95 Series

Operator’s Guide

Personal Portable Gas Monitor

HS-95, CO-95, OX- 95

PROPRIETARY STATEMENT

Thermo GasT ech owns proprietary rights in the information disclosed within. By

receiving this document, the recipient agrees that neither this document nor the

information disclosed within nor any part shall be reproduced or transferred to other

documents or used or disclosed to others for manufacturing or for any other purpose

except as specifically authorized in writing by Thermo GasTech.

COPYRIGHT STATEMENT

Information contained in this document is protected by copyright. No part of this

document may be photocopied, reproduced, or translated to another program or

system without prior written authorization from Thermo GasTech. , © 2001,

Thermo GasTech.

TRADEMARK STATEMENT

Protected through use and/or registration in the United States and many foreign

countries are the trademarks and service marks of Thermo Gas Tech. The use of the

® symbol indicates registration in the United States only; registrations may not

have been issued at present in other countries. All other product names and logos

are trademarks of their respective owners.

®

GASTECH

Patent and Trademark Office.

is a trademark of Thermo GasTech and is registered with the U.S.

DISCLAIMER

Under no circumstances will Thermo GasTech be liable for any claims, losses, or

damages resulting from or arising out of the repair or modification of the equipment

by a party other than Thermo GasTech or its authorized service representatives, or

by operation or use of the equipment other than in accordance with the printed

instructions provided by Thermo GasTech or if the equipment has been improperly

maintained or subject to neglect or accident. Any of the foregoing will void the

warranty.

EXPORT STATEMENT

Export of the information and products in this manual from the U.S.A., or re-export

from another country, may require written authorization from the U.S. Department

of Commerce. Prin ted in th e U.S.A .

REVISIONS TO MANUAL

All information contained in this manual is believed to be true and correct at the

time of printing. However, as part of its continuing efforts to improve its products

and their documentation, Thermo GasTech reserves the right to make changes at

any time without notice. Any revised copies of this manual can be obtained by

writing Thermo GasTech.

ii 71-0011 — REV E

WARNING

T

HIS INSTRUMENT IS DESIGNED TO DETECT

ONE

FLAMMABLE VAPORS, OXYGEN CONTENT, AND/OR TOXIC

GAS

HARMFUL

WILL

ESSENTIAL

PARTICUL ARLY THOSE CONCERNING START UP

OPERATION, CALIBRATI ON, AND MAINTEN ANCE, BE

READ

AND TO GIVE WARNING BEFORE THEY REACH

CONDITIONS. IN ORDER TO ENSURE THAT IT

WARN OF DANGEROUS CONCENTRATIONS, IT IS

,

UNDERSTOOD, AND FOLLOWED

OR MORE OF THE FOLLOWING

THAT THE INSTRUCTIONS IN THIS MANUAL

:

.

,

,

NOTATION CONVENTIONS

Notices are used in this operator’s guide to alert you to hazardous

conditions to person or instru ment and to n otify you of a dditional

informat ion. This operator’s guide use s the following notices:

WARNING

Notifies you of potential da ng er of persona l injury .

CAUTION

Notifies you of potential da m age to equi pm e nt.

NOTE

Notifies you of additional or critical information.

71-0011— REV E iii

SERVICE POLICY

Thermo GasTech maintains an instrument service facility at the

factory as well as authorized service facilities around the world.

Should your instrument require service, you may contact us toll free

at 1-877-GASTECH (427-8324) for US only or 1-510-745-8700,

or visit our website www.thermogastech.com for authorized service

locations.

For warranty or non-warranty repairs, call us to complete a Return

Material Authoriz atio n (RMA) fo rm, obtai n bi llin g and shippin g

information and tell us the nature of the problem. For non-warranty

repairs, you will n eed to pro vide a purchase ord er numb er. If you

need to set a limit to the repairs costs, state a “Not to Exceed” figure.

If you need a quotation before you can authorized the repair costs,

so state, but understand this will incur additional costs and may

delay processing of the rep air.

You may send the unit, prepaid, to: Thermo GasTech, 8407 Central

Ave., Newar k, C A 94 56 0-3431 , Attn.: Service Department.

Enclose the copy of the RMA (Return Material Authorization) that

was previously faxed to you. Pack the instrument and all its

accessories (preferab ly in its original packing) and any special

instructions.

Repairs are warranted for 90 days from the date of shipment.

Sensors have individual warranties.

NOTE

Thermo GasTech assumes no liability for wo rk pe rform ed by

unauthorized service facilities.

iv 71-0011 — REV E

WARRANTY STATEMENT

Thermo GasTech (the “Company”) warrants that the Products will

operate substant ia lly in conformance with the Company’s published

specificatio ns, when subjected to norm al , prope r, and intended usage by

properly trained pe r sonnel, for a period of one (1) year afte r shipment to

Customer (the “Warranty Period”). The Compan y agre es during the Warranty

Period, provided it is promptly notified in writing upon the disc ove r y of any

defect and further provided that all costs of returning the defective Products to

the Company are prepaid by Customer, to repair or replace, at the Company’s

option, defective products so as to cause the same to oper a te in substantial

conformance with said specifications. Re placement parts may be ne w or

refurbished, at the election of the Company. All replaced parts shall become

the property of the Company.

Lamps, pump diaphragms/valves, batteries, fuses, bulbs, and other expendable

items are expressly excluded from the warranty.

The Company’s sole liability with respe c t to e quipment, ma te r ials, parts, or

software furnished to the Company by third party suppliers shall be limited to

the assignment by the Company to Customer of any such third-party

supplier’s warranty, to the extent the same is assignable. In no event shall the

Company have an y obligation to make repa ir s, replacements, or corre c tions

required, in whole or in part, as the result of (i) normal wear and tear, (ii)

accident, disaster, or event of force majeure, (iii) misuse, fault, or negligence

of or by Customer, (iv) use of the Products in a ma nne r for whic h the y we r e

not designed, (v) causes external to the Products such as, but not limited to,

power failure or electrical power surges, or (vi) use of the Pr oduc ts in

combination with equipment or soft ware not supplied by the Com pa ny.

ANY INSTALLATION, MAINTENANCE, REPAIR, SERVICE,

RELOCATION, OR ALTERATION TO OR OF, OR OTHER TAMPERING

WITH, THE PRODUCTS PERFORMED BY ANY PERSON OR ENTITY

OTHER THAN THE COMPANY WITHOUT THE COMP ANY’S PRIOR

WRITTEN APPROVAL, OR ANY USE OF REPLACEMENT PARTS NOT

SUPPLIED BY THE COMPANY, SHALL IMMEDIATELY VOID AND

CANCEL ALL WARRANTIES WITH RESPECT TO THE AFFECTED

PRODUCTS.

THE OBLIGATION TO REPAIR OR REPLACE A DEFECTIVE

PRODUCT SHALL BE THE SOLE REMEDY OF CUSTOMER IN THE

EVENT OF A DEFECTIVE PRODUCT. EXCEPT AS EXPRESSLY

PROVIDED IN THIS SECTION, THE COMPANY DISCLAIMS ALL

WARRANTIES, WHETHER EXPRESS OR IMPLIED, ORAL OR

WRITTEN, WITH RESPECT TO THE PRODUCTS, INCLUDING

WITHOUT LIMITATION ALL IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR

PURPOSE. THE COMPANY DOES NOT WARRANT THAT THE

PRODUCTS ARE ERROR-FREE OR WILL ACCOMPLISH ANY

PARTICULAR RESULT.

