Thermo Neslab RTE 140 Instruction And Operation Manual

RTE 140 Bath/Circulator

with Microprocessor Controller

Thermo NESLAB Manual P/N 000018

Rev. 09/20/00

Instruction and Operation Manual

RR

TE-140 RefrigTE-140 Refrig

R

TE-140 Refrig

RR

TE-140 RefrigTE-140 Refrig

erated Bath/Cirerated Bath/Cir

erated Bath/Cir

erated Bath/Cirerated Bath/Cir

culatorculator

culator

culatorculator

Instruction and Operation ManInstruction and Operation Man

Instruction and Operation Man

Instruction and Operation ManInstruction and Operation Man

PREFACEPREFACE

PREFACE

PREFACEPREFACE

SECTION ISECTION I

SECTION I

SECTION ISECTION I

SafetySafety

Safety

SafetySafety

SECTION IISECTION II

SECTION II

SECTION IISECTION II

General InformationGeneral Information

General Information

General InformationGeneral Information

SECTION IIISECTION III

SECTION III

SECTION IIISECTION III

InstallationInstallation

Installation

InstallationInstallation

SECTION IVSECTION IV

SECTION IV

SECTION IVSECTION IV

ControllersControllers

Controllers

ControllersControllers

SECTION VSECTION V

SECTION V

SECTION VSECTION V

MaintenanceMaintenance

Maintenance

MaintenanceMaintenance

SECTION VISECTION VI

SECTION VI

SECTION VISECTION VI

TroubleshootingTroubleshooting

Troubleshooting

TroubleshootingTroubleshooting

ualual

ual

ualual

TT

abab

le of Contentsle of Contents

T

ab

le of Contents

TT

abab

le of Contentsle of Contents

Compliance ............................................................................................. 2

Unpacking ............................................................................................... 2

Warranty ................................................................................................. 2

NES-care ................................................................................................ 2

After-sale Support ................................................................................... 2

Warnings................................................................................................. 3

Description .............................................................................................. 4

Specifications.......................................................................................... 4

Site.......................................................................................................... 5

Electrical Requirements .......................................................................... 5

Plumbing Requirements.......................................................................... 6

Fluids ...................................................................................................... 8

Filling Requirements ............................................................................... 8

Microprocessor Controller .......................................................................9

Start Up...................................................................................................11

Temperature Adjustment ........................................................................ 12

Alarm/External Functions........................................................................13

Program Functions .................................................................................14

Program Control......................................................................................17

Error Messages ......................................................................................20

Miscellaneous .........................................................................................20

PID Control .............................................................................................21

Restoring Factory Preset Values ............................................................21

Calibration............................................................................................... 22

High Temperature/Low Liquid Level Safety ............................................24

Service Contracts ...................................................................................25

Condenser ..............................................................................................25

Reservoir Cleaning..................................................................................26

Algae.......................................................................................................26

Checklist .................................................................................................27

Service Assistance and Technical Support.............................................28

APPENDIX A RS-232 OPERATION AND REMOTE PROGRAMMING APPENDIX A RS-232 OPERATION AND REMOTE PROGRAMMING

APPENDIX A RS-232 OPERATION AND REMOTE PROGRAMMING

APPENDIX A RS-232 OPERATION AND REMOTE PROGRAMMING APPENDIX A RS-232 OPERATION AND REMOTE PROGRAMMING

APPENDIX B PROGRAMMING SOFTWARE APPENDIX B PROGRAMMING SOFTWARE

APPENDIX B PROGRAMMING SOFTWARE

APPENDIX B PROGRAMMING SOFTWARE APPENDIX B PROGRAMMING SOFTWARE

- 1 -

APPENDIX C INTERNATIONAL QUICK REFERENCE GUIDESAPPENDIX C INTERNATIONAL QUICK REFERENCE GUIDES

APPENDIX C INTERNATIONAL QUICK REFERENCE GUIDES

APPENDIX C INTERNATIONAL QUICK REFERENCE GUIDESAPPENDIX C INTERNATIONAL QUICK REFERENCE GUIDES

Preface Preface

Preface

Preface Preface

ComplianceCompliance

Compliance

ComplianceCompliance

Products tested and found to be in compliance with the requirements defined

in the EMC standards defined by 89/336/EEC as well as Low Voltage Directive

(LVD) 73/23/EEC can be identified by the CE label on the rear of the unit. The

testing has demonstrated compliance with the following directives:

LVD, 73/23/EEC Complies with UL 3101-1:93

EMC, 89/336/EEC EN 55011, Class A Verification

EN 50082-1:1992

IEC 1000-4-2:1995

IEC 1000-4-3:1994

IEC 1000-4-4:1995

For any additional information refer to the Letter of Compliance that shipped

with the unit (Declaration of Conformity).

UnpackingUnpacking

Unpacking

UnpackingUnpacking

Retain all cartons and packing material until the unit is operated and found to

be in good condition. The unit control box for microprocessor units is packed

in a separate carton. Be sure to locate this separate carton; do not dispose

of it by mistake.

WarrantyWarranty

Warranty

WarrantyWarranty

NES-care NES-care

NES-care

NES-care NES-care

Warranty ContractWarranty Contract

Warranty Contract

Warranty ContractWarranty Contract

After-sale SupportAfter-sale Support

After-sale Support

After-sale SupportAfter-sale Support

ExtendedExtended

Extended

ExtendedExtended

If the unit shows external or internal damage, or does not operate properly,

contact the transportation company and file a damage claim. Under ICC

regulations, this is your responsibility.

