Page 1

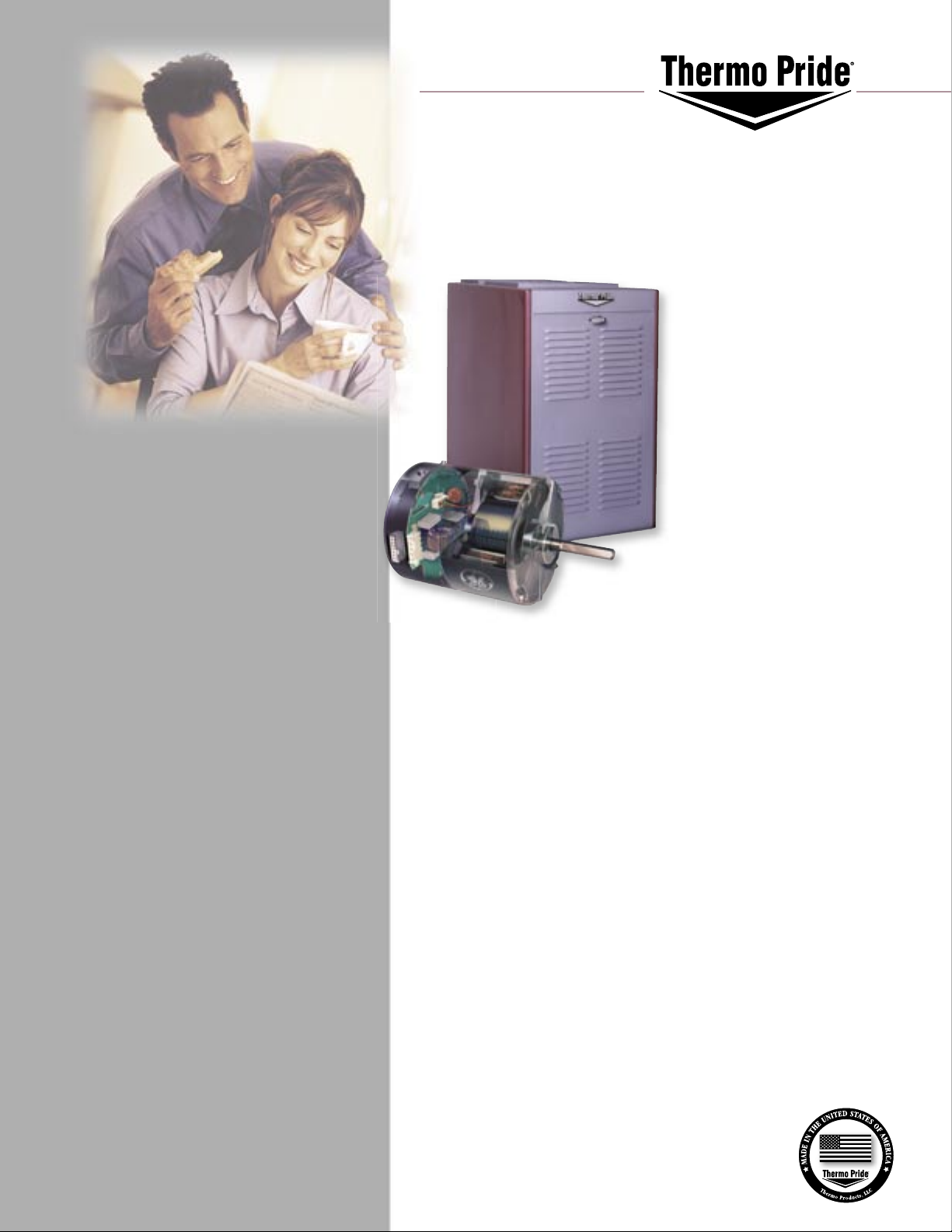

Saving to Experience

Since the ECM variable-speed

blower motor uses less electricity

than a conventional blower motor,

not only will you have increased

comfort, but you can also save

money (based on 0.08/kWh

electric cost).

