Page 1

MC

COMBOMAX

Electric boiler with integrated instantaneous water heater

Models from 8 kW to 24 kW :

240 Volts ( single phase )

Use and Care Manual

With installation instructions for the contractor

Your COMBOMAX® electric boiler has been carefully assembled and factory tested to

provide years of trouble-free service. This manual contains instructions for the safe and

proper installation, operation and maintenance of the boiler, in order to ensure your full

satisfaction

It is imperative that all persons who are expected to install, operate or adjust this boiler read

the instructions carefully.

Any questions regarding the operation, maintenance, service or warranty of this water

heater should be directed to the dealer or distributor you purchased it from. When all

installation steps have been completed, replace this installation manual in its original

envelope, and keep in a safe place near the heater for future reference.

THERMO 2000 INC. revised : January 2006

Printed in Canada

Page 2

Section 1 : Technical specifications

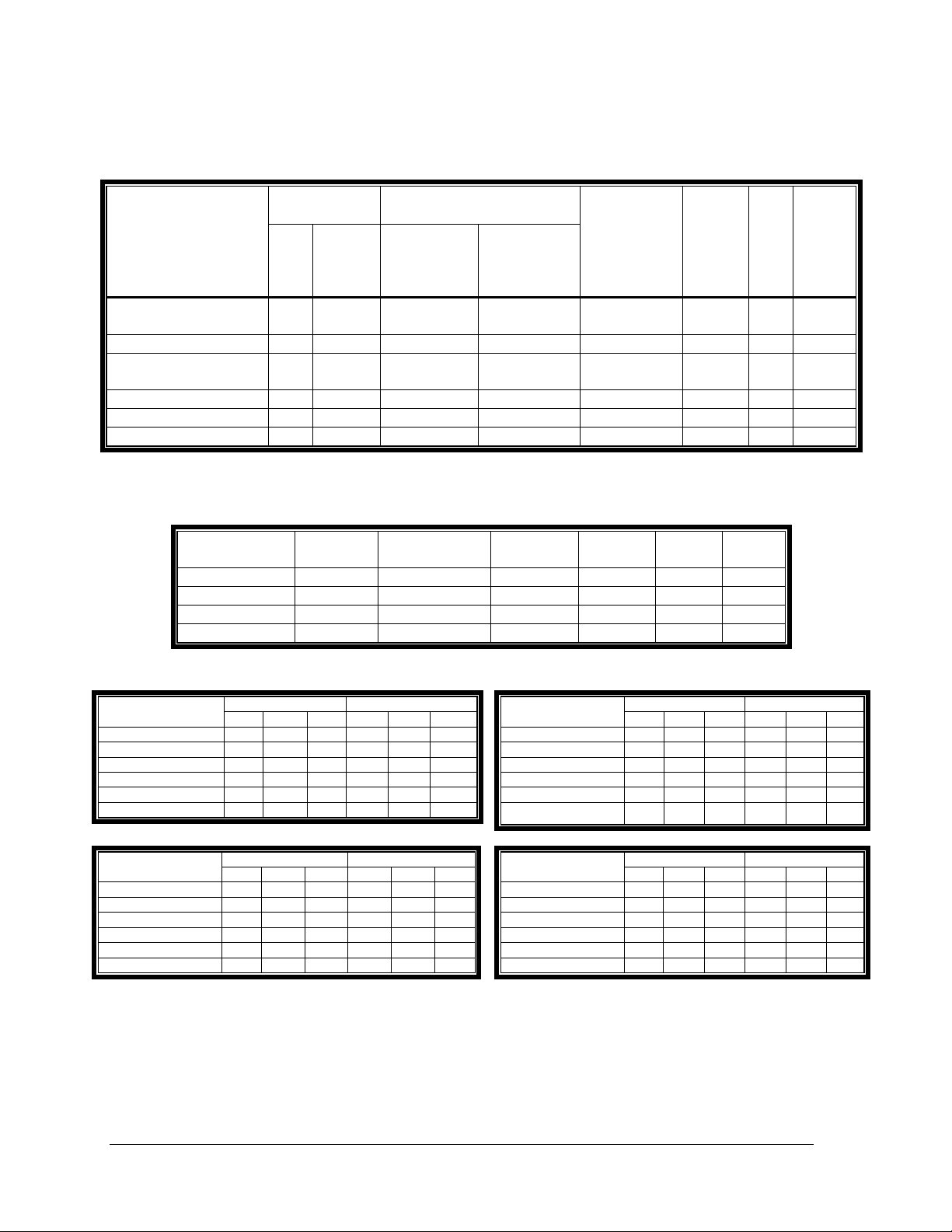

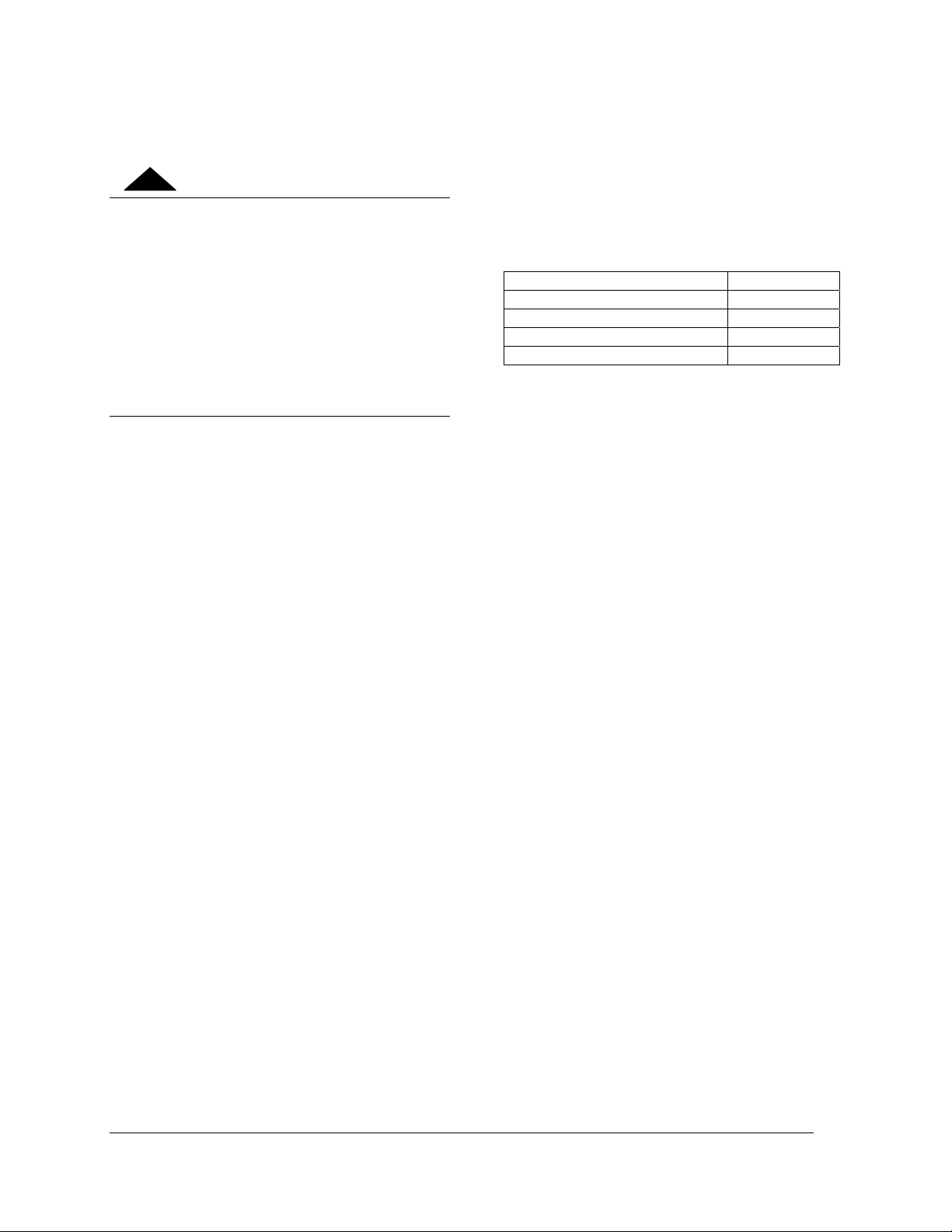

Table 1: Boiler specifications 240 Vac (single phase) :

Power Nominal load in amps

Model

Kw BTU/h

Heating

elements

COMBOMAX XX-8 8 27 296 33.3 34.3

Including

the

circulator

elements

Number of

1 X 3KW

1 X 5KW

Stages \

COMBOMAX XX-10 10 34 120 41.6 42.6 2 X 5KW 2 6 60

COMBOMAX XX-15 15 51 180 62.5 63.5

2 X 3KW

2 X 4.5KW

COMBOMAX XX-18 18 61 416 75.0 76.0 4 X 4.5KW 4 3 100

COMBOMAX XX-20 20 68 240 83.4 84.4 4 X 5KW 4 2 125

COMBOMAX XX-24 24 81 888 100.0 101.0 4 X 6KW 4 1 125

Wire

Cu

pilots

Thermostats \

2 8 50

4 3 100

Fuse

Amps

Table 2 : Boiler and connection dimensions

Model Capacity Utility

connection

Boiler

connection

Height Diam. Ship.

