Instruction Manual

Models 135A and 136S

Waterproof and Intrinsically Safe

Portable Conductivity Meters

Software V ersion: 1.x

TA–193.204–ORE02 260201

AQUAfast, Cahn, ionplus, KNIpHE, ORION, PerpHecT, perpHecTion, Sensing the future, SensorLink, Sure-Flow, Titrator PLUS and TURBO2 are registered trademarks of Thermo Orion.

1-888-pHAX-ION, All in One, AssuredAccuracy, AUTO-BAR, AUTO-CAL,

AUTO DISPENSER, AUTO-LOG, AUT O-STIR, AUT O-READ, Cable-Free,

CERTI-CAL, CISA, DataCOLLECT, digital LogR, DirectCal, DuraProbe,

Extra Easy/Extra Value, F AST QC, GLPcal, GLPcheck, GLPdoc, Ionalyzer,

KAP, KNIpHE, LogR, Minimum Stir Requirement, MSR, NISS, One-Touch,

One-Touch Calibration, One-Touch Measurement, Optimum Results, PENPal, pHISA, pHix, Phuture, Pure Water, QuicKcheK, rf link, ROSS, ROSS

Resolution, Sage, SAOB, Stat Face, The Enhanced Lab,ThermaSense,

Triode, TRIUMpH, Unbreakable pH, Universal Access and Wine Master are

trademarks of Thermo Orion.

Guaranteed Success and The Technical Edge are service marks of

Thermo Orion.

PerpHecT meters are protected by U.S. patent 4,321,544. Other patents

pending.

ROSS and PerpHecT ROSS are protected by U.S. patent 4,495,050. Other

patents pending.

ORION Series A meters and 900A printer are protected by U.S. patents

5,108,578, 5,198,093, D334,208, D346,753.

ORION 81, 82, 91, and 92 series glass electrodes are protected by U.S.

patents 4,661,236 and 4,687,500.

Sure-Flow electrodes are protected by European patent 278,979 and Canadian patent 1,286,720. Other patents pending.

ionplus electrodes and Optimum Results solutions have patents pending.

E Copyright 1999, Thermo Orion. All rights reserved.

The specifications, descriptions, drawings, ordering information and part

numbers within this document are subject to change without notice.

This publication supersedes all previous publications on this subject.

Models 135A and 136S Portable Conductivity Meters

Information III

Safety Precautions

Be sure to read and follow these instructions !

The Model 136S Conductivity Meters may only be opened

to change the batteries outside hazardous areas. If repairs

are necessary, the meter must be sent in to the factory.

Never operate the remote interface or printer within hazardous areas.

When using the meter in hazardous areas, watch for electrostatic charges! For example, never wipe off the meter

with a dry cloth. Observe the relevant regulations concerning ESD.

Whenever it is likely that the protection has been impaired, the meter shall

be made inoperative and secured against unintended operation.

The protection is likely to be impaired if, for example:

❏ the meter shows visible damage

❏ the meter fails to perform the intended measurements

❏ after prolonged storage at temperatures above 70 °C

❏ after severe transport stresses

Before recommissioning the meter, a professional routine test according to

EN 61 010-1 shall be performed. This test should be carried out at our factory.

cal

Note

Warning

Information IV

Information on this Instruction Manual

ITALICS are used for texts which appear in the display of

Thermo Orion Model 135A or 136S.

Bold print is used to represent keys, e.g. cal.

Display examples

or

keys whose functions are explained are frequently shown

in the left-hand column.

Notes provide important information which should always

be observed when using the meter .

Warning means that the instructions given must always be

followed for your own safety. Failure to follow these

instructions may result in injuries.

Models 135A and 136S Portable Conductivity Meters

Contents V

Contents

Safety Precautions III. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Information on this Instruction Manual IV. . . . . . . . . . . . . . . . . . . . . . . . . .

1 The Models 135A and 136S Conductivity Meters 1. . . . . . . . . . . . . . .

Package Contents 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Short Description of Meters 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Operation 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Meter Design 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keypad 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connection and Start-up 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measurement 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Log Memory 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Log 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clock Mode 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial Interface 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard Setting for PRT300 Printer 22. . . . . . . . . . . . . . . . . . . . . . .

Configuring the PRT300 Printer 22. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printing Measured Values and GLPdoct Report 23. . . . . . . . . . . . .

3 Troubleshooting and Maintenance 24. . . . . . . . . . . . . . . . . . . . . . . . . . .

Error Messages 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing batteries 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the meter 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents VI

Appendix 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Declarations of Conformity 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Certificate of Conformity 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Drawing 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ordering Information 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications for PRT300 Printer 40. . . . . . . . . . . . . . . . . . . . . . . . . .

Warranty 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Terms 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Models 135A and 136S Portable Conductivity Meters

Models 135A and 136S 1

1 The Models 135A and 136S

Conductivity Meters

Package Contents

Please check the completeness of the shipment after unpacking.

The package should include:

❏ Thermo Orion Model 135A or 136S Conductivity Meter

(ready for operation)

❏ Neck strap

❏ This instruction manual

❏ Quickstart instructions

❏ Interface cable with adapter for printer and PC

❏ PC software

Short Description of Meters

❏ The Models 135A and 136S measure conductivity, sali-

nity, TDS and temperature in industry, the environment,

food processing and waste-water treatment.

❏ Operation of the Model 136S is also permitted in Zone 1

hazardous areas.

❏ The meters meet the European EMC regulations

(89-336-EEC) and the recommendations of NAMUR

NE 21.

❏ The meters are IP 66 protected to EN 60 529.

Warning

Models 135A and 136S 2

❏ T emperature compensation is automatic with a conducti-

vity probe with integral temperature sensor or a separate ATC probe, or the temperature may be manually

entered.

❏ Calibration can be carried out by directly entering the

cell constants, by calibrating with Thermo Orion Conductivity Standards, or with any other buffer solutions.

❏ The data log records up to 100 measured values with

the temperature, date and time. Recording takes place

either manually, interval or event-controlled.

❏ To minimize battery consumption, the meter switches off

after either one or twelve hours when it is not operated.

❏ Only three alkaline AA batteries are required for uninter-

rupted operation for approx. 1,000 hours.

❏ PC software allows complete remote control of the me-

ter via PC. All measured values and parameters can be

read out and easily processed further (e.g. using Microsoft Excel).

❏ Measured values and GLPdoct can also be sent di-

rectly to a printer via the serial interface.

Never use the remote interface to PC or printer in hazardous areas!

