Page 1

THERMOLEC

Installation

Instructions

for

Electric

Boilers

(CANADA)

December 2011

VERSION 11

Page 2

Page 3

Installation Guidelines for Thermolec Electric Boilers Model B

1 Important

1.1 These instructions should be used as a general guide only. Electrical Code and local utility requirements must

be followed and take precedence over these instructions.

1.2 Thermolec electric boilers are manufactured with quality components for maximum life, durability and

minimum service. To ensure a satisfactory installation it is imperative that you read these instructions

carefully before installing and operating the heating system.

Failure to do so may result in breach of warranty.

2 Unpacking

2.1 Inspect the unit and check whether there are missing parts.

2.2 Report any damage or claims to the carrier immediately.

2.3 For all returns to be accepted they must be authorized by the manufacturer.

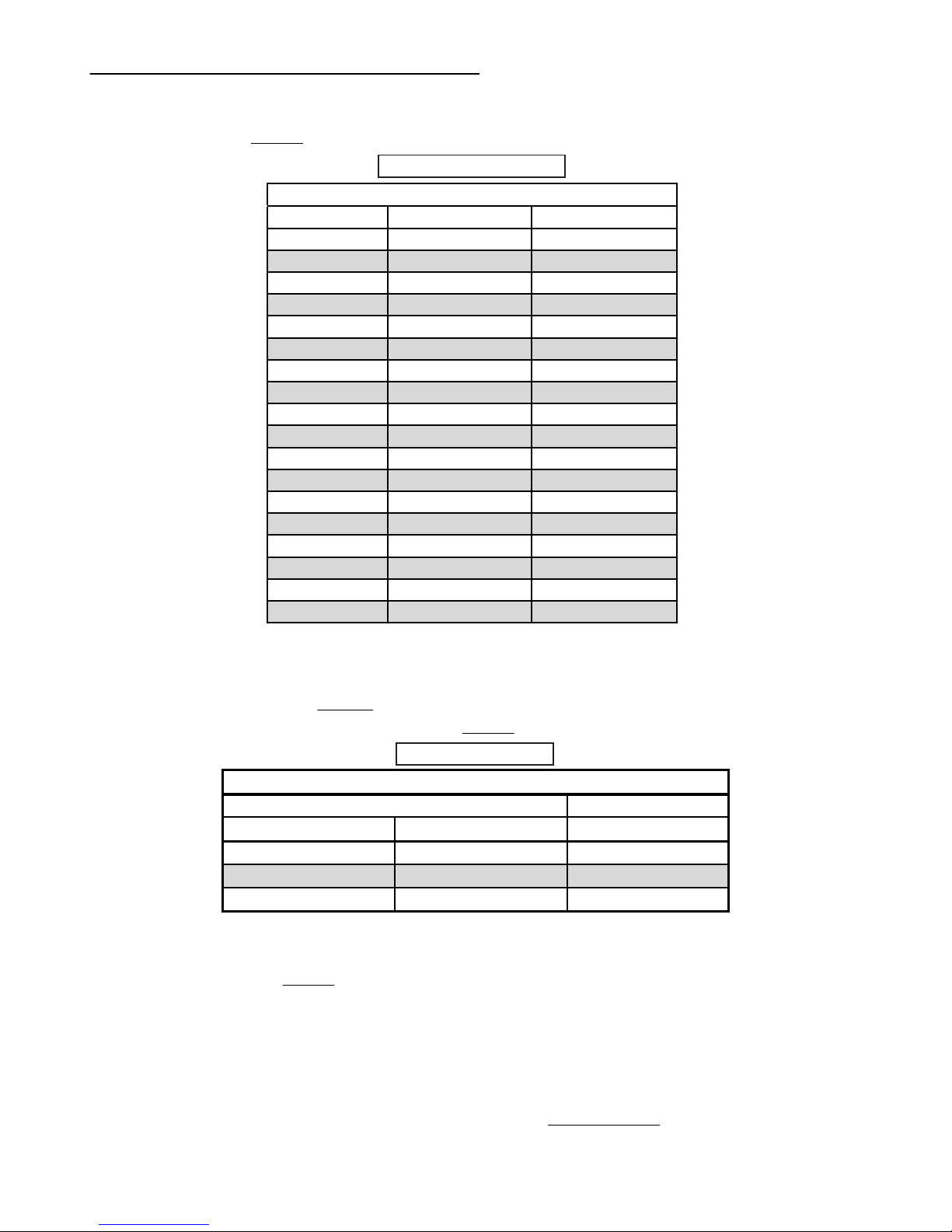

3 Location and dimensions

3.1 These boilers are designed for wall mounting. Please see Table 1 below for overall dimensions.

Table 1 also gives the minimum clearances to combustible material as well as recommended distances for

ease of service (e.g. replacement of tubular elements).

Table 1

Dimensions and Clearances

Overall dimensions Clearances

Models Width Height Depth Front Back Top Right Others

Short Models

up to 23 kW 1ph

18" 18" 9-1/2"

36" 0" 12" 6"

up to 18 kW 3ph

Long Models

18" 28" 9-1/2"

36" 0" 24" 6" 12"

up to 40 kW

TMB

3.2 The boiler room should be well ventilated as to maintain the temperature below 25°C (77°F).

3.3 The unit must be mounted level on a vertical wall with the outlet tting on the left side of the unit.

13" 18" 9"

36" 0" 12" 6"

12"

12"