71-0011— REV E v

vi 71-0011 — REV E

TABLE OF CONTENTS

Chapter 1 INTRODUCTION.............................................1-1

OVERVIEW ............................................................1-1

DESCRIPTION........................................................1-1

SPECIFICATIONS..................................................1-2

Chapter 2 PHYSICAL DESCRIPTION...........................2-1

OVERVIEW ............................................................2-1

PHYSICAL DESCRIPTION................ ...................2-1

Electronics Assembly................ .................... .....2-3

Buzzer................ ............................................... ..2-4

Housing/Housing Gasket....................................2-4

Sensor .................................................................2-5

Battery Compartment..........................................2-5

Chapter 3 START UP & OPERATION ...........................3-1

OVERVIEW ............................................................3-1

START UP................. .............................. ................3-2

INSTRUMENT OPERATION................................3-3

Alarm Indications...............................................3-3

Low or Dead Battery Indications........................3-4

Weak or Failed Sensor Indications.....................3-5

INTERFERENCE CHARTS...................................3-6

OPTIONAL ACCESSORIES..................................3-8

Hand-aspira ted Samp le -dr aw Ada pt er..... ...........3-8

Earphone............... ...................................... ........3-9

Vibrating Alarm ..................................................3-9

71-0011 — REV E vii

Chapter 4 CALIBRATION & MAINTENANCE............ 4-1

OVERVIEW ....................................................... .....4-1

TEST KIT ................................................................4-2

Test Gas Cylinders......... ............................. ........4-2

H2S Regulato r (for HS-95). ... ... ... ... ... ... ..... ... ... ... 4-2

Dispensing Val ve (for CO-95 and OX-95)... ... ... 4- 2

Flowmeter (f or CO-9 5 and OX-95)........... ... ... ... 4- 3

Test Cup......................... ............................. ........4-3

Tubing.............. ........... ...................................... ..4-3

Test Kit Instruction Sheet...................................4-3

CALIBRATION PROCEDURES............................4-3

Preparing for Calibration ( all m odels).......... ... ... 4-4

How to Use the Control Buttons.........................4-4

Calibration (HS-95, CO-95) ............................... 4-6

Calibratio n (OX-95) .......... ............................. .....4-7

If Calibration Fails ..............................................4-8

Switch to Default Zero (OX-95).........................4-9

Return to Normal Operation.............................4-10

MAINTENANCE ..................................................4-11

How to Open and Close Your Monitor.............4-11

Troubleshooting Guide.....................................4-12

Changing Alarm Setpoints................................4-13

Changing the Alarm Delay...............................4-14

Replacing Defective Components....................4-14

FRUs AND ACCESSORIES LIST........................4-19

viii 71-0011 — REV E

INTRODUCTION

OVERVIEW

This Operator’s Guide provides information on the proper

set-up, use, calibration, and maintenance of the 95 Series of

single-gas monitoring instruments.

Chapter 2 contains a physi c al description of yo ur monitor.

Instructions to use and interpret monitor readings are in

Chapter 3, Start Up and Operation. Chapter 4, Calibrat ion

and Maintenance, also contains troubleshooting information

and a list of replacement part numb ers.

CHAPTER 1

DESCRIPTION

The 95 Series is a li ne of three personal, portable gas

monitors that eac h detect one gas. Each pocket-size

instrument detect s either oxygen (O2), hydrogen sulfide

S), or carbon monoxide (CO), and actuates an alarm to

(H

2

alert you sho uld th e m easu re d g as surp ass t he ala rm settin g.

Table 1-1 lists specificatio ns for each model.

71-0011 — REV E 1-1

95 Series Operators Guide

SPECIFICATIONS

Table 1-1 95 Series Gas Monitor Specific a tio ns

Model Designat ion

(Gases D etected)

OX-95 (0-30.0% O2 in 0.1% increments)

HS-95 (0-100 ppm H

S in 1 ppm increments)

2

CO-95 (0-500 ppm CO in 1 ppm increments)

Detection Method Diffusion, electrochemical

Response Time

Accuracy

Repeatability

90% in 30 seconds

±5% of reading (±0.2% O

±3% of reading (±012% O

for OX-95**)

2

for OX-95**)

2

Gas Alarm Setpoints OX-95: 19.5% vol, decreasing, (programmable)

23.5% vol, increasing, (pro grammable)

HS-95: 10 ppm, and 15 ppm, (programmable)

CO-95: 25 pp m, 200 ppm, (progr am mable)

Gas Alarm Delay 3 sec. (programmable to 0, 1, 2, or 3 sec.)

Other Alarm Modes Weak or failed sensor, low or dead battery

Operator Controls - Power

- ZERO/-

switch

button

- SPAN/+ button

Dimensions

Weight

Battery Life

(approxim ate)

4.5 in. H x 2.5 in.W x 1.0 in. D

6.5 ounces

Continuous, non-alarm operation per one 9V

alkaline ba ttery:

OX-95: 3,200 hours

CO-95 and HS-95: 2,500 hours

Standard* a nd

Optional Accessories

Operating Temper ature and Humidity

Regulatory

Approvals

Operator’s guide*, hand-aspirated sample-draw

adapter, earphone, test kits, vibrating alarm,

*strap.

-4º F (-20º C) to 113º F (45º C)

0-95% relative humidity (RH), non-condensing

UL classified; CSA classified

Class I, Division 1, Groups A, B, C, and D

DEMKO EEx ia IIB T2

** In range of ±2% O2 from calibration point.

Specifications are subject to change without notice.

