Thermo Life Sciences Plc RDSRXUS1, RDSTXUS1 Users Manual

Thermo

Cryotechnics

REMOTE DATA/ALARM SYSTEM

SYSTEM ADMINISTRATORS

MANUAL

ABRIDGED FOR FCC

APPLICATION

FULL VERSION AVALIABLE IF

REQUIRED (85 Pages)

REMOTE DATA SYSTEM

FCC REGULATONS

NOTE: This equipment has been tested and found to comply with the limits for a

class A digital device, persuant to part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses and can

radiate radio frequency energy and if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user wil be required to correct the interference at his

own expense.

IMPORTANT INFORMATION !

READ BEFORE USE

CAUTION Modifications to this equipment which are not expressly approved

By Thermo Life Sciences development department could void the

Users authority to operate this equipment.

WARNING Do NOT short circuit the battery as this may cause a risk of explosion.

ELECTRIC SHOCK RISK. Isolate the power supply before removing any cover.

BURN HAZARD. Installation and maintenance of temperature probes should only be

carried out by users who are qualified and are familiar with the required safety

procedures applicable to the equipment to which the probe is being fitted.

Ensure each part of the system is installed securely and in such a way that it does not

obstruct normal access to surrounding areas and is kept away from excessive heat and

moisture.

Read the user manual before installing or making changes to the system.

Version 1.00

2001-03-05

CONTENTS

IMPORTANT INFORMATION !....................2

READ BEFORE USE................................................................................................2

INTRODUCTION........................................................................................................5

CHAPTER ONE ..........................................................................................................6

SYSTEM PLANNING ..............................................................................................6

SITE SURVEY ........................................................................................................8

CHAPTER TWO .......................................................................................................11

INSTALLING THE SYSTEM ................................................................................11

RECEIVER INSTALLATION ...............................................................................11

TRANSPONDER INSTALLATION ......................................................................12

TESTING THE TRANSPONDER.........................................................................13

TRANSMITTER INSTALLATION ........................................................................13

TESTING THE TRANSMITTER ..........................................................................14

TRANSMITTER BATTERY OPERATION............................................................14

TRANSMITTER MAINS OPERATION ................................................................14

CHAPTER THREE ...................................................................................................16

PROGRAMMING THE RECEIVER......................................................................16

CHAPTER FOUR......................................................................................................17

PROGRAMMING THE TRANSMITTERS ...........................................................17

CHAPTER FIVE .......................................................................................................18

OPERATING THE RECEIVER..............................................................................18

MAIN DISPLAY MODE.......................................................................................18

CHAPTER SIX ..........................................................................................................19

ALARMS.................................................................................................................19

CHAPTER SEVEN....................................................................................................20

SYSTEM MANAGEMENT....................................................................................20

DAY TO DAY SYSTEM OPERATION ........................................................20

CHAPTER EIGHT....................................................................................................21

PROGRAMMING THE SD1+ AUTODIALLER...................................................21

CHAPTER NINE .......................................................................................................22

DATA LOGGING ...................................................................................................22

CHAPTER TEN.........................................................................................................23

SYSTEM FAULT FINDING ..................................................................................23

CHAPTER TEN.........................................................................................................24

RF EMMISIONS TESTS ........................................................................................24

CHAPTER ELEVEN.................................................................................................25

RDS WINDOWS SOFTWARE ..............................................................................25

APPENDIX A .............................................................................................................26

SOURCES OF INTERFERENCE...........................................................................26

APPENDIX B .............................................................................................................27

POWER REQUIREMENTS....................................................................................27

RECEIVER POWER.......................................................................................27

TRANSMITTER POWER...............................................................................27

TRANSPONDER POWER .............................................................................27

APPENDIX C .............................................................................................................28

SETTING UP THE SD1 AUTODIALLER.............................................................28

APPENDIX D .............................................................................................................29

TYPES OF PROBES AND INPUTS ......................................................................29

INDEX .....................................................................................................................30

INTRODUCTION

The RDS system has been designed as an integrated data acquisition and equipment

monitoring system. Installation and maintenance of the system is simplified as

All data and alarm signals are sent using a wireless protocol specially developed to

ensure complete data integrity and reliability.

There are no wires or cables to run which eliminates the need for physical connections

between each part of the system, thus removing one of the main difficulties in the

installation of any new system in an existing environment.

The transmission protocol incorporates many advanced data protection features to

ensure that all transmitted data is received without error.

All elements of the RDS system have undergone stringent RF emissions and

Susceptibility testing by a recognised independent testing facility, See the section

RF EMISSIONS TEST for details.

The RDS system is self monitoring

Sensors thus avoiding the need for the user to manually test each unit.

All Data received by the system, including any alarms, can be logged onto a computer

using the RDS system software for easy equipment monitoring and retrospective

analysis of equipment performance. The software also provides you with a permanent

record of all the received data and any alarms.

Most aspects of the system can be automated allowing equipment to be monitored and

Data to be logged with a minimal of time and effort from the end user.

When connected to a suitable telephone line the system can automatically call for

assistance should any equipment develop a fault.