weight

Combomax 23 30 Gal US 3/4 ’’ Sweat F 1’’ NPT F 49’’ 18’’ 265 lbs

Combomax 34 40 Gal US 3/4 ’’ Sweat F 1’’ NPT F 65’’ 18’’ 315 lbs

Combomax 44 52 Gal US 3/4 ’’ Sweat F 1’’ NPT F 55’’ 22’’ 345 lbs

Combomax 64 76 Gal US 3/4 ’’ Sweat F 1’’ NPT F 67’’ 24’’ 425 lbs

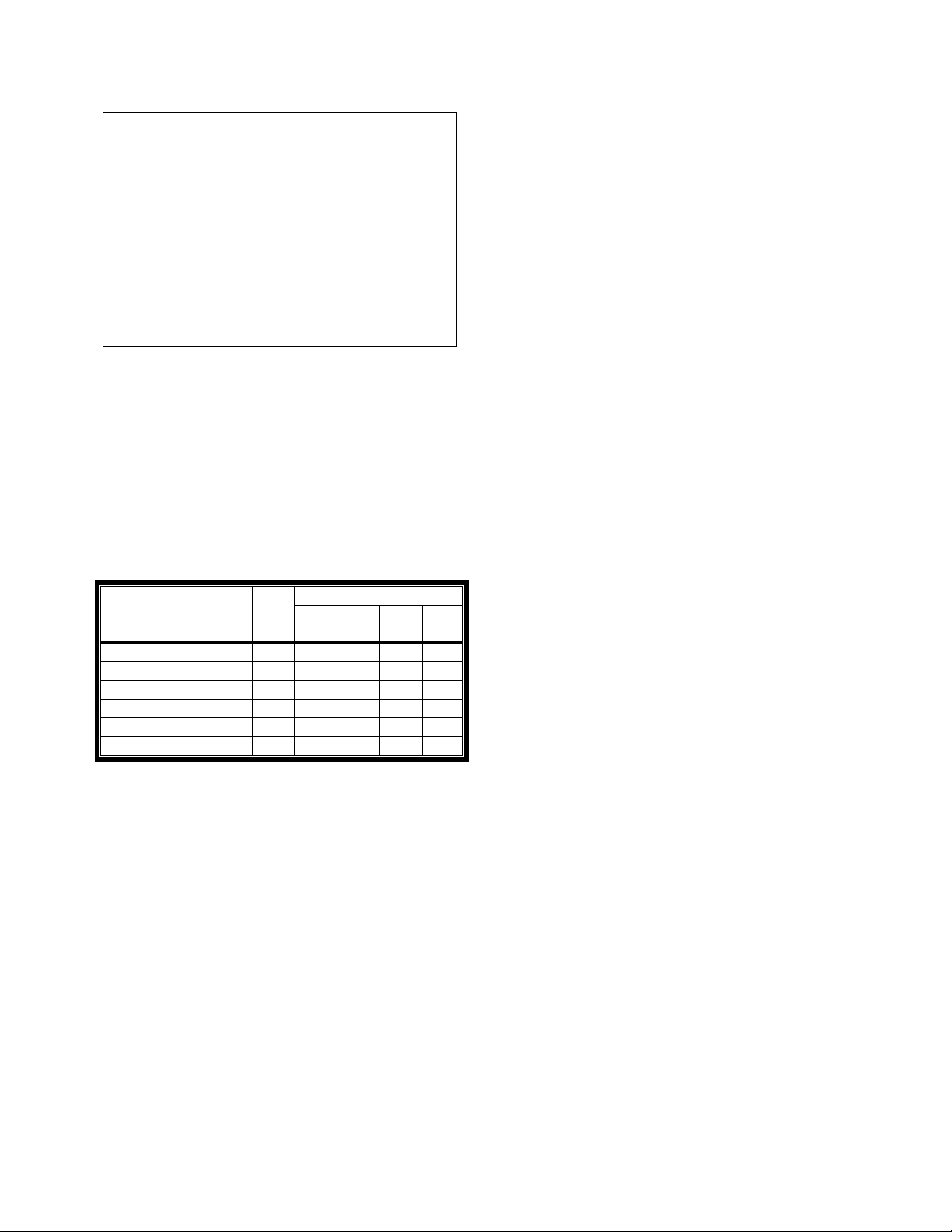

Table 3 : Domestic hot water production capacity in US gallons

1st hour Continuous Model

COMBOMAX 23-8 75 44 28 47 33 24

COMBOMAX 23-10 87 52 33 59 41 29

COMBOMAX 23-15 116 73 48 88 62 44

COMBOMAX 23-18 134 85 57 106 74 53

COMBOMAX 23-20 145 93 63 117 82 59

COMBOMAX 23-24 169 110 75 141 99 71

Model

COMBOMAX 44-8 97 53 31 47 33 24

COMBOMAX 44-10 109 61 36 59 41 29

COMBOMAX 44-15 138 82 51 88 62 44

COMBOMAX 44-18 156 94 60 106 74 53

COMBOMAX 44-20 167 102 66 117 82 59

COMBOMAX 44-24 191 119 78 141 99 71

110F 140F 180F 110F 140F 180F

1st hour Continuous

110F 140F 180F 110F 140F 180F

With domestic cold water at 40°F and heating water at 180°F

Operating temperature : from 50°F to 190°F; Maximum operating pressure: 30 psi

Model

COMBOMAX 34-8 85 48 29 47 33 24

COMBOMAX 34-10 97 56 34 59 41 29

COMBOMAX 34-15 126 77 49 88 62 44

COMBOMAX 34-18 144 89 58 106 74 53

COMBOMAX 34-20 155 97 64 117 82 59

COMBOMAX 34-24 179 114

Model

COMBOMAX 64-8 121 63 34 47 33 24

COMBOMAX 64-10 133 71 39 59 41 29

COMBOMAX 64-15 162 92 54 88 62 44

COMBOMAX 64-18 180 104 63 106 74 53

COMBOMAX 64-20 191 112 69 117 82 59

COMBOMAX 64-24 215 129 81 141 99 71

1st hour Continuous

110F 140F 180F 110F 140F 180F

76

1st hour Continuous

110F 140F 180F 110F 140F 180F

141 99 71

COMBOMAXMC Electric boiler Set-up, use and care guide (revised January 2006), Page 2.

