas valve must be disconnected from the gas supply during pressure testing of the gas

supply system at pressures in excess of 1/2 PSIG or 14.0" wc.

I. INSTALLATION OF NATURAL GAS PIPING

The installation of the gas piping and the following test procedures must be performed by a qualified installer or

service person.

1. The following chart is to be used as a guide in sizing natural gas supply piping. The input loading of all gas

appliances installed on any main or trunk line must be totaled to determine its needed carrying capacity.

9

Page 12

All installations and services must be performed by qualified service personnel.

EXAMPLE: A line must supply a furnace of 110,000 BTU/hr input, a hot water heater of 40,000 BTU/hr input and

gas range with a 30,000 BTU/hr input capacity. The total BTU/hr input loading on the line is 180,000 BTU/hr. The

200,000 BTU/hr column on the chart must be used in sizing the pipe.

┌─────────────┬────────────────────────────────────────────────┐

│BURNER FIRING│ FEET OF PIPE FROM METER TO BURNER │

│RATE, BTU/HR │10' 20' 30' 40' 50' │

├─────────────┼─────────┬─────────┬─────────┬─────────┬────────┤

│50,000 │1/2 │1/2 │3/4 │3/4 │3/4 │

├─────────────┼─────────┼─────────┼─────────┼─────────┼────────┤

│100,000 │3/4 │3/4 │3/4 │3/4 │1 │

├─────────────┼─────────┼─────────┼─────────┼─────────┼────────┤

│150,000 │3/4 │1 │1 │1 │1-1/4 │

├─────────────┼─────────┼─────────┼─────────┼─────────┼────────┤

│200,000 │1 │1 │1-1/4 │1-1/4 │1-1/4 │

├─────────────┼─────────┼─────────┼─────────┼─────────┼────────┤

│250,000 │1 │1 │1-1/4 │1-1/4 │1-1/4 │

├─────────────┼─────────┼─────────┼─────────┼─────────┼────────┤

│300,000 │1 │1 │1-1/4 │1-1/4 │1-1/4 │

└─────────────┴─────────┴─────────┴─────────┴─────────┴────────┘

Use black iron steel pipe and malleable iron fittings for Natural gas service lines. Provide rigid supports for the pipe.

If the pipe size must be reduced, use reducing couplings only. Avoid the use of reducing bushings. Remove all burrs

and inspect the pipe for dirt or other foreign material prior to connecting.

Maximum supply pressure for natural gas is 14" wc and minimum supply for purpose of input adjustment is 5-1/2"

wc.

J. INSTALLATION OF LIQUIFIED PETROLEUM GAS (LP) PIPING

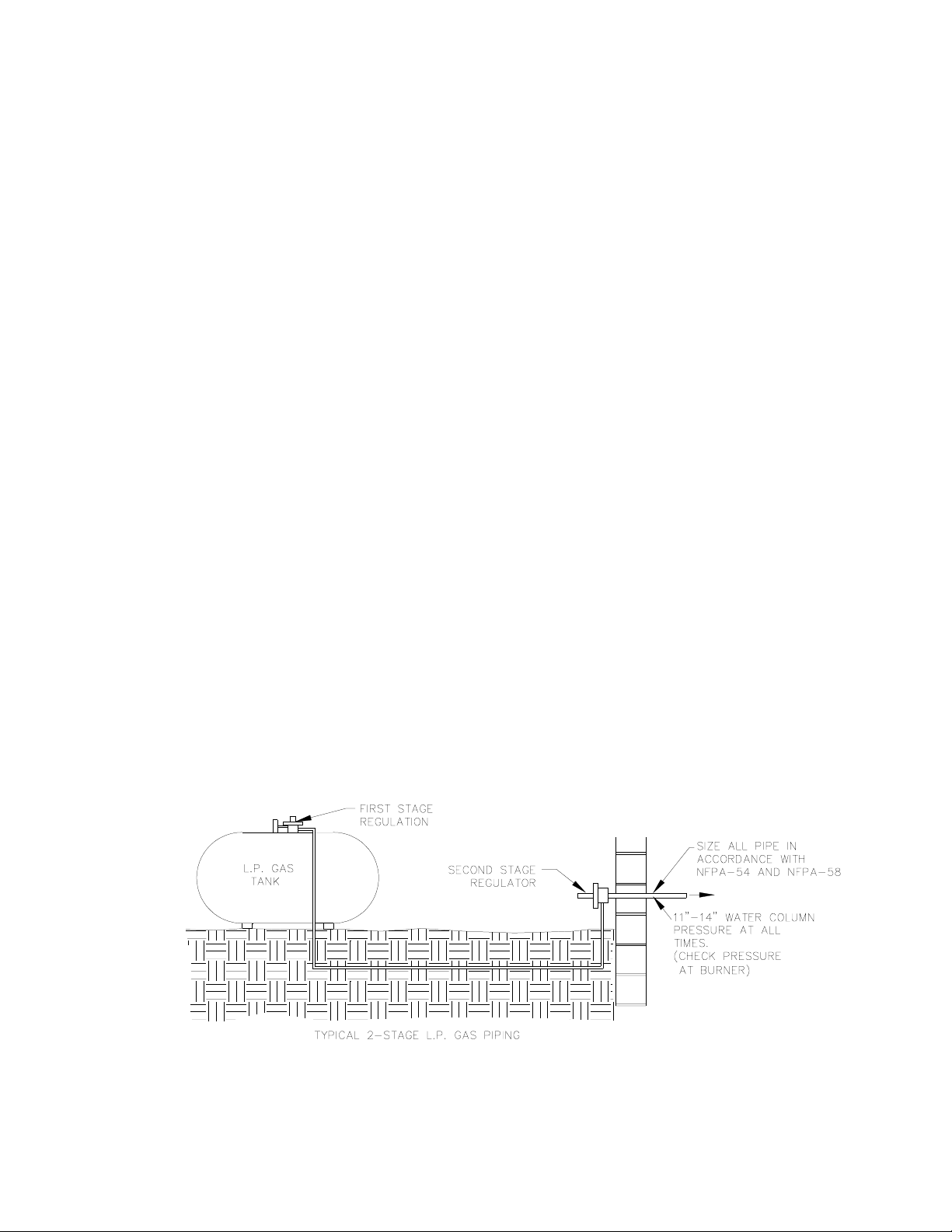

1. Experience has proved that the pressure drop in the gas line running from the outside propane gas tank to the gas

appliances in a home, is the most frequent cause of equipment malfunctions. A single pressure regulator, located at

the tank, will not reliably regulate the high tank pressures (up to 200 lbs.) down to 11" wc. Varying pressures will

occur at the appliances as outside temperatures and usage demands vary. Two stage regulations are the only effective

method of controlling these variables.

