Thermo Products OH6FA072DV4R, OH6FA072DV4B, OH6FA072D48R, OH6FA072D48B User Manual

OIL FIRED FURNACE

INSTALLATION AND OPERATION MANUAL

WITH USERS INFORMATION SECTION

MODEL:

OH6FA072D48B

OH6FA072DV4B

OH6FA072D48R

OH6FA072DV4R

c WARNING

OR EXPLOSION MAY RESULT CAUSING PROPERTY DAMAGE, PERSONAL INJURY, OR LOSS OF LIFE.

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER APPLIANCE.

: IF THE INFORMATION IN THESE INSTRUCTIONS IS NOT FOLLOWED EXACTLY, A FIRE

c WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE, OR MAINTENANCE

CAN CAUSE INJURY OR PROPERTY DAMAGE. REFER TO THIS MANUAL. FOR ASSISTANCE OR

ADDITIONAL INFORMATION CONSULT A QUALIFIED INSTALLER, OR SERVICE AGENCY.

PLEASE READ THESE INSTRUCTIONS PRIOR TO INSTALLATION, INITIAL FIRING, AND BEFORE

PERFORMING ANY SERVICE OR MAINTENANCE. THESE INSTRUCTIONS MUST BE LEFT WITH THE

USER AND SHOULD BE RETAINED FOR FUTURE REFERENCE BY QUALIFIED SERVICE PERSONNEL.

THERMO PRODUCTS, LLC.

PO BOX 217

NORTH JUDSON, IN 46366

PHONE: (574) 896-2133

MO-437

ECN 4229-PH

MADE IN USA

I. SAFETY SECTION

This page contains various warnings and cautions found throughout the Oil Furnace

Manual. Please read and comply with the statements below.

cWARNING AND CAUTIONS:

cWARNING:

This furnace is not to be used as a construction heater. See Page 1.

c CAUTION MUST BE TAKEN NOT TO EXCEED 90° ROTATION (OF THE FLUE

ELBOW) COUNTERCLOCKWISE OR RIGHT FROM THE VERTICAL POSITION.

See Page 2.

cWARNING:

The predetermined limit locations on all of the Thermo Pride oil fired furnaces

have been tested and approved by Thermo Products, LLC. Any attempt to relocate these safety

controls or replace these safety controls with a control that is not approved, or is incompatible,

may result in personal injury, substantial property damage or death. See Page 4.

cWARNING:

THE HEAT EXCHANGER MUST BE CLEANED BY A QUALIFIED

SERVICE PERSON. See Page 7.

cCAUTION: DO NOT ATTEMPT TO MAKE REPAIRS YOURSELF! See Page 8.

cWARNING: The area around the furnace should be kept free and clear of combustible

liquids and material, especially papers and rags. See Page 8.

cWARNING: NEVER burn garbage or refuse in your furnace. Never try to ignite oil by

tossing burning papers or other material into your furnace. See Page 8.

cWARNING:

fuel oil. NEVER USE GASOLINE OR A MIXTURE OF OIL AND GASOLINE.

Thermo Products oil furnaces are designed to burn No. 1 or No. 2 distillate

See Page

8.

cCAUTION: DO NOT ATTEMPT TO START THE BURNER WHEN:

1. Excess oil has accumulated,

2. The furnace is full of vapors

3. The combustion chamber is very hot.

IF ONE OR MORE OF THESE CONDITIONS EXIST, CONTACT A QUALIFIED

SERVICE PERSON. See Page 8.

i

All installations and services must be performed by qualified service personnel.

