Thermomax THX-DL User & Installation Manual

USER & INSTALLATION MANUAL V3.2016

www.thermomax-refrigeration.com

THX-DL

Data Logger

Refrigeration

TempControl

|

3 2 | TempControl

Contents

PRESENTATION

Summary of Features 2

INSTALLATION

Safety Precautions 4

THX Unit 4

Sensors 4

Alarm Relay 4

Power Connection and Wiring Diagram 5

Battery

5

Wall & Panel Mount 6

Panel Mount diagrams 7

New Email Connectivty Setup 8

THX OPERATION

1.0 Summary Screens 10

1.1 Sensor Summary 10

1.2 Door Summary 11

1.3 Alarm Summary 11

1.4 Daily Min / Max 12

2.0 Channel View 12

3.0 Alarm Settings 13

4.0 Settings

4.1 Set Clock 14

4.2 Alarm Mute Setup 14

4.3 Channel On / Off 15

4.4 Sensor Type 15

4.5 Door ON / OFF 16

4.6 Door Setup 16

4.7 Relay Setup 17

4.8 Relay Normally Closed / Normally

Open Setup 17

4.9 Calibration 18

4.10 Network 19

5.0 Plot

5.1 Current Day 19

5.2 History 20

6.0 Service Screen

6.1 Test 21

6.2 Contrast 21

6.3 Keypad 21

6.4 Relay 22

7.0 Language Select 22

8.0 Sample Period 23

9.0 Unit Information 23

10.0 Diagnostics

10.1 Databank 24

10.2 Channel 24

USB

1. Download Data 25

2. Download Setup 26

3. Upload Setup 26

4. Service 26

WEB SERVER 27

1. Live Data 28

2. Status 28

3. Setup 29

4. User 30

5. Time 30

6. Graph 31

7. Network 31

SPECIFICATION 32

Presentation

SUMMARY OF FEATURES

Datalogger

• Temperature /humidity from each Channel can be set to

sample every 1/5/15/30/60 minutes and stored to an internal

databank

• Up to 12 channels of data logging can be employed using the

module configuration

• Power Supply 100 – 240V AC Mains

• Contents of internal databank can be transferred to the USB

Flash Memory and viewed or transferred to the PC via website

• Universal panel mount or wall mount box

• Expandable modular design

• IP54 Rated

• Battery Back-up up to 6hrs

• Backward compatible with old sensors (PT 100 terminated

with RJ 11)

• EN12830 certified

• CE tested

• On Board Web Server (IP addressable)

• Large data storage capacity

• USB Firmware Upgrade Functionality

• Module Auto-Detect and self-configuration

• Door Alarm Configuration Function (4 doors per module)

Alarm

• 2-Stage high and low level alarms with mute facility

• Stage 1 temperature threshold with trigger delay

• Stage 2 limit temperature with immediate trigger

• Alarm history record for low alarm, high alarm and power fail

• Battery back-up for power-fail operation

• Summary screen for Alarm Overview

Note: The information supplied in this manual is for guidance only – no part

of this may be used for any agreement, whether express or implied, or to

form any contract.