Units have a one year warranty against defective parts and workmanship

from date of shipment. See back page for more details.

• Extend parts and labor coverage for an additional year.

• Worry-free operation.

• Control service costs.

• Eliminate the need to generate repair orders.

• No unexpected repair costs.

Other contract options are available. Please contact Thermo NESLAB for

more information.

Thermo NESLAB is committed to customer service both during and after the

sale. If you have questions concerning the operation of your unit, contact

our Sales Department. If your unit fails to operate properly, or if you have

questions concerning spare parts or Service Contracts, contact our Customer Service Department. Before calling,

information from the unit's serial number label:

please

obtain the following

- BOM number

- Serial number

- 2 -

WarningsWarnings

Warnings

WarningsWarnings

Section I SafSection I Saf

Section I Saf

Section I SafSection I Saf

Make sure you read and understand all instructions and safety precautions

listed in this manual before installing or operating your unit. If you have any

questions concerning the operation of your unit or the information in this

manual, contact our Sales Department.

Performance of installation, operation, or maintenance proceduresPerformance of installation, operation, or maintenance procedures

Performance of installation, operation, or maintenance procedures

Performance of installation, operation, or maintenance proceduresPerformance of installation, operation, or maintenance procedures

other than those described in this manual may result in a hazardousother than those described in this manual may result in a hazardous

other than those described in this manual may result in a hazardous

other than those described in this manual may result in a hazardousother than those described in this manual may result in a hazardous

situation and may void the manufacturer's warranty.situation and may void the manufacturer's warranty.

situation and may void the manufacturer's warranty.

situation and may void the manufacturer's warranty.situation and may void the manufacturer's warranty.

Transport the unit with care. Sudden jolts or drops can damage theTransport the unit with care. Sudden jolts or drops can damage the

Transport the unit with care. Sudden jolts or drops can damage the

Transport the unit with care. Sudden jolts or drops can damage theTransport the unit with care. Sudden jolts or drops can damage the

refrigeration lines.refrigeration lines.

refrigeration lines.

refrigeration lines.refrigeration lines.

Observe all warning labels.Observe all warning labels.

Observe all warning labels.

Observe all warning labels.Observe all warning labels.

Never remove warning labels.Never remove warning labels.

Never remove warning labels.

Never remove warning labels.Never remove warning labels.

Never operate damaged or leaking equipment.Never operate damaged or leaking equipment.

Never operate damaged or leaking equipment.

Never operate damaged or leaking equipment.Never operate damaged or leaking equipment.

Never operate the unit without bath fluid in the bath.Never operate the unit without bath fluid in the bath.

Never operate the unit without bath fluid in the bath.

Never operate the unit without bath fluid in the bath.Never operate the unit without bath fluid in the bath.

Above 115°C, never use pure ethylene glycol as a bath fluid.Above 115°C, never use pure ethylene glycol as a bath fluid.

Above 115°C, never use pure ethylene glycol as a bath fluid.

Above 115°C, never use pure ethylene glycol as a bath fluid.Above 115°C, never use pure ethylene glycol as a bath fluid.

etyety

ety

etyety

For 220 - 240 volt units supplied without a line cord, use a harmonizedFor 220 - 240 volt units supplied without a line cord, use a harmonized

For 220 - 240 volt units supplied without a line cord, use a harmonized

For 220 - 240 volt units supplied without a line cord, use a harmonizedFor 220 - 240 volt units supplied without a line cord, use a harmonized

(HAR) grounded 3-conductor cord, type (HAR) grounded 3-conductor cord, type

(HAR) grounded 3-conductor cord, type

(HAR) grounded 3-conductor cord, type (HAR) grounded 3-conductor cord, type

listed below. A suitable cord end is required for connecting to thelisted below. A suitable cord end is required for connecting to the

listed below. A suitable cord end is required for connecting to the

listed below. A suitable cord end is required for connecting to thelisted below. A suitable cord end is required for connecting to the

equipment (see unit socket) and must terminate with an IEC approvedequipment (see unit socket) and must terminate with an IEC approved

equipment (see unit socket) and must terminate with an IEC approved

equipment (see unit socket) and must terminate with an IEC approvedequipment (see unit socket) and must terminate with an IEC approved

plug for proper connection to power supply.plug for proper connection to power supply.

plug for proper connection to power supply.

plug for proper connection to power supply.plug for proper connection to power supply.

22

2

Nominal 1.0 mmNominal 1.0 mm

Nominal 1.0 mm

Nominal 1.0 mmNominal 1.0 mm

Always turn off the unit and disconnect the line cord from the powerAlways turn off the unit and disconnect the line cord from the power

Always turn off the unit and disconnect the line cord from the power

Always turn off the unit and disconnect the line cord from the powerAlways turn off the unit and disconnect the line cord from the power

source before performing any service or maintenance procedures, orsource before performing any service or maintenance procedures, or

source before performing any service or maintenance procedures, or

source before performing any service or maintenance procedures, orsource before performing any service or maintenance procedures, or

before moving the unit.before moving the unit.

before moving the unit.

before moving the unit.before moving the unit.

Always empty the bath before moving the unit.Always empty the bath before moving the unit.

Always empty the bath before moving the unit.