1-2 71-0011 — REV E

PHYSICAL

DESCRIPTION

CHAPTER 2

OVERVIEW

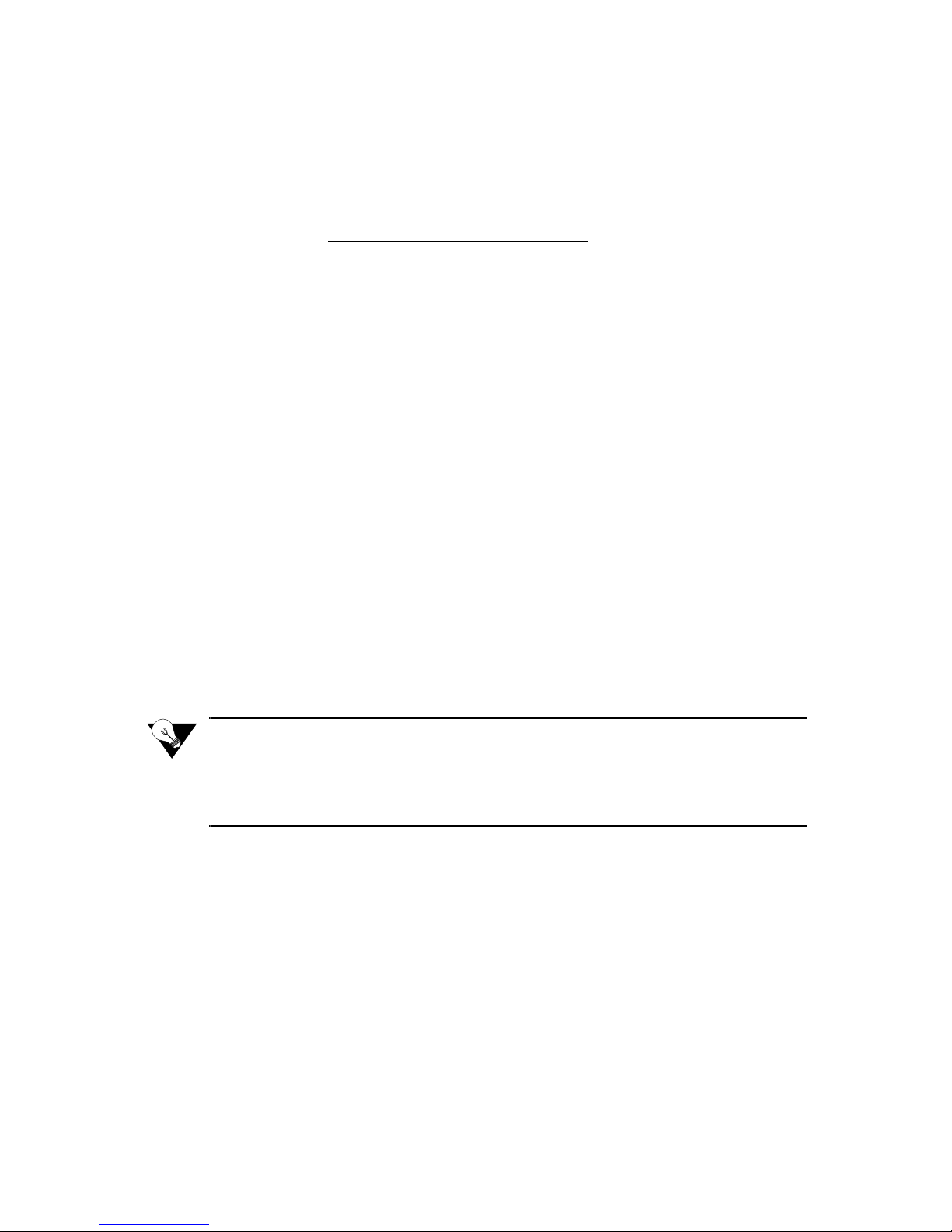

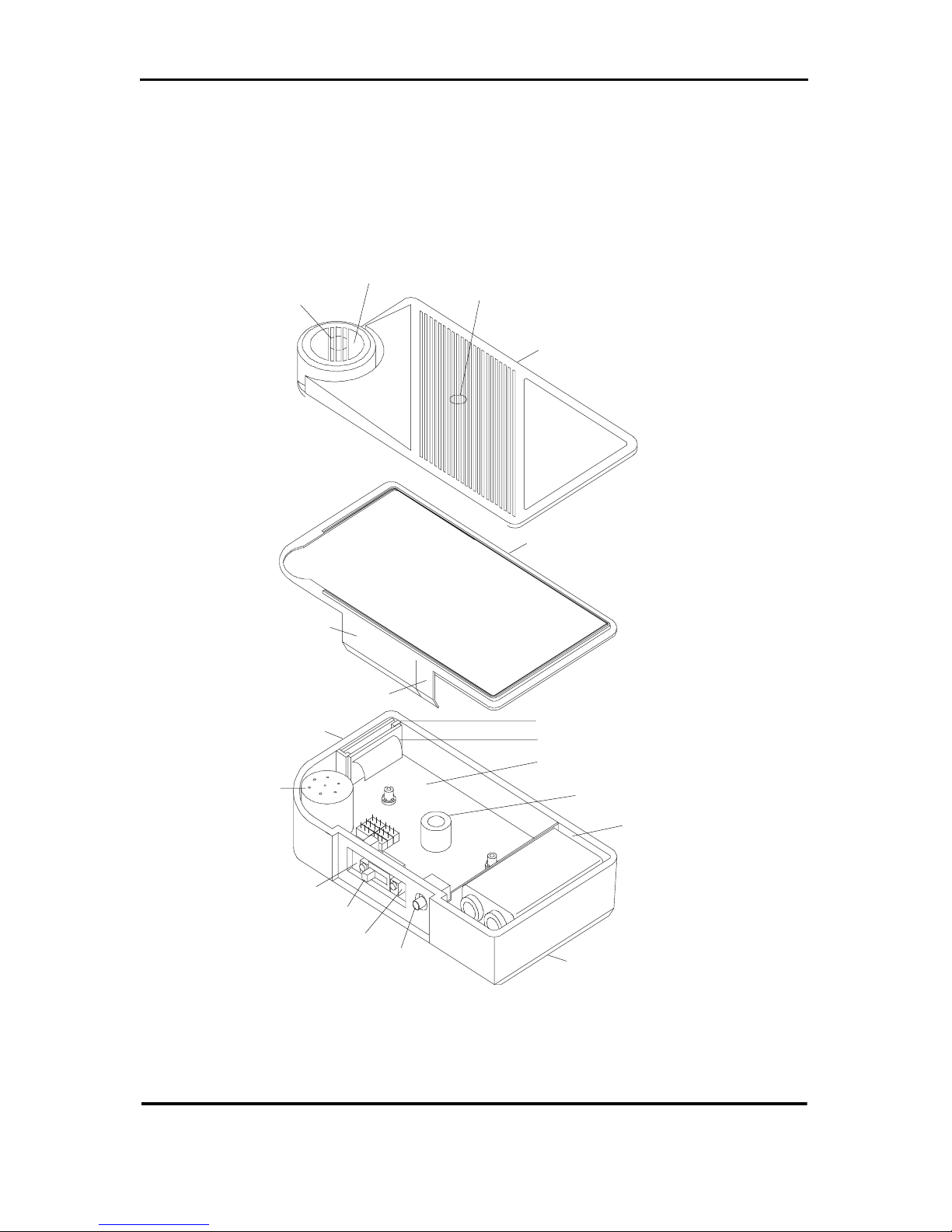

This chapter describes the physical components of your

95 Series gas monitor. For purposes of identification throughout

this guide, the monitor is describ ed as having front and rear

housing hal ves, as shown in Figure 2-1.

PHYSICAL DESCRIPTION

To open your mo nitor, loosen the two captive screws on the rear

cover, then separate the two halves.

The components identified in Figure 2-1 are described in this

chapter. The field replacea ble units (FRUs) include the housing

gasket, sensor, and battery.

71-0011 — REV E 2-1

95 Series Operator’s Guide

(Hydrophobic

membrane

behind grille)

Sens or P o r t

Buzzer Port

FRONT HOUSING

Operator Controls C over

Earphone Jac k Cover

LCD

Plug-in

Sensor

Zero Button

Power Switch

Span Button

Earphone Jack

HOUSING GASKET

ELECTRONICS ASSEMB L Y:

Display Board

Display Cable

Main Board

Buzzer

Battery

Compartment

REAR HOUSING

Figure 2-1 Components of the 95 Series Gas Monitor

2-2 71-0011 — REV E

Physical Description

Electronics Assembly

The electronics assembly consi sts of the main board, operator

controls (power switch, buttons, and earphone jack), display

board with li qu id cr ystal d isplay (LCD), and t he display cable. If

any of these components fail , contact the factory for repair.

