Page 1

HIGH-EFFICIENCY DOWNFLOW / HORIZONTAL FURNACE

INSTALLER'S INFORMATION MANUAL

S

I

G

E

N

D

C

E

D

R

E

I

T

I

F

DOWNFLOW POSITION SHOWN

ATTENTION, INSTALLER! After installing the

furnace, show the user how to turn off gas and electricity to

the furnace. Point out control and switch locations for

turning off gas and electricity. Go over the User’s

Information Manual and Section 23, “Maintaining Fu rnace

In Good Working Order" in this manual with the user. Make

sure the user understands the importance of following all

safety precautions, including what could happen if they do

not.

Attach the following documents to or adjacent to the

furnace. Tell the user where these documents are located.

• User's Information Manual

• Installer's Information Manual

• Parts List

• Warranty Information

While these instructions have been written as accurately

and thoroughly as possible, they can not cover every

system variation or contingency. Questions of

interpretation may arise. For more information, solutions to

particular problems or clarification, contact your local

distributor or the manufacturer.

ATTENTION, USER! Your furnace installer should

give you the documents listed on opposite side. You

should immediately read the User’s Information Manual for

important safety information to keep you and your family

safe. Keep these as long as you keep your furnace. Pass

them on to future furnace purchasers or users. If any of the

documents are missing or illegible, contact your installer or

furnace manufacturer for replacement. Throughout this

manual, when we use the word "you" we refer to the

qualified service technician who is responsible for

application, installation and service of your furnace.

?? Do not store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other appliance.

?? WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch.

• Do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

• If you cannot reach gas supplier, call the fire

department.

431570 G

Page 2

WARNING: Individuals who install this fu rnace, must have the training and experience necessary to install gas

furnaces. They must also have training and experience necessary to install related comfort air conditioning appliances.

Improper installation could create a hazard, resulting in the possibility of damage, injury or death.

TABLE OF CONTENTS

SECTION 1. IMPORTANT SAFETY RULES ............................................................................................................. 2

SECTION 2. MEETING CODES .............................................................................................................................. 3

SECTION 3. DETERMINING BEST FURNACE LOCATION...................................................................................... 3

SECTION 4. PROVIDING VENTING AND COMBUSTION AIR.................................................................................. 6

SECTION 5. CONDENSATE DRAIN.......................................................................................................................17

SECTION 6. INSTALLIN G GAS PIPING ..................................................................................................................19

SECTION 7. INSTALLIN G ELECTRICAL WIRING...................................................................................................20

SECTION 8. SEQUENCE OF OPERATION ............................................................................................................21

SECTION 9. INSTALLIN G DUCT SYSTEM.............................................................................................................23

SECTION 10. SELECTIN G AND INSTALLING FILTERS ........................................................................................24

SECTION 11. CHECKS BEFORE STARTING FURNACE ........................................................................................24

SECTION 12. GAS SUPPLY PRESSURE AND PILOT ADJUSTMENT .....................................................................25

SECTION 13. MANIFOLD PRESSURE ADJUSTMENT...........................................................................................25

SECTION 14. CHECKING GAS INPUT RATE .........................................................................................................26

SECTION 15. DERATING FOR HIGH ALTITUDE ....................................................................................................27

SECTION 16. DETERMINING CORRECT ORIFICE SIZE ........................................................................................27

SECTION 17. CHANGING MAIN BURNER ORIFICE S ............................................................................................28

SECTION 18. ADJUSTIN G BLOWER SPEED.........................................................................................................28

SECTION 19. MEASURING DUCT SYSTEM STATIC PRESSURE ..........................................................................29

SECTION 20. MEASURING AIR TEMPERATURE RISE ..........................................................................................30

SECTION 21. CHECKING CONTROLS ..................................................................................................................30

SECTION 22. SETTING BLOWER TIMINGS ...........................................................................................................31

SECTION 23. MAINTAINING FURNACE IN GOOD WORKING ORDER ...................................................................31

SECTION 24. ACCESSORIES .............................................................................................................................32

SECTION 25. OTHER INFORMATION AND PUBLICATIONS ..................................................................................32

SECTION 1. IMPORTANT SAFETY

RULES

To alert you to potential hazards, we use the signal words

"WARNING" and "CAUTION" throughout this manual.

"WARNING" alerts you to situations that could cause or

result in serious injury or death. "CAUTION" alerts you to

situations that could cause or result in minor or moderate

injury or property damage. For a safe and reliable

installation be sure to read and follow all warnings and

cautions.

We also use the words "must" and "should" in this manual.

"Must" is mandatory. "Should" is advisory.

WARNING: Read and follow the safety rules in

this section and throughout this manual. Failure to do so

could cause improper furnace operation, resulting in

damage, injury or death.

Rule 1. Use only gas approved for use in this fu rnace, as

indicated on fu rnace rating plate. Use only natural gas in

furnaces designed for natural gas. Use only propane (LP)

gas in furnaces designed for propane (LP) gas. Make sure

furnace will operate properly on the gas type available to

user. Do not use butane gas in this furnace.

WARNING: Use of a non-approved gas (such as

butane) in this furnace could cause sooting or overheating

of heat exchanger.

Rule 2. Do not install this furnace outdoors or in a mobile

home, trailer or recreational vehicle. It is not design

certified for these installations. This furnace is suitable for

a home built on site or a manufactured home completed at

the final site.

Rule 3. Air for combustion must not come from a corrosive

or contaminated atmosphere. Make sure all combustion

and ventilation air requirements are adhered to in addition

to local codes and ordinances.

Rule 4. This furnace is not to be used for temporary

heating of buildings or structures under construction.

Rule 5. Provide adequate combustion and ventilation air to

space where furnace is being installed unless combustion

air is provided directly through an inlet air pipe. Connect

this furnace to an approved vent system--venting

combustion products outdoors.

Rule 6. Check for gas leaks anytime work is done on gas

supply line, fu rnace gas control, pilot and pilot line or main

burner manifold.

431570 G

Page 3

Rule 7. Never test for gas leaks with an open flame. Use a

commercial soap solution made specifically for leak

detection to check all connections.

Rule 8. Completely seal supply and return air ducts to

furnace casing. Duct system must run to an area outside

furnace room or closet. Seal duct work wherever it runs

through walls, ceilings or floors of furnace room or closet.

subject to continuous higher or lower temperatures.

Continuous operation outside of this range may shorten

furnace life.

WARNING : Do not install furnace on its back or

front. Doing so could cause heat exchanger blockage and

damage to heat exchanger.

SECTION 2. MEETING CODES

This furnace complies with American National Standard

and National Standard of Canada for Gas Fired Central

Furnaces, ANSI Z21.47 ? CAN/CGA-2.3. It is certified for

operation with either natural gas or propane (LP) gas for

indoor installation in a building constructed on site. It meets

the requirement for a 100% shut -off gas control system.

Before installing this furnace, make sure you know all

applicable codes. Be sure to consult local authorities

having jurisdiction over furnaces for information on

electrical wiring, gas piping and venting. The installation of

this furnace must conform with local building codes or in the

absence of local codes, with ANSI Z223.1, National Fuel

Gas Code or CAN/CGA B149, Canadian Installation Codes.

Electrical wiring must conform with local building codes or

in the absence of local codes, with the current National

Electrical Code, ANSI/NFPA 70 or current Canadian

Electrical Code, CSA C22.1.

SECTION 3. DETERMINING BEST

FURNACE LOCATION

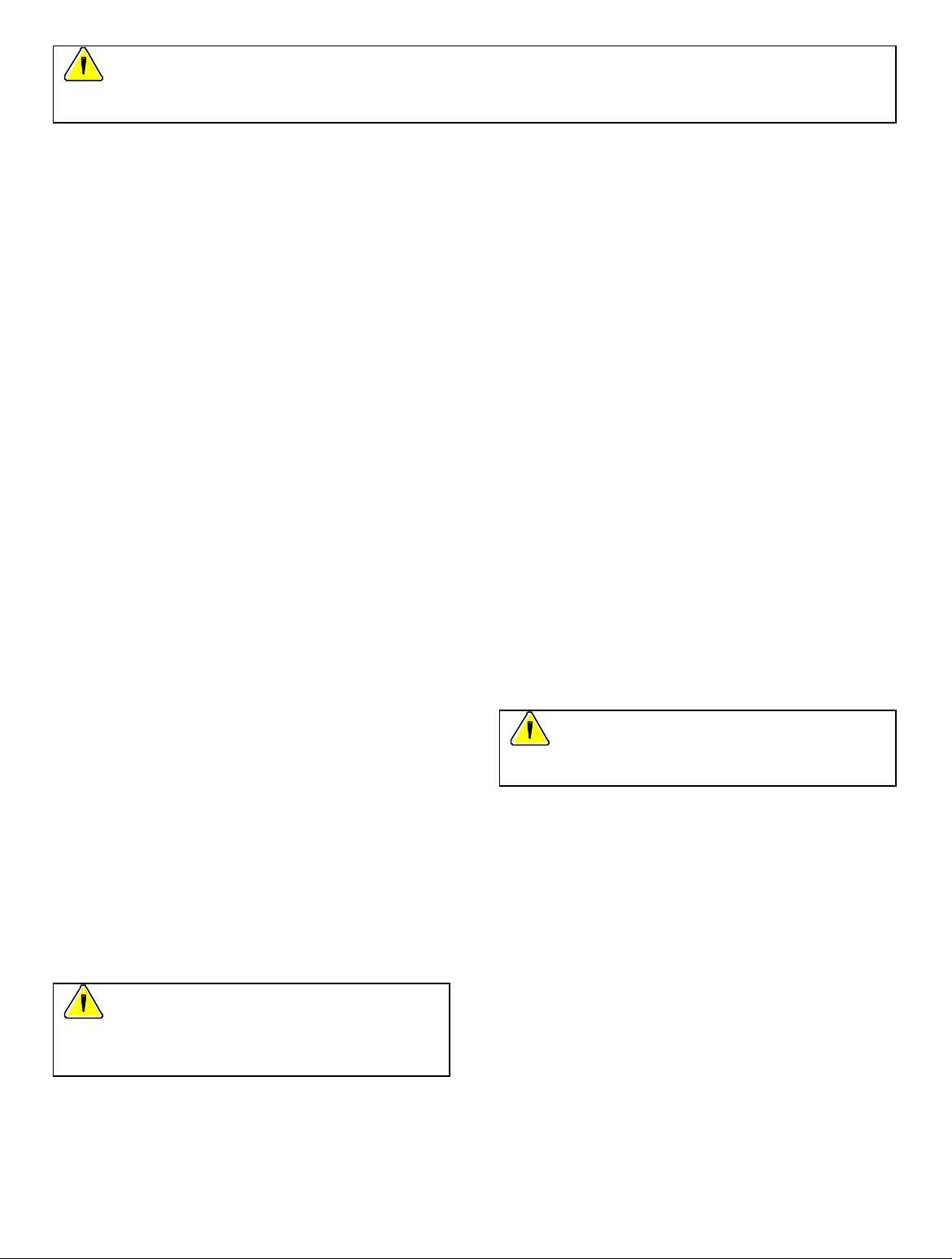

You may install this fu rnace in the downflow position in an

alcove, attic, basement, closet, garage or utility room. See

Figure 1.

Select a location that meets all requirements described in

this manual for the following:

?? Safety

?? Minimum Clearances

?? Combustion and Ventilation Air

?? Venting

?? Duct System

?? Gas Piping

?? Electrical Wiring

Locate furnace as near to the center of the air distribution

system as possible.

Provide ample space for servicing and cleaning. Location

must allow 30 inches minimum front clearance for service.

WARNING : Some insulating materials are

combustible. When a furnace is installed in an attic or other

insulated space, keep all insulating materials at least 12

inches away from furnace and combustion air inlet. Failure

to do so could cause a fire.

You may install fu rnace on non-combustible flooring or for

horizontal installations on wood flooring. You may also

install furnace on wood flooring in the downflow position

when using a combustible floor base, available from the

manufacturer. See parts list.

You may install this furnace in the horizontal air-left or

horizontal air-right position in an alcove, attic, basement,

garage or utility room. See Figure 1.