Models 135A and 136S Portable Conductivity Meters

Operation 3

2 Operation

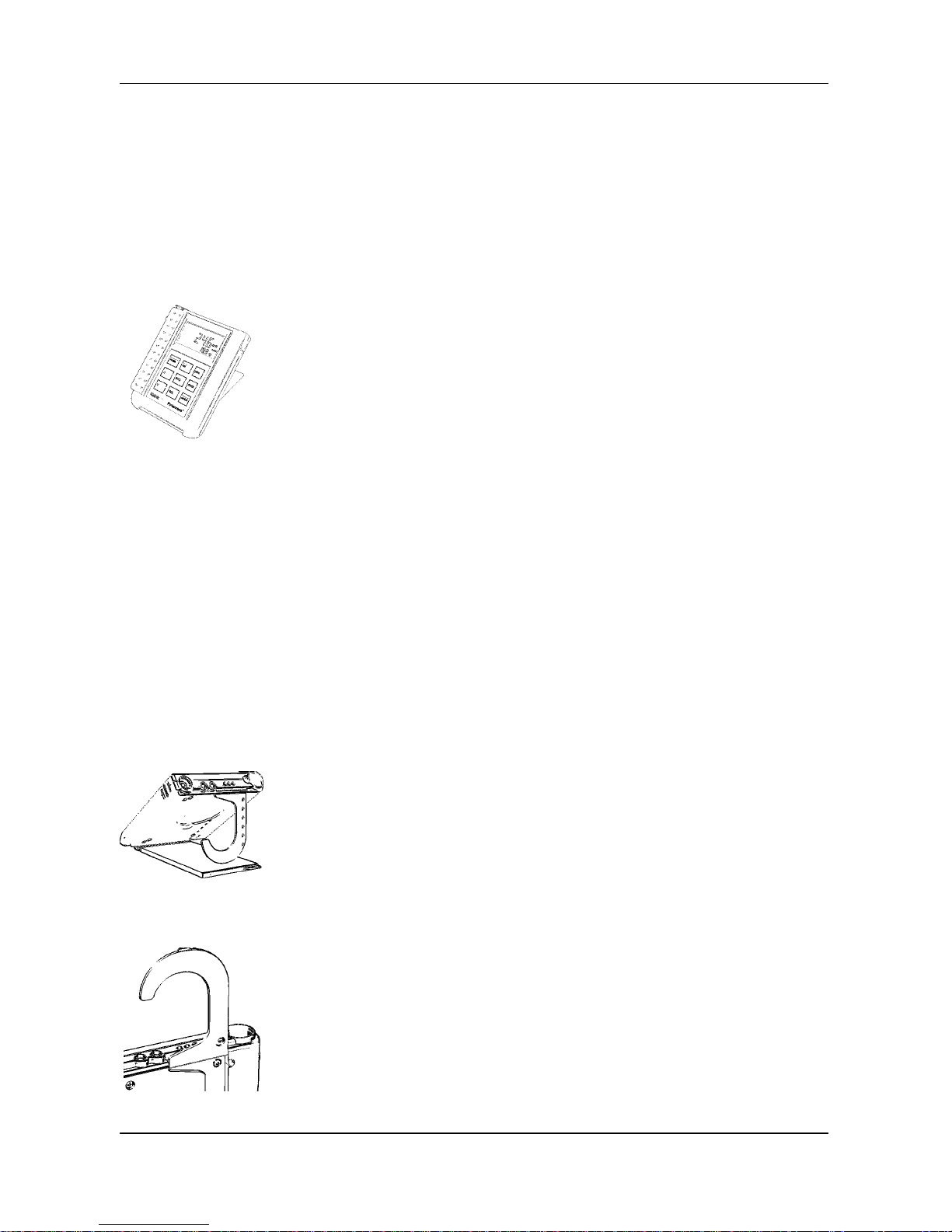

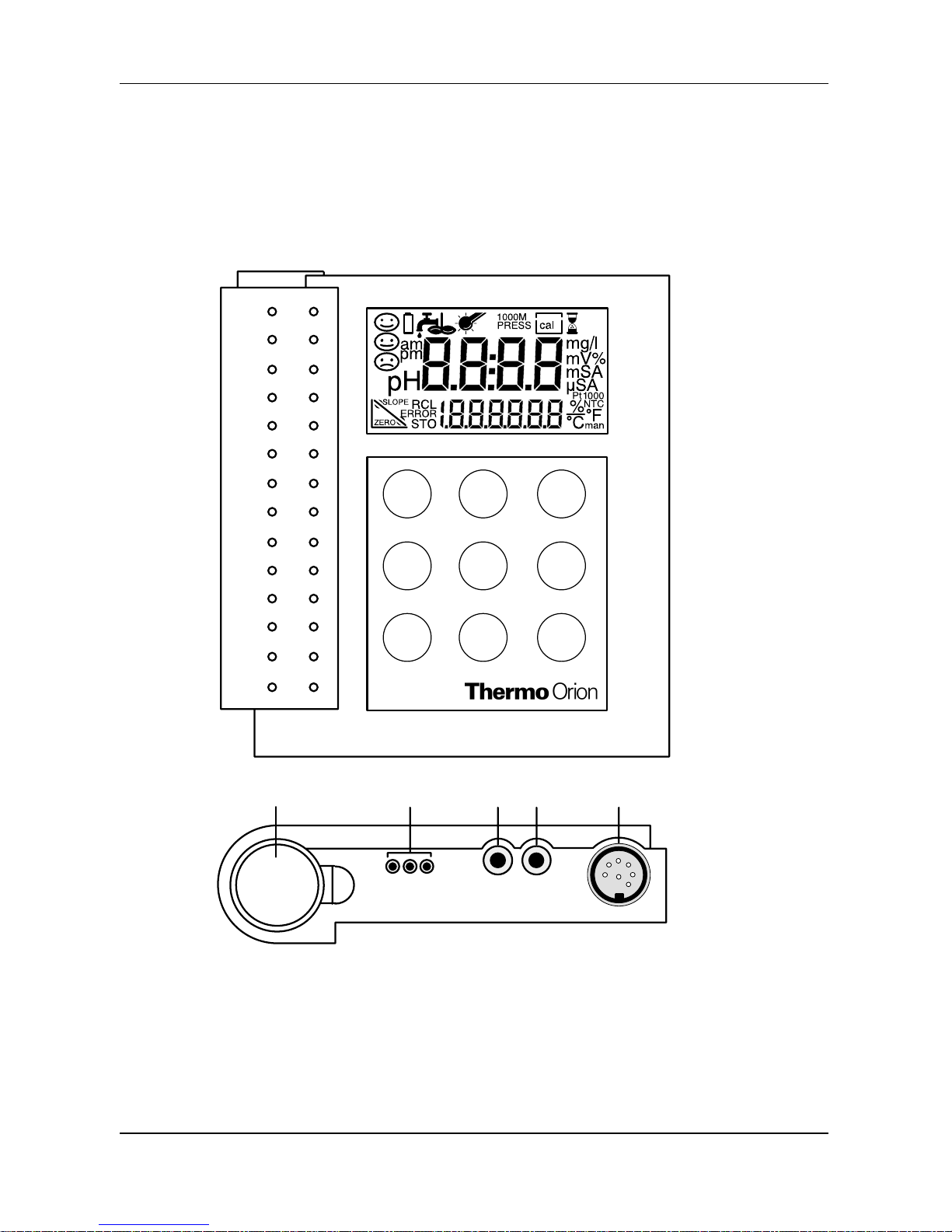

Meter Design

1

2

3

4

5

1 Sensor connection

2, 3 Separate temperature probe connection

4 PC/printer interface connection

5 Probe holder , removable

meas

cal

STO

RCL

Y

B

print

clock

power

power

meas

Note

cal

Operation 4

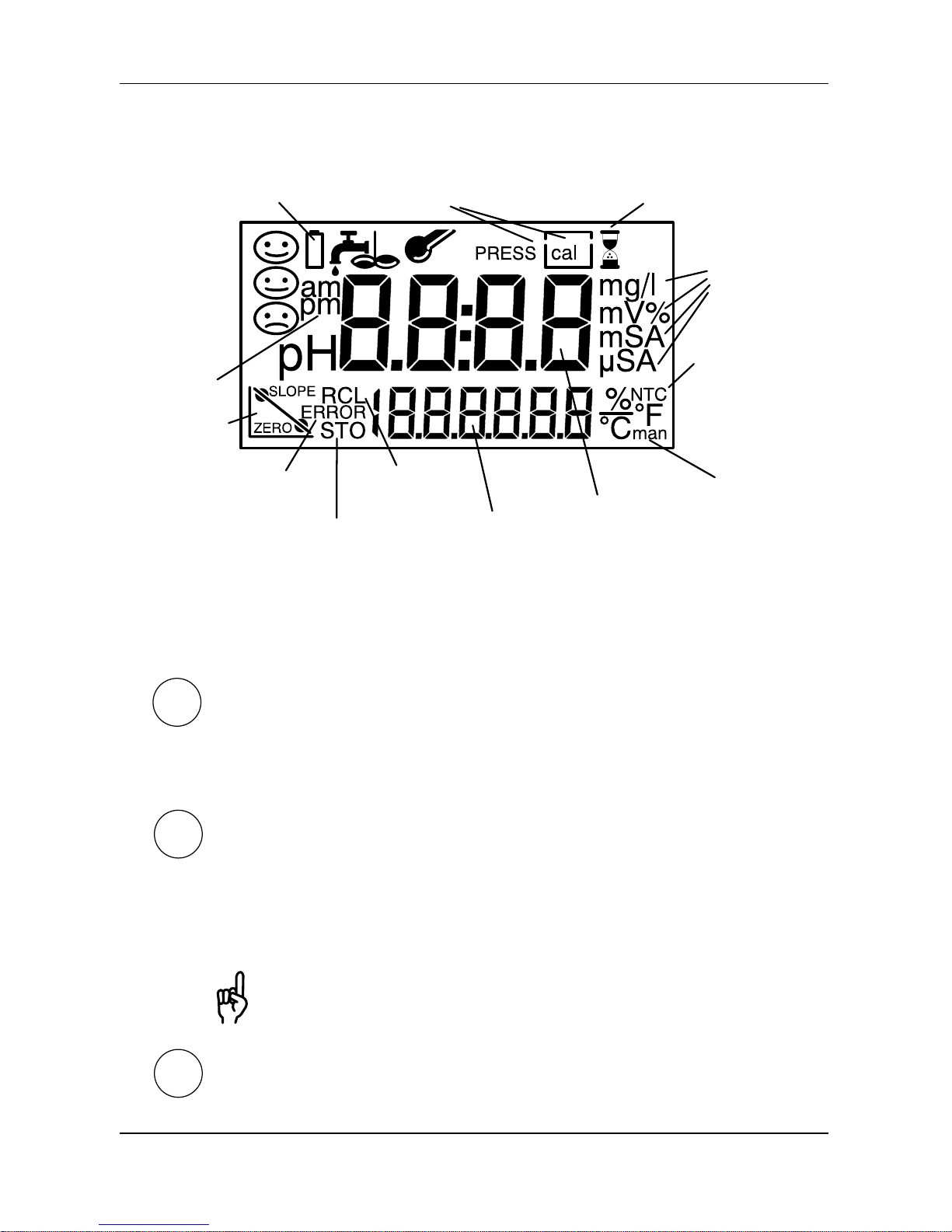

Display

Battery

empty

Press

cal key

Wait

Manual

temperature

detection

Temperature

detection

using NTC

Write

memory

Read

memory

Slope

(cell

constant)

