Page 1

13 & 14 SEER

AIR HANDLER

INSTALLATION & SERVICE MANUAL

MODELS: AH2436AE1, AH4260AE1,

AH2436BE1, AH4260BE1

PLEASE READ THESE INSTRUCTIONS PRIOR TO INSTALLATION AND BEFORE

PERFORMING ANY SERVICE OR MAINTENANCE. THESE INSTRUCTIONS MUST

BE LEFT WITH THE USER AND SHOULD BE RETAINED FOR FUTURE

REFERENCE BY QUALIFIED SERVICE PERSONNEL.

: Improper installation, adjustment, alteration, service, or maintenance can

cause injury or property damage. Refer to this manual. For assistance or additional

information consult a qualified installer, service agency, or manufacturer listed below.

THERMO PRODUCTS, LLC.

BOX 217

NORTH JUDSON, IN 46366

PHONE: (574) 896-2133 MADE IN USA

MAC-202

ECN 5320-MA 130307

Page 2

TABLE OF CONTENTS

SECTION BEGINNING PAGE

SAFETY SECTION 1

KNOCKDOWN OF AIR HANDLER 2

REASSEMBLY OF AIR HANDLER 3

SETTING UP THE A-COIL FOR AIR CONDITIONING 4

COUNTERFLOW ORIENTATION 6

INSTALLATION OF HOT WATER COIL 8

BLOWER AIR ADJUSTMENT 9

DUCT SYSTEM 13

DUCT SIZING CHART 14

INDOOR EVAPORATOR COIL 14

TUBING LINE SETS 14

HOW TO MEASURE LIQUID SUB-COOLING 18

MEASURING TEMPERATURE DROP ACROSS THE “A” COIL 19

ELECTRICAL 19

UA ADAPTER CABINET 22

RECOMMENDED SUSPENSION PROCEDURE FOR AH AIR HANDLER 22

ECM TROUBLE SHOOTING 23

TROUBLE SHOOTING CHARTS 26

SEQUENCE OF OPERATION 28

REPLACEMENT PARTS LIST 29

Page 3

1

SAFETY SECTION

This page contains various warnings and cautions found throughout this Service and Installation Manual.

Please read and comply with the statements on the cover and the statements below.

: Improper installation, adjustment, alteration, service, or maintenance can cause injury

or property damage. Refer to this manual. For assistance or additional information consult a

qualified installer, service agency, or manufacturer listed below.

: If drilling or screwing into panel or plate is necessary, make certain drill or screw does not

penetrate into any part of evaporator coil or hot water coil and cause damage. Personal injury and/or

property damage may result.

: Do not use this system if any part has been under water. Immediately call a qualified

service agency to inspect the system and to replace any part of the electrical or control system which has

been under water.

: The cooling and heating coils must be cleaned by a qualified service person.

: This air handler is not to be used to condition during construction.

: When testing electrical equipment, always follow standard electrical procedures and

precautions.

: DO NOT wet electronic components during hydronic testing. Wetting electronic

components may damage circuitry and cause a hazardous situation. Dry moisture from all leads and

terminals if wetting occurs. Wait at least 24 hours for the circuit to fully dry before energizing the system.

: Personal injury or property damage could result from major repair or service of this system

by anyone other than a qualified contractor.

: If you do not follow these instructions exactly an unsafe condition may result causing

personal injury, loss of life or property damage.

Installation and service personnel are required by some states to be licensed. Persons not qualified shall

not install this equipment nor interpret these instructions.

All local codes and regulations take precedence over the instructions in this manual and should be

followed accordingly. In the absence of local codes, installation must conform with these instructions,

regulations of the National Fire Protection Association and provisions of the National Electric Code.

Page 4

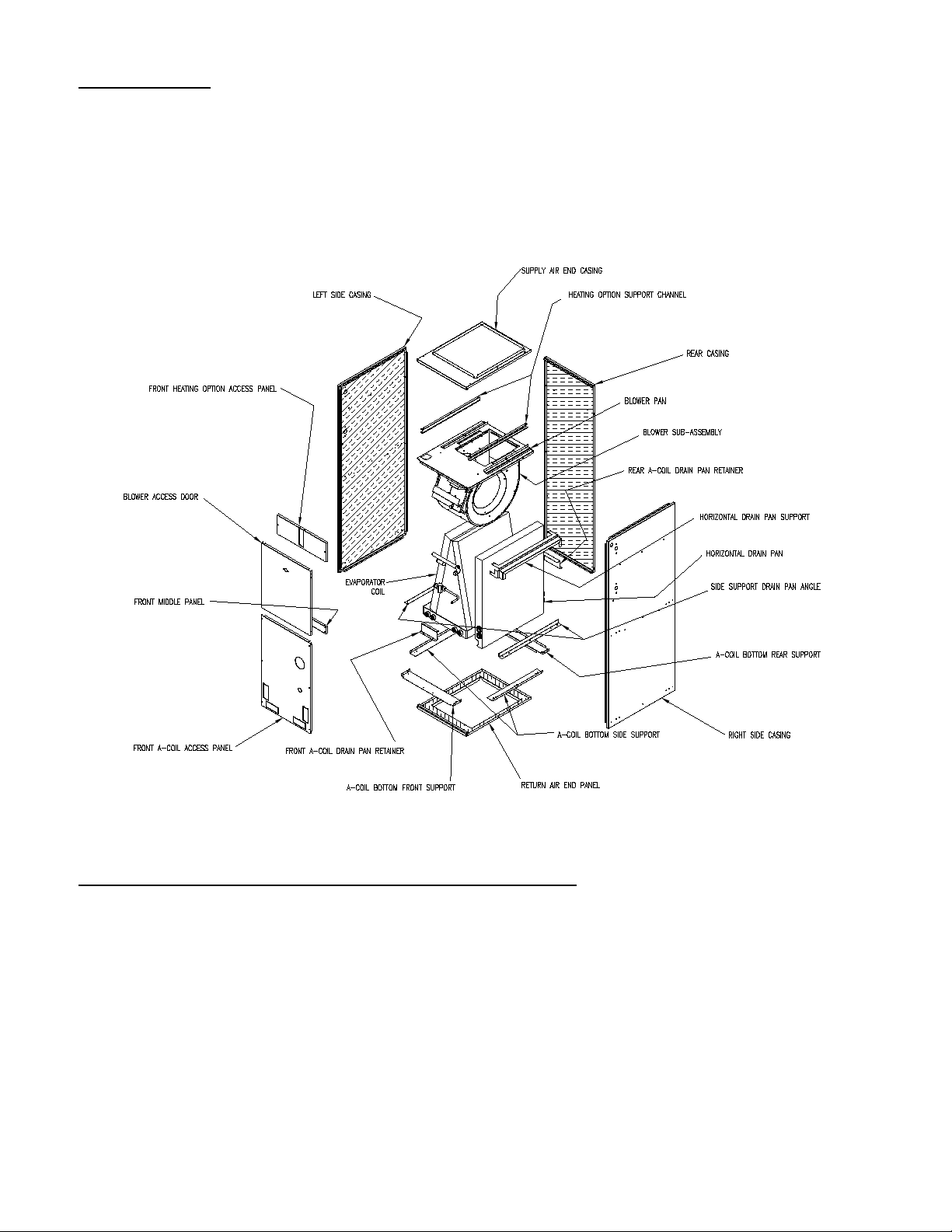

2

AIR HANDLER

Each air handler is shipped with an evaporator coil preinstalled. The AH2436A(B)E1 is shipped with a

13U2436AB14 evaporator coil for 2 to 3 ton operation. The AH4260A(B)E1is shipped with a

13U4848AH20 evaporator coil for 3 to 5 ton operation.

