ThermoFLUX EcoLogic, EcoLogic 25, EcoLogic 44, EcoLogic 35, EcoLogic 55 Series Manual

Pellet boiler

ThermoFLUX d.o.o.

Bage 3, 70101 Jajce,

Bosnia and Herzegovina

Tel/fax:+387-30–657-100

www.thermoflux.ba; tfinfo@thermoflux.ba

2

3

Dear users,

Congratulations on choosing a boiler from ThermoFLUX d.o.o.

Please note that all persons handling this boiler thoroughly

inspect and observe the operating and safety instructions.

Always keep the instructions in place near the boiler.

Due to constant improvement and development of our

products some pictures or illustrations in this guide may vary.

Important information:

The first commissioning and training of the user must be done by a

servicer authorized by ThermoFLUX d.o.o or the importer, otherwise the

guarantee will not be valid.

4

Content:

Content: ....................................................................................................................... 4

1. Notes ....................................................................................................................... 6

Simple and safe operation ............................................................................................................................. 6

Technical changes......................................................................................................................................... 6

Copyright ...................................................................................................................................................... 6

Security measures ......................................................................................................................................... 6

Obligatory informing ...................................................................................................................................... 7

Warning signs ............................................................................................................................................... 8

Other warnings ............................................................................................................................................. 9

2. SAFETY INSTRUCTIONS ................................ ..................................................... 11

Proper use .................................................................................................................................................. 11

Obligatory information..........................................................................................................................................13

Safety instructions for boiler room........................................................................................................................13

Local standards ........................................................................................................................................... 13

Boiler safety devices .................................................................................................................................... 14

3. GENERAL OVERVIEW ......................................................................................... 15

EcoLogic ..................................................................................................................................................... 16

Technical data ............................................................................................................................................. 17

4. Installation ............................................................................................................. 18

Conditions for installation ............................................................................................................................. 18

Boiler Dimensions....................................................................................................................................... 19

