Page 1

REV-1

6.1

CT / CTM / CTS / CTMS / CBT / CBTM / CTMC / TS

SECTION 6

© 2011 by Thermoplan AG, Änderungen vorbehalten

Technical manual

TROUBLESHOOTING

FOX2

Page 2

REV-1

6.2

1 X X

2 X X

3 X X

4 X X

5 X X

6 X X

7 X X

8 X X

9 X X

10 X X

11 X X

12 X X

13 X X

14 X X

15 X X

16 X X

17 X X

18 X X

19 X X

20 X X

21 X X

22 X X

23 X X

24 X X

25 X X

26 X X

27 X X

28 X X

29 X X

30 X X

31 X X

32 X X

33 X X

34 X X

35 X X

36 X X

37 X X

38 X X

39 X X

40 X X

41 X X

42 X X

43 X X

44 X X

45 X X

46 X X

47 X X

48 X X

49 X X

50 X X

51 X X

0 1 2 3 4 5 6 7 8 9 10

0 1 2 3 4 5 6 7 8 9 10

0 1 2 3 4 5 6 7 8 9 10

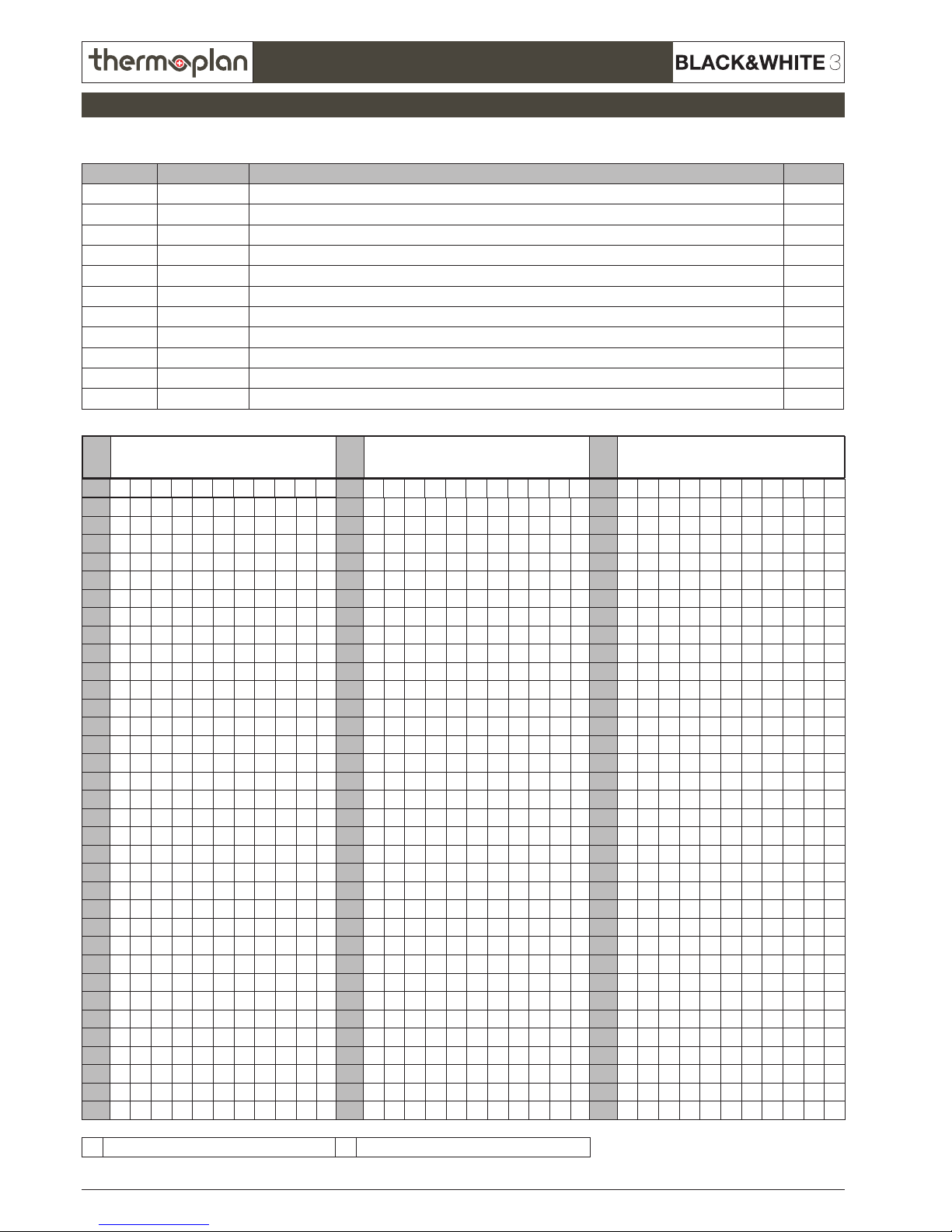

Page

REVISION

Page

REVISION

Page

REVISION

© 2011 by Thermoplan AG, Änderungen vorbehalten

SECTION 6

Technical manual

X Changes in content, corrections S New paging

Overview modications

Modication journal:

Revision: Data: Modication Initials:

0 2011-01-04 Basic document SO

1 2013-03-05 Various changes SO

2

3

4

5

6

7

8

9

10

Document: Troubleshooting

Page 3

REV-1

6.3

SECTION 6

© 2011 by Thermoplan AG, Änderungen vorbehalten

Technical manual

Index

1 Overview display messages ..................................................................................................................................4

2 Service menu „System Check“ ..............................................................................................................................7

2.1 Entering the service menu ...........................................................................................................................................................7

2.2 Inputs .........................................................................................................................................................................................8

2.3 Outputs ......................................................................................................................................................................................9

2.4 Touchpanel Test .........................................................................................................................................................................10

3 Touchscreen FOX .................................................................................................................................................11

3.1 Possible problems with the touchscreen .....................................................................................................................................11

3.2 Troubleshooting on touch screen................................................................................................................................................11

3.3 Overview FOX-Print ...................................................................................................................................................................12

3.4 Overview CPU ...........................................................................................................................................................................13

4 Chassis ................................................................................................................................................................14

4.1 Error messages ..........................................................................................................................................................................14

4.2 CTM Front view .........................................................................................................................................................................17

4.3 CTM Back view .........................................................................................................................................................................18

4.4 CTM Bottom view .....................................................................................................................................................................19

4.5 CTM ISO view ...........................................................................................................................................................................20

4.6 CTM ISO view 2 ........................................................................................................................................................................21

4.7 CBTM Front view .......................................................................................................................................................................22

4.8 CBTM Back view .......................................................................................................................................................................23

4.9 CBTM Bottom view ...................................................................................................................................................................24

4.10 CBTM ISO view .......................................................................................................................................................................25

4.11 CBTM ISO view 2 ....................................................................................................................................................................26

5 Mechanical module .............................................................................................................................................27

5.1 Error messages ..........................................................................................................................................................................27

5.2 Water circulation .......................................................................................................................................................................29

5.3 ISO view ...................................................................................................................................................................................30

5.4 Top view ...................................................................................................................................................................................31

5.5 Back view .................................................................................................................................................................................32

5.6 Bottom view .............................................................................................................................................................................33

5.7 ISO view Brewing unit ...............................................................................................................................................................34

5.8 Quick test .................................................................................................................................................................................35

6 Hydraulic module ................................................................................................................................................36

6.1 Error messages ..........................................................................................................................................................................36

6.2 Top view ...................................................................................................................................................................................37

6.3 Back view .................................................................................................................................................................................38

6.4 Milk way pump unit ..................................................................................................................................................................39

6.5 Water way pump unit ................................................................................................................................................................40

6.6 ISO view Pump unit ...................................................................................................................................................................41

6.7 ISO view Valve block .................................................................................................................................................................42

6.8 Quick test .................................................................................................................................................................................43

7 Brew module .......................................................................................................................................................44

1 Error messages .............................................................................................................................................................................44

2 ISO view ......................................................................................................................................................................................45

3 Back view ....................................................................................................................................................................................46

4 ISO view Sensor ...........................................................................................................................................................................47