WARNING: Do not install fu rnace on carpeting,

tile or other combustible material except wood flooring.

Doing so could cause a fire.

Install fu rnace so all electrical components are protected

from water.

LEVELING FURNACE

Furnace must be installed level for proper condensate

drainage.

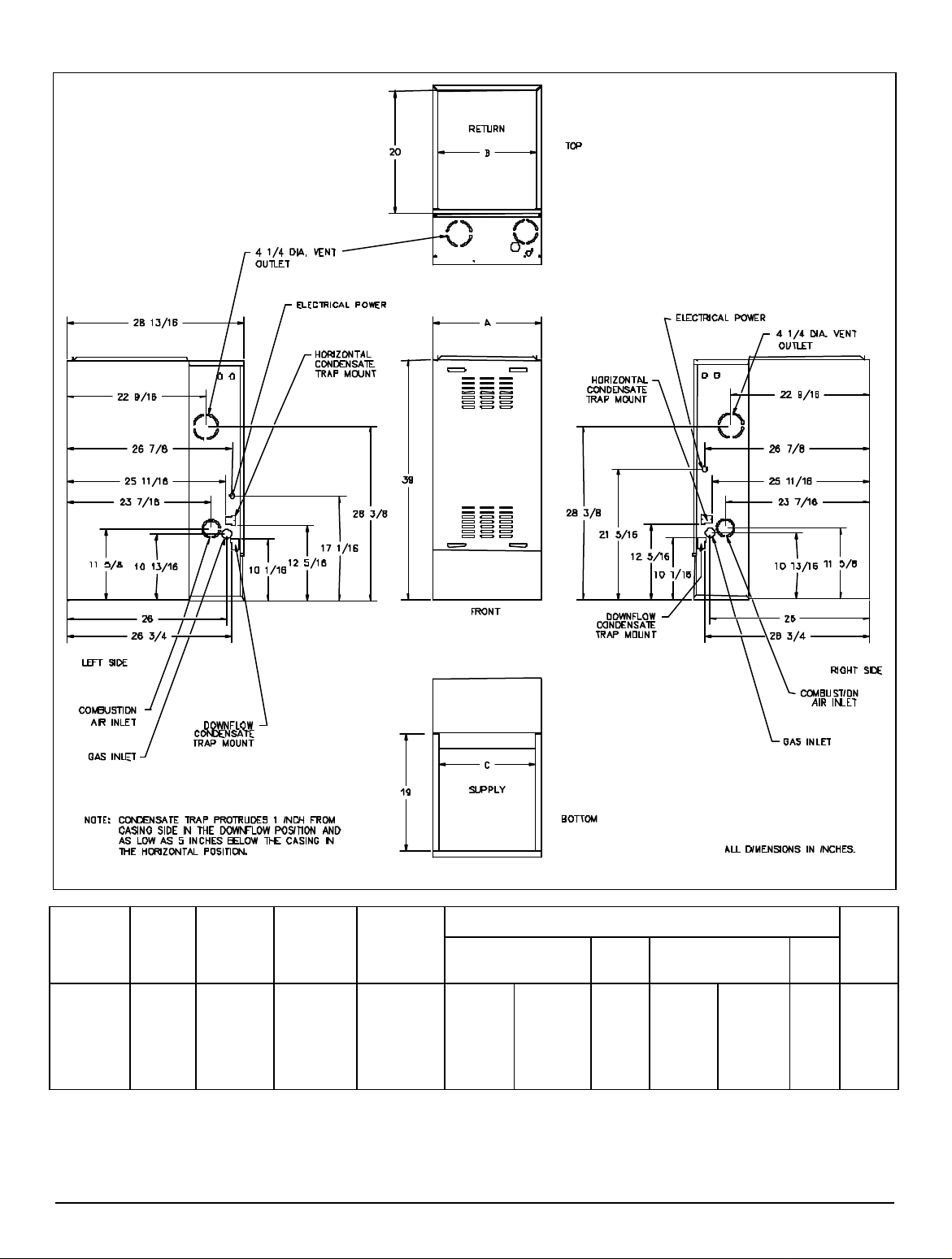

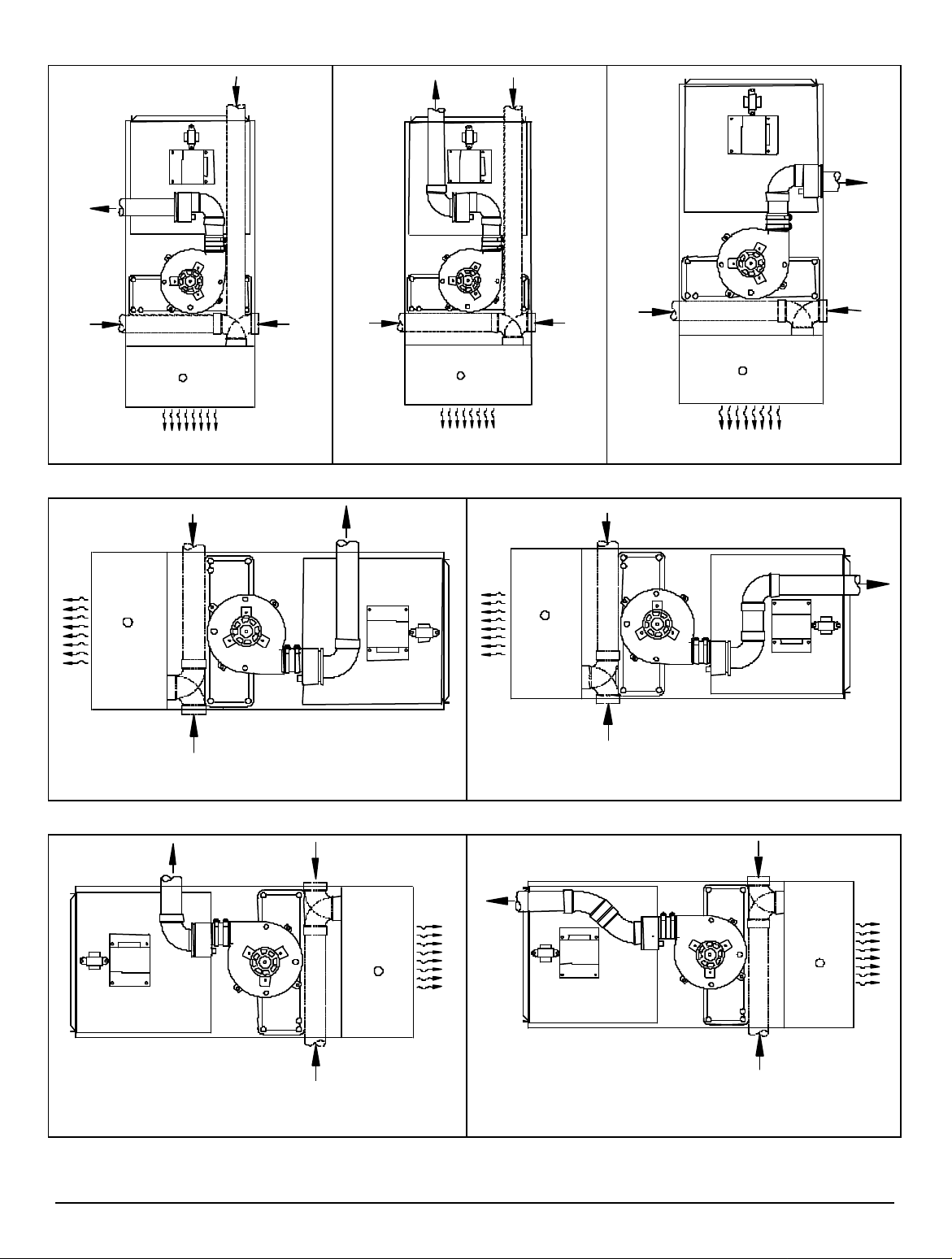

Figure 1. Furnace Installation Positions.

CAUTION: Do not install furnace in an area subject to

freezing temperatures. Doing so could cause condensate

to freeze.

This furnace operates best when return-air temperature is

between 55°F and 80°F. Do not install furnace in a location

Installer’s Information Manual Page 3

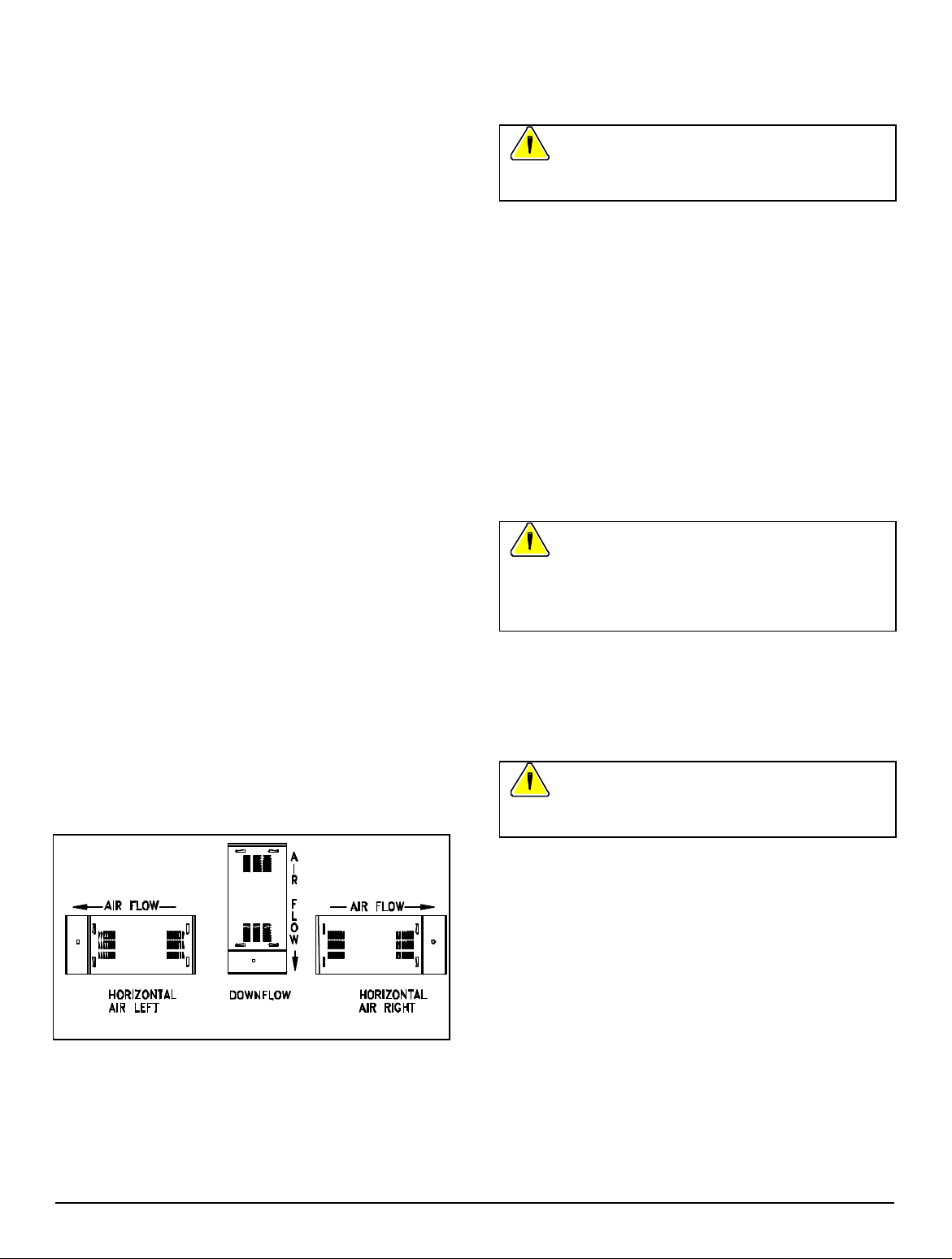

In DOWNFLOW POSITION, furnace must be level or tilted

to the front no more than 1/4 inch. Furnace must also be

level from side to side within 1/4 inch. See Figure 2.

Page 4

Figure 4. Level furnace or tilt toward front no more than 1/4

inch.