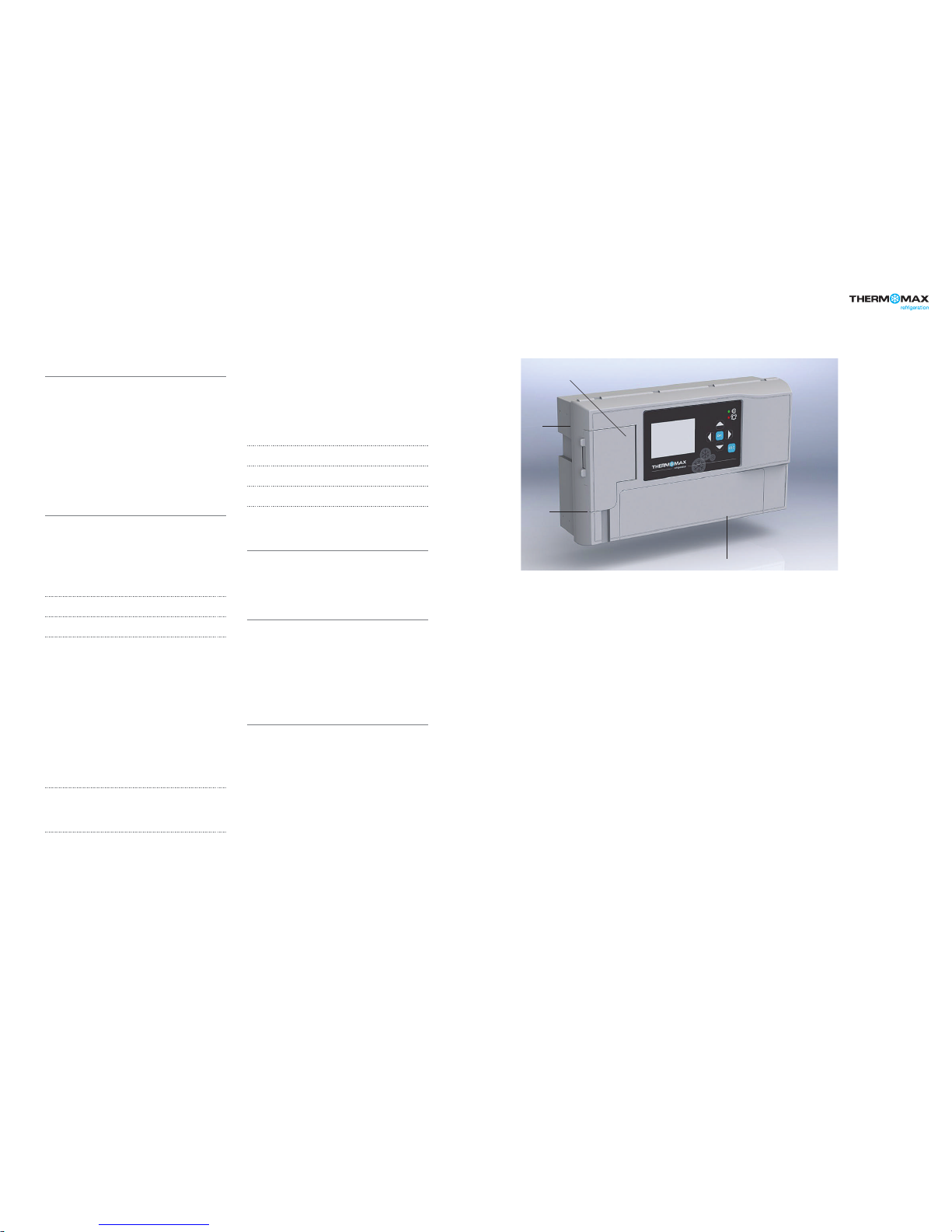

BACK

BOX

FRONT

COVER

FRONT LID

COMMS. AREA

TempControl

|

5 4 | TempControl

Installation

Note: This installation procedure is for guidance only, and its suitability should be verified by the installer.

SAFETY PRECAUTIONS

= WARNING! - Information which is essential for preventing hazard to personnel or device and must be read with care.

= DANGER! - High voltage area. Isolate power supply before any maintenance work.

The following safety precautions are strongly recommended:

1. Before attempting to install and operate the unit, read the instruction and installation manual carefully.

2. Installation and any maintenance should only be carried out by suitably qualified personnel.

3. It is recommended that the unit be connected to the mains supply via a suitably rated isolating switch.

4. WARNING: When the unit is connected to the mains supply and the cover is open, the circuits at mains voltage will be

exposed. Therefore when installing the unit, ensure all required connections (including battery connected, if included), are made and

covers replaced before turning on the mains supply. Ensure that all the connections made are secure. If any maintenance work e.g.

installing a new battery, is required ensure that the unit is isolated from the mains supply before removing the cover. Never leave the

unit unattended if the cover has been removed and the mains supply is connected.

5. Do not exceed unit ratings as shown on the ratings label.

6. It is advisable to route mains cables away from low voltage or sensor cables.

(i) THX Unit

Note: For viewing comfort, the unit should be positioned at eye level. The ambient temperature of the unit is (0°C to +40°C). It is always good practice to keep

electronic equipment away from cold, heat and electrical plant, as extremes of temperature may reduce the lifetime of the device, and heavy electrical loads,

switches, relays or contactors too close to the device may cause electrical and electro-magnetic interference when switched on or off.

