TECHNICAL PASSPORT INSTALLATION and OPERATION MANUAL

Pellet burning boiler BioFlux series

EN

TECHNISCHES DATENBLATT MONTAGE- und BEDIENUNGSANLEITUNG

Pelletkessel Serie BioFlux

MANUEL TECHNIQUE INSTRUCTIONS pour L’INSTALLATION et L’EXPLOITATION

Chaudière à granulés de bois série BioFlux

DE

FR

model:

serial number:

Version p0.8.1

TECHNICAL PASSPORT INSTALLATION and OPERATION MANUAL

Table of contents

1. EXPLANATION OF SYMBOLS AND SAFETY INSTRUCTIONS ..................................................................... 3

EN

1.1. Explanation of symbols .......................................................................................................................... 3

1.2. Requirements to boiler installation room .............................................................................................. 3

1.2.1. Instructions to boiler installer ................................................................................................................. 3

1.2.2. Instructions to installation user ............................................................................................................. 3

1.2.3. Minimum clearances for installation. Combustibility of construction materials ................................... 4

2. PRODUCT DESCRIPTION ......................................................................................................................... 4

3. FUELS ..................................................................................................................................................... 6

4. TRANSPORTATION .................................................................................................................................. 7

5. DELIVERY OF THE BOILER ................................................................................................................... 7

6. INSTALLATION OF THE HEATING BOILER ................................................................................................ 8

7. SETUP OF THE HEATING BOILER ............................................................................................................. 8

7.1. Connecng the boiler to a chimney ....................................................................................................... 8

7.2. Pellet boiler connecon to the pellet burner, auger and fuel hopper ................................................... 8

7.3. Connecng the boiler to the mains power supply .................................................................................. 9

7.4. Connecting the boiler to the heating installation ................................................................................... 9

7.5. Connection diagrams ............................................................................................................................ 11

8. FILLING THE HEATING INSTALLATION ................................................................................................ 11

9. OPERATION OF BOILER ...................................................................................................................... 11

10. CONTROLLER UNIT ............................................................................................................................... 14

10.1. Controller view. Explanation of buttons and indicators ....................................................................... 14

10.2. User menu ............................................................................................................................................ 16

11. MOUNTING OF FUEL HOPPER FH 500 .................................................................................................. 17

12. WARRANTY TERMS .............................................................................................................................. 17

13. TECHNICAL FEATURES .......................................................................................................................... 17

13.1. Technical features of PelleBurn pellet boiler ........................................................................................ 17

13.2. Technical parameters of Pell pellet burner ........................................................................................... 18

13.3. Technical features of fuel hoper FH 500 ............................................................................................... 19

14. RECYCLING ............................................................................................................................................ 20

APPENDIX - DIAGRAMS ........................................................................................................................ 59

2

TECHNICAL PASSPORT INSTALLATION and OPERATION MANUAL

1. EXPLANATION OF SYMBOLS AND SAFETY

1.1. Explanation of symbols

CAUTION! - Important recommendation or

warning concerning safety conditions during

installation and operation of boiler.

DANGER! - fault or improper use may cause

injury or be hazardous to life of humans or

animals.

FIRE HAZARD! - fault or improper installation

and operation may cause fire.

INFORMATION – Important information on

the proper operation of the product.

1.2. Requirements to boiler installation room

This manual contains important information for the

safe and correct installation, start-up and troublefree operation and maintenance of the boiler.

The Pellet boiler can be used for heating rooms only

in the manner described in this manual.

The application and any other was the area of

operation is not recommended by the manufacturer

and is not responsible for the occurrence of defects

or failures.

Note the boiler type data on the factory rating label

and the technical data provided in chapter 13 in

order to ensure proper operation of the product.

1.2.1. Instructions to boiler installer

During installation and operation, the country-

specific requirements and regulations must be

observed:

• Local construction regulations on installation,

air supply and exhaust gas extraction as well as

chimney connection.

• Regulations and norms concerning the fitting of the

heating installation with safety devices.

• Required installation of a smoke detector in the

boiler room.

Use only original BURNiT parts

i

WARNING! Installation and setup of the

boiler should be done by an authorized

specialist / service shop and must follow

the safety instructions and rules of

operation.

INSTRUCTIONS

It is mandatory to assure a backup power

generator of corresponding rated power!

(see table 1)

DANGER of intoxication, suffocation.

Inadequate inflow of fresh air to the

boiler room may result in dangerous leak

of exhaust gases during boiler operation.

- Make sure the air inlets and exhaust gas

outlets are not clogged or closed.

- If faults are not remedied immediately, the

!

1.2.2. Instructions to installation user

$

3

boiler must not be operated.

- The user must be provided with written

instructions on the fault and the hazard it

entails.

DANGER of fire when burning flammable

materials or liquids.

- Flammable materials/liquids must not be

left in close proximity of the burner and

heating boiler.

- Instruct system user of the allowed

minimum clearances from surrounding

objects.

Customer must undergo boiler operation/

maintenance training by authorized

installer/service shop.

Table 1.

Electricity consumpon of the boiler

Maximum electrical input 780 W

Electrical input at nominal heat output 80 W

Electrical input at minimum heat output 60 W

DANGER of intoxication or explosion

Toxic gases may be discharged when

burning waste, plastics, liquids.

- Use only the fuels indicated in this manual.

- In case of danger of explosion, ignition or

discharge of exhaust gases in the room,

stop the pellet burner from operation.

CAUTION! Danger of injury / damage of

system due to incompetent operation.

- The boiler must be serviced only by persons

familiar with the operation manual.

- As user, you are only allowed to start the

boiler up, adjust the temperature of the

boiler, shut the boiler down and clean it.

- Unattended children must not be allowed

access to premises with running boiler

inside.

It is mandatory to assure a backup power

generator of corresponding rated power!

(see table 1)

EN

TECHNICAL PASSPORT INSTALLATION and OPERATION MANUAL

Customer must undergo boiler operation/

maintenance training by authorized

installer/service shop.

EN

- Operate the pellet burner on recommended fuel

only, and to that end you must regularly inspect the

boiler room.

- Do not use flammable liquids for ignition or increase

of burner output.

- Clean the burner surface using non-flammable

agents only.

- Do not place flammable objects onto the burner

housing and heating boiler cabinet or in their

proximity. (see diagram 1 for the minimum

clearances)

- Do not store flammable materials in the boiler room.

- It is mandatory to strictly observe instructions for

connecting the burner to power network as well as

to all peripherals.

- Structural changes to Dual-chamber boiler by user

can cause damage to equipment or injury.

- Do not allow contact transmission of electrical wire

or touch any part of the boiler, where the surface

temperature can exceed 70°C.

- This manual should be kept throughout the lifetime

of the boiler.

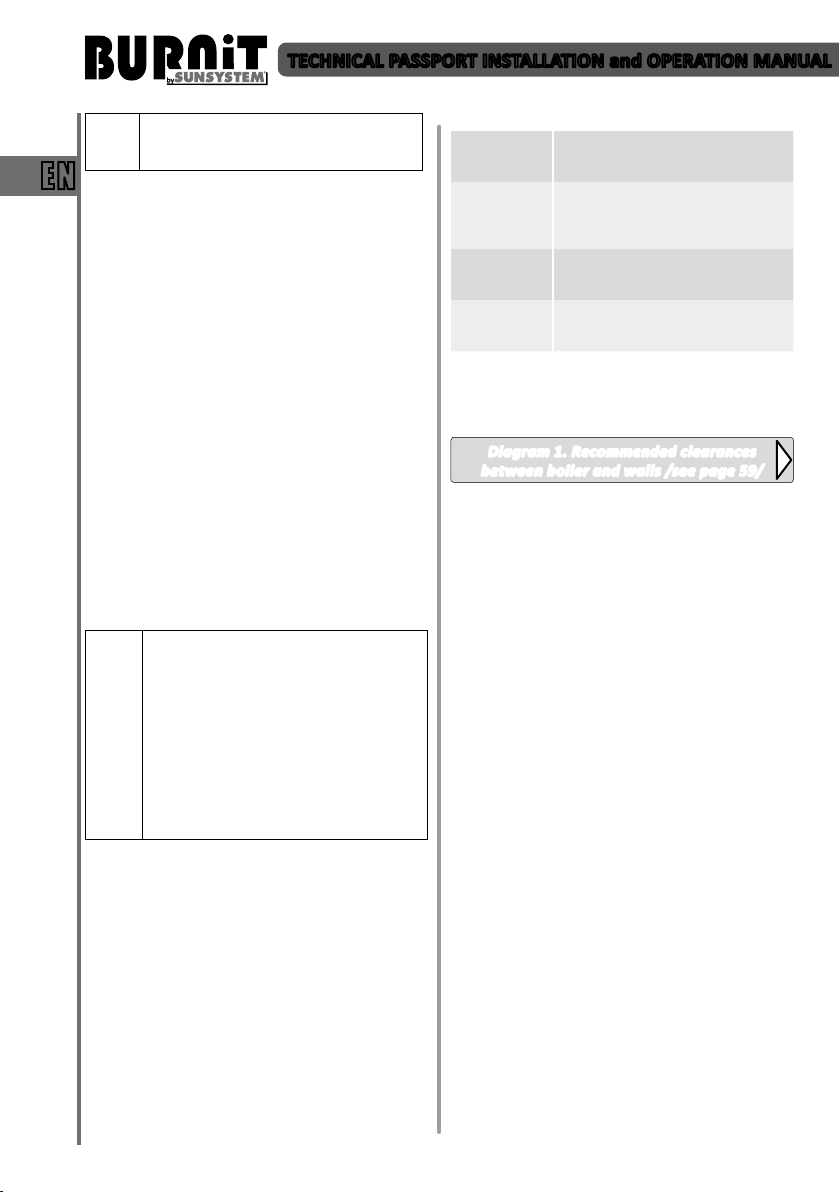

1.2.3. Minimum clearances for installation and

flammability of construction materials

The applicable minimum clearances in your country

may differ from the ones specified below. Please,

consult your installer.

The minimum distance from the burner, heating

boiler or exhaust gas pipe to objects or walls must be

at least 200 mm.

Safety rules for user operation:

CAUTION! Hot surface!

Risk of burns if you touch the running

system. Burner housing, body and flange

are hot surfaces during burner operation.

It is strictly prohibited to open boiler

inspection doors with the burner running.

The hopper hatch cover is not allowed to

remain open for longer periods of time.

Also, exercise caution when touching the

observation port for monitoring the burning

process. It may be hot.

Table 2. Flammability of construction materials

Class А – non-

flammable

Class B – hardly

flammable

Class С1/

С2 – Medium

flammable

Class C3 – easy

flammable

For general safety considerations, we recommend

that the boiler be placed on a foundation made of

class A material, see table 2.

Diagram 1. Recommended clearances

between boiler and walls /see page 59/

Ecological and highly-efficient pellet boiler PelleBurn

is designed for firing wood pellets. The mantle fully

covers the combustion chamber. Efficiency rate

reaching 91%. Approved in accordance with EN 3035, class 5. Set includes pellet boiler, pellet burner,

auger and pellet fuel hopper (option).

2.1. Design structure of boiler PelleBurn.

Cylindrical body design is made of high-quality

boiler steel sheets with thickness of 4 mm for the

combustion chamber and 3 mm for the water mantle.

• Ecological. A high-end pellet boiler. The wood

pellets used for fueling the boiler are a renewable

fuel with minimum carbon emissions and ultimate

burning efficiency.