The construction of the air handler permits easy knockdown and reassembly. See Figure A & B.

Figure A.

FOLLOW THESE STEPS FOR KNOCKDOWN OF AH2436:

1. Start with unit setting in a vertical position (Figure A).

2. Remove blower access door.

3. Remove screws from front a-coil access panel, front heating option access panel, front middle panel

and supply air end casing.

4. Remove the front A-coil drain pan retainer and the horizontal drain pan support shipping screw(s)

from the right side casing.

5. Remove the evaporator a-coil assembly.

6. Remove the side support drain pan angles and A-coil bottom front and rear supports.

7. Disconnect power leads and unplug circulation pump connector from the blower control board.

8. Remove the screws that secure the blower assembly to the blower pan and pull blower sub-assembly

out the front of the unit.

Page 5

3

9. Remove screws that secure the blower pan to the side & rear casings.

10. Push the front edges of the side casings slightly apart and remove the blower pan.

11. Remove screws from the return air end panel and side & rear casings.

12. Remove side & rear casings from the return air end panel.

REASSEMBLY OF AH2436

To reassemble the air handler, reverse steps above starting with number 12.

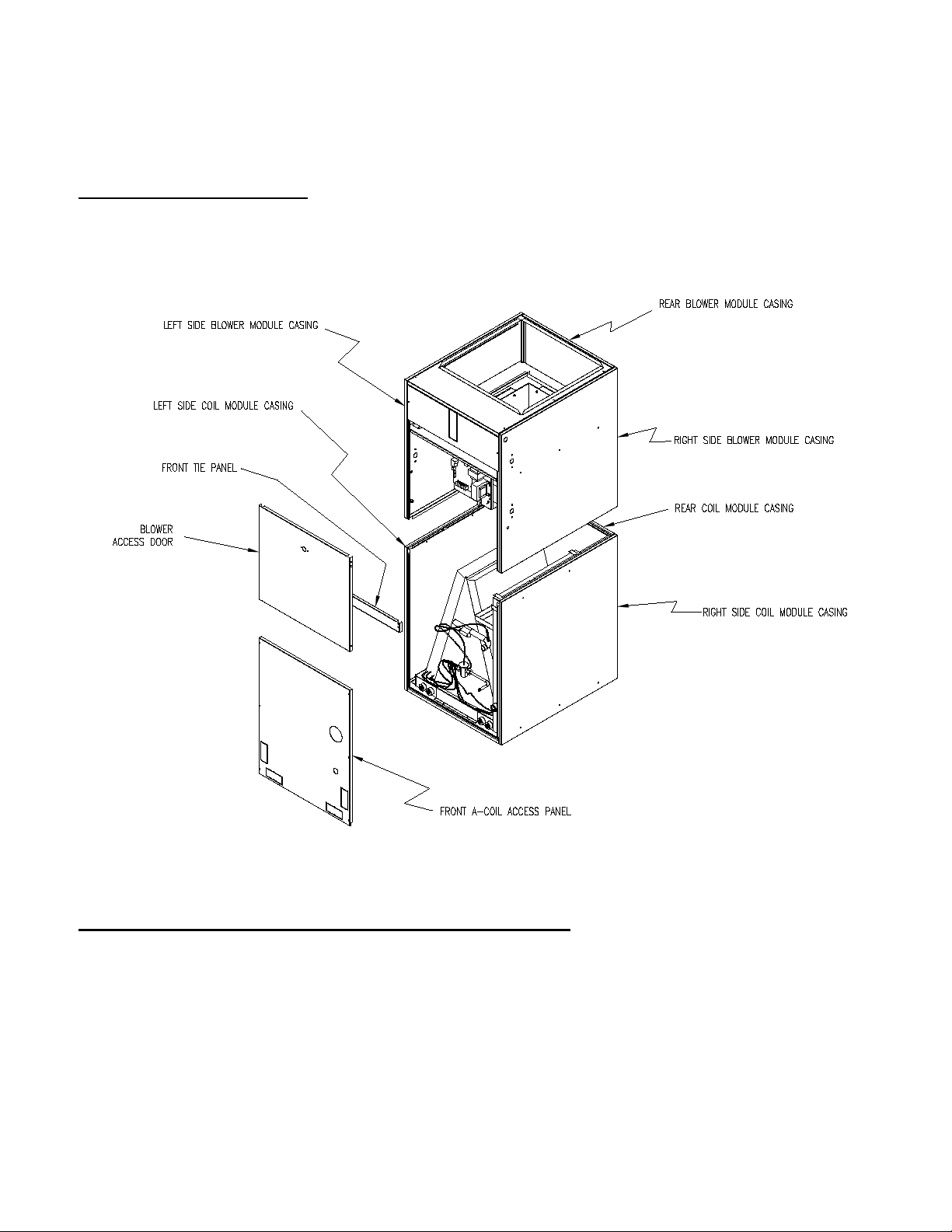

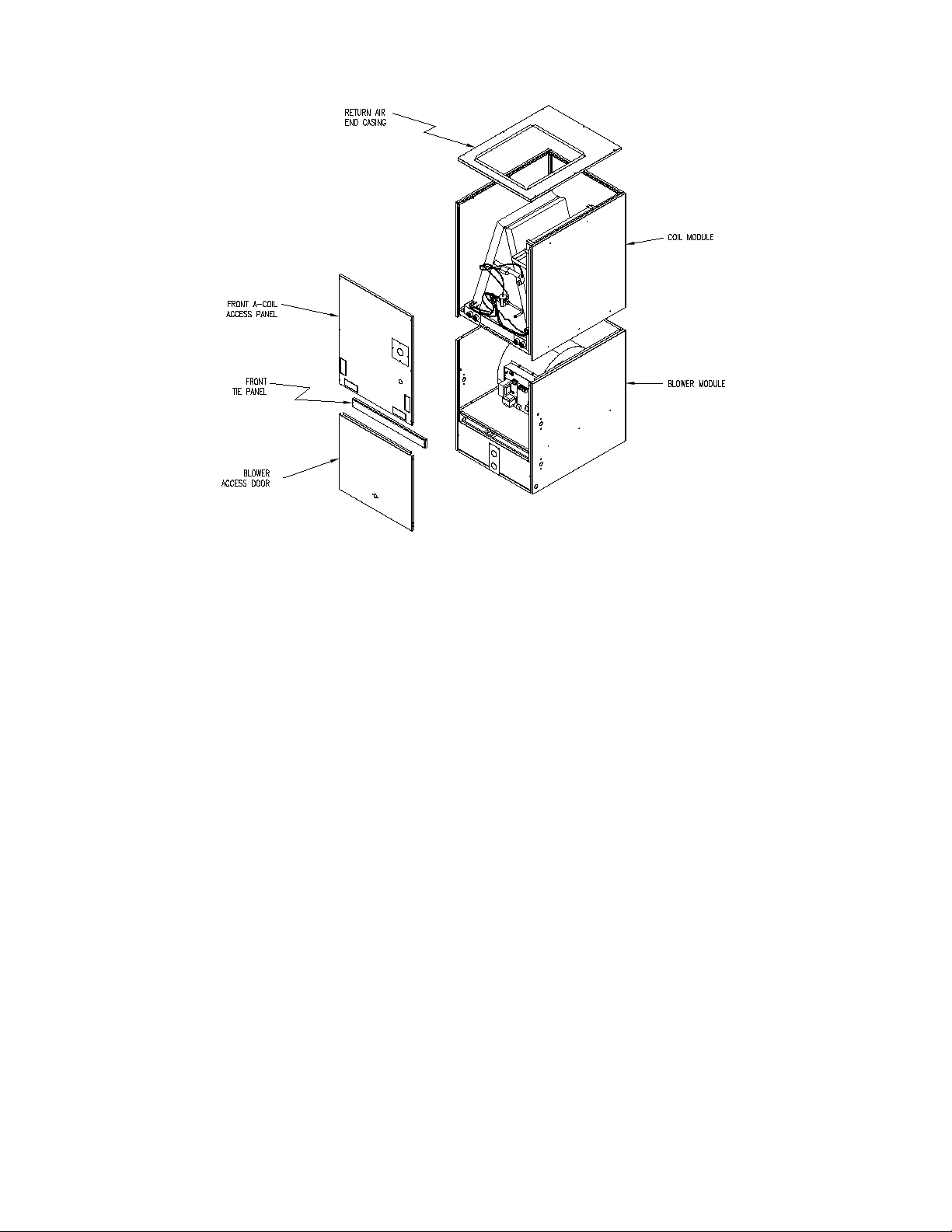

Figure B.