(ii) Sensors

The THX may be used with a variety of sensors of different cable lengths. If required, sensors are available with extended cable lengths or

alternatively, sensor extenders are available also in a variety of lengths. If the sensors need to be extended, but factory-made extenders are

not available, they can be extended using a suitable 3 or 4 core cable, according to the diagram shown below

Please note however, that as with all PT100 sensor applications, a good connection is vital. It is therefore recommended that wherever there

is any doubt, a factory extended sensor or sensor extender should be used.

(iii) Alarm Relay

Note: The alarm relays are 2 contact arrangements which are isolated (volt-free). These relays may be used to trigger an external bell, warning lamp or digital

communicator (telephone dialler).

Max rating of Alarm relays is 5A @ 240 VAC.

The alarm relay is software configurable to accommodate normally open or normally closed operation, as described below.

Normally Closed Operation – This is the default mode.

Normally Open Operation – In this mode, the relay outputs will break contact (open circuit) in the event of an alarm and make contact

(closed circuit) in the event of power failure.

If the external device is used, connect the alarm as appropriate, according to the diagram opposite.

Installation

(iv) Power Connections and Wiring Diagram

Note: This device should be properly earthed. Flexible wires simplify connection to the terminals. All connections should be secure and adequately tightened.

It is good practice to keep mains cables away from sensor cables and other low voltage signal cables.

Connect the supply to the unit, as per diagram below, using the appropriate input voltage according to the application.

(v) Battery

The battery supplied is a 3.7V Lithium-polymer rechargeable battery and is plugged in but switched OFF. This should be switched ON

after installation. See picture below. This battery is not essential for the system operation, but is used in the case of power failure, thereby

continuing to log the 12 sensor inputs for approximately 6 hours.

The system parameters will remain intact, in the event of a power failure, however all interface options (Ethernet, screen, keypad options,

USB etc. will not function as normal)

It is recommended that the battery is changed every 24 months, in order to maintain good power failure backup operation. When replacing,

ensure that the type of rechargeable battery used is as specified.

(3.7V Lithium-polymer rechargeable battery)

WHITE

RED

BLUE

GREEN

GROUND

SENSE

COMPENSATE

TempControl

|

7 6 | TempControl

Installation

WALL MOUNT

1. Drill four holes in the wall, according to the template and insert

the wall plugs

2. Remove the Front Lid by unscrewing two screws

3. Disconnect the modules

4. Separate the front cover by unscrewing two screws

5. Remove the required knock outs from Back Box for the cables

to pass through (always separate front cover before removing

the knock outs)

6. Insert the cable glands

7. Screw in the Back Box to the wall

8. Pass the cables through the glands

9. Mount the Front Cover on the Back Box

10. Insert the modules

11. Connect the power supply cable and sensors

12. Tighten the cable glands

13. Mount the front lid

- An inlet or insulating liner with a smooth rounded opening

- A cord guard made from an insulating material should be firmly

attached to the device. The insulating material should extend

beyond the inlet by at least five times the overall diameter of

the cord with the largest cross-sectional area that can be

used to supply the device. Where the conductors are

connected inside the device, the cord anchorage will relieve

the conductors of the cord from excessive strain, this includes

twisting. The anchorage must also protect the insulation of

conductors from abrasion. The protective earth conductor

must be the last suffer from any strain in the event the cord

should slip in its anchorage. The anchorage must provide relief

from a pull force of 30 Newton and a twisting or torque force

of 0.10 Newton metres. Cord anchorage shall meet the

following requirements.

WARNING: TO PROTECT THE MAINS SUPPLY LEAD FROM ABRASION AND SHARP BENDS AT THE POINT WHERE

THE LEAD ENTERS THE DEVICE, ONE OF THE TWO FOLLOWING METHODS MUST BE EMPLOYED:

- A screw that comes into direct contact with the cord will not

be used to clamp down the cord.

- The cords will not have any knots tied in it.

- It will not be possible to push the cord into the device to such

an extent that it will cause a hazard.

- Should the cord insulation fail in an anchorage that has metal

parts, none of the exposed conductive material of the device

will become live.

- A compression bushing will not be used as cord anchorage

unless it is capable of accommodating all sizes and types of

mains supply cord that meet the requirements in point (2) and

are suitable for connection to the terminals of the device, or

the bushing has been designed to terminate a screened

mains supply cord.