- BLACK PIPE SIZE FOR NATURAL GAS -

TYPICAL PIPING FOR TWO STAGE REGULATION

NOTE: Two stage regulation must be installed for liquified petroleum gas when used with any Thermo Pride LP

furnace. See illustration above of a typical two stage piping system.

10

Page 13

All installations and services must be performed by qualified service personnel.

- COPPER TUBING SIZE FOR LIQUIFIED PETROLEUM GASES -

All black pipe sizes shown are I.D.

Seamless copper tubing may only be used with gases that are not corrosive to it. See note below and check with your

LP gas supplier before using. Seamless copper tubing must comply with standard type K or L for seamless copper

water tube, ASTM B 88; or seamless copper tube for air conditioning field service, ASTM B 280.

NOTE: Copper and brass tubing and fittings (except tin lined) shall not be used if the gas contains more than a trace

(0.3 grains per 100 cubic ft.) of hydrogen sulfide gas.

Maximum supply pressure for liquified petroleum (LP) gas is 14" wc and minimum supply for purpose of input

adjustment is 11" wc.

K. BURNER INSTALLATION

The power gas burner will mount on three stud mounting bolts on the lower mounting plate covering the opening in

the front of the heat exchanger. The end of the burner tube must be inserted no further than 1/4 inch back from the

inside surface of the combustion chamber to ensure proper operation and performance.

NOTE: OVERFIRE AIR TAP IS LOCATED ON LEFT SIDE OF FLAME INSPECTION COVER.

(TOP VIEW)

BURNER INSERTION

ILLUSTRATION (PGL)

11

Page 14

All installations and services must be performed by qualified service personnel.

TWO PIECE MOUNTING PLATE

When mounting the burner, the upper mounting plate must be removed to provide access to the area in front of the

combustion chamber. The combustion chamber can then be moved forward or backward slightly to allow for

adjustment in positioning the burner tube. Do not allow the burner tube or end cone to physically touch the chamber,

as excessive heat transfer could result in distortion of the tube or end cone, or both.

Once the burner tube is properly positioned, at most 1/4 inch back from the inside surface of the combustion

chamber wall, the loose-fill insulation that is included should be lightly

front of the combustion chamber and the burner mounting plate. (DO NOT PACK THE INSULATION DOWN).

The loose-fill insulation should be placed in such a fashion that the surface of the insulation is sloped from the top of

the combustion chamber to the top of the lower mounting plate. The purpose of the loose insulation is to help protect

the burner tube, mounting plates and vestibule area from internal temperatures.

NOTE: Do not place loose insulation around chamber sides and back.

(SIDE VIEW)

BURNER INSERTION

ILLUSTRATION (PGT)

placed around the burner tube between the

CAUTION:

with ceramic fibers. Currently, there are no known chronic health effects in humans associated with long term

exposure to ceramic fibers. The International Agency of Research on Cancer (IARC) based on its review of studies

that injected ceramic fiber into the abdomens of hamsters and rats have classified fibrous glass wool, mineral wool

(both rock wool and slag wool) and ceramic fiber as group 2B carcinogens. A group 2B agent is considered by IARC

When installing the burner, it should be noted that the loose fill insulation and fiber chambers are made

12

Page 15

All installations and services must be performed by qualified service personnel.

to have the possibility of being carcinogenic to humans. IARC has also classified these fibrous materials as group 2A

carcinogens when they have undergone long term exposure to temperatures greater than 18000F. A group 2A agent

is considered to have the probability of being carcinogenic to humans. For these reasons, we suggest the use of a 3M

9900, 3M 8710, or equivalent mask when working with any ceramic fiber products. For further information, contact

the Manager of Customer Service for Rex Roto Corporation at (517) 324-7533.