Page 1

Page 4

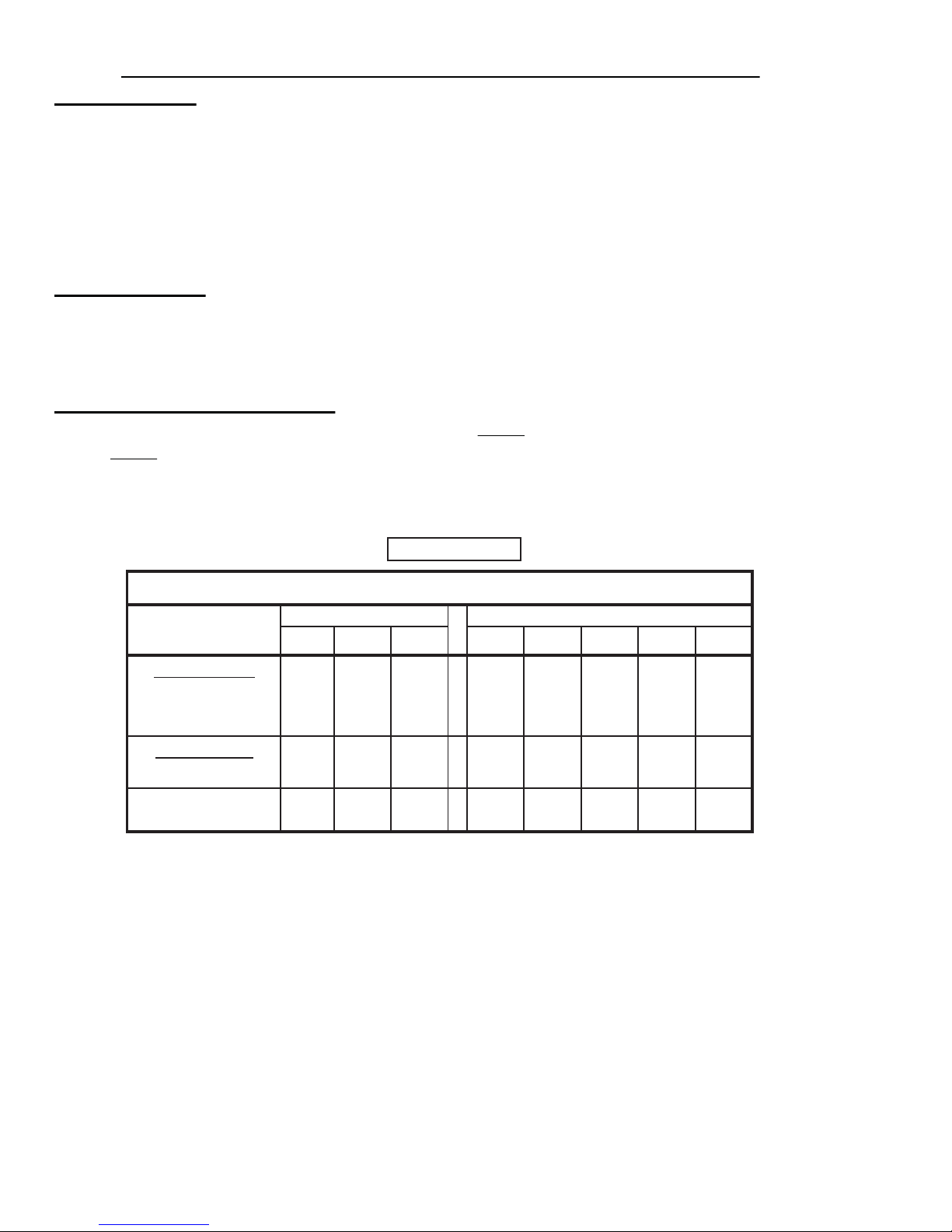

4 Components

Mono or Dual energy

controller

Adjustable

electronic

aquastat

(output

temperature)

Electronic

temperature

sensor

Mounting holes

Outlet 1-1/4’’ NPT

Temperature /

pressure

gauge

Incoloy elements Manual reset

thermal cut-out

Solid state relays

Thermostat terminals Fig. 2

Magnetic back-up contactor

Boiler control

transformer

18”

Circuit breaker (optional)

supplied when required

by N.E.C.

Pump relay

Inlet 1-1/4’’ NPT

Fig. 1

Outdoor reset sensor

Fig. 3

18”

Pump relay terminals

(dry contacts 10A)

Fuse and

fuse holder

Ground lug

Note : The model shown here is a typical Dual-Energy boiler 23kW / 240 Volts / 1phase.