- The cord anchorage will be designed in such a way that cord

replacement does not cause a hazard and will be clear how

strain relief is provided.

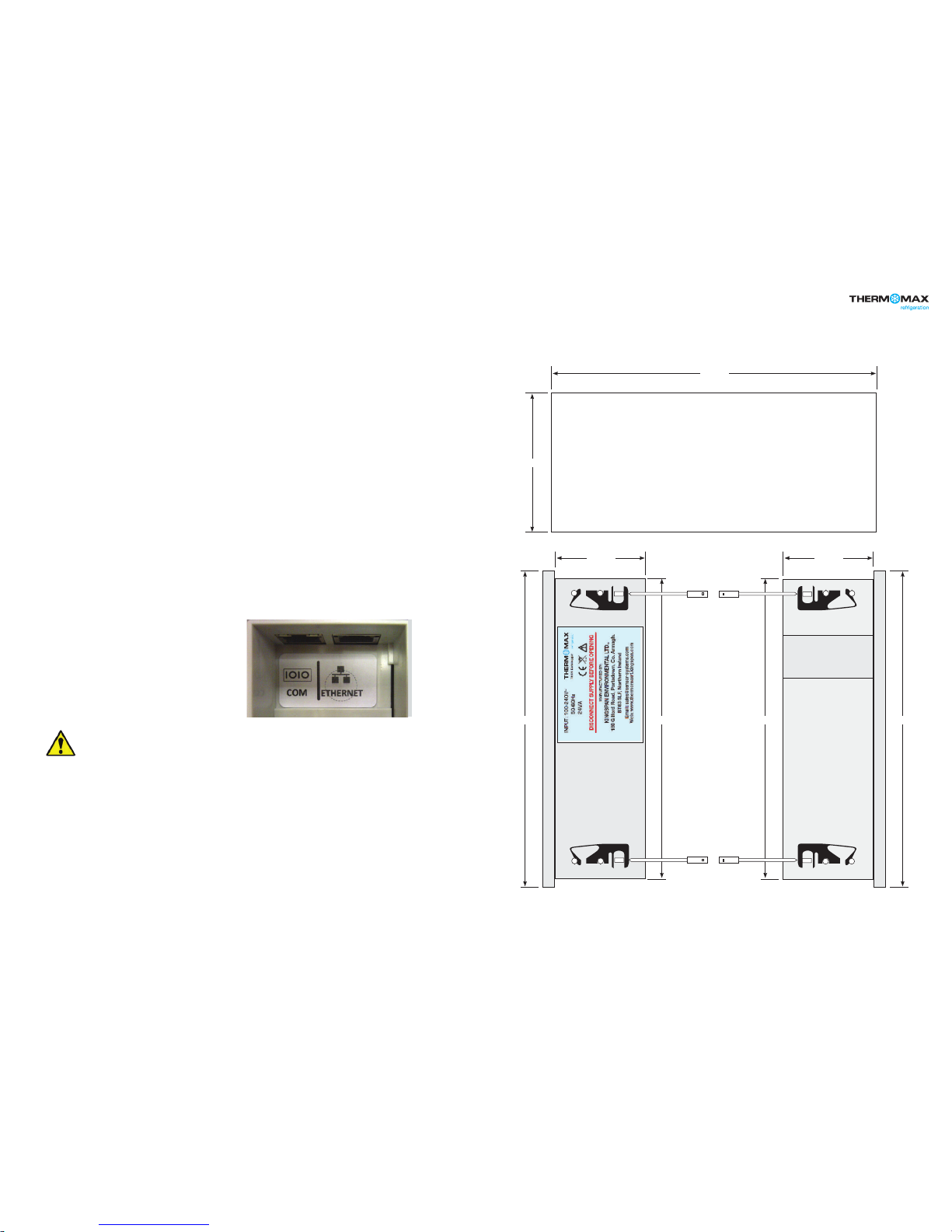

PANEL MOUNT (required panel mount kit)

1. Cut a hole in the panel with the described dimensions,

(see page 7)

2. Remove the Front Lid unscrewing two screws

3. Disconnect the modules

4. Separate the front cover by unscrewing two screws

5. Remove the required knock outs from Back Box for the cables

to pass through (always separate front cover before removing

the knock outs). Ethernet cable can be passed through the

hole which is under the label on the front cover (see picture

below)

6. Attach the Panel Mount Seal, ensure that it is on the right position

7. Insert the Back Box into the panel cut out

8. Attach the four Panel Mount Fixing Clips (supplied), to the four

studs at either side of the unit, (see page 7).