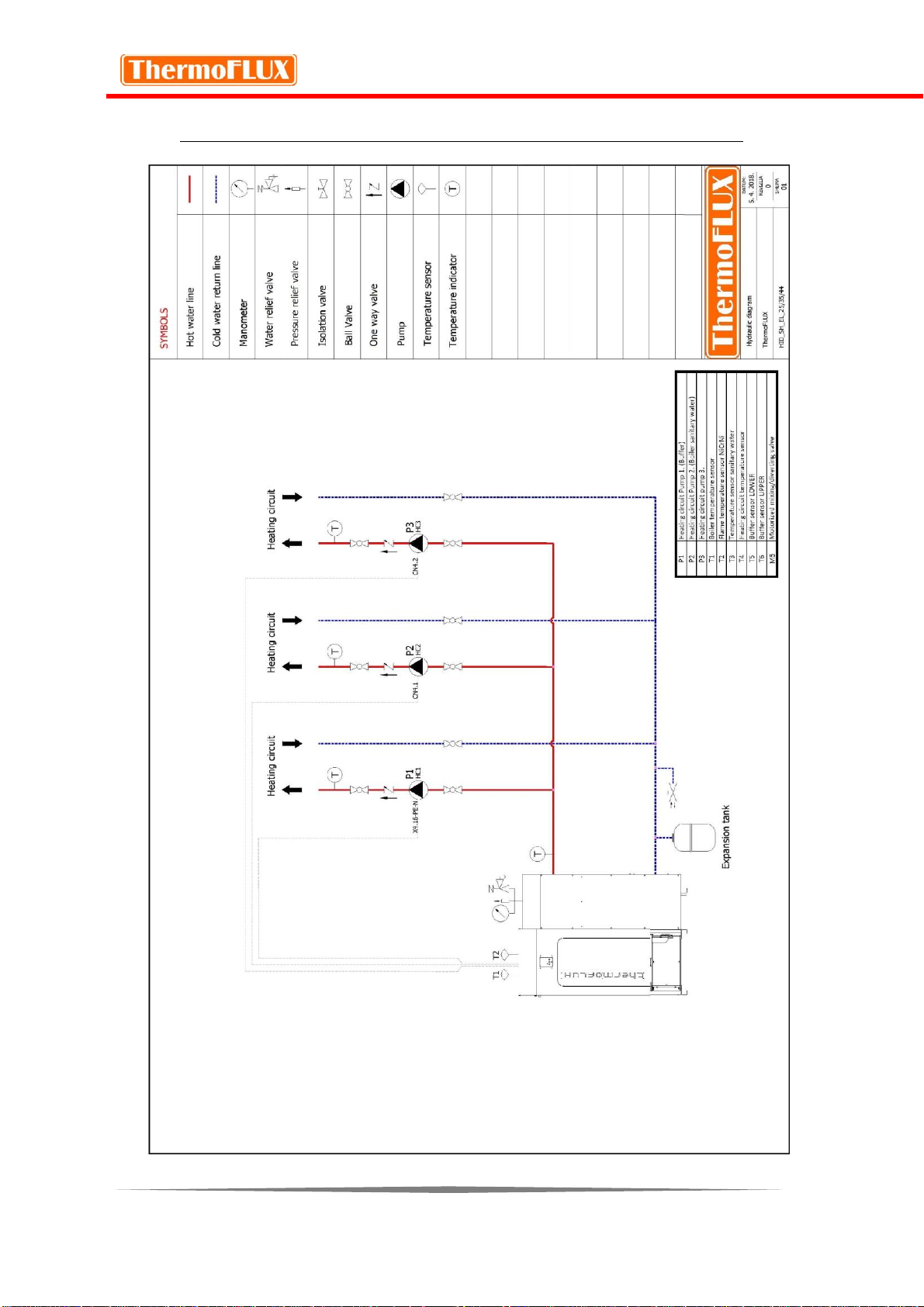

Hydraulic digrams and connection modes for individual system configurations .............................................. 21

Chimney and pipes for flue gas .................................................................................................................... 29

Electrical conection ...................................................................................................................................... 31

Pellet loading............................................................................................................................................... 35

5. Using the boiler ...................................................................................................... 36

6. Boiler control .......................................................................................................... 37

Navigation ................................................................................................................................................... 37

MENU tree .................................................................................................................................................. 39

User menu .................................................................................................................................................. 40

Manual mode .............................................................................................................................................. 42

Service ........................................................................................................................................................ 44

USER MENU............................................................................................................................................... 45

Boiler temperature settings ...................................................................................................................... 45

Water temperature in tank (puffer) ............................................................................................................ 46

5

Sanitary water temperature (HWS temperature) ....................................................................................... 48

Heating circuit ......................................................................................................................................... 48

WLAN modul* .......................................................................................................................................... 51

Language ................................................................................................................................................ 51

CHRONO PROGRAM ............................................................................................................................. 51

Info display .................................................................................................................................................. 54

7. TROUBLESHOOTING ........................................................................................... 55

8. START- UP ............................................................................................................ 58

Ignition - starting ...................................................................................................................................... 58

Boiler shutdown – switch off ..................................................................................................................... 59

Auto-adjusting power operation and extinguishing .................................................................................... 59

Automatic cleaning .................................................................................................................................. 59

Re-ignition ............................................................................................................................................... 59

9. CLEANING AND MAINTENANCE ......................................................................... 60

Regular cleaning of boiler EcoLogic ............................................................................................................. 60

Periodic cleaning of EcoLogic ...................................................................................................................... 63

10. Operation problems ................................ ............................................................. 67

11. Instructions on boiler recycling and proper disposal..............................................68

12. Guarantee............................................................................................................69

Manufactor contact..............................................................................................................................................69

6

1. NOTES

Simple and safe operation

This manual is an integral part of the boiler and contains important information for proper

and safe operation of the EcoLogic boiler. Following the instructions in this manual, the

boiler will work properly and you will avoid the danger, the costs of repairing failures, and

at the same time the lifetime of the boiler continues. Everybody who operates the boiler

operation must apply this instruction.

