ThermoFLUX PELLING 18, PELLING 25, PELLING 35, PELLING 75, PELLING 100 User And Maintenance Manual

...

ThermoFLUX d.o.o., Bage br. 3, 70101 Jajce, Bosna i Hercegovina, Tel/Fax: 030–657-100

www.thermoflux.ba tfinfo@thermoflux.ba

PELLET BOILER

USER AND MAINTENANCE MANUAL

2

PELLING

3

Content:

1 Notes on the manual .................................................................... 5

1.1 Introduction ....................................................................................................... 5

1.1.1 Easy and safe operation .................................................................................... 5

1.1.2 Reading the manual ......................................................................................... 5

1.1.3 Technical changes ............................................................................................ 5

1.1.4 Copyright ....................................................................................................... 5

2 Safety notes ................................................................................ 6

2.1 Proper use ......................................................................................................... 6

2.1.1 Using the boiler ............................................................................................... 6

2.1.2 Permissible fuel for the Pelling boilers ................................................................. 7

2.1.3 Safety instructions for boiler room ...................................................................... 7

2.1.4 Fresh air supply ............................................................................................... 7

2.2 Warnings and safety symbols used......................................................................... 8

2.3 Other risks of the side effects ................................................................................ 8

2.4 Obligatory informing ............................................................................................ 9

2.5 Safety devices .................................................................................................... 9

3 Functional description ................................................................. 10

3.1 General overview .............................................................................................. 10

3.2 Pellet boiler PELLING ......................................................................................... 11

3.3 Technical data .................................................................................................. 12

4 Function of boiler ....................................................................... 13

4.1 Overview of the controls and display and their basic functions .................................. 13

4.2 Principle of boiler operation ................................................................................ 15

4.2.1 How to lock the Display .................................................................................. 15

4.3 Schematic representation of the menu control ....................................................... 16

4.3.1 Clock adjustments ......................................................................................... 18

4.3.2 Adjustments of the programmed on and off mode ............................................... 19

4.3.3 LANGUAGE OPTIONS ...................................................................................... 21

4.3.4 STAND BY mode ........................................................................................... 21

4.3.4.1 STAND BY mode with installed sensor for water temperature ............................. 21

4.3.4.2 STAND BY mode with room thermostat connected ............................................ 22

4.3.5 Option Buzzer ............................................................................................... 22

4.3.6 Filling of spiral dispenser ................................................................................. 23

4.3.7 State of the boiler .......................................................................................... 23

4.3.8 Technical settings .......................................................................................... 23

4.3.9 FUEL TYPE .................................................................................................... 23

PELLING

4

5 Ignition and shutting down of boiler ............................................. 24

5.1 Ignition ........................................................................................................... 24

5.2 Shutting down of boiler ...................................................................................... 25

5.3 Boiler power adjustments ................................................................................... 25

5.4 Adjustment of water temperature in boiler ............................................................ 26

5.5 Modulation ....................................................................................................... 26

5.6 Cleaning of FIRE-POT......................................................................................... 27

5.7 Burning of wood ............................................................................................... 28

6 Cleaning and maintenance .......................................................... 30

6.1 Daily cleaning ................................................................................................... 30

6.2 Weekly cleaning ................................................................................................ 31

6.3 Monthly cleaning ............................................................................................... 32

6.4 Cleaning flue gas temperature sensor ................................................................... 33

7 Installation ................................................................................ 34

7.1 Conditions for installation ................................................................................... 34

7.2 Chimney and pipes for flue gas............................................................................ 34

8 Connection options ..................................................................... 37

8.1 Hydraulic schemes for connection ........................................................................ 37

8.2 Scheme for electric connection ............................................................................ 41

8.2.1 Control unit .................................................................................................. 42

9 Alarms ...................................................................................... 44

10 Instruction about safety removal and proper disposal of boiler ...... 45

10.1 Disposal .......................................................................................................... 45

11 Guarantee .............................................................................. 46

11.1 Guarantee period .............................................................................................. 46

11.2 Guarantee terms ............................................................................................... 46

11.3 Exemption from the guarantee ............................................................................ 46

12 EU Label.................................................................................... 47

PELLING

5

1 Notes on the manual

1.1 Introduction

Eas y a nd safe o pera ti on

This manual contains important information for proper and safe operation of the Pelling

boilers. Following these instructions you will avoid danger and repair costs, and also

increase the operational life of the boiler.

Reading the ma nua l

This manual must be read and applied by everyone who operates or works on the

Pelling boiler.

