Page 1

INSTALLATION AND OPERATION MANUAL

FOR 2 – STAGE RIELLO BURNER

ADDENDUM TO ( Mo – 437 manual )

FOR USE WITH MODEL:

OH6FX072DV4

PLEASE READ THESE INSTRUCTIONS PRIOR TO INSTALLATION, INITIAL FIRING, AND

BEFORE PERFORMING ANY SERVICE OR MAINTENANCE. THESE INSTRUCTIONS

MUST BE LEFT WITH THE HOMEOWNER AND SHOULD BE RETAINED FOR FUTURE

REFERENCE BY QUALIFIED SERVICE PERSONNEL.

THERMO PRODUCTS, LLC.

BOX 217

NORTH JUDSON, IN 46366

PHONE: (574) 896-2133

MO-462

ECN 4865-MA MADE IN USA

Page 2

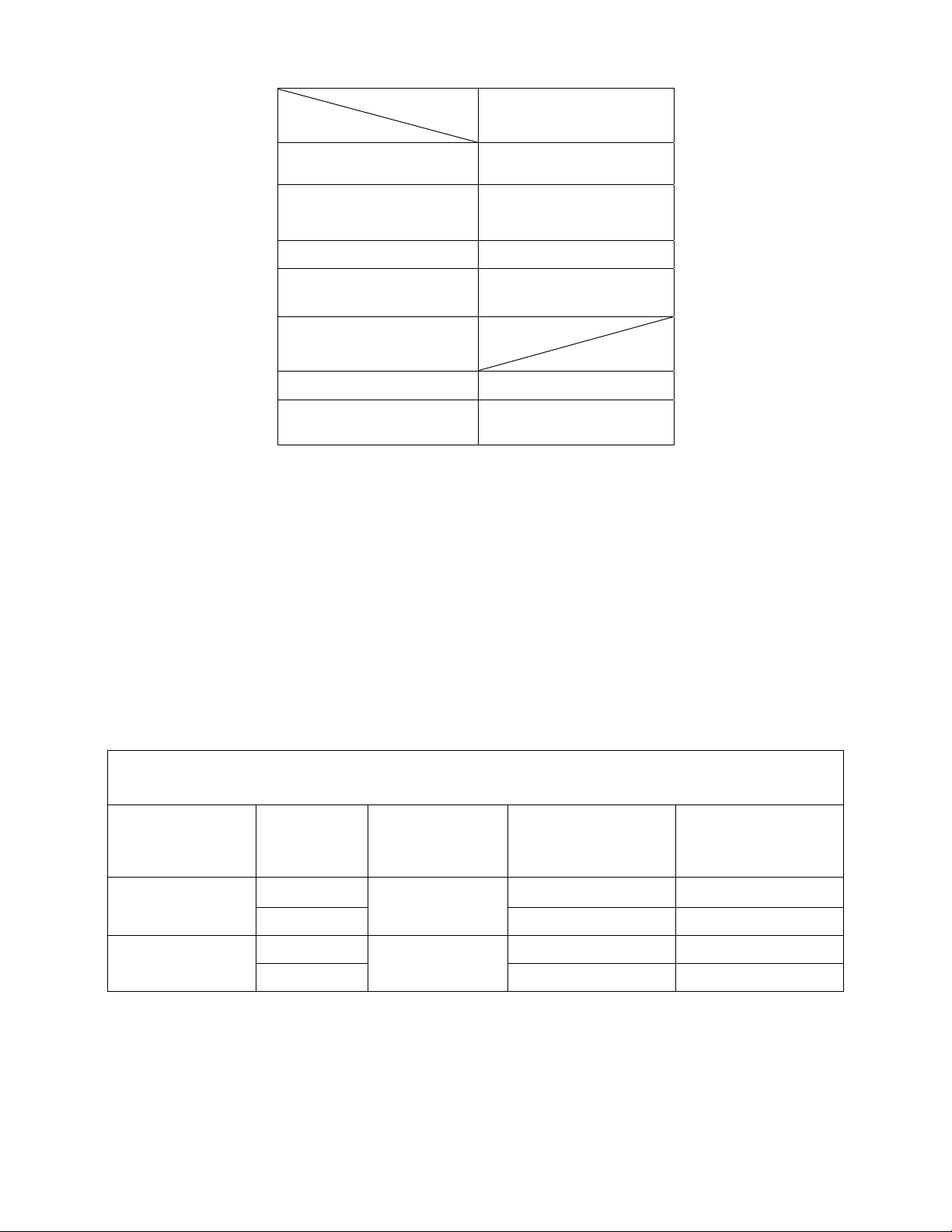

Riello 2-stage burner specifications and applications:

MODEL

PART

MTG. PLATE

PART NO.