Clock

Main

display

Secondary

display

Measurement units

Error

message

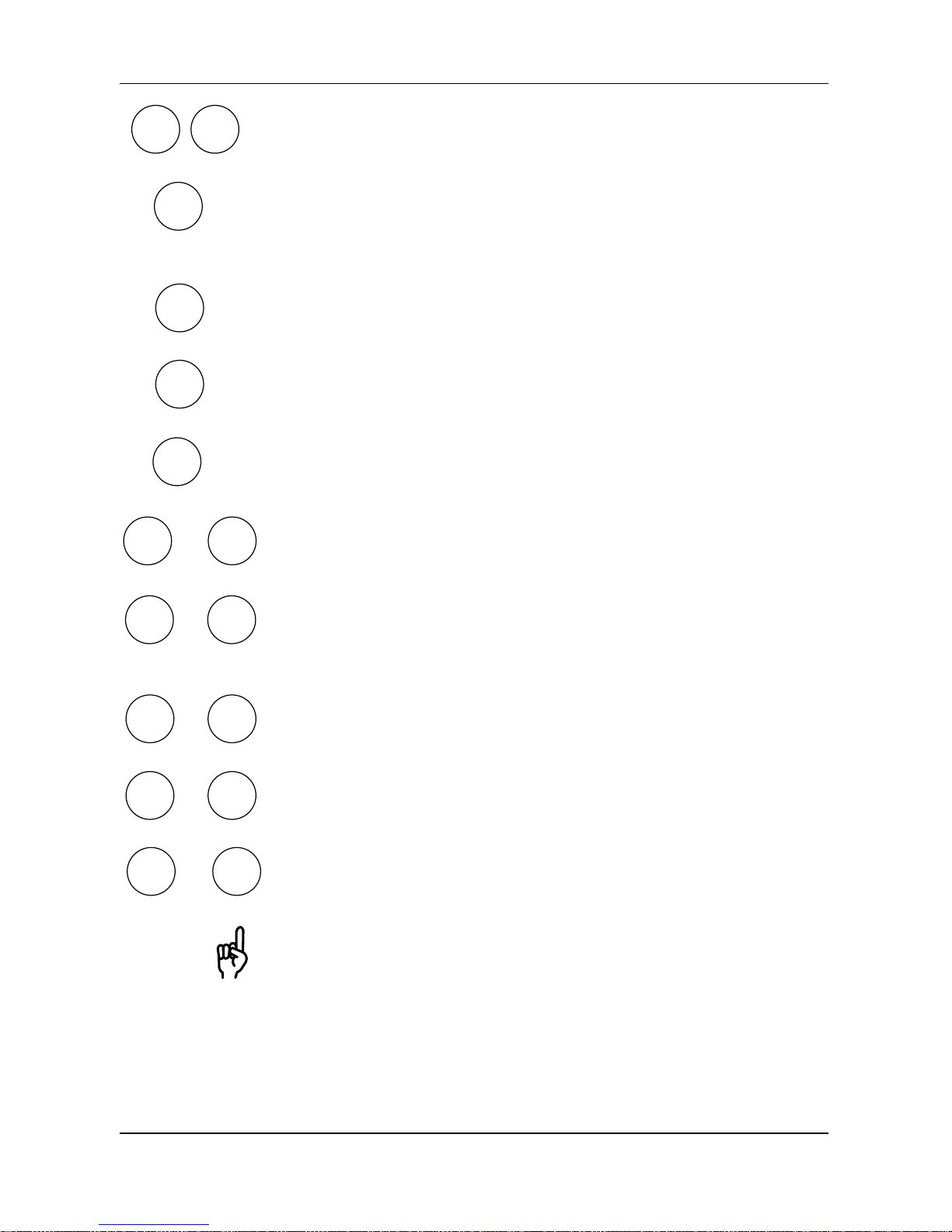

Keypad

Pressing the power key switches the meter on or off.

After switching on, the meter automatically performs a

self-test and checks for the presence of a temperature

probe. Then it goes into the measuring mode.

Pressing the meas key returns the meter to the measuring mode from any function. Pressing the meas key in the

measuring mode displays the following parameters:

Cond measuring mode: temperature compensation

tdS measuring mode: TDS factor

You can also power the meter up using the meas key.

However, only an abbreviated self-test is performed.

Pressing the cal key starts calibration.

Y B

clock

STO

RCL

print

RCL

+

print

cal

+

print

STO

+

clock

STO

+

clock

cal

+

power

Note

Models 135A and 136S Portable Conductivity Meters

Operation 5

With the

Y and B keys you can select and change parame-

ters and select a mode.

Pressing the clock key switches the meter into the clock

mode. All measurement processes are cancelled and the

battery consumption is reduced to a minimum.

Pressing the STO key activates the data logger for writing

measured values.

Pressing the RCL key activates the data logger for reading

measured values.

Pressing the print key sends the currently measured

value to a printer or PC.

Pressing the RCL and print keys prints out the logged

data in memory.

Pressing the cal and print keys prints out the GLPdoct

report.

Pressing the STO and clock keys switches the meter

into the data logger mode.

Pressing the clock and STO keys activates the mode for

setting the date and time.

Pressing the cal and power keys when the meter is

switched off, activates the configuration menu.

When pressing two keys simultaneously, make sure that

the key shown at the left is pressed first.

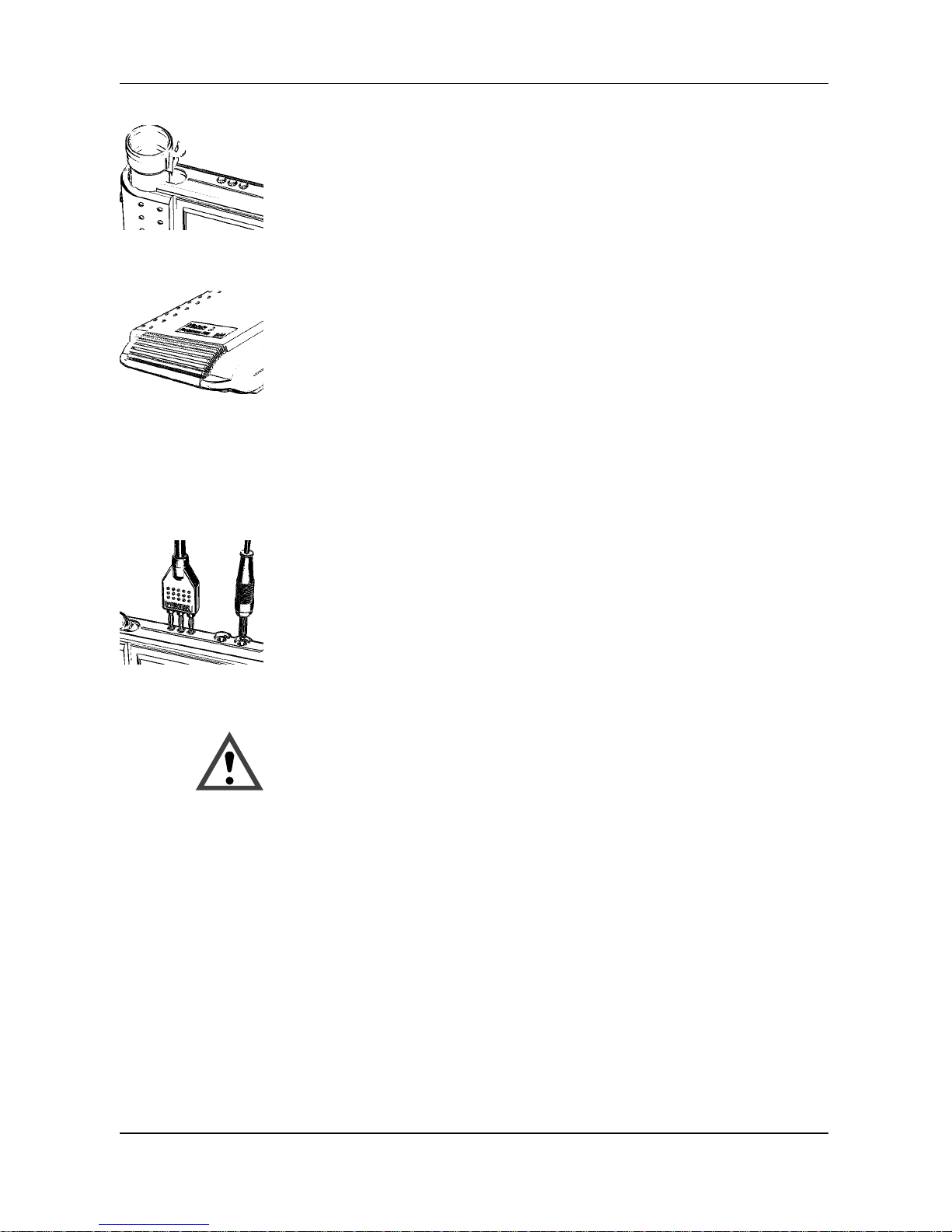

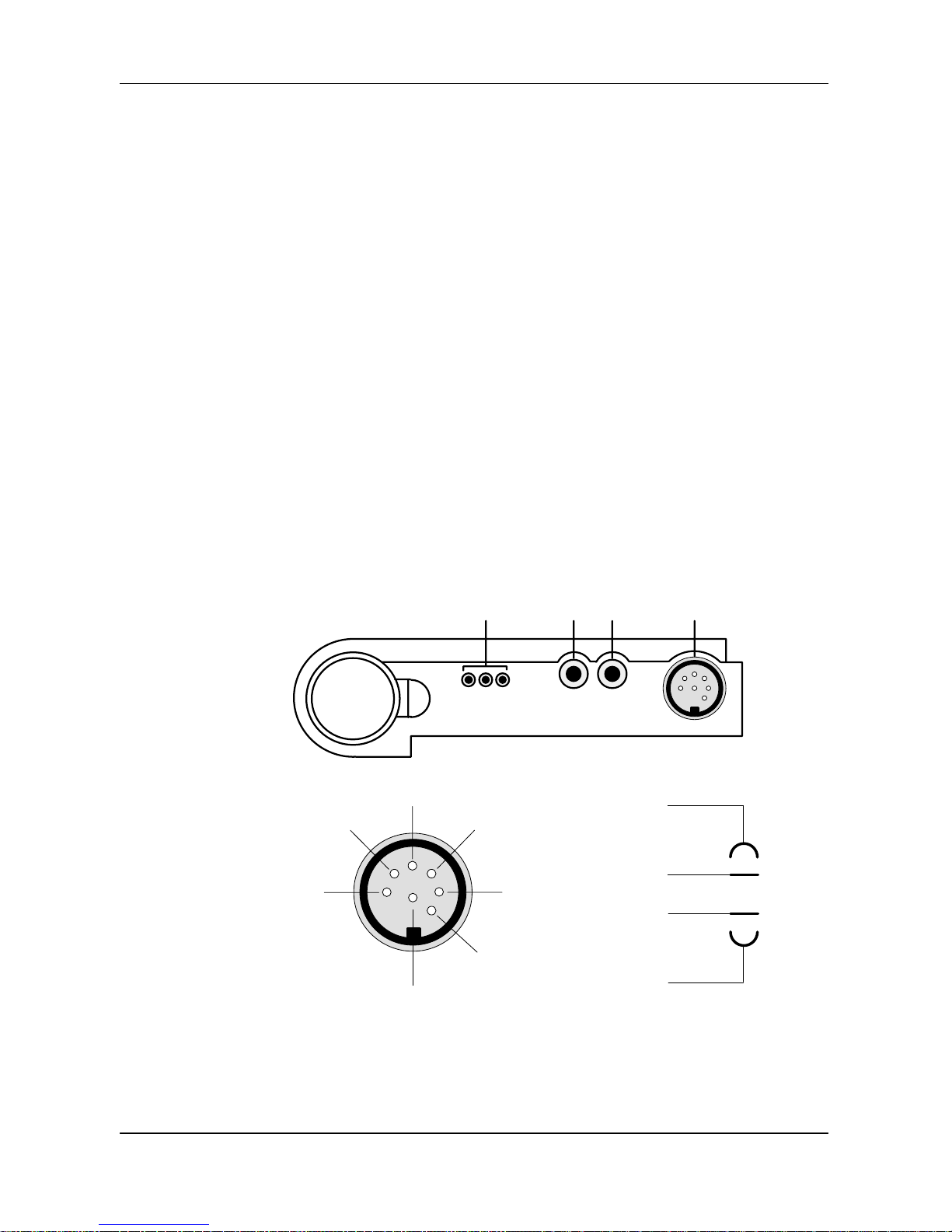

Connecting

sensor

Connection

assignment

Operation 6

Connection and Start-up

The following sensors from the line of accessories can be

connected to the meter .