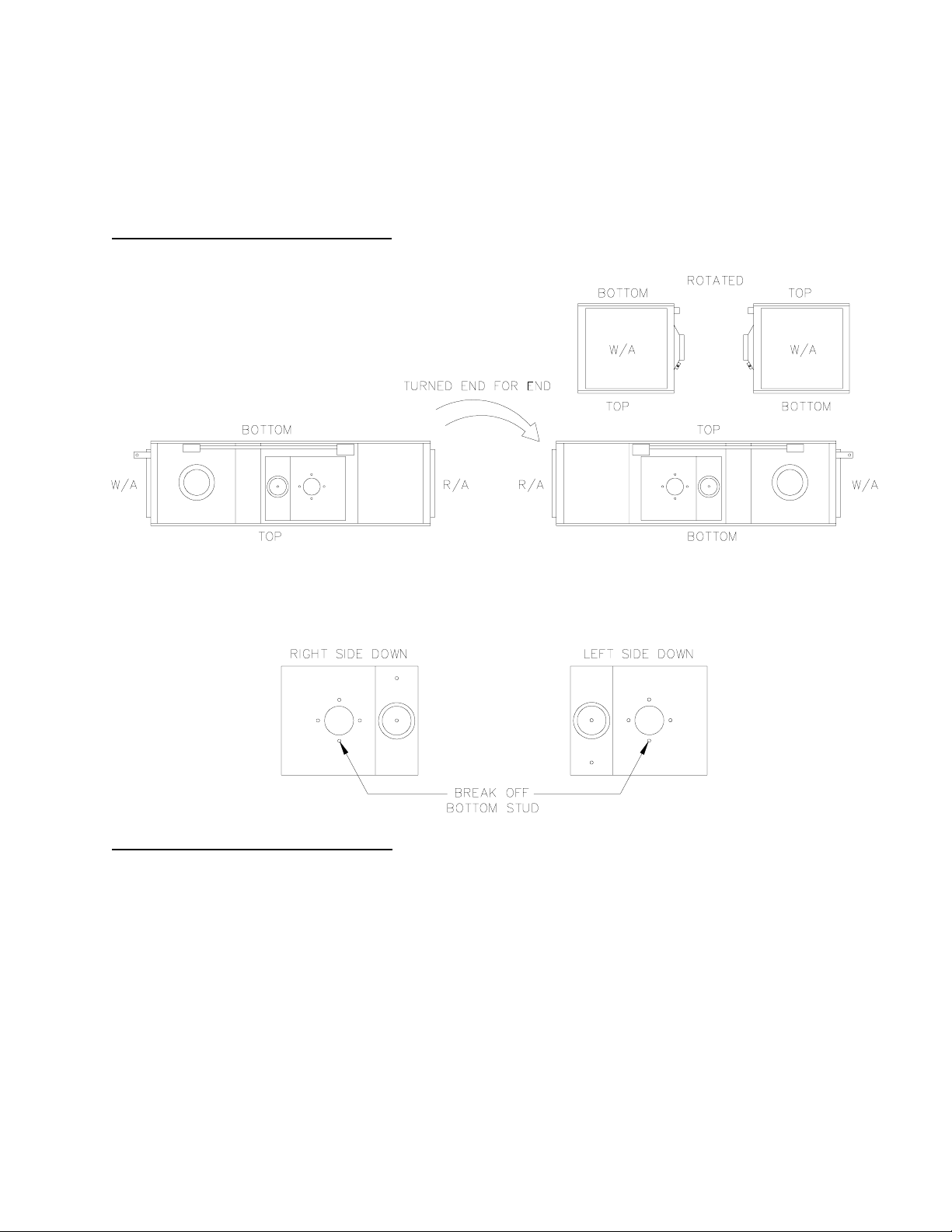

HORIZONTAL FURNACE POSITIONS:

The horizontal furnace may be turned end for end, or rotated, making the top into the bottom, as shown below.

After the furnace has been positioned, the bottom burner mounting stud must be removed before mounting the

burner. Also, the fan & limit and its mounting bracket must be properly positioned once the unit is in place. (See

section N on fan & limit position and location).

MIDCO RE32 BURNER ADJUSTMENT

In order to properly set-up a furnace with a Midco RE32 burner,Thermo Pride’s recommendation is to utilize a

Modified version of Midco’s instruction together with combustion equipment and a carbon monoxide detector. It

must be emphasized that the gas equipment is operating properly and safely requires combustion equipment and a

carbon monoxide detector.

1. Check unit for signs of sooting and clean as necessary, the furnace heat exchanger, flue, and chimney.

2. Open the air adjustment completely. Turn adjustment screw counterclockwise until it stops.

3. To achieve a starting point for proper combustion, adjust the air adjustment screw according to the chart below

For the applicable Thermo Pride furnace utilizing the Midco RE32 burner.

13

Page 16

All installations and services must be performed by qualified service personnel.

Furnace Model Orifice Size Manifold Gas Pressure No. Turns Closed*

** PGL16-160 Nat #J (.277) 2.4” W.C. 24

PGL16-160 LP #8(.199) 2.9” 24

PGL20-180Nat #J(.277) 3.0” 20

PGL20-180 LP #3(.213) 3.0” 20

AGL16-160LP #8(.199) 2.9” 24

AGL20-180Nat #J(.277) 3.0” 20

AGL20-180LP #3(.213) 3.0” 20

*Air Adjustment screw: Number of turns closed from the fully open position.

**PG-160 or PG-180 Power Gas Conversion Burners- use chart for applicable settings.

4. Attach a manifold pressure gauge (Inches of W.C. scale) to the outlet of the gas valve.

5. Turn on the furnace and adjust the manifold pressure to the setting indicated above for the desired rate and

orifice which applies to the unit being tested.

6. Let the furnace run until warm, approximately 10 minutes. Note: If the furnace required cleaning, you may

wish to allow any residual dust or soot to burn off before taking measurements.

7. If the draft exceeds the recommended maximum of .1”, a draft regulator should be used to reduce the draft to

the recommended parameters of –01 W.C. to –1” W.C.

8. IMPORTANT: An accurate CO

or O

2

combustion analyzer is required when setting combustion. A carbon

2

monoxide detector capable of measuring flue gas down to 50 PPM of CO is also required. After the unit has

operated a minimum of 10 minutes and a proper draft is established-between-.01” W.C. and -.1” W.C., perform

a combustion test and make final adjustment to the combustion air to achieve the CO

or O2 as listed below.

2

NATURAL GAS

MIN. MAX.

CO

7.0% 11.0%

2

O2 2.0% 8.9%

CO <50 PPM

L.P. GAS

MIN. MAX. **See

CO2 8.0% 10.4% Note Below

O2 5.5% 8.9% **See Note Below

CO <50PPM

DRAFTOVERFIRE

MIN. .MAX.

-.01 -.1

**Note!! Under absolutely no circumstances should the air adjustment screw (on LP units only) be closed more than

the number of turns indicated by the chart on the previous page.

9. Once the CO

or O

2

is adjusted to the above parameters, a Carbon Monoxide test must be done to insure less

2

than 50 PPM in the flue gas.

Any sign of soot or carboning during combustion indicates that there is insufficient primary air and the air shutter

should be opened more until this condition is corrected. If soot or carboning of the burner is suspected, a smoke

sample should be taken after the burner operates a minimum of 10 minutes. This would typically only occur in the

LP units. Opening the air adjustment screw should reduce the carboning from the combustion process.

14

Page 17

All installations and services must be performed by qualified service personnel.

In summary, setting the combustion air on the Thermo Pride Midco RE32 power gas conversion burner is

extremely critical. This adjustment should only be made by following these instructions and confirming the

set-up with the proper CO

or O2 combustion analyzer and a carbon monoxide reading of less than 50 PPM.

2

L. REQUIREMENTS AND SIZING OF DUCT WORK

The duct system must be sized and installed by a qualified installer or service person, following the design standards

of the Air Conditioning Contractors of America (ACCA) or ASHRAE.

1. When a return air register is located in the same room as the furnace, it must be installed a minimum of 20 feet

away from the furnace.

