Thermopatch NL-33 User Manual

thermopatch.com

NL-33

Eng V1.0

JUN 2018 translation from NL V1.0 June 2018

ATTENTION!

These instructions must be made available to all persons involved in the assembly,

commissioning, operation, maintenance and repair of this product

User manual

thermopatch.com

2

Copyrights

© 2018 Thermopatch bv, Almere, The Netherlands.

No part of this publication may be reproduced by any means without the prior written

permission of Thermopatch bv, The Netherlands.

Thermpatch, the Thermopatch logo, Thermo Seal and Thermocrest are registered

trademarks of Thermopatch.

Introduction

The products by Thermopatch are designed with special attention to your convenience.

Should you discover any fault or damage upon receipt of this product, please contact your

local Thermopatch vendor.

The manual has been prepared in accordance with NEN 5509 and in conformity with the Machinery Directive 2006/42/EC.

This user manual is intended not only for all users of the machine, but also for those who

install and maintain the NL-33. The goal is to familiarize you with the operation, to provide

for safe working instructions and guidelines for maintenance.

ATTENTION!

In order to make safe and optimal use of the NL-33 it is important to take notice of -

and understand the contents of this manual.

thermopatch.com

3

Contents

Copyrights 2

Introduction 2

Contents 3

1. General description 4

1.1 Delivery 4

1.2 Warranty and product liability conditions 4

2. Intended use 4

3. Assembly and installation 5

3.1 Assembly and installation 5

4. Operating Instructions 6

4.1 Operating the NL-33 6

4.2 Operating the control panel 6

4.2.1 Setting the temperature and the heat sealing time 6

4.2.2 Settings by means of the touch screen 8

4.2.3 Full automatic mode 10

4.2.4 Error messages on screen: 11

4.3 Adjusting the setting for the automatic arm swing 12

5. Overview of safety measures and warnings 13

5.1 Safety 13

6. Technical specications 15

6.1 Specifications of the NL-33 15

7. Transport and storage 17

7.1 Transport 17

7.2 Storage 17

8. Maintenance 18

9. Technical annexes (English) 19

9.1 Spare Parts 19

9.2 Troubleshooting 19

9.3 Drawings with parts 20

9.4 Electric diagram 21

9.5 Pneumatics diagram 22

10. End of life 23

11. Declaration of conformity 24

12. Disclaimer 25

thermopatch.com

4

1. General description

The pneumatic NL-33 is a practical, universal heat seal machine. Textile labels, emblems,

repair patches, transfers, in short all Thermopatch materials for marking and repair are

easily and durably pressed onto textile fabrics.

1.1 Delivery

The NL-33 machines are delivered on a pallet covered with a wooden crate.

In the delivery of your NL-33 machine you will nd the following:

• NL-33 heat seal machine

• Power cord

• Air tube 6 mm

• CE declaration with serial number

• Quick installation guide

• Quality checklist

• Manual including the CE declaration, on CD-ROM

1.2 Warranty and product liability conditions

Thermopatch points to its warranty and product liability conditions as laid down in our terms

and conditions. These can be obtained from your Thermopatch supplier.

2. Intended use

The NL-33 heat seal machine is practical and universally applicable.

The machine is designed for applying transfers, emblems and other Thermopatch heat seal

products.

WARNING!

Any use other than described above can be dangerous and cause damage and thus

qualies as ‘misuse’ which excludes Thermopatch bv from any liability.

thermopatch.com

5

3. Assembly and installation

3.1 Assembly and installation

1. Unpacking:

• Remove the wooden protective crate.

• Use a 10 mm spanner to remove the four screws with which the machine is screwed to

the pallet

• Lift the machine onto the work table by means of the tongs that are mounted.

2. Electrical installation (1)

Take the NL-33 out of the box and place the machine on a stable work table in the vicinity of

a grounded socket. The NL-33 is connected to the power supply (230 V alternating current)

with the supplied mains cable. The NL-33 is grounded and equipped with two fuses type T

16 A.

3. Pneumatic installation (2)

In order to be able to work with the NL-33 without problems, it is very important that you

work with clean, dry air that is oered at a minimum of 3 bar up to a maximum of 8 bar.

The supplied water separator / pressure regulator is only an additional protection for the

machine. The user must ensure that the air pressure does not exceed 8 bar. Connect an air

tube with a diameter of 6 mm to the locally provided air pressure system and connect it to

the water separator / pressure regulator of the NL-33.

thermopatch.com

6

4. Operating Instructions

4.1 Operating the NL-33

• Switch on the press by pressing the power switch located at the rear.

• Set the desired temperature according to the chosen type of transfer

• Set the desired time according to the chosen type of transfer

• Set the desired pressure by turning the pressure adjustment knob in the middle, below

the display. Turn left to decrease the heat sealing pressure, turn right to increase the

heat sealing pressure.

• Check the set pressure on the manometer which is mounted to the left of the pressure

adjustment knob.

4.2 Operating the control panel

The settings for temperature and time are displayed on the control panel.

4.2.1 Setting the temperature and the heat sealing time

a) Temperature

• Press the temperature symbol on the screen. Press - or + and hold for decreasing or increasing the setting.

• Press the 'WELCOME' key to conrm and storing of the setting.

• You can also choose to make use of presets by means of the arrow keys on the screen.

b) Time

• Press on one of the two elds for time setting on the screen. Each side, left or right, has

its own setting. Press - or + and hold for decreasing or increasing the setting.

• Press the 'WELCOME' key to conrm and storing of the setting.