• Automated. Owing to an improved algorithm

with optional adjustment of a wide variety of

parameters, the system may befinely tuned to

any particular heating system to achieve optimum

efficiencyand fuel consumption.

1) fully automated ignion and pellet feed;

2) exhaust fan ensures stable operaon of the

boiler;

3) boiler-and-burner self-cleaning funcon;

4) controls the operaon of central heang

circulaon pump;

5) controls the operaon of DHW (domesc hot

water) pump;

6) controls by room thermostat;

7) ue gas sensor

4

Stone, bricks, ceramic tiles, baked

clay, solutions, plaster free of

organic additives.

Gypsum board panels, basalt fiber

needled felt, fiberglass board,

AKUMIN, Izomin, Rajolit, Lignos,

Velox, Heraklit.

Wood beech, oak. Wood softwood,

layered wood

Asphalt, cardboard, cellulose, tar,

fiberboard, cork, polyurethane,

polyethylene.

2. PRODUCT DESCRIPTION

Controller functions:

TECHNICAL PASSPORT INSTALLATION and OPERATION MANUAL

• Efficient. To keep from losing heat into the

ambience, the boiler is insulated on the outside

by 100 mm high-temperature wool. With its

state-of-the-art combustion control system

and cylindrical body design construction the

PelleBurn boiler achieves efficiency rate of as

much as 91%.

2.2. Design of pellet burner Pell

The burner is made of high-quality stainless steel

able to withstand temperatures of up to 1150°С. The

burner must be installed on a heating boiler.

The burner consists of two parts: combustion

chamber tube and external tube with sheet metal

mantle. Longitudinally, under the housing, there are

blow chamber, fuel ignition heater, fan and power

supply. On the upper part of the burner there is a

feeder chute to which the pellet auger is attached. The

combustion chamber consists of two tubes:

Ember resistant steel tube inside the burner with

holes for air intake along its entire length, opening

for the hot air from the fuel ignition heater, opening

for photosensor.

Outer stainless steel tube. Between the two tubes

there is a gap which provides for free circulation of

the air necessary both for cooling and oxygen supply

into the combustion chamber.

The feeder chute allows 360° rotation for its best

convenient positioning when connecting the pellet

auger to the hopper.

Diagram 2. Design of Pellet Burner Pell

/see page 59/

Other elements of the burner are

• Internal auger.

• Dry contactless resistance heater assuring ignion

of fuel.

• Pneumac cleaning system of the combuson

chamber.

• Feed fan, smooth regulaon (0% to 100 %).

• Telescopic pull-out system of burner Pell for easy

maintenance.

2.3. Safety devices of pellet boiler-and-burner

A complex of safety devices provide for the safety of

the appliance. Air-feed fan, step –regulated, controls

the combustion according to energy needs and is

maintained in optimal working order. Independent

STB thermostat shut-off the burner and shut off the

air feeding in the combustion chamber in case of

rising boiler temperature.

• Elbow-shape feeder chute. The geometrical shape

of burner feeder chute prevents backfire entry

from burner into pellet hopper. The flexible tube is

melted at a temperature above 80°C. Thus prevent

access to the hopper of the fire.

• Thermostatic protection (80°С). The thermostatic

protection is fitted on the feeder chute. When

the surface of the feeder chute reaches 80°С, the

control stops the feeding of pellets into the burner

and signals for fault (BB Alarm).

• Fuse. In case of electrical fault in the system of the

burner (short circuit, current overload, etc.), the

overload is borne by the electrical fuse fitted on the

main control panel of the burner (10 А).

• Power interruption. Innovative controller. In case

of power interruption, all parameter settings are

stored in the memory of the controller. Upon the

subsequent restart of the burner, the controller

resumes the execution of the program from the

point when the power interruption occurred.

2.4. Design of pellet auger

The auger transports pellets from fuel hopper to

burner. Auger elements are: auger pipe, auger hose,

motor, conveyor belt for moving the pellets.

D i a g ram 3 . D es ig n of pellet auger

/see page 59/

2.5. Design of fuel hopper FH 500

Pellet hopper, designated to serve biomass

pellet-fired boilers. Pellet hopper design allowing

installation by choice on either side of boiler.

Made of cold-rolled steel sheets with PVC coating.

Comfortable pellet charging hatch. Pellets inside

hopper are fed into auger in order of reception.

Precision leveling of hopper possible via screw-in legs.

Elevated foundation with drain holes and container

for separation and removal of pellet powder.

The hopper capacity is determined using as

calculation base the daily or weekly fuel consumption

rate of burner. The pellet hopper usable volume of

500 litters allows charging of 280-300 kg of pellets

with diameter 6 mm, and top-up/refill once a week

(for burner of rated power up to 40 kW).

Diagram 4. Design of fuel hopper FH 500

/see page 59/

5

EN

TECHNICAL PASSPORT INSTALLATION and OPERATION MANUAL

All pellets are biomass manufactured from common

3. FUEL

low-growing plants and trees. The most common

household type pellets are made of sawdust and

EN

milled wood chippings which are waste material

from wood used in the production of logs, furniture

and other products. Wood is the richest raw material

which does not have any impact on the production

costs of food products or ethyl alcohol (ethanol).

The raw material is processed under high-pressure

and temperature and is pressed to produce smallsize cylindrical pellets. The production process may

utilize soft wood material (such as softwood, pine),

hardwood (oak) as well as recycled waste wood.

Wood pellets are produced in hammer mills or wood

pellet plants.

Advantages of wood pellets:

Convenient storage.

Pellet bags can be stored on a small area in a dry

garage, basement, service room or shed.

Easy loading.

In most cases the boiler hopper needs loading only

once a week – this depends on the hopper capacity.

Better control of fuel quantity.

The small size of the pellets allows for precise fuel

feeding. On the other hand, the supply of air for

reaching optimal combustion efficiency is easier

to adjust since the fuel quantity in the combustion

chamber remains constant and predictable.

Fuel efficiency.

by consistently low moister content of pellets

(consistently under 10% as opposed to 20% to 60%

moisture content of the logs). Low moisture content,

controlled fuel portions and precise air setting means

high combustion efficiency and very low carbon

oxides in the flue gases.

When purchasing pellets, ask for

conformity declaration and certificate

issued by an accredited laboratory

and make sure the fuel meets the

requirements indicated in the manual.

If you purchase large amount of pellets

i

(bulk supply for the entire heating season

for example), ask your supplier to provide

accurate and true information about the

storage conditions.

We recommend to use pellet with size of 6 - 8 mm.

Density 600 - 750 kg/m3 heating value 4.7-5.5 kWh/

kg. Ash content – less than 1% and moisture content

up to 8%., EN 14961-2:2011.

The optimal density of the pellets which guarantees

their quality is 605-700 kg per cubic meter.

Pellet moisture content must not exceed 10%. Make

sure you store your fuel in a dry and well-ventilated

place.

The optimal pellet ash content is ≤ 1%. This also

provides for less frequent cleaning intervals for the

burner.

The table below contains the parameters which we

recommend that you take into consideration when

choosing fuel for your Pell burner.

High combustion efficiency is also determined

Table 3. European Certification of Wood Pellets for Heating Purposes

Parameters Units ENplus-A1 ENplus-A2 EN-B

Diameter mm

6 (± 1)

8 (± 1)

Length mm 15 ≤ L ≤ 40

Bulk density kg / m

2

≥ 600 ≥ 600 ≥ 600

1)

6 (± 1)

8 (± 1)

15 ≤ L ≤ 40

1)

Caloric/heang value MJ / kg ≥ 16,5-19 ≥ 16,3-19 ≥ 16,0-19

Humidity /moisture Ма .-% ≤ 10 ≤ 10 ≤ 10

Dust Ма .-% ≤ 1

Mechanical durability Ма .-% ≥ 97,5

Ash Ма .-%

2)

≤ 0,7 ≤ 1,5 ≤ 3,5

3)

4)

≤ 1

≥ 97,5

3)

4)

Melng point of ash °C ≥ 1200 ≥ 1100 Chlorine content Ма .-%

Sulfur content Ма .-%

Nitrogen content Ма .-%

Copper content mg / kg

2)

2)

2)

2)

≤ 0,02 ≤ 0,02 ≤ 0,03

≤ 0,03 ≤ 0,03 ≤ 0,04

≤ 0,3 ≤ 0,3 ≤ 1,0

≤ 10 ≤ 10 ≤ 10

6 (± 1)

8 (± 1)

15 ≤ L ≤ 40

3)

≤ 1

≥ 96,5

1)

4)

6

TECHNICAL PASSPORT INSTALLATION and OPERATION MANUAL

Chromium content mg / kg

Arsenic content mg / kg

Cadmium content mg / kg

Mercury content mg / kg

Lead content mg / kg

Nickel content mg / kg

Zinc content mg / kg

1)

not more than 1% of the pellets may be longer than 40 mm, max. length 45 mm;

2)

dry weight;

3)

particles <3.15 mm, particulate matter, before handing over the goods;

4)

measurements with Ligno-Tester limit value ≥ 97,7% by weight.

4. TRANSPORTATION OF THE BOILER

We recommend to transport the heating boiler to the

installation site in its packaging placed on the pallet.

During transport and installation, depending on the

weight, suitable safety devices should be used in

accordance with Directive 2006/42/EC.

When transporting items weighing more than 30 kg,

the use of pallet jack, fork truck or other hoisting

devices is a must.

Product must be in original packaging following

2)

2)

2)

2)

2)

2)

2)

≤ 10 ≤ 10 ≤ 10

≤ 1,0 ≤ 1,0 ≤ 1,0

≤ 0,5 ≤ 0,5 ≤ 0,5

≤ 0,1 ≤ 0,1 ≤ 0,1

≤ 10 ≤ 10 ≤ 10

≤ 10 ≤ 10 ≤ 10

≤ 100 ≤ 100 ≤ 100

motor drive (noise, friction) or failure of high-tech

elements such as broken controller-screen, contact

your nearest authorized service center for repairs

and maintenance.

The boiler is securely fastened with fasteners to a

wooden pallet.

Important: When installing the boiler, the

wooden pallet onto which the boiler is

placed must be removed by unscrewing

the bolted connections using flat ring

wrench S13.

the instructions on the label - to be protected from

adverse weather conditions (snow, rain and dust)

from the shocks, and other activities likely to cause

Diagram 5. Indications dimensions /see

page 59/

damage. In case of malfunction of the fan or the

Table 4. Overall dimensions of Set Pellet boiler PelleBurn, Pellet burner Pell and Fuel Hopper FH 500

PelleBurn 15 25 40

A1, mm

A2, mm

A3, mm

B1, mm

B2, mm

B3, mm

C, mm

D1, mm

D2, mm

D3, mm

Weight, kg

Pellet boiler, burner and pallet

Auger, box

Fuel Hopper, box

Pellet boiler, burner and pallet

Auger, box

Fuel Hopper, box

Pellet boiler, burner and pallet

Pellet boiler, burner and pallet

Auger, box

Fuel Hopper, box

Pellet boiler, burner and pallet

Auger, box

Fuel Hopper, box

710 710 810

120 120 120

840 840 840

1100 1100 1320

260 260 260

810 810 810

125 125 125

1430 1630 1775

1700 1700 1700

1220 1220 1220

185 200 325

8 8 8

48 48 48

EN

5. DELIVERY OF THE BOILER

• Inspect the integrity of the packaging upon

delivery.

• Check whether all components have been

delivered to you.

Boiler consignment package includes:

1) Pellet boiler PelleBurn with pellet burner Pell

2) Auger

3) Fuel hopper FH 500 (opon)

4) Safety valve 3 bar.