Techn ical c han ges

ThermoFLUX continuously develops and improves its boilers. The information in this

version is correct at the time of going to press.

All details in this manual on standards and regulations should be checked before use

and should be compared with the installed boiler.

We reserve the right to make changes which may then deviate from the technical

details and illustrations in this manual.

Cop yright

Written agreement is required from Thermo FLUX d.o.o. for any reprints, storage in a

data–processing system or transmission by electronic, mechanical or any other means,

for copies and publications, in whole or in part.

NOTE: Please save the received documents. In the event of a malfunction,

service personnel need a serial number and the year of manufacture of the

boiler, without these basic info we can not acknowledge a malfunction or

service it.

PELLING

6

2 Safety notes

2.1 Proper use

Pelling boiler was designed and built in accordance with safety regulations:

UNI EN 303-5 Heating boilers, Heating boilers for solid fuels, manually and

automatically stoked, nominal heat output of up to 500kW

73/23/EEC Low Voltage Electrical Equipment

89/336/EEC Electromagnetic Compatibility (EMC), EU Council Directive

However, its use can result in the injury or death of the user and/or third part and in

impairments to the boiler itself or to other material goods.

The boiler was designed to burn wood pellet and wood. The manufacturer will

accept no responsibility for any damage resulting from improper use. Proper

use includes maintaining the installation, operation and maintenance

specified by the manufacturer. The user may only enter or change the

operating values specified in this manual. Any other entries will affect the

boiler's control program and operation, which can lead to a malfunction.

Usi ng the bo ile r

Use the boiler only when it is in perfect condition. Use it properly, as described in this

manual. Use the boiler as described in this manual. Get to know security measures

and possible hazards. Remove any faults that could affect the safety. The operation of

a faulty boiler can cause fier or explosion.

The boiler is intended for combustion of wood pellets and wood. Any other use is

incorrect. It is forbidden to burn any other fuel other than pellets and wood. The

manufacturer will not assume responsibility for any damage caused by improper

handling. Correct use implies maintenance of the installed boiler, operation and

maintenance conditions prescribed by the manufacturer.

The user can enter or change only the values specified in this manual. Any

other value of the parameters will affect the control program, and the

operation od the boiler, wich can ultimately lead to the termination of the

correct operation. In that case, the boiler is not subject to warranty anymore.

PELLING

7

Permissible fue l f or the Pe lling boi le rs

The boiler is designed for burning wood pellets with a diameter of 6mm and a length

of 10-30mm. In exceptional cases, by inserting additional grid as an alternative can

also be used dry wood. We do not recommend a continuously burning of wood for

more than 30 days.

The pellets quality is derived from the EN 303-5: 2012 Standard (Table 7. Water

content les than 12% according to DIN 51731-HP5, DINplus certification program and

ÖNORM M7135-HP1 or ENPlus-UNI EN 14961-2, UNI EN ISO 17225-2 class A1 or A2.

6mm diameter, length 10-30mm)

Particular attention should be paid to the quality of wood pellets. Low-grade

pellets can cause malfunction of the boiler.

Safe ty in struct ion s f or boil er room

The boiler room must be made according to current regulations, especially regarding

fire protection. No flammable material should be stored in the boiler room.

The room where the boiler is installed must be frost-resistant.

The boiler should not be exposed to cold or freezing temperatures. Extreme cold

temperatures can cause mailfunction and unexpected behavior of electronic

components.

Fresh air su pply

For combustion of pellets and normal work boiler needs fresh air. The room in wich the

boiler is installed must have an opening for fresh air supply. The recommended

minimum dimension is 30x15cm.