MTG. PLATE

GASKET

PART NO.

**NOZZLE SIZE

OD6 2-STAGE

11700

330212

.70 X 45° W

NOZZLE

PART NO.

OIL PUMP

PRESSURE

130 LOW

170 HIGH

380702

BURNER G5D

BURNER

PART NO.

Table 8: Riello burner application

380529

THE NOZZLE SIZE GIVES THE NOMINAL FLOWRATE, IN GPH, FOLLOWED BY THE SPRAY ANGLE, IN

DEGREE’S, AND THE SPRAY PATTERN, EITHER “H” FOR HOLLOW CONE OR “S” FOR SOLID CONE.

FOR EXAMPLE, A NOZZLE RATED AT 0.65 GPH @ 100 PSIG THAT PROVIDES AN 80° SPRAY ANGLE

AND A HOLLOW SPRAY PATTERN WOULD BE ABBREVIATED IN THE TABLE AS “0.65 X 80°H”.

** NOTE: The reason the Riello burner nozzle sizes are smaller than the standard Thermo Pride burner nozzles

is that pre-set pump pressures are higher, therefore achieving the same firing rate with a smaller nozzle.

For more specific burner information, specifications or service information, reference the training manual enclosed

with each Riello burner or contact:

Riello Corporation of America,

5 Pond Park Road Hingham, Massachusetts 02043

Phone: (617) 749-8292

2 STAGE FIRING RATES

CAPACITY

FIRING

RATE

NOZZLE SIZE

Riello

INPUT RATE*

(BTU/HR)

EFFECTIVE**

HEATING

CAPACITY

HIGH CAPACITY

LOW CAPACITY

HIGH FIRE 106,250/170psi 90,000

LOW FIRE

HIGH FIRE 85,000/170psi 74,000

LOW FIRE

.70 X 45° W

85,000/130psi 74,000

.50 X 45° W

70,000/130psi 60,000

Table 9: Riello 2-stage firing rates

* Based on #2 domestic heating fuel oil having heating value of 140,000 BTU per gallon.