5) Fire irons

6) Technical passport. Installaon and operaon

manual

7) Service booklet and Warranty card

If any of the above items are missing, contact your

supplier.

7

TECHNICAL PASSPORT INSTALLATION and OPERATION MANUAL

6. INSTALLATION OF THE HEATING BOILER

The assembly, installation and set-up of the

EN

boiler must be performed by a technician

authorized for such operations.

Installer must indicate to the user of the

installation the minimum clearances from

flammable materials and liquids.

Requirements:

- Boiler room must be frost-proof;

- Boiler room must allow for continuous access of air

necessary to maintain combustion;

- Boilers must not be placed in inhabitable rooms;

- All boiler rooms must have correctly calculated vent

depending on the boiler output. The vent must be

protected by means of a net or grate.

The size of the vent is calculated according to the

formula:

А=6,02*Q - where:

А – area of the vent in cm2,

Q – boiler output in kW

- Remove the packaging without polluting the

environment;

- Observe building supervision instructions, in

particular the existing Ordinance on combustion

devices and storage of combustion materials, on

building requirements applicable to installation sites

and on ventilation;

- The boiler must be placed on a foundation whose

surface area is larger than the base of the heating

boiler according to diagram 1;

- The boiler must be placed in a position which allows

for the easiest possible cleaning and servicing;

- Installation must be carried out according to

installation diagram 1 which shows the boiler

housing;

- No objects made of flammable materials or liquids

may be placed on/near the boiler;

7. SETUP OF THE HEATING BOILER

7.1. Connecng the boiler to a chimney

Boiler-to-chimney connecon must always comply

with the exisng standards and rules. The chimney

must provide sucient draught for evacuaon of the

smoke under any condions.

The proper funconing of the chimney requires

adequate sizing of the chimney itself since the

draught it produces aects combuson, boiler’s

output and life span.

The draught created by the chimney is in funconal

relaon to its cross-secon, height and the roughness

of its interior walls. No other appliance may be

connected to the chimney serving the boiler. Chimney

diameter must not be smaller than the ue outlet

of the boiler. Flue outlet must be connected to the

chimney opening. In terms of mechanical properes,

the ue outlet must be sturdy and properly sealed (to

avoid gas leak) and allow for easy access for cleaning

on the inside. The inner secon of the ue outlet

must not be greater than the eecve secon of the

chimney and must not narrow. Avoid using elbow

joints.

The chimney cleaning opening has to be in its lowest

part. The chimney’s wall has to be three plied where

the medium layer is from mineral wool. The thickness

of the insulaon is not less than 30 mm when the

chimney is seng up inside the house and the

thickness is 50 mm, when the seng up is outside.

Please entrust choosing a chimney and its installaon

by a qualied professional. The required distance

between the boiler and the chimney is 300-600 mm.

Draught regulator (1) must be installed at least 600

mm from the joint (connecon).

Diagram 5.1. Boiler size and chimney

parameters /see page 60/

Table 5. Recommended minimum sizes and chimney

Boiler

output

15 kW Ø 130 10-20

25 kW Ø 130 10-20

40 kW Ø 150 10-20

Data in the tables are for indicative

purposes.

Draught depends on the diameter, height,

uneven sections along the chimney

surface and differences in temperature of

i

combustion products and outside air. We

recommend that you use chimney fitted

with flue terminal. Heating specialist must

calculate the precise sizing of the chimney.

7.2. Pellet boiler connecon to the pellet burner,

auger and fuel hopper

- Take the auger hose (from the auger set). Using a

bracket, clamp one end of the hose onto the motorend outlet of the pellet auger.

- Using a bracket, clamp other end onto the feeding

chute of burner

- Remember pellet auger must be installed at 45°

angle to the ground horizontal surface.

- Fill the hopper with fuel (see table 2 for parameters

of the fuel types used)

8

dra

Chimney

diameter, mm

Chimney

dra, Pа

TECHNICAL PASSPORT INSTALLATION and OPERATION MANUAL

- Plug the power cord of the pellet auger into the

indicated Schuko-type boiler socket on the le side

of the boiler housing.

Diagram 6. Pellet burner Pell and Fuel

Hopper FH connected to Pellet boiler

PelleBurn /see page 60/

1. Pellet boiler PelleBurn;

2. Pellet burner Pell;

3. Auger hose;

4. Auger;

5. Fuel Hopper FH.

7.3. Connecng the boiler to the mains power

supply

Such connecon must be performed by a

technician / service shop authorized for

such operaons.

Cauon! ELECTRIC SHOCK HAZARD!

- Before opening the unit: switch o the

voltage and secure the unit against

accidental restart.

- Observeinstallaoninstrucons.

Improper cable connecons may damage

the regulator!

The device may be damaged if struck by

a lightning. Make sure it is unplugged

during the storms.

It is mandatory to assure a backup power

generator of corresponding rated power!

(see table 1)

Legend /Diagrams 7 and 8/

To bring into exploitaon the boiler and auger must

be connected to the electricity network 220V/50Hz

with power cord. Create ght connecon with

the electrical mains which complies with the local

regulaons.

Diagram 7. Wiring diagram of connecon

of boiler elements to the controller

/see page 61/

Diagram 8. Wiring diagram of connecon

of burner elements to the controller

and connecng socket /see page 62-63/

7.4. Connecng the boiler to the heang

installaon.

Such connecon must be performed by a

technician / service shop authorized for

such operaons.

When the boiler is connected to a heang system,

it is mandatory to install a 3 bar relief valve and

expansion vessel. No shut-o ngs may be installed

between the relief valve, expansion vessel and boiler.

It is mandatory to install a three-way valve

(Laddomat or similar) or a four-way mixing

valve which to ensure that the temperature

of the heang medium fed into the boiler

from the heang installaon is at least

65°С.

Elements INPUTS Symbol

Room thermostat I02 RT

Boiler sensor I03 B

STB termostat of the burner I04 RB

Sensor water heater I05 WH

Sensor exhaust I06 PT

Temperature sensor at the top of the buffer I08 AT

Temperature sensor at the bottom of the buffer I17 NA1

EN

Elements OUTPUTS Symbol

Fan smoke gases О 01 FSG

Ignitor О 03 IGN

Fan cleaning of the burner О 04 FC

Screw fuel О 05 SF

Screw burner О 06 SB

Pump heang О 07 PH

Pump water heater О 08 PHW

Electric motor of self-cleaning system О 10 CS

Electric motor of clean ash О 11 CA

9

TECHNICAL PASSPORT INSTALLATION and OPERATION MANUAL

Table 6. TROUBLE-SHOOTING TABLE

Cause Solution

EN

Duetounsealedconnecons Installtheconnecngpipingstrain-freetotheboilerconnecons.

Due to freezing

Boiler water too hot, heang bodies too cold

1. Hydraulic resistance is too high.

2. Air in the system

3.Inoperablecirculaonpump

The STB safety thermostat has been

triggered.

Unable to reach normal temperature mode of 65°-85° С

Inadequate sizing and/or

combinaonofheangappliances

Ejecon of unburned pellets into the combuson chamber of the boiler

Poor adjustment of the fuel-to-air

raofromtheburnercontroller

Ulizaonoflow-qualitypellets

Formaon of clinkers and noncombusble inclusions inside burner body

Ulizaonoflow-quality pellets(see

secon3.Fuel)

Low performance of the automac

cleaning system

Impropersengoffuel-airmixture Adjust using gas analyzer

Poor chimney draught or high

internal resistance of the boiler

combusonchamber

Blockage of burner combuson

chamber due to build-up of

noncombusblematerials

Impropersengoffuel-airmixture Adjust using gas analyzer

Dust on the photosensor It is necessary to clean the photosensor. Refer to the manual for the

Boiler temperature too high. Controller failure.

Gridpoweructuaons

Power failure

High temperature of exhaust gases.

High temperature alarm is turning

on

High temperature in boiler water

jacket and low temperature in the

buertank.

Installaon damage

Ifthe heang installaon,including thepipingnetwork, hasnotbeen

built frost-proof,we recommend that you llthe heanginstallaon

withaliquidwhichhaslowfreezingpointandcorrosionproteconand

anfreezeagent.

Make sure the circulaon pump has been properly selected and the

heanginstallaonisoftheproperdimensions.(Youmustcontactyour

installer.)

Uponreachingatemperatureof95°С,thethermostacsafetyprotecon

device is triggered and the fan is turned o. To resume protecon,

remove the black cap on the front panel of the boiler and press the

buonon theSTB-thermostat.Contactyourinstallertodeterminethe

causeofprotecontriggering.

Low boiler temperature.

Immediately consult your installer about the problem.

Contactyour installer.It is necessarytoset the burnerproperlyusing

gas analyzer

Use only fuelwhichmeetstherequirementsspecied in the manual.

(seesecon3.Fuel)

Useonlyfuelwhichmeetstherequirementsspeciedinthemanual.

Increaseturn-onfrequencyoftheautomaccleaningsystem.

Smoke in the pellet hopper

Immediately consult your installer about the problem.

Itisnecessarytocleantheburnercombusonchamberusingbrush

cleaning procedure.

It is mandatory to assure a backup power generator of corresponding

ratedpower!(seetable1)

Fume exhaust tubes of boiler water jacket are clogged with soot.

Reduced heat transfer. The boiler should be cleaned. Please contact an

authorized specialist / service shop to clean the boiler.

1.IncorrectON/OFFtemperaturesengsofpumps.

2.Incorrectsizingofheangsystem.

10

TECHNICAL PASSPORT INSTALLATION and OPERATION MANUAL

7.5. Connection diagrams

Such connecons must be performed by

a technician / service shop authorized for

such operaons.

Diagram 9. Connecon of boiler PelleBurn to three-way valve/see page 64/

Diagram 10. Connecon of boiler PelleBurn to P type buer tank

Diagram 11. Connecon of boiler PelleBurn to combi tank KSC2,

at plate solar collector PK and three-way valve/see page 65/

Diagram 12. Connecon of boiler PelleBurn to solar tank SON, buer thank P,

at plate solar collector PK and three-way valve /see page 65/

Problem Prevenon

Possible installaon damage due

to strains in the material caused by

temperature dierences

Danger of installaon damage due to

accumulaon of deposits

Condensate formaon and tar deposits

may shorten boiler’s operaonal life.

and three-way valve /see page 64/

8. FILLING THE HEATING INSTALLATION

Table 6

Fill the heang installaon only in cold condions (inlet

temperature must not exceed 40°C).

- Do not operate the heang boiler for a long period of me in

paral load mode

- The temperature at the boiler inlet must not be less than 65°C,

boiler water temperature must be between 80°C and 85°C.

- Use the boiler for a short period to heat warm water in the

summer.

EN

9. OPERATION OF BOILER

Failure to observe the installation and

operating requirements described in the

manual and the service booklet voids the

warranty.

9.1. Operaon of pellet boiler PelleBurn with pellet

burner Pell

Ignion. Aer starng the burner up from the

control panel, the main pellet auger conveys certain

amount of fuel from the pellet hopper to the burner.

This specic amount of pellets is set by the installer

and depends on the fuel characteriscs. The fedin quanty of pellets is conveyed from the auger

conveyor built in the burner to the combuson

chamber where it is being ignited using hot air.