FOLLOW THESE STEPS FOR KNOCKDOWN OF AH4260

1. Start with unit setting in a vertical position (Figure B).

2. Remove the blower access door and front A-coil access panel.

3. Remove front tie panel (four screws).

4. Remove four screws between left/right side blower module casings and left/right side coil module

casings.

5. Remove two screws between rear blower module casing and rear coil module casing.

6. Top blower section is now disengaged from bottom coil section. Lift top off of bottom section.

7. If the Air Handler needs to be completely knocked down, follow steps in procedure for the

knockdown of the AH2436.

Page 6

4

REASSEMBLY OF AH4260

To reassemble the air handler, reverse steps above starting with number 7.

SETTING UP THE A-COIL FOR AIR CONDITIONING

The AH2436 & AH4260 come with the A-coil pre-installed for vertical and left to right horizontal airflow. The A-coil can also be re-positioned for counterflow operation.

IMPORTANT: When air handler is installed in attic above a finished ceiling, it is recommended that a

safety overflow pan with its own separate drain be installed under the entire unit.

For a right to left horizontal air flow the following steps 1-7 must be followed.

Otherwise skip to step 8.

Reversing the horizontal orientation

1. Remove the front a-coil access panel of the air handler.

2. Remove the front a-coil drain pan retainer.

3. Remove the horizontal drain pan support shipping screw(s) from the right side casing.

4. Remove the A-coil assembly and slip the horizontal drain pan assembly off of the right side of the

A-coil.

5. Slip the horizontal drain pan assembly onto the left side of the A-coil.

6. Re-install the A-coil assembly into the air handler. The A-coil drain pan should slide under the rear

retention clip. The horizontal drain pan assembly should rest against the left side casing insulation

and the side support angle.

7. Re-install the front a-coil drain pan retainer in front of the a-coil drain pan.

For all orientations

8. Cut open the appropriate drain pan drain access hole in the front A-coil access panel.

9. Slip the Suction line grommet panel over the suction line up to the access panel surface.

Page 7

5

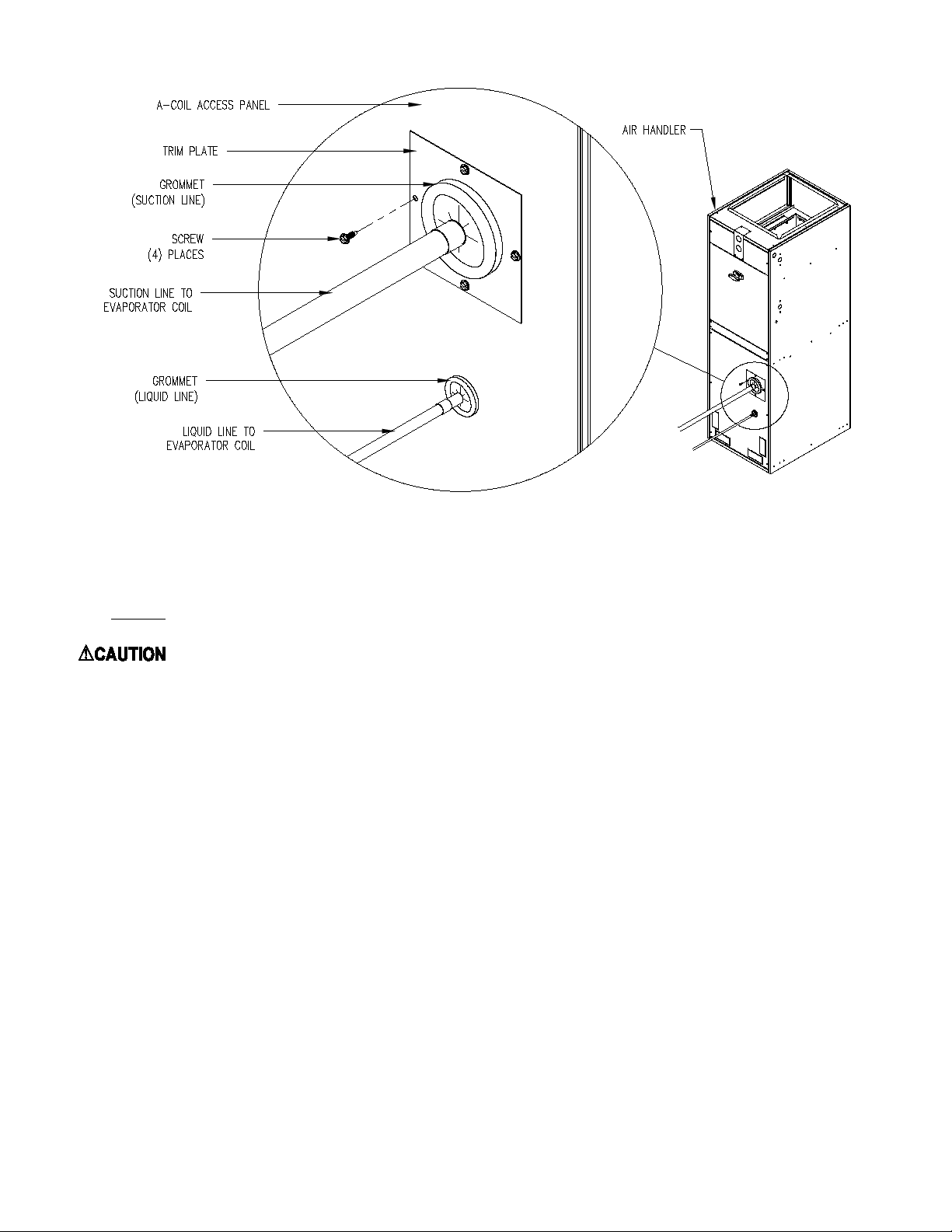

Figure C

11. Make appropriate liquid and suction line connections to coil and braze connections.

NOTE: A wet rag makes an excellent heat sink for tubing and grommets.

: If drilling or screwing into panel of plate is necessary, make certain drill does not penetrate

into any part of evaporator coil or hot water coil to avoid personal injury and/or property damage.