5 ISO view Chassis ..........................................................................................................................................................................48

6 Quick test ....................................................................................................................................................................................49

8 Steam module .....................................................................................................................................................50

8.1 Error messages ..........................................................................................................................................................................50

8.2 ISO view ...................................................................................................................................................................................51

8.3 Front view .................................................................................................................................................................................52

8.4 Back view .................................................................................................................................................................................53

8.5 Quick test steam module ...........................................................................................................................................................54

Page 4

REV-1

6.4

© 2011 by Thermoplan AG, Änderungen vorbehalten

SECTION 6

Technical manual

1 Overview display messages

Error no. Text Affects module

TX0101 NTC coffeeboiler open Hydraulics (Kap. 6.1)

TX0104 Empty grounds drawer Chassis (Kap. 4.1)

TX0105 Drain tub Brew module (Kap. 7.1)

TX0106 Grounds drawer missing Chassis (Kap. 4.1)

TX0107 Bean hopper empty (left-hand side) Mechanics (Kap. 5.1)

TX0108 Service required Chassis (Kap. 4.1)

TX0109 Clean appliance Chassis (Kap. 4.1)

TX0110 Voltage low Chassis (Kap. 4.1)

TX0111 Voltage high Chassis (Kap. 4.1)

TX0113 Piston error Chassis (Kap. 4.1) / Mechanics (Kap. 5.1)

TX0114 Bean hopper empty (right-hand side) Mechanics (Kap. 5.1)

TX0115 Flow error Mechanics (Kap. 5.1) / Hydraulics (Kap. 6.1)

TX0116 Overtime error Mechanics (Kap. 5.1) / Hydraulics (Kap. 6.1)

TX0117 Change water lter Chassis (Kap. 4.1)

TX0118 Interface error Chassis (Kap. 4.1)

TX0119 Powder error Mechanics (Kap. 5.1)

TX0121 NTC steamboiler error Steam (Kap. 8.1)

TX0122 Steamboiler not ready Steam (Kap. 8.1)

TX0123 Low water level in steamboiler Steam (Kap. 8.1)

TX0124 Hot water rinse

Press rinse key

Steam (Kap. 8.1)

TX0125 Waterow error Hydraulics (Kap. 6.1)

Page 5

REV-1

6.5

SECTION 6

© 2011 by Thermoplan AG, Änderungen vorbehalten

Technical manual

1 Overview display messages

Error no. Text Affects module

TX0128 Cleaning interrupted

Open POD

Chassis (Kap. 4.1)

TX0136 Please ask for assistance Chassis (Kap. 4.1)

TX0137 Please add milk Chassis (Kap. 4.1)

TX0138 Steamboiler ll error Steam (Kap. 8.1)

TX0139 Bean hopper missing or command unit open Chassis (Kap. 4.1) / Mechanics (Kap. 5.1)

TX0141 NTC coffee boiler short-circuit Hydraulics (Kap. 6.1)

TX0143 Machine locked

Start cleaning

Chassis (Kap. 4.1)

TX0145 Add coffee beans

Press ok to proceed product dispensing

Mechanics (Kap. 5.1)

TX0146 Press stop key Chassis (Kap. 4.1)

TX0149 Insert coffe pad Chassis (Kap. 4.1)

TX0150 Remove cleaning tablets Chassis (Kap. 4.1)

TX0151 No waterow detected Hydraulics (Kap. 6.1)

TX0153 Cleaning done

Standby

Chassis (Kap. 4.1)

TX0154 Milk pump: no pulse Hydraulics (Kap. 6.1)

TX0155 Water pump: no pulse Hydraulics (Kap. 6.1)

TX0161 Please wait Hydraulics (Kap. 6.1)

TX0162 Error grinder right-hand side Mechanics (Kap. 5.1)

TX0163 Error grinder left-hand side Mechanics (Kap. 5.1)

TX0164 Cleaning interrupted

Please press rinse key

Chassis (Kap. 4.1)

TX0167 Cleaning interrupted

Remove grounds drawer

Chassis (Kap. 4.1)

TX0174 Remove and empty grounds drawer Chassis (Kap. 4.1)

Page 6

REV-1

6.6

© 2011 by Thermoplan AG, Änderungen vorbehalten

SECTION 6

Technical manual

Error no. Text Affects module

TX0188 Check milk temperature Chassis (Kap. 4.1)

TX0201 Cold start rinse

Please press rinse key

Chassis (Kap. 4.1) / Hydraulics (Kap. 6.1)

TX0241 Machine rinsing

ATTENTION HOT!

Chassis (Kap. 4.1)

1 Overview display messages

Page 7

REV-1

6.7

SECTION 6

© 2011 by Thermoplan AG, Änderungen vorbehalten

Technical manual

2. Service menu „System Check“

2.1 Entering the service menu

To enter the different service levels, follow these steps:

1. Push and hold left top corner.

2. The „Enter PIN“ window appears. Enter code and conrm with

.

The service menu can always be left by pressing the top left corner of the display.

23

1

56

4

89

7

Enter PIN

******

3. Following screen appears:

There are two different codes which each provide another programming level in the software:

User level: Code 111111

In the user level only few settings like product parameters, datetime and language can be set.

Technician level: Code 137900

In the technician level all settings can be looked-up and set.