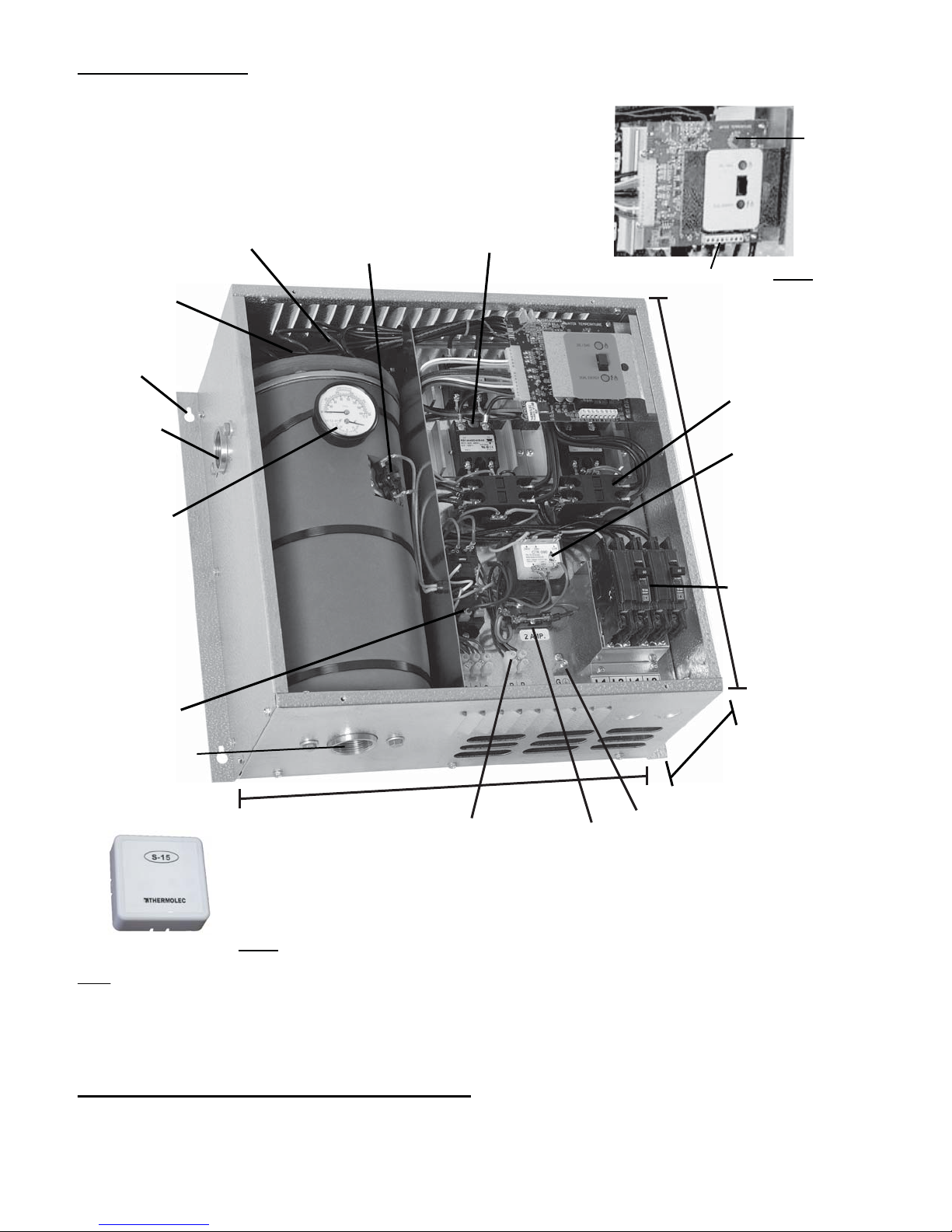

5 Standard specifications for all models

Table 2 on the following page give specifications and current for the standard models.

9 1/2”

Page 2

Page 5

@

Table 2

(Canada)

(Canada)

Mono Models B-3TMB B-6TMB B-9TMB B-11TMB

kW 36911

BTU/H 10,236 20,472 30,708 37,532

Total Amps 12.5 25.0 37.5 45.8

Breaker size 1 x 20A 1 x 40A 1 x 50A 1 x 60A

TMB MONO Model Specifications @ 240V / 1ph (Canada)

Standard Model Specifications @ 240V / 1ph

Dual-Energy Models B-5 B-6 B-8 B-9 B-10 B-12 B-15

kW

BTU / H

Total Amps 20.83 25.00 33.33 37.50 41.67 47.92 62.50

No. Of Power Supplies 1 x 30A 1 x 30A 1 x 50A 1 x 50A 1 x 60A 1 x 60A 1 x 80A

(Amps Per Breaker)

Dual-Energy Models B-18 B-20 B-23 B-27 B-30 B-35 B-40

kW

BTU / H

Total Amps 75.00 83.37 95.83 112.50 125.00 145.83 166.67

No. Of Power Supplies 1 x 100A 1 x 125A 1 x 125A 2 x 80A 2 x 80A 2 x 100A 2 x 125A

(Amps Per Breaker)

56891011.515

17,060 20,472 27,296 30,708 34,120 39,238 51,180

18 20 23 27 30 35 40

61,416 68,240 78,476 92,124 102,360 119,420 136,480

Standard Model Specifications @ 3ph

Dual-Energy Models B-18 B-24 B-30 B-35 B-36 B-42

kW

BTU / H

Amps

208V / 3ph 48.00 66.69 83.37 96.00

Disconnect Switch 60A 100A 100A 100A

Amps @ 600V / 3ph 17.34 23.12 28.90 34.68 40.46

18 24 30 35 36 42

61,416 81,888 102,360 119,420 122,832 143,304

n/a

n/a

Disconnect Switch 30A 30A 30A 60A 60A

NOTE: Other models, voltages and capacities available upon request. Please contact the factory.

Please use Table 3 below to select the wire size for the power supply. (It is not mandatory to use copper wire).

Table 3

Cable Amps Capacity vs Wire Size (Copper)

Wire Size 12 10 864321000000

Amps @ 75°C (167°F)

Amps @ 90°C (194°F)

Notes :

1- This table should be used as a guide only. Always select the wire size according to the local

Electrical Code.

2- Always use wire suitable for 75°C (167°F) minimum, 300V or 600V as required.

20 30 45 65 85 100 115 130 150 175 200

20 30 45 65 85 105 120 140 155 185 210

3- All models with suffix "U" over 12 kW at 240V / 1ph require two feeders. Divide the total

Amps by 2 to select the proper wire size.