13. Position grommet panel on bottom door surface and secure in place with screws. Refer to Figure C.

14. Make appropriate condensate drain connections and seal the access opening.

Page 8

6

For counterflow orientations:

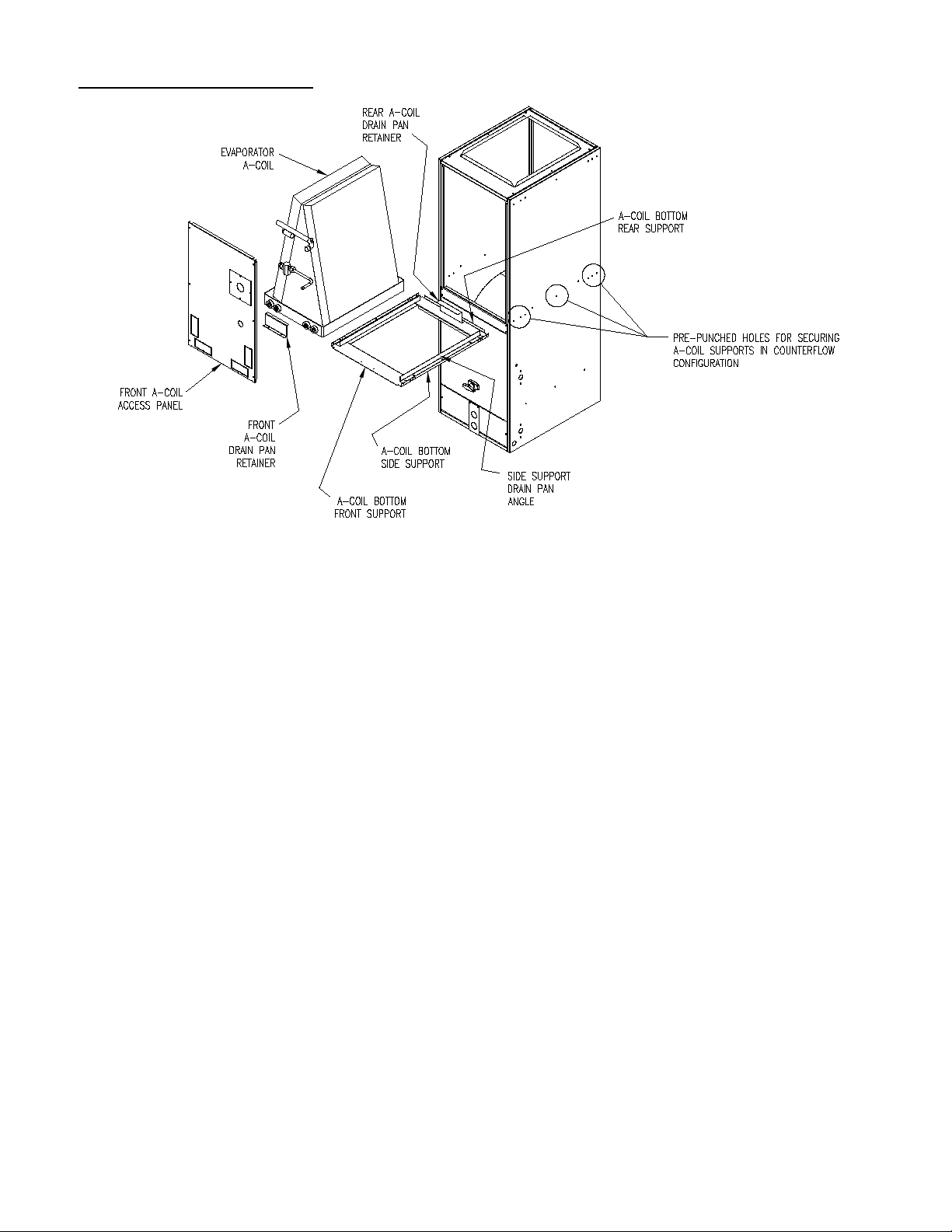

Figure D

To convert AH2436 to counterflow:

1. Remove front A-coil access panel

2. Remove front a-coil drain pan retainer and the horizontal drain pan support shipping screws from

the right side casing.

3. Remove the A-coil assembly. Slide the horizontal drain pan assembly off of the right side of the

A-coil and discard.

4. Remove A-coil bottom front, side, rear supports, side support drain pan angles and rear a-coil

drain pan retainer.

5. Turn air handler over.

6. Re-install supports, angles and retainer removed in step 4 in the counterflow configuration using

pre punched holes located in the center of the casings.

7. Re-install A-coil and front a-coil drain pan retainer.

8. Re-install front A-coil access panel.

Page 9

7

Figure E

To convert AH4260 to counterflow:

1. Remove the blower access door and front a-coil access panel.

2. Remove front tie panel (four screws).

3. Remove four screws between left/right side blower module casings and left/right side coil module

casings.

4. Remove two screws between rear blower module casing and rear coil module casing.

5. Top blower section is now disengaged from bottom coil section.

6. Lift blower module off of coil module.

7. Turn blower module over.

8. Remove return air end casing from coil module.

9. Place coil module on top of inverted blower module.

10. Re-install return air end casing on top of coil module and secure with screws.

11. Re-install all screws which secure blower module to coil module.

12. Re-install front tie panel.

13. Re-install blower access door and front a-coil access panel.

Page 10

8

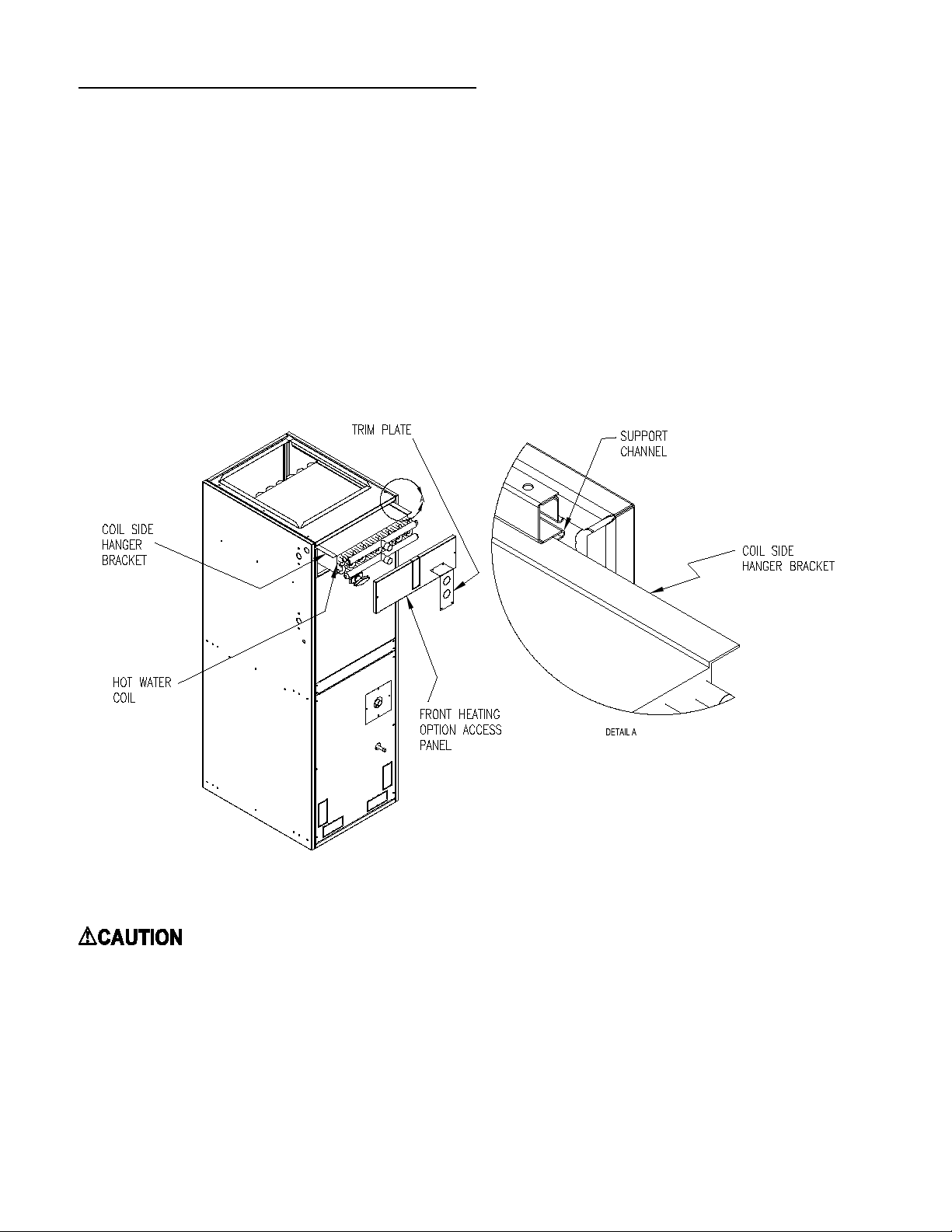

INSTALLATION OF THE HOT WATER COIL:

1. Remove top door of air handler.

2. Slide hot water coil's side hanger brackets into coil channel (retaining channel) in the air handler. See

Figure F.

3. Push coil into unit until the coil is stopped by the back casing.

4. Cut out appropriate holes in insulation, realign top door and secure into place.

5. Make appropriate hydronic connections to inlet (blower side) and outlet (duct side) of coil and braze

into place.

6. Seal connections through panel with duct sealer or equivalent.

Figure F

: If drilling or screwing into panel or plate is necessary, make certain drill does not penetrate

into any part of evaporator coil or hot water coil. Personal injury and/or property damage may result.

Page 11

9

Figure G

NOTE: Drain lines must be pitched no less than 1/4" per foot away from the air handler.

BLOWER AIR ADJUSTMENT

The ECM blower control must be set in order to establish p rop er a ir movement. Use th e f o ll ow i n g s tep s to do this:

1. Identify to tonnage of the condensing unit that will be

used.

2. If Hydronic heat is to be used, identify your BTU heat

requirements, preferred supply air temperature, water

temperature and water flow through the coil in gallons per

minute.

3. Locate the blower control board mounted to the front of

the blower assembly.

4. Locate the red switch block labeled SW1 for adjusting the

Heating and Cooling blower speed.

5. Locate SW2, just below SW1, for adjusting Blower

delays.

Figure H

Page 12

10

Table C1 COOLING SWITCH SETTINGS

AH2436A/BE1 COOL

Settings (SW1)

AH4260A/BE1 COOL

Settings (SW1)

4 5 6 4 5 6 2

800

OFF

OFF

OFF

2-1/2

1000

ON

OFF

OFF

3 1200

OFF

ON

OFF

OFF

ON

OFF

3-1/2

1400

ON

ON

OFF

4

1600 OFF

OFF

ON

1800

ON

OFF

ON

2000

OFF

ON

ON

2200

ON

ON

ON

Shaded cells represent the factory settings

BLOWER COOLING SPEEDS Refer Table C1 for setting switches 4, 5 & 6 for the A/C sizing.

A/C

TONS

CFM

5

BLOWER HEATING SPEEDS WITH HYDRONIC COIL

In the next two pages:

1. Locate the page that refers to the Air Handler to be set up.

2. Find the line(s) on the chart that best represents the water temperature and gallons per minute available.

3. Find the point along the curve that best fits the BTU and Supply Air temperature desired.

4. Read the letter associated with that point and use it to find the switch settings in the table below the chart.

(The table below the switch settings represent the actual numbers represented by the chart.)

Page 13

11

AH2436*E1 Temperature & Heat Values at 140, 160 & 1800F and

3,4,5,6 & 7 gallons per minute at selected speeds

95

105

115

125

135

145

155

25 35 45 55 65 75 85

Heating Capacity (KBTU/H)

Supply Air w/70º Return (ºF)

7gpm:180

6pgm

5gpm

4gpm

3gpm

7gpm:160

6gpm

5gpm

4gpm

3gpm

7gpm:140

6gpm

5gpm

4gpm

3gpm

1400F

Water

1800F

1600F Water

A

B

C

D

E

F

G

H

Motor Speed (A,B,C etc.)

SPEED CFM

1 2 3

A

689 OFF OFF OFF

B

754 ON OFF OFF

C 819

OFF ON OFF

D 897

ON ON OFF

E 975 OFF OFF ON

F 1066 ON

OFF ON

G

1170

OFF

ON ON

H

1300 ON ON ON

Water

Temperature

Flow

Tubeside

PD

CFM 689 (A) 754 (B)

819 (C) 897 (D) 975 (E) 1066 (F)

1170 (G) 1300 (H)

Supply Air (ºF) 151º 148º 145º 142º

139º 136º 133º 129º

Heat (Kbtu/H)

61517 64858 67946 71362

74504 77871 81378 85332

Supply Air (ºF) 149º 146º 143º

140º 137º 134º 131º 127º

Heat (Kbtu/H) 60283 63437 66346

69553 72493 75631 78888 82545

Supply Air (ºF)

147º 144º 141º 138º 135º 132º 128º

125º

Heat (Kbtu/H) 58593 61512 64191 67131

69813 72663 75606 78893

Supply Air (ºF) 144º 140º 137º 134º 131º 128º

125º 121º

Heat (Kbtu/H) 56163 58766 61139 63727

66073 68549 71090 73907

Supply Air (ºF)

139º 135º 132º 129º 126º 123º 120º 116º

Heat (Kbtu/H) 52393 54554 56507

58615 60509 62490 64505 66717

Supply Air (ºF) 136º 133º 131º 128º 126º 124º

121º 118º

Heat (Kbtu/H)

50092 52795 55294 58057 60597 63317 66151 69343

Supply Air (ºF) 134º 132º 129º 127º

124º 122º 119º 116º

Heat (Kbtu/H) 49061

51611 53962 56554 58928 61461 64090 67039

Supply Air (ºF) 132º 130º 127º 125º 122º 120º

117º 114º

Heat (Kbtu/H)

47654 50011 52174 54547 56711 59009 61382 64031

Supply Air (ºF) 130º 127º 125º 122º

120º 117º 114º 111º

Heat (Kbtu/H) 45639 47738 49652 51738 53629 55624 57670 59939

Supply Air (ºF) 126º 123º 120º 118º

115º 113º 110º 107º

Heat (Kbtu/H)

42530 44272 45845 47544 49069 50664 52286 54068

Supply Air (ºF) 121º 119º 117º 115º

113º 111º 109º 107º

Heat (Kbtu/H) 38730 40806 42723 44842 46788 48872 51041 53484

Supply Air (ºF) 120º

118º 116º 114º 112º 110º 108º 106º

Heat (Kbtu/H) 37900 39865 41666 43651 45468 47406 49417 51672

Supply Air (ºF) 118º 116º

114º 112º 110º 108º 106º 104º

Heat (Kbtu/H) 36792 38597 40252 42067 43721 45478 47290 49313

Supply Air (ºF) 116º

114º 112º 110º 108º 106º 104º 102º

Heat (Kbtu/H) 35200 36806 38268 39862 41305 42828 44390 46121

Supply Air (ºF) 113º 111º 109º 107º

105º 103º 101º 99º

Heat (Kbtu/H) 32760 34090 35291 36588 37751 38968 40206 41565

1.16

1.94

1.13

5.67

4.25

4.15

2.95

3.02

1.99

2.88

1.89

1.11

5.54

Heat Settings (SW1)

180º F

7 gpm

6 gpm

5 gpm

4 gpm

3 gpm

5.42

4.05

160º F

7 gpm

6 gpm

5 gpm

4 gpm

3 gpm

140º F

7 gpm

6 gpm

5 gpm

4 gpm

3 gpm

HYDRONIC COIL MODEL HC1-B

Page 14

12

AH4260*E1 Temperature & Heat Values at 140, 160 & 180°F

and 7,8,9 & 10 gallons per minute at selected speeds

100

110

120

130

140

150

40 60 80 100 120

Heating Capacity (KBTU/H)

Supply Air w/ 70° Return (°F)

10gpm:180

9gpm

8gpm

7gpm

10gpm:160

9gpm

8gpm

7gpm

10gpm:140

9gpm

8gpm

7gpm

1800 F Water

1600 F Water

1400 F

Water

A

B

C

D

E

F

G

H

Motor Speed (A,B,C etc.)