2. If supply ducts carry circulated air to areas outside the space containing the furnace, the return air duct shall also

be sealed to the furnace and also terminate outside of the furnace space.

3. The return air duct system must equal the supply air duct system in its CFM capabilities. Use a supplier's catalog

for proper sizing of outlet and return air registers and grills to ensure that they meet the CFM requirements of the run

to which they are connected.

4. If the furnace is used in connection with an air conditioning evaporator coil, the furnace must be installed parallel

with or on the upstream side of the coil, to prevent condensation in the heat exchanger. If the evaporator coil is

installed with a parallel flow arrangement, dampers or other means to control flow of air should prevent chilled air

from entering the furnace. If such a device is manually operated, it must be equipped with a means to prevent

operation of either the furnace or air conditioner unless it is in the full heat or cool position.

5. The duct system shall be sized for the maximum CFM requirement of the installation, whether it is for heating or

cooling. Two common rules for heating and cooling follow:

A. 400 CFM (1200 BTU's) per ton of cooling is required.

B. 1.4 CFM of heating per 100 BTU's of furnace output based on its steady state efficiency and a 50° to 80°

temperature rise.

15

Page 18

All installations and services must be performed by qualified service personnel.

EXAMPLE: Heating output of furnace is 100,000 x 1.4

÷ 100 = 1400 CFM. Air conditioning installed is 4 tons x

400 CFM = 1600 CFM or 48,000 BTU's. NOTE: The duct system must be sized for the larger CFM requirement for

cooling. If only 3 tons 36,000 BTU's of cooling x 400 CFM = 1200 CFM was installed, the duct would have to be

sized for the 1400 CFM heating requirement.

To insure obtaining the necessary air handling capacity of a duct system, each of the system components (trunk lines,

take offs, runs and register and grill-free areas) must be properly sized and matched together. A 12"x8" duct with a

400 CFM capacity for example will not flow 400 CFM if the register(s) to which it connects only flow a total of 200

CFM.

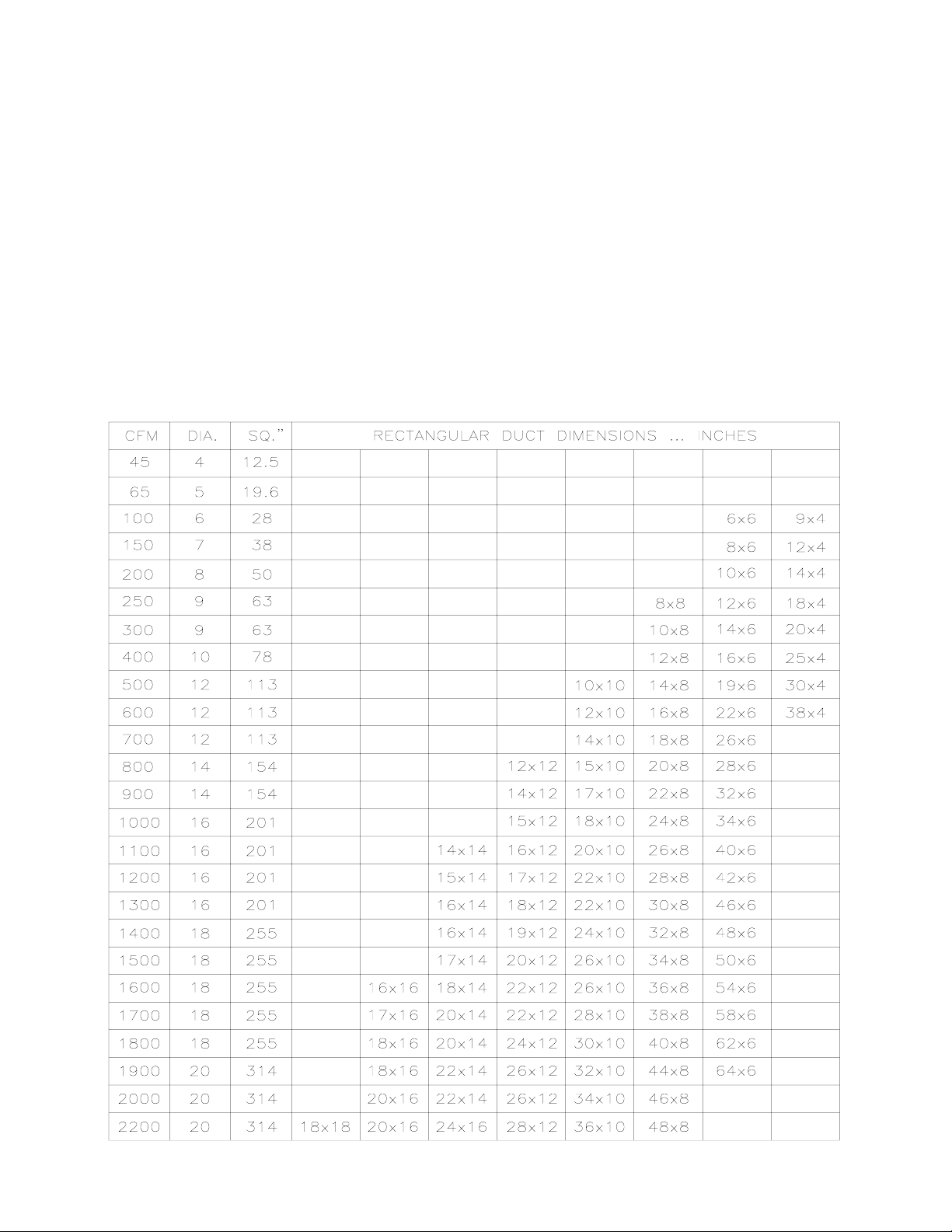

To achieve proper air movement, the main trunk lines, take offs, registers and grills of the supply return air duct

system must have an adequate square inch area to move the desired CFM. The chart shows the CFM air-handling

capability based on a 0.1" SP loss, in the supply duct system.

DUCT SIZES FOR HOMES, QUIET OFFICES OR SIMILAR INSTALLATIONS

16

Page 19

All installations and services must be performed by qualified service personnel.