013610 4-electrode epoxy/graphite sensor

with integrated temperature probe,

3 meter cable

K = 0.55 /cm

013660 4-electrode epoxy/graphite sensor

with integrated temperature probe,

20 meter cable

K = 0.55 /cm

Connection Socket. . . . . . . . . . . . . . . . . . . . . . . . . . .

Sensor 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Separate temperature probe 2, 3. . . . . . . . . . . . . . .

Interface 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1234

NTC

V–

V+

I+

Shield

NTC

I–

V+

V–

I–

I+

If no temperature probe is used for measurement, the meter operates with the manually set temperature and man

appears in the display.

Note

Note

Note

Note

power

Note

Note

Models 135A and 136S Portable Conductivity Meters

Operation 7

When using a sensor with temperature probe, an external

temperature probe may not be connected simultaneously.

If the meter is connected to a PC and is used to take measurements in a grounded liquid, measuring errors may

result.

Prior to first use, the cell constant, temperature compensation and time and date must be checked and set, if required.

The calibration and configuration data and the contents of

the data log remain permanently stored both with the meter

switched off and with the batteries removed (battery replacement).

Pressing the power key switches the meter into measuring mode.

When switched on, the meter determines the connected

temperature probe and conducts a self-test:

❏ Simultaneous appearance of all display segments

❏ Display of the model number

❏ Display of the software version

For recognition of the temperature probe, the conductivity

sensor must be connected to the meter before power-up.

The meter can also be switched on with the meas key.

However, only an abbreviated test is performed. The meter

assumes that the last temperature probe determined is

used.

cal

+

power

meas

Function

Operation 8

Configuration

The following basic settings can be changed in the configuration:

❏ Function Cond (conductivity), SAL (salinity) or tdS (Total

Dissolved Solids)

❏ Calibration by entering the cell constants (AutCal Off) or

calibration with Thermo Orion Conductivity Standards

(AutCal On)

❏ Autoshutoff after

1 hour or 12 hours

❏ Remote interface

Printer output On/Off, baud rate

❏ T emperature display

°C or °F

❏ Date and time format

24 hours and day, month, year or

12 hours (a.m./p.m.) and month, day, year

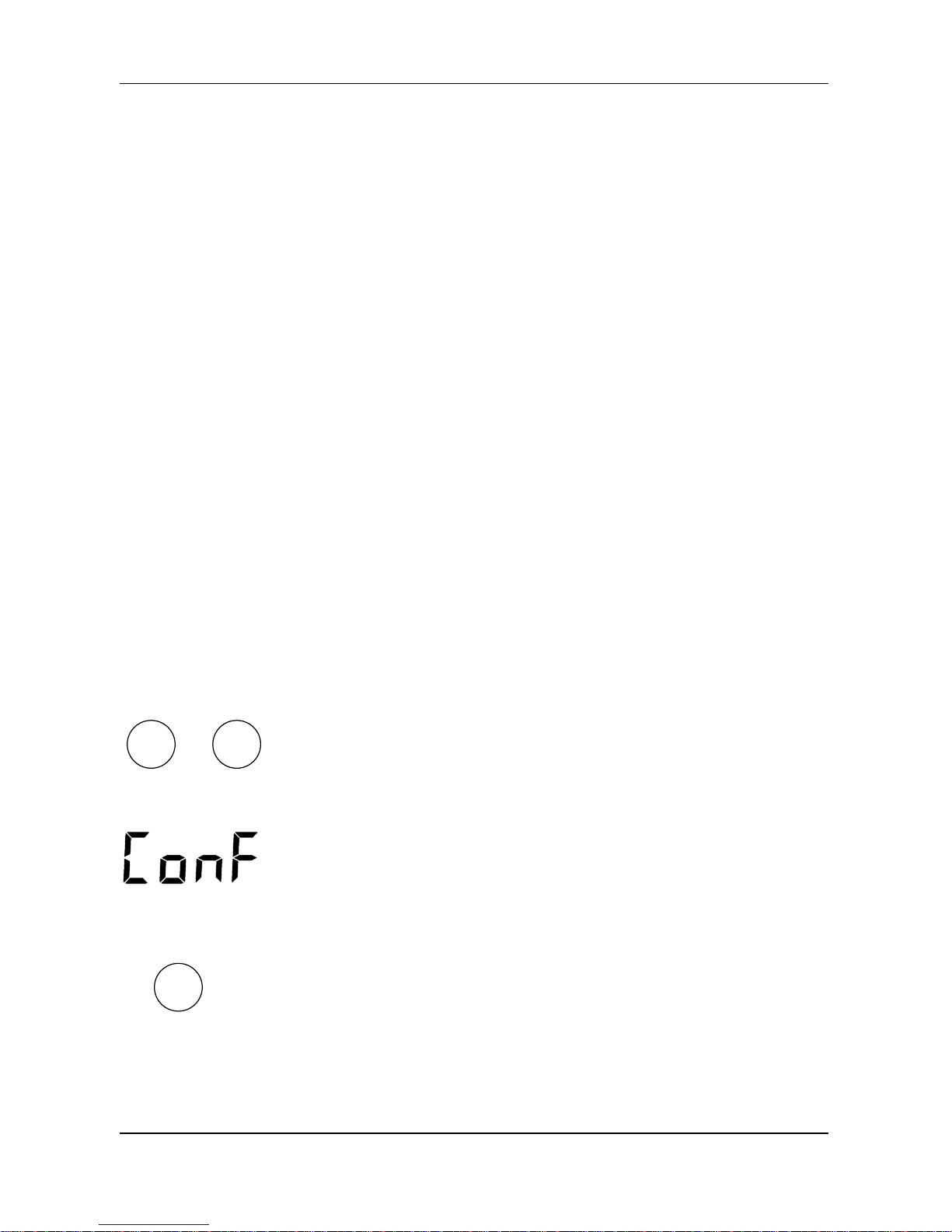

To activate the configuration hold down the cal key with

the meter switched off and then press the power key.

The menu items of the configuration menu are worked

through in sequence. Press the Y or B key to change the

setting of the respective menu item. The STO key saves

the parameters and switches to the next menu item.

Pressing the meas key exits the configuration menu at

any time. The value last displayed will not be saved unless

the STO key was pressed.

Select the measuring function Cond (conductivity), SAL

(salinity) or tdS (Total Dissolved Solids).

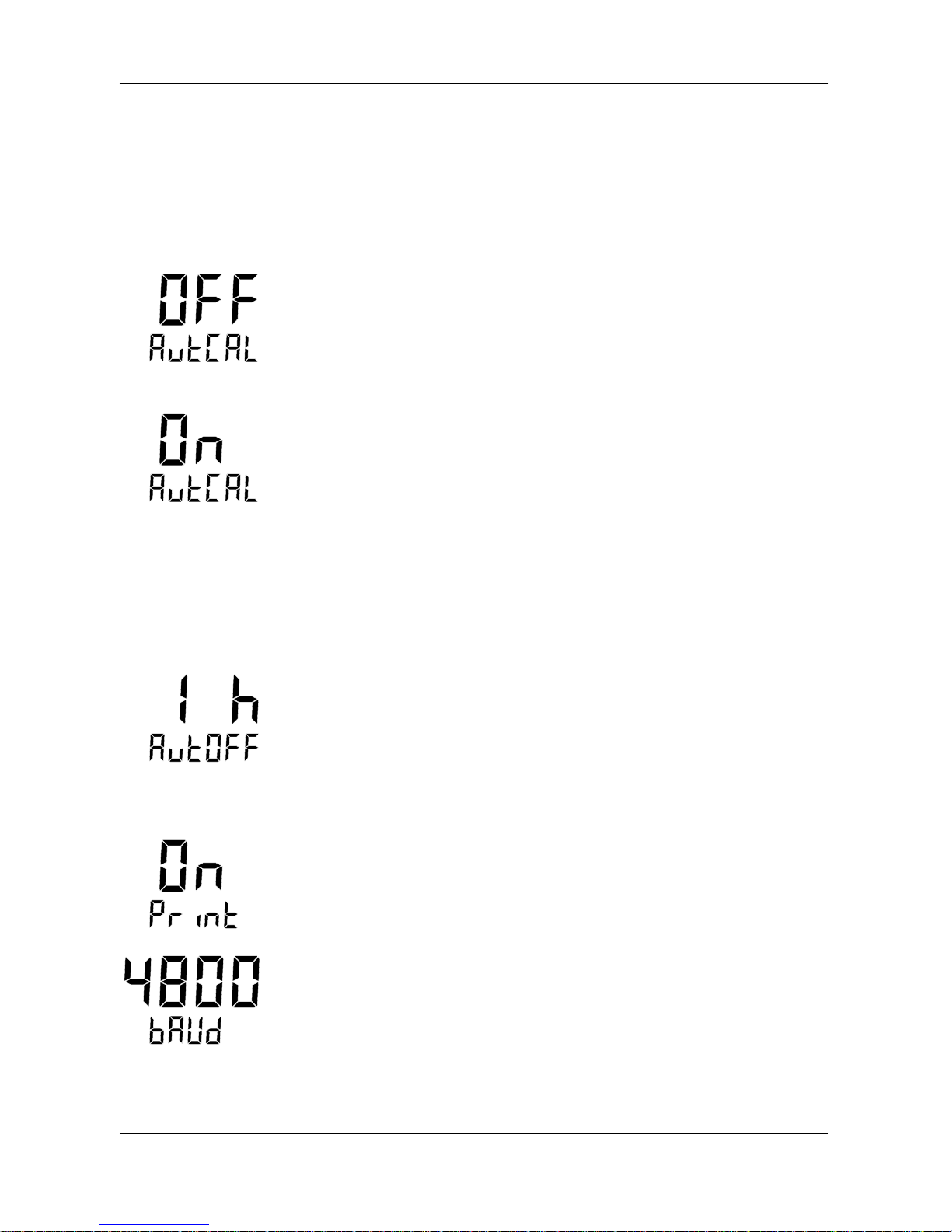

Automatic

or manual

calibration

Autoshutoff

Interface

Models 135A and 136S Portable Conductivity Meters

Operation 9

Select whether you wish to manually set the cell constant

or calibrate using Thermo Orion Conductivity Standards

and automatic drift check.