Heat Settings (SW1)

SPEED CFM 1 2 3

A 1007 OFF OFF OFF

B 1102 ON OFF

OFF

C 1197 OFF ON OFF

D 1311 ON ON OFF

E 1425 OFF OFF ON

F

1558 ON OFF ON

G 1710 OFF ON ON

H

1900 ON

ON ON

Supply Air (oF)

148 146 144 141 139 136 133 130

Heat (Kbtu/H) 86 91 96 101 106 112 117 124

Supply Air (oF)

147 145 142 140 137 135 132 129

Heat (Kbtu/H) 85 90

94 99 104 109 115 121

Supply Air (oF)

146 144 141 138 136 133 130 127

Heat (Kbtu/H) 83 88 92 97 102 107 112 118

Supply Air (

o

F)

145

142 139 137 134 131 129 125

Heat (Kbtu/H) 82 86 90 95 99 104

109 114

Supply Air (oF)

134 132 130 128 126 124

121 119

Heat (Kbtu/H)

70 74 78 82 86 91 95 101

Supply Air (oF)

133 131 129 127 125 123 120 118

Heat (Kbtu/H) 69 73 77 81 85 89 94 99

Supply Air (oF)

132 130 128 126 124 121 119 117

Heat (Kbtu/H) 68 72 75 79 83 87 91 96

Supply Air (oF)

131 129 127 124 122 120 118 115

Heat (Kbtu/H) 66 70 73 77 81 84 88 93

Supply Air (oF)

119 118 116 115 113 111 110 108

Heat (Kbtu/H) 54 57 60 64 67 70 74 78

Supply Air (oF)

119 117 116 114 112 111 109 107

Heat (Kbtu/H) 53 56 59 62 66 69 72 76

Supply Air (oF)

118 116 115 113 111 110 108 106

Heat (Kbtu/H) 52 55 58 61 64 67 70 74

Supply Air (oF)

117 115 114 112 110 109 107 105

Heat (Kbtu/H) 51 54 57 60 62 65 68 72

Inlet Water

Temperature

Flow

Tubeside

PD

CFM

1007 (A)

1102 (B)

1197 ('C)

1311 (D)

1425 (E)

1558 (F)

1710 (G)

1900 (H)

180oF H2O

10 gpm

1.88

9 gpm

1.54

8 gpm

1.23

7 gpm

0.95

160OF H2O

10 gpm

1.92

9 gpm

1.57

8 gpm

1.25

7 gpm

0.97

140oF H2O

10 gpm

1.95

9 gpm

1.6

8 gpm

1.27

7 gpm

0.99

HYDRONIC COIL MODEL HC2-A

Page 15

13

Table D1: Delays before blower cycles “ON or “OFF”

SW2 Positions

“ON” Delay

SW2 Positions

“OFF” Delay

1 2 (Seconds)

3 4 (Minutes)

OFF

OFF

30

OFF

OFF

2

ON

OFF

60

ON

OFF

4

OFF

ON

120

OFF

ON

6

ON

ON

480

ON

ON

8

BLOWER TIME DELAY

In cases where the yellow wires are used to start and stop the hydronic pump, SW2 may be used to delay

when the blower is cycled on or off to increase comfort and efficiency.

Use Table D1 to set the switches appropriately

DUCT SYSTEM

The duct system and load sizing calculation should follow the design standards of Air Conditioning

Contractors of America (ACC A) - manuals D & J - or t he Am eri can S oci et y of Heating, Refri geratio n and

Air Conditioning Engineers, Inc. (ASHRAE) Latest Edition Fundamentals Volume.

To aid you in evaluating existing duct systems quickly, review the chart on Page 14 which shows the CFM

capacity for square inch areas, based on .10" wc static pressure (SP) loss on the supply systems.

Each of the system's components (trunk lines, take-offs, runs and register and grill-free areas) must be

properly sized and matched together to ensure you are obtaining the air handling capacity of the duct

system. A 12x8 duct with a 400 CFM capacity, for example, MAY NOT flow 400 CFM if the register(s)

to which it connects can only flow a total of 200 CFM.

The air handling capacity MUST BE EQUAL TO the supply system at a minimum when sizing the

return air duct system. It is recommended to follow design parameters set down by ACCA or ASHRAE on

the return air duct systems.

Page 16

14

DUCT SIZES FOR HOMES

Velocity Approximately 800 Feet Per Minute

THE INDOOR EVAPORATOR COIL

1. EVAPORATO R COIL is a finned coil through which air in the home is circulated. Heat from the air

is transferred to the liquid refrigerant inside the evaporator coil. The coils for use in AH air handlers are in

an A-shaped configuration (A Models).

2. CONDENSATE DRAIN PAN is attached to the bottom of the evaporator coil to collect water

condensed out of the air. Two drain fittings are provided for connection to a convenient drain point.

3. HORIZONTAL CONDENSATE DRAIN PAN is attached to the right side of the first one for

horizontal left to right air flow. It may relocated to the left side as well. A drain fitting is provided for

connection to a convenient drain point.

TUBING LINE SETS

1. SUCTION LINE is an insulated large copper tube connecting the outlet of the A/C evaporator to the

suction inlet of the A/C CONDENSER.

Page 17

15

Tube Diameter for Total Line Length

0-50’

50-75’

75-100’

MODEL

Suction

Liquid

Suction

Liquid

Suction

Liquid

HP14241A1, HP14301A1,

AC14241E2, AC14301E2

HP14361A1, HP14421A1,

HP1448xA1, HP1460xA1

AC14361E2, AC14421E2,

2. LIQUID LINE is a single small tube connecting the outlet of the A/C condenser to the expansion valve

inlet on the A/C evaporator coil.

TUBING SIZE REFERENCE CHART

3/4” 3/8” 7/8” 3/8” 1-1/8” 1/2”

7/8” 3/8” 1-1/8” 1/2” 1-1/8” 5/8”

AC1448xE2, AC1460xE 2

7/8” 1/2” 1-1/8” 1/2” 1-1/8” 5/8”

NOTES:

For line lengths over 25’ adjust charge accordingly per foot of variation from chart.

.65 oz. per foot for 3/8” and 3/4” line set

.674 oz. per foot for 3/8” and 7/8” line set

.694 oz. per foot for 1/2” and 7/8” line set

.72 oz. per foot for 1/2” and 1” line set

.76 oz. per foot for 5/8” and 1-1/8” line set

These charges are to be used in conjunction with a liquid sub-cooling measurement for best performance.

Page 18

16

TUBING INSTALLATION

The compressor oil is constantly pumped through the refrigerant lines in normal operation of an air

conditioning system. To ensure proper lubrication of the compressor by avoiding oil accumulation at

undesirable points in the system, follow the guidelines listed below:

1. No traps in the suction line are necessary if the outdoor condensing unit is level with the indoor

evaporator coil or the indoor evaporator coil is 4 feet or less lower then the outdoor condensing unit.

