ThermoPlus Air KACE-018A, KACE-009A, KACE-012A, KACE-015A, KACE-024A Installation, Operation And Maintenance Manual

...

WATER COOLED AIR CONDITIONERS

HORIZONTAL & VERTICAL MODELS

R410A

INSTALLATION, OPERATION AND MAINTENANCE

SERIES KACE-009A KACE-012A KACE-015A KACE-018A

KACE-024A KACE-030A KACE-036A KACE-042A

KACE-048A KACE-060A KACE-072A KACE-096A

KACE-120A KACE-144A

Warning

Mechanical Thermostat may affect Electronic

Control card in unit. Connect an electronic

Thermostat to unit.

Each air conditioner has been operated and checked out

prior to shipment. Failure to operate after installation

indicates damage in transit or improper installation.

INSPECTION

Check packaging during unloading. Note transit damage on

all copies of bill of lading. Inspect air conditioners for hidden

shipping damage after packaging is removed. Transit

damage claims must be filed promptly with Freight

Company by purchaser.

HANDLING

Always handle Vertical units upright and Horizontal

units flat on their base. Moving a vertical unit on its side,

placing a horizontal unit on end, or dropping it may damage

internal parts and displace oil from the compressor's

crankcase.

STORAGE

If job site storage is necessary, place the unit in a clean,

warm dry area. Follow instructions under Handling.

LOCATION

Note that units with different capacities may have identical

dimensions. Labels on unit packaging must be carefully

scrutinized and matched to job location. These units are not

approved for outdoor installation and therefore must be

installed inside the space being conditioned.

PLACEMENT

Install air conditioners in a level plane and locate unit

around the service panel to ensure that proper access is

available including that for filter removal.

¨ For Vertical Units: Install the air conditioner with a piece of

sound insulating material between unit and floor to avoid

possible transmission of noise into the building structure.

(rubber backed carpeting will suffice for vertical models).

For units installed in closets adjacent to conditioned space,

provide insulated return air ducting with at least one 90o

elbow or provide a sound baffle between the return air grille

and unit filter.

1

¨ Horizontal units are provided with isolation hanger

support. See Fig. 2 for proper installation when the unit is

suspended.

LOCATION OF SUPPLY & RETURN CONNECTIONS

(SEE FIG. 1 & 2)

WIRING

All wiring should conform to the CEC and/or local code

requirements. Power disconnect shall be field provided (by

others). The wiring diagram is located on electrical box

cover on vertical models and on the back of the service

panel on horizontal models. Make certain the line voltage

and the 24 volt control circuit are properly identified and

wired in accordance with the unit wiring diagram.

¨ Water cooled air conditioners are classified as direct

(permanently) connected devices by the CEC. Air

conditioners must be properly grounded as per instructions

on the unit wiring diagram.

CONDENSATE DRAINAGE

Vertical Units: Ensure that the plastic drain tube is

connected to the bottom of the coil drain pan at one end

and the other end of the condensate drain tube should

extend through the left post on the front side of the unit, see

Fig. 1. Connect the drain through a trap to the condensate

drain system in conformance to local plumbing codes.

Slope the drain line for proper gravity flow of condensate

away from unit. The top of the trap and further connections

must be below the unit drain connection level.

Horizontal Units: The condensate drain tube should be

connected to the side of the unit, see Fig. 2. Follow the

above instructions (given for the vertical units) for proper

condensate draining.

WATER SUPPLY (UNIT CONNECTED ON OPEN WATER

CIRCUIT)

The source of water for air conditioner operation is the

responsibility of the owner and/or the installing contractor.

The air conditioner must not function without water, and

predetermined rates of flow (l/s or USGPM) must be

maintained for the unit to opera-te at rated capacity. Since

the water function is to absorb heat from the refrigerant, the

flow rate for each model varies with the entering water

temperature (EWT). A pressure-operated water valve is

installed for this reason inside the unit and SAE-13 calibra-

ted at the factory for a condensing pressure of 1400 kPa

"gauge" (205 PSIG.). Piping size to and from unit must

match or exceed the inlet and outlet water connection

sizes on the air conditioner.

¨ Never use a hose of a smaller inside diameter than that of

the water connection sizes on the unit.