** Based on thermal efficiency of 84%-85%.

2

Page 3

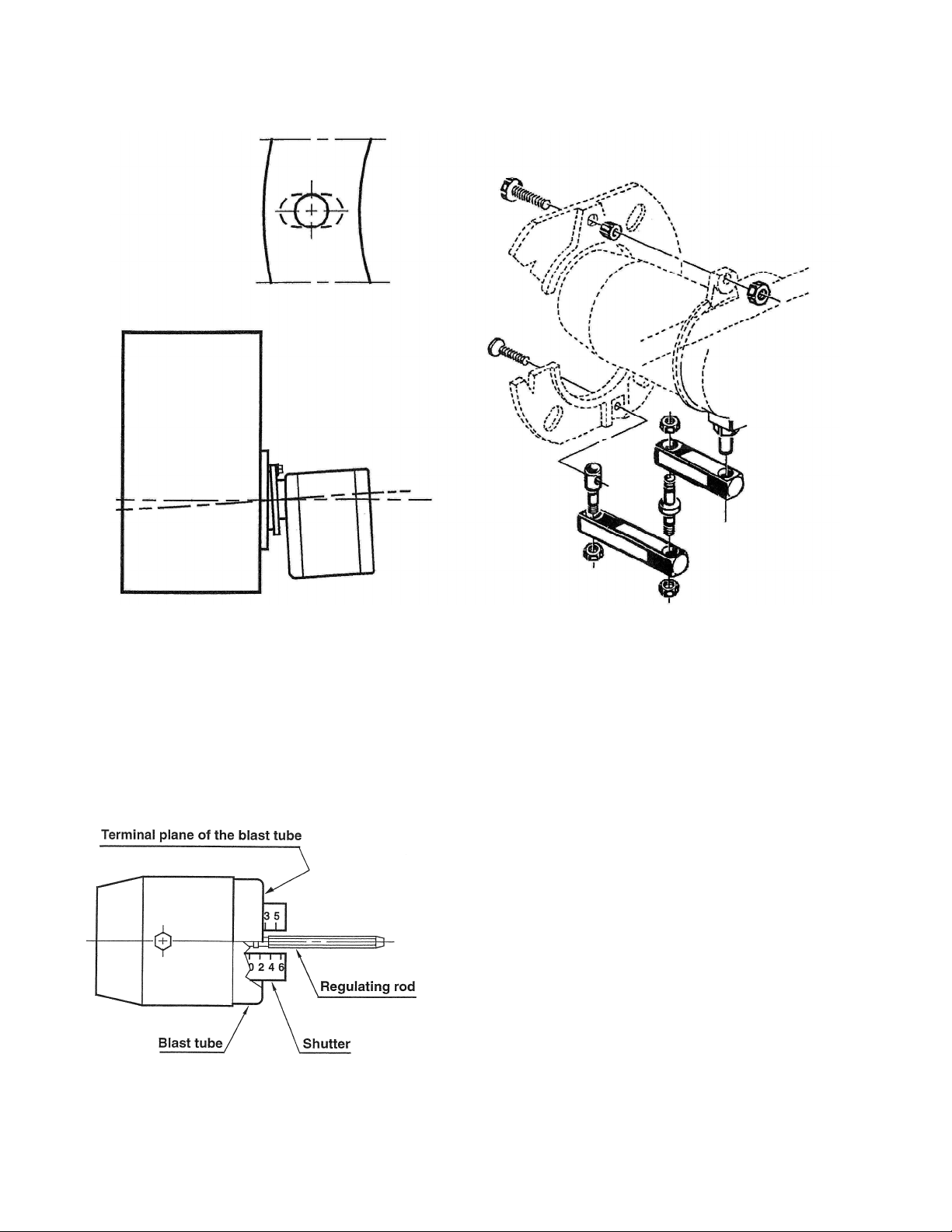

MOUNTING THE 2-STAGE RIELLO BURNER:

It is necessary that the insulation gasket be placed between the mounting plate and the burner flange. The

insulating gasket has six holes, which, if necessary, can be modified as shown. (see figure 14-1)

Figure 14-1: Burner gasket and mounting Figure 14-2: Burner fixing and hinge assembly

Verify that the installed burner is lightly leaned towards the button. (See figure 14-1) The burner is designed to

allow entry of the flexible oil-lines on either side of the burner.

COMBUSTION HEAD SETTING FOR 2-STAGE RIELLO BURNER:

This is done when fitting the nozzle, with the blast tube removed. It depends on the output of the burner and is

carried out by rotating the regulating rod, till the terminal plane of the blast tube is level with the set-point, as

indicated in the schedule.

Figure 20

In figure 20 the combustion head is set for an output of 0.75

GPH at 130 psi, while the shutter is level with set-point 2.5, as

required by the above schedule.

3

Page 4

The setting of the fan output according to the installation

should be done only through the air damper. Should you want

to adjust the setting of the combustion head, with the

burner running, turn the rod (1) with a 6mm wrench (2) as

follows:

TURN TO THE RIGHT: (SIGN + )

In order to increase the volume of air entering the

combustion chamber and thus diminishing its pressure.

There is a reduction of CO2 and the adhesion of Figure 21

the flame to the air diffuser disc improves.

(Setting advisable for ignitions at low temperatures).

TURN TO THE LEFT: (SIGN - ) Figure 21

In order to reduce the volume of air entering the combustion chamber and thus increasing its pressure. The CO2

improves and the adhesion of the flame to the diffuser tends to reduce. (This setting is not advisable for ignitions

at low temperatures).

In any case do not bring the combustion head setting more than one point away from that indicated in the

schedule. One set-point corresponds to 3 turns of the rod; a hole (3) at its end facilitates counting the number of

turns.