Figure 2. Level furnace or tilt toward front no more than 1/4

inch. Also, level from side to side within 1/4 inch.

In HORIZONTAL POSITIONS, furnace must be level or

tilted to the front no more than 1/4 inch and must also be

level from side to side or tilted toward burner end no more

than 1/4 inch. See Figures 3 and 4.

CAUTION: Furnace must be installed level. Failure to

properly level furnace may result in heat exchanger

damage.

OTHER LOCATION INFORMATION

Sufficient air must be provided to ensure there will not be a

negative pressure in fu rnace room or space. In addition,

there must be a positive seal between furnace and return

air duct to avoid pulling air from furnace room.

When a cooling unit is installed with this furnace, the

furnace must be installed parallel with or on the upstream

side of the cooling unit to avoid condensation in fu rnace

heat exchanger. With a parallel flow arrangement, the

dampers or other means used to control flow of air must be

adequate to prevent chilled air from entering the fu rnace

and, if manually operated, must be provided with a means

to prevent operation of either unit unless damper is in the

full heat or cool position.

When furnace is in a residential garage, it must be installed

so that pilot and main burners are located no less than 18

inches above the floor. Also, fu rnace should be protected

from physical damage by vehicles.

When fu rnace is in a public garage, airplane hanger, or

other building having hazardous atmosphere, install unit in

accordance with recommended good practice requirements

of the National Fire Protection Association, Inc. Consult

local code authorities for additional location requirements.

See Figure 5 for furnace dimensions and clearances.

Figure 3. Level furnace or tilt toward burner end no more

than 1/4 inch.

Page 4 Installer’s Information Manual

Page 5

GAS

INPUT*

(Btu/hr) (HP) “A” “B” “C” TOP SIDES FRONT*** VENT Inches

54,000 1/3 17 1/2 15 15/16” 15 3/4” 0 1 0 1 18 0 2

72,000 1/2 17 1/2 15 15/16” 15 3/4” 0 1 0 1 18 0 2 OR 3

72,000 3/4 20 1/2 18 15/16” 18 3/4” 0 1 0 1 18 0 2 OR 3

90,000 1/2 17 1/2 15 15/16” 15 3/4” 0 1 0 1 18 0 2 OR 3

90,000 3/4 20 1/2 18 15/16” 18 3/4” 0 1 0 1 18 0 2 OR 3

108,000 3/4 23 1/2 21 15/16” 21 3/4” 0 1 0 1 18 0 3

126,000 3/4 23 1/2 21 15/16” 21 3/4” 0 1 0 1 18 0 3

* See Furnace Rating Plate.

** These are furnace dimensions. See Sections 9 and 10 for proper ductwork and floor opening dimensions.

*** 30-inch front clearance required for service.

MOTOR

SIZE*

FURNACE

WIDTH**

RETURN-

AIR SIZE**

SUPPLY -

AIR SIZE**

Downflow

CLEARANCE TO COMBUSTIBLES

Horizontal

(Inches)

and

BACK Downflow

Horizontal

VENT

SIZE

Figure 5. Furnace Dimensions and Clearances.

Installer’s Information Manual Page 5

Page 6

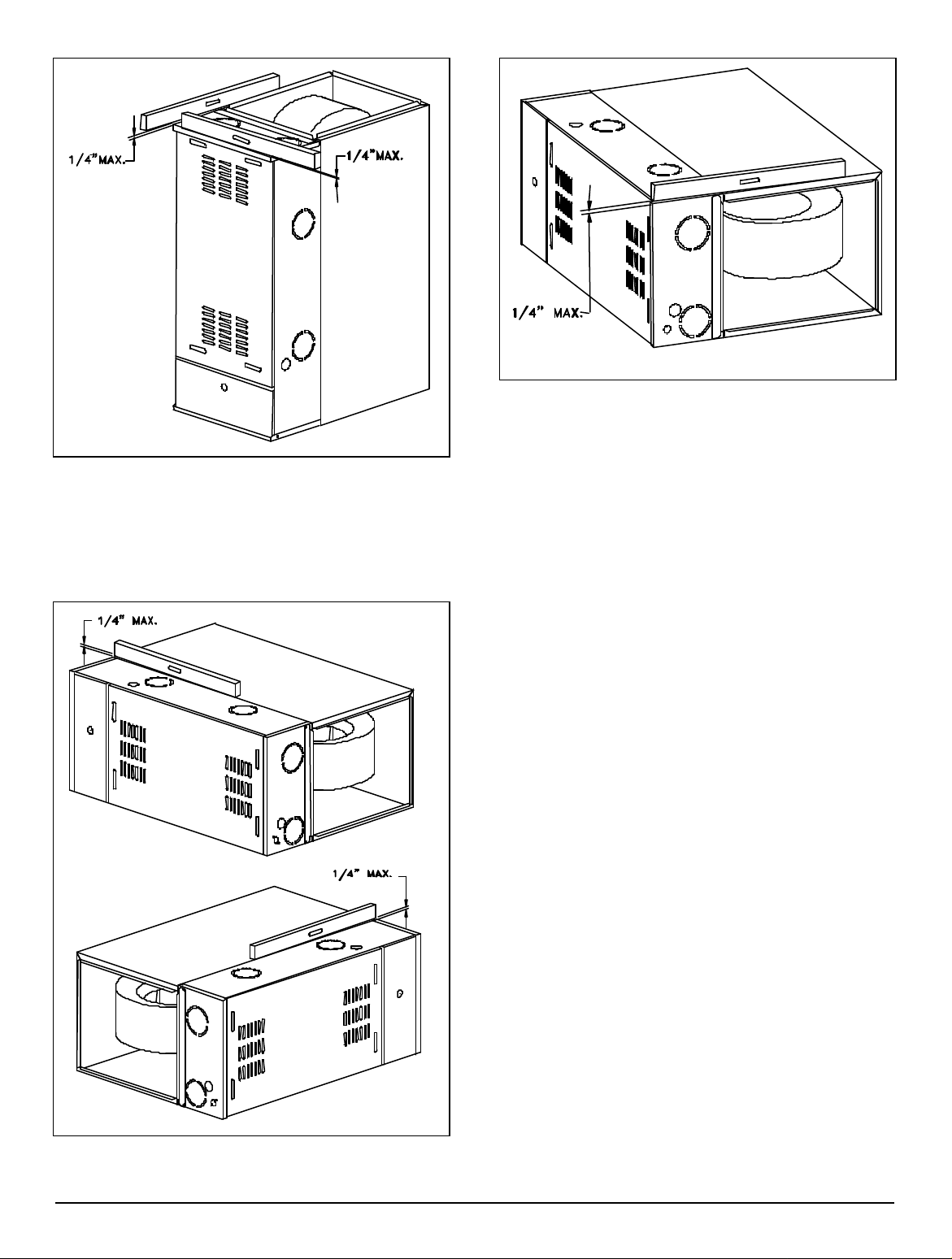

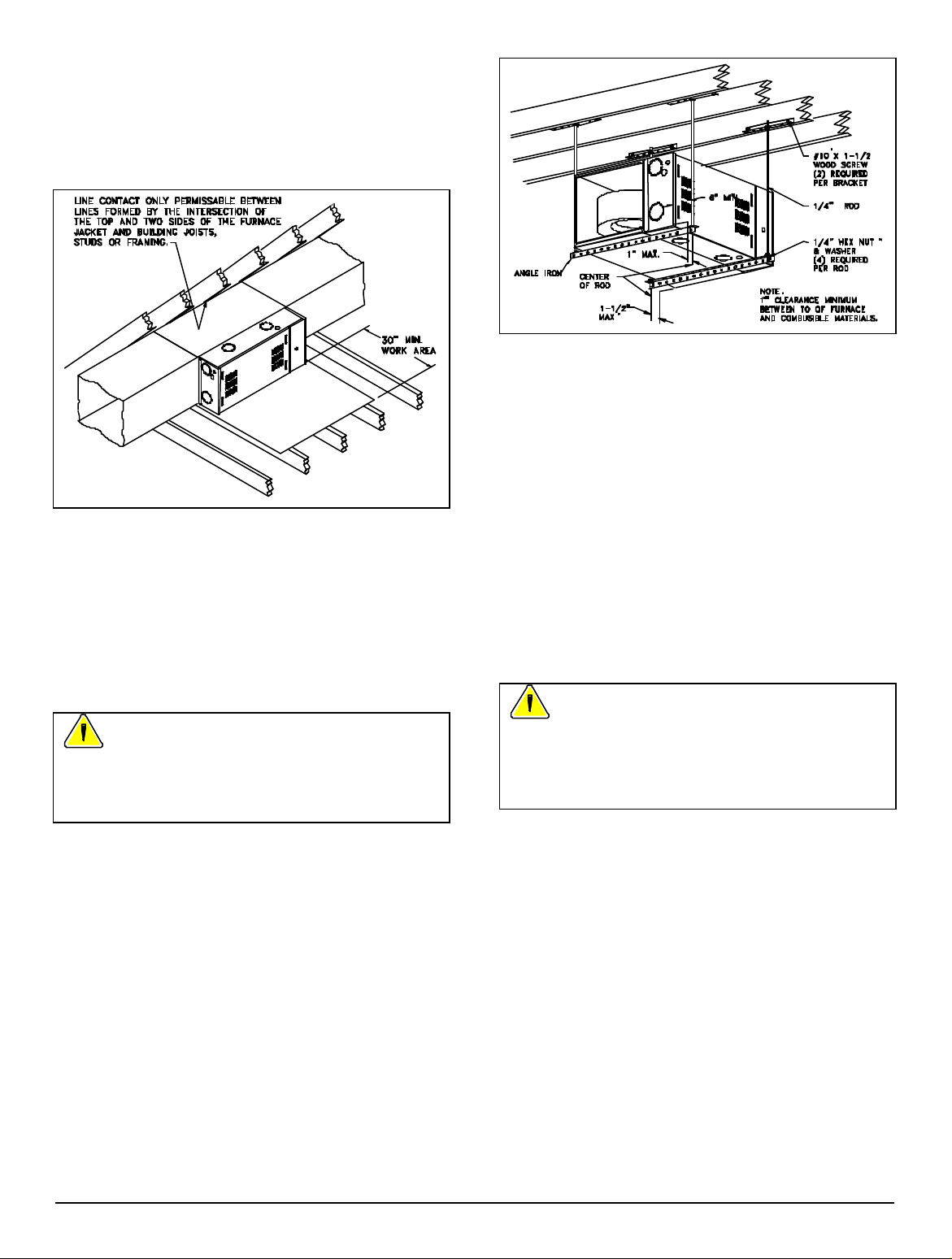

ATTIC INSTALLATION

Line contact is permissible for furnaces installed in

horizontal positions. The intersection of furnace top and

sides forms a line as shown in Figure 6. This line may be in

contact with combustible material.

Figure 6. Typical Attic Installation.

Install a platform under furnace that extends a minimum 30

inches in front of furnace. This provides a work area and

keeps insulating materials away from combustion air

openings. Secure platform to joists.

Note: In horizontal position, condens ate trap hangs as low

as 5 inches below furnace. Provisions must be made for

condensate trap and drain lines. See Section 5 for details

on condensate trap installation.

WARNING : Some insulating materials are

combustible. When a furnace is installed in an attic or other

insulated space, keep all insulating materials at least 12

inches away from furnace and all burner combustion air

openings. Failure to do so could cause fire.

Figure 7. Suspending Using Threaded Rod.

SECTION 4. PROVIDING VENTING

AND COMBUSTION AIR

This furnace must be connected to a plastic venting system

adequate to remove flue gases to the outside atmosphere.

It must be vented in accordance with these instructions and

local building codes.

The fu rnaces covered by this manual are design-certified

as Category IV appliances. Category IV appliances operate

with a positive vent static pressure and with a flue-gas

temperature that will produce significant condensate in the

vent. The vent system for this furnace must be installed so

as to prevent leakage of flue gases into the building. This

furnace may be installed using either direct venting or nondirect venting.

WARNING : Do not connect this furnace to a vent

system shared by any other appliance. Do not connect it to

any other type of vent system other than described by these

instructions. Improper venting could allow combustion

products to collect in building during use resulting in nausea

or death by asphyxiation.