The RDS system itself can be linked to and existing alarm system to provide an

additional level of security.

The system is supplied with full technical support from the manufacturer to provide

you with any installation and configuration needs that you may have.

1

and is able to detect failure of any of the remote

1

Subject to any local legislation

CHAPTER ONE

SYSTEM PLANNING

Please read this manual carefully before attempting to install or modify an

RDS system. Maximum system performance and reliability can only be

obtained by proper installation and setting up of this system.

A complete RDS system consists of four main parts.

Receiver

Transmitter(s)

Transponder(s)

Computer

1

2

3

The receiver is the hub of the RDS system as all data and alarms are sent to and

processed by it. Each transmitter is configured and programmed into the system using

the receiver and once entered into the system they are constantly monitored.

When connected to a suitable phone line the system can be configured to selectively

call for assistance should an alarm be detected.

The RDS system can discriminate between different types of alarms allowing

different actions to be taken depending on the type of alarm encountered. All alarm

settings are under the control of the end user so the system can be tailored to suit any

environment.

If required then a computer

4

can be connected to the system allowing all data and

alarm codes to be saved as a permanent record. The computer software also allows

The user to view specific information about any or all remote transmitters including

All data received, any alarms received and the location of each piece of equipment

being monitored.

The system can be expanded

5

transmitter.

The use of one or more transponders allows the system to be extended beyond the

normal range of the transmitters or can be used to provide multiple signal paths for

difficult environments thus maintaining system reliability.

Each RDS receiver can be programmed with a unique GROUP code which allows

more than one RDS system to operate in the same location. This enables the system to

IMPORTANT

as and when required by simply adding a new

1

One transmitter is required for each piece of equipment to be monitored.

2

Transponders are used to extend the range of the system and may not always be required.

3

A computer is not essential to system operation unless data logging is required.

4

The computer must have the RDS system software installed.

5

Each unit can monitor a maximum of 255 units (unlimited if unique identification is not required).

be extended still further and also enables the system to be set so as not to interfere

with any existing installations.

Once installed the RDS system will maintain a constant watch over any equipment

Connected to the system so giving the user complete peace of mind and maximum

Response speed should any problems arise.

The RDS system itself can be wired to a fail safe alarm so that if the system itself

Fails then the user is made aware of the problem.