• You can also choose to make use of presets by means of the arrow keys on the screen.

c) Pressure

• Use the grey pressure adjustment knob in the middle, under the display. The actual

pressure setting is shown on the manometer, placed to its left.

• Pull the knob outwards to unlock and turn left for a decrease in pressur and right for an

increased pressure.

• Push the knob back into place again to lock it.

d) Adjusting the swing speed of the press

• Please contact your supplier to adjust this setting.

thermopatch.com

7

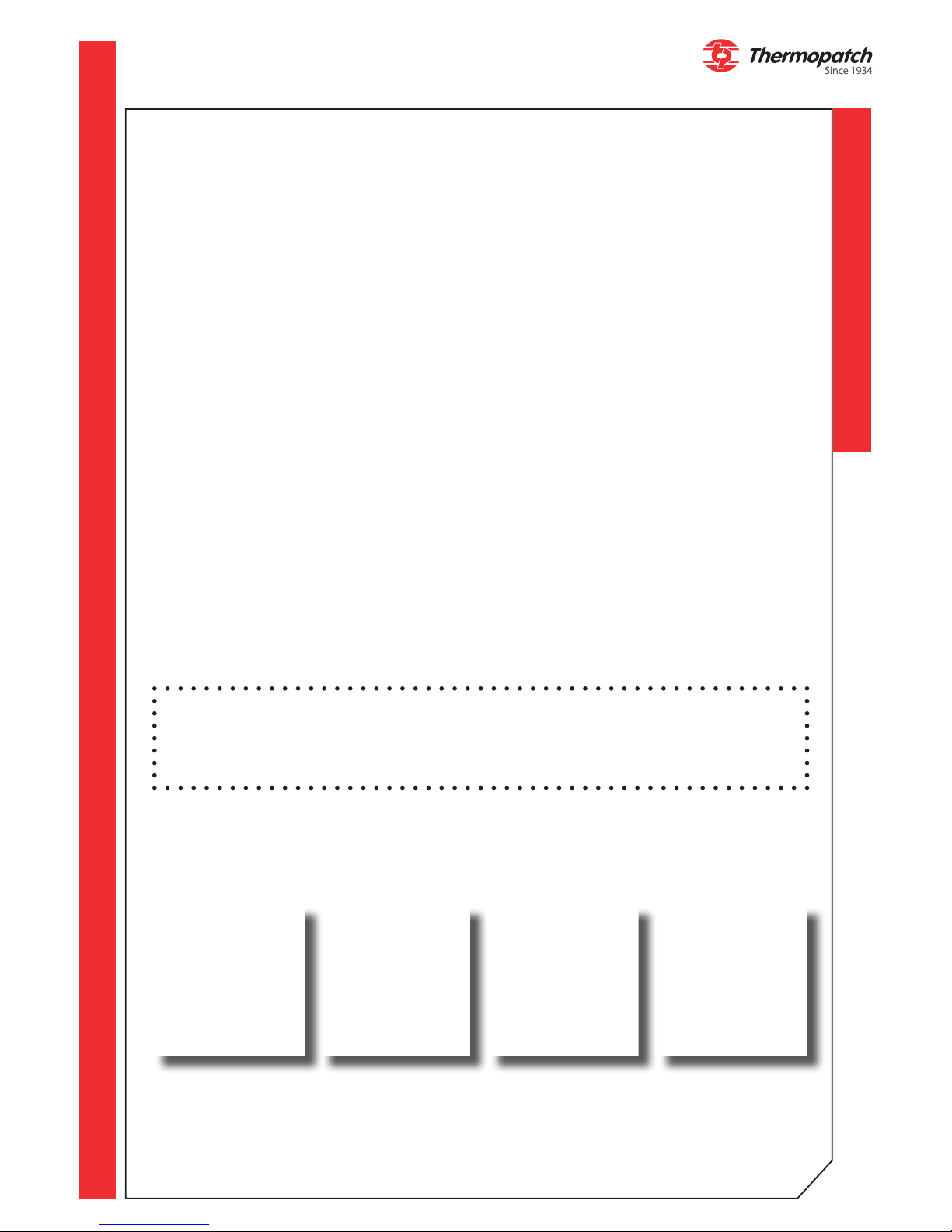

Presets

Date and

time

Actual temperature

Heat indicator

Timer left Timer right

resettable counter

Key for menu settings

decrease setting,

open next menu,

browse presets

increase setting,

open next menu,

browse presets

Touchscreen

Pressure

adjustment

knob

Emergency

Stop button

Manometer

thermopatch.com

8

4.2.2 Settings by means of the touch screen

a) Presets

This menu contains 9 stored operating programs; for each of these 5 presets can be added

by entering the required parameters. The operating programs must be suited for the chosen

application. The temperature adjustment is set to each program.

Available programs:

Browsing program

presets

Browsing programs

End of cycle

buzzer settings

User comfort

settings

Sleeping mode Energy saving

Machine

settings

Diagnostic mode

Next screen

• Flex: for placing ex and ock

• DTG 1: for drying pre-treated materials

• DTG 2: for pressing pre-treated materials

• SUBLI T: for sublimation printing on textiles

• SUBLI R: for sublimation printing on rigid materials

• SCREEN: for placing screen transfers

• LASER: for placing laser transfers

• QUICKFLEX: for placing ex in under 5 seconds

b) Settings menu

Press the green button in the middle of the touch screen in order to open the settings

menu.

Press again to open the desired menu.

Press the arrow button in the middle, below to leave the settings screen.

c) Sleeping mode

Loading...

Loading...