9. Tighten the four Panel Mount Fixing Screws

10. Insert the cable glands

11. Pass the cables through the glands

12. Mount the Front Cover on the Back Box

13. Insert the modules

14. Connect the power supply cable and sensors

15. Tighten the cable glands

16. Mount the front lid

Installation

296mm

50mm 50mm

169mm

177mm177mm 168mm 168mm

Right side view

Panel mount xing clip

Panel mount xing clip

Left side view

Panel mount xing clip

Panel mount xing clip

Panel mount

xing screw

Panel mount

xing screw

Panel mount

xing screw

Panel mount

xing screw

Area required to be cut out for panel mount

TempControl

|

98 | TempControl

NEW Email connectivity set-up

NEW Email connectivity set-up

Email alert functionality only available on firmware version 1.8 and above.

* Visit http://www.thermomax-refrigeration.com/uk/en to download the latest firmware.

Benefits

• NO SIM REQUIRED

• NO EXTRA HARDWARE NEEDED

• NO ANNUAL FEES TO PAY

• Up to 3 users can be made aware of an

alarm status remotely.

• Easy to install and maintain.

• No need for Auto-Dialer system.

How the new Email Alert functions?

Example: High Alarm threshold set at in settings on THX-DL,

– when the above temperature has been exceeded

– The THX-DL will initiate the Email Alert.

Example: Low Alarm threshold set at in settings on THX-DL,

– when the above temperature has been exceeded

– The THX-DL will initiate the Email Alert.

An Email alert will also be sent in the event of loss of power from the

THX-DL

* It is the customers responsibly to keep power to the network infrastructure.

How do I test the new Email feature ?

Brief Set up summary

• Select Enable on your webserver page.

• Enter the email address/addresses of recipients to be alerted during

alarm sequences - up to 3 recipients can be selected with no

prioritisation.

• Select the Test and Save icon

• A Test Email will be sent to entered Email Addresses.

How will the Email look ?

Example: The Email/Emails will be sent to the inbox displaying the

THX-DL Serial number where alarm has occurred.

Example: The Email will display the channel/channels where the alarms

have occurred.

PC: CPU 2.0GHZ or above

Memory Size: 256MB or above

Display Card: 64M or above

Supported OS: Microsoft Windows XP/Vista/Win7 or above, Mac OS

Browser: IE8 and above version or compatible browser, Firefox or

other standard browsers. Java environment required to

view webpage.

Connectivity:

Network and Internet connection

Opened (non-encrypted) port for outgoing emails (25, 2525, 587)

Technical Support: Telephone: +44 (0) 28 3836 4460

Connectivity and networking minimum

requirements:

TempControl

|

11 10 | TempControl

THX-DL Operation

In order to fully understand the operation of the unit, this section should be read carefully.