TABLE OF CONTENTS

SECTION BEGINNING PAGE

I. SAFETY SECTION i

II. GENERAL INSTRUCTIONS 1

A. VENTING 2

B. DRAFT REGULATORS 3

C. DUCT WORK/AIR CONDITIONING 3

D. FILTERS MOUNTED EXTERNAL TO FURNACE 3

E. LIMIT POSITION AND LOCATION 4

F. BURNER INSTALLATION 5

G. BURNER SPECIFICATIONS AND APPLICATIONS 6

H. HEAT EXCHANGER CLEANING INSTRUCTIONS 7

III. USERS INFORMATION SECTION 8

A. OIL SUPPLY 8

B. COMBUSTION AIR SUPPLY 8

C. INSPECTION AREAS 8

D. STARTING THE BURNER 8

E. FILTER CLEANING AND LOCATIONS 9

APPENDIX – A REPLACEMENT PARTS LIST 11

APPENDIX – B WIRING DIAGRAMS 12

ii

All installations and services must be performed by qualified service personnel.

II. GENERAL INSTRUCTIONS - READ BEFORE START OF INSTALLATION

1. The heating output capacity of the furnace proposed for installation should be based on a heat loss calculation

made according to the manuals provided by the Air Conditioning Contractors of America (ACCA) or the American

Society of Heating, Refrigeration and Air Conditioning Engineers, Inc. (ASHRAE).

2. All local codes and/or regulations take precedence over the instructions in this manual and should be followed

accordingly. In the absence of local codes, installation must conform with these instructions and regulations of the

National Fire Protection Association, and to the provisions of the National Electrical Code

(ANSI/NFPA 70-1999 or

latest edition).

3. The installed furnace must be level and positioned in a central location with respect to outlet registers. It should

be located near the chimney to minimize any horizontal run of flue pipe, which may be required.

4. A furnace installed in a residential garage must be installed so the burner and ignition source are located higher

than 18 inches above the floor, unless the required combustion air is taken from the exterior of the garage. Also, the

furnace must be located or protected to avoid physical damage by vehicles.

cWARNING: This furnace is not to be used as a construction heater.

5. Listed below are definitions of "COMBUSTIBLE MATERIAL" and "NON-COMBUSTIBLE MATERIAL."

COMBUSTIBLE MATERIAL:

Material made of or surfaced with wood, compressed paper, plant fibers, plastics, or other material that will ignite

and burn, whether flame resistant or not.

NON-COMBUSTIBLE MATERIAL:

Material that is not capable of being ignited and burned. Such materials consist entirely of, or a combination of,

steel, iron, brick, tile, concrete, slate, or glass.