Page 8

REV-1

6.8

© 2011 by Thermoplan AG, Änderungen vorbehalten

SECTION 6

Technical manual

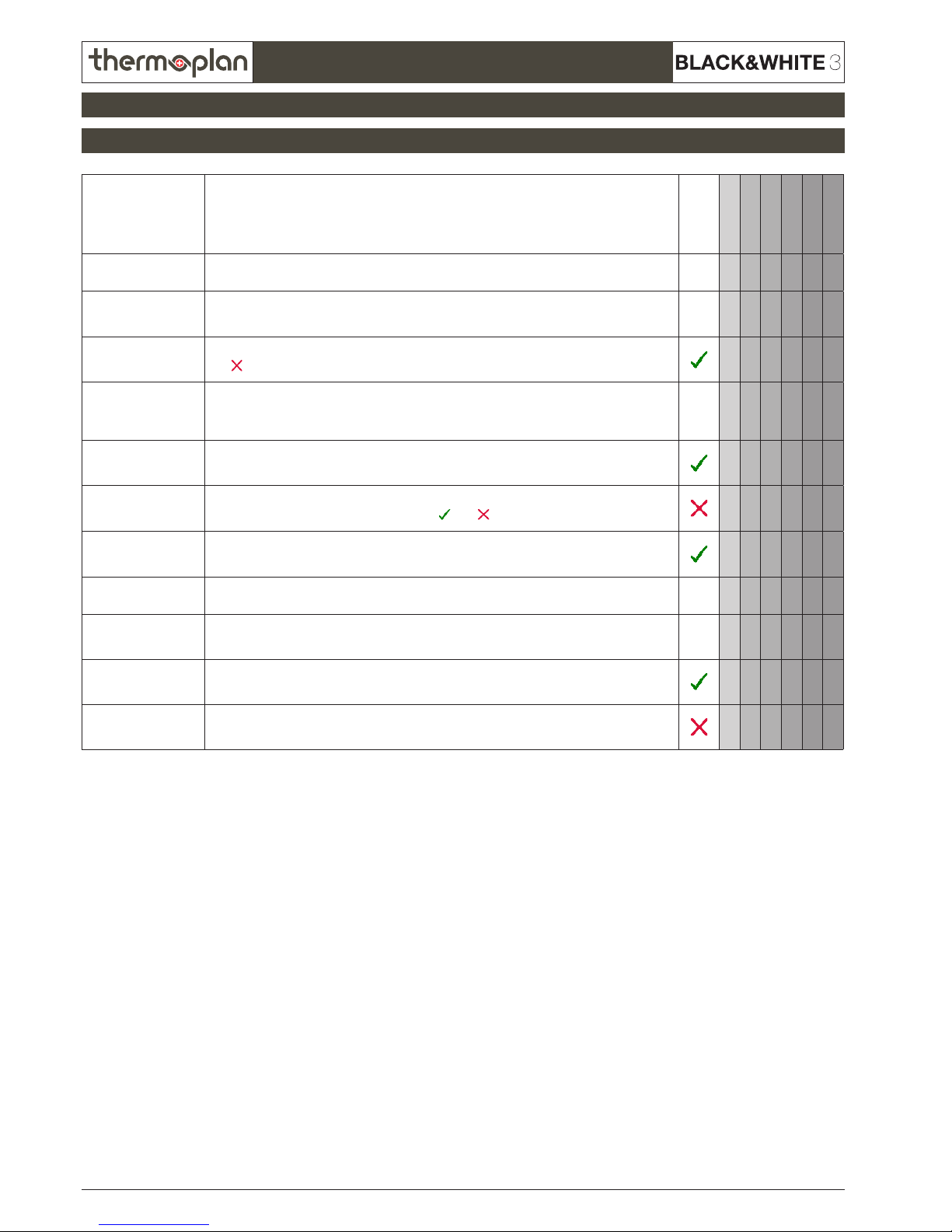

Parameter Description

Status

NormalbetriebCTCTM

CTS

CTMS

CBT

CBTM

Boiler temperature

Shows the temperature of coffee boiler

91 °C

x x x x x x

Pot temperature

Shows the temperature of coffee brewer

50 °C

x x

Ground Drawer

detected

Remove grounds drawer to check the contact.

If a

is shown, insert the grounds drawer correctly.

x x x x x x

Flowmeter ticks/sec

The value (ticks) must not change in the system check menu. If the value changes, it

means that the owmeter turns without the machine running -> there is a leakage in the

area right after the owmeter.

0

x x x x x x

Brewing motor in

endposition

Shows if the brew chamber on the mechanical module is in it‘s starting position

(touches the end switch).

x x x x x x

Motorrotation

detected

Turn the spindle wheel of the brew chambre slowly manually to check the 24VDC

motor. The value should alternate between

and .

x x x x x x

Beanhopper &

panel ok

Remove bean hopper or move up the control panel to check the signal.

x x x x x x

Pot level

Shows current ll state in % of the full coffee brewer tank‘s capacity.

20%

x x

Pot level step

Shows the current level of the coffee brewer‘s tank.

0

x x

Milkcleaningkey

Remove cleaning key to check the contact.

x x x x x x

Milkcleaningtablet

Remove cleaning key and press the contact pin inside the cleaning key‘s housing to

check the contact.

x x x x x x

1.1 Inputs

2.2 Inputs

2. Service menu „System Check“

Page 9

REV-1

6.9

SECTION 6

© 2011 by Thermoplan AG, Änderungen vorbehalten

Technical manual

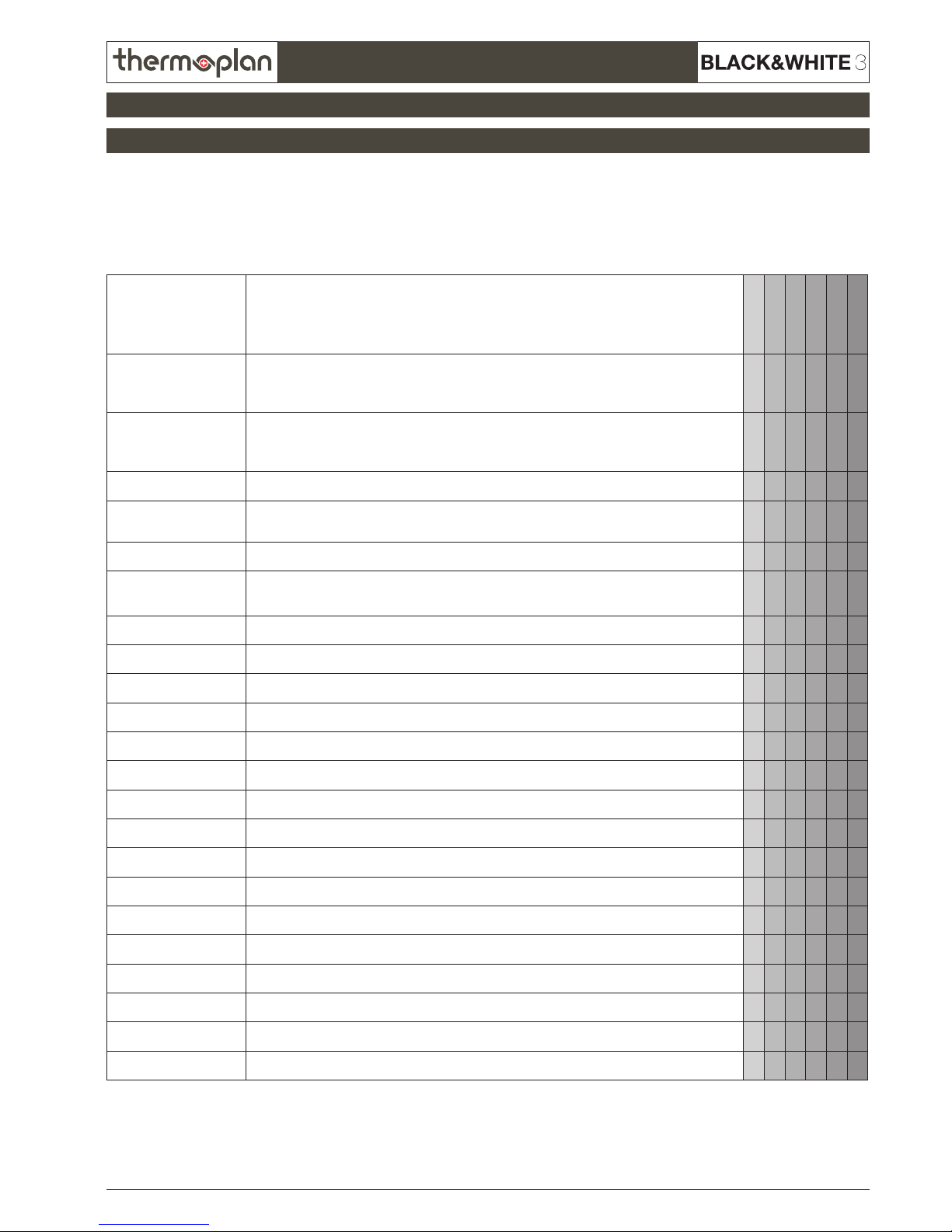

Press the output you wish to check to start it‘s function. For example press on „Grinder 1“ so the left grinder starts to

move. Press a valve to open it.

Following outputs can be checked:

Parameter Description

CT

CTM

CTS

CTMS

CBT

CBTM

Grinder 1

Function check: Grinder motor (230V). The rotation of the motor is in direction of the left

grinder which will grind coffee. If the grinder should be blocked, use the parameter

„Grinder 2“ so that grinder 1 turns in the opposite direction.

x x x x x x

Grinder 2

Function check: Grinder motor (230V). The rotation of the motor is in direction of the right

grinder which will grind coffee. If the grinder should be blocked, use the parameter

„Grinder 1“ so that grinder 2 turns in the opposite direction.

x x x x x x

Coffeeheater

Coffee boiler is heating. Attention: The heater is not secured against overheating!

x x x x x x

Coffeepump

Water pump starts. Attention: Only press shortly because the valves are closed and the

pump is heating up!

x x x

Milkpump

Milk pump starts.

x x x

Potpump

Tank pump starts. Attention: Only press shortly because the valves are closed and the pump

is heating up.

x x

Potheater

Tank is heating. Attention: Heater is not secured against overheating!

x x

Brewvalve

Brew valve on valve block opens (you should hear a „click“ noise)

x x x x x x

Bypassvalve

Bypass valve on valve block opens (you should hear a „click“ noise)

x x x x x x

Teavalve

Tea valve on valve block opens (you should hear a „click“ noise)

x x x x x x

Milkdrainvalve

Milk drain valve on valve block opens (you should hear a „click“ noise)

x x x

Milkselectvalve

Milk selection valve on valve block opens (you should hear a „click“ noise)

x x x

Milkdraingatevalve

Milk drain gate valve on valve block opens (you should hear a „click“ noise)

x x x

Milkairvalve

Milk air valve on valve block opens (you should hear a „click“ noise)

x x x

Milkrinsevalve

Milk rinse valve on valve block opens (you should hear a „click“ noise)

x x x

Milkcleanvalve

Milk clean valve on valve block opens (you should hear a „click“ noise)

x x x

Coldmilkvalve

Cold milk valve on valve block opens (you should hear a „click“ noise)

x x x

Refrigeratorrinsevalve

Refrigerator rinse valve on valve block opens (you should hear a „click“ noise)

x x x

POD/Cleaningvalve

Cleaning valve on valve block opens (you should hear a „click“ noise)

x x x x x x

Potvalve

Tank valve on valve block opens (you should hear a „click“ noise)

x x

Coffeeoutletvalve

Coffee outlet valve on valve block opens (you should hear a „click“ noise)

x x

Tankdrainvalve

Tank drain valve on valve block opens (you should hear a „click“ noise)

x x

2.3 Outputs

2. Service menu „System Check“

Page 10

REV-1

6.10

© 2011 by Thermoplan AG, Änderungen vorbehalten

SECTION 6

Technical manual

To leave the test screen, press for 2 seconds

on any place on the touchscreen.