Page 3

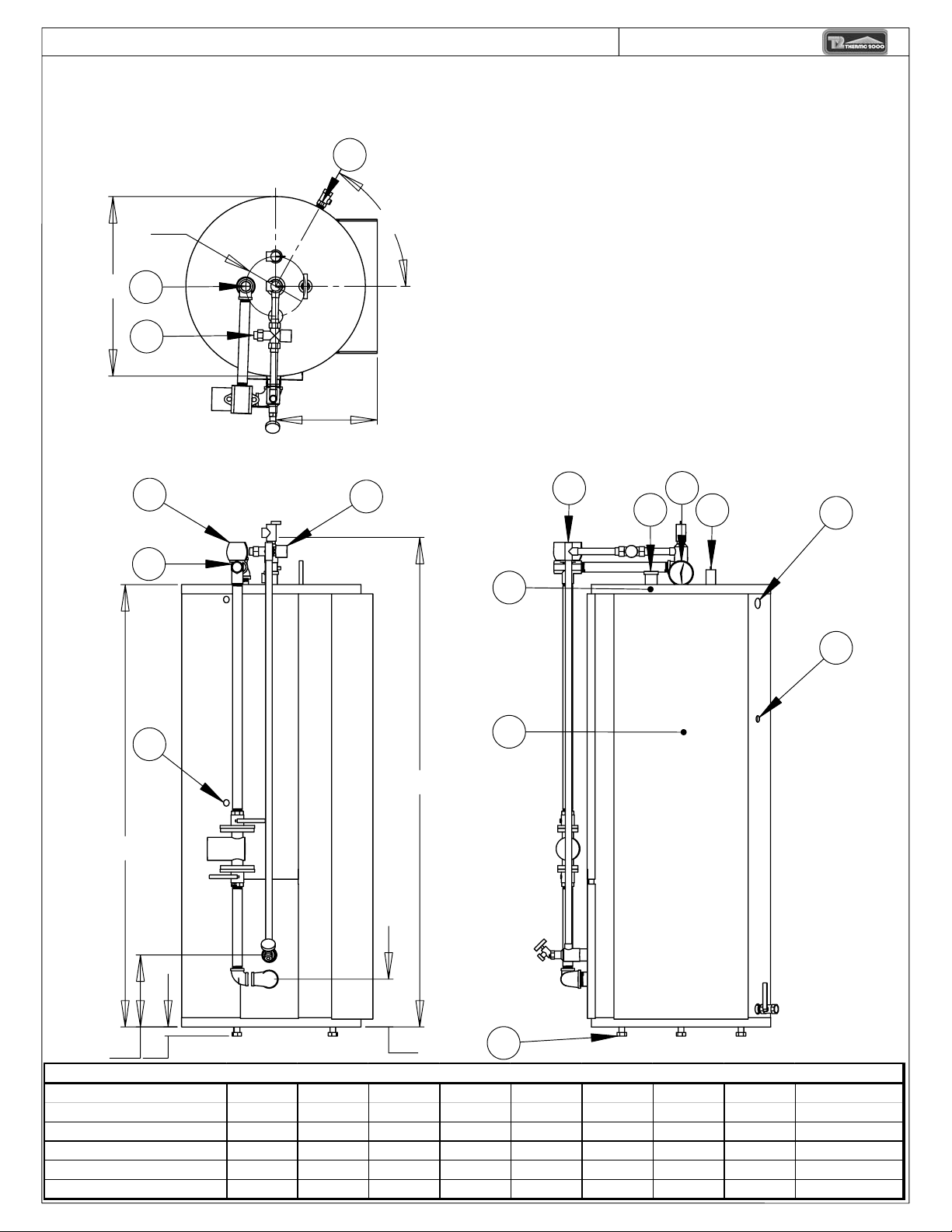

DESSIN D'ATELIER / GENERAL DIMENSIONS COMBOMAX XX-XX

Figure 2

Page 3

Legeng/Légende:

1) Boiler Water Supply Connection /

Alimentation du chauffage (1" npt F)

2) Boiler Water Return/

Retour du chauffage (1" npt F)

3) Domestic Water inlet /

Entrée eau domestique (3/4" Sweat F)

7

H

1

F

I

4

G

14

15

4) Domestic Water outlet/

Sortie eau domestique (3/4" Sweat F)

5) Safety relief valve/

Soupape de sûreté (3/4" npt M.)

6) Temperature and pressure Gage/

Indicateur de Température et pression (1/2'' npt. M)

7) Drain Valve/

Valve de drainage (3/4'' npt F)

8) Power supply wiring/

Alimentation électrique

9) Pilot Ligh ts/

Lampe témoin

10) Electrical Compartments/

Compartiment électrique

11) Circulator wiring/

Alimentation pompe

12) Thermostat wiring/

Connection thermostat

13) Air vent/

Purgeur d'air

14) Valve 3 voies/

3 ways valve

15) Valve thermostatique/

Thermostatic mixing valve

16) Adjustable leg/

Patte de support

3

THERMO 2000 inc.

6

13

5

8

2

9

12

10

11

A

B

C

E

DIM ENSI ON/ DIM ENS IO NAL

Modèle/ A B C D E F G H I

Model in. in. in. in. in. in. in. in. degrés/degree

COM B OM A X 23-XX 49 3/16 42 1/4 7 1/4 4 1 18 10 1/2 8 75

COM B OM A X 34-XX 65 1/ 2 59 7 1/ 4 4 1 18 10 1/ 2 8 75

COM B OMAX 44-XX 57 3/ 4 49 1/2 9 1/2 5 3/4 1 22 12 1/2 8 60

COM B OMAX 64-XX 65 1/ 2 58 1/2 9 1/2 6 1/2 1 24 13 1/2 8 60

D

16

Page 4

!

General Safety Precautions

Be sure to read and understand the entire Use & Care Manual before attempting to

install or operate this water heater. Pay particular attention to the following General

Safety Precautions. Failure to follow these warnings could cause property damage,

bodily injury or death. Should you have any problems understanding the instructions in

this manual, STOP, and get help from a qualified installer or technician.

Section 2 : Introduction

!

The important safeguards and instructions

appearing in this manual are not meant to

cover all possible conditions and situations

that may occur. It should be understood that

common sense, caution and care are factors

which cannot be built into every product.

These factors must be supplied by the

person(s) caring for and operating the unit.

2.1 LOCAL INSTALLATION

REGULATIONS

This water heater must be installed in

accordance with these instructions and must

conform to local, or in the absence of local

codes, with the current edition of the National

Plumbing Code and the National Electric Code.

In any case where instructions in this manual

differ from local or national codes, the local or

national codes take precedence.

2.2 CORROSIVE ATMOSPHERE

The heater should not be located near an air

supply containing halogenated hydrocarbons or

high humidity. The limited warranty is voided

when failure of the water heater is due to a

corrosive atmosphere.

2.3 SHIPMENT INSPECTION

Inspect the water heater for possible shipping

damage. The manufacturer’s responsibility

ceases upon delivery of goods to the carrier in

good condition. Consignee must file any claims

for damage, shortage in shipments, or nondelivery immediately against carrier.

WARNING

2.4 CHECKLIST

Please check the technical information plate to

ensure you have the right model.

The following items are shipped with the

unit :

• 30 PSI pressure relief valve.

• Drain cock.

• Thermo manometer (heat and

pressure indicator).

• Thermostatic mixing valve

!

The boiler should not be located in an area

where leakage from the tank or water

connections will result in damage to the

adjacent area or to lower floors of the

structure. When such areas cannot be

avoided, a suitable drain pan or nonflammable catch pan, adequately drained,

must be installed under the boiler. The pan

must be connected to a drain.

NOTE: Auxiliary catch pan MUST conform to

local codes.

WARNING

COMBOMAXMC Electric boiler Set-up, use and care guide (revised January 2006), Page 4.

Page 5

Section 3 : INSTALLATION

WARNING

!

The manufacturer’s warranty does not cover

any damage or defect caused by installation

or attachment or use of any special

attachment other than those authorized by

the manufacturer into, onto, or in

conjunction with the water heater. The use of

such unauthorized devices may shorten the

life of the water heater and may endanger life

and property. The manufacturer disclaims

any responsibility for such loss or injury

resulting from the use of such unauthorized

devices.

3.1 SAFETY MEASURES

All domestic and commercial installations will

include a pressure relief valve limiting the

operating pressure to 30 psi.

This COMBOMAX

for a maximum operating temperature of 190°F.

It is designed as a hot water heating system

only. A 30 to 50% water and ethylene- or

propylene-glycol blend is allowed.

3.2 LOCATION

The COMBOMAXMC water heater should be

installed in a clean, dry location. Long hot water

lines should be insulated to conserve water and

energy. The water heater and water lines should

be protected from exposure to freezing.

COMBOMAX

vertically. Use the adjustable feet to level the

unit.

The COMBOMAX

located or protected so as not to be subject to

physical damage, for example, by moving

vehicles, area flooding, etc..

All models can be installed on combustible floors

and in alcoves. If the water heater is to be

installed in a restaurant or other location where

the floor is frequently cleaned, it must be

elevated to provide at least 6 inches of

clearance from the floor to comply with NSF

International recommendations.

The room temperature must not exceed 80°F or

27°C.

MC

electric boiler is designed

MC

water heaters must be installed

MC

water heater must be

3.3 CLEARANCE

The minimum clearances required for proper

inspection and servicing are as follows:

Table 4: Clearances

Left side 3 inches

Right side 3 inches

Top 24 inches

Front 24 inches

Back 3 inches

3.4 SYSTEM SETUP

Figures 2, 3 and 4 are general connection

diagrams including the circulator, the expansion

tank, the drain cock, the safety valve, the air

bleeder, the flow check valve and the thermo

manometer. Set-up details follow.

3.5 HEATING WATER CIRCUIT

3.5.1 Connecting the heating water

piping

The boiler may be set up alone or in parallel with

others. Parallel connections should be made

using the reverse-piping method to ensure equal

flow through each boiler.

The boiler water supply connector is located on

top of the boiler and the boiler water return

connector is located to the left of the three-way

valve. They are both threaded NPT female

connectors.

Unions are recommended on the hot and cold

water lines to disconnect the water heater easily

for servicing if necessary.

Dielectric (insulating) unions are required for

protection of the water heater if copper-steel

connections are made.

Use only clean copper or approved plastic pipe

for water connections. Local codes or

regulations shall govern the exact type of

material to be used.

Insulate all pipes containing hot water,

especially in unheated areas.

COMBOMAXMC Electric boiler Set-up, use and care guide (revised January 2006), Page 5.

Page 6

Install shutoff (ball) valves for servicing

convenience. Install thermometers on the inlet

and outlet lines.

Never plug the pressure relief valve to avoid

creating a hazardous situation.

3.5.2 Flow-check valve

If the heating system uses a single circulator, a

flow-check valve must be installed to

minimize gravity flow and heat loss during nondraw periods.