(Default setting: Direct entry of the cell constant [AutCAL

OFF])

Direct entry of the cell constants (AutCal OFF) from

0.010 cm

–1

to 199.9 cm–1.

(Default setting 0.475 cm

–1

)

Automatic calibration (AutCAL On) with 0.1 molar KCl solution (Thermo Orion 12.9 mS Conductivity Standard,

Cat. no. 011006), 0.01 molar KCl (Thermo Orion 1413 mS

Conductivity Standard, Cat. no. 011007) or entry of the

temperature-compensated conductivity of another known

calibration solution.

To protect the batteries, the meter switches off automatically when not operated for a longer time than specified.

You can select whether shut-off is to take place after one

hour or after twelve hours (default setting: 1 hour).

If the data logger is active and during remote interface

operation, the autoshutoff feature is disabled.

If the meter is controlled with a PC and interface conflicts

occur when the print key is pressed, the print function

should be deactivated (Print OFF).

(Default setting: Print On, 4,800 baud)

The transmission speed can be set to 600, 1,200, 2,400,

4,800 or 9,600 baud.

The transmission speed must correspond to that set in the

printer or PC.

The data format and protocol are permanently set to 7 bit,

one stop bit, even parity and XON/XOFF protocol

(NAMUR NE 28).

Temperature

display

Date and

time

format

Operation 10

The temperature can be displayed either in °C or °F.

(Default setting: °C)

You can choose between the display format 24 hours and

day.month.year and the format 12 hours a.m./p.m. and

month.day.year.

(Default setting: 24 hours and day.month.year)

Calibration

solutions

Clean

sensors

Cell constant

4-electrode

sensors

2-electrode

sensors

Models 135A and 136S Portable Conductivity Meters

Operation 11

Calibration

With calibration the Models 135A and 136S are adjusted to

the cell constants of the sensor .

General information on calibration

Solutions for calibration of conductivity meters are unbuffered systems. Care should be taken to use fresh

conductivity standards and to avoid contamination of the

conductivity standard by water droplets adhering to the

conductivity sensor .

Before calibration, make sure that the conductivity sensor

is clean. Residues should be rinsed off with distilled water.

Afterwards, the sensor should be wiped dry and rinsed with

the calibration solution to be used.

The cell constant is determined by the size and geometric

arrangement of the measuring electrodes. It is the characteristic parameter of conductivity sensors. The cell constant changes very little over time.

With 4-electrode sensors the principle of separate current/

voltage electrodes results in virtually no measuring errors

even in the case of partial soiling of the measuring electrodes. However, electrodes completely soiled with insulating coatings cause the measurement to fail.

With 2-electrode sensors for the measurement of low conductivities, e.g. ultrapure water , calibration should be carried out using Thermo Orion 100 mS Conductivity Standard

(Cat. no. 011008).

cal

Operation 12

Calibration by direct entry of the cell constants (AutCAL OFF)

Press the cal key to activate calibration. The cell constant

determined or set during the last calibration is displayed.

Pressing the meas key exits calibration again.

Set the cell constant of the sensor used with the Y and B

keys and confirm with the cal key. Then the meter

switches back into the measuring mode.

Note

cal

Models 135A and 136S Portable Conductivity Meters

Operation 13

Calibration with 0.1 or 0.01 molar KCl solution (AutCAL On)

(Thermo Orion 12.9 mS or 1413 mS Conductivity Standard)

Impurities must always be prevented from getting into the

calibration solutions.

Pressing the cal key activates calibration.

Calibration can be cancelled by pressing the meas key.

Then the cell constant of the last calibration is displayed

briefly.

Select the calibration solution used (CALSoL). A 0.1 and a

0.01 molar KCl solution are available to choose from. Confirm the corresponding solution with the cal key.

Immerse the clean and dry sensor in the calibration solution (also see “Clean sensors”, Pg. 11).

Press the cal key to start calibration. If calibration is not

desired, cancel the process with the meas key.

During calibration the lower line indicates the temperature.

The automatic drift check checks the stability of conductivity and temperature. The hour glass flashes.

When the measured values are stable, the temperaturecompensated table value of the KCl solution is displayed.

The measured conductivity value flashes.

Confirm with the cal key.

The determined cell constant is displayed for a few seconds. Then the meter switches back into the measuring

mode.

Note

cal

Operation 14

Calibration with any calibration solution (AutCAL ON)

Impurities must always be prevented from getting into the

calibration solutions.

Pressing the cal key activates calibration.

Calibration can be exited again with the meas key. Then

the cell constant of the last calibration is displayed briefly.

First confirm any of the 0.1 or 0.01 mol/l KCl solutions

(CALSoL) with the cal key.

Immerse the clean and dry sensor in the calibration solution (also see “Clean sensors” Pg. 11).

Press the cal key to start calibration. If calibration is not

desired, cancel the process with the meas key.

During calibration the lower line indicates the temperature.

The automatic drift check checks the stability of conductivity and temperature. The hour glass flashes.

When the measured values are stable, the temperaturecompensated table value of the KCl solution is displayed.

The measured conductivity value flashes.

See the table of your calibration solution for the conductivity value which belongs to the displayed measuring temperature.

Set the temperature-compensated conductivity in the meter with the Y and B keys, then confirm it with the cal

key.

The determined cell constant is displayed for a few seconds. Then the meter switches back into the measuring

mode.

Measuring

mode

Note

Temperature

compensation

Note

Models 135A and 136S Portable Conductivity Meters

Operation 15

Measurement

Pressing the meas key accesses the measuring mode

from all functions. In the measuring mode the main display

indicates the measured variable and the secondary display

shows the temperature.

If the meter is connected to a PC and measurements are

taken in a grounded liquid, measuring errors may result.

Measuring the conductivity (Cond)

The main display indicates the measured conductivity, the

secondary display shows the temperature.

The instrument offers various temperature compensation

methods. With the meas key and the Y or B key, the

temperature compensation method can be selected and

set:

(tc OFF) No temperature compensation

(tc nLF) Temperature compensation with non-linear characteristic for natural water and ultrapure water (reference

temperature 25 °C). In the secondary display tc also appears.

(tc 0.01 – 9.99 %/°C) Temperature compensation with linear characteristic and definable temperature coefficients

(reference temperature 25 °C). In the secondary display tc

also appears.

When you have selected temperature compensation with

linear characteristic, you can only exit this function or select the nonlinear function when the temperature coefficient

has been set to 0.00.

TDS factor

Note

Manual

temperature

Operation 16

Measuring the salinity (SAL)

The main display indicates the measured salinity in ‰

(parts per thousand), the secondary display shows the

temperature.

TDS determination (TDS)

The main display indicates the concentration of the dissolved solids contributing to the solution conductivity (TDS,

comparable to the evaporation residue) in mg/l, the secondary display shows the temperature.

Pressing the meas key and then the Y or B key sets the

TDS factor within the range 0.40 – 1.00.

The TDS factor depends on the composition of the water

to be tested and must be determined for each water type.

The man indicator signals that no temperature probe is

connected. The meter operates with the manually specified

temperature. The manual temperature can be edited with

the Y and B keys in the Cond measuring mode.

Write

memory

STO

Read

memory

RCL

Clear

memory

STO

clock

Models 135A and 136S Portable Conductivity Meters

Operation 17

Data Log Memory

Up to one hundred measured values can be stored in the

data log memory together with temperature, date and time.

Storage is performed either manually or automatically using the data log. The currently measured parameter (conductivtiy, salinity or TDS) is stored.

Press the STO key. The currently measured value is

shown on the display.

Select any memory location using the Y and B keys.

Press the STO key to store the measured value in the

selected memory location. After storing, the memory location number is automatically incremented and the meter

returns to measuring mode.

Pressing the RCL key displays the last measured values

stored.

Select any memory location using the Y and B keys.

Pressing the RCL key switches between the measured

value and the time/date of storage.

Pressing the meas key returns to the measuring mode.

To clear the entire data log memory , press the STO key to

access memory mode and then press the clock key to

access data log mode. Select Clear (Clr) using the Y and

B keys.

By confirming this with the STO key, the entire memory is

cleared.

If you do not want to clear the data log, press the meas

key to abort the procedure.

Data log

STO

clock

STO

meas

Data logging

modes

Operation 18

Data Log

The data log records up to 100 measured values together

with temperature, time and date. Data storage is performed either manually (at the press of a key), interval or

event-controlled. The data log always stores the currently

measured parameter (conductivtiy, salinity or TDS).

Press the STO key to access the memory mode and then

the clock key to access the data log mode. Now choose

between three different logging modes and the parameter

setting of the data logger using the Y or B keys.

Pressing the STO key confirms the selected mode. In the

Continue and Start mode this also activates the data log.

The current data memory location is shown on the display.

If “Clear” has been selected, all memory locations are

cleared and the meter returns to the measuring mode.