Main Board

All buttons and operator co ntrols are part of the main board.

Control circuitry for other components is also located on the

main boa rd.

ZERO/- and SPAN/+ Buttons

The ZERO/- button alone is used to zero the sensor and decrease

parameter settings. The SPAN/+ button alone is used to set

sensor span and increase parameter settings.

The ZERO/- and SPAN/+ buttons are pressed together to select

setting modes.

Power Switch

Set to the left position (toward the sensor) to turn the instrument

on. Set to the right position (away from the sensor) to turn the

instrument off.

Earphone/Vibrating Alarm Jack

The earphone or vibrating alarm accessory is connected to th is

jack.

71-0011 — REV E 2-3

95 Series Operator’s Guide

Display Board/Display Cable

The display board is attached to th e main board by a

nondetachable ribb on cable.

Liquid Crystal Display (LCD)

The LCD panel is visible through the window in the top of the

housing. A red LED is visi ble through the displa y panel as a

visual indication of alarm cond itions. Display readings are

described in Chapter 3.

Buzzer

The buzzer is mounted on the main board.

Housing/Housing Gasket

The instrument housing is a two- piece plastic c a se held together

by two captive screws. A mylar gasket covers the operator

controls to keep water and dust away from the internal

components. The case is sealed using a detachable rubber gasket

and two flaps to protect the operator controls and earphone/

vibrating alarm jac k.

The letters Z, P, and S on the inside of the flap identify the

position of the ZER O/- b utton, the po wer switch, and the SPAN/+

button, respectively. The arrow next to the P indicates the

direction to m o ve the power switch to t urn th e i nstrum ent o n an d

off.

2-4 71-0011 — REV E

Physical Description

Sensor

Each model has a dedicated, detachable sensor that plugs into the

main boa rd. A hyd rophobi c (wat erproof ) membra ne on the insi de

of the case sensor opening i s held down by a gasket. The

membrane permits diffusion of the surrounding atmosphere to

the sensor.

When sufficiently exposed to the target gas, the electrical output

of the sensor ca uses a readin g on the displa y. Readings are in

parts per million (PPM) for H

volume for O

.

2

S and CO, or percent ( %) by

2

Battery Compartment

The battery com part ment houses a standard 9V alkaline battery.

71-0011 — REV E 2-5

95 Series Operator’s Guide

2-6 71-0011 — REV E

START UP &

OPERATION

CHAPTER 3

OVERVIEW

This chapter describes the normal operation of your 95 Series gas

monitor, and how to respond to abnormal operat ion. Normal

operation is any time that start up has been completed, and the

monitor is not indi cating an alarm, fa ult, or low batte ry condition.

This chapter also contains interference charts listing other gases

that can affect the sensor in the HS-95 or CO-95 monitor, and

procedures to use the optional accessories available for your

monitor.

71-0011 — REV E 3-1

95 Series Operator’s Guide

START UP

Perform the following steps to start up your monitor. Refer to

Figure 2-1 as needed.

CAUTION

Perform start up only in a fresh air environment.

1. Flip open th e housing gasket flap that covers the operator

controls, and move the power switch toward the sensor to

turn the monitor on. The unit should sound a single audible

tone, and display the installed ve rsion of software. A

number will then be displayed. Allow a few seconds for the

reading to stabilize, then check the display. If your HS-95 or

CO-95 shows a readin g of 0 PPM, or your OX-95 a reading

of 20.9%, proceed to Step 4. If the reading is anything other

than this, perform Step 2 or 3, as appropriate.

2. Zero the HS-95 or CO-95 by pressing the ZERO/- button

until the PASS message app ears (about 5 seconds).

3. Span the OX-95 by pressing the SPAN/+button until the

PASS message appears (about 5 seconds).

4. Close the operator controls flap. Your monitor is ready for

use.

3-2 71-0011 — REV E

Start Up & Operation

INSTRUMENT OPERATION

In normal operation, your instrument monitors the environment

and displays the current gas concentration. The instrument

displays alarms to indicate gas concentrations outside preset

limits. Low and dead battery as well as weak and failed sensor

conditions are also indicated.

NOTE

Momentary small negative gas readings are not abnormal with

the HS-95 and the CO-95. The instrument automatically corrects

itself.

Alarm Indications

When a ga s conc ent rati on re aches the alar m set poin t, th e al arm is

indicated by the buzzer pulsing, the red alarm light flashing, and

the gas reading blinking, all in unison. For the HS-95 and the

CO-95, the gas alarm is a pulsing audible tone with a blinking

reading for the low level alarm, and a steady audibl e tone with

pulsin g display for the high level alarm. For the OX-95, you can

tell whether the alarm is a high or low alarm b y the ga s reading .

A high O

signified by a pulsi ng audibl e tone. A low O

reading below the low setpoint, and is signified by a steady

audible tone.

alarm shows a reading above the high setpoint, and is

2

alarm shows a

2

NOTE

Pres et alarm setpoints conform to current OSHA standards, but

can be adjuste d. See Chapter 4 for alarm adjust procedures.

71-0011 — REV E 3-3

95 Series Operator’s Guide

Recommended Action:

When an alarm occurs, follow the established procedure for an

alarm condition. If no procedu r e is in place, please establish one

that is appropriate for your application.

The alarm circuit is self-resetting. When the instrument is moved

from the suspect environment, the al arm ceases, and the

instrument r eturns to normal operat ion. However, this does not

mean that the danger has passed.

Low or Dead Battery Indications

Low Battery: When your monitor senses that t he battery has

approximate ly 8 hours rem aining, th e word L OB AT blinks on the

LCD. In addition, the buzzer emits a short chirp and the red

alarm light flashes every 30 seconds.

Dead Battery: When the battery is past the point of useful

operation, LOBAT appears steadily on the LCD. In addition, the

buzzer sounds continuously and the red alarm light is on steady.

When these indications occur, the instrument is not operable.

Recommended Action:

Replace a dead ba ttery immediatel y or a low battery as soon as

possible, foll owing the procedure in Chapter 4 .

3-4 71-0011 — REV E

Start Up & Operation

Weak or Failed Sensor Indications

Weak sensor: When a weak sensor is detected during

calibration, the word FAULT blinks on the LCD. The instrument

is still functioning normally , b ut you should replace the sensor as

soon as possible.

Failed sensor : When a defective sensor or sensor circuit is

detected, the word FAULT is displayed on the LCD. In addition,

the buzzer sounds continuously and the red alarm light is on

steady. A fault condition is caused by a missing or bad sensor, a

bad connection, or a main board sensor circuit fault.

Recommended Action:

Remove the instrument from the monitoring environment. Refer

to the troubleshooting guide in Chapter 4 to determine the cause

of the alarm conditio n and the recommended course of action.

WARNING

A reading of 23.5% O2 or more must be treated as a hi ghoxygen alar m condit ion unti l pr oven ot h e r w is e.

71-0011 — REV E 3-5

95 Series Operator’s Guide

INTERFERENCE CHARTS

Your HS-95 or C O -95 monitor can respond to gases other than

S and CO. Tables 3-1 and 3-2 ind icate the readings that can

H

2

occur for specified concentrations of other gases.