DUCT WORK/AIR CONDITIONING:

If the furnace is used in connection with summer air conditioning (cooling), the furnace should be installed parallel

with or on the upstream side of the evaporator coil to avoid condensation in the furnace heat exchanger. If the

cooling unit is installed with a parallel flow arrangement, dampers or other means used to control flow of air should

be provided to prevent chilled air from entering the furnace. If such a damper is manually operated, it must be

equipped with a means to prevent operation of either unit, unless the damper is in the full heat or cool position.

The duct system should again follow the design standard of Air Conditioning Contractors of America (ACCA) or

ASHRAE. (Latest Edition Fundamentals Volume).

A slab coil (HE style) is available for the horizontal air flow application on the PGT5-11-16 furnaces. (See Fig.

below).

To obtain proper CFM with air conditioning installed on a belt drive unit, the motor and/or blower pulley may need

to be changed. On a direct drive unit the blower motor speed may need to be changed depending upon the size of the

air conditioning system installed and the static resistance of the duct system.

NOTE: The horizontal units have direct drive blowers and no pulley or motor change is required. See direct drive

motor and blower specifications for air conditioning CFM's at .5 static.

SIZING THE DUCT WORK FOR A COMBINATION HEATING AND COOLING SYSTEM:

Two formulas must be used in determining the CFM requirements of a combustion heating and cooling system.

1. HEATING CFM:

BTU'S OUTPUT OF FURNACE

1.1 X TR (TEMPERATURE RISE) = HEATING CFM

EXAMPLES:

A. 110,000 BTU OUTPUT

1.1 X 850F TR = 1176 CFM FOR HEATING

B. 110,000 BTU OUTPUT

1.1 X 700F TR = 1429 CFM FOR HEATING

2. COOLING CFM: 400 CFM X COOLING TONNAGE (12,000 BTU PER TON) =

CFM FOR COOLING

EXAMPLES:

17

Page 20

All installations and services must be performed by qualified service personnel.

A. 400 CFM X 3 TON (36,000 BTU'S) = 1,200 CFM FOR COOLING

B. 400 CFM X 2.5 TON (30,000 BTU'S) = 1,000 CFM FOR COOLING

NOTE: To obtain the proper 50°F to 80°F temperature rise for heating an air conditioning coil is installed, the speed

of the blower motor may have to be changed. This depends on the static resistance of an individual duct system and

the size of the air conditioner.

M. FILTERS

To clean a dirty filter, first remove the blower compartment door. Remove dirty filter from the filter rack and clean

with a mild soap and water solution. Make sure filter is thoroughly dry before replacing. Put blower compartment

door back into place.

A. PGT HORIZONTAL UNITS

B. PGL LOWBOY

18

Page 21

All installations and services must be performed by qualified service personnel.

N. FAN AND LIMIT POSITION AND LOCATION

Power gas furnace models PGL5 through PGL20 are shipped with the fan and limit control pre-mounted in the

vestibule. Should the installer prefer to mount the fan and limit control in the supply plenum, the installer must

supply additional wire comparable to the original wire size and type which must be routed through either rigid, EMT

or flexible metal conduit to the mounting location as described below.

LOCATION FOR LOWBOYS & HORIZONTALS

WITHOUT AIR CONDITIONING:

FAN & LIMIT LOCATION FOR HORIZONTALS

WITH AIR CONDITIONING:

19

Page 22

All installations and services must be performed by qualified service personnel.

A. FAN & LIMIT LOCATION WITH H-COIL:

The fan & limit control should be mounted between the H-coil cabinet and furnace. For distances from top of plenum

and furnace, see chart above. IMPORTANT: Do not mount fan/limit in H-coil cabinet.

O. WIRING

All wiring must conform to the provisions of local codes or in the absence of these codes with the provisions of the

National Electrical Code, ANSI/NFPA70 (Latest Edition).

The following items are guidelines to complete the wiring portion of the installations.

1. Install the room thermostat according to instructions provided with thermostat. Set the anticipator to .8 amps.

2. The furnace must be grounded in accordance with local codes and with the National Electrical Code,

ANSI/NFPA70 (Latest Edition).

WARNING:

wiring.

WARNING:

from this transformer. If an electric vent damper is used, a separate transformer and relay must be installed.

Thermally actuated vent dampers cannot be used with this power burner because the damper must be in the open

position before the burner ignites.

For information on the electrical internal workings of the burners itself and the procedure for "initial start-up" and

"adjustment" of the power burner, reference power burner manufacturer's instructions.

All wiring must perform to provisions of the National Electrical Code ANSI/NFPA70 (Latest Edition). Wiring

between the furnace and devices that are field installed shall conform to temperature limitations for type T wire (35

C rise) and Local Ordinances. If any of the original wire supplied with the unit needs to be replaced, 105°C

thermoplastic or its equivalent, must be used. The power supply to the furnace is to be on an individual electrical

circuit with properly sized over-current protection.

TURN OFF THE ELECTRICAL POWER to the furnace before attempting to change blower speed

The power gas burner has its own transformer and no other electrical equipment should be operated

20

Page 23

All installations and services must be performed by qualified service personnel.

All electrical wiring must be installed in strict accordance with local ordinances and codes. In the absence of local

ordinances and codes, all electrical wiring must be in accordance with the National Electrical Code (ANSI/NFPA 70LATEST EDITION).