Pressing the meas key ends the data log mode.

After pressing the STO key, logging is continued after the

memory location in which the last measured value was

stored (continue). Press the meas key to end logging.

After pressing the STO key, the entire data log memory is

cleared without starting the data log (clear).

After pressing the STO key, the entire data log memory is

cleared. Storage begins from memory location “00” (start).

Press the meas key to end logging.

Setting

parameters of

the data log

Note

STO

Note

Models 135A and 136S Portable Conductivity Meters

Operation 19

In the parameter setting mode, you select whether data

storage is to be interval, event-controlled or manual.

Press the STO key to access the logging functions.

To select interval-controlled storage of measured values,

press the STO key and set the interval using the Y and B

keys. The interval range is between 5 seconds and 60

minutes. Default time (factory-set) is 2 minutes. After selecting the interval time, press the STO key to enter the

value.

With event-controlled data storage, a measured value is

not stored until it deviates from the last logged value by the

preset differential value. By using the storage time, you

can determine when the value had changed. The differential value is entered in the subsequent parameter-setting

step.

The differential value is always based on the currently set

measured variable (conductivtiy, salinity or TDS). This

means that if differential conductivity values are to be

logged, the meter must be set to conductivity measurement prior to parameter setting and data logging.

With manual data logging, the measured values are saved

with the STO key.

After selecting the above parameters, select “Continue” or

“Start” using the Y and B keys and then press the STO

key to commence logging.

The datalogger is a ring memory, i.e. it does not stop after

reaching the last memory location (99). Recording is automatically continued with memory location number 00. To

avoid losing data by overwriting, download stored data and

clear the logger before beginning a new set of data. Be

aware of this when using interval-controlled data collection.

clock

Setting clock

STO

clock

+

meas

Operation 20

Clock Mode

Pressing the clock key activates the clock mode. The

time and date are displayed.

In this mode the battery consumption of the meter is reduced to a minimum.

To set the time or the date, the clock mode must be activated.

Press the clock and STO keys simultaneously to set the

clock.

The time display flashes. Now the time can be set using

the Y and B keys.

Press the STO key again to store the displayed time. Now

the date can be set.

Press the STO key again to store the date. Now the year

can be set.

Press the STO key to confirm the year . The meter returns

to clock mode.

Press the meas key to return to measuring mode.

Note

Interface

parameters

Note

Models 135A and 136S Portable Conductivity Meters

Operation 21

Serial Interface

If the meter is connected to a PC and measurements are

taken in a grounded liquid, measuring errors may result.

With the remote interface, you can directly send data to a

printer with serial port or set up a direct connection to a

computer. Via the computer , the meter can be completely

remote controlled and all data and parameters can be

read. Using the printer (e.g. PRT 300 printer) you can directly print measured values, data points and GLPdoct

report.

The RS 232 interface can be defined for all common baud

rates.

Setting is carried out in the Configuration menu

❏ Baud rate: 600 Bd

1,200 Bd

2,400 Bd

4,800 Bd (default setting)

9,600 Bd

The data format and protocol are permanently set to:

❏ 7 bits

❏ even parity

❏ one stop bit

❏ XON/XOFF protocol

For the command set of the meter , refer to the online help

of the PC software for data transfer .

Interface

cable

Printer

PC

Meter

configuration

Note

Operation 22

Only one interface cable is required to operate with a

printer or PC. By simply turning the plug around on the

meter’s interface port, the cable can be used to connect to

either a printer or a PC.

The label facing the operator should match the output device being connected.

RXD

GND

TXD

DCD

RXD

TXD

DTR

GND

DSR

RTS

CTS

RI

Connection assignment

1

9

Standard Setting for PRT300 Printer

Parameter Setting

Baud rate 1200

Printer On

Configuring the PRT300 Printer

In the meter , set the baud rate to 1200.

In the printer , set the dip switches, located in paper

compartment, to the following settings:

–Switch 1: Down

–Switch 2: Up

–Switch 3: Up

–Switch 4: Down

–Switch 5: Up

–Switch 6: Down

–Switch 7: Down

–Switch 8: Down

Be sure to plug the RS232 cable into the meter with the

“PRINTER” label facing up.

(You will plug it with the “PC” label facing up if you hook

into a computer .)

Note

Printing

measured

values

print

Printing

memory

RCL

+

print

Note

Printing

GLPdoct

report

cal

+

print

Models 135A and 136S Portable Conductivity Meters

Operation 23

Printing Measured Values and GLPdoct Report

Make sure that the printer function is activated in the configuration (Print On) and the set baud rate corresponds to

that of the printer .

Press the print key while in the measuring mode to print

out the currently measured value. The measured value is

printed out together with temperature, date and time and a

three-digit identification number. The identification number

is reset when the meter is switched off.

Press the RCL and then print keys to print out the logged

data. All stored data points are printed out with temperature, date and memory location number (Sxx).

If you only want to print individual data points, press the

RCL key first. Then select the desired data point using the

Y or B key and confirm with the print key.

If the permissible measurement or temperature range is

exceeded during data logging or if the clock has not been

set, the line on the print-out will be marked with “ # ”.

If temperature compensation was active during data logging, the line on the print-out will be marked with “ ! ”.

To print out the GLPdoct report, press the cal and then

print keys. The report print-out contains:

❏ a calibration record with the data of the last calibration

❏ the settings of the configuration menu

❏ a record of the last self-test performed

Range limits

exceeded

ERROR 1

ERROR 3

Note

Maintenance and T roubleshooting 24

3 Troubleshooting and Maintenance

Error Messages

If a measured value lies outside the ranges accepted by

the meter , an error message appears and the measuredvalue display flashes.

The measurement range was exceeded.

Possible causes:

❏ Sensor defective

❏ Break in sensor cable

❏ Wrong sensor connected

❏ Wrong cell constant entered

The measured temperature is outside the ranges:

Conductivity –20 °C to +120 °C

nLF: 0 °C to 120 °C

Salinity: 0 °C to 30 °C

TDS: 10 °C to 40 °C

Possible causes:

❏ T emperature probe in conductivity sensor defective

❏ Short circuit in temperature probe

❏ Wrong temperature probe connected

When changing the conductivity sensor , note that the temperature probe type is only recognized when the meter has

been switched on with the power key.

Calibration

error

messages

ERROR 6

ERROR 1 1

ERROR 14

Models 135A and 136S Portable Conductivity Meters

Maintenance and T roubleshooting 25

If errors occur during calibration, or if the determined sensor data are outside the valid range, an error message

appears (ERROR 6, ERROR 11).

The cell constant lies outside the permissible range

< 0.01 cm

–1

or > 199.9 cm–1.

Possible causes:

❏ No sensor connected during calibration

❏ Wrong calibration solution

❏ Sensor not immersed far enough in calibration solution

The calibration was cancelled after approx. 2 minutes

because the drift was too large.

This message only appears briefly during calibration.

Possible causes:

❏ Sensor defective or dirty

❏ Sensor cable insufficiently shielded or defective

❏ Strong electric fields influence the measurement

❏ Major temperature fluctuation of the calibration solution

❏ Calibration solution unstable

❏ Conductive connection between potential to ground, PC,

meter and measuring medium

If the clock has not been set, e.g. after battery replacement, this error message is displayed. To clear the message, set the clock (see Pg. 20).

ERROR 15

ERROR 18

ERROR 19

Note

Maintenance and T roubleshooting 26

If errors occur during transmission via the RS 232 interface, this error message appears.

To eliminate the error message, switch the meter off and

then on again. Should the error message occur again,

check the settings in the Configuration menu.

Possible causes:

❏ Wrong transmission rate (baud rate) set

(see Pg. 9)

❏ Error during transmission

❏ Wrong data format (see Pg. 21) e.g. parity bit

Error during the meter self-test sequence.

Possible causes:

❏ Configuration or calibration data are defective.

Completely reconfigure and recalibrate the meter .

Error in the factory settings or system memory.

“FAIL” appears in the display .

Possible causes:

❏ EPROM or RAM defective

❏ Error in meter factory settings

This error message should normally not occur , as the data

are protected from loss with multiple safety functions.

Should this error message appear , the meter must be

repaired and recalibrated at the factory. Contact Thermo

Orion’s Technical Service for a Return Authorization Number and instructions for returning the meter .

Note

Note

Models 135A and 136S Portable Conductivity Meters

Maintenance and T roubleshooting 27

Maintenance

Changing batteries

When the battery symbol appears in the display, the batteries need replacement. However, you can still use the meter

for a few days. If the battery voltage continues to drop, the

meter will switch itself off. (Since battery consumption is

higher when the remote interface is used, the battery symbol is displayed earlier .)

Never change the batteries within a hazardous area. Use

only alkaline AA batteries. Be sure that the meter is carefully closed again and the protective cover is properly

mounted on the meter after changing the batteries.

To replace the batteries, you need 3 alkaline AA cells and

a screwdriver .

❏ Close the protective cover and remove the probe holder.

❏ Unscrew the four screws on the back of the meter and

remove the lid.

❏ Remove the old batteries from the battery holder.

❏ Insert the new batteries in the specified direction.

❏ Make sure the protective cover is in the notches provi-

ded and the rubber seal is correctly seated, especially

near the sensor socket.

❏ Replace the lid and secure it with the screws.

❏ Replace the probe holder.

When changing the batteries, all calibration and configuration data and the logged data are retained. The time and

date must be reset. The current memory location is set to

00.

After battery replacement recording will also be continued

with memory location 00 when the meter is in the datalogger mode “Continue”. If you have stored measured values

Warning

Maintenance and T roubleshooting 28

before battery replacement and you do not want to overwrite them, set the first memory location to be written with

the RCL key and the

Y or B key before restarting the data

log.

If you want to store the meter for a longer time, the batteries must always be removed beforehand. Leaky batteries

may damage the meter .

Cleaning the meter

To remove dust and dirt, the external surfaces of the meter

may be cleaned with water , and also with a mild household

cleaner if necessary.