CRAWL SPACE INSTALLATION

Furnace can be hung from floor joists or installed on

suitable blocks or pad. Pad or blocks must provide enough

height to eliminate potential for water damage. Maintain

clearances listed in Figure 5.

SUSPENDING FURNACE

Some installations require that the furnace be suspended

from rafters or floor joists. A common way to do this using

threaded rods is shown in Figure 7. Consider this means

when people may walk underneath furnace. Other means

that provide adequate support may be used.

Level furnace from front to back and from left to right and

maintain clearances as described previously.

Page 6 Installer’s Information Manual

GENERAL VENTING GUIDELINES

?? Vent system and combustion air supply components

must be constructed of schedule 40 PVC, PVC -DWV,

SDR26, SDR21 or ABS plastic. Use pipe, fittings,

sealants, and installation procedures that conform to

the following ANSI/ASTM standards:

PVC ASTM D-1785

SDR26, SDR21 ASTM D-2241

PVC-DWV ASTM D-2665

PVC-DWV CELLULAR CORE ASTM F-891

PVC Primer And Solvent Cement ASTM D-2564

ABS Pipe And Fittings ASTM D-2235

Procedure For Cementing Joints ASTM D-2855

?? All condensate formed in the vent must run back

toward fu rnace for proper drainage. Install vent pipe

with no less than a 1/4 inch per foot slope toward

furnace from vent terminal.

Page 7

?? Install vent pipe without dips or sags that may hold

water. Support horizontal portions of vent pipe every 5

feet (3 feet for SDR-21 or SDR-26 pipe).

?? Protect vent from freezing. Long runs of vent pipe

installed in an unconditioned space may require

insulati on to prevent freezing of condensate.

PVC PIPE INSTALLATION INSTRUCTIONS

1. Cut ends of pipe square using a miter box or PVC

tubing cutter. Remove any burrs, dirt, grease, and

moisture. Check joint for proper fit.

2. Freely coat outside end of pipe and inside of fitting

socket with cleaner-primer. The purpose of the primer

is to dissolve and penetrate the surface of the pipe.

Several coats may be necessary to do this.

3. While primer is still wet, apply a heavy coat of solvent

cement to outside of pipe. Next, apply a generous coat

of cement to the inside of socket.

4. While both surfaces are still wet with cement, insert

pipe into fitting socket until it bottoms out, using a slight

twisting motion (1/4 turn). Hold pipe in socket 30

seconds to allow cement to set.

5. Allow joint to cure before handling.

IN THE UNITED STATES:

?? Allow a minimum clearance of 4 feet from electric

meters, gas meters, regulators, and relief equipment.

?? When non-direct venting, terminal must be at least 4

feet below, or 4 feet horizontally from or one foot above

any door, window or gravity air inlet into a building.

Terminal must also be at least 3 feet above any forcedair inlet located within 10 feet horizontally.

?? When direct venting, vent terminal must be at least one

foot from any opening through which flue gases could

enter a building.

IN CANADA:

?? Allow 6 feet clearance to any mechanical air supply or

service regulator vent and 6 feet horizontally to any gas

meter, electric meter, or relief device.

?? Do not terminate above a meter/regulator assembly

within 3 feet horizontally of the vertical center line of

the regulator

?? Do not terminate within one foot (3 feet for 108,000 and

126,000 Btu models) of a window or door which can be

opened, a non-mechanical-air-supply inlet, or the

combustion-air inlet of any other appliance

Caution: Keep solvent cement container sealed when not

in use. Do not use solvent cement that has thickened or is

gel-like.

WARNING : PVC cements are highly flammable.

Do not use near open flames. A fire or explosion could

result. Avoid prolonged breathing or contact with skin or

eyes.

TERMINATION LOCATION AND CLEARANCES

Vent pipe and combustion-air-supply pipe (when direct

vented) may terminate through a roof or through a sidewall.

Roof termination has the advantages of better pipe

protection and fewer condensate -damage concerns. Use

the following guidelines when choosing a vent location:

?? Flue gases can be corrosive. When sidewall venting,

protect walls with a corrosion resistant material. Also,

terminate away from plants and shrubs.

?? Locate termination consistent with the National Fuel

Gas Code, ANSI Z223.1/NFPA 54 or the CAN/CGA

B149 Installation Codes.

?? Locate termination away from other air-intake or

exhaust vents such as dryer vents, other gas appliance

vents, or plumbing vents. Allow at least 3 feet to any

other vent.

?? Terminal must not be located above a walkway,

driveway or within 10 feet of an adjacent building.

?? Do not locate termination underneath a veranda,

porch, or deck.

EXISTING VENT CONSIDERATIONS

When a Category I fu rnace is removed or replaced, the old

venting system may not be properly sized to vent the

remaining appliance(s), for example, a gas water heater.

An improperly sized venting system may promote the

formation of condensa te, leakage or spillage.

The following steps shall be followed with each appliance

connected to the old venting system placed in operation,

while any other appliances connected to the venting system

are not in operation:

1. Seal any unused openings in the venting system;

2. Inspect the venting system for proper size and

horizontal pitch, as required in the National Fuel Gas

Code, ANSI Z223.1/NFPA 54 or the CAN/CGA B149

Installation Codes. Determine that there is no

blockage or restriction, leakage, corrosion and other

deficiencies which could cause an unsafe condition;

3. In so far as is practical, close all building doors and

windows and all doors between space in which

appliance(s) connected to the venting system are

located and other spaces of building.

4. Close fireplace dampers.

5. Turn on clothes dryers and any appliance not

connected to the venting system. Turn on any exhaust

fans, such as range hoods and bathroom exhausts, so

they shall operate at maximum speed. Do not operate

a summer exhaust fan.

Installer’s Information Manual Page 7

Page 8

6. Follow the lighting instructions. Place the appliance

being inspected in operation. Adjust thermostat so

appliance shall operate continuously;

7. Test for drafthood equipped appliance spillage at the

drafthood relief opening after 5 minutes of main burner

operation. Use the flame of a match or candle;

8. After it has been determined that each appliance

connected to the venting system properly vents when

tested as outlined above, return doors, windows,

exhaust fans, fireplace dampers and any other gas burning appliance to their previous conditions of use;

9. If improper venting is observed during any of the above

tests, the venting system must be corrected. Follow

the National Fuel Gas Code, ANSI Z223.1/NFPA 54 or

CAN/CGA B149 Installation Codes to correct improper

vent operation. Any "common vent" re-sizing must

approach minimum size determined using current

venting tables.