During the operation of the device, energy that heats the surfaces, doors, handles and

flue pipes is released. Avoid contact with these elements without proper protective

clothing (gloves). Make sure that children are aware of these hazards and keep them

away from the stove during her work.

Technica l change s

ThermoFLUX d.o.o. is constantly developing and improvng its boilers. The information in

this manual is accurate at the time it is printed.

All the details in this guide on standards and regulations should be checked and compared

with the nstalled boiler before using it.

We reserve the right to make any change that may result in deviation from the technical

details and illustrations shown in this manual.

Copyright

It is forbidden to copy and download the content from this manual!

Written permission by ThermoFLUX d.o.o. is required before any copying or any storage

in data transmission systems electronically, mechanically or in any other way, as well as

copying and publication of parts or the entire instruction.

Security measure s

Boilers are designed and manufactured in accordance with all legally prescribed

standards and norms The boiler consists of several parts that are under a constant voltage

of 230 V ~ AC. It is forbidden to perform any interventions and repairs during operation of

the boiler. All interventions of assembling, replaceing and repairing must only be

performed by qualified and licensed persons. Changes on security devices or electronic

regulation are prohibited. Never pull out electrical cables coming out of the boiler, separate

or bend them, even when it is disconnected from the network.

Avoid closing or reducing the dimensions of the ventilation holes of the room in which the

device is installed.

7

Standards:

• UNI EN 303-5 Boilers for heating. Boilers for solid fuels, with manual and automatic

power supply, with nominal heat output up to 500 kW

Directives:

• 2006/42 / EC: Directive MD

• 2014/30 / EU: EMCDDA

• 2014/35 / EU: LVD Directive

• 2011/65 / EU: RoHS Directive 2 "

Obl igatory informi ng

Everyone who operates with the boiler must read the instructions before using it, in

particular, the chapter "Safety Instructions".

This applies especially to persons who occasionally work on a boiler, for example,

cleaning and maintenance of the boiler. This instruction manual should always be kept

near the installed boiler.

Children aged 8 and over, persons with reduced physical, motor or mental capacity,

persons with insufficient experience and training, may use a device of this kind if they

have been provided with supervision or have been given instructions regarding the safe

use of the device and have been presented the dangers arising from it. Children should

not play with such devices. The devices must not be cleaned or maintained by children

without proper supervision.

The boiler room must be made according to regulations specifically related to fire

protection. In the boiler room, no flammable materials, cleaning agents can't be stored.

Extreme cold can cause malfunction and unexpected behavior of electronic components.

After you unpack the boiler and remove the packing, make sure that the contents are

complete. In case something is missing or damaged during transportation, contact the

dealer where you purchased the boiler.

All electrical components of the product that guarantee the correct operation must be

replaced with the original parts.

Before signing the warranty and leaving the boiler, the service technician authorized for

the first commissioning must control the functioning of the boiler during the full working

cycle. General cleaning must be done at least once a year.

8

Warning signs

WARNING SIGNS

RISK OF ELECTRIC SHOCK.

Working in areas marked with this symbol must be done by a qualified

electrician.

WARNING!

Warning for hazardous locations and actions. Failure to follow can

result by fatal injuries.

CHOKING HAZARD DUE TO CARBON MONOXIDE

CAUTION!

Risk of injury. Work on locations marked with this symbol can cause

injuries.

CAUTION!

Hot surfaces. Work on locations marked with this symbol can lead to

burns.

CAUTION!

Risk of flammability. Work on locations marked with this symbol may

cause ignition injuries.

CAUTION!

Risk of frost. Work on the locations marked with this symbol may result

in freezing.

Instructions for proper disposal of waste.

NO ACCESS

Access to the boiler room to unauthorized persons, especially children

should be disabled .