Models 135A and 136S Portable Conductivity Meters

Appendix 29

Appendix

Declarations of Conformity

Appendix 30

Models 135A and 136S Portable Conductivity Meters

Appendix 31

Certificate of Conformity

Appendix 32

Models 135A and 136S Portable Conductivity Meters

Appendix 33

Control Drawing

Appendix 34

Meters

Models 135A and 136S Portable Conductivity Meters

Appendix 35

Ordering Information

Thermo Orion Description

Cat. No.

0130A0 Model 130A Basic Waterproof

Conductivity Meter and Probe

0130A2 Model 130A Basic Waterproof

Conductivity Meter Only

0130A3 Model 130A Basic Waterproof

Conductivity Meter, Probe and Field Kit

0131S0 Model 131S Basic Waterproof Intrinsically

Safe Conductivity Meter and Probe

0131S2 Model 131S Basic Waterproof Intrinsically

Safe Conductivity Meter Only

0131S3 Model 131S Basic Waterproof Intrinsically

Safe Conductivity Meter, Probe and Field Kit

0135A0 Model 135A Advanced W aterproof

Conductivity Meter and Probe

0135A2 Model 135A Advanced W aterproof

Conductivity Meter Only

0135A3 Model 135A Advanced W aterproof

Conductivity Meter, Probe and Field Kit

0136S0 Model 136S Advanced W aterproof Intrinsi-

cally Safe Conductivity Meter and Probe

0136S2 Model 136S Advanced W aterproof Intrinsi-

cally Safe Conductivity Meter Only

0136S3 Model 136S Advanced W aterproof

Intrinsically Safe Conductivity Meter ,

Probe and Field Kit

0260A0 Model 260A Basic Waterproof pH Meter and

Electrode

0260A2 Model 260A Basic Waterproof pH Meter

Only

0260A3 Model 260A Basic Waterproof pH

Meter, Electrode and Field Kit

Appendix 36

Thermo Orion Description

Cat. No.

0261S0 Model 261S Basic Waterproof Intrinsi-

cally Safe pH Meter and Electrode

0261S2 Model 261S Basic Waterproof Intrinsi-

cally Safe pH Meter Only

0261S3 Model 261S Basic Waterproof Intrinsi-

cally Safe pH Meter , Electrode and Field

Kit

0265A0 Model 265A Advanced W aterproof pH

Meter and Electrode

0265A2 Model 265A Advanced W aterproof pH

Meter Only

0265A3 Model 265A Advanced W aterproof pH

Meter, Electrode and Field Kit

0266S0 Model 266S Advanced W aterproof In-

trinsically Safe pH Meter and Electrode

0266S2 Model 266S Advanced W aterproof In-

trinsically Safe pH Meter Only

0266S3 Model 266S Advanced W aterproof In-

trinsically Safe pH Meter , Electrode and

Field Kit

0830A0 Model 830A Basic Waterproof

Dissolved Oxygen Meter and Probe

0830A2 Model 830A Basic Waterproof

Dissolved Oxygen Meter Only

0830A3 Model 830A Basic Waterproof Dissolved

Oxygen Meter, Probe and Field Kit

0835A0 Model 835A Advanced W aterproof

Dissolved Oxygen Meter and Probe

0835A2 Model 835A Advanced W aterproof

Dissolved Oxygen Meter Only

0835A3 Model 835A Advanced W aterproof

Dissolved Oxygen Meter , Probe and

Field Kit

Probes

Standards

Accessories

Models 135A and 136S Portable Conductivity Meters

Appendix 37

Thermo Orion Description

Cat. No.

013610 4-electrode epoxy/graphite cell,

3 meter cable, K = 0.55 /cm

013660 4-electrode epoxy/graphite cell,

20 meter cable, K = 0.55 /cm

013016 2-electrode stainless steel cell,

1 meter cable, K = 0.1 /cm

013016A 2-electrode stainless steel cell,

1 meter cable, K = 0.1 /cm

011006 Conductivity standard 12.9 mS

(0.1 KCl), 5 x 60 mL

011007

Conductivity standard 1413 mS

(0.01 KCl), 5 x 60 mL

011008

Conductivity standard 100 mS,

5 x 60 mL

026AKT Field Case for Thermo Orion Water-

proof Meters

013650 Replacement Quiver for 130A/135A/

131S/136S WP Meters

026650 Replacement Quiver for 260A/265A/

261S/266S WP Meters

083550 Replacement Quiver for 830A/835A

WP Meters

013651 Replacement Neck Strap for WP Meters

013652 Replacement PC/Printer Cable for

Advanced WP Meters

013653 Replacement Software for Advanced

WP Meters

013654 Replacement Gender Adapter for PC/

Printer Cable for Advanced WP Meters

Appendix 38

Thermo Orion Description

Cat. No.

PRT300 Ink-based Printer , 110 V, Cable Included

PRT301 Ink-based Printer, 220 V, Cable Included

PRT302 Replacement Printer Ribbon, 1 each

Models 135A and 136S Portable Conductivity Meters

Appendix 39

Specifications

Ranges

Conductivity: 0.1 mS/cm to 1,000 mS/cm

(c > 0.8 cm

–1

)

0.1 mS/cm to 500 mS/cm

(c = 0.2 to 0.8 cm

–1

)

0.01 mS/cm to 199.9 mS/cm

(c < 0.2 cm

–1

)

Temperature: –20.0 to +120.0 °C / –4 to 248 °F

nLF: 0 to 120 °C

Salinity: 0.0 to 45.0 g/kg (0 to 30°C)

TDS: 0 to 1,999 mg/l (10 to 40°C)

Display LCD 35 x 67 mm, character height 15 mm

Measurement cycle Approx. 2 sec

Accuracy

(+ 1 count)

Conductivity: < 0.5 % of measured value

1)

Temperature: < 0.3 K

Input 1

(Sensor)

Multi-contact for 2 and 4-electrode sensors with integrated temperature probe

Input 2

(Temperature)

4 mm sockets for separate temperature probe

Permissible cell

constant

0.010 to 199.9 cm–1 (adjustable)

Sensor

standardization

Direct entry of the cell constants,

Automatic determination of the cell constants with

Thermo Orion conductivity standards

Sensor standardization with any known solutions

Meter self-test During power-up, segment test, memory test, display

of model no. and software version

Temperature

measurement

NTC 30 kW (automatic recognition during power-up)

or manual temperature entry

Temperature

compensation

Linear characteristic: 0.01 to 9.99 %/°C

nLF (non-linear characteristic for ultrapure water and

natural water)

Data logger Manual, interval-controlled or event-controlled

Data points 100 memory locations: conductivity, salinity or TDS,

with temperature, date and time

1)

For conductivities > 500 mS/cm < 1% meas. value

Appendix 40

Remote interface

Serial RS 232 interface, bidirectional, asynchronous,

baud rate user-defined (600 to 9,600 baud), can be

used as either printer or computer interface

Data retention Configuration/calibration data and factory settings

>10 years

Autoshutoff After either 1 or 12 hours, disabled during interface

or data logger operation

Explosion Protection

(only Model 136S)

EEX ia IIC T6, PTB No. Ex-97.D.2118

FM approved

Ambient

temperature

Operation: -10 to +55 °C

Transport and storage: -20 to +70 °C

Power supply 3 alkaline AA batteries

Operating time Approx. 1,000 h, clock operation > 2 years

Enclosure Material: PA, IP 66 protected, with integrated probe

holder

Dimensions 133 x 160 x 30 mm (W x H x D)

Weight Approx. 560 g with batteries

Specifications for PRT300 Printer

Printer type Impact printer

Interface Serial RS 232 interface

Paper Normal paper, width 57.5 mm (2.25 inches)

Data transfer Baud rate: 1,200 baud, data bits: 7, stop bits: 1,

parity: even, protocol: no

Power supply 110 V (PRT301 is 220 V)

Models 135A and 136S Portable Conductivity Meters

Appendix 41

Warranty

The Thermo Orion warranty covers failures due to manufacturer’s workman-

ship or material defects from the date of purchase by the user . User should return the warranty card to Thermo Orion and retain proof of purchase. Warranty

is void if product has been abused, misused, or repairs attempted by unauthorized persons.

Warranties herein are for product sold/installed by Thermo Orion or its authorized dealers.

Any product sold by a U.S. or Canadian distributor must be returned to Thermo

Orion for any warranty work. A Return Authorization Number must be obtained

from Thermo Orion’s Laboratory Technical Service before returning any prod-

uct for in-warranty repair or replacement.

In the event of failure within the warranty period, Thermo Orion will at Thermo

Orion’s option, repair or replace product not conforming to this warranty . There

may be additional charges, including freight, for warranty service performed in

some countries. For service, call Thermo Orion (or its authorized dealer outside

the United States and Canada). Thermo Orion reserves the right to ask for

proof of purchase, such as the original invoice or packing slip.

Laboratory pH Meters, SensorLink

, pH/ISE Meters, PerpHecT pH/ISE

Meters, Sage

t Pumps, Cahn

Balances, 930 Ionalyzert, 950 ROSSt F AST

QC

t Titrator, 960 Titrator PLUS

, Karl Fischer Titrators, pHuturet Conver-

sion Box, Wine Master

t, 607 Switchbox, rf linkt, V acuum degasser , Flowme-

ter are warranted to be free from defects in material and workmanship for a period of twelve (12) months from the date of purchase by the user or eighteen

(18) months from date of shipment from Thermo Orion, whichever is earlier,

provided use is in accordance with the operating limitations and maintenance

procedures in the instruction manual and when not having been subjected to

accident, alteration, misuse, or abuse.

The warranty period for 960 Titrator PLUS, 950 Fast QC Titrator, Wine Master

and 930 Ionalyzer pumps is three (3) months from date of purchase.

ThermaSense

t Dataloggers are warranted for a period of twelve (12) months

from date of purchase.