Burning. The burning process takes place in the

combuson chamber and, aer it has been fed into

the combuson chamber, the fuel is then transported

from the internal auger conveyor to the combuson

chamber in porons. This allows for constant

and opmal burning rate of the fuel. The boiler is

controlled and operated by sensor exhaust. This

sensor measures the temperature of exhaust gases

and provides informaon to the control unit ignion

or disconnuaon of combuson. The output of the

burner is determined by the intervals preset on the

control panel taking into account the heang value,

size and density of the pellets.

Automac cleaning system. The pellet boiler is

equipped with innovave automac cleaning system

for combuson chambers of both devices.

A powerful cleaning motor built in the burner

body, air is being blown in at high speed and rate

thus removing all residues – ash, noncombusble

inclusions, etc. built up into the combuson chamber

of the boiler.

At the same me the boiler turns on automac ash

removal which is transported to the ash container

through screw located in the lower part. These

automac cleaning cycles last several seconds and

can be addionally adjusted as well as their repeat

rate depending on the load of the burner.

9.2. Important recommendaons for long-lasng

and correct operaon of the boiler

- For assembly and installaon of the burner follow

the requirements in this manual.

- Use only recommended in this manual fuel.

- Disassemble the burner from the boiler body

before clean it. Depending on fuel and burner

sengs, clean the pellet burner once a month.

- User`s training for operaon and maintenance of

11

TECHNICAL PASSPORT INSTALLATION and OPERATION MANUAL

burner is performed by an authorized installer or

service shop.

Failure to observe the installation and

EN

9.3. Requirements for the cleaning and maintenance

of PelleBurn pellet boiler with pellet burner.

- It is mandatory to clean the ashes from the container

once a week. Unhook the buckles on both sides of

ash container. Pull ash container out of the boiler

and clean it. Once you have emped the container

of ashes, please make sure you close the container

cover ghtly, buckle-lock it to the container buckles,

then buckle-lock the container to the boiler buckles.

- It is mandatory to clean once a month the

Before the start of the heang season it is mandatory

to check and clean the following components of the

boiler:

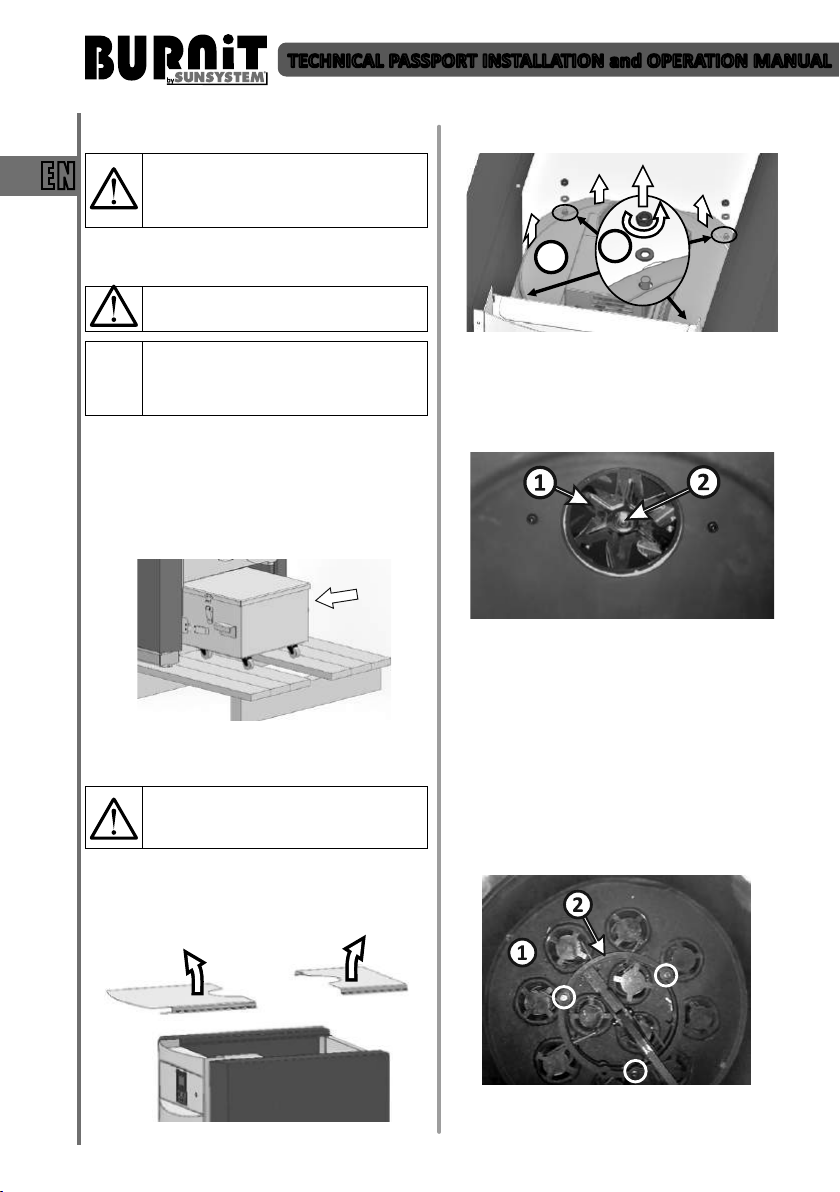

9.3.1 Cleaning and maintenance of sucon fan

operating requirements described in the

manual and the service booklet voids the

warranty.

Attention! Important instructions

regarding cleaning of boiler.

Caution! Hot surfaces.

Before cleaning the boiler, make sure the

fire in it has died out and the boiler has

cooled down.

Diagram 13

combuson chamber of the burner.

Attention! Cleaning and maintenance of

the boiler should be carried out only by an

authorised installer/service shop.

- Remove the two parts of the boiler top cover by

liing them upwards

2

- Remove the cover of the inner boiler body (2) using

wrench S13.

- Clean the fan blade (1) and the dust and soot

deposits. Use a brush. If the fan is not properly

cleaned, this will aect the boiler performance.

- Check the nut holding the fan blade (2) to be well

ghtened. Aenon: the nut is le threaded!

- Upon assembling the gasket of the fan must t well

in place. If necessary, change the fan gasket.

- Mount back the top cover

9.3.2. Cleaning and maintenance of the cleaning

system:

- Remove the top cover (9.3.1).

- Cleaning system (1). Clean the ash deposits using a

vacuum cleaner and/or a brush.

1

Diagram 15

Diagram 16

Diagram 14

- Hold a visual inspecon of the condion of the

Diagram 17

12

TECHNICAL PASSPORT INSTALLATION and OPERATION MANUAL

enre cleaning system. Also check the drive

mechanism, located outside the combuson

chamber.

- Upon detecon of worn piece/part, it is

recommended to have it replaced with a new one.

- Dismantle ue pipes from the cleaning system of

the boiler and clean them well. For this purpose:

remove the upper ring of the automac cleaning

system (2). Use wrench S10. Use a brush to clean

the ue pipes thoroughly one by one. Mount back

the ue pipes and the upper ring of the cleaning

system.

- Check silicone gasket mounted on the edge of the

boiler. Replace if cracked or hardened.

- Mount back the top cover.

- The ashes from the cleaning system are collected

in a drawer container for ash and soot. Upon

compleon of the cleaning procedure, empty the

container.

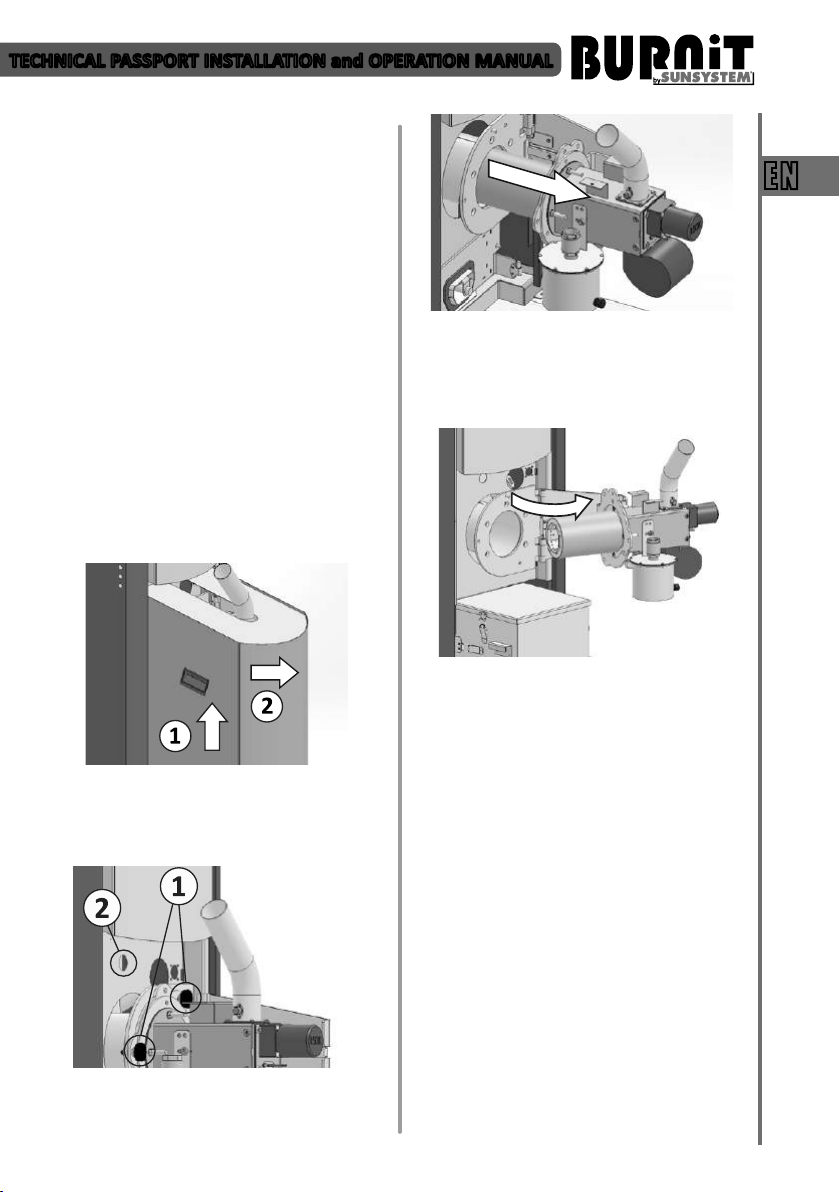

9.3.3. Servicing of the burner:

- Remove the burner casing from the boiler cabinet

body – using the handles (1) li it up then pull it

towards yourself (Diagram18).

- The rail itself is hinge-xed to the boiler body, swing

it to the right to withdraw the burner from the

boiler body. Unscrew the marked bolts to dismount

the burner from the ange holding it xed to the

rail.

EN

Diagram 20

- Remove connector (2) housing the wire connecons

Diagram 18

between the burner and the controller. Unscrew

the 2 marked plasc head bolts (1) to release the

slide rail onto which the burner is mounted.

Diagram 19

- Carefully slide out the rail with the burner mounted

on.

- Disassemble the burner combuson chamber.

Diagram 21

- Clean the inside of the burner chamber thoroughly

from residues. Use a bodkin to release all clogged

orices along the combuson chamber.

- Remove the ashes from inside the burner. Use a

vacuum cleaner and a brush.

- Inspect and clean the motors and sensors in the

boiler.

- When mounng the burner back onto the boiler,

replace the seal between the burner ange and the

boiler.