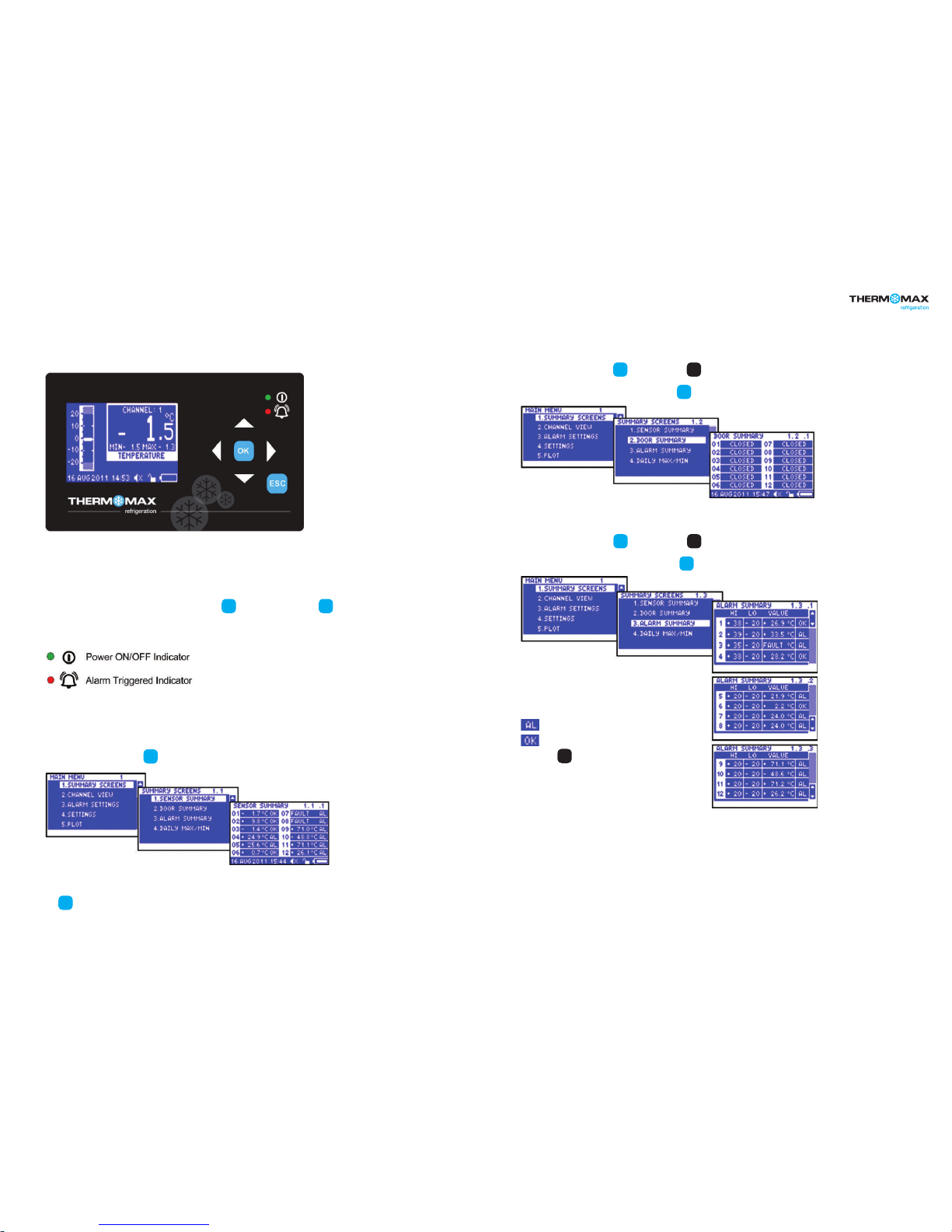

(i) Graphic LCD Display

Displays all the information. The contrast is adjustable to suit the user. (Refer to section 6.2)

(ii) Function Keys

The six keys are used to navigate through the unit’s menus, allowing for easy access to the THX many options and settings.

The four arrow keys select an option in the displayed menu, the key select the menu and the key returns to the previous menu.

A menu I.D. is displayed at the top of each screen to indicate to the user which particular menu is being addressed.

(iii) Indicators

1.0 SUMMARY SCREENS

These screens allow the user to view all the data logged by the unit for each channel, e.g. Sensor Summary, Door Summary, Alarm

Summary, and Daily Max/Min Temperatures.

1.1 Sensor Summary

From the Main Menu screen, press key twice to reveal the Sensor Summary Screen.

This screen displays the current temperature/humidity readings of each of the connected channels and indicates if that channel

is in alarm or not.

The key will return the user to the previous menu option.

1.2 Door Summary

From the Main Screen, press the key, followed by the key to select

Door Summary in the menu. Confirm selection using the key to reveal the Door Summary Screen.

This screen displays the status of each of the 12 digitals inputs, indicating whether it is OPEN, CLOSED or OFF. (Default status is OFF)

1.3 Alarm Summary

From the Main Screen, press the key, followed by the key to select

Alarm Summary in the menu. Confirm selection using the key to reveal the Alarm Summary Screen.

These screens display the High and Low Alarm Limit settings for

each channel and also display the current temperature/humidity

readings. The sensor’s status is also displayed, i.e., in alarm or ok.

alarm limit or alarm threshold has been reached

no alarms

Pressing the key will reveal information for channels 5 to 8,

and pressing once more, reveals information for channels 9 to 12.

THX-DL Operation

ESC

ESC

OK

OK

OK

OK

▼

OK

OK

▼

▼

Loading...

Loading...