PELLING

8

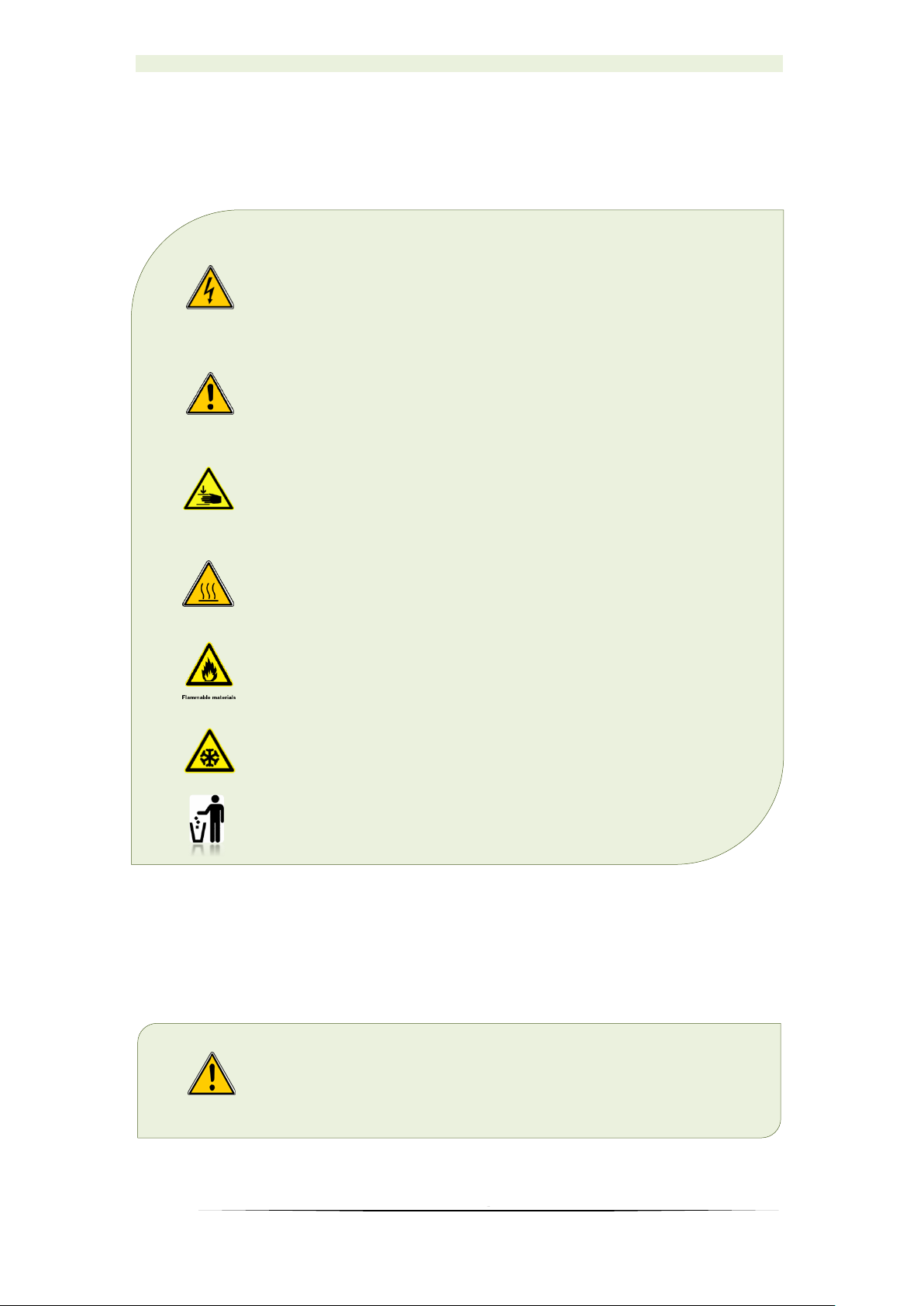

2.2 Warnings and safety symbols used

2.3 Other risks of the side effects

Despite the precautions taken there are also certain risks of side effects:

DANGER OF CARBON MONOXIDE.

If the boiler is running during cleaning time may occur

transmission of CO through the open door. Do not open

the door longer than necessary.

DANGER OF ELECTRIC SHOCK.

Work on areas marked with this symbol may only be done by

a qualified electrician.

WARNING!

Warning about a dangerous location. Work on areas marked

with this symbol can lead to serious injuries or to extensive

material damage.

CAUTION!

Hand injuries. Work on locations marked with this symbol can

lead to hand injuries.

CAUTION!

Hot surface. Work on locations marked with this symbol can

lead to burns.

CAUTION!

Danger of fire. Work on locations marked with this symbol can

lead to a fire.

CAUTION!

Frost danger. Work on locations marked with this symbol can

lead to frost damage.

Instructions for proper disposal of waste.

PELLING

9

2.4 Obligatory informing

Everyone who operates with the boiler must read the instructions before using it, in

particular, the chapter ’’Safety Instructions’’.

This applies especially to persons who occasionally work on a boiler, for example,

cleaning and maintaining boilers. This manual should always be kept near the installed

boiler.

Pay particular attention to the applicable local standards and guidelines. All

local laws must be respected during installation, as well as standards and

norms that are in force in the country where the boiler is installed even

though it is not listed in this manual.

The Installation can be carried out only by persons (service technicians) who

are trained/educated and have a license for this job.