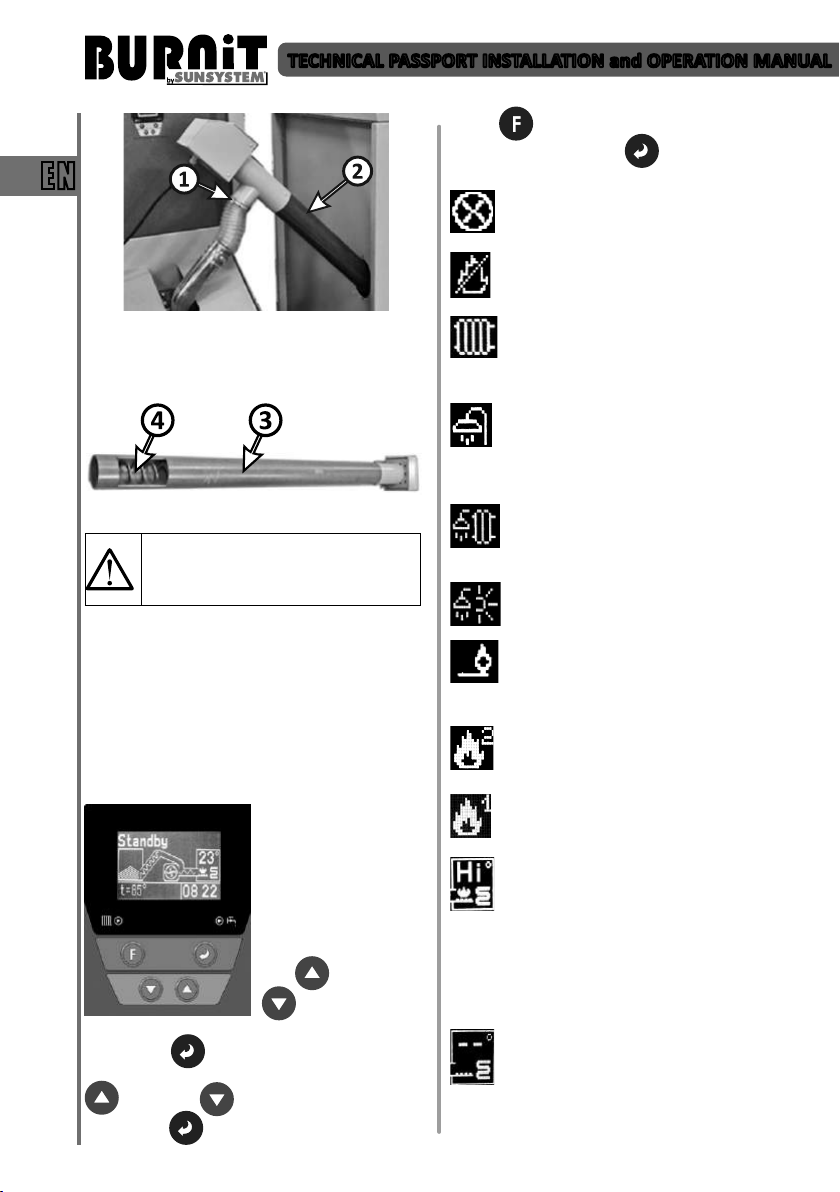

9.3.4. Feeding auger:

- Completely empty the pellet hopper.

- Dismantle the auger from the pellet hopper: release

the top of the exible hose (1) from the auger tube;

extract the auger (2) by pulling it out of the hopper.

13

TECHNICAL PASSPORT INSTALLATION and OPERATION MANUAL

EN

Diagram 22

- Clean the Auger from the ashes of the transport of

pellets: Dust o (3) and clean the ashes from the

collected (4)

- Mount the feeding auger back to the pellet hopper.

Important! Fill Auger and calibrate

it. If auger remain without fuel for

transportation will deteriorate normal

boiler operation.

9.3.5. Pellet hopper:

- Completely empty the pellet hopper

- Clean the pellet ash residues from the boom of

the hopper. Use the scraper and a vacuum cleaner.

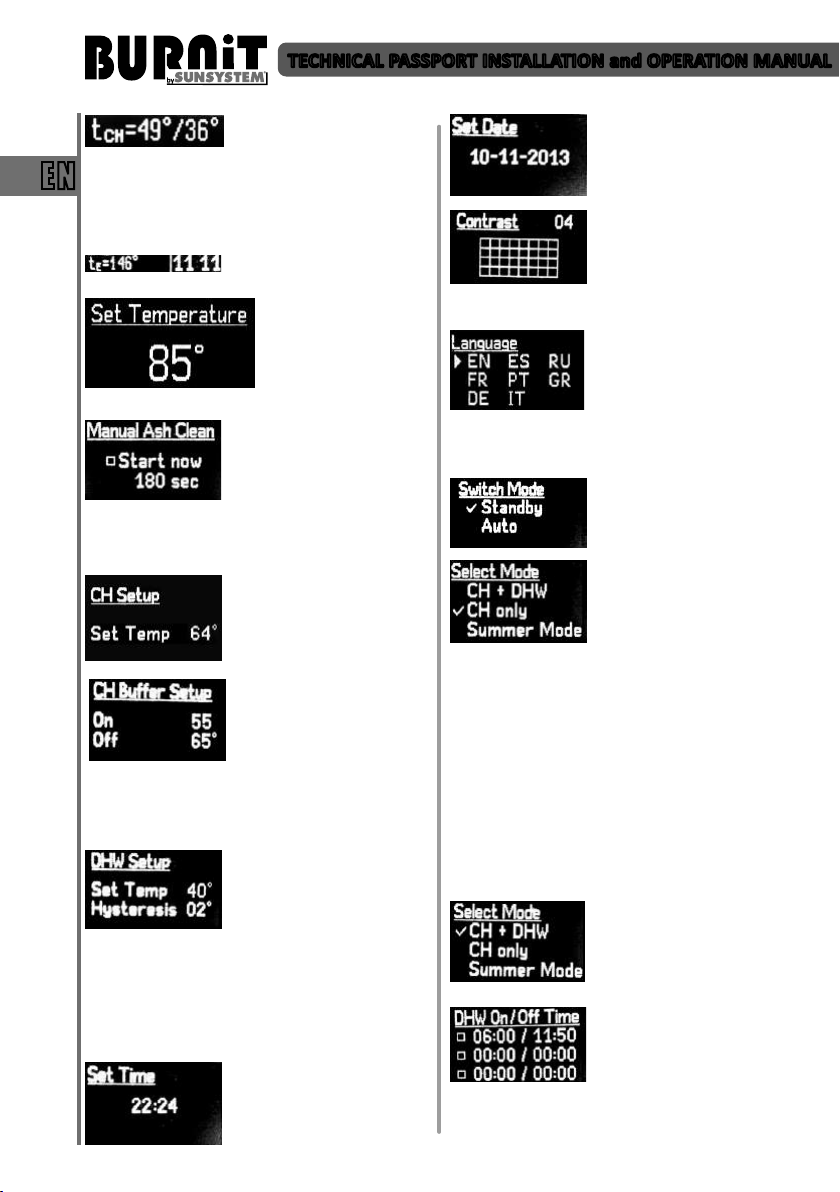

10. CONTROLLER UNIT

10.1. Controller view. Explanaon of buons and

indicators.

LCD screen:

The controller screen

displays the informaon

for the operaon of the

facility.

Explanaon of buons:

When logging into a

menu, use arrow keys

UP and DOWN

to move from

one page to another.

Enter buon permits adjustment of the page.

When adjustment is enabled, use arrow keys UP

and DOWN to adjust the parameter.

Press ENTER to change the parameters.

Press F to exit the menu.

Conrm with Enter buon .

Display symbols explanaon:

Auto Clean symbol appears in right upper

part of display. Acve auto cleaning symbol

means boiler automac cleaning mode.

Crossed-out ame symbol appears in upper

right part of display. Means that the boiler

enters into Exnguish mode.

CH priority /Radiator /symbol appears in

upper part of display. Means than Central

Heang priority is set to heat up the central

heang.

Domesc Hot Water /shower/ priority symbol

appears in upper part of display. Means than

DHW priority is set to heat up the domesc

hot water. When set DHW temperature is reached,

DHW pump stops and CH pump is acvated.

Parallel pumps /shower and radiator/

symbol appears in upper part of display.

Means that is set equal priority to both

pumps. They work in parallel and are

controlled by temperature sensors.

Summer mode /shower and sun/ symbol

means than is set Summer heang mode.

Only DHW pump is acve.

Burner ame symbol appears in upper right

part of display. Means that burner is

acvated. Burner goes into Ignion mode

and upcoming boiler re up.

Flame 2 symbol means Maximum output

mode of boiler. In this mode the boiler

operates at maximum output.

Flame 1 symbol means Low output mode of

boiler. In this mode the boiler operates at

minimum output.

The noce “Hi” appearance on the screen

where the boiler temperature is displayed

means that the measured boiler body

temperature is above 120°C. Flashing and

beeping alarm is acvated. When the issue is

corrected, nocaon can be deleted. Disconnect

fuel auger from boiler plug-in socket. Upon any such

occurrence please contact immediately your installer

for system checkup.

Boiler increased temperature. Those two

symbols appearance on the screen where the

boiler temperature is displayed means that

boiler temperature has increased up to 99°C.

In such a case, please contact immediately to your

installer to check the system.

14

TECHNICAL PASSPORT INSTALLATION and OPERATION MANUAL

Error symbol appears in right upper part of

display. Flashing and beeping error symbol

mean error or fault in boiler operaon. Use

“Enter“ buon to move to next screen with

error nocaon in lower le part of display. When

the issue is corrected, error nocaon can be

deleted. When disconnect the boiler from electrical

supply for few seconds and then switch on it again,

boiler goes back to normal operaon (error

nocaon is deleted).

Cleaning system of exhaust gas tubes is

activated.

S

Ash cleaning system is activated.

A

Factory seng - Alarms

BB ALARM

SENSOR E1

SENSOR E2

IGNITION FAIL Failure ignion

BURNOUT

DHW E1

DHW E2

Cleanup

TE Alarm

TE E1

TE E2

CH btm E1

CH btm E2

CH top E1

CH top E2

When restarng the controller alarm is deacvated.

Reverse re Alarm (when the

thermostat contact RB input is

open)

Boiler Temperature Sensor is

missing (input B)

Boiler Temperature Sensor Short

circuit ( input B)

Exhaust gas temparature is too

low in Operation mode. If the

exhaust gases temperature drops

below 85°C the boiler will shift into

extinguishing mode.

Water Heater Temperature Sensor

is missing (input WH)

Water Heater Temperature Sensor

Short circuit (input WH)

This alarm appears when gas

temperature rises above 180°C

This alarm appears when gas

temperature rises above 220°С

Temperature sensor of exhaust

gases is missing

Short circuit of temperature sensor

of exhaust gases

Temperature sensor of lower part

of buffer tank is missing (when in

chosen scheme with buffer tank)

Short circuit of temperature sensor

of lower part of buffer tank (when

in chosen scheme with buffer tank)

Temperature sensor of upper part

of buffer tank is missing (when in

chosen scheme with buffer tank)

Short circuit of temperature sensor

of upper part of buffer tank (when

in chosen scheme with buffer tank)

Notify the authorized installer/ service to

be performed immediately inspection of

the boiler and heating installation.

”С” symbol means that the

motor of automac cleaning

system is acvated.

The symbol “T” indicates

that a room thermostat is

connected to the controller

In “CH Priority” mode the room thermostat controls

the burner by starng and stopping it. In “DHW

Priority” mode the room thermostat controls the

heang installaon pump by starng it when the

temperature of the domesc hot water has reached

the maximum preset temperature. In “Parallel

Pumps” mode the room thermostat controls the

heang installaon pump regardless of the

temperature of domesc hot water. In “Summer

Mode” the room thermostat is disabled.