AIR DAMPER ADJUSTMENT:

The settings indicated in the schedule refer to the burner with its metal cover fitted and the combustion chamber

with “zero” depression. These regulations are purely indicative. Each installation however, has its own

unpredictable working conditions: actual nozzle output; positive or negative pressure in the combustion-chamber,

the need of excess air, etc. All these conditions may require a different air damper setting.

It is important to take account of the fact that the air output of the fan differs according to whether the

burner has its metal cover fitted or not.

Therefore we recommended to proceed as follows:

• adjust the air damper as indicated in the schedule (3);

• mount the cover, simply by means of the upper screw;

• check smoke number;

• should it become necessary to modify the air output, remove the cover by loosening the screw, adjust the

air damper, remount the cover and finally recheck the smoke number.

The burner is provided with a hydraulic device controlled by the economizer which reduces the max. output of oil

and air by approximately 70%.

4

Page 5

Figure 22

1st STAGE ADJUSTMENT:

Adjustment of air shutter: place the small plug (9) of the economizer (10) into the position I (Item A). In this

way the burner will remain permanently in the 1

st

stage.

Loosen the nut (2), turn the screw (3) until the air shutter (1) reaches the position desired. Then lock the nut (2).

Pressure regulation: this is set at 130 psi at the factory. Should such pressure be reset or changed, just turn

the screw (4). The pressure gauge must be mounted in place of cap (5).

2nd STAGE ADJUSTMENT:

Adjustment of air shutter: place the small plug (9) of the economizer (10) into the position II (Item B). In this

way the burner remains permanently in the 2

nd

stage. Loosen the nut (6), turn the screw (7) until the air shutter

(1) reaches the position desired. Then lock the nut (6).

Pressure regulation: this is set at 170 psi at the factory. Should such pressure be reset or changed, just turn

the screw (8). The pressure gauge must be mounted in place of cap (5).

i. SMOKE: A smoke sample should be drawn from the heat exchanger flue passageway, which is covered by

the vent terminal. (Remove a large machine screw from the front face of the vent terminal for direct access to

the flue through the opening.) If the first smoke reading is zero (0), close the air band, or shutter, on the

burner until a trace smoke reading is measured.

NOTICE: To achieve proper combustion and the efficiencies listed in sales brochures,

instruments must be used to secure CO2 or O2 readings.

5

Page 6

ii. CARBON DIOXIDE (CO2) OR OXYGEN (O2): Take a CO2 sample from flue passageway. It is possible to

achieve readings of up to 14% CO2 (or 2% O2 ), but it is better to have a slightly lower CO2 (or higher O

reading with zero smoke measured. To achieve a lower CO2 reading, open the air band, or shutter, on the

burner until zero smoke is measured.

For example, if a 13% CO2 (or 3.5% O2) is recorded at a trace of smoke, open the air shutter until zero smoke is

measured with a 12% CO

Adjustment of the burner to achieve a slightly lower CO2 reading is recommended, although it slightly reduces

combustion efficiency, to keep the heating system within normal operating conditions though external conditions

may vary. Some “out-of-spec” conditions which may adversely affect burner performance are, low oil supply

temperature, dirty (contaminated) oil, low heating content (BTU/gal) oil, cold heat exchanger surfaces, and

downdraft conditions. By adjusting the burner in this manner, an operational tolerance is established allowing the

burner to function well, even under less than ideal conditions. This results in less service and maintenance during

a heating season.

iii. FLUE GAS TEMPERATURE: The flue gas temperature will vary to some extent depending on the heat input

rate, duct design, and the amount of air flow across the heat exchanger. The suggested minimum net flue gas

temperature is 350ºF, and the maximum gross flue gas temperature is 500ºF. The lower the flue gas

temperature, the higher the heating efficiency. However, stack temperatures under 350ºF may result in

condensation of water vapor in the flue gases, which in turn promotes corrosion of the heat exchanger.

iv. TEMPERATURE RISE: Temperature rise is equal to the supply air temperature minus return air temperature.