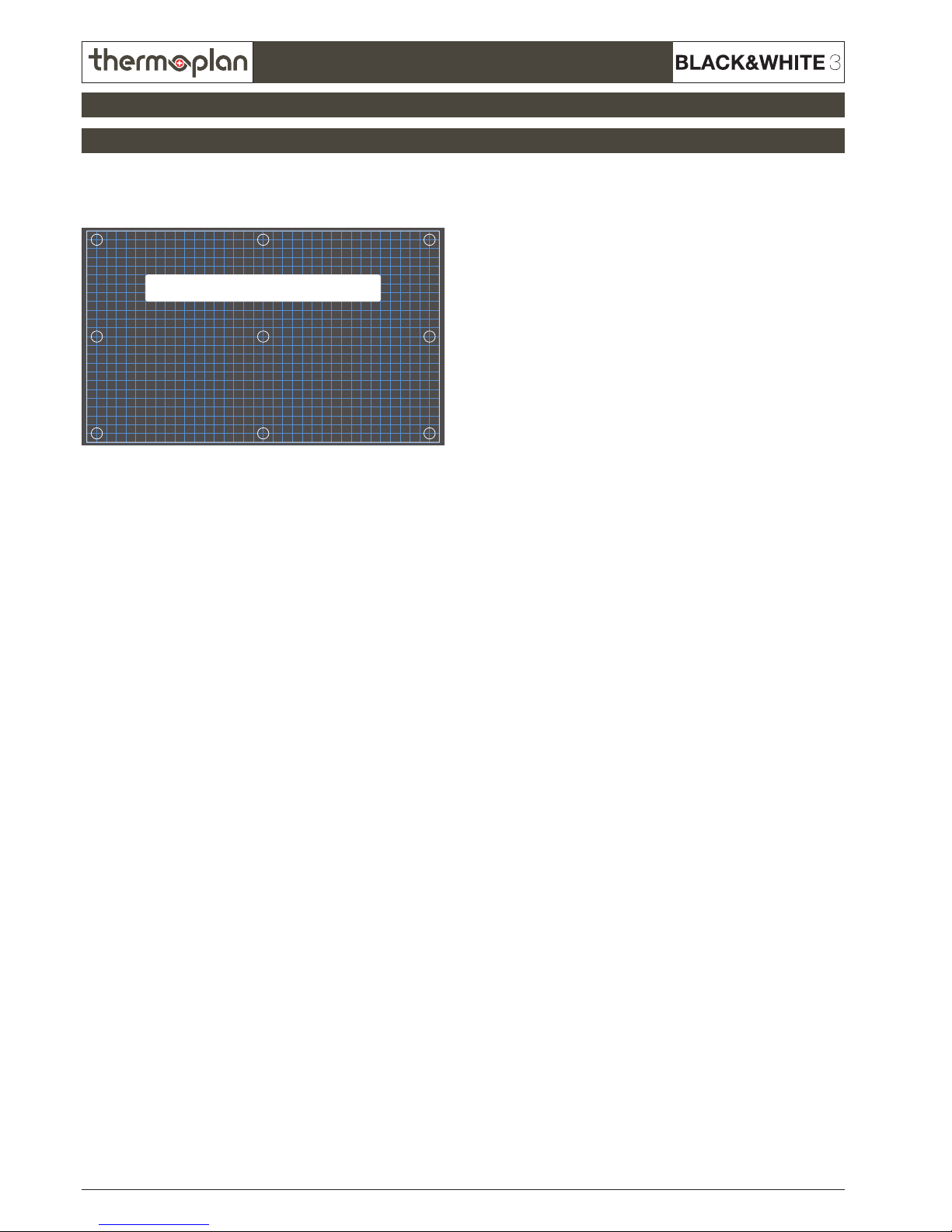

The system check menu also contains an option to check the touchscreen for it‘s functionality. Press on „Touchpanel test“

to start the test program. A grid will appear on the screen. After every touch on the screen a red „dot“ should appear on

the same spot.

2.4 Touchpanel Test

2. Service menu „System Check“

Zum Verlassen Touch 2s berühren

to leave, press and hold for 2s

Page 11

REV-1

6.11

SECTION 6

© 2011 by Thermoplan AG, Änderungen vorbehalten

Technical manual

3.1 Possible problems with the touchscreen

3. Touchscreen FOX

3.2 Troubleshooting on touch screen

• Slow reaction of the touchscreen

• Screen is ickering

• Some product buttons have disappeared

• Display shows unreadable hieroglyphics instead of text

• Machine does not start completely: „Ready“ is not displayed

• Blue box with error message on left top corner of the screen

• Screen stays black

• White screen (screen only returns white light)

Follow these instructions step by step to determine the error the fastest way.

Requirement: The CF card must be formatted with FAT or FAT32!

NTFS data system does not work!

Step 1

• Switch off machine

• Wait for 10 seconds

• Switch machine back on

• If this action does not solve the problem, proceed with step 2

Step 2

• Switch off machine

• Remove CF card (position CF card can be seen in section „3.3 Overview FOX-Print“)

• Check if there are any defects on the pins in the CF card slot

• Reinsert the CF card

• Switch machine back on

• If this action does not solve the problem, proceed with step 3

Step 3

Check FOX-Print index (see section „3.3 Overview FOX-Print“)

• Recommendation of CF card for FOX 70-Print version A-C: CF card type „take MS“

• From FOX 70-Print version D the CF card type does not matter anymore

• If this action does not solve the problem, proceed with step 4

Page 12

REV-1

6.12

© 2011 by Thermoplan AG, Änderungen vorbehalten

SECTION 6

Technical manual

3.2 Troubleshooting on touch screen

3. Touchscreen FOX

Step 4

Perform a touch panel test in the service menu „System Check“ to check the reaction time

Zum Verlassen Touch 2s berühren

to leave, press and hold for 2s

Step 5

Communication control CPU <--> FOX-Print by LEDs.

LEDs must be blinking on both CPU and FOX-Print!

If the LEDs do not blink (LEDs are marked in section „3.3 Overview FOX-Print“ and „3.4 Overview CPU“), but are out

of action or glow permanently, follow these steps:

• Switch off machine

• Plug out connection cable (see section „3.3 Overview FOX-Print“ and „3.4 Overview CPU“)

CAUTION: The machine must be turned off at the main switch before plugging the connection cable in or out. Else

there can be discharges on the electronincs, which can cause errors like in section „3.1 Possible problems with the

touchscreen“.