3.5.3 Pressure relief valve

No boiler set-up is complete without a pressure

relief valve. Its pressure rating must not exceed

30 psi (207 kPa). It must conform to the « ASME

Boiler and Pressure Vessel Code» and limit the

boiler operating pressure. It is a safety device,

not a control device.

The BTU per hour rating of the relief valve must

equal or exceed the BTU per hour input of the

boiler(s) or heat source(s) as marked on the

boiler(s) rating plate.

Connect the outlet of the relief valve to a

suitable open drain, with the discharge at most

6” above the floor, far from any live electrical

parts. The discharge line must pitch downward

from the valve to allow complete draining and be

no smaller than the outlet of the valve. The end

of the discharge line should not be threaded or

concealed and should be protected from

freezing. No valve of any type, restriction or

reducer coupling should be installed in the

discharge line. Local codes shall govern the

installation of relief valves.

3.5.4 Operating pressure control :

expansion tank

Operating pressure control components ensure

minimum and maximum operating limits are

observed within the design operating

temperature range. These components allow

bleeding air from the piping, prevent boiling and

cavitation at the circulator inlet, while minimizing

the amount of fresh water input. Please contact

a qualified plumber or contractor for more

information on this subject.

The expansion tank connection point must be

carefully chosen to prevent a situation where

closing a valve would isolate the tank from the

boiler or any part of the circuit. It is preferable to

use a calibrated diaphragm expansion tank.

3.5.5 Makeup valve

Connecting a makeup valve must be done

according to code. This valve must include a

flow-check valve to maintain the minimum

operating pressure by admitting fresh water from

the cold water supply line in case a leak occurs.

3.5.6 Air bleeder

There should be as little oxygen as possible in

the heating circuit to prevent corrosion. As

foreseen in section 3.5.4, this excludes the use

of air as a pressure regulator within the circuit.

Installing manual or automatic air bleeders

prevents air accumulation within the system.

The bleeders must be set at the highest points

of the system to purge any air accumulated

during system set-up and to check its air

tightness. Bleed the air regularly from the piping,

making sure the heating water causes no bodily

harm or material damage.

3.5.7 Circulator zoning

A flow-check valve must be installed in each

zone, preferably at the outlet of each circulator,

to prevent water flowing to zones where no heat

is currently required. (see figure 4).

3.5.8 Zone valve zoning

Zone valves with low pressure drop are

recommended. (see figure 3)

3.5.9 Circulator selection criteria

The COMBOMAXMC boiler includes a premounted circulator. The information below will

help you select additional units for multiple

circulator set-ups.

3.5.9.1 Pump flow rate calculation

The boiler output rating must correspond to the

calculated heating load. Use the equation below

to calculate the pump flow rate:

COMBOMAXMC Electric boiler Set-up, use and care guide (revised January 2006), Page 6.

Page 7

Pump flow rate = Boiler output ÷ BWTD ÷ 500

• Pump flow rate is expressed in U.S. gallons

per minute or GPM.

• The Boiler output ( in net BTU per hour) is

the maximum amount of heat to be

transferred through the heating circuit to

meet the hot water demand.

• BWTD is the boiler water temperature drop

through the heating circuit.

For example, a 24 Kw COMBOMAX

a rated output of 81,964 BTU/hour. The system

is designed for a boiler water temperature drop

(BWTD) of 20°F.

Pump flow rate = 81,964 ÷ 20 ÷ 500 = 8,2 GPM.

The following table shows the required flow rate

as a function of boiler water temperature drop

(BWTD) and rated power output.

Table 5 : BWTD vs. flow (GPM)

Model Kw

10

F

COMBOMAX XX-8 8 5,5 2,7 1,8 1,4

COMBOMAX XX-10 10 6,8 3,4 2,3 1,7

COMBOMAX XX-15 15 10,2 5,1 3,4 2,6

COMBOMAX XX-18 18 12,3 6,1 4,1 3,1

COMBOMAX XX-20 20 13,7 6,8 4,6 3,4

COMBOMAX XX-24 24 16,4 8,2 5,5 4,1

3.5.9.2 Selecting a circulator

Consult the manufacturer’s operating

characteristic curves to select the proper model.

These curves plot flow versus pressure, together

with other information such as efficiency and

power. Ask your pump dealer or HVAC

wholesaler to recommend the circulator which

best fits your needs.

3.6 DOMESTIC HOT WATER CIRCUIT

3.6.1 Connecting the domestic hot water

piping

The COMBOMAX

be set up alone or in parallel combination with

other COMBOMAX

Parallel connections should be made using the

MC

domestic hot water coil may

MC

units or storage tanks.

o

MC

boiler has

BWTD

o

20

F

30

F

o

40

F

reverse-piping method to ensure equal flow

through each boiler.

The HOT WATER OUTLET and the COLD

WATER INLET connections are clearly marked.

Inlet water connections (COLD WATER INLET)

are to be made to the copper pipe (sweat

connection) at the bottom of the heater. Outlet

water connections (HOT WATER OUTLET) are

to be made to the three-way thermostatically

controlled valve (sweat connection) at the top of

the heater.

The installation of copper unions or copper alloy

unions is recommended on the HOT and COLD

water lines, so that the water heater may be

easily disconnected for servicing if necessary.

These unions must be dielectric (insulating) if

you are making steel-copper connections.

A shutoff (ball) valve is present on the

COMBOMAX

MC

domestic hot water outlet for

servicing convenience.

Use only clean copper or approved plastic pipe

for water connections. Local codes or

regulations shall govern the exact type of

o

material to be used.

Insulate all pipes containing hot water,

especially in unheated areas.

Thermometer(s) should be installed to indicate

the temperature of the water at or near the outlet

of the water heater and storage tank(s), if

provided.

3.6.2 Expansion tank on the cold water

supply line

Determine if a flow check valve, a back flow

preventer, a pressure-reducing valve, a water

meter or a water softener is present on the cold

water supply line.

A flow check valve creates a closed system and

prevents the water, as it is being heated, from

expanding back into the cold water supply line.

Pressure can build up within the water heater,

causing the pressure relief valve to operate

during a heating cycle. This excessive operation

can cause premature failure of the relief valve

and possibly of the water heater itself.

Replacing the relief valve will not correct the

problem. One method of preventing pressure

build-up is to install an expansion tank on the

COMBOMAXMC Electric boiler Set-up, use and care guide (revised January 2006), Page 7.

Page 8

cold water supply line between the

COMBOMAX

Contact your installing contractor, water

supplier, local plumbing inspector or plumbing

supply house for assistance.

MC

unit and flow check valve.

3.6.3 Recirculation line (if applicable)

If a recirculation line is installed, the return

connection should be made to a tee close to the

inlet connection on the water heater. A check

valve should always be installed in the

recirculation line to prevent cold water from

entering.

3.6.4 Domestic hot water temperature

and pressure relief valve

An automatic temperature and pressure relief

valve must

of any type should be placed between the safety

relief valve and the water heater. Use a tee to

set the relief valve onto the hot water outlet. The

pressure rating of the relief valve must not

exceed 150 psi.

The BTU per hour rating of the relief valve must

equal or exceed the BTU per hour input of the

boiler(s) or heat source(s) as recorded on the

boiler(s) rating plate. For a circulating tank

installation, the separate storage tank(s) must

have similar protection.

Connect the outlet of the relief valve to a

suitable open drain, with the discharge at most

6” above the floor, far from any live electrical

parts. The discharge line must pitch downward

from the valve to allow complete draining and be

no smaller than the outlet of the valve. The end

of the discharge line should not be threaded or

concealed and should be protected from

freezing. No valve of any type, restriction or

reducer coupling should be installed in the

discharge line. Local codes shall govern the

installation of relief valves.

be installed at set-up time. No valve

3.6.5 Thermostatically controlled mixing

valve (included)

For general-purpose hot water requirements in a

domestic environment, a thermostatically

controlled mixing valve is recommended to

reduce the risk of scald injury. Contact a

licensed plumber or the local plumbing authority

for further information. Adjust the mixing valve to

the lowest required temperature setting.

3.7 BOILER WIRING

The boiler cabling and grounding must conform

to local codes or, in their absence, to the

National Electrical Code.

Power must be provided by a 120/240 volt

(single phase, 60 Hz) circuit, appropriately fused

and with 3-wire plus ground cabling of sufficient

gage. The fuse and cabling gauge may be

determined from the boiler rating plate.

3.8 CIRCULATOR WIRING

The COMBOMAXMC heating pump (120 Vac,

1/25 Hp) is connected to the C&C terminals on

the boiler electrical panel. The control circuit is

designed to start the pump upon receiving a

heating signal from the thermostat or priority

aquastat.

3.9 CONNECTING THE THERMOSTAT

3.9.1 240V models

3.9.1.1 Single heating zone

Connect the low-voltage thermostat to the T&T

terminals on the COMBOMAX

(DO NOT apply current to these terminals).