Lights for operang:

- Pump heang system

- Pump Domesc hot water.

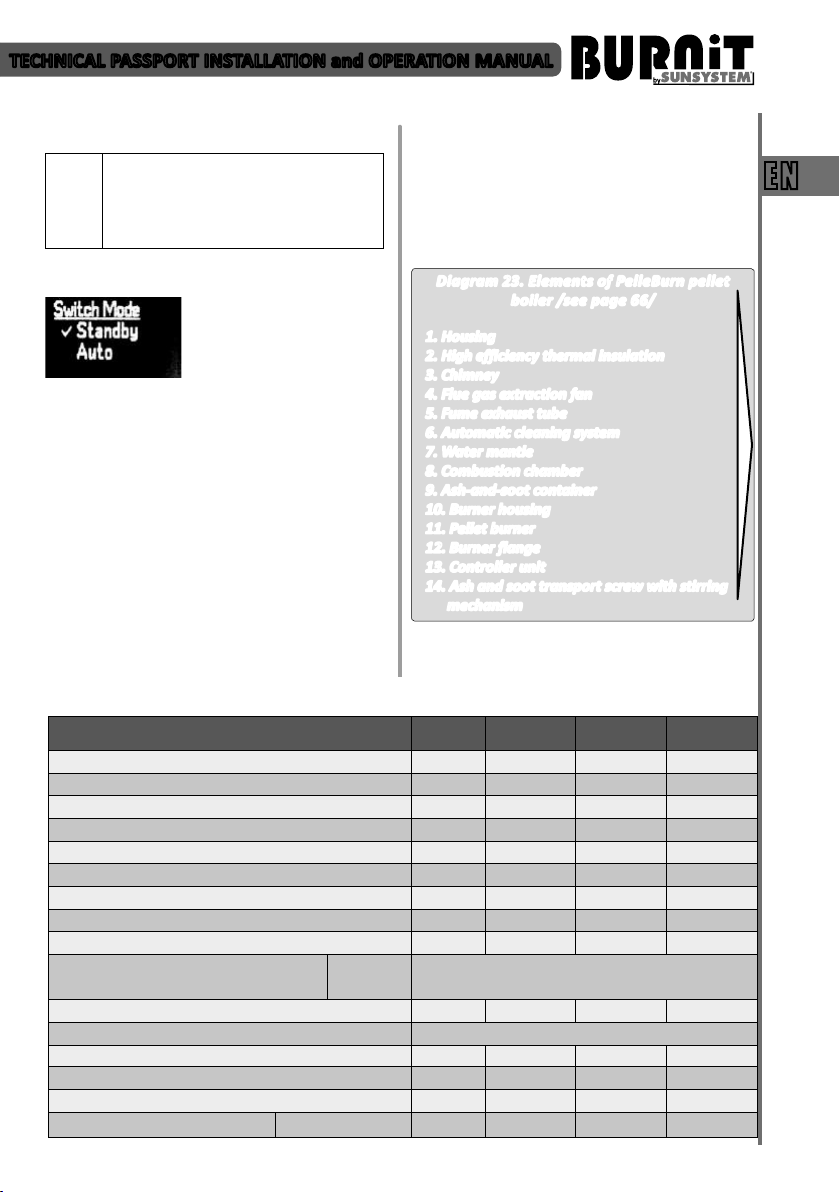

10.2. User menu

10.2.1. Inial (start-up screen) „Standby“

buon you can browse the quick menu (boom le)

where the following read-only data is displayed:

Maximum set temperature t=85oC, temperature

of domesc hot water where such heang circuit

is connected); Light intensity in the burner; Burner

status (detected errors, if any); Date.

the facility for any reason will be displayed as an

error.

temperature of domesc hot water inside the water

heater.

15

of the burner (the boiler).

The burner is in standby

mode.

The display shows:

Temperature in the boiler

(23 degrees), me, and

by pressing the Enter

Error message. If there is an

emergency in the operaon of

Мaximum set boiler

temperature.

Current date.

Parameter t

indicates

DHW

EN

TECHNICAL PASSPORT INSTALLATION and OPERATION MANUAL

Parameter tСН indicates the

temperature at upper and boom part of the buer

tank.

EN

This screen is acve only when has been selected the

menu opon for boiler control according to buer

temperature.

set the follow parameters:

“Navigaon arrow Up” and “Navigaon arrow

Down”. Aer entering the correct value press buon

“Enter”.

. From this menu you can

scheme (with buer tank included) is selected,

whereas the two sensors reading these temperatures

are mounted in the upper, respecvely lower part of

the buer tank (cf. boiler connecon schemes).

down and using the Enter buon you can change the

parameters. You can adjust the maximum domesc

hot water temperature inside the storage tank, as

well as the switch-on hysteresis for the circulaon

pump aer a drop of DHW temperature inside the

storage tank.

value of instantaneous

Parameter tE indicates exhaust

gases temperature.

Set maximum

temperature of the boiler

through navigaon

arrows. Press buon F

and hold for 3 seconds to

Possibility for forced turn on of

ash and soot transport screw.

Time seng of screw

operaon. To set start and

operang me use buons

Use this menu to adjust switch-

on temperature of central

heang pump.

preset buer tank circulaon

pump switch-on and switcho temperatures provided

such heang installaon

From this menu you can adjust

the maximum temperature in

the domesc hot water storage

tank, whereas by navigang

from the arrow keys up and

Use UP and DOWN arrow keys

in Set Time menu to set the

unit’s built-in mer/clock.

Use UP and DOWN arrow keys

in Set Date menu to set the

date.

Use UP and DOWN arrow keys

in Contrast menu to adjust the

LCD display backlight level.

Conrm sengs by shiing to

next submenu through a single

pressing of the funconal key F.

Use this menu to choose the

language of the controller.

Choose a language by pressing

navigation arrows and button

“Enter”.

10.2.2. Burner start-up „Switch mode“

Burner start-up. Aer pressing

the “F” buon and using the

navigaon arrows, the “Auto”

or „Standby” menu is selected.

Set the priority mode of the

burner through “navigaon

arrows.”

- CH + DHW – Both pumps /CH-central heang

pump and DHW – domesc hot water pump /are

acve.

- CH only – In this mode of operaon the only acve

pump is the CH circulaon pump for the heang

installaon (CH pump). In this mode, the boiler

can be managed via a room thermostat or be

temperature-controlled by the temperature inside

the connected buer tank to it (depending on the

connecon scheme)

- Summer Mode – Boiler works for heang of

domesc hot water only.

If you have selected the (CH +

DHW) opon, upon

conrmaon of command via

the F buon you may navigate

to the next screen.

From this menu you can set up

and adjust DHW pump acvity

periods. Use the arrow keys to

set me (HH:MM). Use “Enter”

buon to checkmark desired

me period opon. If no opon is check-marked, the

controller will maintain DHW temperature as a

16

TECHNICAL PASSPORT INSTALLATION and OPERATION MANUAL

priority. Only when its preset value is reached, the CH

circulaon pump will start.

Important – The use of “External room

thermostat for the burner” option

(Thermostat) is active only if option is

selected (CH Priority – priority of central

heating installation pump).

10.2.3. Burner shut-down „Standby“

Pressing the “F” buon will

take you to the main menu and

by using the navigaon arrows

menu and conrm the selecon by pressing “F”. The

burner goes into exnguishing mode. Set the

temperature to start heang pump.

11. MOUNTING OF FUEL HOPPER FH 500

Fuel hopper FH 500 has a capacity of 500 liters

pellets. Its design allowing installation by choice on

either side of boiler. An important condition is to be

leveled. Before loading the pellets, make sure that

the hopper is clean. Empty the container for pellet

powder and dust.

Fuel hopper hatch-cover must be closed during

operation. Detailed description for the assembly of

a fuel hopper FH 500 will find the User manual for

assembling the fuel hopper FH 500.

you can select the “Standby”

12. WARRANTY TERMS

The warranty terms are described in the Service

booklet included in the supply.