• Control the contacts on both: CPU and FOX-Print

• Plug connection cable back in

• Switch machine back on and check LEDs

• If there is still no connection repeat this step using a new connection cable

• If this action does not solve the problem, proceed with step 6

Step 6

• Switch off machine

• Change the FOX-Print

• Reconnect all cables and switch machine back on

• If this action does not solve the problem, proceed with step 7

Step 7

• Switch off machine

• Change the CPU

• Reconnect all cables and switch machine back on

Page 13

REV-1

6.13

SECTION 6

© 2011 by Thermoplan AG, Änderungen vorbehalten

Technical manual

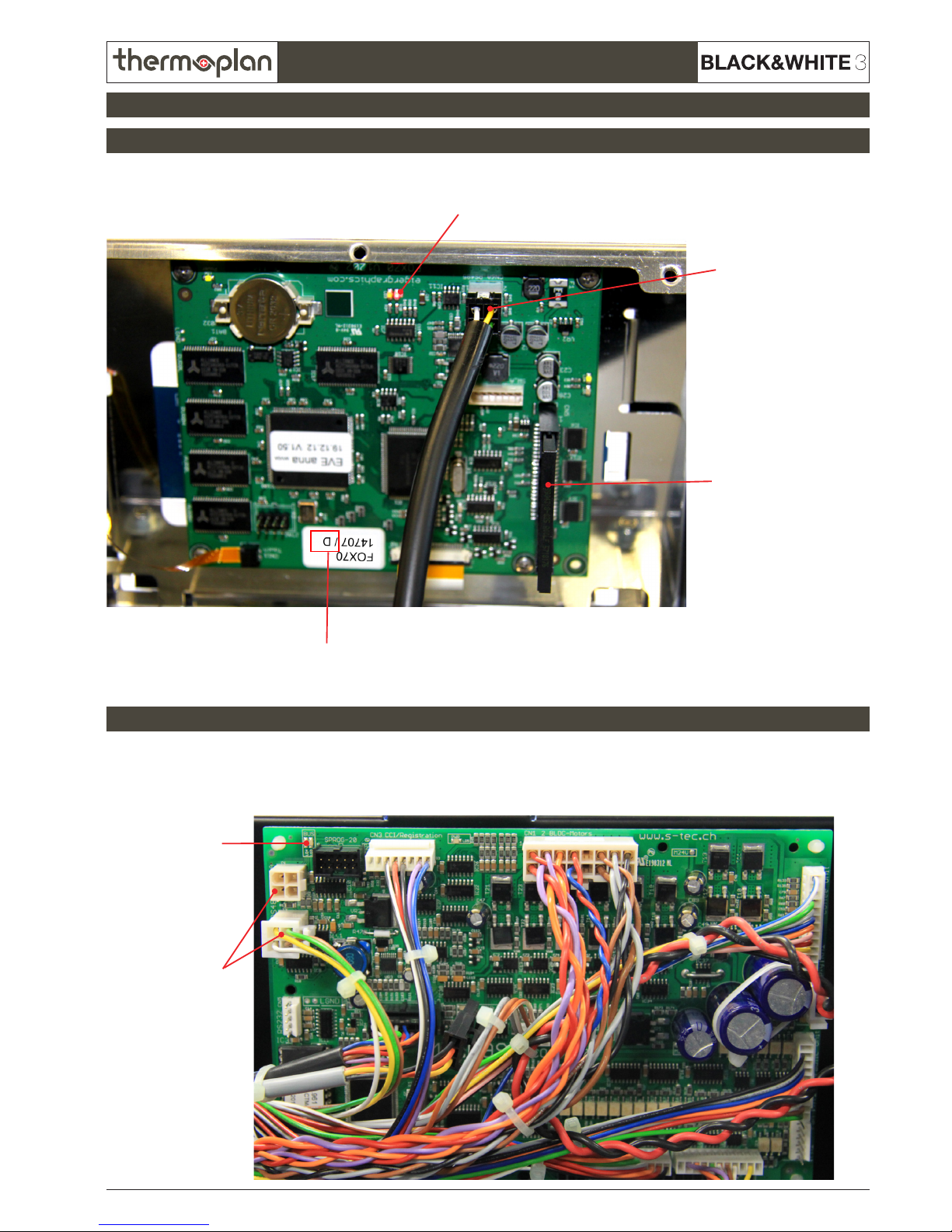

3.3 Overview FOX-Print

3.4 Overview CPU

3. Touchscreen FOX

Connection-LED CPU (blinking = connection OK)

The FOX-Print is located on the back of the touchscreen.

The CPU is located on the back of the chassis (see particular chassis ISO views).

Connection-

cable CPU - FOXPrint + slot

CF card in slot

FOX-Print index

Connection-LED

FOX-Print

(blinking =

connection OK)

Connection-

cable CPU -

FOX-Print slot

Page 14

REV-1

6.14

© 2011 by Thermoplan AG, Änderungen vorbehalten

SECTION 6

Technical manual

4.1 Error messages Chassis

4. Chassis

Error no. / picture Text Cause Fix

TX0104 Empty grounds drawer - Grounds drawer full

- No magnet on grounds drawer

- Magnet switch on chassis

defective

- Cable between magnet switch and

CPU has short circuit

- Remove grounds drawer, empty,

reinsert (wait min. 5 seconds)

- Mount magnet again

- Replace magnet switch

- Check cable and replace if

necessary

TX0106

Grounds drawer missing - Grounds drawer not inserted

correctly

- No magnet on grounds drawer

- Magnet switch on chassis

defective

- Cable between magnet switch and

CPU has short circuit

- Remove grounds drawer, empty,

reinsert (wait min. 5 seconds)

- Mount magnet again

- Replace magnet switch

- Check cable and replace if

necessary

TX0108

Service required Amount of brew cycles programmed

into machine has been reached

Provide annual service on machine.

Reset counter in service menu „Statistics“, to delete message. Machine

starts counter again from 0.

TX0109

Clean appliance Since the rst product dispensing

48 hours have passed (coffee products only) or 24 hours have passed

(if milk products were dispensed).

Machine must be cleaned to unlock.

Clean machine

TX0110

Voltage low Voltage too low, operation is

stopped as soon as voltage is below

the set tolerance (adjustable from

0-30%).

If the voltage gets too low during

a product dispensing, the product

will be nished, then the operation

stops.

Wait until voltage stabilises

TX0111

Voltage high Voltage too high, operation is

stopped as soon as voltage is above

the set tolerance (adjustable from

0-30%).

If the voltage gets too high during

a product dispensing, the product

will be nished, then the operation

stops.

Wait until voltage stabilises

TX0113

Piston error - Brew cylinder cannot travel to

desired position

- The gear belt between motor and

drive screw of the brew cylinder

is defective or not mounted

- The way of the brew cylinder is

blocked

- The mobile piston is blocked and

the brew cylinder cannot travel

back to the micro switch

- The brew cylinder cannot travel

over the x piston.

- Try dispensing product again

- Perform a rinse

- Check mechanical module

- gear belt

- brew cylinder

- mobile piston

- micro switch

- x piston

Page 15

REV-1

6.15

SECTION 6

© 2011 by Thermoplan AG, Änderungen vorbehalten

Technical manual

Chassis

4.1 Error messages Chassis

4. Chassis

Error no. / picture Text Cause Fix

TX0117 Change water lter Pre-set amount of water has own

through water lter

Change water lter, then reset

counter in service menu.

TX0118

Interface error „Interface“ is activated in software:

- Wrong payment interface

- No payment interface connected

Check interface settings in service

menu. If no interface is connected,

switch option to „off“

TX0131

Cleaning interrupted

Open POD

Cleaning switch on POD on wrong

side

Change POD‘s switch to product

mode

TX0136

Please ask for assistance Only shows up in self-service mode

so consumers do not try to x the

problem themselves.

Press and hold

until actual

display message shows up.

Follow orders or look the actual

message up in error list for further

information.

TX0137

Please add milk Milk is empty 1. Rell milk

2. Check level sensor

TX0139

Bean hopper missing or command

unit open

Bean hopper is not mounted or the

command desk is open

1. Place bean hopper correctly

2. Close command desk

3. Check contacts

TX0143

Machine locked

Start cleaning

Cleaning has not been performed.

Machine is locked until cleaning is

done.

Clean machine

TX0149

Insert coffe pad Coffee machine preparing for

dispensing a POD product

Open POD, insert coffee pod, close

POD

TX0150

Remove cleaning tablets Cleaning tablets are in cleaning key

when cleaning not in progress

Remove cleaning tablets from cleaning key. They must only be inserted

during cleaning.