(see figure 10).

3.9.1.2 Zone valve zoning

Connect the low-voltage thermostat to the zone

valve. The components must wired such that,

upon a heating signal from a thermostat, only

the corresponding zone valve will be actuated

and will in turn activate the COMBOMAX

circulator relay. Connect the zone valve switch

to the T&T terminals on the COMBOMAX

electrical panel (DO NOT apply current to

these terminals). See figures 9 and 10.

The transformer used to power the zone valves

must be of sufficient capacity to handle the load

represented by all zone valves.

MC

electrical panel

MC

MC

3.9.1.3 Multiple circulator zoning

Connect the low-voltage thermostat to the relay

(Honeywell #RA-889, RA-89A). The components

must wired such that, upon a heating signal from

a thermostat, only the corresponding circulator

will be activated. See figure 9.

3.10 PRIORITIZING TERMINAL POST

The K&K terminals on the electrical panel create

a dry contact when the domestic hot water

priority aquastat contact closes.

COMBOMAXMC Electric boiler Set-up, use and care guide (revised January 2006), Page 8.

Page 9

3.11 BI-ENERGY SETUP

To take advantage of a special domestic electric

utility rate, your COMBOMAX

combined with an existing oil or gas-fired

furnace. Please contact your utility to make sure

your building is eligible and to find out about the

new wiring configuration. Please refer to figures

7 and 8 for the set-up required.

The CBE-EM bi-energy switching control

(available as an option) is especially designed to

satisfy utility requirements. The CBE-EM control

selects the cheapest energy source according to

the outdoor temperature, the indoor temperature

setting and any signal provided by the utility.

The CBE-EM bi-energy control starts up the oil

burner upon receiving the appropriate signal,

even if the thermostat is sending no heating

signal. The oil burner stops when the boiler

reaches its high-limit point. For this reason, the

plumbing system must be equipped with a flow

check valve or zone valves.

The 3-way zone valve (1’’ NPT F) which comes

with the CBE-EM control, directs the heating

water to the oil burner or the COMBOMAX

unit depending on the signal sent to it by the

external bi-energy sensor. Thus, your oil burner

can cool down while eliminating energy losses

up the chimney or by conduction in the furnace

room .

MC

boiler can be

MC

COMBOMAXMC Electric boiler Set-up, use and care guide (revised January 2006), Page 9.

Page 10

Section 4 : Operation

SAFETY PRECAUTIONS !

Before operating this water heater, be sure to

read and follow these instructions, as well as

the warnings printed in this manual. Failure

to do so can result in unsafe operation of the

water heater resulting in property damage,

bodily injury, or death. Should you have any

problems reading, following or difficulty in

understanding the instructions in this

manual, STOP, and get help from a qualified

person.

Do not turn on the water heater unless it is

filled with water. Do not turn on water heater

if cold water supply shut-off valve is closed.

Once the plumbing and electrical connections

are completed, your COMBOMAX

ready for automatic operation.

4.1 FILLING THE TANK

Open the outlet valve (in a zone valve system,

manually open the zone valves).

Open the boiler inlet valve. Bleed the air from

the boiler tank by opening the safety valve atop

the boiler while you are filling the tank.

Leave all valves open. Reset the zone valves to

automatic operation. Check for leaks and repair

if necessary.

Bleed the air from all zones if required. Check

the boiler pressure gauge. A pressure reading

between 15 and 20 psi is normal for most

installations.

4.2 FILLING THE HEATING COIL

Make sure all drain cocks are closed.

Open the nearest domestic hot water tap as well

as any control valve on the water heater outlet

(the copper tube atop the boiler).

Open the cold water inlet valve on the heater

inlet tube. (the copper tube on the left side of the

unit).

Close the domestic hot water tap as soon as

water flows out of it. Fix any leaks

Open all other hot water taps fed by this heating

coil to bleed the air trapped behind them.

MC

unit is

4.3 ADJUSTING THE AQUASTATS

Once all air has been bled from the system and

all components (valves, bleeders, controls) have

been properly adjusted, the boiler can be put

into operation. Never operate the boiler before

these adjustments are complete.

Bear in mind safety and energy-saving

considerations when adjusting the boiler water

temperature with the aquastats. It is most

energy-efficient to set them as low as possible,

in a manner consistent with your heating needs.

However, a minimum temperature of 160°F is

recommended for domestic hot water

production.

Each aquastat controls a boiler stage (in the

240V model, each element has its own

aquastat). Adjust the setting of each aquastat by

turning the dial scaled in degrees Celsius and

Fahrenheit. See figure 10 for aquastat

identification.

Set the first aquastat to the highest outlet

temperature required by the heating system.

Thermo 2000 inc. recommends a setting of

180°F.

Adjust the second aquastat 1°F to 20°F below

the first aquastat setting. Usually, a setting 5°F

below that of the first aquastat, or 175°F,

provides good results in a system designed for a

20°F temperature drop between the tank inlet

and outlet.

Proceed in a similar manner for the 3rd and 4th

aquastats, which will result in settings of 170°F

and 165°F. Thus, the number of elements in

operation will increase (or decrease) according

to the settings and the drop (or rise) in the

heating water temperature.

The domestic hot water priority aquastat should

be adjusted to a setting 5

stage or 4

At system start-up (on the first heating day of the

season), ìt may take quite some time for the

boiler water to reach its operating temperature.

Check the thermo manometer.

th

aquastat, i.e., 160°F.

o

F below that of the last

COMBOMAXMC Electric boiler Set-up, use and care guide (revised January 2006), Page 10.

Page 11

R

Adjust the boiler aquastats as required. Please

note that lowering the setting will not have an

immediate effect as the heat stored in the boiler

water must first be consumed. Check the boiler

water temperature periodically. Further

adjustments may be required as the system

goes through several space and water heating

cycles.

Note: The maximum setting for the boiler outlet

temperature is 190°F.

4.4 STARTUP PROCEDURE

1. Fill tank and coil as described in

sections 4.1 and 4.2.

2. Adjust temperature levels as described

in section 4.3

3. Set domestic thermostat level(s) below

room temperature.

4. Activate boiler breakers.

5. The main boiler contact should close

and all elements should turn on, along

with their pilot lights.

6. The circulator should start up and the 3way valve should switch to the A side.

7. Boiler temperature should rise.

8. Circulator stops and the 3-way valve

switches to the B side when boiler

temperature exceeds the setting of the

domestic hot water priority aquastat.

9. Boiler temperature rises and the

elements and corresponding pilot lights

turn off one after the other as their

temperature setting is reached.

10. When all elements are off, increase the

setting of the domestic thermostat(s) to

a point above room temperature.

11. Circulator should start up following a

delay period.

12. Heating elements should turn back on

as their temperature setting is reached;

this could take a few minutes.

13. Circulator runs as long as a demand

exists for heating. When circulator turns

off …

14. Boiler temperature rises. Heating

elements and corresponding pilot lights

should turn off as their temperature

setting is reached.

Thus, boiler power requirements depend on

heating demand within the building. If only one

heating element is required to satisfy the

demand, only one is activated ; if two are

required, two are activated, etc ... You thus

avoid excessive wear and tear on the

components due to numerous on-off cycles and

reduce your total heating costs.

4.5 DOMESTIC HOT WATER STARTUP

Maximum boiler water temperature is 190°F.

This should be 20°F to 40°F above the desired

temperature for domestic hot water. In practice,

the boiler water temperature should be between

160°F and 180°F.

!

DANGE

An excessively high setting can cause

scalding. Use the thermostatically controlled

mixing valve included with the unit to lower

the domestic hot water temperature and thus

the risk of injury.

When the boiler water temperature falls below

the setting of the domestic hot water priority

aquastat, the 3-way valve switches to side A and

the circulator starts up.

When the boiler water temperature reaches the

setting of the domestic hot water priority

aquastat, the 3-way valve returns to side B

unless other zones are calling for heat. The

heating elements remain on until they reach

their set points. It is normal to observe the boiler

cycling on and off close to the highest set point,

particularly if a single zone is calling for heat.

Considerable time may elapse from a cold start

to the moment when the highest set point is

reached. Check the domestic hot water

temperature as soon as the first heating cycle is

complete.

Lowering the set points has no immediate effect.

The boiler water heat must first be transferred to

the coil. Additional checks will be necessary at

the end of successive heating cycles. Further

adjustments may be required as time goes by.

The domestic hot water priority aquastat is set at

its minimum at shipping time. It can be

increased to 190°F for commercial use.

Remember that domestic hot water hotter than

125°F can cause scalds. Use this minimum

setting as a starting point for any further

adjustments. Normally, the domestic hot

water priority aquastat is set to 5°F below the

lowest heating element aquastat set point.

COMBOMAXMC Electric boiler Set-up, use and care guide (revised January 2006), Page 11.