Page 3

Page 6

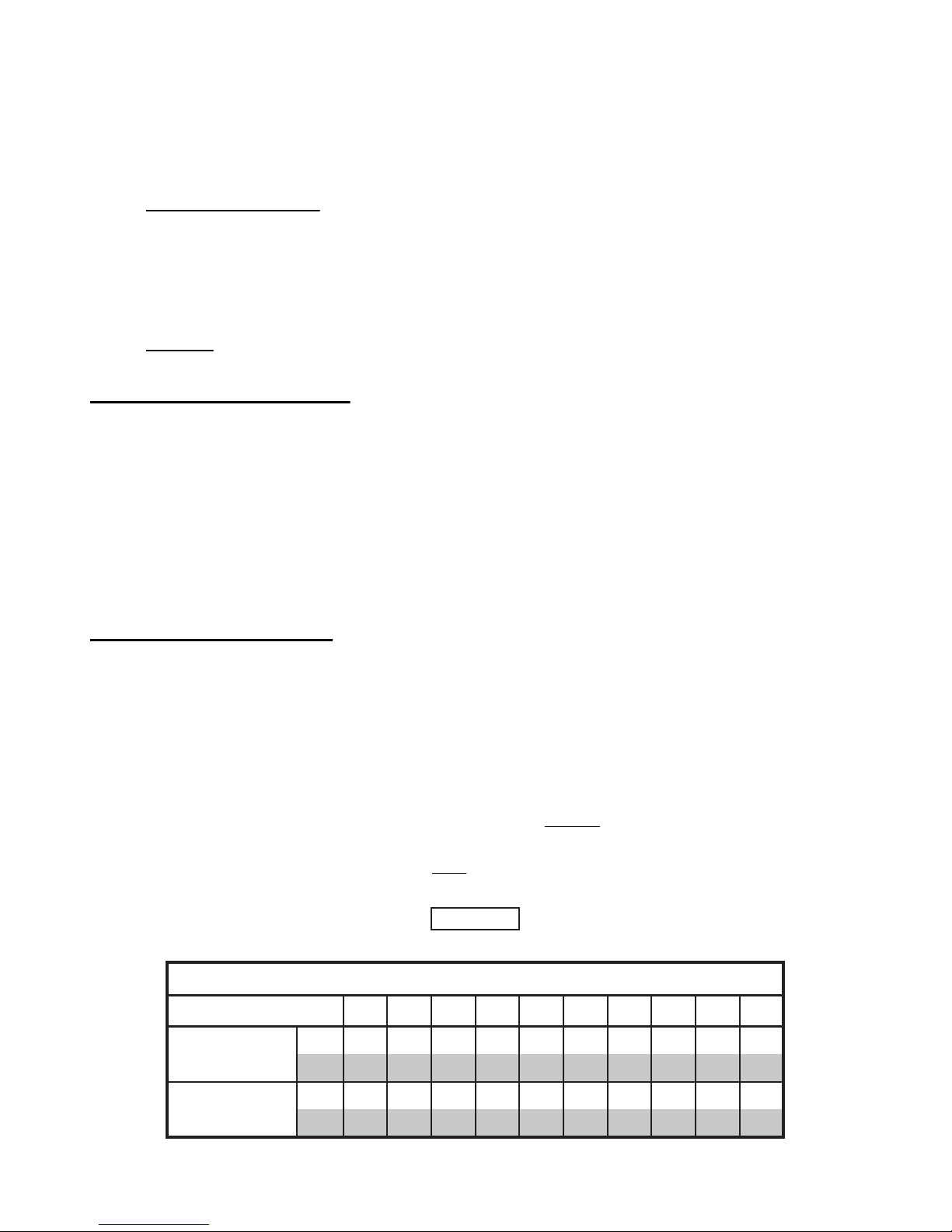

6 Water circulation and plumbing notes

Pipe Diameter

Imp. Gallons / min US Gallons / min (Type L Copper)

3.6 4.3 3/4"

8.4 10.1 1"

14.4 17.3 1-1/4"

Maximum Flow Rate

Maximum Flow Rate @ 15 psi

Capacity (kW) Imp. Gallons / min US Gallons / min

30.9 1.1

51.5 2.0

61.7 2.0

82.3 2.8

92.6 3.1

10 2.9 3.5

11 3.2 3.9

12 3.5 4.2

15 4.4 5.3

18 5.2 6.2

20 5.8 7.0

23 6.7 8.0

25 7.3 8.8

30 8.7 10.4

35 10.2 12.2

36 10.4 12.5

40 11.6 13.9

42 12.2 14.6

Recommended Water Flow Rate vs Capacity

6.1 The system is designed to operate with a maximum output temperature of 180°F or

lower and a temperature rise across the unit of 20°F or lower.

Please refer to Table 4 for the recommended flow rate versus the capacity of the boiler.

Table 4

6.2 In order to ensure an adequate flow rate :

6.21 Pressure loss (referred as "Head") caused by water friction in the system should not exceed the

capacity of the pump.

6.22 Please refer to Table 5 below to find the copper pipe diameter (type L) recommended to

accommodate the water flow found in Table 4 above.

6.23 Elbows and valves will greatly add to the head loss in the system. An appropriate water flow rate

must be maintained to avoid tripping of the temperature limiter. Pipes with diameters larger than

specified in Table 5 will not help to increase water flow.

6.3 The installation must have a drain valve, an expansion tank, maintenance valves and an automatic

pressure reducing fill valve set at 15 PSI (104 kPA). A "T" fitting (1-1/4" NPT) must be installed at the

supply outlet of the unit. This "T" must be equipped with a reducing bushing 1-1/4" to 3/4" NPT, facing

upwards, to accept a 3/4" NPT pressure relief valve. This safety valve must be installed vertically. Except

for the pressure relief valve, the above plumbing supplies are not supplied with the unit. Please refer to

illustrations A, B and C at the end of this manual.

Table 5

Page 4

Page 7

6.4 The automatic pressure relief valve supplied with the boiler is required to prevent dangerous pressure

build-ups in the system in case of system malfunction and may under certain conditions vent hot water.

Do not install the system where water could damage rugs, furniture, etc. When piping the relief valve to a

drain, check with local authority for recommended method of installation. Do not open or tamper with the

relief valve. If operated frequently or used to drain or flush the system, the valve could fail to seat properly

and thus leak.

Important safety notice : This safety valve is mandatory and must be installed as shown in the

illustrations A, B and C at the end of this manual. The omission of the safety valve installation will

create a very serious safety hazard and will void all warranties.

6.5 Automatic air vents should be installed at the highest point of the installation, ideally on all radiator units

for best results or at points where air could possibly be trapped in the system.

Caution : Make sure the system has been reasonably vented before starting the unit.

7 Mechanical installation

7.1 Mounting brackets are located on the sides of the boiler. Depending on the size of the unit, four or six

holes are provided. The unit may be attached directly to a combustible surface.

7.2 Use a circulator pump of appropriate capacity for the intended application. The pump should be placed as

close as possible to the boiler. Ensure that the water direction is correct. An arrow indicating the

circulation direction is generally visible on the pump casing.

7.3 Install inlet and outlet piping.

7.4 Install air vents, valves, the pressure relief valve supplied with the unit, expansion tank, etc.

7.5 When everything is finished, install the temperature / pressure gauge.

8 Electrical installation

8.1 Disconnect all power sources before opening the main panel and working within.

8.2 Read the nameplate and other markings carefully and wire strictly in accordance with the wiring diagram.

8.3 Wires and protective equipment must be sized according to the applicable Electrical Code.

8.4 Use only wires suitable for minimum 75°C (167°F).

8.5 Install the outdoor sensor on an exterior North wall and connect it with 18/2 wire to terminals

"OT / OT" on the electronic board (TH-600 series controller).

8.6 On the electronic aquastat (marked "WATER TEMPERATURE"), select the maximum water temperature

required (1-10) by the type of installation. Please see Table 6 below for the temperature obtained

according to the knob position. The minimum water temperature is reset automatically by the outdoor

sensor. Please see the variation graph in Fig 5.