Always empty the bath before moving the unit.Always empty the bath before moving the unit.

Never operate equipment with damaged line cords.Never operate equipment with damaged line cords.

Never operate equipment with damaged line cords.

Never operate equipment with damaged line cords.Never operate equipment with damaged line cords.

Refer service and repairs to a qualified technician.Refer service and repairs to a qualified technician.

Refer service and repairs to a qualified technician.

Refer service and repairs to a qualified technician.Refer service and repairs to a qualified technician.

In addition to the safety warnings listed above, warnings are posted

throughout the manual. These warnings are designated by an exclamation

mark inside an equilateral triangle with text highlighted in bold print. Read

and follow these important instructions. Failure to observe these instructions

can result in permanent damage to the unit, significant property damage,

personal injury or death.

22

cross section rated 10 Amps Unit Socket: IEC - 320 C13 cross section rated 10 Amps Unit Socket: IEC - 320 C13

cross section rated 10 Amps Unit Socket: IEC - 320 C13

cross section rated 10 Amps Unit Socket: IEC - 320 C13 cross section rated 10 Amps Unit Socket: IEC - 320 C13

H05H05

H05

H05H05

VVVV

VV

VVVV

-F-F

, with conductors, with conductors

-F

, with conductors

-F-F

, with conductors, with conductors

- 3 -

DescriptionDescription

Description

DescriptionDescription

SpecificationsSpecifications

Specifications

SpecificationsSpecifications

Temperature RangeTemperature Range

Temperature Range

Temperature RangeTemperature Range

Temperature StabilityTemperature Stability

Temperature Stability

Temperature StabilityTemperature Stability

Cooling CapacityCooling Capacity

Cooling Capacity

Cooling CapacityCooling Capacity

Pump CapacityPump Capacity

Pump Capacity

Pump CapacityPump Capacity

Section II General InfSection II General Inf

Section II General Inf

Section II General InfSection II General Inf

ormationormation

ormation

ormationormation

The RTE 140 Refrigerated Bath/Circulators are designed to provide temperature control for applications requiring a fluid work area or pumping to an

external system.

Units consists of a non-CFC air-cooled refrigeration system, circulation

pump, seamless stainless steel bath, work area cover, and a microprocessor

temperature controller.

-40°C to +150°C

11

1

11

22

2

22

±0.05°C

500 Watts @ 0°C

15 lpm at 0' (0 M)

0 lpm at 16' (4.9 M)

HeaterHeater

Heater

HeaterHeater

Watts

Bath Work AreaBath Work Area

Bath Work Area

Bath Work AreaBath Work Area

(L x W x D)

Inches

Centimeters

Bath VolumeBath Volume

Bath Volume

Bath VolumeBath Volume

Gallons

Liters

Case DimensionsCase Dimensions

Case Dimensions

Case DimensionsCase Dimensions

(H x W x D)

Inches

Centimeters

Power RequirementsPower Requirements

Power Requirements

Power RequirementsPower Requirements

33

3

33

800

4 3/4 x 8 x 5

12.1 x 20.3 x 12.7

1.9

7.0

26 x 12 3/8 x 18 3/8

66.0 x 31.4 x 46.7

44

4

44

1. Specifications listed for units operating at +20°C bath temperature with tap water as bath fluid.

2. 60 Hertz units. 50 Hertz units have a 375 watt coolinig capacity at 0°C. Specifications listed for

units operating at +0°C bath temperature, +20°C (+68°F) ambient, using fluid with specific heat

of 0.5.

3. 60 Hertz units. 50 Hertz units have a 1000 watt heater.

4. Power Board Transformer Fuse–T 2.0A 250V (Qty) [T=Time Delay]

115 V, 60 Hz, 16 Amp

220/240 V, 50 Hz, 8.6 Amp

- 4 -

SiteSite

Site

SiteSite

Section III InstallationSection III Installation

Section III Installation

Section III InstallationSection III Installation

The indentations on the sides of the unit are designed to function as handles.

Lift the unit by the handles and locate it on a sturdy table or bench top.

Ambient temperatures should be inside the range of +50°F to +104°F (+10°C

to +40°C).

Never place the unit in a location where excessive heat, moisture, orNever place the unit in a location where excessive heat, moisture, or

Never place the unit in a location where excessive heat, moisture, or

Never place the unit in a location where excessive heat, moisture, orNever place the unit in a location where excessive heat, moisture, or

corrosive materials are present.corrosive materials are present.

corrosive materials are present.

corrosive materials are present.corrosive materials are present.

The unit has an air-cooled refrigeration system. Air is drawn through the

front panel and discharged through the rear panel. The unit must be

positioned so the air intake and discharge are not impeded. A minimum

clearance of 12 inches (30 centimeters) at the front and rear of the unit is

necessary for adequate ventilation. Inadequate ventilation will reduce

cooling capacity and, in extreme cases, can cause compressor failure.

Excessively dusty areas should be avoided and a periodic cleaning schedule

should be instituted (see Section VI, Cleaning).

ElectricalElectrical

Electrical

ElectricalElectrical

RequirementsRequirements

Requirements

RequirementsRequirements

The unit is rated for heat load at 20°C (68°F) ambient temperature. Above

this temperature reduce the cooling capacity 1% for every 1°F above +68°F,

to a maximum ambient temperature of +104°F. In terms of Celsius, reduce

the cooling capacity 1% for every 0.5°C above +20°C, to a maximum ambient temperature of +40°C.