Premiere Oil Furnace

Dependable Craftsmanship

with Maximum Comfort

When you want to experience

exceptional comfort, increased

effi ciency, and quieter operation while still receiving the

handcrafted quality and proven

warranty of ermo Pride’s

traditional oil furnace, select

the Premiere Oil Furnace with

the ECM variable-speed blower

motor. Since the ECM motor

automatically adjusts its speed

for varying heating and cooling

modes your home’s maximum

comfort is achieved.

ECM Blower Motor

1. Annual Savings for heating

your house — average $58

2. Annual Saving for heating and

cooling your house — average $76

3. When using a constant fan that

runs for air fi ltration, your annual

savings can average $480 for just

heating your house or $429 for

heating and cooling your house.

“ is Furnace is much quieter. Heats

rooms that were cool with previous

furnace. So far we have used less kw

of power each month compared to the

previous year.”

Bob Williams, VP of Rossoe Energy

Systems & Oil Company

Some of the ECM benefi ts include:

• quieter start up, greater effi ciency, and more comfortable

operation due to infi nite fan motor speeds

• delivery of comfortable airfl ow in both the heating and

cooling modes. On a call for heat or cooling the blower

motor starts at the slower speed and builds to the correct

running speed

• automatically compensates for restricted ducts or a dirty

air fi lter by increasing the motor speed (routine fi lter

cleaning is still recommended.)

• energy bills will be lower due to quieter effi ciency of the

ECM motor (especially when you run the blower for

long periods of time.)

• reduced fan speeds will run quietly and save energy

when the blower runs constantly as with

air fi ltration, for example.