Table 6

Water Temperature controlled by Electronic Aquastat

Set-point

Maximum

temperature

10987654321

°C

88 81 75 67 58 50 45 42 39 36

°F

190 178 167 153 137 122 113 107 102 97

Minimum

temperature

°C

°F

48 48 48 45 40 38 34 31 29 28

118 118 118 113 104 100 93 88 84 82

Page 5

Page 8

Electronic Aquastat

MAXIMUM

WATER TEMPERATURE

MINIMUM

WATER TEMPERATURE

°C°F-10

+14-5+230+32+5+41

+10

+50

Fig. 4 Fig. 5

8.7 The outdoor sensor will :

a) Maintain the selected maximum water temperature when the outdoor temperature is at -10°C

(+14° F) or colder.

b) Automatically and proportionally compensate by varying the water temperature between the

maximum and minimum when the outdoor temperature is between –10°C (+14°F) and +10°C

(+50°F).

c) Maintain the minimum water temperature when the outdoor temperature is between +10°C (+50°F)

and +20°C (+68°F).

d) Prevent boiler operation above +20°C (+68°F).

NOTE : If you choose not to use the outdoor sensor, don't connect it to the "OT / OT" terminals nor jumper

these terminals. You will not use this feature and the water will simply be maintained at the maximum

selected temperature.

8.8 Connect the thermostat or the zone valve end switch wires to "C" and "W1" terminals on the electronic

board.

8.9 Circulating Pump Control. The "P / P" terminals are connected to dry contacts of a relay (capacity up

to 1 HP) and are used to start the pump. This relay is switched ON with the first heating step and OFF

after the last one. A separate 120V / 1Ø service must be provided from the electrical panel to the boiler

for the pump. For Mono-Energy Boilers, refer to the wiring diagram. See the diagram for dual-energy as

the pump must also run when another source of heat is selected.

Follow the extra steps dedicated to a dual-energy installation in the start-up sequence.

8.10 Set the room thermostat heat anticipator (when available) to 0.2 Amperes.

8.11 If the system is used with Load Management control, connect the Utility signal to "S1 / S2" terminals.

A closed contact enables the boiler, an open contact disables the boiler.

8.12 The installation is now ready for start-up procedure and testing.

9 Start-up procedure and test sequence

Double check the following carefully :

9.1 All wiring and plumbing is complete.

9.2 Pipes have been cleaned, the system has been flushed and filled again.

9.3 Without powering the entire unit, install a jumper between the "P / P" terminals and switch the pump

breaker ON as to let the pump run alone. Verify that the pump is running freely and check for leaks. During

this test, a lot of bubbles will travel through the system and air will be eliminated by the automatic vents.

You can accelerate the process by purging the radiators manually. Shut off the pump breaker at the panel,

then remove the jumper between the "P / P" terminals.

9.4 The pressure in the system has been stabilized at approximately 15 PSI (104 kPA).

9.5 The entire system is now almost free of air.

9.6 The room thermostat anticipator (when available) has been set at 0.2 Amperes.

9.7 Switch the boiler breaker ON at the main panel.

Page 6

Page 9

9.8 Set the thermostat above the room temperature. The system should start.

9.9 Make sure the pump starts running as soon as the system starts.

9.10 Heating stages will be switched ON in sequence at 30 second intervals, confirmed by green lights on the

left hand side of the PC board on the TH600 or by red lights on the right hand side on the D22-B.

9.11 Wait for two minutes and measure the current drawn by the boiler and compare it with the one shown on

the nameplate.

9.12 When the required maximum water temperature selected on the aquastat (0-10) or controlled by the

outdoor sensor is reached, the electronic controller will modulate the boiler capacity to maintain the water

temperature, as long as the demand for heating is not satisfied. The bottom green light flashes

continuously on the TH600 or one of the red lights on the D22-B to indicate that the boiler is maintaining

the setpoint. When the room thermostat is satisfied, the heating stages will come OFF in sequence at 5

second intervals.

9.13 Set the room thermostat to the desired set point.

9.14 The boiler is now ready and functional.

Extra test steps for "Dual-Energy" installation.

9.15 Disconnect the room thermostat wires from the existing boiler and connect them to "C" and "W1" terminals

on the electronic board of the electric boiler.

9.16 Connect two (2) wires from "B / B" control terminals of the electronic board to the thermostat terminals of

the existing boiler.

9.17 Terminals "S1 / S2" on the electronic board should receive the utility Dual-Energy Signal wires.

9.18 Connect the pump terminals "P / P" in parallel to the existing thermostatic pump control as to allow the

operation of the pump in any of the "Dual-Energy" modes selected.

10 Test sequence for "Dual-Energy" systems

10.1 A "Dual-Energy" boiler is supplied with a three-position mode selector switch. Because of differences in

regional regulations, the electronic board has been factory set so as to allow the activation of the electric

mode depending on the unit destination. In the "Mazout / Oil" position the thermostat will call upon the

gas or oil boiler or furnace to maintain the house temperature at the desired level. The "Dual-Energy"

mode gives automatic control to the outdoor sensor or alternate switching signals from the local utility for

"Dual-Energy" control. When the "Dual-Energy" contacts are closed, the "Electric" mode is selected.

When these contacts are open, the "Mazout / Oil" mode is selected. If the "Electric" mode is manually

selected the controller allows only the electric mode operation. A green pilot light indicates the mode that

has been selected.

10.2 The positions of the manual selector are :

MAZOUT / OIL

BI-ÉNERGIE /

DUAL ENERGY

ÉLECTRIQUE /

ELECTRIC

Heating by means of original furnace (electric or mazout/oil).

Dual-Energy mode

(signal given by the

utility company)

Electric mode only

Fig. 6

Models with manually

selected Electric mode

available

Page 7

Page 10

10.3 Simulate a heating demand by setting the thermostat higher than the room temperature.

10.4 Switch the mode selector to position and check that the burner responds to the thermostat demand.

10.5 Switch the mode selector to the "Dual-Energy" position . Install a jumper between terminals "S1 / S2";

the electric mode is automatically selected. The pump will start and the heating stages will be switched

ON in sequence at 5 second intervals. Measure the current drawn by the boiler and compare it with the

one shown on the nameplate. If you remove the jumper from terminals "S1 / S2", the system should switch

back to the "Mazout / Oil" mode. Switch the mode selector to the "Electric" position . The controller

allows only electric heating even if the contact "S1 / S2" is open.