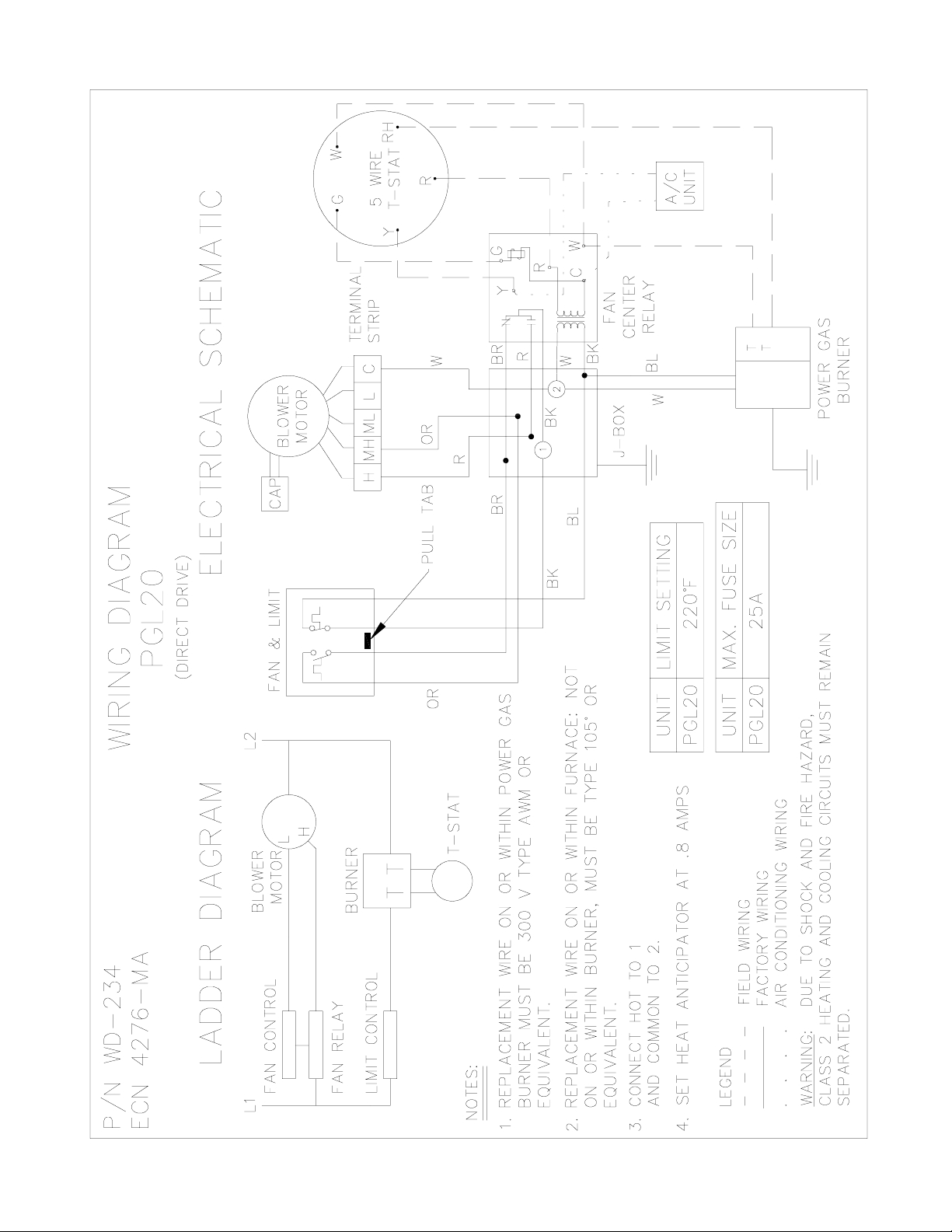

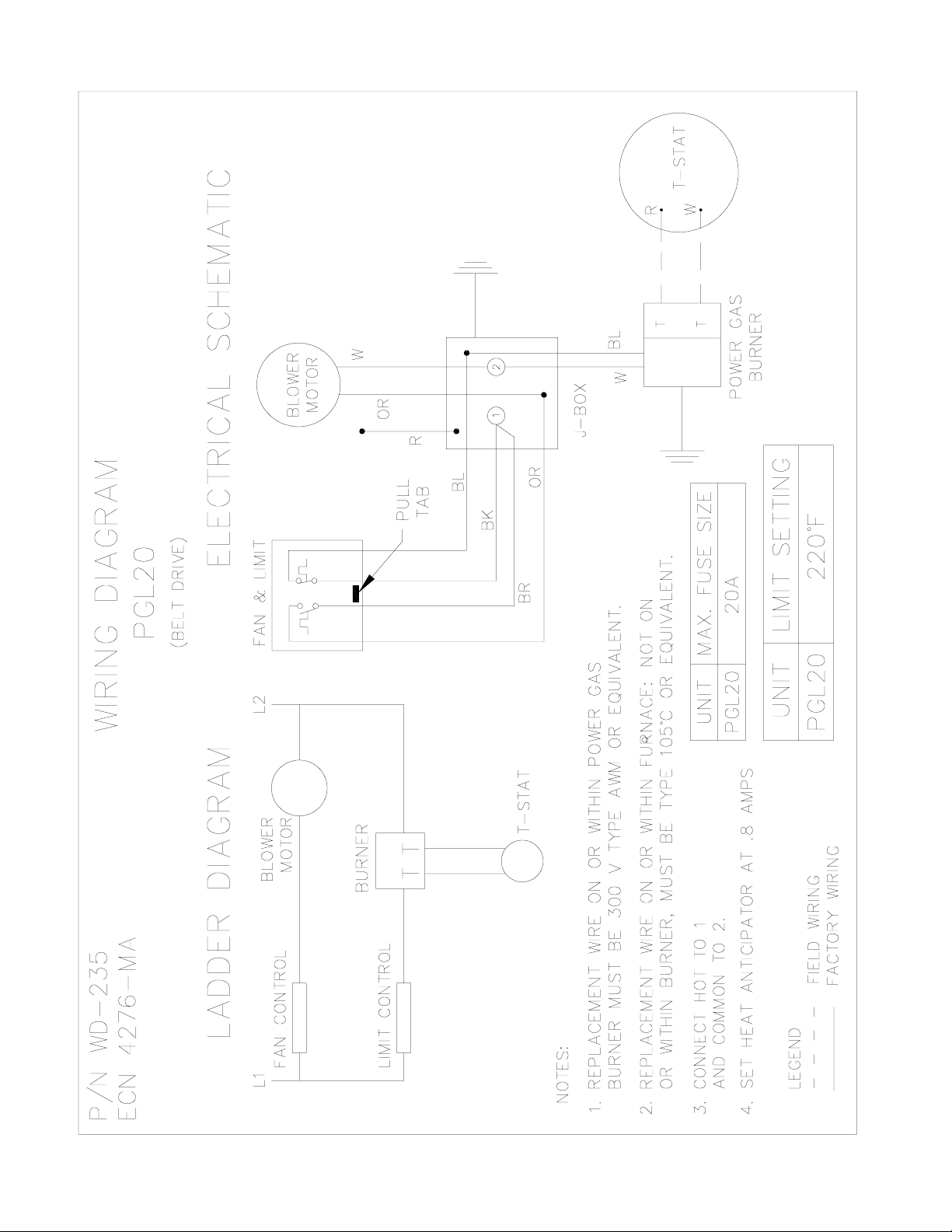

On the following pages are the wiring diagrams for the various Thermo Pride gas furnace models.