¨ The hoses must be rated to match or exceed

temperatures and pressures which occur during normal

operation of system (temperature between 4o C (40o F) and

43o C (110o F); and pressures up to 1380 kPa (200 PSI).

¨ When hoses are connected they must not be subjected to

any stress in tension or by twisting or kinking.

¨ Hoses available as an accessory to the unit are provided

with hexagonal surfaces on the fittings as are the water

fittings on units. Use a properly sized wrench on the

hexagonal surface to tighten connections. Never use a

wrench on the hose or sleeve that crimps the fitting into the

hose.

¨ Do not over-tighten connections. Turn in the mating

threads by hand or with a wrench until snug, then tighten

with a wrench beyond the point just enough to seal the joint

(for tapered pipe threads this would be an additional 1/2 to

one full turn; for union or flare connections no more than

1/4 of a turn).

¨ Before pressurizing the system, closely inspect the hose

and fittings to be sure there are no cuts, abrasions, twists or

kinks. Hoses must not be in contact with any sharp edge

while in use.

¨ Hose supplier will not take responsibility for hose leakage,

failure or damage resulting from water leaks.

SUPPLY DUCTING

Flanges around the blower opening are intended for a

flexible supply air duct connection to unit. Be certain

blower wheel turns freely before making the duct

connection. Supply air ductwork must be insulated with 25

or 38 mm thick (1" or 1 1/2") fibreglass, sealed at all joints

and must have an exterior vapour barrier. The air

conditioner's life expectancy and efficient performance are

dependent on adequate air flow. Under no circumstance

should the unit be installed where the total external static

pressure exceed those shown in the Table 1.

TABLE 1

MODEL EXTERNAL STATIC PRESSURE

Pa inch wg

009 75 0.30

012 75 0.30

015 75 0.30

018 75 0.30

024 188 0.75

030 188 0.75

036 188 0.75

042 188 0.75

048 188 0.75

060 188 0.75

072 25 to 275 0.10 to 1.1

096 25 to 275 0.10 to 1.1

120 25 to 275 0.10 to 1.1

144 25 to 275 0.10 to 1.1

WIRING - LINE VOLTAGE

WATER CONNECTIONS

If flexible hoses are used to make the water in-out

connections to the unit, certain precautions must be taken

to ensure proper unit operation and avoid hose damage.

Check mainpower voltage. Refer to unit wiring diagram and

make changes (if required) to permit the unit to operate on

the available supply voltage. Connect power as per the unit

wiring diagram, conforming to the local and national

electrical code requirements.

CONNECTION AND LOCATION OF THERMOSTAT

Wiring the thermostat to the unit should be done as per the

wiring diagram (inside the panel of the electrical box on the

vertical units and on the inside of the service panel for

horizontal units). Thermostat must be absolutely level when

installed and located to best sense the actual room

temperature. Avoid false sensing heat or cold from sunlight,

open doors or window drafts, supply air outlets, fireplaces,

ovens, etc.

HIGH PRESSURE PROTECTION

Your unit is protected against excessive high pres-sure by a

pressure limiting control. If the pressure rises above 560 psi

(2,758 kPa), the pressure switch will shut down the unit.

RESET UNIT

To restart, the unit must be turned "OFF" at the thermostat

or at the main power switch. Then switch to "ON" position;

the unit will start functioning. If not, call a technician to

solve the problem. Repeated resetting on unit without

getting the fault corrected will cause compressor failure.

START UP INSTRUCTIONS

After installation of unit and the ductwork, water and

condensate connections, the wiring in accordance with

preceding instructions, the unit is ready for start-up. Check

all wire connections to the unit and to external control

devices for tightness.

¨ Set temperature on the thermostat below room

temperature and start the unit. After operating for five(5)

minutes, air supply should have a minimum temperature

drop of 10-12o C (18-22o F). Use a surface temperature

device or any other device to check the temperature of

supply water and return water. The minimum temperature

rise should be 6o C (10o F).

¨ If the above conditions are not met, one or more of the

following problems exist: low air flow, low water flow, or unit

is possibly defective.

MAINTENANCE AND SERVICE

¨ Do not operate the air conditioner without the air filter in

place. Filters should be serviced regularly, at least every

three months.

Dirty filters will result in inefficient performance.

¨ Check the air coil and fan wheel yearly for cleanliness and

clean if necessary.