Line voltage may be easily accessible inside the pump/control box.Line voltage may be easily accessible inside the pump/control box.

Line voltage may be easily accessible inside the pump/control box.

Line voltage may be easily accessible inside the pump/control box.Line voltage may be easily accessible inside the pump/control box.

Always unplug the unit prior to removing pump/control box cover.Always unplug the unit prior to removing pump/control box cover.

Always unplug the unit prior to removing pump/control box cover.

Always unplug the unit prior to removing pump/control box cover.Always unplug the unit prior to removing pump/control box cover.

Refer to the serial number label on the rear of the unit to identify the specific

electrical requirements of your unit.

En sure the voltage of the power source meets the specified voltage, ±10%.

The unit construction provides extra protection against the risk of electric

shock by grounding appropriate metal parts. The extra protection may not

function unless the power cord is connected to a properly grounded outlet. It

is the user's responsibility to assure a proper ground connection is provided.

For 220 - 240 volt units supplied without a line cord, use a harmonizedFor 220 - 240 volt units supplied without a line cord, use a harmonized

For 220 - 240 volt units supplied without a line cord, use a harmonized

For 220 - 240 volt units supplied without a line cord, use a harmonizedFor 220 - 240 volt units supplied without a line cord, use a harmonized

(HAR) grounded 3-conductor cord, type (HAR) grounded 3-conductor cord, type

(HAR) grounded 3-conductor cord, type

(HAR) grounded 3-conductor cord, type (HAR) grounded 3-conductor cord, type

listed below. A suitable cord end is required for connecting to thelisted below. A suitable cord end is required for connecting to the

listed below. A suitable cord end is required for connecting to the

listed below. A suitable cord end is required for connecting to thelisted below. A suitable cord end is required for connecting to the

equipment (see unit socket) and must terminate with an IEC approvedequipment (see unit socket) and must terminate with an IEC approved

equipment (see unit socket) and must terminate with an IEC approved

equipment (see unit socket) and must terminate with an IEC approvedequipment (see unit socket) and must terminate with an IEC approved

plug for proper connection to power supply.plug for proper connection to power supply.

plug for proper connection to power supply.

plug for proper connection to power supply.plug for proper connection to power supply.

22

2

Nominal 1.0 mmNominal 1.0 mm

Nominal 1.0 mm

Nominal 1.0 mmNominal 1.0 mm

22

cross section rated 10 Amps Unit Socket: IEC - 320 C13 cross section rated 10 Amps Unit Socket: IEC - 320 C13

cross section rated 10 Amps Unit Socket: IEC - 320 C13

cross section rated 10 Amps Unit Socket: IEC - 320 C13 cross section rated 10 Amps Unit Socket: IEC - 320 C13

- 5 -

H05H05

H05

H05H05

VVVV

VV

VVVV

-F-F

, with conductors, with conductors

-F

, with conductors

-F-F

, with conductors, with conductors

Plumbing RequirementsPlumbing Requirements

Plumbing Requirements

Plumbing RequirementsPlumbing Requirements

EnsurEnsur

e the unit is off before connecting tubing to the unit.e the unit is off before connecting tubing to the unit.

Ensur

e the unit is off before connecting tubing to the unit.

EnsurEnsur

e the unit is off before connecting tubing to the unit.e the unit is off before connecting tubing to the unit.

To prevent damage to the plumbing lines, always support the ¾"To prevent damage to the plumbing lines, always support the ¾"

To prevent damage to the plumbing lines, always support the ¾"

To prevent damage to the plumbing lines, always support the ¾"To prevent damage to the plumbing lines, always support the ¾"

fittings while installing/removing the pumping caps and lines.fittings while installing/removing the pumping caps and lines.

fittings while installing/removing the pumping caps and lines.

fittings while installing/removing the pumping caps and lines.fittings while installing/removing the pumping caps and lines.