Table 3-1 HS-95 Interference Chart, H2S Sensor

Interfering Gas Concentration Tested Reading

Acetylene

C

2H2

Chlorine

Cl

2

Dimethyl sulfide

3)2

6H14

2

4

OH

3

SH

3

2

2

S

(CH

Hexane

C

Hydrogen

H

Methane

CH

Methanol

CH

Methyl me rc a ptan

CH

Nitrogen dioxide

NO

Sulfur dioxide

SO

50 ppm 170 ppm

5 ppm Negative response

(AVOID)

2.8 ppm No response

4400 ppm No response

10,000 ppm 8 ppm

2.5% No response

1000 ppm No response

5 ppm 6 ppm

10 ppm 1 ppm

10 ppm 1 ppm

3-6 71-0011 — REV E

Start Up & Operation

Table 3-2 CO-95 Interference Chart, CO Sensor

Interfering Gas Concentration Tested Reading

Acetylene

C

2H2

Chlorine

Cl

2

Hexane

C

6H14

Hydrogen

H

2

Hydrogen sulfide

S

H

2

Methane

CH

4

Methanol

OH

CH

3

Methyl me rc a ptan

SH

CH

3

Nitrogen dioxide

NO

2

Sulfur dioxide

SO

2

100 ppm No response

7 ppm No response

4400 ppm No response

100 ppm 12 ppm

10 ppm No response*

2.5% No response

1000 ppm No response*

5 ppm No response*

10 ppm No response*

10 ppm No response*

* The CO sensor has an internal filter that absorbs certain gases

to keep them from interfering with the CO reading. The internal

filter is good for appro ximately on e year. If the filter is saturated,

the gases marked with an asterisk (*) may produce an

interference reading.

71-0011 — REV E 3-7

95 Series Operator’s Guide

OPTIONAL AC CESSORIES

This section de scrib es the o pt ion a l acce ssori es av a ilable for your

95 Series gas monitor, and how to use them.

Hand-aspirated Sample-draw Adapter

Description

The sample-draw adapter is used to draw a gas sample from a

particular location. The adapter consists of a test cup, aspirator

bulb, 10 feet of tubing, fittings, and a probe.

How to Use

1. Attach the test cup o v er the sen sor po rt. The c up f its into t he

groove around the port, and is held snugly by the retainer

arm pressing onto the back of the instrument.

2. Place the probe in the sampling location.

3. Squeeze the aspirator bulb repeatedly until the display

stabilizes. Continue to squeeze the bulb repeatedly during

the monitoring process, to maintain the sample flow to the

monitor.

4. After use, the adapter can remain connected for the next use.

Ke ep in min d that the mo nitor is not operationa l in the

diffusion mode if the adapter is in place.

3-8 71-0011 — REV E

Start Up & Operation

Earphone

Description

The earphone has an ea rpiece on one end, w ith a cord and

adapte r plu g e xtendin g fr o m it. The ea rphone rep e ats the a ud ible

alarms of your monit or. Since the earph one is in your ear during

operation, y ou can hear the alarm in noisy environments.

How to Use

1. Open the earphone flap, then insert the adapter plug into the

earphone jack.

2. Insert the earpiece into your ear.

Vibrating Alarm

Description

The Vibrating Alarm is housed in its own compact case with a

cord and adapter that plug into the 95 Series earphone/vibrating

alarm jack. It operates from its own batteries and vibrates

simultaneously with t he ala rms of the mon itor. It has its ow n clip

that can be attached to the belt or shirt pocket.

How to Use

1. Plug the Vibrating Alarm into the instrument.

2. Place the plastic housing on your belt or po cket, (the belt is

recommended for maximum effectiveness).

3. Turn the instrument on.

4. Vibration should occur for approximatel y 1 second.

71-0011 — REV E 3-9

95 Series Operator’s Guide

Note: V ibration should always occur with the audible buzzer and

display l ight. If it does not vib rate, replace the batt ery. (see

chapter 4 for maintenance).

NOTE

Close the earphone flap when the earphone or vibrating alarm is

not in use.

3-10 71-0011 — REV E

CALIBRATION &

MAINTENANCE

CHAPTER 4

OVERVIEW

This chapter contains calibration instructions for all models of

the 95 Series single - g as monito rs.

A troubleshooting guide, alarm setting procedures, and field

replaceable unit (FRU) replacement procedures are also provided

in this chapter. A part number list for FRUs and accessories is on

the final page.

CAUTION

Calibrate or perform maintenance on you r instrument only in a

“fresh air” environment. For the HS-95, this is an environment

free of H

the OX-95, this i s an environment kno wn to consis t o f normal O

content.

71-0011 — REV E 4-1

S. For the CO-95, this is an environment free of CO. For

2

2

95 Series Operator’s Guide

TEST KIT

The test kits includes test ga s cylin ders, a re gulator or di spensing

valve and flowmeter, a test cup, and flexibl e tubing. The test kit

is hous e d i n a custo m storag e case.

Test Gas Cylinders

The test gas cylinder for the CO-95 contains 200 ppm of CO in

air. The test gas cylinder for the HS-95 co ntains 25 ppm of H

in N

is listed on the cylind er label. Th e cylinde r for zeroing th e O X-95

contains pure nit rogen (N2). The gas is released when the

regulator or dispensing valve is attached to the cylinder and the

flow control knob is opened.

. These concentrations are nominal; the actual concentration

2

S

2

H2S Regulator (for HS-95)

The H2S regulator allows the test gas to flow to the HS-95 at a

fix ed flow rate. T he regulator gauge sho ws the pressure of the gas

in the cylinder. The flow control knob opens and closes the

regulator. To connect, screw the regulator onto the c ylin de r, and

install the tubing leading to the test cup .

Dispensing Valve (for CO-95 and OX-95)

The dispensi ng va lve con trols the flo w of test gas to th e CO-95 or

the OX-95. The flow control knob opens and closes the valve and

controls the flow rate of the test sample. To connect, screw the

val ve on to the test c ylind er. Insert the gas outlet into the sample

tubing.

4-2 71-0011 — REV E

Calibration & Maintenance

Flowmeter (for CO-95 and OX-95)

The ball in the flowmeter column indicates the flow rate of the

gas from 0.2 to 2.0 standard cubic feet per hour (SCFH). The

inlet is on the bottom and the outlet is on the top.

Test Cup

The test cup is a rubber cylinder that fits into the groove around

the sensor port and is held in place by a retainer arm. A metal

fitting connects to the tubing.

Tubing

The 3/16 in. I.D flexible vinyl tubing connects the cylinder, the

flowmeter (CO-95 and OX-95) , and the test cup.

Test Kit Instruction Sheet

The test kit instruction sheet describes how to prepare and

operate the test kit with the 95 Series gas monitors.

CALIBRATION PROCEDURES

Calibration procedures include preparing your instrument,

verifying or adjusting zero, verifying or adjusting span, then

returning your instrument to normal operation.

WARNING

Accurate calibration is essential for correct gas or oxygen

readings. Incorrect calibration can impair the performance of

the instrument, placing you in potential danger if hazardous

conditions exist.