Any horizontal runs of suction line should have minimum 1/2" pitch for every 10 feet of line towards

the outdoor condensing unit. See Figure I.

Figure I.

2. A trap is necessary in the suction line at the indoor evaporator coil if the indoor evaporator coil is

more than 4 feet below the outdoor condensing unit.

Figure J.

Page 19

17

NOTE: Multiple suction line traps are recommended for longer or multiple suction lines. See Figure J.

An inverted trap should be installed on the horizontal suction line near the evaporator coil to prevent

liquid flood back to the compressor (See Figure K.) if the indoor evaporator coil is located 10’ or more

above the condensing unit.

Figure K.

A gradual loop in the tubing can be constructed to take up the excess tubing if you find that too much

tubing has been brought onto a job. Such a loop MUST be kept in a horizontal (flat) plane to avoid

trapping the oil.

Refrigerant lines should be inserted into a suitable conduit or raceway when the lines are to be buried

between the building and the outdoor condensing unit. The lines must be provided with sufficient

protection and support to prevent damage when installed above ground.

When making "on the job" tubing, a solder of 95% tin, 5% antimony or any of the silver solders such as

SilFos, Phos-Copper, Easy-Flo 35 or 45, should be used. No attempt will be made here to instruct proper

soldering or brazing technique but it is necessary that the installer be properly instructed in accordance

with good existing practices.

All joints and fittings must be properly leak tested as per EPA guidelines after “on the job” tubing has

been made up. The line set and the evaporator coil must be evacuated to 29.96” Hg (1000 microns) or

lower when all joints and fittings are leak free. The service valves on the condenser may then be opened to

release the refrigerant to th e system. Verify proper system performance. See condensing unit manual for

additional performance data.

Page 20

18

HOW TO MEASURE LIQUID SUB-COOLING

(NOTE: A good electronic thermometer and accurate liquid pressure gauge with a check valve in the

Schraeder fitting are necessary).

: Failure to use a liquid side hose fitting with a built in check valve may result in personal

injury and significant refrigerant loss.

Sub-cooling is measured by taking a temperature and pressure reading. See Figure L. The pressure reading

is gauged at the pressure port located on the liquid service valve. The temperature reading is taken at the

liquid line at the 3:00 o'clock or 9:00 o'clock position with the liquid line as the center of the clock.

Figure L.

Make sure the tube where the temperature is measured is not in direct sunlight.

Read the temperature at the liquid line.

Read the liquid pressure.

Then convert pressure into temperature.

Next, subtract the measured tube temperature from the converted suction temperature.

The end result is the liquid sub-cooling.

EXAMPLE:

Measured Temp = 95oF

Measured Pressure = 211PSI which equates to a 105oF saturation temperature.

(Listed temperature for measured pressure according to R-22 temperature scale on manifold gauge or R22 section of pressure temperature chart)

The difference equals the degrees superheat = 10oF

Page 21

19

A liquid sub-cooling of about 10oF leaving the condenser is good over a wide range of operating

conditions for a system with a TXV in the evaporator like the AH2436A/BE1 & AH4260A/BE1.

MEASURING TEMPERATURE DROP ACROSS THE “A” COIL:

The temperature drop across the coil should be around 18oF to 23oF difference between inlet an d outlet

air. This should be measured as close to the air handler as possible, to eliminate duct losses.

ELECTRICAL

All wiring must conform to the provisions of local codes or in the absence of local codes with the

provisions of the National Electrical Code, ANSI/NFPA No. 70-Latest Edition and this instruction

manual. Equivalent type wire must be used if any of the original wire supplied with the unit needs to be

replaced.

NOTE: Condensing unit is not included in above amp rating.

Page 22

20

Max fuse size for AH2436BE1 w\ EH104A 30A EH108A 45A

Max fuse size for AH4260BE1 w\ EH208A 50A EH212A 70A EH216A 85A

The following points must be checked by the installer and/or electrician before the air conditioning system

is started:

1. Check every electrical connecti on of "PUSH-ON " or "SCR EW-ON" terminals to ensure it is on tightly

on its proper post.

2. Review wiring diagram for proper routing.

Page 23

21

Page 24

22

UA ADAPTER CABINET

The UA adapter cabinet is designed to be used in conjunction with the AH AIR HANDLER to allow a

free standing (vertical discharge) installation. The UA cabinet is shipped completely assembled and ready

for installation.

The return air opening can face either left or right by exchanging the front filter door and rear filter blockoff assemblies.

The AH AIR HANDLER is then placed on the UA adapter cabinet, inlet side down.

The UA cabinet is equipped with a permanent washable air filter.

AH AIR HANDLER RECOMMENDED SUSPENSION PROCEDURE

The detail below is the proper and safest way to suspend the AH. These components should be easily

found at your local hardware store.

FIG M

Page 25

23

SYMPTOM

CAUSE/PROCEDURE

Motor rocks slightly when starting

• This is normal start-up for ECM

Motor won’t start

• Check power at motor

• Run Moisture Check

• Motor rocks, but won’t start

• Check for loose or compliant motor mount

• Perform motor/control replacement check

Motor oscilla tes up & down while being tested off

of blower

• It is normal for motor to oscillate with no load on

shaft.

Motor starts, but runs erratically

• Perform Moisture Check

• “Hunts” or “puffs” at high CFM (speed)

• Does removing panel or filter reduce “puffing”?

Reduce max airflow

• Stays at low CFM despite system call for cool or

• Check low voltage (T’stat) wires and connections

• Perform motor/control replacement check

ECM TROUBLE SHOOTING

DIAGNOSTC FEATURES

The control board is equipped with 4 green Input Status LEDs and 1 red Board Status LED. These are

intended to provide a quick view into furnace performance without requiring a voltmeter.

The green Input Status LEDs are driven by the “Y”, “W”, “G”, and “DEHUM” inputs and are located

directly below those inputs. They will light to indicate the presence of these signals.

The red Board Status LED has two functions:

It will light when the board recognizes a valid input signal and will stay lit until all valid signals are

removed. This is intended to show that the board is functioning and able to respond to input signals.

B. GENERAL GUIDELINES TO TROUBLESHOOTING GE ECM – DRIVEN SYSTEMS

: Disconnect power from unit before removing or replacing connectors, or servicing

motor. Wait at least 5 minutes after disconnecting power before opening motor.

• No movement

• Varies up and down or intermittent

• Check low voltage (24 VAC R to C) at motor

• Check low voltage connections (G,PWM,W,R,C,)

at motor

• Check for unseated pins in connectors on motor

harness

• Test with a temporary jumper between R – G

• Check motor for tight shaft

• Perform motor/control replacement check

• Make sure blower wheel is tight on shaft

• Check line voltage for variatio n or “sag”

• Check low voltage connections (G,PWM,W,R,C,)

at motor, unseated pins in motor harness

connectors

• Check “Bk” for erratic CFM command (in

variable speed applications)

• Check-out system controls – T’stat?

heat CFM

Reduce restriction

• Verify fan is not in delay mode – wait until delay

complete

• “R” missing/not connected at motor

Page 26

24

• Stays at high CFM

• “R” missing/not connected at motor

• Perform motor/control replacement check

• Blower won’t shut off

• Current leakage fr om controls into G,Y or W?

Check for Triac switched t’stat or solid state relay

Excessive noise

• Determine if it’s air noise, cabinet, duct or motor

noise – interview customer, if necessary

• Noisy blower or cabinet

• Check for loose blower housing, panels, etc.