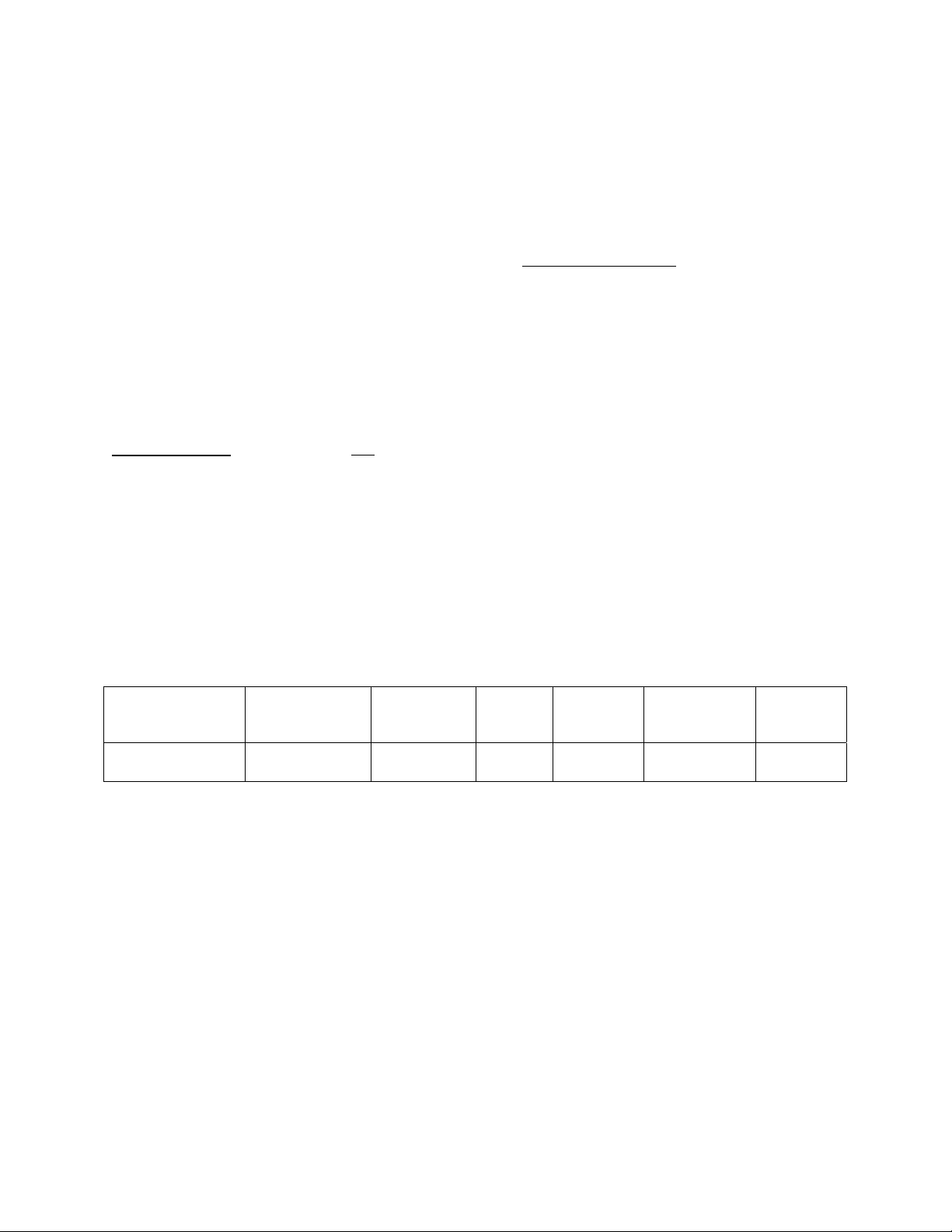

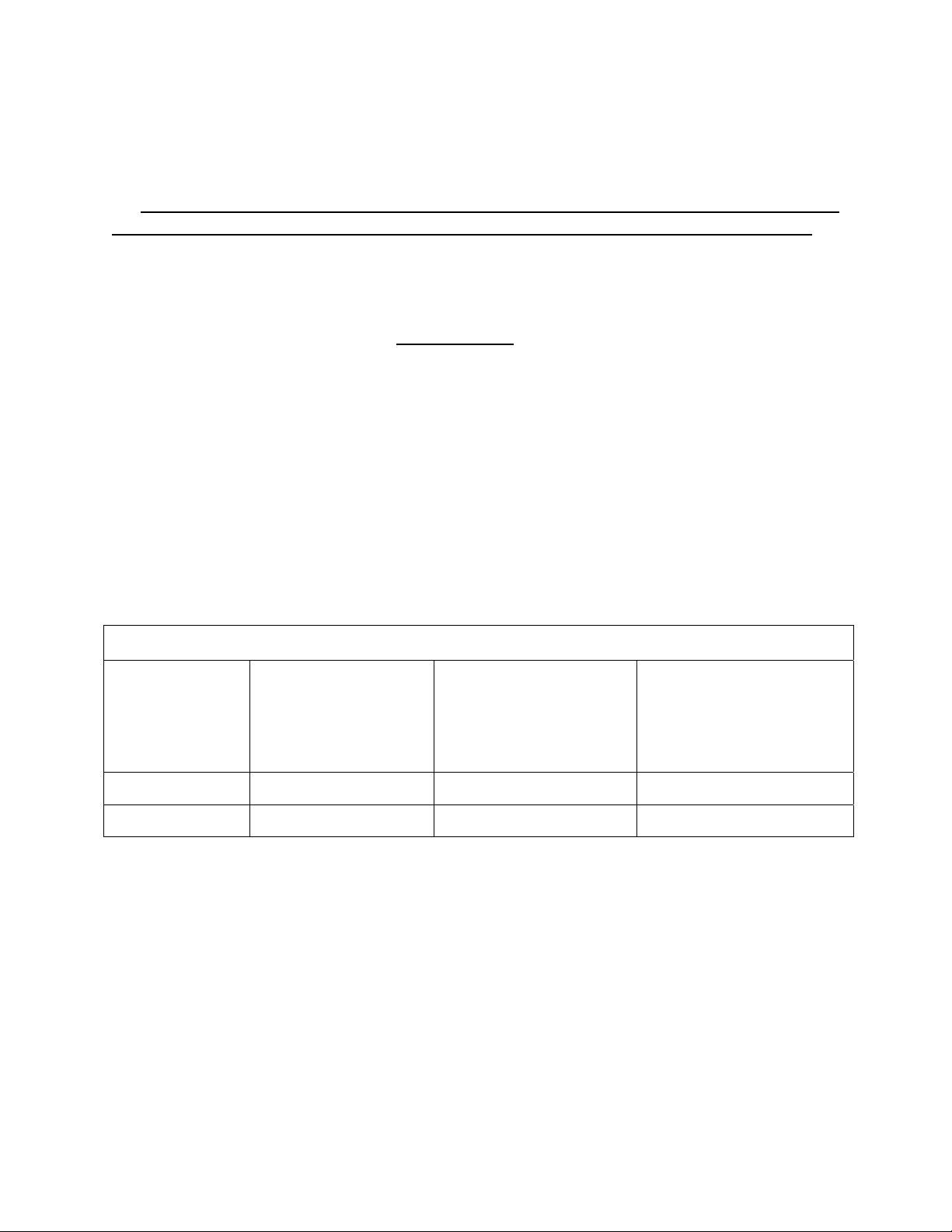

TYPE OF UNIT MODEL NO.1

HIGHBOY

MINIMUM CLEARANCES TO COMBUSTIBLE MATERIALS

FROM

SIDES OF

FRONT

FURNACE

OH6FA072D*** 0” Note

TOP &

SIDES OF

PLENUM

1

1” 7” 0”

FROM THE

FLUE/VENT

REAR

Notes:

1

OH6FA072D*** front clearance 6” for Closet, 24” for Alcove.

The minimum clearances listed in the preceding table are for fire protection. Clearance for servicing the front of the

furnace and the rear of the lowboy models should be at least 24 inches. A clearance of 24 inches is recommended

for passage to all points on the furnace requiring service access.

The OH6FA072D*** furnaces may be installed on combustible flooring.

NOTE: The OH6FA072D*** furnace is approved for closet installation. If the OH6FA072D*** is installed in a

closet, it requires two openings in the closet door for combustion air, each having a minimum area of 162 sq. inches.

This free area for the OH6FA072D*** intentionally exceeds the recommended minimum free area of 2 square

inches per 1000 BTUH of input rate.

NOTE: When power venting a Thermo Pride oil fired furnace with a power venting system other than the system

supplied by Thermo Pride, a fiber chamber and an isolated combustion air kit (PVB or Beckett boot) is to be used

with the other manufacturers power venting system.

1

All installations and services must be performed by qualified service personnel.

A. VENTING:

NOTE: On the OH6FA072D*** it is possible to rotate the flue elbow (which is factory installed for vertical

discharge) 90° counterclockwise from the vertical position to adapt to various venting systems.

c CAUTION MUST BE TAKEN NOT TO EXCEED 90° ROTATION (OF THE FLUE

ELBOW) COUNTERCLOCKWISE OR RIGHT FROM THE VERTICAL POSITION.

ROTATION OF FRONT FLUE ELBOW

When an installation requires that the flue exit out the left hand side casing on a front flue unit, remove screw

securing the 90 deg. elbow and rotate it 90° counterclockwise.

vent through the opening.

A trim collar may be ordered from Thermo Products to hide the gap around the flue pipe. This trim collar, however,

is not required for operation. Trim collar/gasket part numbers(s) 14121 / 330073.

NOTE: ROTATION OF FLUE PIPE IS ONLY ALLOWED FOR LEFT HAND SIDE VENTING

APPLICATIONS.

The OH6FA072D*** may be vented through a standard correctly sized chimney.