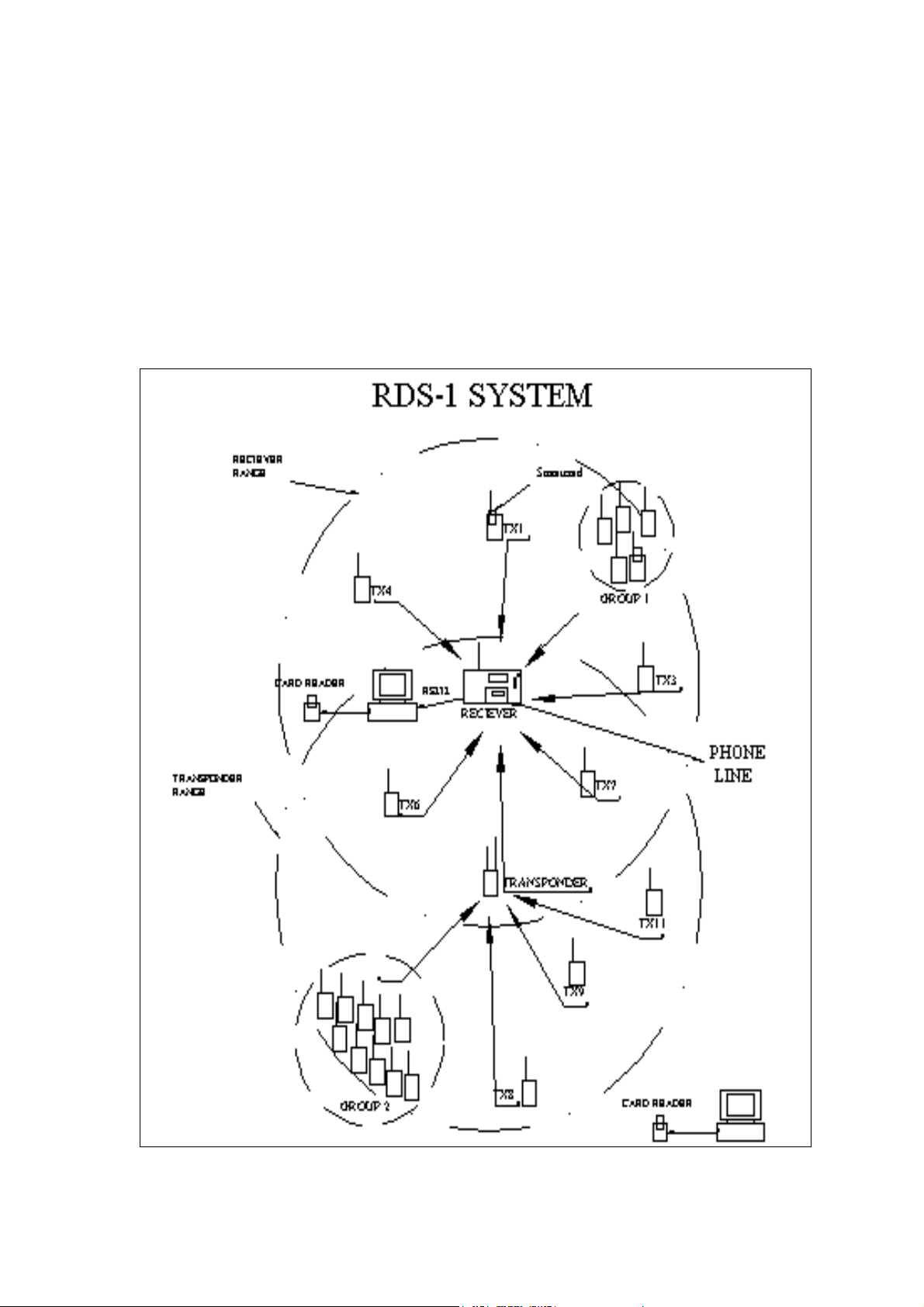

Figure 1 shows a typical RDS system set-up

Figure 1

The rest of this manual explains how to install and get the best from the RDS system.

Please read this manual carefully before attempting to install or modify an

RDS system. Maximum system performance and reliability can only be

obtained by proper installation and setting up of this system.

IMPORTANT

The RDS system comprises several separate components which must all be

Correctly installed in order for the system to operate properly.

The following sections explain how to install the equipment.

Later sections detail how to configure and program the system along with

Suggestions and guidelines as to how to get the most out of this equipment.

The steps involved for installing an RDS system are.

SITE SURVEY

RECEIVER INSTALLATION

TRANSPONDER INSTALLATION

COMPUTER INSTALLATION

PROGRAMMING THE RECEIVER

PROGRAMMING THE TRANSMITTERS

INSTALLING THE TRANSMITTERS

TESTING THE TRANSMITTERS

COMPUTER SOFTWARE INSTALLATION

SD1 PROGRAMMING

SYSTEM TESTING

1

2

3

4

SITE SURVEY

A site survey is desirable to determine the best location for the receiver and any

transponders that may be required. All installed transmitters will need to be able to

communicate with the receiver either directly or via one or more transponders.

Unfortunately it is not possible to specify an absolute range for a transmitter as this

will be largely influenced by environmental conditions such as power conduits,

heating ducts, other equipment etc. It is therefore necessary to first decide on a

location for the receiver and then to check any locations in which transmitters are to

1

A separate site survey form should be filled out for each receiver installed.

2

Transponders are only required to extend the range of the system or provide multiple signal paths.

See the section SITE SURVEY for details

3

A computer is not essential for system operation unless data logging is required.

4

This step only applies if a computer is added to the system.

be used to determine if a transponder is required in order to give reliable

communications.

Should it be found that a transponder is required then the best location for this should

Be determined in order that the maximum area be covered and to avoid installing

more transponders than are required.

If possible the site survey should be carried out by an installation engineer and the

person (or persons) who will be responsible for the day to day running of the system.

This will ensure that the system is set up exactly the way the customer requires.

Although the system can be set up using trial and error the best solution will be found

By using a ground plan of the site in which the system is to be installed and marking

on it any known sources of interference. See appendix A for a list of possible sources

Of interference.

Once this is complete the location for the receiver should be determined bearing in

mind the following requirements.

1 A source of electrical power will be required. See Appendix B

2 Choose a central location if possible.

3 The receiver must be accessible.

4 Try not to locate it too close to Sources of interference. See Appendix A

5 Locate as high as possible.

6 If automatic calling is required then access to an outside phone line is

required.

7 To use the fail safe alarm or local ‘switchboard’ alarm a hardwired local

alarm connection will be required.

8 If connection to a computer is used then provision for this must be

considered.

9 Avoid excessive Heat, Cold, Humidity and vibration.

10 The receiver does NOT need to be in a place where it can be constantly

monitored.

During this phase of the survey a GROUP code should be agreed upon.

A group code is a unique code range used by the transmission protocol so that

multiple receivers can be used in the same location. If this is the only Receiver in use

Then the code may be left at the default setting

1

otherwise it will need to be set to a

code that is NOT used by any other receiver on the same site2.

Make a note of the GROUP code agreed upon and enter it into site survey form.

Once the receiver location has been determined each location where a transmitter is to

be used Will require checking to ensure that reliable communications with the

receiver is Possible. Take into account any equipment on the site which may cause

interference intermittently when carrying out this testing.

During this testing include any areas where transmitters may be added in the future

otherwise any transponders that may be Required may not be Installed in the best

location. This could result in you having to relocate transponders when new

transmitters are added to the system or even installing more transponders than would

otherwise be necessary.

During this testing it may become evident that one or more transponders are required.

1

The default GROUP code is 00

2

Unless the other systems are well out of range including any transponders.

Loading...

Loading...