MAN-KACE-A-E-001

2

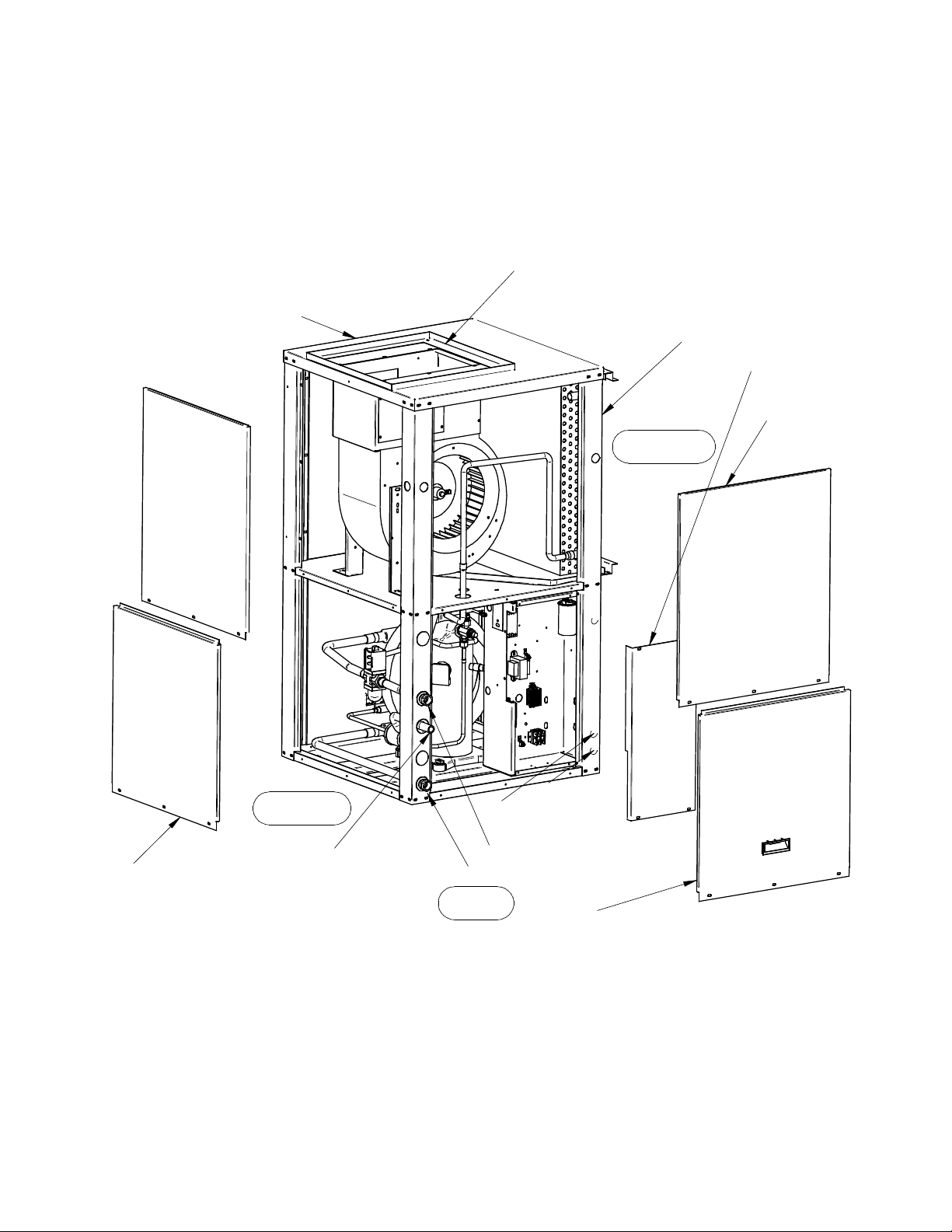

FIGURE 1

BLOWER AND MOTOR

ACCESS PANEL

SUPPLY AIR

RETURN AIR

RIGHT SIDE

ELECTRICAL

ACCESS PANEL

BLOWER

ACCESS PANEL

WATER REGULATING

ACCESS PANEL

3

LEFT SIDE

CONDENSATE

DRAIN TUBE

POWER IN

LOW VOLTAGE IN

WATER OUT

WATER IN

FRONT

ELECTRICAL AND

COMPRESSOR ACCESS PANEL

Loading...

Loading...