Obligatory use of protective gloves

9

Other warnings

WARNING

Do not open the door for ash cleaning during

operation

Opening the door on the boiler during operation

may cause the termination of boiler operation,

injury, damage and leakage of flue gases.

The door open only during regular cleaning and

maintenance.

WARNING

Never touch hot surfaces!

The hot parts of the boiler, flue gas pipes and heating

pipes can cause severe burns!

Use gloves when working with the boiler.

Maintain the boiler only according to the instructions.

Insulate the flue pipes and avoid possible contact

WARNING

NEVER SWITCH OFF THE BOILER FROM

ELECTRIC NETWORK DURING OPERATION

BOILER

Connection to the power should be with a

permanent connection to avoid the possibility of

the accidental shutdown

Although the boiler is secured with several levels of

protection, forced power shutdown can cause

unplanned failures.

10

System overheating

If the heating system overheats despite all the

elements, it is necessary to proceed as follows.

Do not open doors on the boiler

Turn off the boiler pressing the

button for 3 seconds

Open all heating circuits and switch

on all pumps (boiler regulation does

this automatically)

Leave the boiler room and close the

door

Open all available valves on the

radiators / distribution boxes

If the temperature in the system is not decreasing, call the authorized

service center.

Smoke

Flue gases can cause poisoning!

Do not open doors on the boiler

Turn off the boiler pressing the

button for 3 seconds

Ventilate the room where the boiler is

located

Leave the boiler room and close the

door

Fire in boiler room

In case of fire in the boiler room:

Turn off the boiler pressing the

button for 3 seconds

In case of fire use only extinguishers

type AB with powder.

11

2. SAFETY INSTRUCTIONS

Proper u se

Basic principles

The EcoLogic boiler has been designed and tested in accordance with the safety

regulations deriving from the EN 303-5: 2012 directive. However, improper use of the boiler

can result in bodily injuries that can ultimately result in the death of users and / or third

parties as well as damages to the boiler itself or other material assets.

Handling the boiler

The boiler can only be used when it is in its proper condition. Use the boiler in the manner

described in this manual. Get informed with security measures and possible dangers.

Remove all faults and malfunctions that could affect your safety.

Using the boiler

The boiler is intended for combustion of wood pellets. Any other use is improper. The

manufacturer will not be held responsible for any damage caused by improper handling.

Proper use implies maintenance of the installed boiler, operation and maintenance

conditions prescribed by the manufacturer.

The user can enter or change only those values that are specified in this manual. Any other

parameter value will affect the control program and boiler operation, which can ultimately

lead to a break or improper operation.

Changes on the boiler

It is forbidden to make any changes on the boiler or equipment supplied. It is forbidden to

deactivate the security functions. The manufacturer will not give any warranty if the user or

a third party performs an unauthorized intervention on the boiler and equipment that comes

with it.

The boiler may only be used for the purpose for which it is produced.

The manufacturer does not accept any responsibility for damage

caused to persons, animals or property resulting from faults in

installation, incorrect regulation and maintenance or improper use of

the boiler.

12

Pellets that can be used in boilers

The boiler is designed exclusively for burning wood pellets with a

diameter of 6 mm and a length of 10-30 mm.

What is pellet

Pellet is obtained from wood, if it is

possible, from the core of the trunk with

the lowest proportion of bark. The bark

contains the most moisture, dust and

impurities that wood gets during growth,

therefore has a lower caloric value than

the core, and another problem is that it

leaves the sediment when burning. Ideal

wood for pellet production is one that

does not burn too long or too short and

creates a long-lasting glow. Pellets are

made from sawdust waste (typically in a

ratio of 20-40% softwood + 60-80%

hardwood), in special machine under

high pressure which leads to thickening.

It is not allowed to use any additives or

glue during the pellet. production The

pellet contains a minimal amount of

moisture and ash, and has a maximum

energy value for the type of wood from

which they are produced.