10.6 Switch the mode selector to the desired position and set the room thermostat to the desired temperature.

10.7 Your boiler is now ready and functional.

11 Installation examples

11.1 Installation A shows a Thermolec electric boiler in a Full-Electric Configuration.

11.2 Installation B shows a Thermolec electric boiler in a Dual-Energy-Series Configuration.

Water is always passing through both boilers even if only one heat source is selected at a time.

11.3 Installation C shows a Thermolec electric boiler in a Dual-Energy-Parallel Configuration.

Water is forced only through the selected heat source by means of a motorized valve.

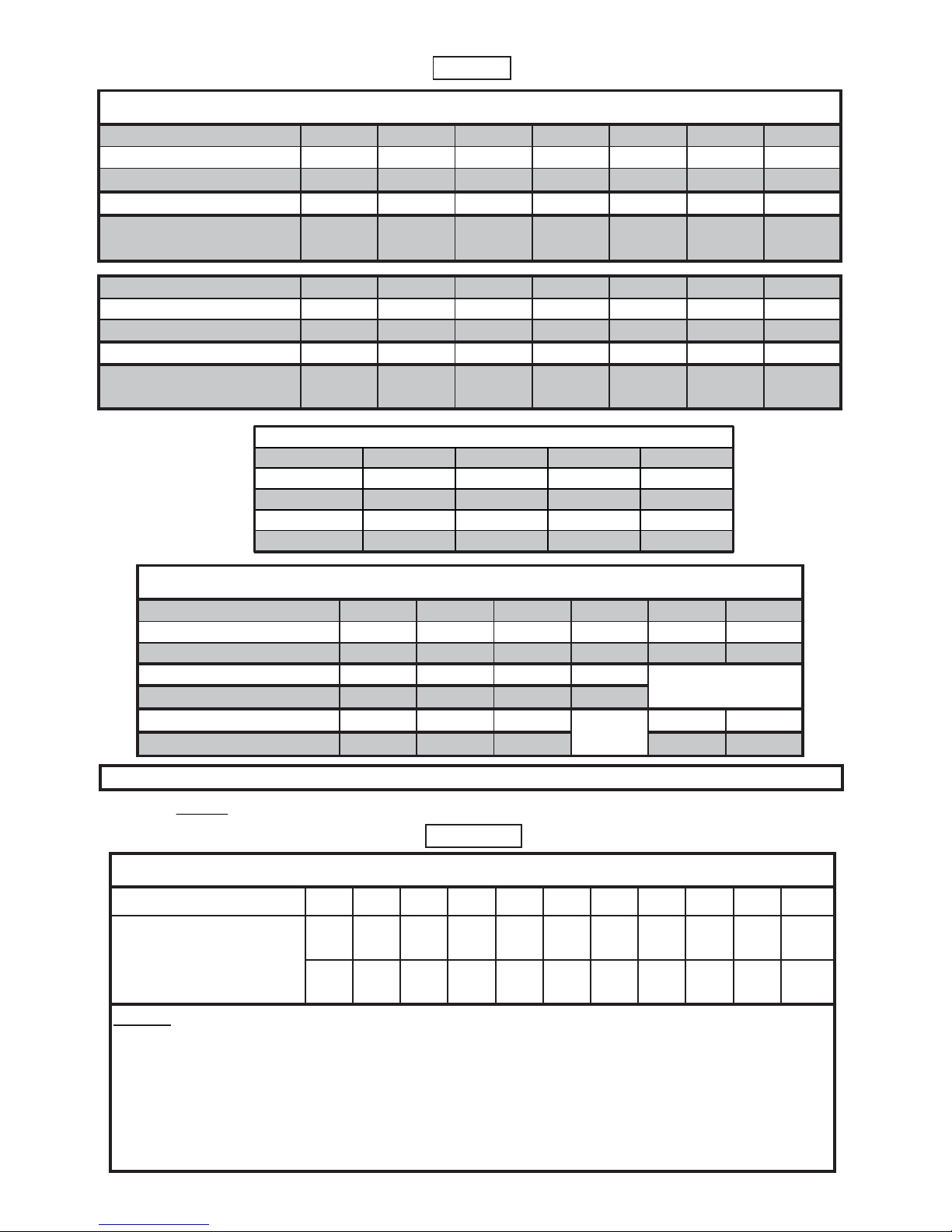

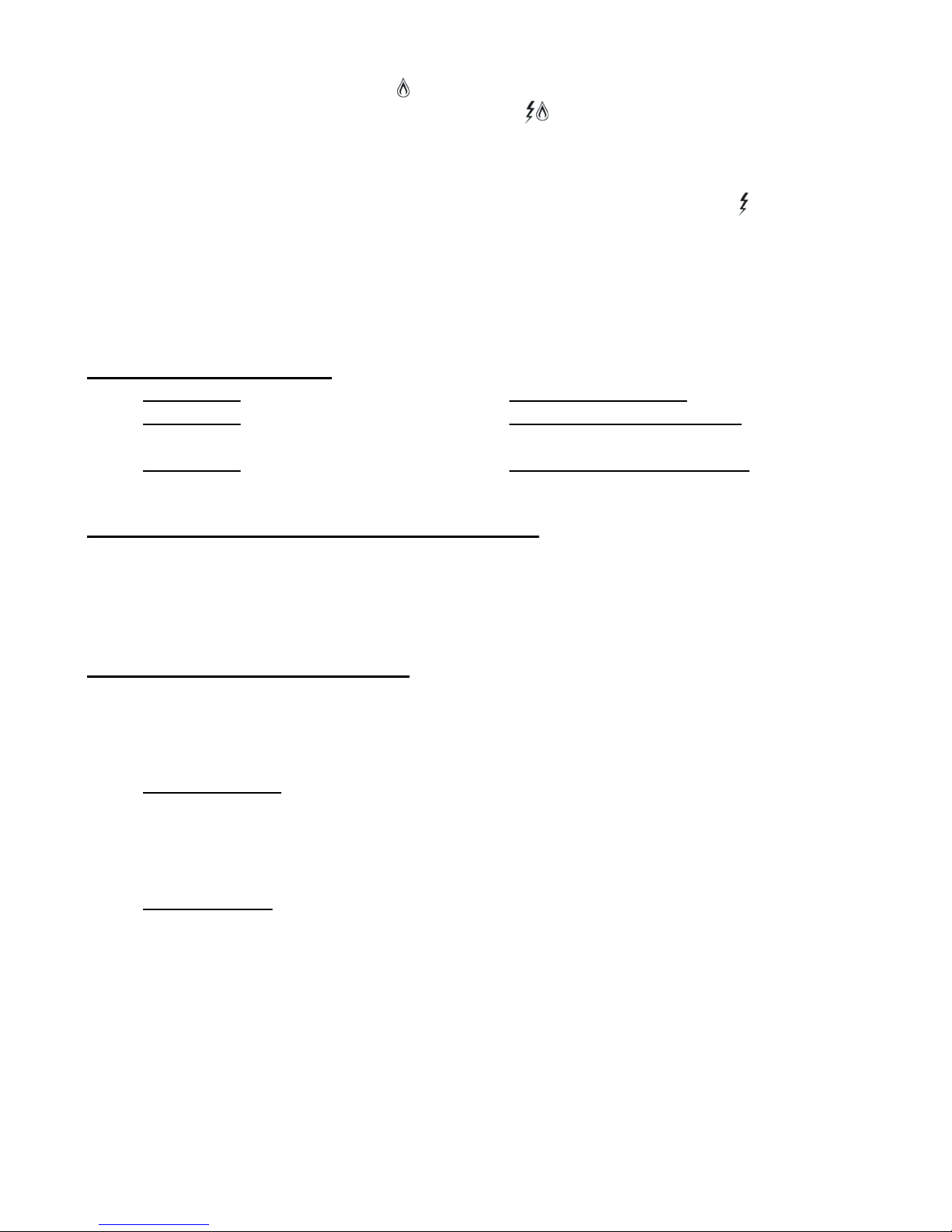

12 Position and electric values of heating elements

Standard values of heating elements at 240 Volts are 3kW, 5kW, 5.75kW, 8.75kW et 10 kW. Please refer

to the following sketches and tables to find the position and test value in ohms of each element. Please

ensure you disconnect the element completely before you make the resistance reading.

13 Replacement of heating elements

Heating elements nuts and cover bolts have been factory torqued with a calibrated tool. Please make

sure you have a torque driver and the proper sockets handy before you open the boiler tank.

Elements nuts should be torqued at :

14.6 Newton-meter (Nm) or equivalent

Please ensure you use the double wrench method (i.e. an open key inside of the tank to hold the

element hexagon flange firmly and the torque wrench outside). Don't let the element turn while tightening.

Cover hex bolts should be torqued at :

7.8 Newton-meter (Nm) or equivalent

Please make sure to tighten all nuts by hand first, then tighten them as per fig. 8 and finally apply the

proper torque with the torque wrench. Resist the feeling that the bolts could get torqued more (even if

possible) because that action would simply squash the silicone gasket to the point where it would

eventually lose all its resiliency and sealing properties.

Keep in mind that an equal torque is far more important.

Page 8

Page 11

L

C

L

C

3

5

Torque Element

Nuts at

Torque Cover

Bolts at

70 inch-lbs

14 Warranty

1

Cylinder

Output

8

6

Manometer

130 inch-lbs

7

2

4

Fig. 8

Thermolec Ltd. warrants against defects in materials and workmanship the heat generator casing of its boiler and

the heating elements for ten ( 10 ) years and all other components for two ( 2 ) years after date of shipment from

its factory.