71-0011 — REV E 4-3

95 Series Operator’s Guide

Preparing for Calibration (all models)

NOTE

With a HS-95 or CO-95 , i f th e battery has gone de ad or the

battery has been out of the instrument for 30 minutes or more,

allow 1 hour afte r the new battery ha s bee n installed fo r the

sensor to stabil i ze before beginning calibration procedures.

1. Check that th e flow co ntrol kn ob or dis pensin g v al ve is shut

off. Sc re w the re g ulator or t he dispensin g v alv e onto th e test

cylinder for your de tector.

2. Securely attach one end of the tubing to the gas outlet of the

regulator or dispensing valve. For the HS-95, securely

attach the other end of the tubing directly to the test cup.

3. For the CO-95 or OX-95, attach the other end of the tubing

from the dispensin g valv e to th e i nlet (b ot tom ) c onnec to r of

the flowmeter. Attach a second piece of tubing between the

outlet (upper) connector of the flowmeter and the test cup.

CAUTION

The flowmeter must be vertical and right side up in order for you

to atta in accurate readings.

How to Use the Control Buttons

• The control buttons are ZERO/- and SPAN/+.

• A button should be pressed for at least 1/2 second to be sure

that it is recognized.

• The ZERO/- button is used to set zero. The SPAN/+ button

is used to set span. See the Calibration section for details.

4-4 71-0011 — REV E

Calibration & Maintenance

• When you press and release the ZERO/- and SPAN/+

buttons at the same time, the mode changes. In the HS-95

and CO-95, the modes are: span calibration (C), set low gas

alarm (L), set high gas alarm (H), set alarm delay (d), and

normal. In the OX-95, the modes are: set low alarm (L), set

high alarm (H), set alarm delay (d), and normal.

• When any setting mode is active, the mode letter is

displayed to the left of the setting: (C) for setting the span

calibration, (L) for setting the low and (H) for setting the

high alarm, and (d) for setting the alarm delay.

• Normal mode is not indicated by a letter. The space to the

left of the current gas reading is bl ank.

• In all setting mo des, press and release ZERO/- to decrease

and SPAN/+ to increase the setting by one count. Press for

at least 1/2 second before releasing. Hold the button do wn to

change the setting rapidly.

71-0011 — REV E 4-5

95 Series Operator’s Guide

Calibration (HS-95, CO-95)

Open the operator contr ols flap , and slide the power switch on

(toward the sensor). Allow a few seconds for the instrument to

stabilize.

1. Make sure the instrument is in a fresh air environment, free

of H

S or CO gas. Press and hold the ZERO/- b utto n. A lo w

2

bar is displayed to the left of the gas reading during the

automatic zero calibration. Release the button when the

PASS or FAIL message is displayed . The in strument returns

to normal mode, with the alarm inhibited for 2 minutes.

2. Go to span calibration mode by pressing and re leasing t he

ZERO/- and SPAN/+ buttons at the same time. The letter C

appears. The value display ed is the current span cal ibration

setting. If necessary, press the ZERO/- or SPAN/+ button to

change the setting to match the concentration indicated on

the test gas cylinder.

3. When the values match, return to normal mode by pressing

and releasing ZERO/- and SPAN/+ twice. The instrument

passes thro ugh set gas alarm (L & H) mo des and set delay

(d) mode and enters normal mode.

4. Fit the t e st cup into the groove around the sensor po rt with

the retainer arm around the back of the instrument holding

the cup in place. The fitting should extend to the right across

the top of the instrument.

5. Open the flow control knob on the H

the CO cyl inder dispensing va lve. F o r the HS-95, v erify that

the regulator gauge shows a pressure greater than 0. For a

CO-95, set the flow rate to 1.0 SCFH. Allow 90 seconds for

the reading to stabilize.

4-6 71-0011 — REV E

S cylinder re gulator o r

2

Calibration & Maintenance

6. Press and hold the SPAN/+ button. A high bar is displayed

to the left of the gas reading during the automatic span

calibration. Release the button when the PASS or FAIL

message is displayed. The instrument returns to normal

mode, with the alarm inhibited for 3 0 seconds.

NOTE

The HS-95 and CO-95 gas alarm is inhibited for 2 minutes after a

successful (PASS) zero calibration and after an unsuc ce ssfu l

(FAIL) span cal ib ration. The alarm is also inhibited for

30 seconds after a successful (PASS) span calibration. The alarm

is inhibit ed to allow you to finish cal i b rat ion witho ut s etting off

the alarm. Durin g the inhibit peri od, a rotating pa tt ern of

horizontal bars appears to the left of the gas reading to remind

you that t he alarm is shut off.

Calibration (OX-95)

Open the operator contr ols flap , and slide the power switch on

(toward the sensor). Allow a few seconds for the instrument to

stabilize.

1. Fit the t e st cup into the groove around the sensor po rt with

the retainer arm around the back of the instrument holding

the cup in place. The gas inlet should extend to the right

across the top of the instrument.

2. Open the N

1.0 SCFH. Allow 90 seconds for the reading to stab ilize.

cylinder dispensing valve. Set the flow rate to

2

The low oxygen alarm will sound. This is normal.

71-0011 — REV E 4-7

95 Series Operator’s Guide

3. Press and hold the ZERO/- b utton . A low b ar is display ed to

the left of the gas reading during the automatic zero

calibration. Release the button when the PASS or FAIL

message is displayed. The instrument retur ns to normal

mode, with the alarm inhibited for 2 minutes.

4. Turn off the gas and remove the test cup.

5. Let the instrument stabilize for 90 seconds in fresh air . Pres s

and hold the SPAN/+ button. A high bar is displayed to the

left of the gas reading du ring the automatic span calibration.

Release the button when the PASS or FAIL message is

displayed. The instru m ent return s to norm al mode, with no

additional alarm inhibition.

NOTE

The OX-95 gas alarms are inhibited for 2 minutes after a

successful (PASS) zero calibration and after an unsuc ce ssfu l

(FAIL) span cal ibration. This all ows y ou to finish calibration

without setting off an alarm. During the inhibit period, a rotating

pattern of horizontal bars appears to the left of the gas reading to

remind you that the alarms are shut off. The OX-95 alarms are

NOT inhibited after a successful (PASS) span calibration.

If Calibration Fails

On all models, if the zero or span calibration fails, the FAIL

message is displayed. Try the zero or span procedure a second

time. If the FAIL message appears again:

1. Turn the instrument off.

2. Replace the sensor.

4-8 71-0011 — REV E

Calibration & Maintenance

3. For the HS-95 or CO-95, all ow the new sensor to stabilize

for 1 hour. For the OX-95, allow the new sensor to stabilize

for 5 minutes.

4. Turn the instrument on.

5. Run the zer o and span calibrati on procedures from the

beginning.

WARNING

You should not ignore the al arm even if you de ci de that it was

caused by this mistake. Move immed ia tely to a safe area.

Switch to Default Zero (OX-95)

If you press and hold the ZERO/- button on the OX-95 while the

instrument is in fresh air, the sensor becomes uncalibrated, the

reading goes to 0%. A rotating pattern of horizontal bars appears

for 2 minutes and then the low O

pulses, the red alarm light flashes, and the reading blin ks.