Recommended wood pellets and standards

Pellets quality arises from Standard pellets C1 to EN 303-5: 2012 Table 7; Water content

less than 12% according to DIN 51731 - HP 5, DINplus certification program and ÖNORM

M 7135 - HP 1 or EN PLUS - UNI EN 14961 - 2 (UNI EN ISO 17225-2) class A1 or A2, 6

mm diameter, length 10-30 mm.

Particular attention should be paid to the quality of wood pellets. Lowgrade pellets can cause malfunction of the boiler.

13

Unallowed fuels

The pellets not consisting the standards mentioned in this manual is not allowed to burn

in a boiler. Using a bad quality pellet or any other material can lead to damaging your

boiler's important functions and may result in the termination of the warranty and

associated liability.

Obligatory information

All persons managing the boiler must read the manual before starting

to use it and in particular the "Safety instructions".

This applies especially to persons who occasionally work on a boiler,

e.g. cleaning and maintaining boilers.

This instruction should always be kept near the installed boiler.

Children aged 8 and over, persons with reduced physical, motor or mental capacity,

persons with insufficient experience and training, may use a device of this kind if they

have been provided with supervision or have been given instructions regarding the safe

use of the device and have been presented the dangers arising from it. Children should

not play with such devices. The devices must not be cleaned or maintained by children

without proper supervision.

Local stan dards

All local laws must be respected during installation, as well as standards and

norms that are in force in the country where the boiler is installed even though

it is not listed in this manual.

During the first installation of the boiler or in the event of changes on central heating system,

it is necessary to inform the competent authority in charge for control, and provide all the

necessary permits.

Safety instruction s for bo ile r room

The boiler room must be made according to current regulations, especially regarding fire

protection. Storage of flammable materials, cleaning agents and similar materials must not

be stored in the boiler room

14

The room where the boiler is installed must be frost-resistant

The boiler must not be exposed to colds or freezing temperatures. Extreme cold can cause

malfunction and unexpected behavior of electronic components.

Fresh air supply

For combustion of pellets and normal work boiler needs fresh air. The room in which the

boiler is installed must have an opening for fresh air supply. The recommended minimum

dimension is 30x15 cm.

Boi ler safety de vice s

The boiler is equipped with safety systems which, in the case of

unforeseen situations, serve to stop the power supply and thus stop

the boiler operation.

Microprocessor control on the boiler: intervenes directly, turns off the boiler until

it cools down and shows an error on the display screen in case of a failure of flue

gas fan, malfunction of the dispenser engine, failure of the ignition.

Fuse: Quick fuse, protects the boiler of large current drops and short circuit inside

the boiler.

Safety Thermo Switch (STB): If boiler overheats (at 90 ° C), all pumps in the

system turn on, attempting to cool the boiler. If this fails and the temperature

continues to increase, the STB intervenes by sending the signal to the regulation,

ERROR BOILER OVERHEAT and STB ACTIVATED are displayed and the boiler

stops working. After the boiler is cooled, it is necessary to manually reset the switch

and start the boiler.

Safety switches – in case the door is not closed, the grate in the burner does not

return to its original position, an error is shown on the display and the boiler stops

working.