EN

13. TECHNICAL FEATURES

13.1. Technical features of PelleBurn pellet boiler

13.1.1. Elements of PelleBurn pellet boiler

Diagram 23. Elements of PelleBurn pellet

boiler /see page 66/

1. Housing

2. High efficiency thermal insulation

3. Chimney

4. Flue gas extraction fan

5. Fume exhaust tube

6. Automatic cleaning system

7. Water mantle

8. Combustion chamber

9. Ash-and-soot container

10. Burner housing

11. Pellet burner

12. Burner flange

13. Controller unit

14. Ash and soot transport screw with stirring

mechanism

13.1.2. Technical parameters of PelleBurn pellet boiler

PelleBurn 15 PelleBurn 25 PelleBurn 40

Nominal heat output

Min / Max heat output

Height H

Width L / Depth D

Mantle volume

Combuson chamber volume

Combuson chamber resistance

Water side pressure drop (ΔT = 20°C) Pa/mH2O 480/0,048 850/0,085 1350/0,135

Required chimney draught

Insulaon

Electric power supply

Recommended fuel

Operang temperature range

Operang pressure

Pellet burner Pell Power kW 5÷15 8÷25 10÷40

Boiler

Doors

Weight

kW 15 25 40

kW 5÷15 8÷25 10÷40

mm 1290 1430 1700

mm 640/1120 640/1120 700/1120

l 55 70 101

l 43 53 73

Pa/mbar 10/0,10 11/0,11 12/0,12

Pa 10÷20 10÷20 10÷20

100 mm high-eciency thermal wool

lined with aluminum foil

20 mm high-eciency black veil rockwood

V/Hz/A 230/50/10 230/50/10 230/50/10

wood-pellets, diameter 6÷8 mm

°C 65-85 65-85 65-85

bar 3 3 3

kg 220 240 358

17

TECHNICAL PASSPORT INSTALLATION and OPERATION MANUAL

EN

Pellet fuel hopper

Cold water inlet

Hot water outlet

Safety line sleeve

Air vent

Cleaning opening

Combuson viewer

Boiler ue gas extracon fan

Burner air-feed fan

Automac cleaning device

Cleaning device motor

Burner ange

Ash and soot transport motor

Ash-and-soot container

Control unit

L 500 500 500

A, mm R ¾’’/100 R ¾’’/100 R ¾’’/100

B, mm R ¾’’/980 R ¾’’/1120 R ¾’’/1417

К

I

F,

Flue

J,

O, mm 140/300 140/300 140/300

Drain

E

V

W1,

mm

W2,

mm

P, mm 950 1090 1390

M

Z

N, mm 170 170 170

Т

U

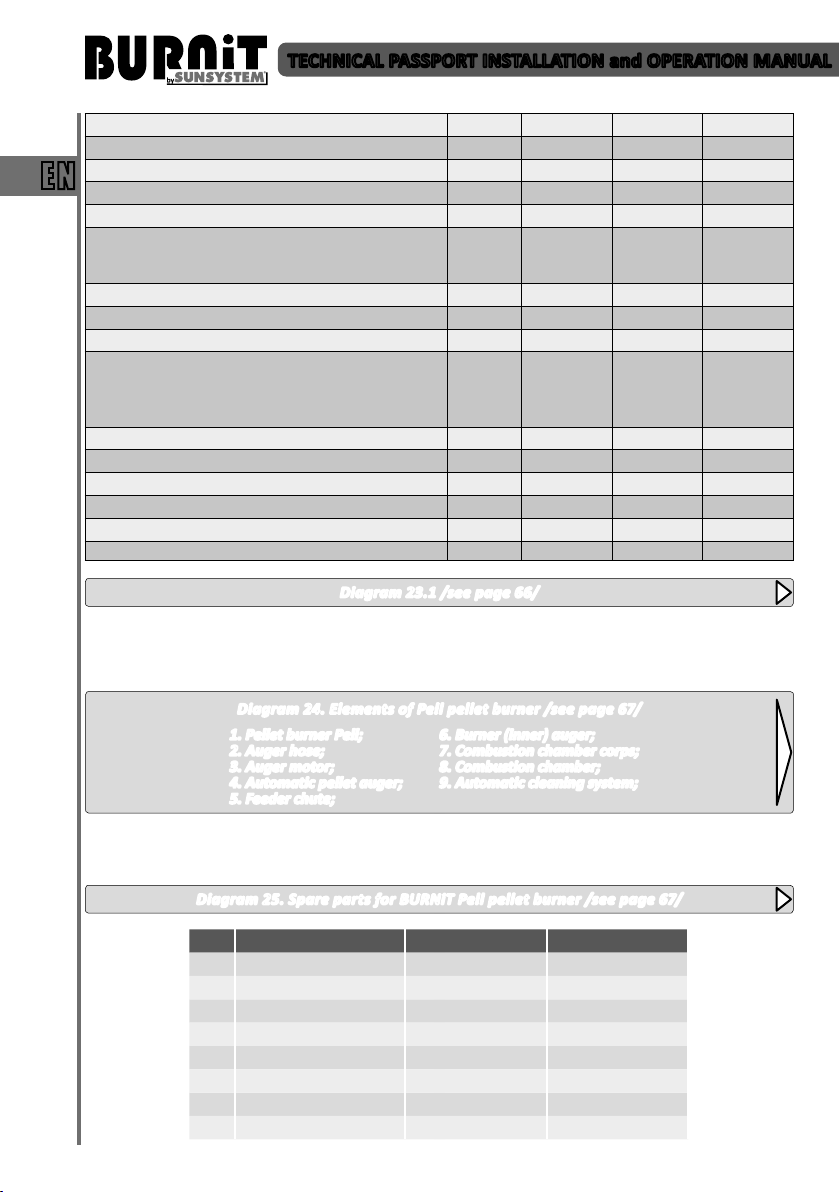

Diagram 23.1 /see page 66/

13.2. Technical features of Pell pellet burner

13.2.1. Elements of Pell pellet burner

ø

mm

mm

133

1280

320

1220

510

133

1480

320

1385

510

150

1700

350

1665

565

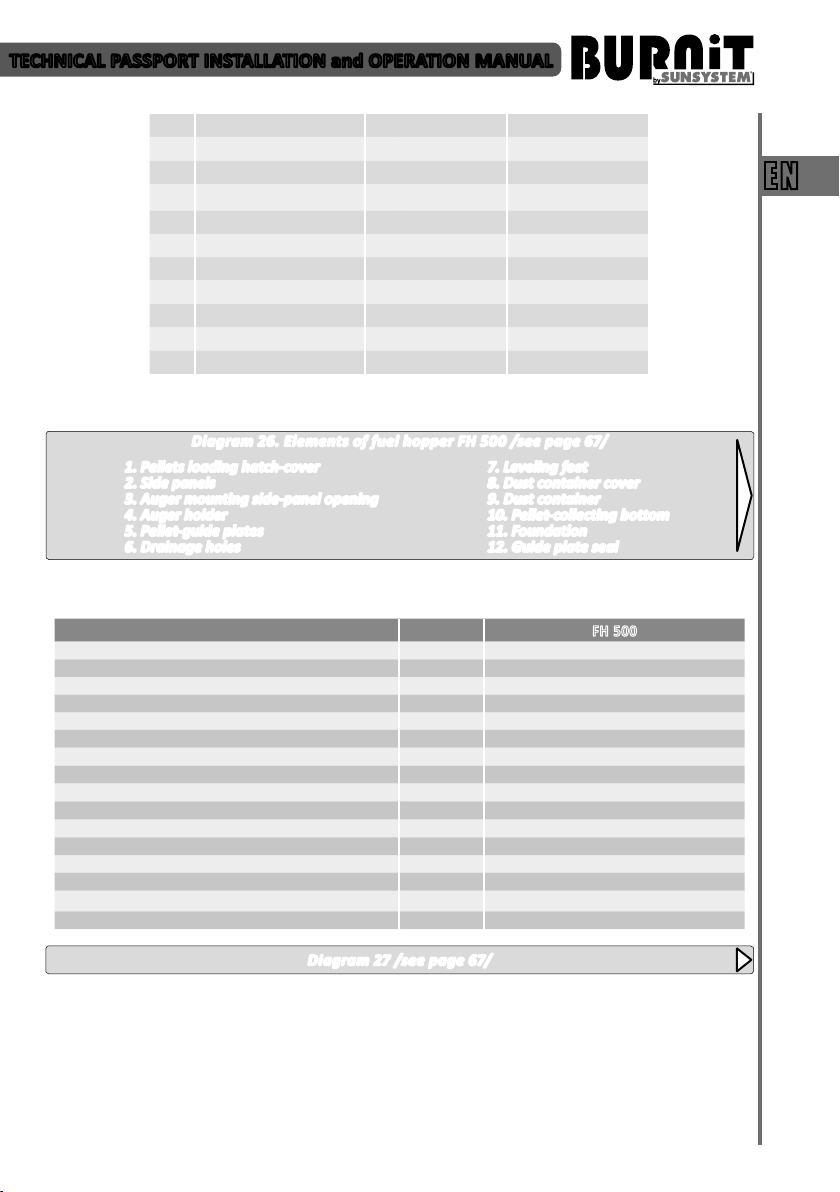

Diagram 24. Elements of Pell pellet burner /see page 67/

1. Pellet burner Pell;

2. Auger hose;

3. Auger motor;

4. Automatic pellet auger;

6. Burner (inner) auger;

7. Combustion chamber corps;

8. Combustion chamber;

9. Automatic cleaning system;

5. Feeder chute;

13.2.2. Spare parts for Pell pellet burner

Diagram 25. Spare parts for BURNiT Pell pellet burner /see page 67/

№ Part Number Model PEll 25 Model PEll 40

1 82801300000002 х

1 82801300000003 х

2 82801300000010 Х

2 82801300000011 х

3 89801300000006 х

3 89801300000024 Х

4 89800000000005 Х Х

5 89801381000001 Х

18

TECHNICAL PASSPORT INSTALLATION and OPERATION MANUAL

5 89801381000002 Х

6 78801100000001 Х Х

7 32800032000001 Х Х

8 89080000000006 Х Х

9 89801200000006 Х Х

10 89800000000004 Х Х

11 32590000000092 Х Х

12 89080000000007 Х Х

13 32640000000004 Х

13 32640000000003 Х

14 32800000000006 x(C130) x(C130)

13.3. Technical features of fuel hoper FH 500

13.3.1. Elements of fuel hopper FH 500

Diagram 26. Elements of fuel hopper FH 500 /see page 67/

1. Pellets loading hatch-cover

2. Side panels

3. Auger mounting side-panel opening

4. Auger holder

5. Pellet-guide plates

6. Drainage holes

13.3.2. Technical parameters of fuel hopper FH 500

Capacity l 500

Max/Min wood pellets load ø, 6÷8 mm kg 280÷300 / 15

Height H mm 1260

Width L / Depth D mm 772 / 730

Foundaon B, mm 53

Auger mounng opening C, ø mm 76

Auger holder E

Pellet-load hatch F, mm 400 / 772

Hinges G

Drainage holes J

Dust container X

Inclinaon of guide plates P 45°

Pellet-colecng boom R, mm 300 / 300

Leveling feet Z

Guide plate seal

Weight kg 82

7. Leveling feet

8. Dust container cover

9. Dust container

10. Pellet-collecting bottom

11. Foundation

12. Guide plate seal

EN

FH 500

Diagram 27 /see page 67/

19

TECHNICAL PASSPORT INSTALLATION and OPERATION MANUAL

14. RECYCLING

Submit all packaging material for recycling according

to the local regulations and requirements.

At the end of life cycle of each product its

EN

components are due to be disposed of in conformity

with regulatory prescriptions.

Obsolete equipment shall be collected separately

from other recyclable waste containing materials

with adverse effect on health and environment.

According to Directive 2002/96/EC regarding

electrical and electronic equipment waste, disposal

thereof is required separately from the normal flow

of solid household waste.

Expired appliances must be collected separately

from other recyclable waste containing substances

hazardous to health and environment. Both metal

and non-metal parts are sold out to licensed

organizations for recyclable metal or non-metal

waste collection. In any case they should not be

treated as household waste.

20

TECHNISCHES DATENBLATT MONTAGE- und BEDIENUNGSANLEITUNG

INHALT

1. ERLÄUTERUNG DER SYMBOLEN UND SICHERHEITSHINWEISE .............................................................. 22

1.1. Erläuterung der Symbolen .................................................................................................................... 22

1.2. Hinweise für den Raum der der Kesselaufstellung ................................................................................ 22

1.2.1. Hinweise für den Installateur ................................................................................................................ 22

1.2.2. Hinweise für Anlagebenutzer ................................................................................................................ 22

1.2.3. Mindestabstände bei der Montage und Brennbarkeit der Baumaterialien .. ........................................ 23

2. BESCHREIBUNG VOM ERZEUGNIS ..................................................................................................... 23

2.1. Konstruktion des Pelletkessels .............................................................................................................. 23

2.2. Konstruktion von Pelletbrenner ............................................................................................................ 24

2.3. Sicherheitsschutz des Pelletkessels und des Brenners ......................................................................... 24

2.4. Schneckeneinrichtungen für Beförderung von Pellets .......................................................................... 25

2.5. Einrichtungen für Pelletsbunker FH 500 ................................................................................................ 25

3. BRENNSTOFFE ....................................................................................................................................... 25

4. BEFÖRDERUNG VON KESSEL ................................................................................................................. 26

5. KESSELLIEFERUNG ............................................................................................................................... 27

6. MONTAGE VOM HEIZKESSEL ............................................................................................................. 27

7. MONTAGE DES HEIZKESSELS .............................................................................................................. 27

7.1. Anschluss des Kessels an einen Schornstein ......................................................................................... 27

7.2. Anschluss des Kessels an Bunker und Schnecke .................................................................................... 28

7.3. Anschluss des Kessels und Brenner an das Stromnetz .......................................................................... 28

7.4. Kessel - Anschluss an das Heizsystem ................................................................................................... 29

7.5. Schema Zusammenfügung .................................................................................................................... 31

8. FÜLLEN DER HEIZANLAGE ................................................................................................................... 31

9. NUTZUNG VOM KESSEL ......................................................................................................................... 31

DE

10. MIKROPROZESSORSTEUERUNG ............................................................................................................ 34

10.1. Ansicht vom Kontroller. Erläuterung der Druckknöpfe und der Indikatoren ........................................ 34

10.2. Benutzermenü ..................................................................................................................................... 35

11. MONTAGE VON PELLETBUNKER ........................................................................................................... 37

12. GARANTIEBEDINGUNGEN ..................................................................................................................... 37

13. TECHNISCHE CHARATERISTIKEN ............................................................................................................ 37

13.1. Technische Charakteristiken des Pelletskessels PelleFlux .................................................................... 37

13.2. Technische Parameter für Pelletbrenner BioFlux ........................................................................................ 38

13.3. Technische Charakteristiken des Pelletsbunker FH500 ......................................................................... 39

14. RECYCLING UND AUSWURF ............................................................................................................... 39

ANHANG - Diagramme .................................................................................................................................... 59

21

TECHNISCHER DATENBLATT MONTAGE- und BEDIENUNGSANLEITUNG

1. ERLÄUTERUNG DER SYMBOLE UND

SICHERHEITSHINWEISE

1.1. Erläuterung der Symbole

ACHTUNG! – Wichtiger Hinweis oder

Warnung, die die Sicherheitsbedingungen bei

Montage, Installation und Bedienung des

Pelletkessels betrifft.