Page 16

REV-1

6.16

© 2011 by Thermoplan AG, Änderungen vorbehalten

SECTION 6

Technical manual

4.1 Error messages Chassis

4. Chassis

Error no. / picture Text Cause Fix

TX0153 Cleaning done

Standby

After daily cleaning, the machine

changes to standby mode

Press OK to get the machine back

from standby.

TX0164

Cleaning interrupted

Please press rinse key

Cleaning has been interrupted Press rinse key to restart cleaning

procedure

TX0167

Cleaning interrupted

Remove grounds drawer

Cleaning has been interrupted Remove and reinsert grounds

drawer

TX0174

Remove and empty grounds drawer Grounds drawer has to be removed

for next action

Remove grounds drawer

TX0188

Check milk temperature Milk temperature too high 1. Check milk temperature

2. Switch on refrigerator

3. Check temperature sensors

TX0201

Cold start rinse

Please press rinse key

Rinse for start- and warm-up of

machine

Press rinse key

TX0241

Machine rinsing

ATTENTION HOT!

Warning note during rinse Wait until rinse has nished

Page 17

REV-1

6.17

SECTION 6

© 2011 by Thermoplan AG, Änderungen vorbehalten

Technical manual

Hydraulic clip

Cleaning

Cleaning

Check valveTea

Brew

Brew

(not used)

Mechanical clip

Cleaning key

Connection mechanical module

Hydraulic clip

Mechanical clip

Main switches

CPU

Connections

hydraulic module

4.2 CTM Front view

4. Chassis

Page 18

REV-1

6.18

© 2011 by Thermoplan AG, Änderungen vorbehalten

SECTION 6

Technical manual

Connections hydraulic moduleNet clips

Connectioin mechanical module

4.3 CTM Back view

4. Chassis

Page 19

REV-1

6.19

SECTION 6

© 2011 by Thermoplan AG, Änderungen vorbehalten

Technical manual

Flooding area

Flooding sensors

Drain Main water connection

4.4 CTM Bottom view

4. Chassis

Page 20

REV-1

6.20

© 2011 by Thermoplan AG, Änderungen vorbehalten

SECTION 6

Technical manual

Main switch

Cleaning key

CPU

4.5 CTM ISO view

4. Chassis

Page 21

REV-1

6.21

SECTION 6

© 2011 by Thermoplan AG, Änderungen vorbehalten

Technical manual

Cleaning key

Power print

(Powerboard)

Milk valve Drain gate valve

4.6 CTM ISO view 2

4. Chassis

Page 22

REV-1

6.22

© 2011 by Thermoplan AG, Änderungen vorbehalten

SECTION 6

Technical manual

Connection

Hydraulic module

Main switch

Hydraulic clip

Hydraulic clip

Cleaning

Cleaning

Check valveTea

Brew

Brew

(not used)

Hydraulic clip

Cleaning

key

Connection

Brew module

Connection mechanical module

CPU Mechanical clip

4.7 CBTM Front view

4. Chassis

Page 23

REV-1

6.23

SECTION 6

© 2011 by Thermoplan AG, Änderungen vorbehalten

Technical manual

Connection hydraulic moduleNet clips

Connection

brew module

Connection mechanical module

4.8 CBTM Back view

4. Chassis

Page 24

REV-1

6.24

© 2011 by Thermoplan AG, Änderungen vorbehalten

SECTION 6

Technical manual

Flooding area

Flooding sensors

Check valve Main water connection

4.9 CBTM Bottom view

4. Chassis

Page 25

REV-1

6.25

SECTION 6

© 2011 by Thermoplan AG, Änderungen vorbehalten

Technical manual

Main switches

Cleaning key

CPU

4.10 CBTM ISO view

4. Chassis

Page 26

REV-1

6.26

© 2011 by Thermoplan AG, Änderungen vorbehalten

SECTION 6

Technical manual

Cleaning key

Powerprint

(Powerboard)

Milk valve Drain gate valve

4.11 CBTM ISO view 2

4. Chassis

Page 27

REV-1

6.27

SECTION 6

© 2011 by Thermoplan AG, Änderungen vorbehalten

Technical manual

5.1 Error messages mechanical module

5 Mechanical module

Error no. / picture Text Cause Fix

TX0107 Bean hopper empty (left-hand side) - Bean hopper left is empty

- Lock of bean hopper is closed /

not connected

- After grinding, the brew cylinder

moves completely over the x

piston (like in rinse).

- Grinder motor or starting

condenser is defective

- Grinder motor triac on power print

is defective.

- Rell coffee beans in left bean

hopper

- Check grinding position and

powder way

- Check if coffee beans are

grinded

- Check cable connections between

mechanical module - power print

and CPU.

- Check gear belt, gear belt plates

and voltage

TX0113

Piston error - Brew cylinder cannot travel to

desired position

- The gear belt between motor and

drive screw of the brew cylinder

is defective or not mounted

- The way of the brew cylinder is

blocked

- The mobile piston is blocked and

the brew cylinder cannot travel

back to the micro switch

- The brew cylinder cannot travel

over the x piston.

- Try dispensing product again

- Perform a rinse

- Check mechanical module

- gear belt

- brew cylinder

- mobile piston

- micro switch

- x piston

TX0114

Bean hopper empty (right-hand

side)

- Bean hopper right is empty

- Lock of bean hopper is closed /

not connected

- After grinding, the brew cylinder

moves completely over the x

piston (like in rinse).

- Grinder motor or starting

condenser is defective

- Grinder motor triac on power print

is defective.

- Rell coffee beans in right bean

hopper

- Check grinding position and

powder way

- Check if coffee beans are

grinded

- Check cable connections between

mechanical module - power print

and CPU.

- Check gear belt, gear belt plates

and voltage

TX0115

Flow error Too low water ow 1. Open mains water connection

2. Empty grounds drawer

3. Perform rinse

4. Check owmeter

5. Check pump

TX0116

Overtime error Product is not dispensed correctly

because of too low water ow

1. Dispense product again

2. Check owmeter

3. Check pump

TX0119

Powder error Grinders blocked 1. Empty grounds drawer +

vacuum-clean grinders

2. Perform rinse

3. Check mechanical module

TX0139

Bean hopper missing or command

unit open

Bean hopper is not mounted or the

command desk is open

1. Place bean hopper correctly

2. Close command desk

3. Check contacts

Page 28

REV-1

6.28

© 2011 by Thermoplan AG, Änderungen vorbehalten

SECTION 6

Technical manual

5.1 Error messages mechanical module

5 Mechanical module

Error no. / picture Text Cause Fix

TX0145 Add coffee beans

Press ok to proceed product

dispensing

Run out of beans during product

dispensing

Rell beans and conrm with OK

button

TX0162

Error grinder right-hand side Grinder error right-hand side 1. Empty grounds drawer +

vacuum-clean grinders

2. Perform rinse

3. Check mechanical module

TX0163

Error grinder left-hand side Grinder error left-hand side 1. Empty grounds drawer +

vacuum-clean grinders

2. Perform rinse

3. Check mechanical module

Page 29

REV-1

6.29

SECTION 6

© 2011 by Thermoplan AG, Änderungen vorbehalten

Technical manual

Brew cycle

Rinse cycle

Cleaning cycle

Every second cycle also runs through the brew valve!