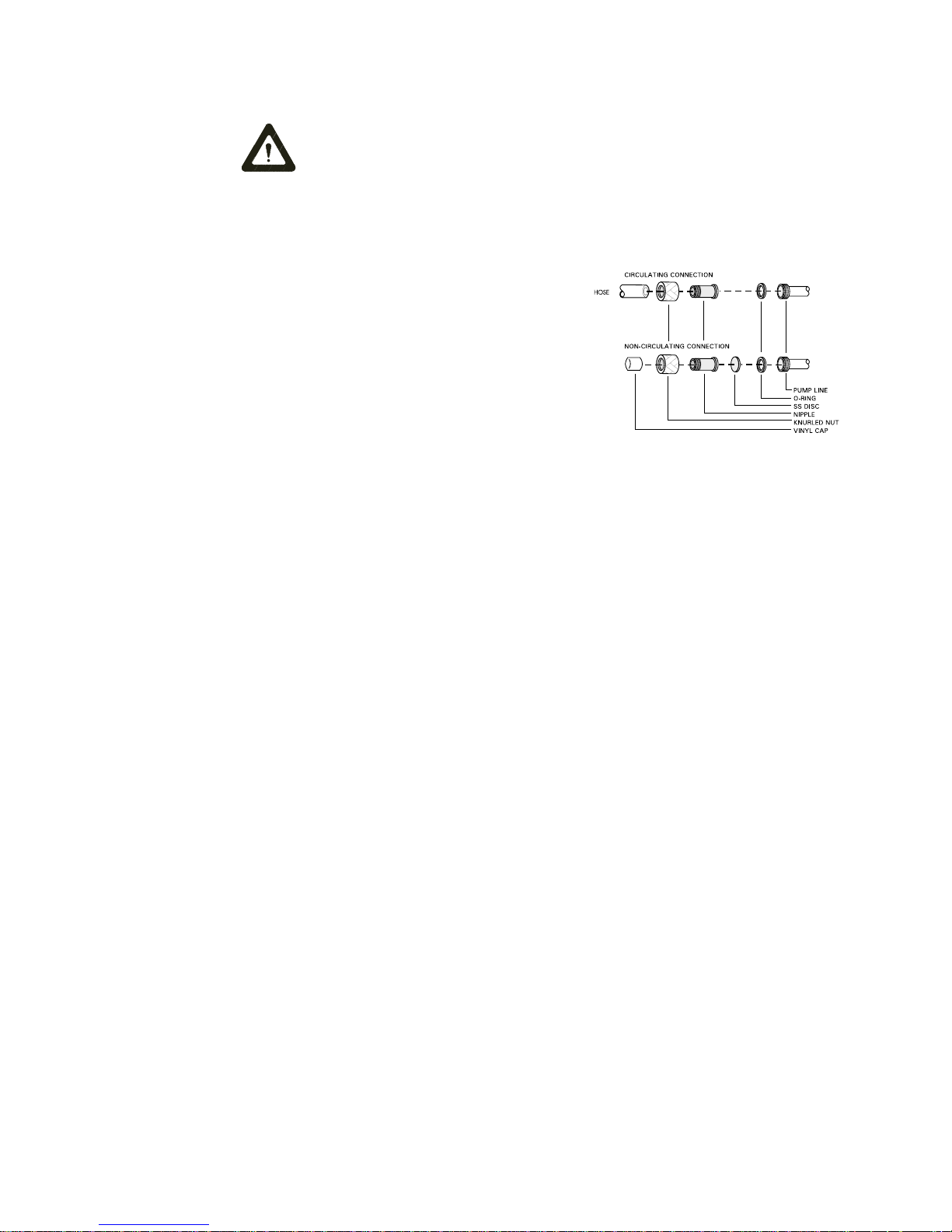

Hose ConnectionsHose Connections

Hose Connections

Hose ConnectionsHose Connections

The pump connections are located at the rear of the pump box and are

labelled PUMP INLET and PUMP

OUTLET. These connections are bent

upward so the recirculating fluid will

drain back into the reservoir when the

hoses are disconnected. Both connections are capped with stainless steel

serrated plugs.

The pump lines have ¼" male pipe

threads for mating with standard

plumbing fittings. For your convenience two stainless steel adapters, ¼" female pipe thread to 3/8" O.D.

serrated fitting, are provided. (To assure proper fit, they should be installed

using Teflon® tape around the threads.)

Flexible tubing, if used, should be of heavy wall or reinforced construction.

Make sure all tubing connections are securely clamped. Avoid running

tubing near radiators, hot water pipes, etc. If substantial lengths of tubing

are necessary, insulation may be required to prevent loss of cooling capacity.

Tubing and insulation are available from Thermo NESLAB. Contact our Sales

Department for more information (see Preface, After-sale Support).

It is important to keep the distance between the unit and the external system

as short as possible, and to use the largest diameter tubing practical. Tubing

should be straight and without bends. If diameter reductions must be made,

make them at the inlet and outlet of the external system, not at the unit.

If substantial lengths of cooling lines are required, they should be pre-filled

with bath fluid before connecting them to the unit. This will ensure that an

adequate amount of fluid will be in the bath once it is in operation.

PumpingPumping

Pumping

PumpingPumping

The pump is designed to deliver a flow of 15 liters/minute (4 gallons

minute) at 0 feet head. To prevent external circulation, the PUMP INLET and

PUMP OUTLET lines on the rear of the unit are capped. The caps must be

removed when external circulation is required.

To properly secure external hose connections to the unit, wrap Teflon® tape

around the pipe line threads before installation. Once the hose connections

are made, the hoses must be properly plumbed to an external system.

It is

important the bath is not in operation until all plumbing is complete.

NOTE: NOTE:

NOTE: To increase agitation in the bath when not circulating externally,

NOTE: NOTE:

connect a short loop of hose between the inlet and outlet lines.

If the bath is not used for external circulation, make sure the stainless steel

caps are in place prior to operating the bath.