The central heating system must be properly calculated and dimensioned.

The chimney should be calculated and made according to EN 13384-1. The

chimney must be thermally insulated to prevent condensation.

Storage of pellets can be done only in places that are dry and free from

moisture.

In certain countries, it is necessary to measure the emissions of gases by an

authorized person during the first commissioning.

2.5 Safety devices

Boiler is equiped with safety devices that in case of unexpected situations

stop the power supply and thereby stop the operation boiler.

Microprocessor control on the boiler: Intervenes directly, turns off the boiler until

it cools down and shows an error on the display screen in case of a fan failure, failure

of the motor for auger, or the ignition.

Fuse F4A 250V: Fast fuse, protects the boiler from large voltage changes of electricity

and short circuits inside the boiler.

Safety limiting thermostat (STB): intervenes by breaking the circuit in the boiler

(automatically stops motor of the auger and exhaust gasses fan) if the boiler

temperature reaches the limit of 95°C.

Vacuum switch: intervenes in case of low underpressure in burnerroom(open door,

chimney jammed).

PELLING

10

3 Functional description

3.1 General overview

Accompanying material

Tools for the pipeline and firebox cleaning

Instructions booklet

Guarantee

PELLING

11

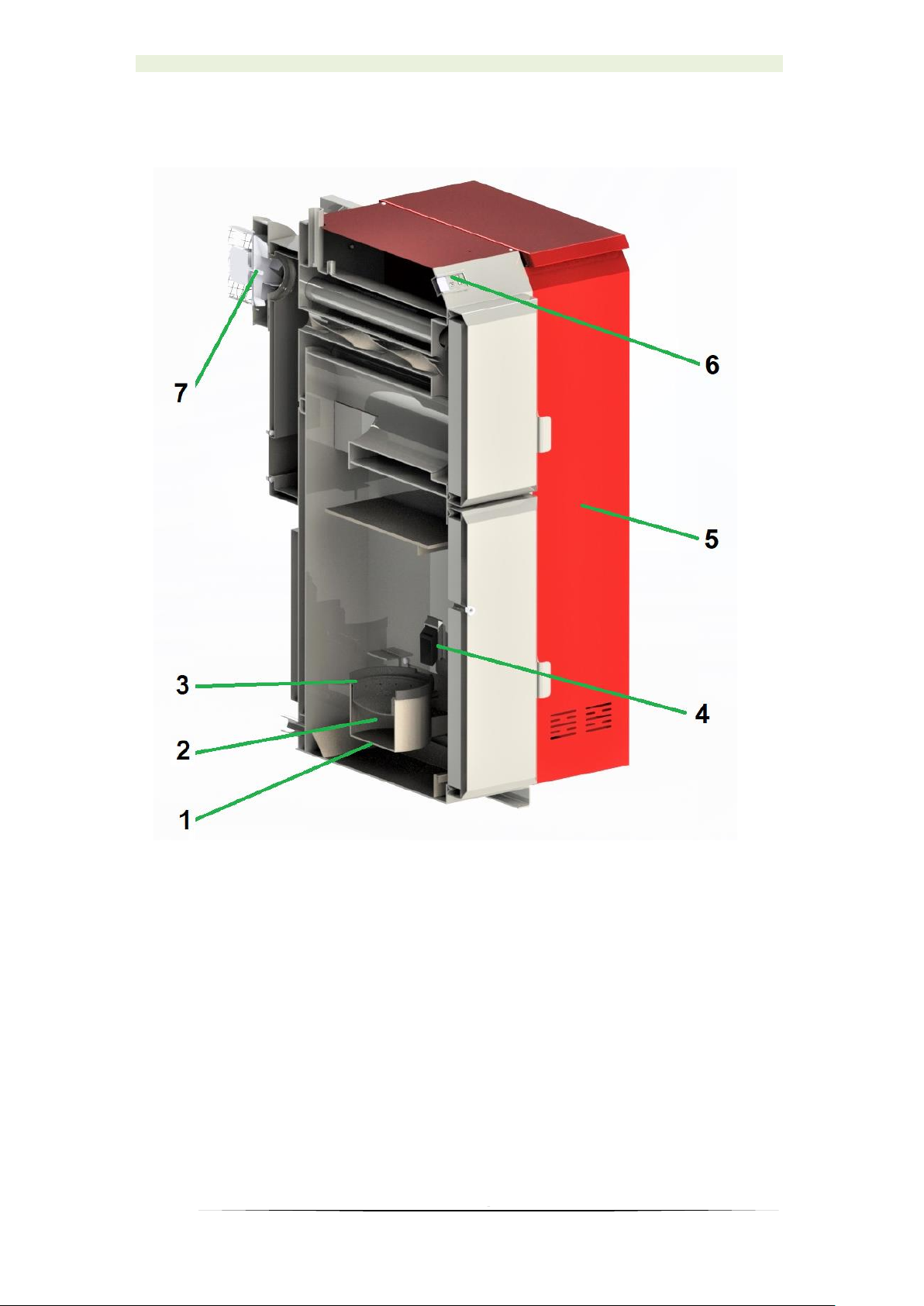

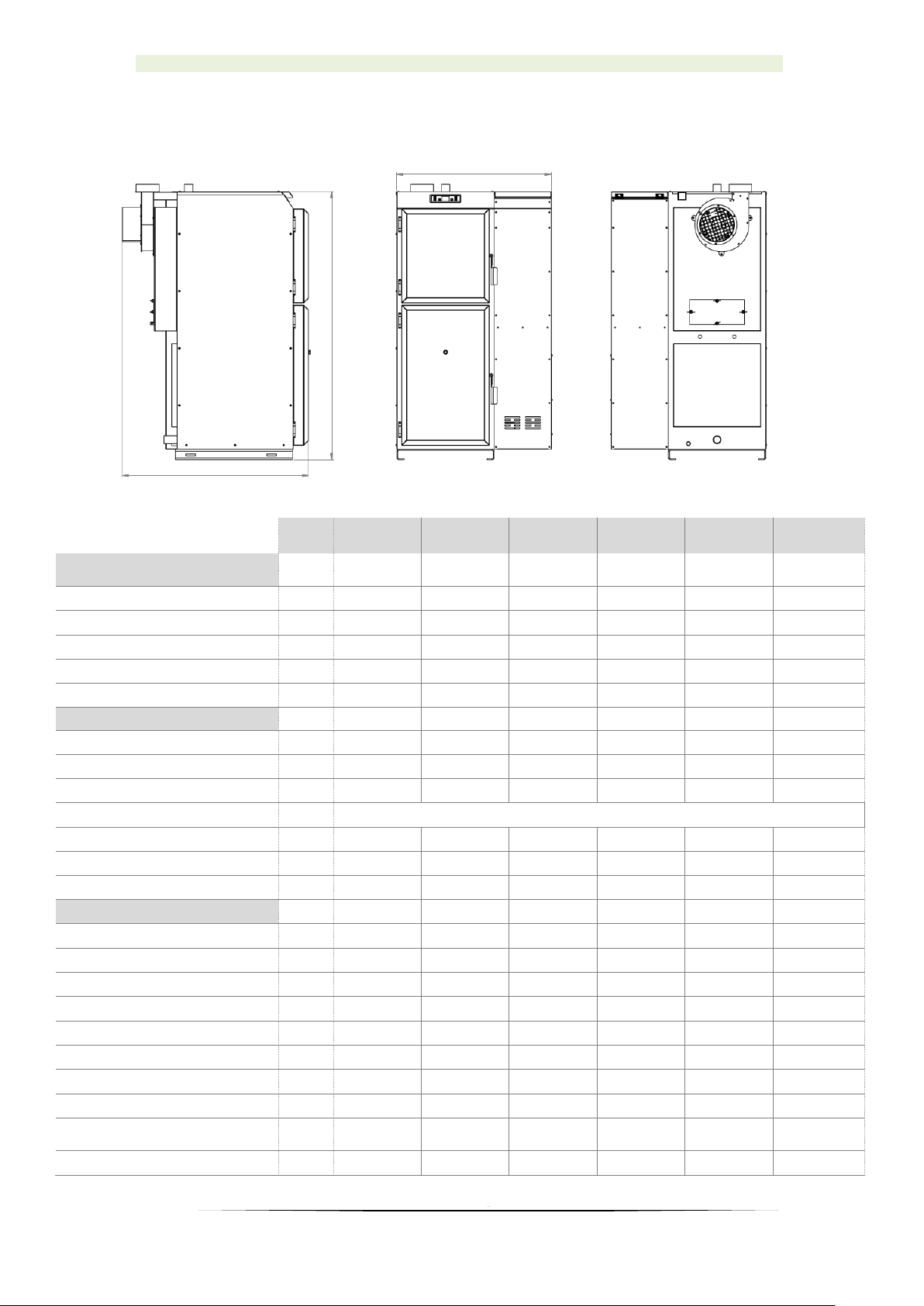

3.2 Pellet boiler PELLING

1. Combustion burner

2. Heater

3. Combustion chamber

4. Dispenser

5. Silo

6. Control unit

7. Exhaust fan

In the Pelling boiler the pellets introduced into the combustion burner 1. They are

automatically ignited with an electric heater 4. Burnt pellet (ash) is collected in the ash

pan 3. which is placed under the combustion burner. The air necessary for combustion

is supplied to the combustion burner.

