Solid fuel boiler

BM series

THERM LEV

Instruction and Operation Manual

Solid fuel boiler BM series

ΨThank you for your trust to Thermolev products.

ΨFor the effective use of this boiler it is necessary to read carefully the present

guidance manual, before the operation of the boiler.

ΨKeep the guidance manual in a safe place with the guarantee of the boiler, for

any possible use

01.Technical data Table [A] page 03

02.Boiler Control Panel Wiring Diagram page 04

03.Placement page 05

04.Protection page 05

05.Operation page 06

06.Security systems page 06

07.Necessary check page 07

08.Service and cleaning page 07

10.BM boiler- operation with oil page 07

09.Part replacement page 08

11.Locate and problem solve page 08

12.Audit card page 08

Contents

THERM LEV

Page 02

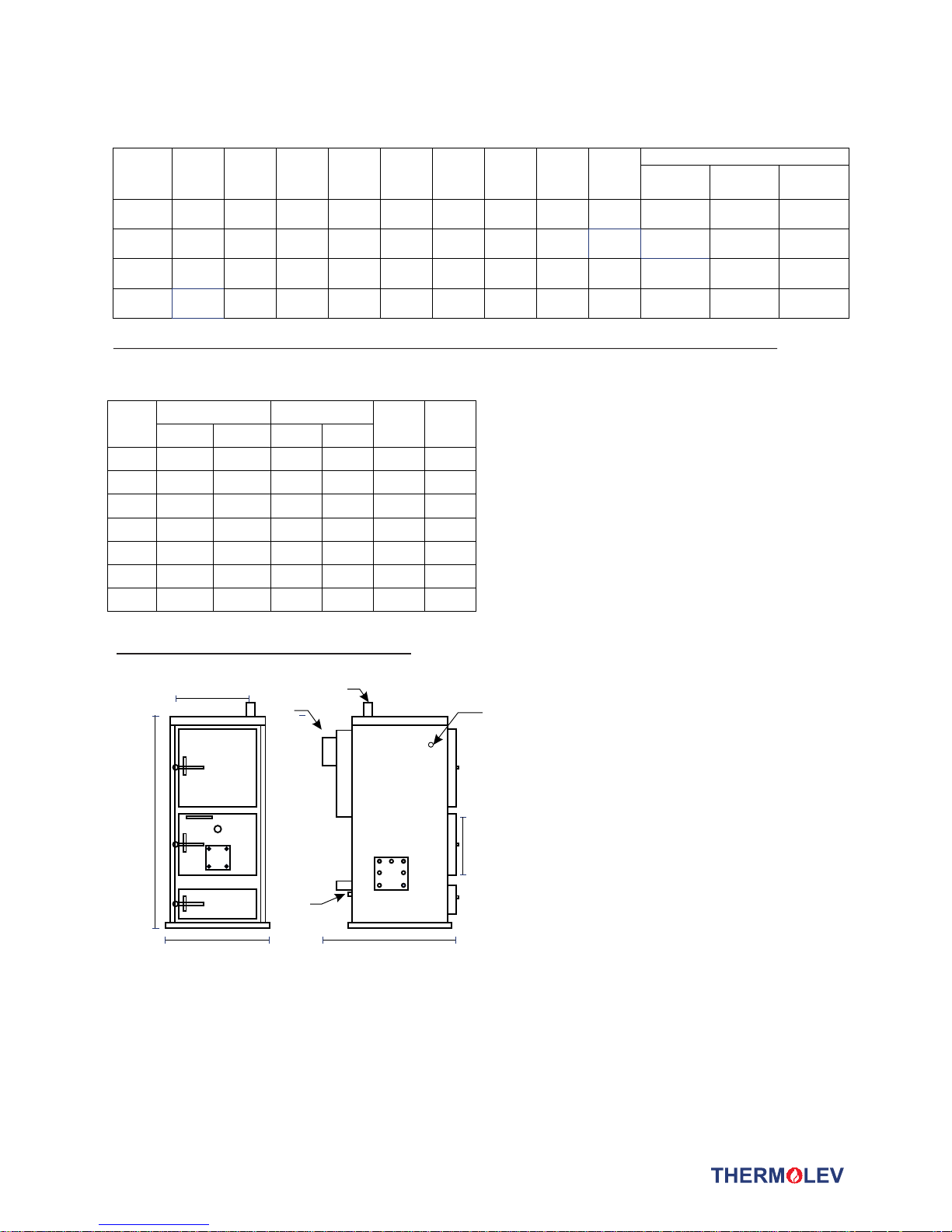

01.Technical data of BM series [A] - Table

Page 03

H

D2

C

D1

D3

Φ

G

B

A

Weight

[ kg ]