- 6 -

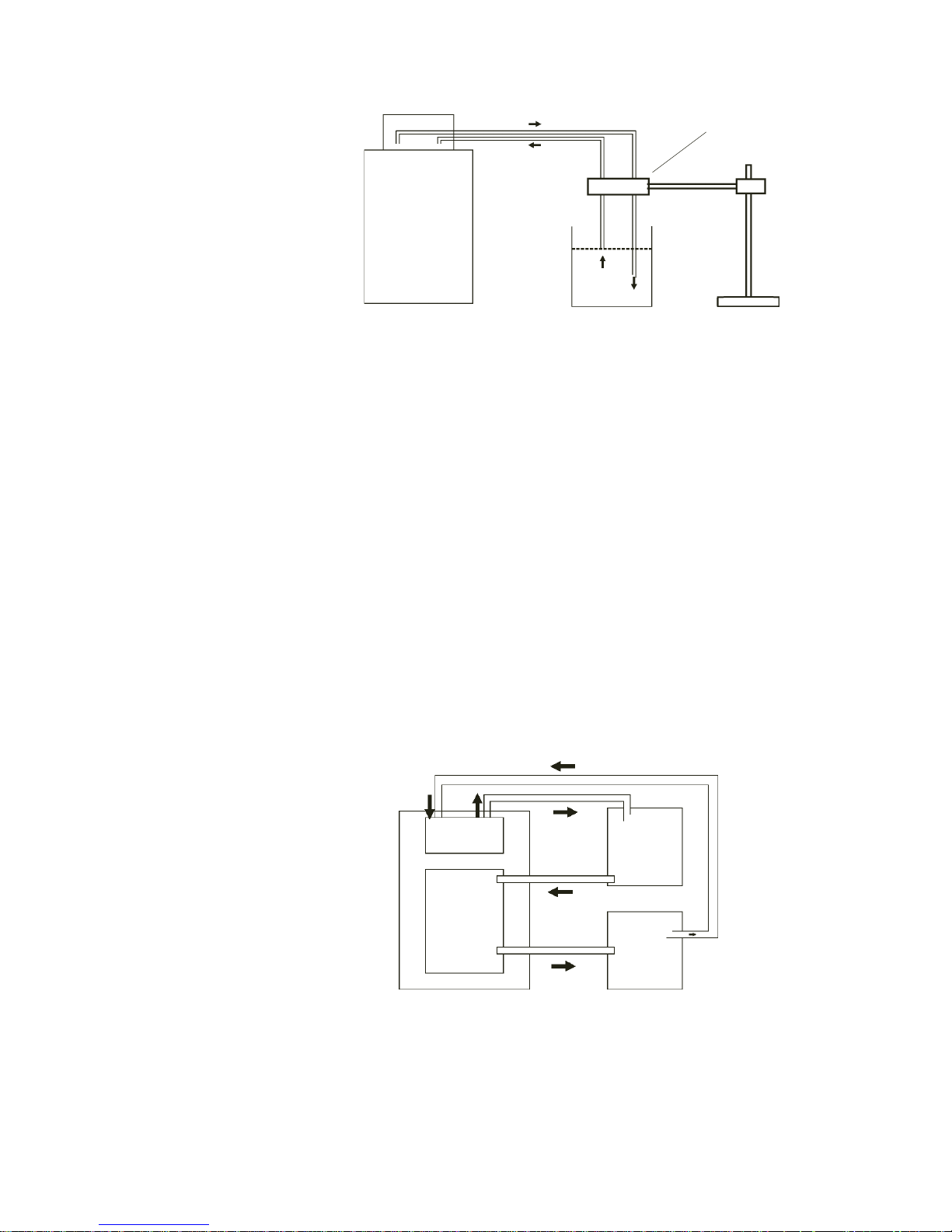

Circulating to an open containerCirculating to an open container

Circulating to an open container

Circulating to an open containerCirculating to an open container

Levelling Device

Outlet

Bath (Rear View) Open Container

Inlet

A stainless steel leveling device is available to aid circulation to an open

vessel. Contact our Sales Department for more information (see Preface,

After-sale Support).

Support the leveling device over the open container with a ringstand. Stagger

the tubes in the leveling device so one tube is submerged in the vessel fluid,

and the other tube is level with the fluid surface. Connect the deeper tube to

the PUMP OUTLET and the shorter tube to the PUMP INLET.

Adjust the flow rate using the accessory flow control valve connected to the

PUMP OUTLET, or by partially restricting the outlet tubing. When properly

adjusted, the pump inlet will draw an occasional air bubble to prevent over

flow, and the pump outlet will force fluid through the submerged tube to

prevent aeration of the vessel.

To avoid siphoning the bath work area when the unit is shut off, lift the

leveling device out of the vessel and above the level of the unit.

Circulating through two closed loopsCirculating through two closed loops

Circulating through two closed loops

Circulating through two closed loopsCirculating through two closed loops

Pump Box

Bath

Work Area

Bath (Top View)

System #1

System #2

The pump can be used to circulate through two closed loop systems.

Connect the shortest practical length of flexible tubing from the PUMP

OUTLET to the inlet of external system #1. Connect the outlet of system #1

directly into the bath work area. Connect tubing from the bath work area to

the inlet of system #2. Connect the outlet of system #2 to the PUMP INLET.

- 7 -

FluidsFluids

Fluids

FluidsFluids

DrainDrain

Drain

DrainDrain

Ensure the temperature of the bath fluid is safe before draining the unit.Ensure the temperature of the bath fluid is safe before draining the unit.

Ensure the temperature of the bath fluid is safe before draining the unit.

Ensure the temperature of the bath fluid is safe before draining the unit.Ensure the temperature of the bath fluid is safe before draining the unit.

The unit is equipped with a drain located at the back of the unit at the base of

the bath. The drain has ¼ inch male pipe threads and is capped with a

stainless steel plug. To drain the reservoir simply remove the cap.

To assure proper fit when replacing the cap, be sure to line the threads with

Teflon tape.

Never use flammable or corrosive fluids with this unit.Never use flammable or corrosive fluids with this unit.

Never use flammable or corrosive fluids with this unit.