Any claim under this warranty shall be considered only if the product has been installed and operated in

accordance with Thermolec’s written instructions.

Any misuse of the system or any repair by persons other than those authorized by Thermolec, carried out without

its written consent, voids this warranty.

Thermolec’s responsibility shall be limited in any case to the replacement or repair, in its factory or in the field, by

its own personnel or by others choosen by Thermolec, at its option, of such boiler or parts thereof, as shall prove

to be defective within the warranty period.

Thermolec Ltd. will not be held responsible for accidental or consequential damages, nor for delays, nor for

damages caused by the replacement of the said defective boiler.

Page 9

Page 12

Page 13

Electric Boiler Warranty Registration Form

_

_

_

Name : _______________________________________________________________________________

Address : _____________________________________________________________________________

City : ________________________________________ Province / State : _______________

Postal / Zip Code : _________ Telephone : ___________________

Model No : ___________________ Serial No : _____________________

Installer Name : _________________________________________ Telephone : ________________

Date Installed : _____________________

Comments / Suggestions :

____________________________________________________________________________________

____________________________________________________________________________________

____________________________________________________________________________________

Please send this registration form to

Thermolec Ltd.

Warranty Registration

2060 Lucien-Thimens St.

Ville St-Laurent, Montreal

Quebec, Canada

H4R 1L1

Or fax it to (514) 336-3270

Page 14

Page 15

W

4

L

C

1

3000 19.2 CBLR065

5000 11.5 CBLR055

Four Element Configuration

C

Three Element Configuration

3

L

C

Cylinder

Output

3

L

2

L

C

Cylinder

Output

2

Front of cylinder

1

Front of cylinder

Elements Position, Electric Data and Part #

Position 1 Position 2 Position 3 Position 4

Volts / Total

3000 19.2 CBLR065

Watts Ohms Part # Watts Ohms Part # Watts Ohms Part # Watts Ohms Part #

3.00

Height Phases K

5750 10.0 CBLR060

5000 11.5 CBLR055

5.00

5000 11.5 CBLR055 3000 19.2 CBLR065

6.00

8.00

5000 11.5 CBLR055 5000 11.5 CBLR055

9.00 5750 10.0 CBLR060 3000 19.2 CBLR065

10.00

12.00 5750 10.0 CBLR060 5750 10.0 CBLR060

240/1

13"