Hot water from coffee boiler

Connector for mec. module

Teon pipe to brew chamber

Brew chamber over mobile piston

Through grinded coffee

Through x piston

Coffee outlet

Brew valve

Hot water from coffee boiler

Brew valve

Connector for mec. module

Teon pipe to brew chamber

Through x piston

Brew chamber over mobile piston

Coffee outlet

Hot water from coffee boiler (through cleaning key)

Connector for mec. module

Teon pipe to brew chamber

Through x piston

Brew chamber over mobile piston

Coffee outlet

5.2 Water circulation

5 Mechanical module

Page 30

REV-1

6.30

© 2011 by Thermoplan AG, Änderungen vorbehalten

SECTION 6

Technical manual

Grinder right

Brew chamber motor

Grinder left

Grinder motor

Brew chamber

Coffee outlet

Connection

Gear belt

Brew chamber drive

Coffee

outlet valve

5.3 ISO view

5 Mechanical module

Page 31

REV-1

6.31

SECTION 6

© 2011 by Thermoplan AG, Änderungen vorbehalten

Technical manual

Gear

Gear belt

Brew chamber drive

Connection

mechanical module

Connection

cleaning

Brew chamber motor

Grinder right

Grinder left

Coarsness setting Coarsness setting

Grinder motor

Brew chamber

ne necoarse coarse

Spindle

5.4 Top view

5 Mechanical module

Page 32

REV-1

6.32

© 2011 by Thermoplan AG, Änderungen vorbehalten

SECTION 6

Technical manual

GearConnection

cleaning

Gear belt

Grinder drive

Connection

mechanical module

Gear belt

Brew chamber drive

Grinder motor

5.5 Back view

5 Mechanical module

Page 33

REV-1

6.33

SECTION 6

© 2011 by Thermoplan AG, Änderungen vorbehalten

Technical manual

Connection

cleaning

Connection

mechanical module

Gear belt

Grinder drive

5.6 Bottom view

5 Mechanical module

Page 34

REV-1

6.34

© 2011 by Thermoplan AG, Änderungen vorbehalten

SECTION 6

Technical manual

Brew chamber

Spindle

Backmost

bearing block

Front

bearing block

Brew chamber motor

Fix piston

5.7 ISO view Brewing unit

5 Mechanical module

Page 35

REV-1

6.35

SECTION 6

© 2011 by Thermoplan AG, Änderungen vorbehalten

Technical manual

Rapid test mechanical module

Connection settings:

1 Brew motor 24VDC+ 8

not set

15

not set

22 L1 (Grinder motor, heaters)

2 Brew motor 24VDC- 9

not set

16

not set

23

not set

3 Brew motor 5VDC+ 10

not set

17

not set

24 N Grinder 1

4

GND micro switch, brew motor 11 Reed bean hopper 2 18

not set

25 N Grinder 2

5 Signal brew motor 12

24VDC+ (reed, valve) 19

not set

6 Micro switch 5VDC 13 Coffee outlet valve 20 Grounding

7

not set

14

not set

21 Heater N

1

20

25

6

5.8 Quick test

5 Mechanical module

Page 36

REV-1

6.36

© 2011 by Thermoplan AG, Änderungen vorbehalten

SECTION 6

Technical manual

6.1 Error messages Hydraulic module

6 Hydraulic module

Error no. / picture Text Cause Fix

TX0101 NTC coffeeboiler open Problem with NTC in coffee boiler Check NTC and if necessary

exchange

TX0115

Flow error Too low water ow 1. Open mains water connection

2. Empty grounds drawer

3. Perform rinse

4. Check owmeter

5. Check pump

TX0116

Overtime error Product is not dispensed correctly

because of too low water ow

1. Dispense product again

2. Check owmeter

3. Check pump

TX0125

Waterow error No water pressure or owmeter

defective

1. Open mains water connection

2. Empty grounds drawer

3. Perform rinse

4. Check owmeter

5. Check pump

TX0141

NTC coffee boiler short-circuit NTC on coffee boiler had a short

circuit

Change NTC on coffee boiler

TX0151

No waterow detected No water pressure or owmeter

defective

1. Open mains water connection

2. Empty grounds drawer

3. Perform rinse

4. Check owmeter

5. Check pump

TX0154

Milk pump: no pulse Milk pump not recognised

TX0155

Water pump: no pulse Milk pump not recognised

TX0161

Please wait Machine rinses Wait until rinse is nished

TX0201

Cold start rinse

Please press rinse key

Rinse for start- and warm-up of

machine

Press rinse key

Page 37

REV-1

6.37

SECTION 6

© 2011 by Thermoplan AG, Änderungen vorbehalten

Technical manual

Flowmeter

Cleaning

connection

Connection

hydraluic module

Tea

connection

Air regulator

warm

Air regulator

cold

Heater cutout

(after over-

heating press

middle button

in again)

Tea valve

Milk outlet

Overpressure

/ Drain

Hot water boiler Heater cutout

(after overheating press middle button in again)

Cleaning

valve

6.2 Top view Hydraulic module

6 Hydraulic module

Page 38

REV-1

6.38

© 2011 by Thermoplan AG, Änderungen vorbehalten

SECTION 6

Technical manual

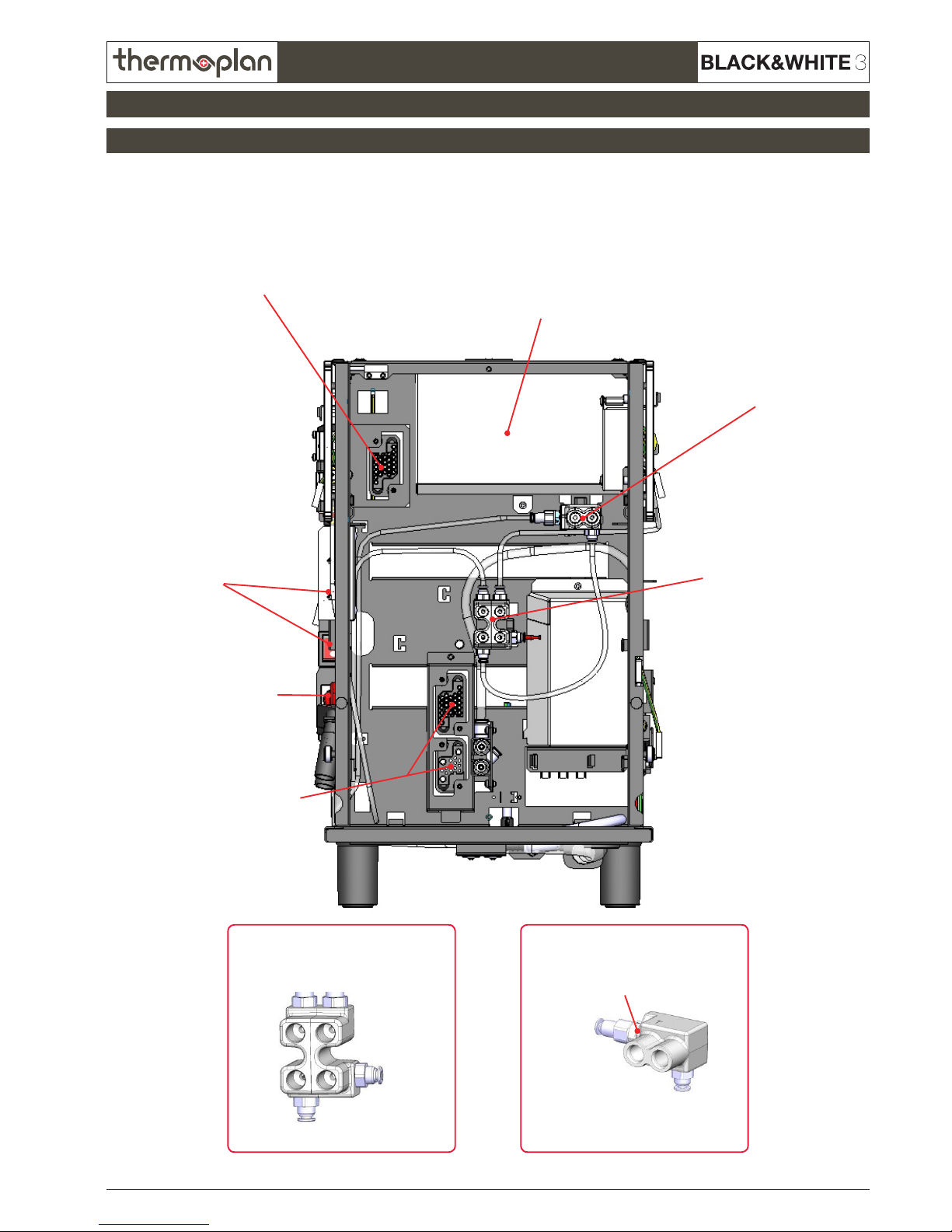

Air valve

Tea valve

Connections

Hydraulic module

Flowmeter

Hot water boiler

Overpressure valve

Brew valve

Tea connection

Cleaning

connection

Brew

connection

Pump unit

NTC coffee boiler

6.3 Back view

6 Hydraulic module

Page 39

REV-1

6.39

SECTION 6

© 2011 by Thermoplan AG, Änderungen vorbehalten

Technical manual

Milk way / Cleaning way

Rinse way

6.4 Milk way pump unit

6 Hydraulic module

Page 40

REV-1

6.40

© 2011 by Thermoplan AG, Änderungen vorbehalten

SECTION 6

Technical manual

Water way

Cleaning way

6.5 Water way pump unit

6 Hydraulic module

Page 41

REV-1

6.41

SECTION 6

© 2011 by Thermoplan AG, Änderungen vorbehalten

Technical manual

Water pump

Clean valve

Rinse valve

Milk nozzle

Milk pump

Air valve

Rinse valve: Needed to rinse the milk system after every milk product dispensing.