The boiler power is aligned to the requirements of the cetral heating system.

The usability and efficiency of the boiler is pre-optimized.

PELLING

12

3.3 Technical data

Pelling

18

Pelling

25

Pelling

35

Pelling

50

Pelling

75

Pelling

100

Performance (measured

according to EN 303-5: 2012)

Maximum power

kW

18

25

35

50

75

100

Minimum power

kW 6 8

11,7

16,5

25

33

Power supply

V,Hz

230V,50 Hz

230V, 50 Hz

230V, 50Hz

230V, 50Hz

230V, 50 Hz

230V, 50 Hz

Electrical conection (current)

A 6 6

6

6

6

6

Boiler class

5

5

5

5

5

5

General information

Max. Permited presure

bar

2,5

2,5

2,5

2,5

2,5

2,5

Max. Permited temperature

°C

80

80

80

80

80

80

Min. permited return temperature

°C

50

50

50

50

50

50

Fuel

EN PLUS - UNI EN 14961 - 2 (UNI EN ISO 17225-2) Class A1/A2

Pellet consumption (min/max)

kg/h

1,3/3,9

1,6/5,2

2,3/6,7

3,5/11,1

5,2/16,6

6,5/22,2

Pellet storage capacity

kg

75

75/135

95/151

110/185

270

290

Minimal fresh air opening

cm

30x15

30x15

30x15

30x15

30x15

30x15

Technical data

Boiler width

mm

410

410

510

510

560

650

Boiler width with pellet storage

mm

710

710/910

810/1010

810/1010

1060

1150

Height

mm

1245

1245

1385

1385

1670

1650

Depth

mm

798

948

948

1098

1240

1240

Water content

l

48

60

90

120

154

181

Weight

kg

197

267

348

392

494

580

Height out/return

mm

1280/88

1280/88

1415/85

1415/85

1568/70

1532/75

Minimal chimney underpresure

Pa 5 5

5

5

5

5

Flue gas pipe height

(direction UP)