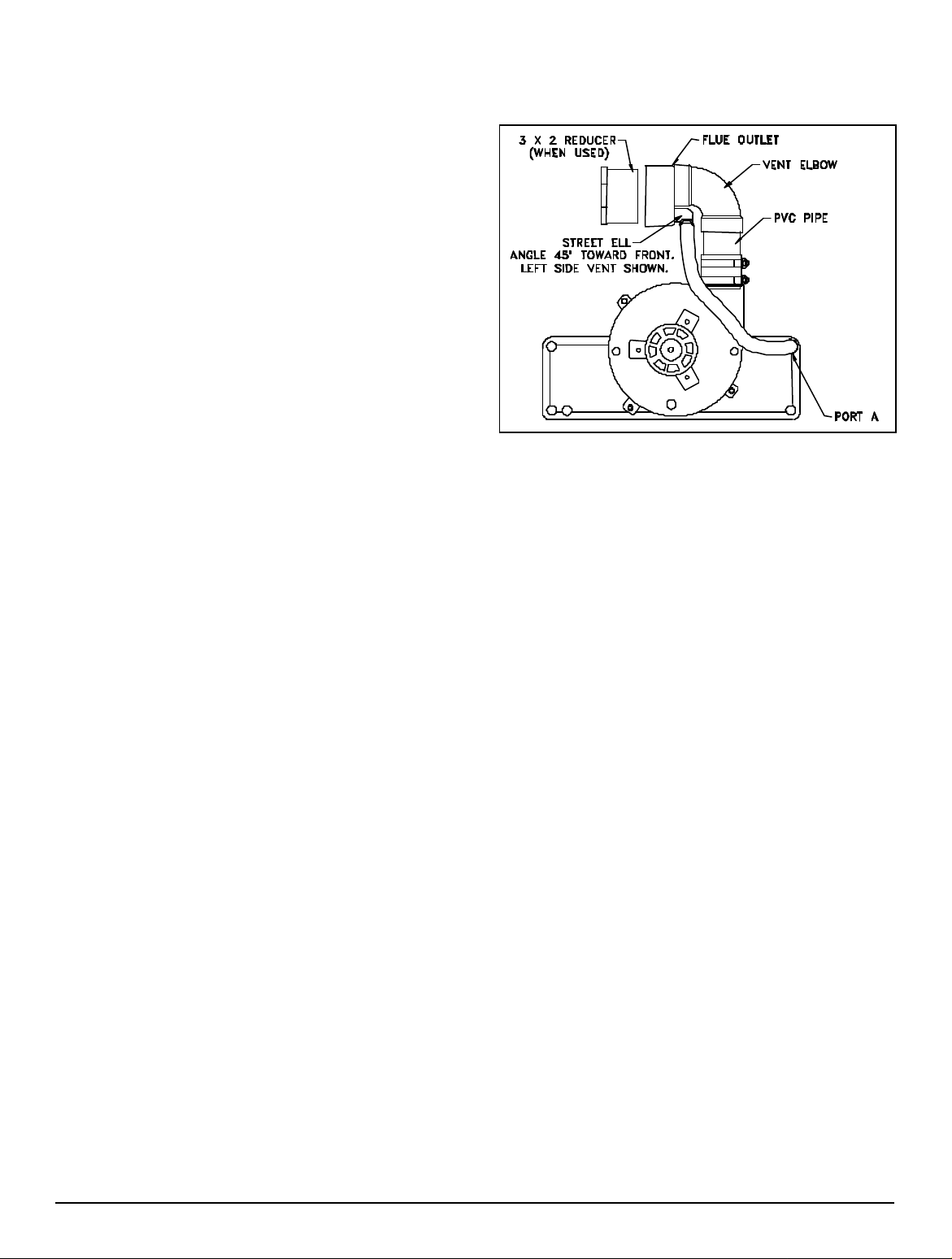

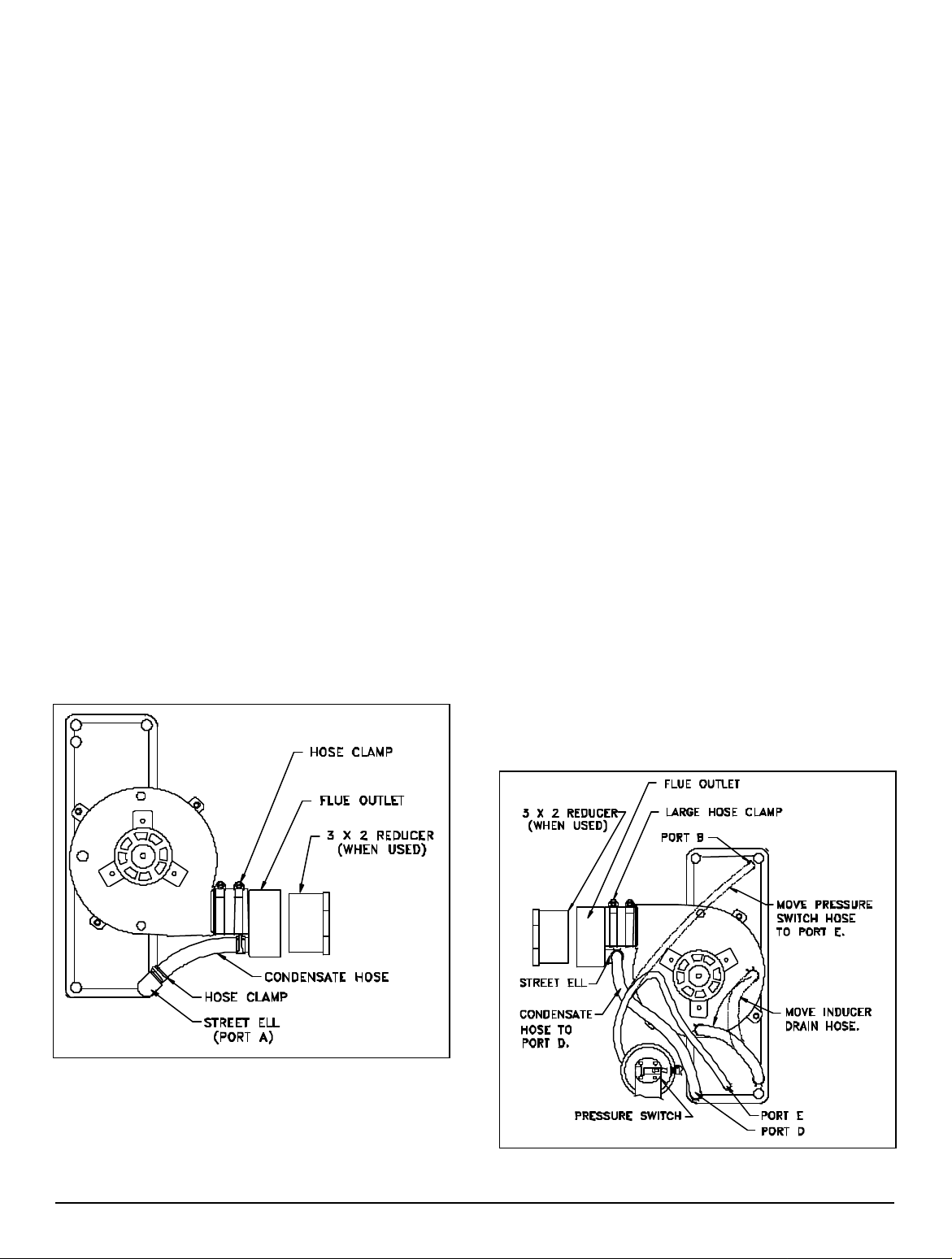

3. Cement 2” PVC pipe, 2” PVC elbow, and flue outlet

together as shown in Figure 8. Position flue outlet

such that street ell will be directly below vent elbow.

DIRECT OR NON-DIRECT VENTING?

This furnace may be installed using either direct venting or

non-direct venting.

A direct-vented fu rnace takes all air for combustion directly

into the fu rnace through a pipe from outdoors. To direct

vent this furnace you must install two pipes to the outdoors.

One pipe supplies combustion air that the furnace needs to

operate. The other pipe vents flue gases to the outdoors.

Use direct venting when indoor air may be contaminated

with chemicals such as chlorine, fluorine, bromine or iodine.

When these chemicals are burned with natural gas or

propane gas, acids are produced which may decrease heat

exchanger life. You should also consider direct venting

when furnace is installed in a space with limited combustion

and ventilation air. See “CONFINED SPACE

INSTALLATION” under the “NON-DIRECT VENTING”

instructions.

A non-direct vented furnace takes all air for combustion

from the room in which furnace is installed. Non-direct

venting requires only one pipe for venting the flue gases to

the outdoors but you must make sure there is enough air for

combustion and ventilation.

VENTING INSTRUCTIONS: DOWNFLOW

1. Select venting option from Figure 9 that fits your

installation. Downflow furnaces can be vented through

top or either side. For direct venting, combustion air

can come through top or either side.

2. From parts package find the following parts: section of

2” PVC pipe, 2” PVC elbow, PVC flue outlet fitting, and

1/2” street ell.

Figure 8. Downflow Vent Connection.

4. Cement 1/2” street ell to flue-outlet drain. Position

street ell so that it will be angled down and toward front

of furnace at a 45° angle when assembly is installed in

furnace.

5. Install large hose clamp over rubber coupling on

furnace draft inducer. Do not tighten hose clamp.

6. Push vent assembly into rubber coupling until it

bottoms out and tighten hose clamp securely.

7. From parts package find long condensate hose and

two hose clamps.

8. Attach condensate hose and one hose clamp to

inducer-pan port A, located in upper right-hand corner

of inducer pan. Hose should be curved toward 1/2”

street ell in flue outlet.

9. Attach other end of hose and remaining hose clamp to

1/2” street ell.

10. Some models are shipped with a 3-inch to 2-inch

reducer bush ing. When venting with 2-inch pipe, install

reducer bushing in flue outlet fitting. See Table 1 or

Table 2 for correct vent diameter for your application.

11. Complete installation of venting system with field

supplied parts.

12. Support vent pipe at furnace. Do not allow draft

inducer and rubber coupling to support the weight of

the vent pipe.

Page 8 Installer’s Information Manual

Page 9

Left Vent Top Vent Right Vent

Downflow Position

Top Vent Right Vent

Horizontal Air-Left Position

Top Vent Left Vent

Horizontal Air-Right Position

Figure 9. Venting Options. Dashed lines show optional combustion air pipes for direct venting.

Installer’s Information Manual Page 9

Page 10

VENTING INSTRUCTIONS: HORIZONTAL

AIR-LEFT

1. Select venting option from Figure 9 that fits your

installation. Horizontal furnaces can be vented through

top or through blower end of furnace (in most

applications). For direct ve nting, combustion air can

come through top or bottom.

2. From parts package, get PVC flue outlet fitting and

large hose clamp.

3. Install large hose clamp over rubber coupling on

furnace draft inducer. Do not tighten hose clamp. See

Figure 10.

4. Push flue outlet fitting into rubber coupling until it

bottoms out. Rotate flue outlet fitting until drain is on

bottom as shown in Figure 10. Tighten hose clamp

securely.

5. From parts package, get long condensate hose and

two hose clamps.

6. Long condensate hose must be cut to fit between flue

outlet drain and street ell. Proper length is 6¼ inches

for 17½ or 20½ inch wide furnaces and 8½ inches for

23½ inch wide furnaces.

7. Attach condensate hose and one hose clamp to flue

outlet fitting.

8. From parts package, get 1/2” street ell. Attach hose

and remaining hose clamp to 1/2” street ell. Test fit

street ell and hose assembly to inducer-pan port A,

located in lower right -hand corner of inducer pan. Note

the angle of the street ell.

9. Solvent weld street ell to inducer-pan port A at angle

noted in previous step.

11. Complete installation of venting system with field

supplied parts.

12. Support vent pipe at furnace. Do not allow draft

inducer and rubber coupling to support the weight of

the vent pipe.

VENTING INSTRUCTIONS: HORIZONTAL

AIR-RIGHT

1. Select venting option from Figure 9 that fits your

installation. Horizontal furnaces can be vented through

top or through blower end of furnace (in most

applications). For direct venting, combustion air can

come through top or bottom.

2. Move inducer drain hose from middle drain port of

inducer to inducer drain port at bottom of inducer-located near pressure switch. To do this, remove cap

from inducer drain port near pressure switch. Save

cap. Move hose from middle inducer drain hole to

uncapped port. Install cap on open port.

3. Move pressure switch hose from inducer pan port “B”

to inducer-pan port E. To do this, remove cap from

inducer-pan pressure port E, at pressure switch end of

inducer pan. Save cap. Move h ose from inducer-pan

pressure port B to port E. Install cap on port B.

4. From parts package, get PVC flue outlet and 1/2” street

ell.

5. Cement 1/2” street ell to flue-outlet drain. Position

street ell so that it will be angled down and toward front

of furnace at a 45° angle when assembly is installed in

furnace.

6. Install large hose clamp over rubber coupling on

furnace draft inducer. Do not tighten hose clamp.

7. Push flue outlet into rubber coupling until it bottoms

out. Rotate flue outlet until street ell is on bottom as

shown in Figure 11. Tighten hose clamp securely.

Figure 10. Horizontal Air-Left Vent Connection.

10. Some models are shipped with a 3-inch to 2-inch

reducer bushing. When venting with 2-inch pipe, install

reducer bushing in flue outlet. See Table 1 or Table 2

for correct vent diameter for your application.

Figure 11. Horizontal Air-Right Vent Connection.

Page 10 Installer’s Information Manual

Page 11

8. Move rubber cap from inducer-pan port D (located in

lower left-hand corner) to inducer-pan port A (located in

top left corner).

9. From parts package, get long condensate hose and

two hose clamps.

10. Attach condensate hose and one hose clamp to

inducer-pan port D. Hose should be curved toward

1/2” street ell in flue outlet.

11. Attach hose and remaining hose clamp to 1/2” street

ell. Position hose on street ell so that hose does not

kink. On some models it will be necessary to reduce

condensate hose length for proper fit.

12. Some models are shipped with a 3-inch to 2-inch

reducer bushing. When venting with 2-inch pipe, install

reducer bushing in flue outlet fitting. See venting Table

1 or Table 2 for correct vent diameter for your

application.

13. Complete installation of venting system with field

supplied parts.

14. Support vent pipe at furnace. Do not allow draft

inducer and rubber coupling to support the weight of

the vent pipe.

Note that some of the larger furnace models may require a

high altitude pressure switch at elevations between 3000

and 6000 feet. For example, the table shows that the

126,000 Btu/hr model may need a high altitude pressure

switch when installed at elevations between 3000 and 4000

feet. Above 4000 feet, this model requires a high altitude

switch for all installations.

All furnace models require the high altitude pressure switch

when installed at elevations above 6000 feet.

The high altitude pressure switch is supplied with the LP

Conversion Kit #4226000 and the Natural Gas Conversion

Kit #4225600. These kits also contain the other

components required for furnace installation at high

elevations.

DIRECT VENTING (two-pipe system)

DETERMINING VENT LENGTH

See Table 1 for maximum vent and combustion-air pipe

length. Include any termination elbows when determining

maximum allowable vent length. Minimum vent length is

five feet with 1 elbow.

Table 1 shows the maximum allowable pipe lengths for

direct vent systems depending on:

?? altitude (elevation) of the installation

?? gas input rating of furnace

?? diameter of the air and vent pipes

?? number of elbows

(a) (b)

Figure 12. (a) Sweep 90? Elbow. (b) Hard 90? Elbow.

NOTE: Table 1 assumes Sweep 90? elbows like that in

Figure 12a. If using Hard 90? elbows similar to the one in

Figure 12b, decrease the vent length by 3 feet for every

elbow used.

When using a concentric vent kit the following exceptions

apply:

?? 90,000 BTU input furnaces must be vented with 3-inch

pipe.

?? For 108,000 BTU input furnaces, reduce the maximum

vent length by 5 feet when 2 sweep elbows are used,

10 feet when 3 sweep elbows are used, 15 feet when 4

sweep elbows are used and so on. For hard 90°

elbows reduce vent length in 8-foot intervals.

?? 126,000 BTU input furnaces may not be vented using a

concentric vent .