Cylinder

18.00 5000 11.5 CBLR055 5000 11.5 CBLR055 5000 11.5 CBLR055 3000 19.2 CBLR065

15.00 5000 11.5 CBLR055 5000 11.5 CBLR055 5000 11.5 CBLR055

20.00 5000 11.5 CBLR055 5000 11.5 CBLR055 5000 11.5 CBLR055 5000 11.5 CBLR055

5750 10.0 CBLR060 5750 10.0 CBLR060 5750 10.0 CBLR060 5750 10.0 CBLR060

23.00

27.00 8750 6.6 CBLR058 8750 6.6 CBLR058 5000 11.5 CBLR055 5000 11.5 CBLR055

240

8750 6.6 CBLR058 8750 6.6 CBLR058 8750 6.6 CBLR058 8750 6.6 CBLR058

10000 5.8 CBLR059 10000 5.8 CBLR059 5000 11.5 CBLR055 5000 11.5 CBLR055

35.00

40.00 10000 5.8 CBLR059 10000 5.8 CBLR059 10000 5.8 CBLR059 10000 5.8 CBLR059

30.00

240/1

23"

Cylinder

3000 19.2 CBLR065

3000 19.2 CBLR065 3000 19.2 CBLR065

3000 19.2 CBLR065 3000 19.2 CBLR065

3.00

6.00

9.00

240/1

13”

TMB

L

C

Two Element Configuration

3000 19.2 CBLR065 3000 19.2 CBLR065

11.00

L

C

One Element Configuration

Cylinder

1

2

Cylinder

Output

1

Cover Top View

Pressure\Temp. Guage Pressure\Temp. Guage Pressure\Temp. Guage

Front of cylinder

L

C

Pressure\Temp. Guage

Front of cylinder

L

C

Page 13

Cylinder

Output

Page 16

W

Position 1, 2, 3

208

277

347

element élém. Watts Ohms Part #

Elements Position, Electric Data and Part #

30.00 3 10000 7.7 CBLR062

35.00 3 11600 6.6 CBLR063

480/3

23" Cyl.

40.00 3 13300 5.8 CBLR064

24.00 3 8000 15.1 CBLR066

30.00 3 10000 12.0 CBLR067

600/3

13" Cyl. 18.00 3 6000 20.1 CBLR057

23" Cyl.

Volts / Total V noitarugifnoC#/ tlo

Height Phases K

13" Cyl. 18.00 6 3000 14.4 CBLR051

24.00 6 4000 10.8 CBLR052

30.00 6 5000 8.7 CBLR053

36.00 6 5750 7.5 CBLR054

208/3

23" Cyl.

24.00 3 8000 9.6 CBLR061

13" Cyl. 18.00 3 6000 12.8 CBLR056

42.00 3 14000 8.6 CBLR069

36.00 3 12000 10.0 CBLR068

Page 14

Page 17

ALL-ELECTRIC INSTALLATION

(Illustration A)

SUPPLY

POWER SUPPLY

120V / 1Ø

PUMP POWER

RADIATORS

RETURN FROM

LOAD

CONTROL

SENSOR

MANAGEMENT

OUTDOOR RESET

ROOM THERMOSTAT

CIRCULATING PUMP

TEMPERATURE /

PRESSURE GAUGE

BLEEDING VALVE

SAFETY VALVE

VALV E

MAINTENANCE

AIR VENT

AUTOMATIC

E

R

U

T

A

N

R

O

É

I

P

S

S

M

E

E

R

T

P

/

/

E

E

R

R

U

U

T

S

A

S

R

E

E

R

P

P

M

E

T

AIR

PURGER

VALV E

BOILER

ELECTRIC

MAINTENANCE

DRAIN

CONNECTION

WATER

DRAIN OR

PURGE VALVE

FLOW

VALV E

MAINTENANCE

SUPPLY TO

RADIATORS

VALV E

SHUT-OFF

TAN K

EXPANSION

PRESSURE

REDUCING VALVE

WATER FEED

Page 18

Page 19

DUAL-ENERGY SERIES INSTALLATION

(Illustration B)

LOAD

SENSOR

OUTDOOR RESET

CONTROL

MANAGEMENT

POWER SUPPLY

ROOM THERMOSTAT

CIRCULATING PUMP

CONTROLLER

DUAL-ENERGY

TEMPERATURE /

PRESSURE GAUGE

SAFETY VALVE

BLEEDING VALVE

VALV E

MAINTENANCE

PUMP

BURNER

CONTROL

VALV E

MAINTENANCE

E

R

U

T

A

N

R

O

É

I

P

S

S

M

E

E

R

T

P

/

/

E

E

R

R

U

U

T

S

A

S

R

E

E

R

P

P

M

E

T

BOILER

ELECTRIC

WATER

FLOW

BOILER

OIL / GAS

DRAIN OR

PURGE VALVE

DRAIN

CONNECTION

VALV E

MAINTENANCE

AIR VENT

AUTOMATIC

VALV E

MAINTENANCE

SUPPLY TO

RADIATORS

AIR

PURGER

VALV E

SHUT-OFF

PRESSURE

WATER FEED

RADIATORS

RETURN FROM

TAN K

EXPANSION

REDUCING VALVE

Page 20

Page 21

ROOM

THERMOSTAT

DUAL-ENERGY PARALLEL INSTALLATION

(Illustration C)

LOAD

CONTROL

SENSOR

OUTDOOR RESET

CONTROLLER

DUAL-ENERGY

MANAGEMENT

POWER SUPPLY

CIRCULATING PUMP

TEMPERATURE /

SAFETY VALVE

VALV E

BLEEDING

VALV E

MAINTENANCE

AIR VENT

AUTOMATIC

E

R

U

T

A

N

R

O

É

I

P

S

S

M

E

E

R

T

P

/

/

E

E

R

R

U

U

T

S

A

S

R

E

E

R

P

P

M

E

T

PRESSURE GAUGE

BOILER

ELECTRIC

PUMP

DRAIN

CONNECTION

VALV E

MAINTENANCE

CONTROL

BOILER

OIL / GAS

MAINTENANCE

BURNER

VALV E

VALV E

MAINTENANCE

DRAIN OR

PURGE VALVE

C

B

A

VALV E

MAINTENANCE

SUPPLY TO

RADIATORS

AIR PURGER

VALV E

SHUT-OFF

WATER FEED

PRESSURE

REDUCING VALVE

TAN K

EXPANSION

A-B PORT

NORMALLY OPEN

A-C PORT

NORMALLY CLOSED

MV

MOTORIZED

VALV E

RADIATORS

RETURN FROM

Loading...

Loading...