Page 2

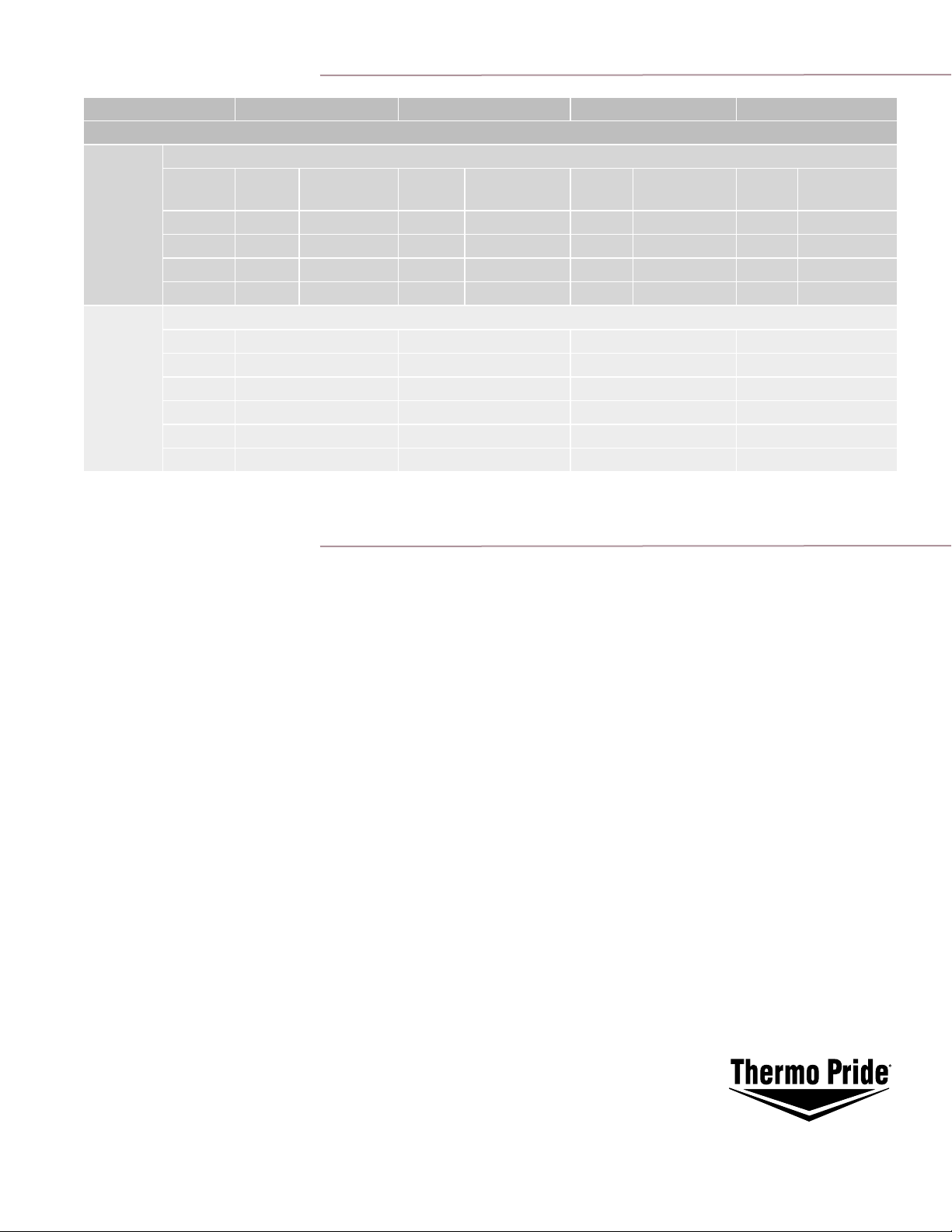

ECM Specifications

Model Number * OL5-85...E OL11-105...E OH5-85...E OH11-105...E

CFM from .1 - .6” W/C

A/C Tonnage Selection

Cooling

(100 cfm

steps

available

for A/C)

Heating

(at approx.

rated input

BTU)

The standard motor size may not support this cfm at high static pressures.

* Model numbers end with ‘E’ to signify ECM motor.

2 ton 800 500 800 500 800 500 800 500

2.5 ton 1000 500 1000 500 1000 500 1000 500

3 ton 1200 600 1200 600 1200 600 1200 600

3.5 ton 1400 700 1400 700 1400 700 1400 700

Air Temperature Rise Selection

57° Rise 1400 — 1400 —

63° Rise 1260 1500 1260 1500

69° Rise 1162 1350 1162 1350

75° Rise 1050 1245 1050 1245

83° Rise 938 1125 938 1125

A/C

CFMs

Continuous

Fan

Heating CFM Heating CFM Heating CFM Heating CFM

A/C

CFMs

Continuous

Fan

A/C

CFMs

Continuous

Fan

A/C

CFMs

Continuous

Fan

Additional Features

General

• Eliminates the need for air temp thermostat to control fan cycling by using time instead.

• Selectable blower turn-on and turn-off delays to adjust comfort & efficiency

(turn-on: 30, 60, 120 & 240 sec; turn off: 2, 4, 6 & 8 min)

• ree blower operating choices: HEAT, COOL & FAN for best efficiency for each mode.

• Reduces A/C blower speed 50% on demand to increase dehumidification.

• Cooling blower delays of 10 seconds on, and 45 seconds off to enhance cooling comfort and efficiency.

Cycle Control

• 4 minute minimum A/C off time to reduce Short-Cycle related failures.

• A high limit will cause the blower run at the selected HEAT speed. It will then run for the HEAT turn off

time afterwards in the absence of a HEAT call.

• Blower operation will “time out” before mode is switched between HEAT & COOL to prevent stress related

evaporator failures.

• Burner Cut-Off on high limit

Speed Control

• Selectable air temperature (heat) rise from Return to Supply Plenum (choose from: 63, 69, 75 and 85ºF)

• Selectable CFM rates for matching A/C tonnages. ese CFM selections support from 2.0 to 3.5 tons.

• Maximum CFM’s are limited by the maximum RPM of the ECM motor and the duct static pressure.

Please refer to the manual addendum for guidelines.

Diagnostics

• Control Input LED’s indicate active thermostat input lines.

• Diagnostic LED indicate:

1. Active Operation (turn full on during burner or compressor operation)

2. A HIGH LIMIT condition. (flash on/off at 2 ½ times per second)

Form No. PL81410021002 - 6/05 - 20Ms

Printed in the U.S.A.

© 2005 ermo Pride - North Judson, IN

Phone: 574-896-2133

www.thermopride.com

Loading...

Loading...