Installer’s Information Manual Page 11

Page 12

Table 1. Maximum Pipe Length--Direct Vent

54,000

2" 40 40 40 40 40 40 40 40

72,000

2" 40 40 37 33 30 27 23 20

72,000

3" 40 40 40 40 40 40 40 40 0'-1000' 90,000

2" 30 26 22 19 15 11 - -

90,000

3" 40 40 40 40 40 40 40 40

108,000

3" 40 40 40 40 40 40 40 40

126,000

3" 40 40 40 40 35 30 25 20

54,000

2" 40 40 40 40 40 40 40 40

72,000

2" 40 37 33 29 25 21 19 15

72,000

3" 40 40 40 40 40 40 40 40 1001'-2000' 90,000

2" 25 22 19 16 12 - - -

90,000

3" 40 40 40 40 40 40 40 40

108,000

3" 40 40 40 40 40 40 40 40

126,000

3" 40 38 33 28 22 16 11 -

54,000

2" 40 40 40 40 40 40 40 40

72,000

2" 35 33 29 25 21 17 13 -

72,000

3" 40 40 40 40 40 40 40 40 2001'-3000' 90,000

2" 22 19 16 14 - - - -

90,000

3" 40 40 40 40 40 40 40 40

108,000

3" 40 40 40 40 40 40 40 40

126,000

3" 35 30 25 20 15 10 - -

54,000

2" 40 40 40 40 40 40 40 40

72,000

2" 30 28 26 24 22 20 18 17

72,000

3" 40 40 40 40 40 40 40 40

3001'-4000' 90,000

2" 15 13 11 - - - - -

90,000

3" 40 40 40 40 40 40 40 40

108,000

3" 40 40 40 40 40 40 40 40

126,000

3" 30 25 20 15 10 - - -

126,000

3" 40 40 40 40 35 30 25 20

See Note 2

54,000

2" 40 40 40 40 40 40 40 40

72,000

2" 26 22 17 14 12 - - -

72,000

3" 40 40 40 40 40 40 40 40 4001'-5000' 90,000

3" 40 40 40 40 40 40 40 40

108,000

3" 40 40 40 35 30 25 20 15

108,000

3" 40 40 40 40 40 40 40 40

See Note 2

126,000

3" 40 40 40 40 35 30 25 20

54,000

2" 40 40 40 40 40 40 40 40

72,000

2" 21 18 14 11 - - - -

72,000

3" 40 40 40 40 40 40 40 40 5001'-6000' 90,000

3" 40 40 40 40 40 40 40 40

108,000

3" 40 35 30 25 20 15 10 -

108,000

3" 40 40 40 40 40 40 40 40

See Note 2

126,000

3" 40 40 40 40 35 30 25 20

54,000

2" 40 40 40 40 40 40 40 40

72,000

2" 40 40 40 40 36 32 28 24

72,000

3" 40 40 40 40 40 40 40 40 6001'-7000' 90,000

3" 40 40 40 40 40 40 40 40

See Note 2

108,000

3" 40 40 40 40 40 40 40 40 126,000

3" 40 40 40 40 35 30 25 20

54,000

2" 40 40 40 40 40 40 40 40

72,000

2" 40 40 40 37 35 32 28 24

72,000

3" 40 40 40 40 40 40 40 40 7001'-8000' 90,000

3" 40 40 40 40 40 40 40 40

See Note 2

108,000

3" 40 40 40 40 40 40 40 40

126,0

00 3" 40 40 40 40 35 30 25 20

54,000

2" 40 40 40 40 40 40 40 40

72,000

2" 40 40 37 34 31 28 24 21

72,000

3" 40 40 40 40 40 40 40 40 8001'-9000' 90,000

3" 40 40 40 40 40 40 40 40

See Note 2

108,000

3" 40 40 40 40 40 40 40 40

126,000

3" 40 40 40 35 30 25 20 15

54,000

2" 40 40 40 40 40 40 40 40

72,000

2" 40 37 35 31 27 24 21 18

72,000

3" 40 40 40 40 40 40 40 40 9001'-10000'

90,000

3" 40 40 40 40 40 40 40 40

See Note 2

108,000

3" 40 40 40 40 40 40 40 40

126,000

3" 40 35 30 25 20 15 - -

ALLOWABLE PIPE LENGTH (feet of each pipe)

ALTITUDE FURNACE PIPE

NUMBER OF SWEEP ELBOWS (each pipe) (SEE NOTE 1)

INPUT DIA. 1 2 3 4 5 6 7 8

NOTE 1: The table assumes the use of sweep elbows. If using hard 90? elbows, the vent length should be decreased

anadditional 3 feet for every elbow used.

NOTE 2: The shaded portions of the table require the high altitude pressure switch in order to operate the furnace at the

listed vent lengths.

Page 12 Installer’s Information Manual

Page 13

DIRECT-VENT TERMINATION

You may terminate vent and combustion air pipes either

vertically (through the roof) or horizontally (through a

sidewall). Vertical (through the roof) venting is preferred

because it offers protection from pipe damage and

condensate damage. You may use concentric vent

termination except on 126,000 BTU input furnaces. Follow

the instructions supplied with the concentric-vent kit.

For vertical direct venting, combustion-air-inlet pipe must

terminate next to vent pipe and 12 inches above roof (18” in

Canada) or highest expected snow accumulation. Extend

vent pipe at least 6 inches above combustion air inlet. See

Figure 13a for vertical direct vent termination.

Note: When venting with 3-inch pipe, a 3” X 2” reducer must

be used. Locate reducer as close as possible to

combustion-air inlet. You may use up to 20” of 2-inch pipe.

Figure 14. Combustion-Air Pipe Connection to Furnace for

Direct Vent.

NON-DIRECT VENTING (one pipe system)

Figure 13a. Vertical Termination for Direct Venting.

Combustion-air-inlet termination must always be pointed

downward to keep out rain and snow. Furnace will not

operate properly with water in combustion compartme nt.

Note: When properly installed, vent pipe is designed to

drain condensate and will not be affected by rainwater.

For horizontal direct venting, combustion-air inlet must

terminate next to vent pipe and at least 12 inches above

grade or highest expected snow accumulation. Extend vent

pipe at least 12 inches above combustion-air inlet. See

Figure 13b.

Figure 13b. Horizontal Termination for Direct Venting.

Attach a combustion-air pipe to combustion-air-inlet collar

located on top of furnace burner enclosure. Seal air pipe to

collar with RTV silicone caulk. See Figure 14.

Installer’s Information Manual Page 13

DETERMINING VENT LENGTH

See Table 2 for maximum vent pipe length. Include any

termination elbows when determining maximum allowable

vent length. Minimum pipe length is five feet with 1 elbow.

Table 2 shows the maximum allowable pipe lengths for

non-direct vent systems depending on:

?? altitude (elevation) of the installation

?? gas input rating of furnace

?? diameter of the air and vent pipes

?? number of elbows

Note that some of the larger furnace models may require a

high altitude pressure switch at elevations between 3000

and 6000 feet. For example, the chart shows that the

126,000 Btu/hr model may need a high altitude pressure

switch when installed at elevations between 3000 and 4000

feet. Above 4000 feet, this model requires a high altitude

switch for all installations.

All furnace models require the high altitude pressure switch

when installed at elevations above 6000 feet.

The high altitude pressure switch is supplied with the LP

Conversion Kit #4226000 and the Natural Gas Conversion

Kit #4225600. These kits also contain the other

components required for furnace installation at high

elevations.

NOTE: Table 2 assumes Sweep 90? elbows like that in

Figure 12a. If using Hard 90? elbows similar to the one in

Figure 12b, decrease the vent length by 3 feet for every

elbow used.

Page 14

Table 2. Maximum Pipe Length--Non-Direct Vent

54,000

2"

112 108 104 100 96 92 88 84 72,000

2" 55 51 47 43 39 35 31 27

72,000

3"

150 150 150 150 150 150 150 150 0'-

1000' 90,000

2" 36 32 28 24 20 16 - -

90,000

3"

150 150 150 145 140 135 130 125 108,000

3" 85 80 75 70 65 60 55 50

126,000

3" 55 50 45 40 35 30 25 20

54,000

2" 97 93 90 86 83 80 76 73

72,000

2" 44 40 36 33 30 26 23 19

72,000

3"

150 150 150 150 150 150 150 150

1001'-2000' 90,000 2" 30 26 23 19 16 - - -

90,000

3"

140 135 130 125 120 115 110 105 108,000

3" 75 70 65 60 55 50 45 40

126,000

3" 45 40 35 30 25 20 15 -

54,000

2" 84 81 78 74 71 67 64 61

72,000

2" 37 34 30 27 24 21 18 15

72,000

3"

150 150 150 150 150 150

150 150

2001'-3000' 90,000

2" 24 21 18 14 11 - - -

90,000

3"

125 120 115 110 105 100 95 90 108,000

3" 50 45 40 35 30 25 20 15

126,000

3" 36 31 26 21 16 11 - -

54,000

2" 71 68 64 61 58 55 51 48

72,000

2" 30 27 23 20 17 13

72,000

3" 150 150 150 150 150 150 150 150

3001'-4000' 90,000

2" 19 16 12 - - - - -

90,000

3"

100 95 90 85 80 75 70 65 108,000

3" 37 32 27 22 17 12 - -

126,000

3" 30 25 20 15 10 - - -

126,000

3" 55 50 45 40 35 30 25 20

See Note 2

54,000

2" 57 54 50 47 44 40 36 33

72,000

2" 25 22 19 16 12 - - -

72,000

3"

150 150 150 150 150 150 150 150

4001'-5000' 90,000

3" 85 80 75 70 65 60 55 50

108,000

3" 85 80 75 70 65 60 55 50

See Note 2

126,000

3" 55 50 45 40 35 30 25 20

54,000

2" 43 40 37 33 30 27 24 20

72,000

2" 21 18 14 11 - - - -

72,000

3"

150 150 150 150 150 150 150 150

5001'-6000' 90,000

3" 70 65 60 55 50 45 40 35

108,000

3" 85 80 75 70 65 60 55 50

See Note 2

126,000

3" 55 50 45 40 35 30 25 20

54,000

2"

110 106 104 100 96 92 88 84

72,000

2" 50 46 43 40 36 32 29 25

72,000

3"

150 150 150 150 150 150 150 150

6001'-7000' 90,000

3"

150 150 150 145 140 135 130 125 See Note 2

108,000

3" 85 80 75 70 65 60 55 50

126,000

3" 55 50 45 40 35 30 25 20

54,000

2" 97 93 90 86 83 80 76 73

72,000

2" 50 46 43 40 36 32 29 25

72,000

3"

150 150 150 150 150 150 150 150

7001'-8000' 90,000

3"

150 150 150 145 140 135 130 125 See Note 2

108,000

3" 85 80 75 70 65 60 55 50

126,000

3" 53 48 43 38 33 28 23 18

54,000

2" 84 81 78 74 71 67 64 61

72,000

2" 41 38 34 31 28 24 21 17

72,000

3"

150 150 150 150 150 150 150 150

8001'-9000' 90,000

3"

150 150 150 145 140 135 130 125 See Note 2

108,000

3" 70 65 60 55 50 45 40 35

126,000

3" 40 35 30 25 20 15 - -

54,000

2" 71 68 64 61 58 55 51 48

72,000

2" 35 31 28 25 21 18 15 -

72,000

3"

150 150 150 150 150 150 150 150

9001'-10000'

90,000

3"

150 150 150 145 140 135 130 125 See Note 2

108,000

3" 55 50 45 40 35 30 25 20 126,000

3" 31 26 21 16 11 - - -

ALLOWABLE PIPE LENGTH (feet)

ALTITUDE FURNACE PIPE

NUMBER OF SWEEP ELBOWS (SEE NOTE 1)

INPUT DIA. 1 2 3 4 5 6 7 8

NOTE 1: The table assumes the use of sweep elbows. If using hard 90? elbows, the vent length should be decreased an

additional 3 feet for every elbow used.

NOTE 2: The shaded portions of the table require the high altit ude pressure switch in order to operate the furnace at the listed

vent lengths.

Page 14 Installer’s Information Manual

Page 15

NON-DIRECT VENT TERMINATION

You may terminate vent pipe either vertically (through the

roof) or horizontally (through a sidewall). Vertical (through

the roof) venting is preferred because it offers protection

from pipe damage and is less likely to cause condensate

damage.

For vertical non-direct venting, extend PVC vent pipe at

least 12 inches above roof or average snow accumulation.

In Canada, vent pipe must extend at least 18 inches above

roof. See Figure 15.

Figure 15. Vertical Termination for Non-Direct Venting.

Note: When properly installed, vent system is designed to

drain condensate and will not be affected by rainwater.

For horizontal non-direct venting, extend PVC pipe at least

6 inches from structure and 12 inches above grade or

above average snow accumulation. See Figure 16.

there must be a positive seal between furnace and returnair duct to avoid pulling air from furnace room.

Provide for adequate combustion and ventilation air in

accordance with Section 5.3, Air for Combustion and

Ventilation, of the National Fuel Gas Code, ANSI

Z223.1/NFPA 54, or Sections 7.2, 7.3 or 7.4 of CAN/CGA

B149 Installation Codes, or applicable provisions of local

building codes.

WARNING : Furnaces and any other fuel burning

appliances must have enough fresh air for proper

combustion. Lack of adequate combustion air could cause

the fu rnace to produce carbon monoxide and may result in

nausea or asphyxiation.