Page 12

4.6 ADJUSTING THE MIXING VALVE

A thermostatically controlled mixing valve works

automatically thanks to the thermostatic element

controlling the mix of very hot and cold water as

required to provide safe domestic hot water

under variable conditions.

To adjust the mixing valve setting, carefully open

a hot water tap. Protect yourself against the

possibility of scalding. Measure the hot water

temperature and adjust it with the mixing valve,

following the manufacturer’s instructions. Lock

the adjusting valve in place at the proper setting.

A higher boiler water temperature setting is now

possible thanks to this moderating effect. The

boiler water in the COMBOMAX

buffer and increases the boiler efficiency as well

as the amount of domestic hot water produced.

To increase the ad hoc or general hot water

production capacity, first adjust the domestic hot

water priority aquastat setting (e.g., from 140°F

to 180°F), then the mixing valve setting (e.g.,

from 90°F to 120°F).

Some sanitary uses may require different setting

ranges or dedicated piping.

MC

tank acts as a

COMBOMAXMC Electric boiler Set-up, use and care guide (revised January 2006), Page 12.

Page 13

Section 5 : Maintenance

R

Regular boiler maintenance will ensure troublefree service for many years. It is recommended

that you set up and follow a maintenance

program. All components fail eventually. The use

of incorrect replacement parts or disregarding

safety procedures and warnings during repairs

may reduce the boiler safety level and shorten its

useful life.

The owner should set up the following

maintenance program.

5.1 BOILER WATER PIPING :

Annual visual inspection.

Check for leaks close to connections, unions and

valves. Repair as needed.

5.2 BOILER CIRCUIT SAFETY VALVE:

Monthly inspection.

To be checked manually to ensure safety and

proper operation. Air trapped in the boiler is bled.

Make sure the water is discharged to a floor drain

and that no bystander is splashed. Use the lever

to open the safety valve. Hot water should come

flowing out. Upon releasing the lever, the safety

valve should shut tight. If it does not, it must be

replaced by an identical or equivalent model.

Never plug a safety valve.

5.3 DOMESTIC PIPING :

Annual visual inspection.

Check for leaks close to connections, unions and

valves. Repair as needed.

5.4 DOMESTIC CIRCUIT SAFETY VALVE

(TEMPERATURE & PRESSURE):

Annual inspection.

To be checked manually to ensure safety and

proper operation. Air trapped in the boiler is bled.

Make sure the water is discharged to a floor drain

and that no bystander is splashed. Use the lever

to open the safety valve. Hot water should come

flowing out. Upon releasing the lever, the safety

valve should shut tight. If it does not, it must be

replaced by an identical or equivalent model.

Never plug a safety valve.

5.5 SCALE BUILD-UP :

Monthly inspection.

This problem occurs infrequently under very

specific conditions. The main symptom is a drop

in domestic water pressure. A water softener will

solve the problem.

A proper chemical cleaning is a more efficient

solution. A scale dissolving product may be used,

paying careful attention to the manufacturer’s

recommendations. Do not use muriatic or

hydrochloric acid-based products. Carefully flush

the products after use. Contact your plumber to

remove scale build-up from the coil.

!

The manufacturer’s warranty DOES NOT

cover problems caused by improper

installation or maintenance. If the safety valve

opens periodically, it may be due to the

expansion tank. Immediately call a qualified

technician to appraise and repair the problem.

NOTE: To prevent tank breakage, trapped air

must periodically be bled from it by opening

the safety valve.

Before manually opening the safety valve,

make sure no bystander will accidentally be

splashed by the hot water. The discharged

water should be directed to a floor drain to

prevent scalding and damage.

!

DANGE

WARNING

500, 9

THERMO 2OOO INC.

ième

Avenue, C.P. 639, RICHMOND (QUÉBEC) JOB 2HO

TÉL.: (819) 826-5613 FAX: (819) 826-6370

Page 14

R

!

General Safety Precautions

Be sure to read and understand the entire Use & Care Manual before attempting to install

or operate this COMBOMAX

MC

unit. Pay particular attention to the following General Safety

Precautions. Failure to follow these warnings could cause property damage, bodily injury or

death. Should you have any problems understanding the instructions in this manual, STOP,

and get help from a qualified installer or technician.

To meet commercial hot water needs, the

aquastat on this water heater is adjustable up to

190°F. However, water temperatures over 125°F

can cause severe burns instantly or death from

scalds. 125°F is the preferred starting point for

setting the control to supply general-purpose hot

water.

Safety and energy conservation are factors to be

considered when setting the water temperature

on the aquastat. The most energy efficient

operation will result when the temperature

setting is the lowest that satisfies requirements.

Maximum water temperature occurs just after

burner or the energy source has shut off. To find

hot water temperature being delivered, turn on a

hot water faucet and place a thermometer in the

hot water stream.

The following chart details the relationship of

water temperature and time with regard to scald

injury and may be used as a guide in determining

the safest water temperature for your applications.

TIME TO SCALDING VS TEMPERATURE

RELATIONSHIP

Temperature Time to scalding

120°F Over 5 minutes

125°F 1-1/2 to 2 minutes

130°F About 30 seconds

135°F About 10 seconds

140°F Less than 5 seconds

145°F Less than 3 seconds

150°F About 1-1/2 second

155°F About 1 second

With kind permission from the Shriners Burn Institute

The temperature of the water in the heater can be

set by turning the temperature dial on the

aquastat. To comply with safety regulations the

aquastat was set at its lowest setting before water

heater was shipped from the factory.

There is a hot water scald potential if the

aquastat is set too high. When this water

heater is supplying general purpose hot water

requirements for use by individuals, a

thermostatically controlled mixing valve for

reducing point-of-use water temperature is

recommended to reduce the risk of scald

injury. Contact a licensed plumber or local

plumbing authority for further information.

!

DANGE

COMBOMAXMC Electric boiler Set-up, use and care guide (revised January 2006), Page 14.

Page 15

THERMO 2000 inc.

Figure 2

Page 15

COMBOMAX

Schéma d'installation général/

General installation

Réducteur de pression/

Reducing valve

Valve de mélange thermostatique/

Thermostatic mixing valve

Eau chaude domestique/

Domestic h ot water mixed

Simple Zone/

Single Zone

Tuyauterie chauffage/

Boiler piping

Tuyauterie eau domestique/

Domestic piping

Manomètre & thermomètre/

Manometer & thermometer

Valve anti-gravité/

Flow check valve

Valve de sécurité (T&P)

Safety valve (T&P)

Vase d'expansion/

Expansion tank

Valve à bille/

Ball valve

Vent d'air/

Air vent

Anti retour/

Back flow preventer

Pompe/

Pump

Eau froide domestique/

Domestic cold water supply

B

AB

A

Valve de sécurité (T&P)/

Safety valve (T&P)

à ajouter/ to add

Thermostat

L1 L2 N

T T

Plinthes à ailettes/

Finnes-Tube baseboard

Valve 3 voies/

3 way-valve

Tuyauterie eau domestique/

Domestic water piping

Tuyauterie eau de chauffage/

Boiler water piping

Page 16

THERMO 2000 inc.

Figure 3

Page 16

COMBOMAX

Schéma d'installation général/

General installation

Réducteur de pression/

Reducing valve

Valve de zonage électrique/

Electric zone valve

Eau chaude domestique/

Domestic h ot water mixed

Système mul ti z ones (valves)/

Multi-zone system using valves

Tuyauterie chauffage/

Boiler piping

Tuyauterie eau domestique/

Domestic piping

Manomètre & thermomètre/

Manometer & thermometer

Valve anti-gravité/

Flow check valve

Valve de sécurité (T&P)

Safety valve (T&P)

Vase d'expansion/

Expansion tank

Valve à bille/

Ball valve

Vent d'air/

Air vent

Thermostat

Valve de mélange thermostatique/

Thermostatic mixing valve

Anti retour/

Back flow preventer

Pompe/

Pump

Eau froide domestique/

Domestic cold water supply

B

AB

A

Valve de sécurité (T&P)/

Safety valve (T&P)

à ajouter/ to add

L1 L2 N

T T

Plinthes à ailettes/

Finnes-Tube baseboard

24 Vac

120 Vac

Electrical serv i ce

Raccordement de zone valves/ Wiring for zoned valves system

Zone

valves

Transfo

40Va Transfo (3 zones)

20Va Transfo (2 zones)

Diagramme électrique/ Wiring diagram

Thermostat

Zone 1

22

4

1

3

Zone

valves

Thermostat

Zone 2

22

4

1

Thermostat

Zone

valves

3

1

Valve 3 voies/

3 way-valve

Zone 3

Note 1

Block terminal thermostat/Thermostat terminal block

COMBOMAX: sur panneau électrique COMBOMAX/

on COMBOMAX electric pannel

22

4

3

TT

Note 1

Tuyauterie eau domestique/

Domestic water piping

Tuyauterie eau de chauffage/

Boiler water piping

Page 17

THERMO 2000 inc.