To restore proper function, the instrument must be rezeroed with

test gas. To keep the instrument operational in the meanti me,

N

2

you can switch to the default ze ro value:

1. Go to default zero mode by pressing and releasing the

ZERO/- and SPAN/+ buttons simultaneously one or mo re

times, until 0CAL is displayed.

2. Press and hold the ZERO/- button until 0CAL changes to

alarm occurs—the buzzer

2

0dEF, indicating that the de fault zero v alue has been loaded.

3. To exit, press and release the ZERO/- and SPAN/+ buttons

simultaneously until normal mode comes up.

4. Respan in fresh air. Press and hold the SPAN/+ button until

PASS or FAIL appears.

71-0011 — REV E 4-9

95 Series Operator’s Guide

Using the default zero value, the readings are approxi mat e. You

should recalibra te as soon as possi ble, usin g N

fresh air for span. The reading with N

may be several percent off

2

gas for zero and

2

zero until you pre ss the ZERO/- b utto n .

Return to Normal Operation

After calibration, return to normal operation.

1. Clos e the f low control knob or the dis p e ns ing va lve.

2. Remove the test cup and close the flap that covers the

operator controls .

3. Disassemble the test kit. Store the components in the

storage case. You can leave the hoses attached for the next

calibration. Your instrument is now ready for normal

operation.

NOTE

While in normal mode, the HS-95 or CO-95 goes into a FAULT

condition if you press the SPAN/+ button for seve ral seconds

without introducing calibra ti on gas t o the sensor. To return to

normal operation, turn the power switch off, wait a few seconds,

then turn the power switch back on.

If the HS-95 or CO-95 “fails” a calibratio n (wi th gas introduced

to the sensor), see page 4-9.

4-10 71-0011 — REV E

Calibration & Maintenance

MAINTENANCE

This section contains troubleshooting and maintenance

procedures, including procedures for alarm point ad ju stment.

How to Open and Close Your Monitor

To open your monitor, open both gasket flaps, then ensure that

the power switch is off. Loosen the two captive screws on the

rear housing, then se parate th e two halves. The gasket normally

remains attached to the front housing, but may slip out of its

retaining groove.

To close, first verify that the gasket is securely within the groove

around the front housing. Then place the two halves together and

tighten the two screws.

Test the placement and seal of the gasket by closing its two flaps.

Each flap should neat ly click shut.

NOTE

Should you ever replace the gasket, rememb er t o test the

placement and seal of the new gasket.

71-0011 — REV E 4-11

95 Series Operator’s Guide

Troubleshooting Guide

The following troubleshooting guide lists possible indications,

probable cause, and recommended actions.

Table 4-1 95 Se r ies G as Mon itor Troubleshooti ng G uid e

Indication

Blinking LOBAT

message. Buzzer

chirps and alarm

light flashes every

30 sec.

Stead y LO BAT

message. Steady

buzzer and alarm

light.

No gas reading.

Steady FAULT

message. Steady

buzzer and alarm

light.

Condition and

Probable Cause

Low battery. Less than

8 hours of operating life

remaining.

Battery below operating

level. In s trument

inoperative.

Bad sensor or faulty

sensor circuit.

Or, improper

calibration.

Recommended Action

Replace the battery.

Replace the battery immediately.

Recalibrate. If the indication

persists, replace the sensor and

recalibrate. If the indication

persists, contact the factory for

repair.

Blinking FAULT

message.

No buzzer or alarm

light.

FAIL messa ge

during calibration

procedure.

4-12 71-0011 — REV E

Sensor is still

functioning but is near

the end of its life.

Improper calibration.

Or, sensor needs

replacement.

Recalibrate. If the indication

persists, replace the sensor as soon

as practical.

Calibrate the new sensor.

Repeat the entire calibration

procedure. If condition persists,

replace the sensor, then

recalibrate.

Calibration & Maintenance

Changing Alarm Setpoints

The 95 Series has two alarms, low and high, each with its own

setpoint. The low alarm soun ds when the reading is at or above

the low setpoint for the CO-95 and HS -95. The high alarm

sounds w hen th e read ing is a t o r ab ove th e h igh s etp oint. You can

change the low setpoint whe n L is displa y ed on the LCD and th e

high setpoi nt when H is displ ayed.

Preset alarm points are listed in Table 1-1, Specifications. To

adjust an alarm setpoint, turn your monitor on, allow it to

stabilize for a few seconds, then perform the following steps.

Refer to Figure 2-1 for locations of the buttons.

1. Press and release the ZERO/- and SPAN/+ buttons

simultaneously one or more times, until the letter L, or H is

displayed, indicat ing the desired alarm.

2. The current alarm setpoi nt is displayed. Press the ZERO/button to decrease and the SPAN/+ button to increase the

setpoint.

3. When the desired value is displayed, exit by pressing and

releasing the ZERO/- and SPAN/+ buttons simultaneously

one or more times, until normal mode comes up, as

indicated by only the gas reading without any additional

letter.

71-0011 — REV E 4-13

95 Series Operator’s Guide

Changing the Alarm Delay

The instru ment can be programmed to delay the audible and

visual alarm indications for a pre-determined time after a gas

alarm setpoint has been exceeded. This feature prevents nuisance

alarms caused by transient radio frequency interference (RFI).

The alarm delay can be set from 0þ(noþdelay) toþ3 second s

(factory setting). To set the alarm delay, turn your monitor on,

allow it to sta bilize fo r a fe w seconds, th en pe rform th e follo wi ng

steps. Refer to Figure 2-1 for locations of the buttons.

1. Press and release the ZERO/- and SPAN/+ buttons

simultaneously one or more times, until the character d is

displayed on the LCD, indicating the delay setting mode.

2. The current alarm delay is displayed. Press the ZERO/button to decrease and the SPAN/+ button to increase the

alarm delay setting.

3. When the desired value is displayed, exit by pressing and

releasing the ZERO/- and SPAN/+ buttons simultaneously

one or more times, until normal mode comes up, as

indicated by only the gas reading without any additional

letter.