The OH6FA072D*** may also be horizontally vented through a side wall. Thermo Products has available the Field

model FDVS-45/FVOP-415 side wall vent kit for such applications. When installing the FDVS-45/FVOP-415 side

wall vent kit, outside combustion air must also be applied to the burner. The following table identifies application

order information.

Then, remove knock-out in side casing and extend

SIDE WALL VENTING APPLICATION ORDER INFORMATION

FIELD VENT

TERMINATION KIT

(15’ application MAX)

THERMO PRODUCTS

BURNER

Beckett AFG AOPS8393 AOPS8394 AOPS8396

Riello BF3 AOPS8393 AOPS8395 AOPS8396

The Field vent kit is set up with 4 inch diameter vent pipe with concentric through-the-wall vent termination/inlet

air vent hood. The combustion air inlet pipe diameter is also 4 inch diameter. For Riello, the combustion air inlet

pipe will be reduced to 3 inch diameter with the Riello side wall vent kit. For Beckett, the combustion air inlet pipe

will be reduced to 2” diameter with the Beckett side wall vent kit.

The side wall vent may be installed either through the upper knock-out on the left side casing of the unit or

vertically out the top opening of the vestibule.

The combustion air inlet can be installed through the either the lower left side casing knock-out or the lower right

side casing knock-out.

PART NUMBER

SIDE WALL VENT

ACCESSORIES KIT

(BURNER SPECIFIC)

THERMO PRODUCTS

PART NUMBER

COMBUSTION AIR

INTAKE HOOD KIT

(FOR COMBUSTION AIR

APPLICATIONS ONLY)

THERMO PRODUCTS

PART NUMBER

2

All installations and services must be performed by qualified service personnel.

B. DRAFT REGULATORS:

A draft regulator is supplied with the furnace and should be installed according to the regulator manufacturers

recommendations. With the burner operating, use a draft gauge to adjust the regulator to the proper setting. (refer to

the instructions enclosed with draft regulator to adjust to the proper setting). When the burner air supply and draft

are properly adjusted, the overfire draft should be a negative (-).01" to (-).02" WC

overfire air tap (See Fig. 8). This tap is provided in the upper burner mounting plate. To measure the flue draft,

punch a small hole in the vent connector pipe as close to the furnace as possible and always before the draft

regulator.

Note: 1. Draft overfire may be positive for high fire applications but not to exceed (+).02" WC.

C. DUCT WORK/AIR CONDITIONING:

If the furnace is used in connection with summer air conditioning (cooling), the furnace should be installed parallel

with or on the upstream side of the evaporator coil to avoid condensation in the furnace heat exchanger. If the

cooling unit is installed with a parallel flow arrangement, dampers or other means used to control flow of air should

be provided to prevent chilled air from entering the furnace. If such a damper is manually operated, it must be

equipped with a means to prevent operation of either unit, unless the damper is in the full heat or cool position.

The duct system should again follow the current design standard of Air Conditioning Contractors of America

(ACCA) or ASHRAE Fundamentals

volume.The most common location for the A-shaped coil (A style) is shown in

Fig. 2.

1

, as measured at the 5/16"

Fig 2: Acceptable locations for the air conditioner evaporator coil.

NOTICE: The minimum coil pan clearance for a sectional or drum type heat exchanger is three inches unless

specified otherwise by the individual coil manufacturer.

D. FILTERS MOUNTED EXTERNAL TO FURNACE

On highboy

furnaces, it is necessary to cut the return air opening in the side or rear casing, depending upon the

needs of the specific installation.

The filter rack provided with the furnace, refer to Fig. 5, will serve as a template to scribe a mark for the return air

opening on the casing. Place the filter rack on a side casing approximately one inch up from the bottom of the

furnace and centered from side to side. Place the securing flange against the casing when locating the return air

opening. For your convenience, (4) locator knock-outs have been placed at the proper locations on both the left and

right side casings.

PLEASE NOTE:

While scribing the return air opening, the filter rack can be held in position by tape or similar

temporary means.

3

Loading...

Loading...