21

Page 24

All installations and services must be performed by qualified service personnel.

22

Page 25

All installations and services must be performed by qualified service personnel.

23

Page 26

All installations and services must be performed by qualified service personnel.

24

Page 27

All installations and services must be performed by qualified service personnel.

25

Page 28

All installations and services must be performed by qualified service personnel.

Wiring:

All electrical wiring must be installed in strict accordance with local ordinances and codes. In the absence of local

ordinances and codes, all electrical wiring must be in accordance with the National Electrical Code (ANSI/NFPA 70LATEST EDITION).

Below and on the following pages are the wiring diagrams for the various Thermo Pride gas furnace models.

26

Page 29

All installations and services must be performed by qualified service personnel.

II. STARTING THE UNIT

A. INITIAL START UP:

1. Check all wiring for loose connections and proper hook up.

2. Leak test gas piping connections.

3. Check tubing to the pressure switch to make sure it is pushed firmly onto the pressure tap.

4. Check flue pipe, chimney, and all connections for tightness and to make sure there is no blockage.

5. Make sure air filters are in place.

OPERATING INSTRUCTIONS:

WARNING:

line. This should be done by qualified service personnel. If excessive gas escapes when purging the supply at the

union, allow the area to ventilate for at least 15 minutes before starting the furnace. LP gas is especially hazardous

because the specific gravity of LP gas allows it to accumulate at floor level at a hazardous concentration.

WARNING:

occurring more than once, it is suggested that:

1. A window(s) be opened.

2. The thermostat set at highest setting.

3. The furnace remains running at conditions 1 & 2 for 30 minutes or until the odor has dissipated.

B. BURNER COMBUSTION:

Obtain the following recommended values when setting the burner combustion:

CO2 NATURAL GAS - MIN. 8.5%, MAX. 10.5% WITH NO MORE THAN

CO2 LPG - MIN. 10.5% MAX. 12.0% WITH NO MORE THAN

CO ALL GASES - ZERO TO A MAX. 50 *PPM.

After final adjustments are made, lock settings to prevent tampering.

*PPM = PARTS PER MILLION

50 PPM = .005% = 1/200 OF 1%

NOTICE: See burner manufacturer instructions for troubleshooting.

C. ADJUSTMENT OF BTU INPUT RATE:

The orifice for this furnace was sized: 1. For natural gas having a heating value of 1025 BTU per cubic foot and a

specific gravity of .60 or 2. For liquified propane gas with a heating value of 2500 BTU per cubic foot and a specific

gravity of 1.53. The information plate inside the furnace vestibule will specify which gas your furnace is orificed for.

If the furnace is installed at an altitude that is more than 2,000 feet above sea level, it is mandatory that the input to

the burner be reduced 4.0% for every 1,000 feet that it is above sea level. If the furnace is installed at an elevation of

5,000 feet, its input must be reduced 20.0%. Example: a furnace rated at 100,000 BTU at sea level must be reduced

to a firing rate of 80,000 (100,000 x .80 = 80,000) at an elevation of 5,000 feet. If the furnace is installed at an

For initial start-up of the furnace after installation, it may be necessary to purge the air out of the gas

Heat exchanger paint will burn off on initial firing creating an odor. To prevent this odor from

50 *PPM OF CO.

50 *PPM OF CO.

27

Page 30

All installations and services must be performed by qualified service personnel.

elevation of 2,000 feet or less, no reduction in input is required. Your gas supplier will supply you with the correct

BTU and orifice sizing information.

To check the input of your natural gas furnace, proceed as follows:

a. Call your gas supplier and ask for the BTU content (heating valve) of one cubic foot of the gas, supplied to the

installation area. An alternate approach is to assume a value of 1025 BTU/Cu Ft that is the national average.

b. With all other gas appliances turned off, allow the unit to operate for 10 to 15 minutes. Using a stopwatch, clock

the time required for the (small) dial on the gas meter to make one full revolution. The meter will state how many

cubic feet are flowing for each revolution usually one, two or five. The unit must have been in operation at least 10

minutes before clocking.

FORMULA: BTU/Cu Ft x Number of Cu Ft x 3600 Seconds = Input

BTU/hr

Seconds for one revolution

EXAMPLE: 1025 BTU/Cu Ftx2CuFtx3600 = 98.663 BTU Input

74.8 Seconds

Check for the model number of this furnace, its input, the type of gas and the manifold pressure on the information

plate located on the vestibule panel behind the upper front panel. If using the above example, the furnace was a

PGT5-100 model the 98,663 BTU input would be acceptable because it was within 2% of the listed input of

100,000.

c. Make sure that the gas supply pressure to the furnace falls within the maximum range of 5-1/2" to 14" WC

pressure on natural gas and 11.0" to 14.0" WC on LP gases. The pressure to the furnace must be checked while the

furnace burner and any other gas appliances on the same supply system are operating, using the test procedure

outlined in Section H of this manual.

This gas furnace is equipped with a fixed orifice sized for the manifold pressure shown in the burner manual. The

input can be increased or decreased by adjusting the manifold pressure. Remove the 1/8" threaded pipe plug located

on the bottom right side of the gas valve. Use a U tube manometer or pressure gage to measure the pressure. To

adjust the pressure, remove the cap from the regulator on the top of the gas valve and using the adjustment screw,

decrease the pressure by turning the screw counterclockwise or increase it by turning the screw clockwise.

ADJUSTMENTS TO THE LISTED PRESSURE MUST NOT EXCEED the recommended maximum manifold

pressures in the burner manual.

If a gas meter is not available for natural gas, or the unit is installed on liquified petroleum gases which are not

metered, the correct input can be assumed if the furnace manifold pressure is the same as that shown on the

information label and the orifices are sized correctly.