Excessive exposure to air contaminated with chlorine,

fluorine, bromine and iodine may result in safety and

performance related problems. The following types of

installation may require outdoor air for combustion (or direct

venting) due to chemical exposures:

?? Commercial buildings, repair garages, beauty parlors,

and so on

?? Buildings with indoor pools

?? Furnaces installed in laundry rooms

?? Furnaces installed in hobby or craft rooms

?? Furnaces installed near chemi cal storage rooms

?? Furnaces installed near exhaust fans which vent the

above areas

Exposure to the following substances in the combustion air

supply may also require outdoor air for combustion:

?? Aerosols

?? Permanent wave solutions

?? Chlorinated waxes, bleaches and cleaners

?? Cat litter

?? Chlorine-based swimming pool chemicals

?? Cleaning solvents

?? Paint removers and varnishes

?? Adhesives

?? Anti-static fabric softeners

?? Most refrigerants

WARNING : Combustion air that contains chlorine,

fluorine, bromine or iodine could cause corrosion in heat

Figure 16. Horizontal Termination for Non-Direct Venting.

exchanger and may result in nausea or death by

asphyxiation.

UNCONFINED SPACE INSTALLATION (non-direct

COMBUSTION AND VENTILATION AIR (non-direct

vent)

The total amount of combustion and ventilation air provided

within the building must equal the requirements of all gas

appliances in the building. You must also allow for

reduction of air available for combustion and ventilation

caused by exhaust fans, range hoods and fireplaces.

Sufficient air must be provided to ensure there will not be a

negative pressure in fu rnace room or space. In addition,

Installer’s Information Manual Page 15

vent)

The National Fuel Gas Code, ANSI Z223.1/NFPA 54 and

CAN/CGA B149 Installation Codes do not require that you

make special provisions for combustion and ventilation air

when fu rnace is in an "unconfined space" and building is

not of "unusually tight construction".

?? "Unconfined spaces" have a volume of at least 50

cubic feet per 1000 Btu per hour combined input rating

Page 16

of all appliances installed in the space. For example: a

100,000 Btu/hr furnace and a 40,000 Btu/hr water

heater would require a volume of at least 140,000 X 50

÷ 1,000 or 7,000 cubic feet.

?? "Unusually tight construction" means windows and

doors are either tight fitting or are sealed construction

and that walls are covered with a continuous, sealed

vapor barrier and drywall or similar materials having

sealed joints.

If you meet the volume requirements for unconfined space,

the building is not of unusually tight construction and there

are no airborne contaminants, as listed above, you may

install this fu rnace without making special provisions for

combustion and ventilation air. Otherwise, follow the

instructions for "confined space installation" below or direct

vent the furnace using two pipes.

CONFINED SPACE INSTALLATION (non-direct

vent)

?? A 54,000 Btu/hr furnace and a 40,000 Btu/hr water

heater would require the minimum free area openings

of 100 square inches.

Figure 17. Confined Space, All Air From Inside The

Building.

A non-direct vented fu rnace installed in a confined space

must take combustion and ventilation air from an

unconfined space within the building or from outdoors.

However, if the building is of unusually tight construction all

combustion air must come from outdoors. Also, if return air

is taken directly from a hallway or space next to fu rnace

that communicates with furnace spaces, all combustion air

must come from outdoors.

WARNING : You must provide permanent air

openings to a confined furnace installation space from

another area as described below. Failure to do so could

cause inadequate combustion and ventilation air and may

result in nausea or death by asphyxiation.

ALL COMBUSTION AND VENTILATION AIR FROM

INSIDE THE BUILDING

The confined furnace space must be provided with two

permanent openings to an additional room of sufficient

volume so that the combined volumes of the spaces meet

the criteria above for an unconfined space not of unusually

tight construction. The total input of all gas appliances

within the combined space must be considered in making

this determination.

ALL COMBUSTION AND VENTILATION AIR FROM

OUTDOORS

The fu rnace space mus t be provided with two permanent

air openings communicating directly, or by ducts, with the

outdoors or spaces that freely access the outdoors. Wellventilated attics or crawl spaces usually satisfy this

requirement. These openings will give furnace free access

to fresh air for combustion and ventilation.

You must provide air sufficient for all gas appliances within

furnace space. Locate one combustion and ventilation air

opening within 12 inches of top of fu rnace space. Locate

another within 12 inches of bottom of furnace space.

Ducts that supply air from outdoors must have the same

cross-sectional area as the free area of openings to which

they connect.

Each opening must have minimum free area of one square

inch per 1,000 Btu per hour of the total combined input

rating of all gas appliances within the confined furnace

space, but not less than 100 square inches. One opening

must be within 12 inches of the top and one opening within

12 inches of the bottom of the furnace space. The shortest

side of each air opening must be at least 3 inches long.

See Figure 17.

For example:

?? A 90,000 Btu/hr furnace and a 40,000 Btu/hr water

heater would require free area openings of 130,000 ÷

1,000 or 130 square inches.

Page 16 Installer’s Information Manual

Figure 18. All Air Directly From Spaces That Freely Access

The Outdoors.

When directly communicating with the outdoors, each

opening must have a minimum free area of one square inch

per 4,000 Btu per hour of total combined input rating of all

gas appliances within furnace space.

Page 17

For example: A 108,000 Btu per hour furnace requires two

openings of at least 108,000 ÷ 4,000 or 27 square inches.

See Figure 18 and Table 3.

Table 3. Free Opening Area Based On One Square Inch

Per 4000 Btu/hr.

TOTAL

INPUT

(Btu/hr)

54,000 13.5 5 78,000

72,000 18 5 78,000

90,000 22.5 6 113,000

108,000 27 6 113,000

126,000 31.5 7 153,000

144,000 36 7 153,000

REQUIRED

FREE

AREA PER

OPENING

(square inches)

MINIMUM

ROUND PIPE

DIAMETER

(inches)

MAXIMUM

INPUT FOR

GIVEN PIPE

DIAMETER

(Btu/hr)

When communicating with the outdoors through vertical

ducts, openings and ducts must have a minimum free area

of one square inch per 4,000 Btu per hour of total combined

input rating of all gas appliances within furnace space. See

Figure 19 and Table 3.

Figure 20 and Table 4.

Table 4. Free Opening Area Based On One Square Inch

Per 2000 Btu/hr.

TOTAL

INPUT

(Btu/hr)

54,000 27 6 56,000

72,000 36 7 76,000

90,000 45 8 100,000

108,000 54 9 127,000

126,000 63 9 127,000

144,000 72 10 157,000

REQUIRED

FREE

AREA PER

OPENING

(square inches)

MINIMUM

ROUND

PIPE

DIAMETER.

(inches)

MAXIMUM

INPUT FOR

GIVEN PIPE

DIAMETER

(Btu/hr)

Example: Furnace is 90,000 Btu per hour input and is to be

installed in a confined space that contains no other gas

appliances. Rectangular combustion and ventilation air

ducts will run horizontally from outdoors to furnace space.

Calculate the free area required.

Because combustion and ventilation air ducts run

horizontally, allow 2,000 Btu per hour.

Furnace input (Btu/hr) = Free area required

2,000 Btu/hr

per square inch

Figure 19. All Air Through Vertical Ducts From Spaces

That Freely Access The Outdoors.

Figure 20. All Air From The Outdoors Through Horizontal

Ducts.

When communicating with the outdoors through horizontal

ducts, openings and ducts must have a minimum free area

of one square inch per 2,000 Btu per hour of total combined

input rating of all gas appliances within furnace space. See

90,000 = 45 square inches

2,000

Each duct must have a minimum cross sectional area of 45

square inches.

SECTION 5. CONDENSATE DRAIN

This fu rnace produces water as a product of combustion.

Much of this water condenses on the stainless steel tubing

of the heat exchanger and in the vent system. This water

(referred to as condensate) must be drained from the

furnace into a household drain. The following notes should

be considered when connecting condensate drain:

?? The furnace’s drain trap must be primed. This is easily

done by pouring a few cups of water into fu rnace vent

pipe after drain installation is complete.

?? Field installed drain line from furnace must flow down

hill from furnace trap.

?? A frozen or blocked drain line will cause furnace

shutdown and “no-heat” complaints. Protect drain trap

and drain tubing from freezing.

?? When a condensate pump is used, select a pump

designed for furnace condensate.

CAUTION: Make sure that drain connections do not leak.

Air leaks around drain hoses will prevent furnace from

draining and cause the furnace to shutoff. Make sure all

hos e clamps are installed correctly.

Installer’s Information Manual Page 17

Page 18

DRAIN TRAP INSTRUCTIONS-DOWNFLOW POSITION

1. Select drain location option from Figure 21 that best fits

your installation. In downflow position, condensate trap

can be mounted for draining through either side of

furnace.

2. From parts package find the following parts:

condensate drain trap, 8 1/2” section of 13/16” OD

drain hose, and two small hose clamps.

3. From inside of casing, insert drain trap through hole in

side of casing, port B end first. Slide trap down with

casing between first set of guides. Trap will protrude

from casing about 1 inch with port B pointed down.

Port A of trap will be inside of casing and pointed up.

4. Attach condensate hose and one hose clamp to port A

of drain trap. Attach other end of condensate hose and

hose clamp to inducer-pan drain port. For right-side

drain, use inducer-pan port C, located in lower righthand corner of inducer pan. For left-side drain, move

rubber cap from inducer-pan port F, (located in lower

left-hand corner) to port C. Attach condensate hose to

port F.

2. From parts package find the following parts:

condensate drain trap, 8 1/2” section of 13/16” OD

drain hose, and two small hose clamps.

3. From underside of casing, insert drain trap through

hole in casing, port B end first. Slide trap toward

inducer pan with casing between trap mounting guides.

Use first set of guides for 17 1/2” and 23 1/2” wide

models. Use second set of guides for 20 1/2” wide

models. Trap will protrude into casing with port B

pointed toward inducer-pan-drain port C. Port A of trap

will be outside of casing and pointed toward front of

furnace.

4. Cut condensate hose to a length of 4 1/2 inches.

Attach hose and one hose clamp to port B of drain trap.

Attach other end of condensate hose and hose clamp

to inducer pan drain port C.

5. Complete installation of condensate drain system from

condensate trap (port A) with field supplied parts.

Figure 22. Horizontal Air-Left Drain-Trap Installation.

DRAIN TRAP INSTRUCTIONS-HORIZONTAL AIR-RIGHT POSITION

Figure 21. Downflow Drain-Trap Installation.

5. Complete installation of condensate drain system from

condensate trap (port B) with field supplied parts.

1. See Figure 23 for drain trap location for your

installation. In horizontal positions, condensate drain

trap must be mounted through bottom side of furnace.

2. From parts package find the following parts:

condensate drain trap, 8 1/2” section of 13/16” OD

drain hose, and two small hose clamps.

DRAIN TRAP INSTRUCTIONS-HORIZONTAL AIR-LEFT POSITION

1. See Figure 22 for drain trap location for your

installation. In horizontal positions, condensate drain

trap must be mounted through bottom side of furnace.

Page 18 Installer’s Information Manual

Page 19

Figure 23. Horizontal Air-Right Drain-Trap Installation

3. Move cap from inducer-pan port F, located in lower

right-hand corner of inducer pan, to port C, located in

upper right -hand corner of inducer pan.

4. From underside of casing, insert drain trap through

hole in casing, port B end first. Slide trap toward

inducer pan with casing between trap mounting guides.

Use first set of guides for 17 1/2” and 23 1/2” wide

models. Use second set of guides for 20 1/2” wide

models. Trap will protrude into casing with port B

pointed toward inducer-pan-drain port F. Port A of trap

will be outside of casing and pointed toward front of

furnace.

Plan fu rnace gas supply piping so it will not interfere with

removal of burner assembly, front door or blower door for

servicing.

Make sure gas piping is large enough for all appliances

connected to it to operate at once without lowering gas

supply pressure. Failure to do so could cause lighting or

burning problems on any of the appliances.

Always use a pipe thread compound that is resistant to

propane (LP) gas solvent action. Sparingly apply thread

compound to all joints on male threads only, starting two

threads from the end.

INSTALLATION

Gas supply piping can be installed from either side of

furnace casing. Install gas supply piping according to

Figure 24 and the following instructions.

1. Install a 4-inch long x 1/2” NPT black-iron pipe nipple

through gas entry grommet and into gas -control inlet

elbow. Install a black iron pipe elbow on 4-inch nipple.