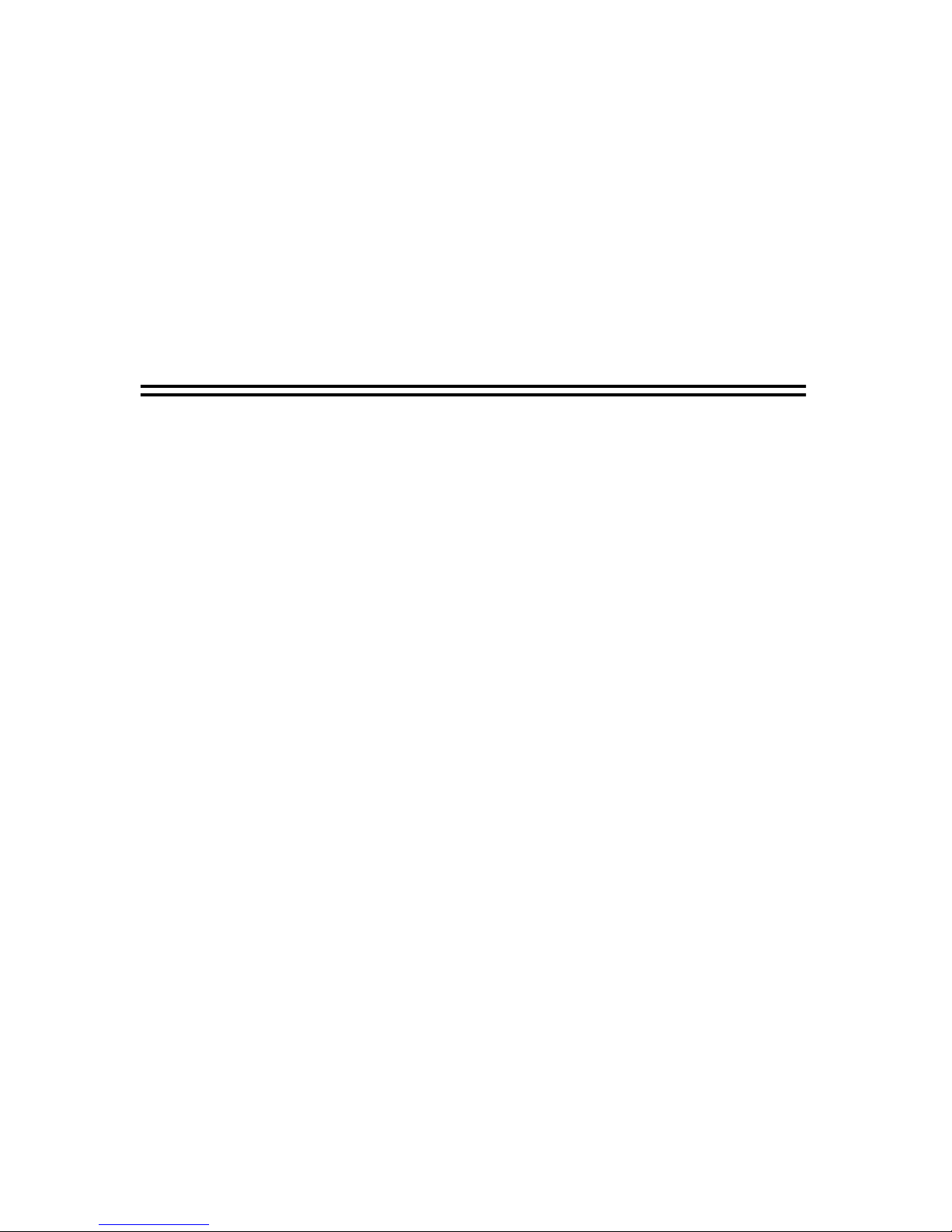

Replacing Defective Components

This section describes how to remove and replace the sensor and

battery. The location of these compone nts is show n in Figur e 4-1.

NOTE

Electronic components can be damaged by electrostatic

discharge (ESD). All standard ESD precautions must be exer cised

while han dling the el ectronic compon ents.

4-14 71-0011 — REV E

Calibration & Maintenance

Replacing the Sensor

Open the instrument, then perform the following steps:

1. Hold the monitor in one hand with your thumb on top of the

buzzer. This holds the electronics assembly in place while

you remove the sensor. Do not touch the main board during

this process.

2. With your other ha nd, pull the sensor stra ight up out of its

socket.

3. The sensor has four pins (H

S and CO) or two pins (O2) that

2

match the socket pattern on the main board. Align the pins

of the new sensor with the socket, then insert them straight

down into the board.

4. Securely close your moni tor.

5. Allow at least 1 hour for the new CO or H

5 minutes for the O

sensor to stabilize before turning on

2

S sensor or

2

your monitor

6. Calibrate the new sensor before using the instrument.

NOTE

If the FAIL message wa s displ ay ed bef ore you replaced the

sensor, the FAIL message wil l ap pear when you tu rn the

instrument on with the new sensor. When you calibrate the new

sensor, the FAIL message is remo ved and the instrument opera t es

properly.

71-0011 — REV E 4-15

95 Series Operator’s Guide

Replacing the Instrument Battery

WARNING

To mainta in ap provals, use only Durace ll PC1604 or Eveready

EN22 batterie s .

Open the instrument, then perform the following steps:

1. Lift the old battery from its compartment.

2. Insert the new battery into the compartment. Make sure to

align the positiv e and negative clips with the f ig ure in the

bottom of the battery compartment.

3. Close your monitor.

4. For the CO-95 and the HS-95, if the old batte ry wa s

completely spent, the sensor has lost its bias. In this case,

allow at least 1 hour after batte r y replacement before

turning on the monitor. If the battery was low but still

functional when it was replaced, allow 15 minutes. For the

OX-95, allow 5 minutes.

5. After turning your moni tor back on, verify pr oper

calibration before actual use. If recalibration is needed for

an HS-95 or CO-95, wait 1 hour after battery replacement.

Replacing the Vibrating Alarm Batteries

1. Unplug the Vibrating Alarm f rom the instrument.

2. Remove the cover by unscrewing the #4 Phillips head screw

located in the middle of the enclosure lid.

3. Remov e t he ba tteries i nside the h ousing b y ge ntly lifting th e

batteries from the retaining clips.

4-16 71-0011 — REV E

Calibration & Maintenance

4. Install a fresh set of “AA” batteries noting the polarity

(+side of battery to + on circuit board).

5. Replace the cover maki ng sure the knotch es line up and

ensuring the cord is not crimped. Replace the screw used in

step 2.

6. Test the Vibrating Alarm using the Testing instructions. If

The alarm does not vibrate after changi ng the batterie s,

contact Thermo GasTech for futher instructions

Electronics Assembly Components

The electronics assembly consi sts of the main board, power

switch, buttons, earphone/vibrating alarm jack, liquid crystal

display ( LCD), and display cabl e. If any of these components

fail, contact the fa c tor y for rep air.

71-0011 — REV E 4-17

95 Series Operator’s Guide

Housing Gasket

Plug-in

Sensor

O-ring (2)

(Place thumb on buzzer when removing sensor)

9V Battery

Figure 4-1 95 Series Gas Monitor FRU Locations

4-18 71-0011 — REV E

Calibration & Maintenance

FRUs AND ACCESSORIES LIST

Table 4-2 lists the field replaceable units (FRUs) and accessories

for all 95 Series instruments.

Table 4-2 95 Series Gas Monitor FRUs and Accessories

Part No. Description

07-0080 Housing gasket

07-0090 Gasket, switch cover

07-6010 O-ring

13-0197 Strap, lanyard

49-1215 (2) AA alkaline batteries (vibrating alarm)

49-1302 9V alkaline battery

52-2022 V ibrating alarm

52-7515 Earphone alarm

65-1059 O

65-2007 CO sensor for CO-95

65-2037 H

71-0011 Operator’s Guide

72-0020-02 OX-95 gas monitor

73-0010-01 CO-95 gas monitor

73-0011-01 HS-95 gas monitor

81-0066 Test gas cylinder, 200 ppm CO in air

81-0078 Test gas cylinder, 100% N

81-0151 Test gas cylinder, 25 ppm H2S in N

81-0249 Test kit, OX-95

sensor for OX-95

2

S senso r fo r HS-95

2

2

2

81-0250 Test kit, CO-95

81-0251 Test kit, HS-95

81-1185 Test cup (all models)

81-1186 Hand-aspirated sample-draw adapter

71-0011 — REV E 4-19

Loading...

Loading...