Output [ kw ]

Max

208,3

57,9

81,0

115,7

138,9

162,0

185,2

Min

185,2

46,3

69,4

92,6

115,7

138,9

162,0

Output [ kcal/h ]

Max

180000

50000

70000

100000

120000

140000

160000

Min

160000

40000

60000

80000

100000

120000

140000

ΒΜ 170

ΒΜ 45

Type

ΒΜ 65

ΒΜ 90

ΒΜ 110

ΒΜ 130

ΒΜ 150

ΒΜ 45

Type

ΒΜ 65

ΒΜ 90

ΒΜ 110

A

[ mm ]

B

[ mm ]

C

[ mm ]

G

[ mm ]

Η

[ mm ]

Πλάτος

[ mm ]

Βάθος

[ mm ]

Ύψος

[ mm ]

D2

[ in ]

D3

[ in ]

Φ

[ mm ]

Dimension

1220

605

985

455

455

655

655

320

320

425

425

1 1/4΄΄

2΄΄

455

430

1 1/2΄΄

600

455

500

660

600

660

700

2΄΄

555

555

430

1440

1440

855

1010

855

1110

1220

605

885

3/4΄΄

198

1/2΄΄

3/4΄΄

1/2΄΄

3/4΄΄

1/2΄΄

3/4΄΄

1/2΄΄

218

218

198

Solid fuel boiler over than 110,000 kcal/h are manufactured under request

D1

[ in ]

Max.operation

pressure

[ bar ]

3

3

3

3

3

3

3

615

270

320

380

450

510

555

Diagramm of BM solid fuel boiler

Hydraulic connection

D1A: boilers water exit (ζεστό)

D1B: return water facility (κρύο)

Φ: chimney connection

D2A: Thermostatic safety valve connection

D2B: metal thermostat connection

D3: Automatic filling and cleaning valve connection

Connection flange

Ventilator

Pellet

Cleaning chimney wicket

Cleaning wicket

Wicket fuel catering

Wicket for removing the ashes

06

N

G

07 L0504030201

P

1 2

1

2

P

1 2

1

2

3

N

L

I / O

Room Thermostat

N

L

N

L

N

LT1

02 .Boiler ‘s control panel - Wiring diagram of BM boiler

TO BE WIRED BY THE INSTALLER

WHITE

RED

BLACK

BLUE

BROWN

YELLOW -GREEN

GREEN

BLACK

Ventilator

Circulator

Page 04

03. Placement

Select the installation place.

ΨSelect the right place for the placement of the boiler, where the water and

the electricity supply are available.

ΨThe existence of correct ventilation apertures is necessary in the boiler's

room.

ΨThe room must be spacious to make easy the installation and the annual

services.

ΨNo inflammable and any other kind of things must be stored in the boilers

room.

Steel solid fuel boiler BM series can operate:

Ψeither with close circuit: it is necessary to have expansion vessel. Also must

be placed safety valve for the heating system ½’and thermostatic safety valve

T90 3/4’’

Ψor with open circuit: it is necesssry to have open circuit vessel or tank

04. Protection

ΨBefore the use

1.It is prohibit the use of any other fuel except wood and oil

2.There should be no leaking fumes from the boiler’s doors.

3.There should be no leaking fumes from the chimney.

ΨCheckpoints before the operation

1.Check if there is any leak at the pipe connections

2.Check the water amount in the heating installation.

Ψ8a check the amount of water in the expansion tank, for open circuit

installation

Ψ8b check the water pressure (adjust the settle up valve), for close circuit

installation

3.Turn on the circulator and take the air out from all the radiators.

Page 05

General description

Steel solid fuel boiler BM of Thermolev is manufactured with high quality steel

type ST 37-2. BM boilers have four way fumes and the movement of the fumes

is through rhomboid diaphragms for the best efficiency of the boiler.