Never use flammable or corrosive fluids with this unit.Never use flammable or corrosive fluids with this unit.

The selected fluid must have a viscosity of 50 centistokes or less at the

lowest operating temperature.

Filtered tap water is the recommended fluid for operation from +8°C to

+80°C.

FillingFilling

Filling

FillingFilling

RequirementsRequirements

Requirements

RequirementsRequirements

For operation from +8°C to -30°C, a 50/50 mixture, by volume, of filtered tap

water and laboratory grade ethylene glycol is suggested.

Above +80°C and below -30°C, the user is responsible for fluids used.

Never use pure ethylene glycol as a bath fluid. Never use pure ethylene glycol as a bath fluid.

Never use pure ethylene glycol as a bath fluid.

Never use pure ethylene glycol as a bath fluid. Never use pure ethylene glycol as a bath fluid.

mixture of Ethylene Glycol and filtered tap water is allowed.mixture of Ethylene Glycol and filtered tap water is allowed.

mixture of Ethylene Glycol and filtered tap water is allowed.

mixture of Ethylene Glycol and filtered tap water is allowed.mixture of Ethylene Glycol and filtered tap water is allowed.

The bath work area has a high and low level marker to guide filling. The

markers are 1 inch horizontal slits located in the center of the stainless steel

baffle separating the work area and the pump assembly. The correct fluid

level falls between these two markers. The heating and cooling coils will be

exposed and may become damaged if the correct fluid level is not provided.

When pumping to an external system, keep extra fluid on hand to maintain

the proper level in both the circulating lines and the external system.

Never run the unit when the work area is empty. Avoid overfilling.Never run the unit when the work area is empty. Avoid overfilling.

Never run the unit when the work area is empty. Avoid overfilling.

Never run the unit when the work area is empty. Avoid overfilling.Never run the unit when the work area is empty. Avoid overfilling.

Overfilling the bath may damage the insulation, and affects stability asOverfilling the bath may damage the insulation, and affects stability as

Overfilling the bath may damage the insulation, and affects stability as

Overfilling the bath may damage the insulation, and affects stability asOverfilling the bath may damage the insulation, and affects stability as

well as low-end performancewell as low-end performance

well as low-end performance.