mm

1420

1420

1440

1440

1598

1630

Flue gas pipe diameter

Ø

120

120

120

120

150

150

*minimal power-30% maximum power

PELLING

13

4 Function of boiler

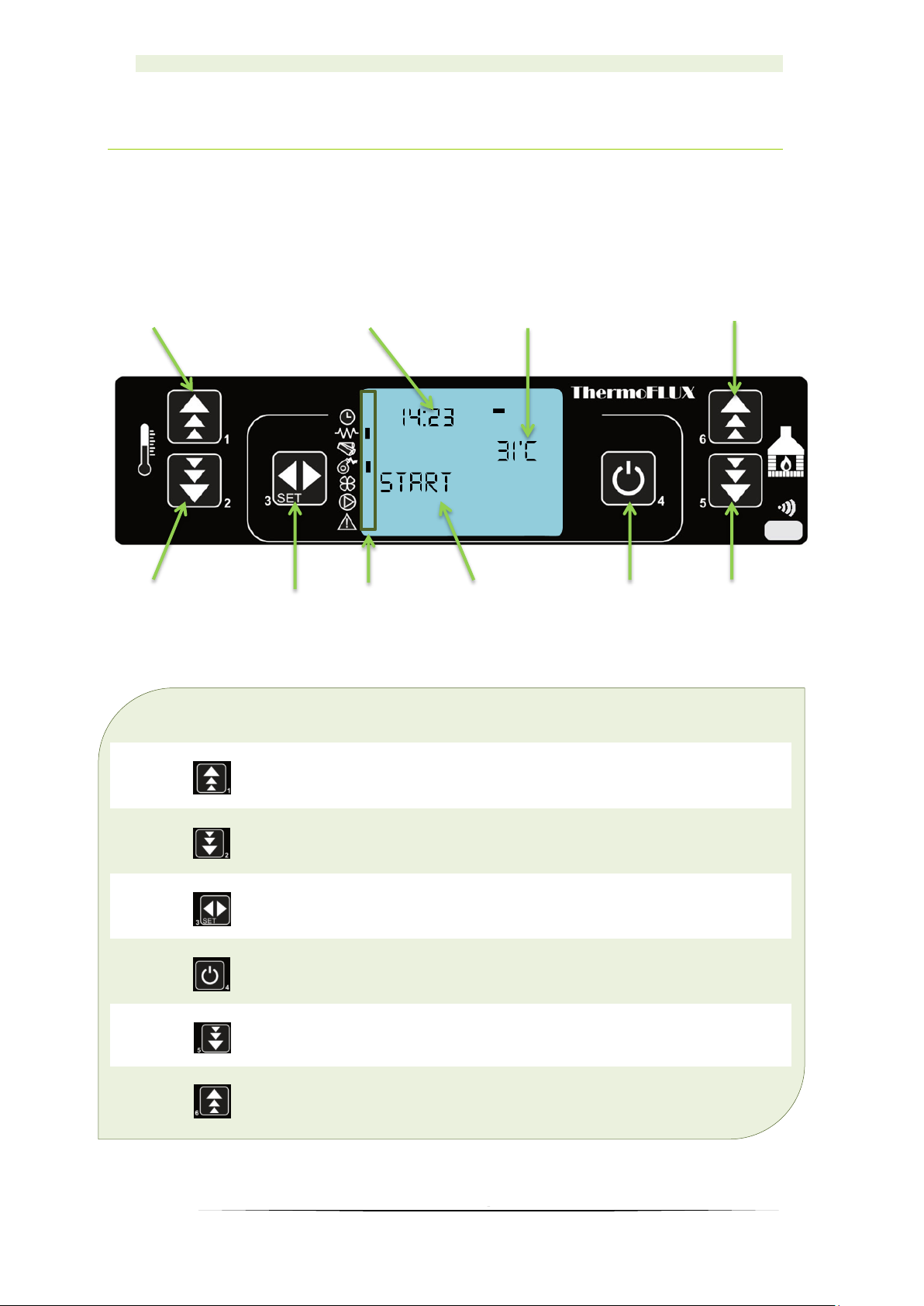

4.1 Overview of the controls and display

and their basic functions

Button

Description

1 -

Increasing temperature and program functions

(adjusting days, time...)

2 -

Decreasing temperature and program functions

(adjusting days, time...)

3 -

Changing – accepting program

4 -

ON / OFF, program exit

5 -

Decreasing power, navigate through the menu

6 -

Increasing power navigate through the menu

1

23 4 5 6 7 8 910

PELLING

14

Display

8

Info

9

Clock

10

Water temperature indicator

Regulation on the boilers ''Pelling'' is most important electronic component. It is

consisted of key controling modul set under the cover of the boiler and controling unit

with display set on the front side of the boiler. With controling unit it is possible to

control functions of the boiler and also to check information about present state of the

boiler.

Due to the possibilty to work in 5 (five) different powers, regulation can satisfy needs

to increase or decrease heating by automatic adjustment of power.

If there is a need to increase power, this is registered by regulation and regulation

gives a signal to increase power by adding more pellet as well as proportional increase

of air flow in the burning basket.

When desired temperature is reached (need for heating energy is satisfied) regulation

is decreasing power ( modulates ), or when room thermostat gives signal that set

temperature is reached, boiler then goes into shut down (if mode STAND-BY is ON).