Check for cabinet/duct deformation

• “Hunts” or “puffs” at high CFM (speed)

• Does removing panel or filter reduce “puffing”?

Reduce max airflow

Evidence of Moisture

• Motor failure or malfunction has occurred and

moisture is present

• Replace motor and perform Moisture Check

• Evidence of moisture present inside air mover

• Perform Moisture Check

DO

DON’T

• Check-out motor, controls, wiring and

connections thoroughly before replacing motor

• Automatically assume the motor is bad.

• Orient connectors down so water can’t get in

Install “drip loops”

• Locate connectors above 7 and 4 o’clock

positions

• Use authorized motor and control model #’s for

replacement

• Replace one motor or control model # with

another (unless an authorized replacement)

• Keep static pressure to a minimum:

replacement

• Use high pressure drop filters – some have ½”

• Size the equipment wisely

• Oversize system then compensate with low

airflow

• Check orientation before inserting motor

connectors

• Plug in power connector backwards

• Force plugs

• Is fan in delay mode? – wait until delay time

complete

• High static creating high blower speed?

Check for air whistli ng t hru

seams in ducts, cabinets or panels

Reduce restriction

Recommend high efficiency, low static

filters

Recommend keeping filters clean

Design ductwork for min sta tic, max

comfort

Look for and recommend ductwork

improvement, where necessary, in

Moisture Check

• Connectors are orientated “down” (or as recommended by equipment manufacturer)

• Arrange harnesses with “drip loop” under motor

• Is condensate drain plugged?

• Check for low airflow (too much latent capacity)

• Check for undercharged condition

• Check and plug leaks in return ducts, cabinet

H2O drop!

• Use restricted returns

Page 27

25

Comfort Check

• Check proper airflow settings

• Low static pressure for lowest noise

• Set low continuous-fan CFM

• T’stat in bad location?

120V or 240V

120V or 240V

Figure N: ECM PIN CONNECTORS

Troubleshooting table above and Figure N adapted from GE Industrial Systems publication GED-7161C,

“Troubleshooting GE ECM – Driven Systems”.

Page 28

26

CONFIRM IF EITHER BLOWER

WHEEL IS RUBBING AGAINST

HOUSING OR MOTOR SHAFT

IS SPINNING FREELY, REPAIR

OR REPLACE AS NECESSARY.

DOES BLOWER SPIN FREELY

?

IS THERE 120V or 240V

SUPPLIED TO MOTOR?

CHECK 120V or 240V SUPPLY,

CONNECTION FUSES,

SERVICE SWITCH AND

DOOR SWITCH.

CHECK HARNESS

CONNECTIONS

AND WIRE.

NO

YES

YES

YES

YES

NO

NO

NO

NO

NO

YES

YES

DISCONNECT 16 PIN

HARNESS FROM

MOTOR. IS THERE 12VDC

ACROSS PIN12 & PIN1

AND PIN12 & PIN3

AT THE HARNESS PLUG?

CHECK CONNECTION ON HARNESS AND MOTOR,

RECONNECT HARNESS TO MOTOR, IF

CONNECTIONS ARE GOOD AND MOTOR STILL

DOES NOT RUN REPLACE MOTOR.

THIS GUIDE SHOULD BE USED IN THE CASE OF A STO P P E D O R MA NFUNCTIONED ECM

BLOWER MOTOR. THE FOLLOWING SHOULD HELP ESTABLISH THE TYPE OF

MALFUNCTION OR DEVIATION FROM THE NORMAL BLOWER OPERATION.

TO USE THIS DIAGRAM, YOU JUST NEED TO FOLLOW THE INSTRUCTIONS IN THE BOXES.

CHECK 24VAC

TO INTEGRATED CONTROL.

IS THERE 24VAC

ACROSS R &

B/C ON THE

INTEGRATED

CONTROL?

REPLACE

INTEGRATED

CONTROL.

TURN THERMOSTAT MANUAL FAN

SWITCH ON (IF AVAILABLE) OR JUMPER

BETWEEN R & G ON INTEGRATED CONTROL.

IS THERE VOLTAGE GREATER THAN

12VDC BETWEEN PIN15 & PIN1?

CHECK CONNECTIONS AND WIRES

AT INTEGRATED CONTROL, IF OK

REPLACE INTEGRATED CONTROL.

DISCONNECT 16PIN

HARNESS FROM

INTEGRATED CONTROL.

IS THERE 12VDC ACROSS

PIN 6 & PIN 1

AT THE CONROL?

TROUBLESHOOTING CHARTS

Page 29

27

BLOWER Off-

Delay Active?

Sequence of Operation

BURNER On

1. A/C Off

BLOWER

= LOW

BLOWER = COOL

COOL

Y

On-Delay

Yes

Yes

Yes

Yes

No

No

No

No

DEHUM

BLOWER = LOW

1. BLOWER Of f (No Delay)

1. HEAT mode On

1. COOL mode On

1. FAN mode On

G Active?

Y Active?

LIMIT

FAN Mode

G

W Act ive?

1. HEAT mode On

Yes

Yes

Yes

Yes

Yes

Yes

No

No

No

No

No

No

Yes

No

1.BURNER Off

HEAT

W

Active?

LIMIT

On-Delay

Yes

Yes

Yes

Yes

No

N

No

No

Mode On?

Mode On?

On?

2. HEAT mode Off

3. BLOWER Of f -Delay S tarted

4. Status LED Off

Active?

2. COOL mode Off

3.BLOWER Of f -Delay S tarted

4. Status LED Off

Active?

Ended?

Ended?

Active?

Active?

Active?

2. Status LED Off

2. BLOWER = HEAT

3. Status LED Flashes

2. Blower On-Delay Started

3. Burner On

4. Status LED On (conti nuous )

2. Blower On-Delay Started

3. Condenser On

4. Status LED On (conti nuous )

2. BLOWER = LOW

3. Status LED On (conti nuous )

Page 30

28

Sequence of Operation Glossary

Inputs:

W- Switched 24vac indicating a Heat call from the thermostat.

Y - Switched 24vac indicating a Cool call from the thermostat.

G - Switched 24vac indicating a call for blower operation from the thermostat.

DEHUM - Switched 24vac indicating a call for Dehumidification from a de-humidistat.

BLOWER Speeds:

HEAT - The Heating Blower speed selected by positions 1, 2 & 3 of SW1

(CFM tables on page 11-12)

COOL - The Cooling Blower speed selected by positions 4, 5 & 6 of SW1

(CFM tables on page 10)

LOW - The LOW Blower speed selected by positions 4, 5 & 6 of SW1

(CFM tables on page 10)

ECM – PSC Replacement for AH2436AE1 or AH4260AE1 only

In an emergency situation, a defective ECM motor can be replace with a PSC motor to provide temporary

circulating air flow for heating or cooling. This is done by replacing the ECM motor in the motor

mounting bracket with a PSC motor of similar Horsepower. Wire the common lead (typically white) of

the replacement PSC motor to the neutral (common) terminal on the fan control board (N - 1 through 7).

Connect the high-speed replacement PSC motor lead (typically black) to the EAC terminal on the fan

control board. The EAC contact is energized with 115VAC any time the control board is calling for fan

operation whether in heating or cooling mode. This replacement should be only used in emergency

situations and only until a replacement ECM motor can be obtained and reinstalled.

ECM – PSC Replacement for AH2436BE1 or AH4260BE1 - call Tech Service.

Page 31

29

REPLACEMENT PARTS

Page 32

30

Loading...

Loading...