GEFAHR! – wegen Beschädigung oder

DE

falscher Bedienung besteht Gefahr für Leib

und Leben von Menschen und Tieren

FEUERGEFAHR! – wegen Beschädigung,

falscher Montage und Bedienung besteht

Feurgefahr.

INFORMATION – das Zeichen weist auf den

Teil der Anleitung, die die genaue Einstellung

und die nötige Parameter des Erzeugniss

betrifft, damit Sie das gewünschte Ergebnis erzielen

können.

1.2. Hinweise auf den Raum der Kesselaufstellung

Die vorliegende Anleitung enthält wichtige

Information für eine sichere und richtige Montage,

Inbetriebnahme, störungsfreie Bedienung und

Instandhaltung des Pelletkessels.

Der Pelletkessel darf für Heizung von Räumen benutzt

werden, nur nach der Art und Weise, beschrieben in

der vorliegenden Anleitung.

Berücksichtigen Sie die Daten für den Typ des Kessels

auf dem Herstellungssticker und die technischen

daten, um die richtige Nutzung des Erzeugnises zu

versichern.

1.2.1. Hinweise für den Installateur

Bei Installierung und Nutzung müssen die

Vorschriften und Normen des entsprechenden

Landes eingehalten werden:

• die örtliche Bauvorschriften für Montage,

Luftversorgung und Abgasentsorgung, sowie der

Anschluss an einen Schornstein

• die Vorschriften und Normen für die

Sicherheitsausrüstung des Heizsystems.

• Es wird vorgeschrieben, dass ein Rauchmelder im

Kesselraum eingebracht wird.

Der autorisierte Installateur / Fachmann

ist verpflichtet den Anlagenbenutzer über

alle Wichtige Besonderheiten bezüglich

der Anlagennutzung und Reinigung

aufzuklären.

Es ist zwingend notwendig, dass eine

Notfallstromversorgung /Generator mit

der notwendigen Leistung/ mitaufgestellt

wird (siehe. Tabelle 1).

ACHTUNG! Die Montage und die

Einstellung des Kessels darf nur von

einem autorisiertem Service oder einem

autorisiertem Fachmann, bei Einhaltung der

Sicherheitsanleitungen und Arbeitsregeln,

ausgeführt werden.

VERGIFTUNGS- UND ERSTICKUNGSGEFAHR.

Der geringere Luftzutritt im Kesselraum

kann eine gefährliche Abgasausströmung

Während der Verbrennung des Kessels

verursachen.

- Vergewissern Sie sich, daß die Öffnungen

für Eintritts- und Abgasluft nicht verstopft

oder geschlossen sind.

- Wenn die Beschädigungen nicht

sofort beseitigt werden können, darf

der Pelletkessel nicht benutzt werden.

- Machen Sie eine schriftliche Anweisung

für den Benutzer der Anlage bezüglich der

Beschädigung und der davon ausgehende

Gefahr.

FEUERGEFAHR wegen brennbare

Materialien oder Flüssigkeiten.

- Brennbare Materialien oder Flüssigkeiten

dürfen in unmittelbarer Nähe des

!

Pelletkessels gesetzt werden.

- Weisen Sie dem Benutzer der Anlage für

die mindesten Abstände bezüglich der

umstehenden Gägenstände an.

Benutzen Sie nur originale Ersatzteile

i

Energieverbrauch des Kessels

Stromversorgung bei maximaler Leistung 780 W

Stromversorgung bei Nennleistung 80 W

Stromversorgung bei minimaler Leistung 60 W

1.2.2. Hinweise für Anlagebenutzer

VERGIFTUNGS UND EXPLOSIONSGEFAHR.

- Benutzen Sie keine Abfälle, Kunststoffe,

Naphthalin oder Flüssigkeiten – Benzin,

Motorenöl zum Zünden des Brenners.

Benutzen Sie nur der, in vorliegender

Anleitung, vorgegebenen Brennstoff.

$

Anderenfalls entfällen die

Garantieansprüche.

-Bei Explosions-, Entzündungs- oder

Abgasausströmungsgefahr im Kesselraum,

schalten Sie den Brenner und Kessel aus.

Tabelle 1.

22

TECHNISCHER DATENBLATT MONTAGE- und BEDIENUNGSANLEITUNG

Es ist zwingend notwendig, dass eine

Notfallstromversorgung /Generator mit

der notwendigen Leistung/ mitaufgestellt

wird (siehe. Tabelle 1).

Der autorisierte Installateur / Fachmann

ist verpflichtet den Anlagenbenutzer über

alle Wichtigen Besonderheiten bezüglich

der Anlagennutzung und Reinigung

aufzuklären.

ACHTUNG! Verletzungsgefahr/ Störung

an der Anlage wegen inkompetenter

Bedienung

- Der Pelletkessel darf nur von Personen

bedient werden, die sich mit der

Gebrauchsanweisungen bekannt gemacht

haben

- Als Benutzer dürfen Sie den Kessel nur

Allgemeine Sicherheitsregeln, die vom Verbraucher

durchzuführen sind:

- Benutzen Sie den Pelletkessel nur mit dem

- Kontrollieren Sie regelmäßig den Kesselraum.

- Verwenden Sie keine Flüssigkeiten bei der Zündung,

- Reinigen Sie die Oberfläche des Kessels nur mit

- Stellen Sie keine brennbare Gegenstände auf dem

- Bewahren Sie keine brennbaren Materialien im

- Es wird vorgeschrieben, dass die Anweisungen

- Veränderungen in der Kesselkonstruktion seitens

- Der Verbraucher darf den Kontakt von Strom-

- Die vorliegende Anleitung ist sorgfältig

in Betrieb nehmen, die Temperatur des

Kessels regeln, den Kessel ausschalten und

reinigen.

- Der Zugang von Kindern ist im Raum mit

laufendem Kessen ohne Aufsicht verboten.

empfohlenen Brennstoff,

sowie auch für die Steugerung der Kesselleistung

nichtbrennbaren Mitteln.

Kessel oder in seiner Nähe (sieh Schema 1 für die

Mindestabstände)

Kesselraum auf.

für Anschliessen des Brenners an das Stromnetz,

sowieauch an die Peripheriegeräte strikt eingehalten

werden müssen.

des Benutzers können zu Beschädigung des Gerätes

oder Verletzung führen.

oder Sensorleiter zu Kesselteilen, die eine

Oberflächentemperatur von 70°C übersteigen nicht

zulassen.

aufzubewahren.

ACHTUNG! Heiße Oberflächen!

Es besteht die Verbrennungsgefahr bei

Berührung des laufenden Kessels. Die

Verkleidung des Brenners, der Brennerkörper

und der Brennerflansch sind warme

Oberflächen während der Brennerarbeit.

Es ist absolut verboten, die Revisionstüren

des Kessels bei laufendem Brenner geöffnet

zu werden.

Achten Sie bei der Berührung des Okulars

für Beobachtung des Brennungsvorgangs. Er

kann heiß sein.

1.2.3. Mindestabstand bei Montage und

Brennbarkeit von Baumaterialien

Es ist möglich, dass in Ihrem Land andere

Mindestabstände als die unten vermerkten gelten.

Bitte, konsultieren Sie sich mit Ihrem Instalateur.

Der Mindestabstand des Brenners, des Heizkessels

oder des Abgasrohres zu Gegenständen und Wänden

muss mindestens 200 mm sein.

Tabelle 2. Entzündbarkeit der Baumaterialien

Klasse А -

feuerbeständig

Klasse В

– schwer

entflammbare

Klasse С1/С2

mittelbrennbare

Klasse С3 leicht

brennbare

Schema 1. Empfehlenswerter Abstand des

Pelletkessels zu den Wänden /siehe Seite 59/

Zwecks allgemeiner Sicherheit empfehlen wir, dass

der Kessel auf einen Fundament aus Material Klasse

A, aufgestellt wird. Sieh Tabelle 2.

2. BESCHREIBUNG VOM ERZEUGNIS

Der hocheffektive Pelletkessel ist für die Heizung

mittels Holzpellets bestimmt. Der speziell

konstruierte Wassermantel bedeckt gänzlich die

Brennkammer zwecks Erhöhung der Effektivität und

des Wirkungsgrades bis 91%.

Der Kessel ist gemäß europäischen Normen EN 3035, Klasse 5 getestet.

Der Satz enthält Kessel mit Pelletbrenner,

Pelletförderschnecke und Bunker (optional) für die

Brennstofflagerung.

2.1. Konstruktion des Pelletkessels.

Der Kesselkörper hat eine zylindrische Form, und ist

23

Stein, Ziegel, keramische Fliesen,

gebrannter Lehm, Mörtel, Putz

ohne organische Zusätze

Platten Gipskarton, basaltiger Filz,

Glasfaser, AKUMIN, Izomin, Rajolit,

Lignos, Velox, Heraklit.

Holz Buche, Eiche

Holz Nadelbäume, aufgeschichtetes

Holz

Asphalt, Karton, Zellulose, Teer,

Holzfaser, Kork, Polyurethan,

Polyethylen.

DE

TECHNISCHER DATENBLATT MONTAGE- und BEDIENUNGSANLEITUNG

aus hochwertigem Kesselstahl mit gebaut, 4 mm für

die Brennkammer und 3 mm für den Wassermantel.

• Ökologisch. Die Holzpellets, die für den

Verbrennungsvorgang benutzt werden, sind aus

nachwachsenden Rohstoffen mit minimaler Menge

schädlicher Emissionen hergestellt worden.

• Automatisiert. Dank des vervollkommenen

Wirkungsalgorithmus und die Fähigkeit Vielzahl

von Parameter zu kontrollieren, kann er

DE

präzis an das Bedürfnis des Heizungssystems

angepasst werden, wobei die Effizienz erhöht

und der Brennstoffverbrauch gesenkt wird. Der

Hauptsteuerungsblock, der sich befindet, steuert

den ganzen Heizungsvorgang.

1) automatisierte Zündung und Pelletvorschub;

2) Rauch – Lüfter am Ausgang der Abgase, sorgt für

stabile Arbeit des Kessels;

3) Selbsreinigungsfunktion des Kessels und des

Brenners;

4) Steuerung der Pumpe für die Heizungsanlage;

5) Steuerung des Außenraumthermostat ;

6) Steuerung der Pumpe für heißes Brauchwasser;

7) Abgassensor/Abgasfühler;

• Effektiv. Der Kesselkörper ist durch eine

Hochtemperaturwatte mit Dicke von 100 mm

isoliert. Durch die Steuerung des Brennvorgangs

und das zylindrische Design des Körpers, erreicht

der Kessel eine Effizienz von bis zu 91% und schont

die Umwelt mit besonders niedrigen Emissionen.

2.2. Konstruktion von Pelletbrenner

Schema 2. K on s tr uk t io n v o n P e ll et b re n ne r