Figure 4

Page 17

COMBOMAX

Système prim a ire/secondaire

Primary/Secondary system

Réducteur de pression/

Reducing valve

Valve de zonage électrique/

Electric zone valve

Eau chaude domestique/

Domestic h ot water mixed

Système multizones /

Multi-zone system

Tuyauterie chauffage/

Boiler piping

Tuyauterie eau domestique/

Domestic piping

Manomètre & thermomètre/

Manometer & thermometer

Valve anti-gravité/

Flow check valve

Valve de sécurité (T&P)

Safety valve (T&P)

Vase d'expansion/

Expansion tank

Valve à bille/

Ball valve

Vent d'air/

Air vent

Valve de mélange thermostatique/

Thermostatic mixing valve

Anti retour/

Back flow preventer

Pompe/

Pump

/

s

ur

e

t

a

i

d

a

s

R

l

i

o

C

d

r

/

a

s

o

e

t

b

t

e

e

l

s

i

a

a

b

à

e

s

ub

he

t

T

-

n

s

i

l

P

ne

n

i

F

e

d

i

o

r

c

f

i

t

s

u

e

a

E

m

o

D

q

i

t

s

e

m

a

o

w

d

d

l

o

c

y

l

/

e

p

u

up

s

r

e

t

Valve de sécurité (T&P)/

Safety valve (T&P)

à ajouter/ to add

L1 L2 N

A

T T

B

AB

Valve 3 voies/

3 way-valve

/

e

g

i

ne

g

e

n

i

d

t

l

e

e

nt

m

o

w

F

o

n

S

/

t

n

a

ne

f

f

o

u

z

a

h

ng

i

c

t

r

a

e

he

h

c

t

n

n

a

l

a

i

P

d

a

à

R

e

p

nj

i

m

o

p

P

m

u

P

n/

o

i

t

c

e

nj

n

i

o

i

t

c

e

Tuyauterie eau domestique/

Domestic water piping

Tuyauterie eau de chauffage/

Boiler water piping

Page 18

L1 G

Figure 5

Page 18

Diagramme électrique/ Wiring diagram

COMBOMAX 240V

Modèle/Model 6 - 10 KW

L2

N

TH

C

HL

TH1

C1

TH2

Légende/ Legend

Aquastat

Élément chauffant/

Heating element

Contacteur de puissance

Power relay

Haute limite

Hi-Limit

Thermostat

F

HL

R5

Voir/see note 2

C1

EL1

R4

CC

C1

EL2

120 V

24 V

TH5

R

Relais

Relay

Lampe témoin

Pilot light

Fusible

Fuse

R3

R3

R1

R2

R3

TT

Cablage en usine/

Factory wir i n g

Cablage par l'installateur/

Wiring by others

Circulateur/

Circulator

Voir/see note 2

R6

Brun/ Brown

Noir / Black

Bleu /

R1

Blue

Chauffage/ Heating

B

AB

A

Recirculation

Valve 3 voies /

3-w ay valve

R4

Note 1: Bloc terminal (24 VAC) pour une installation avec le

controleur bi-énergie Thermo 2000 modèle: "CB E- EM" /

Terminal block (24 VAC) for an ins tallation with Thermo 2000

dual

energy controll er mod el: "CBE-E M "

Note 2: Couper le cavalier lors que vous utilisez le controleur

bi-énergie Thermo 2000 modèle: "CBE-EM" /

Cut open this jumper when using T hermo 2000 dual energy

controller model: "CBE-EM"

Contact sec/

Dry contact

Voir/see note 1

R5

R6

R2

K

K

E2

V2

Page 19

Diagramme électrique/ Wiring diagram

Figure 6

Page 19

COMBOMAX 240V : modèle/ model 15 - 24 KW

L1 G

C1

C1

TH

C

HL

Aquastat

Élément chauffant/

Heating element

Contacteur de puissance

Power relay

Haute limite

Hi-Limit

Thermostat

TH1

TH2

TH3

TH4

Légende/ Legend

L2

F

HL

R5

Voir/see note 2

N

C1

EL1

R4

CC

C1

EL2

EL3

EL4

C1

TH5

120 V

24 V

R1

R2

R3

R3

R3

TT

R

Relais

Relay

Lampe témoin

Pilot light

Fusible

Fuse

Cablage en usine/

Factory wir i n g

Cablage par l'installateur/

Wiring by others

Circulateur/

Circulator

Voir/see note 2

Note 1: Bloc terminal (24 VAC) pour une installation avec le

controleur bi-énergie Thermo 2000 modèle: "CB E- EM" /

Terminal block (24 VAC) for an ins tallation with Thermo 2000

dual

energy controll er mod el: "CBE-E M "

Note 2: Couper le cavalier lors que vous utilisez le controleur

bi-énergie Thermo 2000 modèle: "CBE-EM" /

Cut open this jumper when using T hermo 2000 dual energy

controller model: "CBE-EM"

R6

Brun/ Brown

Noir / Black

Bleu /

R1

Blue

Chauffage/ Heating

B

AB

A

Recirculation

Contact sec/

Dry contact

Voir/see note 1

Valve 3 voies /

3-w ay valve

R5

R6

R4

R2

K

K

E2

V2

Page 20

L1 Diagramme électrique/ Wiring diagram

Figure 7

Page 20

Contrôle Bi-énergy/ Dual control energy CBE-EM

120 Vac

Transfo

24 Vac

Lumière haut tarif/

High tarif light

N

H

Sonde extér i eu r/

Outdoor sensor

V1

120 Vac

H

Interrupteur DP D T

Switch ON-OFF-ON

Cablage en usine/

Factory wir i n g

Cablage par l'installateur/

Wiring by others

Transfo

Bi-energie/ Dual energy

Electrique/ Electric

Mazout/ Oil

SPDT

Relais/ Relay

V3

SPDT

Relais/ Relay

E2

E1

T2

T1

Noir/ Black

Brun/ Brown

Bleu/ Blue

Relais/ Relay

E2

COMBOMAX

T

Relais chaudière

mazout/

Oil boiler Relay

T

Electrique/ Elec t r i c

Mazout/ O i l

Valve 3 voies op t ion nel l e/

Optional 3-way valve

Interrupteur DP D T

Switch ON-OFF-ON

V2

V2

B

AB

A

24 Vac

Sonde extér i eu r/

Outdoor sensor

H H V1V2 V3 T1 T2 E1 E2

Noir/ Black

Bleu/ Blue

Brun/ Brown

Valve 3 voies op t ion nel l e/

Optional 3-way valve

Bi-energie/ Dual energy

Electrique/ Electric

Mazout/ Oil

Lumière haut tarif/

High tarif light

Chaudière élect rique/

Electric boiler

BTH/ GTH/ COMBOMAX

("E2 V2" bornier 24 Vac/

terminal E2 - V 2 )

Chaudière mazout

Oil boiler

("T T" relais de combustion/

oil boiler burner)

Page 21

THERMO 2000 inc.

Figure 8

Page 21

COMBOMAX

Schéma d'installation général/

General installation

Bi-énergie avec Valve 3 Voies/

Dual Energy with 3-way valve

Tuyauterie chauffage/

Boiler piping

Tuyauterie eau domestique/

Domestic piping

Manomètre & thermomètre/

Manometer & thermometer

Valve anti-gravité/

Flow check valve

Valve de sécurité (T&P)

Safety valve (T&P)

Réducteur de pression/

Reducing valve

Valve de mélange thermostatique/

Thermostatic mixing valve

Anti retour/

Back flow preventer

Pompe/

Pump

Eau froide domestique/

Domestic cold water supply

B

Eau chaude domestique/

Domestic h ot water mixed

Valve de sécurité (T&P)/

Safety valve (T&P)

à ajouter/ to add

Thermostat

L1 L2 N

A

T T

E2 V2

Vase d'expansion/

Expansion tank

Valve à bille/

Ball valve

Vent d'air/

Air vent

Raccordement de zone valves pour voie de contournement Bi-énergie/

Diagramme électrique/ Wiring diagram

Wiring for zoned valves system for dual energy by-pass

Zone

valves

valves

24 Vac

Transfo

40Va Transfo (3 zones)

20Va Transfo (2 zones)

120 Vac

Electrical service

Zone

K

K

22

4

1

Block terminal K-K

/K-K terminal block

sur panneau électrique COMBOMAX/

on COMBOMAX electric pannel

3

Sonde extérieure Bi-énergie/

Dual Energy outside sensor

Installation Bi-énergie/

Dual energy installation

Installation d'une voie de contournement

avec valve électrique (à ajouter)/

Install by-pass with zone valve (to add)

Valve 3 voies NO 2/

3 way-valve NO 2

Contrôle Bi-énergie CBE-EM/

Dual energy control CBE-EM

AB

K K

Voir/See Note 1

B

AB

A

T T

Note 1: Ajuster la température d'eau de chauffage

du COMBOMAX de 10 à 15 degré F. en dessous

de la tempé rature d'opératio n de la ch audière au mazout.