The innovative design of the boiler with accesible large openings for the

movement of the fumes has as a result of the boiler’s rare cleaning.

05.Operation

Steel solid fuel boiler BM series can operate with two ways:

1.either with ventilator and control panel in order to achieve controlled burning

and low fuel cost.

Security measures of BM boiler: in case of blackout ventilator stops working and

lowers the flame.

2. Or with metal thermostat with chain for the movement of the wicket and

analogic thermometer.

Checkpoints before the operation of the boiler:

1. Check the existence of water in the heating circuit by opening the clearing

valve.

2. Be sure that the pipes are full of water.

3. Be sure that the burner is earthed.

4. Settle the boiler thermostat in the desired temperature.

5. In case that boiler series BM works with oil, fill the tank with oil before it will

be completely empty. Otherwise air will exist in the circuit and there is a

possibility of flaming weakness.

Ψ Water low level

If the level of the water or the pressure of the water faults down of the permissible

level then:

όBoiler must stop working.

όCheck for any leaks in the circuit.

όWhen the quantity of the water comes again to normal levels then the boiler can

start working.

ΨOverheating

When the boiler's temperature overrun the maximum thermostat temperature,

then the burner stop working for safety reasons.

If this happen again, call authorized technician.

ΨDanger in case of oil leak

06. Security systems

Page 06

ΨRemarks during the operation

1.Keep the boiler's room tidy and never store flammable materials!!

2.Check of the flame in short periods

3.If the boiler is going to be for long time stopped, it is good to disconnect the

power Supply.

08. Service and cleaning

Maintenance of the boiler is easy fast.At the bottom of the boiler there is a

special drawer for the export of the ash. The amount of ash generated by the

use of the boiler and the type of wood used. It’s type of wood leaves different

residue during the combustion for this reason there is an exclusion in the

calculation of the ash.

Steel solid fuel BM needs cleaning about once in 25 days :

Page 07

1.First check for any fume leak that may exist in the installation of the boiler. This is

very important so it is good to be really careful.

2.Check boiler's door to be very well closed in case of fume leak.

3.Clean very well the oil that can be found outside the oil tank

4.Be sure that you close really well the top of the oil tank before the operation of the

boiler.

5.Check if the spark and the combustion are right (from the flame checkpoint) only

for oil use.

6. Check regularly for oil leaks in the oil tank or in the pipes

6.1Often clearing out the water from the oil tank, this helps for the right

operation of the boiler (avoiding unpleasant complications)

Cleaning of the oil filter

6.2In case, the oil filter needs to get clear, you should close the oil supply from

the provider valve.

6.3Clean very good the oil filter and the inside part where the filter lay with light

oil or oil.

Cleaning the oil tank

6.4 It is possible to gather some quantity of water in the oil tank or in the oil

supply pipe, especially after a long time without clearing them. In this situation

open the clear up valve of the tank and let the water to run out of it until oil

start to run out.

Ψ Regular check

1.Take away the flammable materials from the boiler's room.

2.Keep the boiler and the parts around it, clean.

3.Often check for gas or oil leaking.

4.Check the connections of the chimney pipe and look if they are fixed correct

and if there is any fume's leaking.

5.Check if there is any water leaking in the boiler or in the pipes.

07. Necessary check

Steel boiler series BM oil-gas

09. BM boiler operates with oil-oil use

Page 08

a)For solid fuel boilerBM series

If you notice a problem call an authorised technician.

B)For BM boiler operation with oil

If you notice a problem call an authorised technician.

12. Audit card

B)For boiler series solid fuel boiler BM

Technician

Repair and

Replacement parts

Date

10. Part replacement

1.There isn't any part of the boiler which can broken down in a small term time,

but if it is necessary the replacement of any boiler's part, call our commercial

Representative.

2.For any intervene to the boiler, please call only authorized technician.

3.Intervene to the boiler from someone who isn't authorized technician may

cause to you more problems.

ΨCheck fume's exit

5.It is necessary to check the chimney pipe one time per year. If you find

something faults, call authorized technician.

11.Locate and problem solve

Contact details:

Thessaloniki: 11KmThessalonikis- Neohoroudas , 57008 Ionia ,

Tel:+30 2310 780 761-2, fax: +30 2310 780 814,

E-mail: thermolev@thermolev.com, site:www.thermolev.com

Loading...

Loading...