Tighten gas tight. Do not over tighten.

2. Install a ground-joint union and a drip leg immediately

upstream of the fu rnace. Ground-joint union allows

easy servicing of burner assembly and fu rnace gas

control. Ground-joint union must be listed by a

nationally recognized testing laboratory.

5. Cut condensate hose to a length of 4 1/2 inches.

Attach hose and one hose clamp to port B of drain trap.

Attach other end of condensate hose and hose clamp

to inducer pan drain port F.

6. Complete installation of condensate drain system from

condensate trap (port A) with field supplied parts.

SECTION 6. INSTALLING GAS

PIPING

PREPARATION

Refer to the current National Fuel Gas Code ANSI

Z223.1/NFPA 54 or CAN/CGA B149 Installation Codes and

local codes for gas piping requirements and sizing. Pipe

size running to furnace depends on:

?? Length of pipe

?? Number of fittings

?? Specific gravity of gas

?? Input requirements (Btu per hour) of all gas-fired

appliances attached to same main supply line.

Installer’s Information Manual Page 19

Figure 24. Gas Line Installation (downflow position shown).

3. Install a manual “equipment” shut-off valve in gas

supply line immediately upstream of ground-joint union.

Equipment shut -off valve must be listed by a nationally

recognized testing laboratory.

TESTING FOR LEAKS

Isolate furnace and its gas control from gas supply line

during leak checks. Gas-supply line test pressure

determines how you isolate gas control.

Page 20

The furnace and its gas control must be disconnected from

gas supply piping system at ground joint union during any

pressure testing of the system at test pressures greater

than 1/2 psi (14 inches W.C.).

The furnace must be isolated from gas supply piping

system by tu rning off equipment shut-off valve during any

pressure testing of the system at test pressures equal to or

less than 1/2 psi (14 inches W.C.).

WARNING : When test pressure is above 1/2 psi

(14 inches W.C.), completely disconnect fu rnace and gas

control from gas supply line. Failure to isolate furnace and

gas control from test pressure could damage them, causing

gas to leak, resulting in fire or explosion.

Use a commercial soap solution made to detect leaks and

check all gas piping connections. Bubbles indicate gas

leakage. Seal all leaks before proceeding.

SECTION 7. INSTALLING

ELECTRICAL WIRING

CAUTION: Label all wires prior to disconnection when

servicing controls. Wiring errors can cause improper and

dangerous operation. When replacing original wire, use

same type, color, and size wire. Remember to renumber

wire ends. Verify proper operation after servicing.

Figure 25. Field Wiring Diagram.

115 VOLT WIRING

Wire furnace according to the Field Wiring Diagram shown

in Figure 25, local codes, and current National Electrical

Code ANSI/NFPA 70 or Canadian Electrical Code CSA

C22.1. Also, see Furnace Wiring Diagram in Figure 26.

Install proper electrical grounding by attaching grounding

source to green wire in fu rnace junction box. Follow local

codes or in the absence of local codes, the current National

Electrical Code ANSI/NFPA 70 or Canadian Electrical Code

CSA C22.1.

WARNING : Failure to provide a proper electrical

ground could result in electric shock or fire.

Provide fu rnace with its own separate electrical circuit and

means of circuit protection. Furnace must have an

electrical disconnect switch located at furnace.

WARNING : Failure to provide the above shut-off

means could result in electrical shock or fire.

Use electrical wiring that meets current National Electrical

Code ANSI/NFPA 70 or Canadian Electrical Code CSA

C22.1 and local codes. Use Type T (63 degrees C rise)

wire or equivalent.

24 VOLT WIRING

Select a location for room thermostat on a draft-free interior

wall that is away from supply and return air registers, lights,

television, direct sunlight, or other heat sources.

Install thermo stat following field-wiring diagram in Figure 25

and thermostat manufacturer's instructions. Thermostat

wire should be 18 AWG wire for best results.

NOTE: For proper cooling operation, “Y” wire must be

connected to Fan Timer. “Y” wire controls cooling

speed blower operation.

Set the thermostat's heat anticipator following instructions

provided with thermostat. This furnace will have heat

anticipator current of approximately 0.4 amps.

CAUTION: 24 VAC accessories that draw power from the

furnace's transformer should not be installed on this

furnace. Addition of such accessories may cause improper

furnace operation and limit transformer life.

Page 20 Installer’s Information Manual

Page 21

SECTION 8. SEQUENCE OF

OPERATION

HEATING MODE

1. Thermostat calls for heat ("R" and "W" terminals

connected). Fan Timer verifies that burner limits,

primary limit and pressure switch are in normally

closed (NC) position.

2. Draft-inducer relay is energized and draft inducer motor

starts. Pressure switch normally-open contacts close

after a short delay, energizing gas control.

3. Gas control provides power to igniter and pilot valve to

light pilot. After proving pilot flame, the main valve

opens and igniter turns off.

NOTE: If the gas control does not sense a pilot flame

within 30 seconds, it will turn off the igniter while continuing

to purge the gas line. After 30 seconds, the igniter will turn

on again. If a pilot is not sensed in the next 30 seconds,

the gas control will turn off for 5 minutes. This sequence

will continue as long as there is a call for heat.

4. Fan Timer energizes main blower in 30 seconds.

5. After thermostat is satisfied, gas control is deenergized. After a 5 second post-purge, draft inducer

de-energizes and retu rns pressure switch to normally

closed (NC) position.

6. Main blower remains energized for 60 to 180 seconds

depending on heating blower off-delay setting.

NOTE: This fu rnace will lock-out if the main blower fails in

heating mode. During lock-out, the Fan Timer's diagnostic

light signal will be 4 flash es. The furnace's Fan Timer can

be reset by cycling power to furnace.

NOTE: On each heating cycle, this fu rnace verifies that the

pressure switch did not stick closed on the previous cycle.

This condition is detected by checking the pressure switch's

normally closed circuit. If the normally closed circuit is

open, furnace will not operate and the Fan Timer's

diagnostic light signal will be 3 flashes.

CONTINUOUS LOW-SPEED FAN OPTION

Some models are equipped with a fan timer that allows

continuous low-speed fan as an option. When available,

this option can be used to operate the blower on low speed

anytime the blower is not otherwise running on heating or

cooling speed. These models do not have electronic air

cleaner terminals on the fan timer.

To use this option, follow these steps:

1. Disconnect electrical power

2. Remove insulator cap from “CONT” terminal on Fan

Timer.

3. Plug blower low-speed wire (red wire) into “CONT”

terminal.

4. Place insulator cap on “UNUSED MOTOR LEAD”

terminal on Fan Timer.

5. Reconnect power. Motor will start on low speed

immediately.

ELECTRONIC AIR CLEANER OPTION

For models with Electronic Air-Cleaner (EAC) terminals, the

Fan Timer "EAC" terminals are energized with 115 VAC

when the main blower is energized. "EAC" terminals are

1/4 inch quick connect tabs located under breakaway

covers. Use insulated quick connects when connecting to

"EAC" terminals. Limit total "EAC" current plus main blower

current to 15 amps max.

HUMIDIFIER

Fan Timer "HUM" terminals are energized with 115 VAC (1

amp. Max.) when draft inducer is energized. "HUM"

terminals are 1/4-inch quick connect ta bs located under

breakaway covers. Use insulated quick connects when

connecting to "HUM" terminals.

BURNER LIMIT CIRCUIT OPEN

COOLING MODE

Thermostat calls for cooling ("R", "Y" and "G" terminals

connected). Condensing unit contactor closes, energizing

condensing unit. Fan Timer energizes main blower on

cooling speed after a short delay. After thermostat is

satisfied, condensing unit contactor is de-energized. Main

blower remains energized for 60 seconds.

CONSTANT FAN MODE

Thermostat calls for constant fan ("R" and "G" terminals

connected). Fan Timer energizes main blower on heating

speed.

A call for cooling, while in constant fan mode, causes main

blower to change from heating to cooling speed. Sixty

seconds after the call for cooling mode ends, main blower

changes back to heating speed. A call for heating mode

while in constant fan mode does not effect main blower

operation. The main blower runs constantly on heating

speed.

Installer’s Information Manual Page 21

If the burner limit circuit opens: burners turn off, draft

inducer stays on, main blower stays on, there is no 24 volt

power on the "R" terminal and diagnostic light signal is 1

flash.

PRIMARY LIMIT CIRCUIT OPEN

If the primary limit circuit opens: burners turn off, draft

inducer tu rns off, main blower stays on, there is no 24 volt

power on the "R" terminal and the diagnostic light signal is

2 flashes.

VENT LIMIT CIRCUIT OPEN

If vent limit circuit opens: burners turn off, draft inducer runs

during call for heat, and main blower turns off after blower

off-delay. There is 24-volt power on the "R" terminal and no

diagnostic light signal.

Page 22

Figure 26. Furnace Wiring Diagram.

Page 22 Installer’s Information Manual

Page 23

SECTION 9. INSTALLING DUCT

SYSTEM

Properly size duct system based on heat -loss and heat -gain

calculations to ensure good heating and cooling

installations, potentially fewer call-backs, and delivery of

required circulating air. Install duct system to meet current

Standard for Installations of Warm Air Heating and Air

Systems ASHRAE/NFPA 90 and local codes.

CAUTION: Failure to follow these standards could reduce

airflow or increase air leakage, resulting in reduced system

performance or furnace damage.

Note: A combustible floor base, available from the

manufacturer, is required for downflow furnace installation

on wood flooring.

On fu rnaces not equipped with a cooling coil, a removable

access panel that is large enough to allow viewing of the

heat exchanger should be provided in the supply duct. The

access panel should be accessible when the fu rnace is

installed. Seal access-panel cover to prev ent leaks.

If you install furnace in horizontal position with a cooling

coil, an eighteen-inch transition between furnace and

cooling coil should be used to allow free airflow into the coil.

Also, consult cooling coil installation instructions.

Design duct system so furnace will operate at a static

pressure of less than 0.50 inches W.C. on high blower

speed. This static pressure limitation includes the total

pressure losses on both supply air side and return air side

of system. Supply side pressure loss includes cooling coil,

ducts and room registers. Return side pressure loss

includes return grilles and ducts. Pressure losses are

calculated based on 400 CFM per ton of cooling.

SUPPLY AIR DUCT WORK

Supply air duct (plenum) connections must be at least as

big as furnace supply opening. Seal supply -air ductwork to

furnace casing, walls, ceilings or floors it passes through.

End ductwork outside furnace space.

See Figure 27 for floor cutout dimensions for combustible

floor base.

RETURN AIR DUCT WORK

When fu rnace is installed so that supply air ducts carry air

to areas outside the space containing the furnace, return air

must be handled by a duct(s) sealed to furnace casing and

terminating outside the space containing furnace.

WARNING : Failure to seal return-air ductwork

could allow combustion products to enter circulating air

stream resulting in injury or death by asphyxiation.

In downflow position, return-air duct must have a minimum

inside depth of 19-7/8 inches for filters to fit. See Figure 28.

Figure 27. Floor Cutout Dimensions.

Installer’s Information Manual Page 23

Figure 28. Downflow Filter Application.

Page 24

DUCT DAMPERS

You may balance airflow with dampers installed in each

branch run duct and adjust for even temperature throughout

the heated space. For proper furnace operation, make sure

of the following:

?? Supply air registers and return air grilles are open;

?? Rugs, carpets, drapes or furniture are clear of registers

and grilles;

?? Size and shape of supply air plenum is correct;

?? Number of supply air ducts is correct.

LOCATION OF COOLING COIL

If fu rnace will share common duct system with a separate

cooling unit, install furnace parallel to or upstream of

cooling unit. This avoids condensation in heating element.

Do not install cooling coil in return-air ductwork. With

parallel flow, dampers must be installed to prevent chilled

air from entering fu rnace. If dampers are not in full heat or

full cool position, furnace or cooling unit must not operate.

SECTION 10. SELECTING AND

INSTALLING FILTERS

Properly installed air filters keep blower motor, blower

wheel and cooling coil (if installed) clean. Filters and filter

mounting hardware are not supplied with this furnace.

Filter system must be field supplied. The manufacturer has

downflow filter kits available.