Shut off the gas supply to the furnace. Remove the pressure gage and re-install the pipe plug using a thread

compound resistant to the action of LP gases.

If the rated input cannot be obtained with the present orifice at the correct pressure, your local gas supplier will assist

in sizing the proper orifice. Our Engineering Department will gladly assist in sizing the orifice if you provide them

with the heating value in BTU per cubic foot and the specific gravity of the gas.

28

Page 31

All installations and services must be performed by qualified service personnel.

ORIFICE CHART

FURNACE

L.P. NAT.

MODEL NO.

PGT5-100

PGT11-125

PGT16-160

PGL20-180

PGL33-250

PGL37-312

PGL39-400

D. FURNACE CHECKOUT PROCEDURE

Before any system of gas piping is finally put into service, it shall be carefully tested to assure that it is gas tight as

indicated in Gas Piping Section of Burner Manual.

NOTICE:

leaving the job site. Specifically the following should be checked:

With furnace in normal heating operation, check to make certain blower will start and stop automatically under

control of fan switch.

a. Check safety limit control as follows:

1. Shut off incoming power.

2. Block return air opening or remove blower belt on belt drive or unplug blower at terminal strip on direct drive.

3. Restore power to furnace.

4. Set thermostat above room temperature calling for heat.

5. When temperatures are reached in furnace at limit control setting with blower out of operation, burner should be

shut off.

6. Shut off electrical power, remove blockage and restore power.

b. Make certain thermostat will automatically start and stop the burner and fan control operates blower properly.

IV. INSTALLER'S INSTRUCTIONS TO USER:

After completing the installation, the installer shall inform and demonstrate to the homeowner: 1. The Sequence of

Operations. 2. Operating Instructions and Routine Maintenance. 3. Review label reproductions at beginning of this

manual.

All controls on the unit should be checked for proper functioning prior to the qualified service personnel

.113 OR #33 DMS

.1285 OR #30 DMS

.144 OR #44 DMS

.213 OR #3 DMS

.265 OR 17/64 DMS

.297 OR 19/64 DMS

.332 OR Q DMS

.196 OR #9 DMS

.213 OR #3 DMS

.238 OR B DMS

.277 OR J DMS

.332 OR Q DMS

.390 OR 25/64 DMS

.468 OR 15/32 DMS

29

Page 32

All installations and services must be performed by qualified service personnel.

V. DEALER MAINTENANCE

A. ELECTRICAL:

1. Check all wiring for loose connections.

2. Check for correct voltage at the furnace when operating.

3. Check amp-draw on blower motor and burner to assure they are not exceeding name plate amp rating.

B. CLEANING HEAT EXCHANGER:

WARNING: THE HEAT EXCHANGER MUST BE CLEANED BY A QUALIFIED SERVICE

TECHNICIAN.

It is important to inspect and clean the heat exchanger once a year or as necessary to remove any build-up of soot. A

layer of soot on the inside of the heat exchanger will act as an insulator and reduce heat transfer, resulting in less

efficiency. If heavy soot deposits were found in the heat exchanger, this indicates that the burner may be out of

adjustment. Reset the burner as indicated under the "BURNER COMBUSTION" section.

To clean the heat exchanger, first turn off all power to the unit. Next, remove the access panel (see below and

following page) immediately above the burner (on the horizontal furnace, it will be located to the side of the burner)

to gain entry to the cleanout covers.

(Please notice: This panel is identified with a label.) Remove cleanout

covers, the vent connector pipe to the chimney, the burner, and the burner mounting plates. When removing the

cleanout covers, special care must be taken not to damage the gaskets. Should the gaskets separate, crack, break, or

otherwise not be able to provide the necessary seal, the gasket must be replaced before reattaching the cleanout

covers.

With access to the inside of the heat exchanger through the burner area, cleanout openings, and vent pipe connection,

it is now possible to use a long, flexible wire brush and an industrial type vacuum cleaner to remove any soot buildup.

NOTE: A one inch (outside diameter) vacuum cleaner hose will fit into the outer radiator.

To vacuum and brush the outer radiator of the heat exchanger, go through the cleanout openings in both directions,

as shown below.

30

Page 33

All installations and services must be performed by qualified service personnel.

Reassemble the furnace to its original construction. Remount the burner being certain that the air tube is properly

inserted into the chamber opening (see Burner Installation section).

VI. TROUBLESHOOTING

For troubleshooting the power gas burner, reference the burner manufactures instructions.

If the burner is producing an excessive combustion sound level, perform the following procedures:

1. Re-check the position of the burner tube to assure that the end of the tube is 1/4 inch in from the inside surface of

the combustion chamber. Also, make sure the burner is firing squarely into the center of the combustion chamber.

2. Verify the correct burner air setting using instrumentation (see initial start up section). If the air setting on the

burner is excessive, this will cause the combustion sound level to be louder than normal.

3. Move the draft control as close to the chimney as possible. Also, face the draft control towards the open area of

the room.

4. Alter manifold pressure of the burner, but stay within normal operating pressures as specified by burner

manufactures instructions.

5. Derate the input of the burner 10% from normal furnace input rate.

6. If the combustion sound is resonating through a particular portion of the ductwork, insulating the ductwork or

using flex duct should isolate that portion of the ductwork.

If the furnace air blower will not come on or cycles abnormally, check the following:

1. If the blower motor is receiving 115 V, it has cutout on thermal overload or is defective. A belt that is very tight

may cause the blower motor to cut out on thermal overload on a belt drive blower. An incorrect or faulty capacitor

may prevent a direct drive blower motor from operating.

2. If the blower motor is not receiving 115 V, check the power source to the furnace, as well as all wire connections

in the vestibule junction box. Check wire connections at the fan and limit and the fan temperature settings. Also,

check the fan and limit for response to temperature.

31

Page 34

All installations and services must be performed by qualified service personnel.

VII. REPLACEMENT PARTS

32

Page 35

All installations and services must be performed by qualified service personnel.

33

Page 36

All installations and services must be performed by qualified service personnel.

34

Page 37

All installations and services must be performed by qualified service personnel.

35

Page 38

All installations and services must be performed by qualified service personnel.

36

Loading...

Loading...