well as low-end performancewell as low-end performance

A minimum 80/20A minimum 80/20

A minimum 80/20

A minimum 80/20A minimum 80/20

- 8 -

Section IV Micr Section IV Micr

Section IV Micr

Section IV Micr Section IV Micr

MicroprocessorMicroprocessor

Microprocessor

MicroprocessorMicroprocessor

ControllerController

Controller

ControllerController

opropr

DescriptionDescription

Description

DescriptionDescription

ocessor Controcessor Contr

opr

ocessor Contr

opropr

ocessor Controcessor Contr

olleroller

oller

olleroller

ss

s

ss

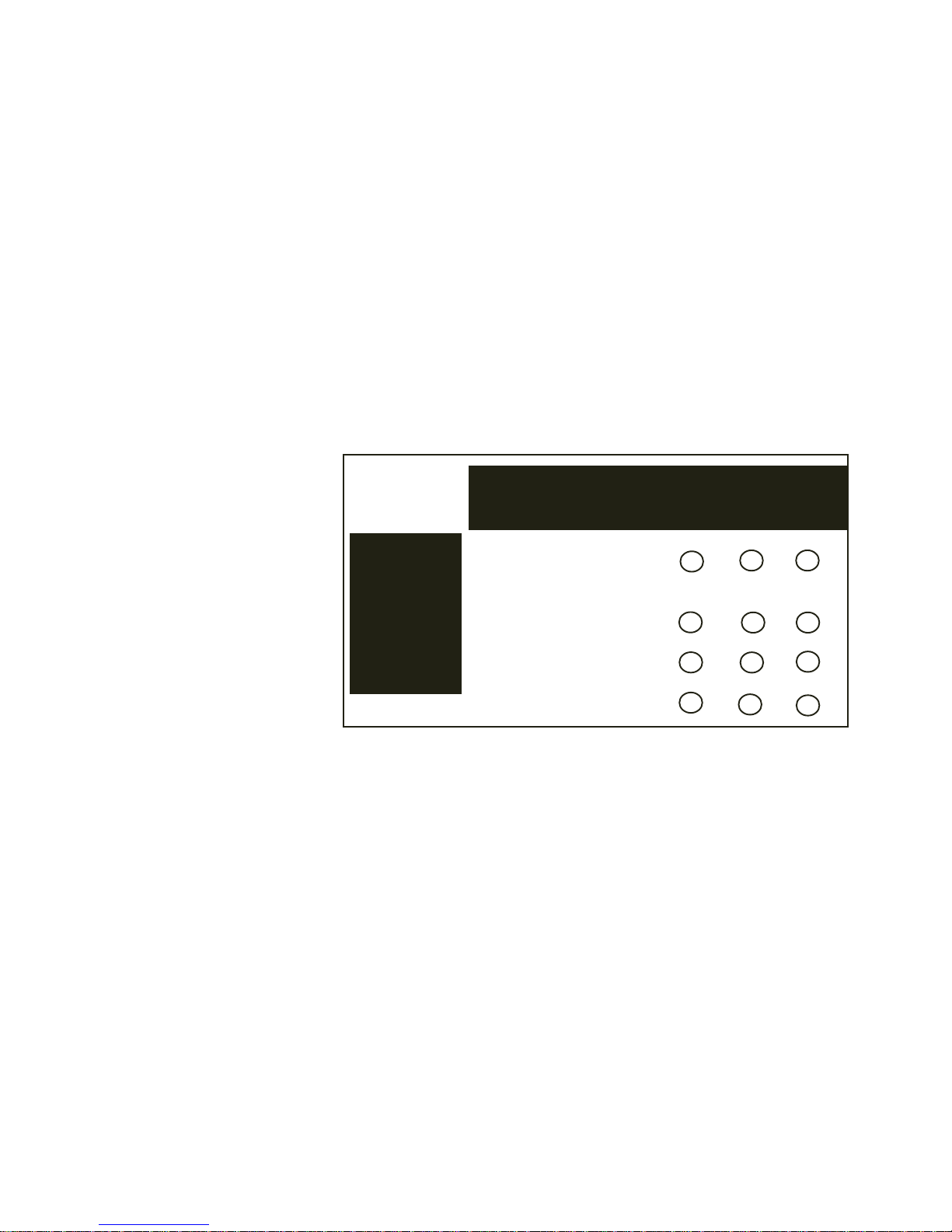

The microprocessor controller is designed as a separate component from the

unit. The controller can be mounted directly on the pump box, or remotely

from the bath. The controller provides proportional with integral and derivative (PID) control.

The controller has two sections. The upper section contains the LED indicators and the Main display which provide feedback to you about the controller

and bath. The ten individual LED indicators provide output on selected

parameters while the Main display will provide information on various unit

conditions. The lower section contains the keypad you use to input data to

the controller.

l SENSOR l HT l PROG l HEAT

l RS232 l LT l HOLD l COOL

EXTERNAL ALARM PROGRAM

l MUTE l FAULT

88.88

SENSORSENSOR

SENSOR

SENSORSENSOR

RS232RS232

RS232

RS232RS232

ON/OFFON/OFF

ON/OFF

ON/OFFON/OFF

Controller MountingController Mounting

Controller Mounting

Controller MountingController Mounting

HT/LTHT/LT

HT/LT

HT/LTHT/LT

mmm m

MUTEMUTE

MUTE

MUTEMUTE

mmm m

mmm

Microprocessor Temperature Controller (Front View)

HOLDHOLD

HOLD

HOLDHOLD

PERIODPERIOD

PERIOD

PERIODPERIOD

LOOPLOOP

LOOP

LOOPLOOP

SETPTSETPT

SETPT

SETPTSETPT

ENTERENTER

ENTER

ENTERENTER

CLEARCLEAR

CLEAR

CLEARCLEAR

mm

PROG/STOREPROG/STORE

PROG/STORE

PROG/STOREPROG/STORE

RUN/STOPRUN/STOP

RUN/STOP

RUN/STOPRUN/STOP

11

1

11

44

4

44

77

7

77

±±

±

±±

22

2

22

55

5

55

88

8

88

00

0

00

33

3

33

66

6

66

99

9

99

..

.

..

The controller can be removed from the bath and placed in a remote location. Extension cables are available from Thermo NESLAB. Contact our

Sales Department for more information.

Controller ConnectionController Connection

Controller Connection

Controller ConnectionController Connection

Microprocessor controllers are supplied with a cable needed to connect the

controller to the pump box. Connect the cable to the 25-pin male connector

on the control box and the female connector on the pump box. Once the

connection is made, the unit is ready for operation.

NOTE:NOTE:

NOTE: The MAIN POWER should be OFF before connecting/disconnecting

NOTE:NOTE:

cables from the control box.

- 9 -

LED IndicatorsLED Indicators

LED Indicators

LED IndicatorsLED Indicators

The following table explains the controller LED indicators. The LEDs can be

on, off or flashing.

LED STATUS INDICATION

SENSOR OF F All controller functions are operating from the

unit's internal probe.

ON All controller functions are operating from

remote sensor input.

FLASHING The Main display indicates the remote sensor

temperature. The controller, however, still uses

the internal probe to control the bath

RS232 OFF Communication port disabled.

ON Communication port enabled.

FLASHING Awaiting next key press

LT OFF No alarm.

ON Main display indicates low limit setpoint.

FLASHING Low limit alarm condition.

HT OFF No alarm.

ON Main display indicates high limit setpoint.

FLASHING High limit alarm condition.

temperature.

HOLD OFF Programming hold feature disabled.

ON Programming hold feature enabled.

PROG OFF No program running.

1

ON The program is suspended

.

FLASHING The program is running.

2

COOL OFF Refrigeration is off

.

ON Refrigeration is on.

HEAT OFF The heater is off.

ON The heater is on.

FLASHING The heater duty cycle.

MUTE OFF The alarm is enabled.

ON The alarm horn is disabled.

FLASHING The alarm horn has been disabled for any

current condition. The alarm horn will automatically reset when the condition is cleared.

FAULT OFF No fault condition.

ON The high temperature/low level safety

has activated.

1.The bath fluid will maintain the setpoint achieved at the time the program is suspended,

except when the bath is in a rapid cool segment. No operator inputs are available to the

controller while in a suspended condition.

2.Below 40°C the refrigeration is on unless the setpoint is more than 2°C above the bath

temperature. This allows rapid heat up. Above 40°C refrigeration is off.

- 10 -

Loading...

Loading...