Economy Line Electrodes, Models 91-05, 91-06, 91-15, 91-16, 91-25, 91-26,

91-35, 91-36 and 92-06, are warranted to be free from defects in material and

workmanship for a period of three (3) months from date of purchase by customer or six (6) months from date of shipment from Thermo Orion, whichever is

earlier . Warranty also includes failure for any reason (excluding breakage), except abuse, provided the electrode is not used in solutions containing silver,

sulfide, perchlorate, or hydrofluoric acid; or in solutions more than one (1) molar

in strong acid or base at temperatures above 50°C.

Ion Selective Electrodes, ionplus

Electrodes, ROSS Electrodes, Sure-Flow

Appendix 42

Electrodes, PerpHecT Electrodes, Standard Line pH Electrodes, Tris pH Electrodes, pHuture pH probes (Cat. Nos. 615900 and 616500), Series 100 Conventional Conductivity Cells, temperature probes and compensators (except

those models noted) are warranted to be free from defects in material and workmanship for a period of twelve (12) months from the date of purchase by the

customer or eighteen (18) months from date of shipment from Thermo Orion,

whichever is earlier , except for abuse or breakage of electrodes. 93 and 97 ionplus Series sensing modules are warranted to give six (6) months of operation if

placed in service before the date indicated on the package, except 93-07 and

97-07 Nitrate modules are warranted to give ninety (90) days of operation if

placed in service before the date indicated on the package.

Thermo Orion pHuture probes (Cat. Nos. 615700, 615800 and 617500), Low

Maintenance Triode

t (Cat. No. 9107BN), and PerpHecT Low Maintenance

Triode (Cat. No. 9207BN), Waterproof Triode (Cat. Nos. 9107WP, 9107WL,

9109WL and 9109WP), QuiKcheK

t Meters, and Micro Electrodes are war-

ranted to be free from defects in material and workmanship for a period of six (6)

months from date of purchase by the customer or twelve (12) months from date

of shipment from Thermo Orion, whichever is earlier when used in accordance

with the operating limitations and maintenance procedure in the instruction

manual and when not having been subjected to accident, alteration, misuse or

abuse.

Series 100 Conductivity Meters (Models 105, 115, 125, 145 and 150), Series

100 DuraProbe

t Conductivity Cells and Series 800 Dissolved Oxygen Meters

(Models 810 and 850) and probes are warranted to be free from defects in material and workmanship for a period of twenty-four (24) months from the date of

purchase by the user or thirty (30) months from the date of shipment from

Thermo Orion, whichever is earlier , provided use is in accordance with the operating limitations and maintenance procedures in the instruction manual and

when not having been subjected to accident, alteration, misuse, or abuse

.

Waterproof meters (Models 830, 830A, 835, 835A, 260A, 261S, 265A, 266S,

128, 130A, 131S, 135A, 136S, 1230, 142 and 842) Conductivity meters (Models 162 and 162A), pH/Conductivity meters (Models 545, 550 and 550A), and

Dissolved Oxygen meters (Models 862 and 862A) are warranted to be free

from defects in material and workmanship for a period of thirty-six (36) months

from the date of purchase by the user or forty-two (42) months from date of shipment from Thermo Orion, whichever is earlier, provided use is in accordance

with the operating limitations and maintenance procedures in the instruction

manual and when not having been subjected to accident, alteration, misuse or

abuse.

Thermo Orion Meter, Electrode, Analytical System Accessories, Solutions, Series 800 Dissolved Oxygen Probe Membranes and Cahn Balance Accessories

Models 135A and 136S Portable Conductivity Meters

Appendix 43

such as cables, printers, and line adapters carry an “out-of-box” warranty.

Should they fail to work when first used, contact Thermo Orion immediately for

replacement. Should Thermo Orion Solutions or Buffers be unusable when first

“out-of-box”, contact Thermo Orion immediately for replacement.

THE WARRANTIES DESCRIBED ABOVE ARE EXCLUSIVE AND IN LIEU OF

ALL OTHER WARRANTIES WHETHER STATUTORY, EXPRESS OR IMPLIED INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED W ARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE AND

ALL WARRANTIES ARISING FROM THE COURSE OF DEALING OR

USAGE OF TRADE. THE BUYER’S SOLE AND EXCLUSIVE REMEDY IS

FOR REP AIR OR REPLACEMENT OF THE NON-CONFORMING PRODUCT

OR P ART THEREOF, OR REFUND OF THE PURCHASE PRICE, BUT IN NO

EVENT SHALL THERMO ORION (ITS CONTRACTORS AND SUPPLIERS

OF ANY TIER) BE LIABLE TO THE BUYER OR ANY PERSON FOR ANY

SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES

WHETHER THE CLAIMS ARE BASED IN CONTRACT, IN TORT (INCLUDING NEGLIGENCE), OR OTHERWISE WITH RESPECT TO OR ARISING

OUT OF THE PRODUCT FURNISHED HEREUNDER.

Autoshutoff

(AutOFF)

cal

Calibration

Calibration

solution

Data log

Data points

Evaporation

residue

GLP

GLPdoct

report

meas

NAMUR

Technical T erms 44

Technical Terms

To protect the batteries, the meter switches off automatically when not operated for a longer period than specified.

Autoshutoff can take place after either one hour or twelve

hours.

When data log or remote interface are active, the autoshutoff feature is disabled.

Key for activating calibration.

Adjustment of the conductivity meter to the cell constant of

the sensor used.

Solution with exactly defined conductivity for calibrating a

conductivity meter .

The data log records up to 100 measured values together

with the temperature, date and time. Logging takes place

either interval or event-controlled (measured-value difference) or manually.

Up to 100 measured values can be stored in the data log

together with temperature, time and date.

See TDS.

Good Laboratory Practice: Rules for conducting and documenting measurements in the laboratory.

Printout of meter parameters, calibration and diagnostic

information for GLP reporting.

This key is used to return to measuring mode from all other

modes. In the Cond measuring mode the set temperature

compensation is displayed by pressing the meas key, in

the TDS mode the TDS factor .

German committee for measurement and control standards in the chemical industry

nLF

Response

time

Salinity

TDS

Models 135A and 136S Portable Conductivity Meters

Technical T erms 45

Non-linear temperature compensation for ultrapure water

with NaCl traces and for natural water , reference temperature = 25 °C.

Time from the start of a calibration step to the stabilization

of the measured value.

The salinity indicates the salt content, particularly of sea

waters as a cumulative parameter. It is specified in parts

per thousand (‰). It is denoted by SA.

Total Dissolved Solids, corresponds to the concentration of

the dissolved solids contributing to the conductivity – comparable to the evaporation residue. It is reported im milligrams per liter (mg/L).

Index 46

Index

A

Autoshutoff, 2, 9

definition, 44

B

Baud rate, setting, 9

C

Calibration, 1 1

configuration, 9

description, 44

direct entry of cell constant, 12

with any calibration solution, 14

with Thermo Orion conductivity

standards, 13

Calibration solution, description,

44

Certificate of Conformity, 31

Changing batteries, 27

Cleaning the meter , 28

Clock mode, 20

Conductivity measurement, 15

Configuration, 8

PRT300 printer, 22

Configuration menu, 8

Connecting, interface, 22

Connection

interface, 6

sensor, 6

separate temperature probe, 6

Connection assignment, 6

Control Drawing, 33

D

Data log, 18

definition, 44

setting, 18, 19

Data log memory, 17

Data points, definition, 44

Date format, configuring, 10

Declarations of Conformity, 29

Display, 4

E

Error messages, 24–26

Evaporation residue

description, 44

measuring, 16

F

Function, configuration, 8

G

GLP, description, 44

GLPdoc report, definition, 44

I

Interface, 21

commands, 21

configuring, 9

data format, 21

parameters, 21

protocol, 21

Interface assignments, interface,

22

Interface cable, 22

Interface commands, 21

Interface parameters, 21

Models 135A and 136S Portable Conductivity Meters

Index 47

K

Keypad, 4

L

Laboratory printer PRT300

configuration, 22

standard settings, 22

M

Maintenance, 27

Manual temperature, 16

Measured values, storing, 17

Measurement, 15

Measuring, 15

conductivity, 15

salinity, 16

TDS, 16

Measuring mode, 15

Memory

clearing, 17

reading, 17

writing, 17

Meter design, 3

N

NAMUR, description, 44

nLF, description, 45

O

Ordering information, 35

P

Package contents, 1

Printer PRT300

configuration, 22

specifications, 40

standard settings, 22

Printing

GLPdoc reports, 23

measured values, 23

R

Response time, description, 45

RS-232 interface, 21

S

Safety precautions, III

Salinity, description, 45

Salinity measurement, 16

Saving, measured values, 17

Sensors, connection, 6

Setting clock, 20

Short description, 1

Specifications, 39

PRT300 printer, 40

Start-up, 6

Storing, 17

automatic, 18

measured values, 17

T

TDS

description, 45

measurement, 16

setting factor , 16

Technical terms, 44

Temperature compensation, 15

Temperature display , configuring,

10

Index 48

Time format, configuring, 10

W

Warranty, 41

A Thermo Electron business232107-001 Rev . B

Thermo Orion

500 Cummings Center

Beverly, MA 01915-6199 USA

Tel: 978-232-6000

Dom. Fax: 978-232-6015

Int’l. Fax: 978-232-6031

Thermo Orion Europe

12-16 Sedgeway Business Park

Wichford, Cambridgeshire

England CB6 2HY

Tel: 44-1353-6661 1 1

Fax: 44-1353-66601 1

Thermo Orion Far East

Room 904, Federal Building

369 Lockhart Road

Wanchai, Hong Kong

Tel: 852-28360981

Fax: 852-28345160

Thermo Orion India

105, 1st Floor, Ashoka Apartments

Ranjit Nagar Commercial Complex

New Delhi 110008, India

Tel: +91-1 1-570-5775

Fax: +91-11-570-5778

Thermo Orion Customer Support

Toll Free: 800-225-1480

WWW: http://www.thermoorion.com

Dom. e-mail: domcs1 @ thermoorion.com

Int’l. e-mail: intcs1 @ thermoorion.com

Loading...

Loading...