Clean valve: Needed to clean the complete system.

Air valve: Needed to add air to the milk for producing milk froth.

Connection

to owmeter

Connection

from milk clip

Connection

to boiler

6.6 ISO view Pump unit

6 Hydraulic module

Page 42

REV-1

6.42

© 2011 by Thermoplan AG, Änderungen vorbehalten

SECTION 6

Technical manual

Tea valve

Cleaning valve

Brew valve

Cleaning

connection

Tea

connection

Brew

connection

6.7 ISO view Valve block

6 Hydraulic module

Page 43

REV-1

6.43

SECTION 6

© 2011 by Thermoplan AG, Änderungen vorbehalten

Technical manual

Rapid test hydraulic module

Connection settings 1:

1 Brew valve 8

not set

15 GND Flowmeter 22 Motor water pump hall C

2 Tea valve 9 Air selection valve / cold milk valve 16

not set

23 Motor milk pump hall A

3 Cleaning valve 10 24VDC+ Valves pump unit 17

not set

24 Motor milk pump hall B

4

not set

11 Milk clean valve 18 Signal Flowmeter 25 Motor milk pump hall C

5 Milk air valve 12 Pump motors 24VDC+ 19 Signal NTC coffee boiler

6 Milk rinse valve 13 Pump motors 24VDC- 20 Motor water pump hall A

7 Air selection valve / cold milk valve 14 NTC coffee boiler / flowmeter 5VDC+ 21 Motor water pump hall B

Connection settings 2:

1

not set

7 Motor water pump coil A A Heater N

2

not set

8 Motor water pump coil B B Heater L

3

not set

9 Motor water pump coil C C Grounding

4

not set

10 Motor milk pump coil A

5

not set

11 Motor milk pump coil B

6

not set

12 Motor milk pump coil C

1

1

A

B

C

3

6

25

Connection 1

Connection 2

20

6.8 Quick test

6 Hydraulic module

Page 44

REV-1

6.44

© 2011 by Thermoplan AG, Änderungen vorbehalten

SECTION 6

Technical manual

7.1 Error messages brew module

7 Brew module

Error no. / picture Text Cause Fix

TX0105 Drain tub - Leckage on mechanical or

hydraulic module.

- Short circuit on tub sensors in

chassis.

- Short circuit on cable between tub

sensors and CPU.

- Check mechanical and hydraulic

module

- Check tub sensors and replace if

necessary

- Check cable and replace if

necessary

Page 45

REV-1

6.45

SECTION 6

© 2011 by Thermoplan AG, Änderungen vorbehalten

Technical manual

Brew Tank

Sensor unit

7.2 ISO view

7 Brew module

Page 46

REV-1

6.46

© 2011 by Thermoplan AG, Änderungen vorbehalten

SECTION 6

Technical manual

Connection

brew tank

Brew tank

7.3 Ruckansicht

7 Brew module

Page 47

REV-1

6.47

SECTION 6

© 2011 by Thermoplan AG, Änderungen vorbehalten

Technical manual

7.4 ISO view Sensor

7 Brew module

Page 48

REV-1

6.48

© 2011 by Thermoplan AG, Änderungen vorbehalten

SECTION 6

Technical manual

Pump

Jug valve

Tank drain valve

7.5 ISO view Chassis

7 Brew module

Page 49

REV-1

6.49

SECTION 6

© 2011 by Thermoplan AG, Änderungen vorbehalten

Technical manual

Rapid test brew module

Connection settings:

1

NTC coffee tank 5VDC+ 8 Print pressure sensor 15

not set

22 Triac A2

2

NTC coffee tank signal 9

not set

16

not set

23 Triac G

3 Print pressure sensor 10

not set

17

not set

24 Triac A1 (N)

4 Print pressure sensor 11

not set

18 Tank drain valve 25 Heater (L)

5

not set

12

not set

19 24VDC+ (Motor coffee p. , print, valve)

6

not set

13 Motor coffee pump 24VDC- 20

not set

7 Print pressure sensor 14

not set

21 Grounding

1

20

25

6

7.6 Quick test Brew module

7 Brew module

Page 50

REV-1

6.50

© 2011 by Thermoplan AG, Änderungen vorbehalten

SECTION 6

Technical manual

8.1 Error messages

8 Steam module

Error no. / picture Text Cause Fix

TX0121 NTC steamboiler error NTC in steam boiler is defective or

short circuit

Exchange NTC in steam boiler

TX0122

Steamboiler not ready 1. Steam boiler is in warm-up phase

2. Temperature sensor defective

1. Let steam boiler heat up

2. Check and replace temp. sensor

TX0123

Low water level in steamboiler 1. Too low water level in steam

boiler

2. Level sensor defective

1. Warten, bis Boiler gefüllt ist

2. Check and replace level sensor

TX0124

Hot water rinse

Press rinse key

Boiler must be rinsed Press rinse button

TX0138

Steamboiler ll error 1. Steam boiler could not be lled

2. Level sensor defective

1. Wait until lled

2. Open mains water connection

3. Check and replace level sensor

Caution:

These error messages of the steam module are only shown on the model BW3-CTS. The BW3-CTMS does not show these messages, because in

the BW3-CTMS a complete TS module is built-in!

Page 51

REV-1

6.51

SECTION 6

© 2011 by Thermoplan AG, Änderungen vorbehalten

Technical manual

8.2 ISO view

8 Steam module

Level sensor

Tea valve

Fill valve

Purge mix

valve

Water inlet

Steam valve

Security probe

Pressure relief valve

Page 52

REV-1

6.52

© 2011 by Thermoplan AG, Änderungen vorbehalten

SECTION 6

Technical manual

8.3 Front view

8 Steam module

Pressure gauge

Tea valve

Main switch

Drain drop

Reset buttons

thermal breakers

Notice

If there is a temperature on the steam

boiler of greater than 165°C (329°F), the

thermal breaker will interrupt the electrical

current.

Pressure switch

Page 53

REV-1

6.53

20 Ω

2700 W

2700 W

20 Ω

SECTION 6

© 2011 by Thermoplan AG, Änderungen vorbehalten

Technical manual

8.4 Back view

8 Steam module

Heater 1

Heater 2

Page 54

REV-1

6.54

1

A

20

F

25

H

6

C

© 2011 by Thermoplan AG, Änderungen vorbehalten

SECTION 6

Technical manual

Connection settings lower connector:

1 Working Level Probe 8

not set

15 24VDC 22 Gate Triac Steam 1

2 Security Level Probe 9 Pressure Switch Signal 16

not set

23 A2 Triac Steam 1

3 GND 10

Pressure Switch 5VDC 17

not set

24 Gate Triac Steam 2

4

not set

11

not set

18

not set

25 A2 Triac Steam 2

5

not set

12 Mixing / tea valve 19

not set

6

not set

13 Steam valve 20 L

7

not set

14 Filling valve 21 N

Rapid test TS module

Connection settings upper connector:

A L2 C N E

not set

G

not set

B

not set

D GND F L3 H N

8.5 Quick test Steam module

8 Steam module

Loading...

Loading...