7

When mark is visible

Clock

programmed ignit. active

Heater

heater active

Pelet dosage

auger active

Smoke fan

fan active

Primary air fan

fan active

Circulating pump

pump active

Alarm

alarm active

7

PELLING

15

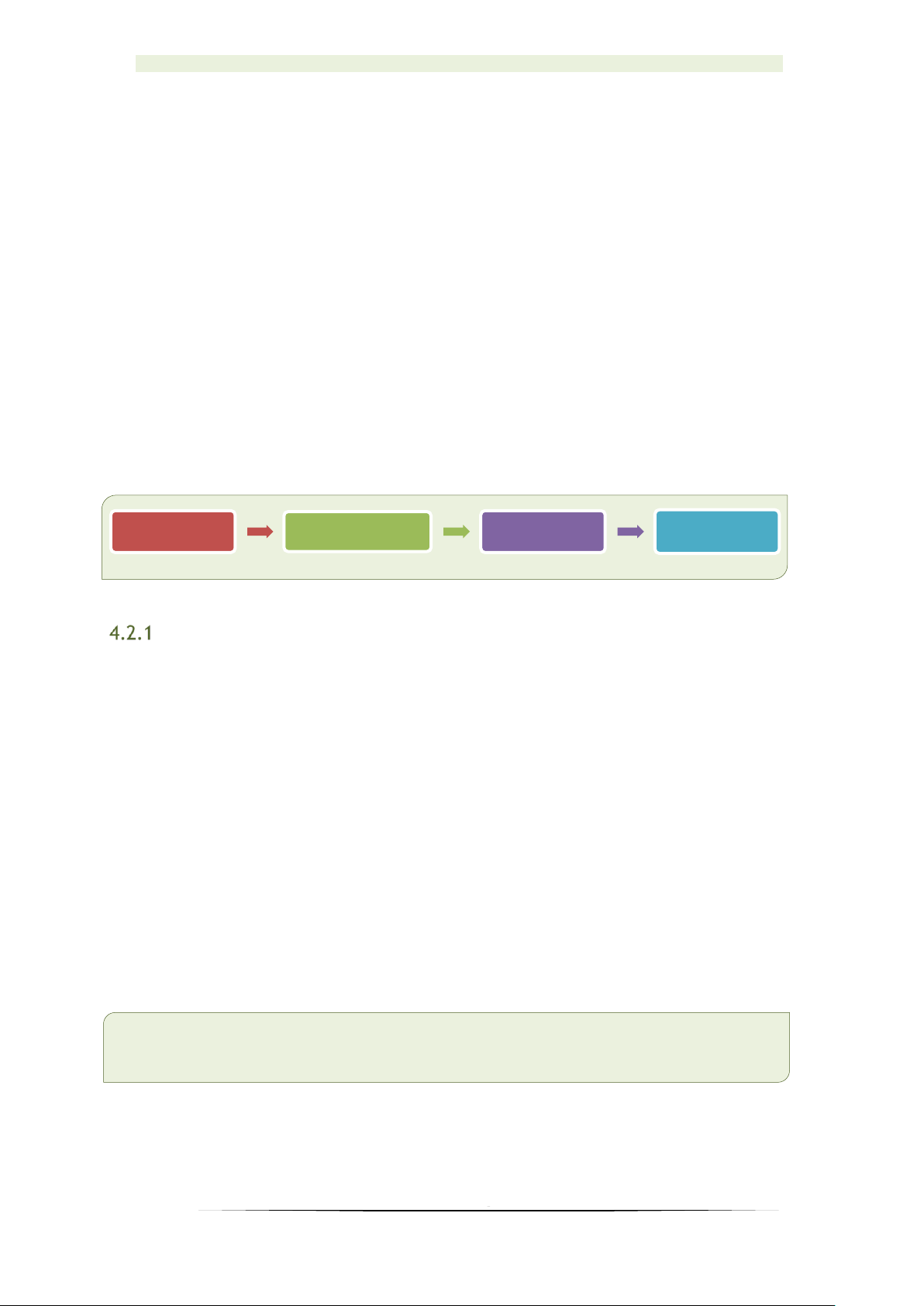

4.2 Principle of boiler operation

Principle of the boiler operation is very simple.

When button for start is pressed boiler goes into IGNITION MODE. START is

displayed, and after that PELLET IGNITION. Usually this phase lasts for 5-15 minutes

depending on type of the boiler and pellet quality. At that point dosing system is

activated, igniter and suction fan. Dispenser is making initial dosing of pellet into

burning basket. At the same point igniter starts to ignite pellet and suction fan is on

and is making necessary underpressure needed for combustion. When temperature

sensor for flue gasses detects that temperature in the chimney has reached necessary

value, regulation then changes working mode of the boiler into FLAME

STABILIZATION.

This phase (FLAME STABILIZATION) lasts for 2-3 minutes (depending on the type

of the boiler) and in this phase igniter goes off. After flame stabilization, boiler goes

into the normal working mode and changes power from power 1 to set power. On

display is written WORK. On the right side set power is displayed and in the last

How to loc k the Display

Press the SET button (key 3) and select from the menu:

M-8 TECHNICAL SETTINGS.

With the (up) arrow (key 1) go to A9 (A9 is found when it exceeds 99). Press

SET, and then go with the (down) arrow (key 5) and select:

M-8-4 GENERAL SETTINGS.

Then, with the (down) arrow select:

M-8-4-10 FROZEN KEYBOARD.

Turn ON and confirm with SET.

Return to the main menu by pressing ON/OFF (key 4).

We lock and unlock the display as follows:

Press the SET button (key 3) and then the ON/OFF button (key 4).

Start

PELLET IGN.

Flame

stabilization

WORK

Loading...

Loading...