Under steady state operating conditions, the temperature rise across the heating section should be

approximately 65ºF. A higher temperature rise will slightly lower the heating efficiency. A lower temperature

rise will slightly raise efficiency, but may cause condensation.

The supply air temperature should be measured in the supply air trunkline approximately 12 inches downstream

of the supply air outlet of the appliance.

(or 4.5% O2).

2

)

2

NOTICE: Minimum temperature rise is 50ºF.; maximum temperature rise is 80ºF.

k. After final adjustments are completed, tighten all screws to fix the positions of the burner air band.

l. Check for the presence of oil leaks. Correct any oil leaks found.

m. Reassemble the burner compartment cover.

n. Start and stop the unit several times while checking for proper ignition of the burner. The flame should ignite

and stabilize without any significant rumbles or pulsations.

1. Adjustment Of Heat Input Rate:

This appliance was shipped from the factory with one, fixed, main burner nozzle sized to produce the low-fire

input rate using no. 2 fuel oil at the pump pressure shown on the rating label. The input rate can be changed to

the high-fire by switching to the larger burner nozzle and increasing the pump pressure.

The main burner oil nozzles for this unit were selected based upon the following assumed characteristic values of

the fuel oil suitable for use with this appliance design:

• For no. 2 distillate fuel (domestic heating) oil having a higher heating value of 140,000 BTU per gallon and a

specific gravity of 0.88 @ 60ºF. (or “gravity” of 30º API @ 60ºF.).

It is possible to make minor adjustments to the heat input rate by adjusting the pump pressure. Sizeable

changes in input rate (especially reductions) should be made by replacing the burner nozzle. To adjust the

pump pressure to the main burner:

6

Page 7

a. With the oil shut off, remove the 1/8 in. NPT threaded pipe plug located on the lower rear side of the oil

pump, refer to Figure 22. Attach a pressure gage, capable of measuring pressure in pounds per square inch

gage, PSIG, in this opening, on the discharge side, of the oil pump.

NOTICE: It may be necessary to remove the oil pump to attach the plumbing required to

connect a pressure gage to the pump.

b. Turn on the fuel oil and cause the appliance to activate the heating section by answering a “call for heat”.

NOTICE: It may be necessary to bleed air from the oil line before the burner can be fired.

c. Allow the heating section to operate for 10 to 15 minutes.

d. Note the oil pressure at the pump.

e. To adjust the pressure, use a common screwdriver to turn in the pressure adjustment screw, located on the

upper front of the oil pump body.

f. Allow the fuel flow rate to stabilize for a moment. Recheck the oil pressure.

g. If required, repeat the oil pressure adjustment again.

h. When the input rate adjustment has been completed, shut off the fuel oil to the appliance. Remove the

pressure gage. Reinstall the pipe plug using a thread compound resistant to the action of LP gases and fuel oil.

To insure the combustion air supply is adequate, it is now necessary to repeat the steps in the previous Initial

Burner Adjustment section of this manual.

2. Setting Supply Air Temperature Rise:

: To avoid injury from moving parts or electrical shock, shut off the power to

the appliance before removing supply air blower compartment door and servicing this

appliance.

All OD6 models are designed and wired at the factory for a blower speed during heating that should result in an

approximate temperature rise of 65°F. The temperature rise through the heating section, for any given blower

speed, may vary depending on a number of factors. A few of these factors are variations in, the actual resistance

of the duct system to airflow at any time, the return air temperatures, and the fuel oil heating value.

Also, fouling of the heat exchanger surfaces will reduce temperature rise. In general, a lower temperature rise

through the heating section will result in higher heating efficiency.

Temperature rise = supply air temperature - return air temperature.

After 15 to 20 minutes of continuous operation, the temperature rise through the furnace must fall within a range

of 50° to 80° F. If the outlet or supply duct temperature is too high, check to make sure the return air filter is

clean, the return air registers are free from obstruction, the outlet registers are properly adjusted and clear, and

the supply and return air ducts are open. The circulating air blower is not moving enough air if the supply air

temperature is still too high. Before proceeding further, turn off the power supply to the appliance and remove the

vestibule cover. The speed of the blower must be increased by changing the switch setting on the control board,

please refer to Figure 18.

7

Loading...

Loading...