Tuyauterie eau domestique/

Domestic water piping

Tuyauterie eau de chauffage/

Boiler water piping

Page 22

Diagramme électrique/ Wiring diagram

Figure 9

Page 22

Raccordement de zone valves/ Wiring for zoned valves system

Thermostat

Zone 1

Thermostat

Zone 2

Thermostat

Zone 3

Note 1

Block terminal thermostat

/Thermostat termi n al b l oc k

sur panneau électrique COMBOMAX/

on COMBOMAX electric pannel

24 Vac

120 Vac

Electrical servic e

22

Zone

valves

Transfo

40Va Transfo (3 zon es )

20Va Transfo (2 zon es )

1

Raccordement de multiples circulateurs/ Wiring for multiple circulators

Thermostat

Zone 1

Relais/Relay

4

T

RA845A

22

Zone

valves

3

4

1

Zone

valves

3

Diagramme électrique/ Wiring diagram

Thermostat

Zone 2

T

4

6

12

3

Circulateur/

5

circulator

Zone 1

T

Relais/Relay

RA845A

2

22

4

1

T

4

3

1

3

Note 1

TT

6

5

Circulateur/

circulator

Zone 2

L2L1

120Vac

electric al service

Diagramme électrique/ Wiring diagram

Raccordement de zone valves pour voie de contournement Bi-énergie/

Wiring for zoned valves system for dual energy by-pass

Zone

valves

24 Vac

120 Vac

Electrical servic e

Zone

valves

Transfo

40Va Transfo (3 zon es )

20Va Transfo (2 zon es )

K

K

22

4

1

Block terminal K-K

/K-K terminal block

sur panneau électrique COMBOMAX/

on COMBOMAX electric pannel

3

Page 23

Aquastat

Figure 10

Page 23

Priorité DHW/

DHW priority

(Sugg: 160F)

Bornier

valve 3 voies/

3 way valve

terminal block

Aquastat

Élément no. 4/

Element no. 4

(Sugg: 165F)

Aquastat

Élément no. 3/

Element no. 3

(Sugg: 170F)

Aquastat

Élément no. 2/

Element no. 2

(Sugg: 175F)

Aquastat

Élément no. 1/

Element no. 1

(Sugg: 180F)

Bornier/

Terminal bl o ck

C-C

(Po mpe/ Pump)

Transformateur

contrôle/

Transformer

Control

Fusible

contrôle/

Control

Fuse

Relais

Valve

3 voies

Relais

Contact

sec K - K

Relais

Priorité

DHW

Relais

Pompe

Relais BE

Éléments

Relais BE

Valve

3 Voies

3 way

Valve

Relay

Dry Contact

K - K

Relay

DHW

Priority

Relay

Pump

Relay

Element

Dual Energy

Relay

3 way valve

Dual Energy

Relay

Mise à

la terre/

Grund

THERMO 2000 inc.

Panneau de contrôlel/

Control pannel

COMBOMAX 240V

Contacteur

principal/

Main

Contactor

Bornier de

raccordement/

Main terminal

Block

Bornier/ Terminal block

K-K (contact sec/ Dry contact)

E2-V2 (Bi-énergie/ Dual Energy)

T-T (Thermostat)

Page 24

COMBOMAX

TM

LIMITED WARRANTY

Warranty Coverage for Residential Installation.

Thermo 2000 Inc. hereby warrants to the original residential purchaser that the

COMBOMAX tank and exchanger (coil assembly) installed in a residential setting

shall be free of leaks during normal use and service for a period of fifteen (15) years

from the date of purchase as long as the original residential purchaser owns the

home in which the unit was originally installed, the ten (10) years in full and years

eleven (11) through fifteen (15) prorated 20% each year at suggested retail price.

Residential setting shall mean usage in a single-family dwelling in which the

consumer resides on a permanent basis. Also, residential setting shall mean use in

multiple family dwellings in which one (1) COMBOMAX tank and exchanger is to be

use in only one (1) dwelling. In the event that a leak should develop and occur

within this limited warranty period due to defective material or workmanship, such

leak having been verified by an authorized company representative, Thermo 2000

inc. will repair or replace at our sole option the failed unit with the nearest

comparable model at the time of replacement.

The original residential purchaser is responsible for all costs associated with the

removal and reinstallation, shipping and handling to and from manufacturing plant.

The replacement unit will be warranted for the remaining portion of the original

Warranty.

Warranty Coverage for Commercial Installation.

Thermo 2000 Inc. hereby warrants to the original residential purchaser that the

COMBOMAX tank and exchanger (coil assembly) installed in a residential setting

shall be free of leaks during normal use and service for a period of fifteen (15) years

from the date of purchase as long as the original residential purchaser owns the

home in which the unit was originally installed, the ten (10) years in full and years

eleven (11) through fifteen (15) prorated 20% each year at suggested retail price.

Commercial setting shall mean use in other than residential setting stated above in

the residential setting definition. In the event that a leak should develop and occur

within this limited warranty period due to defective material or workmanship, such

leak having been verified by an authorized company representative, Thermo 2000

inc. will repair or replace at our sole option the failed unit with the nearest

comparable model at the time of replacement.

The original purchaser is responsible for all costs associated with the removal and

reinstallation, shipping and handling to and from Manufacturer. The replacement

unit will be warranted for the remaining portion of the original Warranty.

Limited one year warranty on all COMBOMAX

components & parts

All other COMBOMAX components & parts are warranted for a period of one (1)

year against defects due to defective material or workmanship. The original

purchaser is responsible for all costs associated with the removal and reinstallation,

shipping and handling to and from Manufacturer. The components, repaired or

replaced are warranted for the residual period of the initial warranty on the unit.

Exclusions.

This warranty is void and shall not apply if:

A) Defects or malfunctions resulting from installation, repair, maintenance

and/or usage that are not done in conformity with the manufacturer’s

installation manual; or

B) Defects or malfunctions resulting from installation, maintenance, or repair that

are not done in accordance with regulations in force; or

C) Defects or malfunctions resulting from improper installation, maintenance or

repair done carelessly or resulting from consumer damage (improper

maintenance, misuse, abuse, accident or alteration); or

D) Installation in which a relief valve (pressure) is not installed or if it is not

functioning properly, or when it is not connected to a drain to avoid damage to

the property; or

E) Installation in which liquid circulating in the tank does not remain in closed

circuit or installation in which piping is leaking; or

F) A polybutylene pipe or radiant panel installation without an oxygen absorption

barrier is used; or

G) Installation where the acidity of water is not wit hin t he normal Environmental

Protection Agency (EPA) (between pH 6.5 – 8.5) guidelines or the domestic

water contains abnormal levels of particulate matter or water exceeding 10.5

gpg; or

H) Your home contains any type of water softener system and the unit is not

installed and maintained in accordance with the manufacturer specifications;

or

I) When installed with a low pressure steam boiler, if sludge is allowed to

accumulate in the COMBOMAX tank and boiler water acidity is lower than pH

6.5 or higher than pH 8.5; or

J) The COMBOMAX unit is being subject to non authorized modifications; or

K) Defects or malfunction resulting of storing or handling done elsewhere than

Thermo 2000’s manufacturing plant; or

L) Units on which the serial number is removed or obliterated.

Limitations.

Thermo 2000 shall not be responsible for any damage, loss, and inconvenience of any

nature whatsoever, directly or indirectly, relating to the breakdown or malfunction of the

unit. This warranty limits its beneficiary’s rights. Nevertheless, the beneficiary may have

other rights, which vary from state to state.

This warranty replaces any other expressed or implicit warranty and constitutes the sole

obligation of Thermo 2000 towards the consumer. The warranty does not cover cost of

removal, reinstallation or shipping to repair or replace the unit, nor administration fees

incurred by the original consumer purchaser.

Thermo 2000 reserves its rights to make changes in the details of design, construction, or

material, as shall in its judgment constitute an improvement of former practices.

This warranty is valid only for installations made within the territorial limits of Canada and

the United States.

In order to receive the benefit of this warranty, the original consumer purchaser

must fill in and return the attached registration card within thirty (30) days of date of

purchase.

Warranty service procedure

Only authorized COMBOMAX dealers are permitted to perform warranty obligations. The

owner or its contractor must provide Thermo 2000’s head office or authorized depot with

defect unit together with the following information: COMBOMAX model and serial number,

copy of the original sales receipt and owner’s identification certificate.

500, 9

THERMO 2OOO INC.

ième

Avenue, C.P. 639, RICHMOND (QUÉBEC) JOB 2HO

TÉL.: (819) 826-5613 FAX: (819) 826-6370

Loading...

Loading...