15

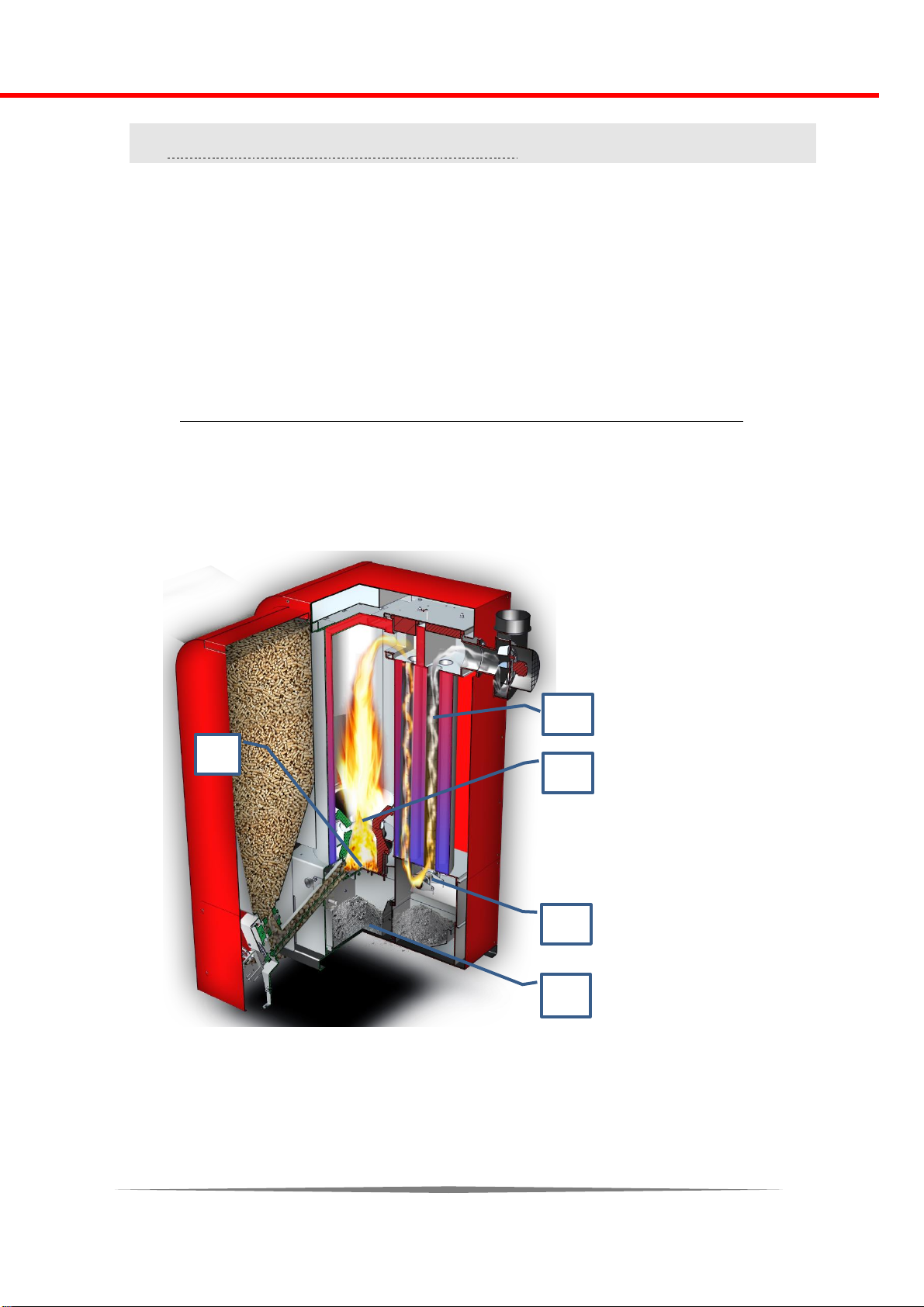

Boiler parts:

1. Burning

chamber

2. Automatic grate

3. Ashtrays

4. Automatic

cleaning system

of the tube heat

exchanger

5. Tube heat

exchanger

3. GENERAL OVERVIEW

EcoLogic boiler is a high-class boiler, in the range of the best boilers at the European

market.

The boiler control supports the connection of up to three circulation pumps, mixing valve

motor, hot water storage tank and sanitary water boiler.

An optional modem for Internet connection can be ordered as an accessory. The user can

have full control of the boiler via the application (to enable/disable, change power,

temperature or program it).

Cross section of the boiler

1 5 4

2

3

16

EcoLogic

Identification and serial number

The technical data label and the serial number are located on the back of the boiler.

17

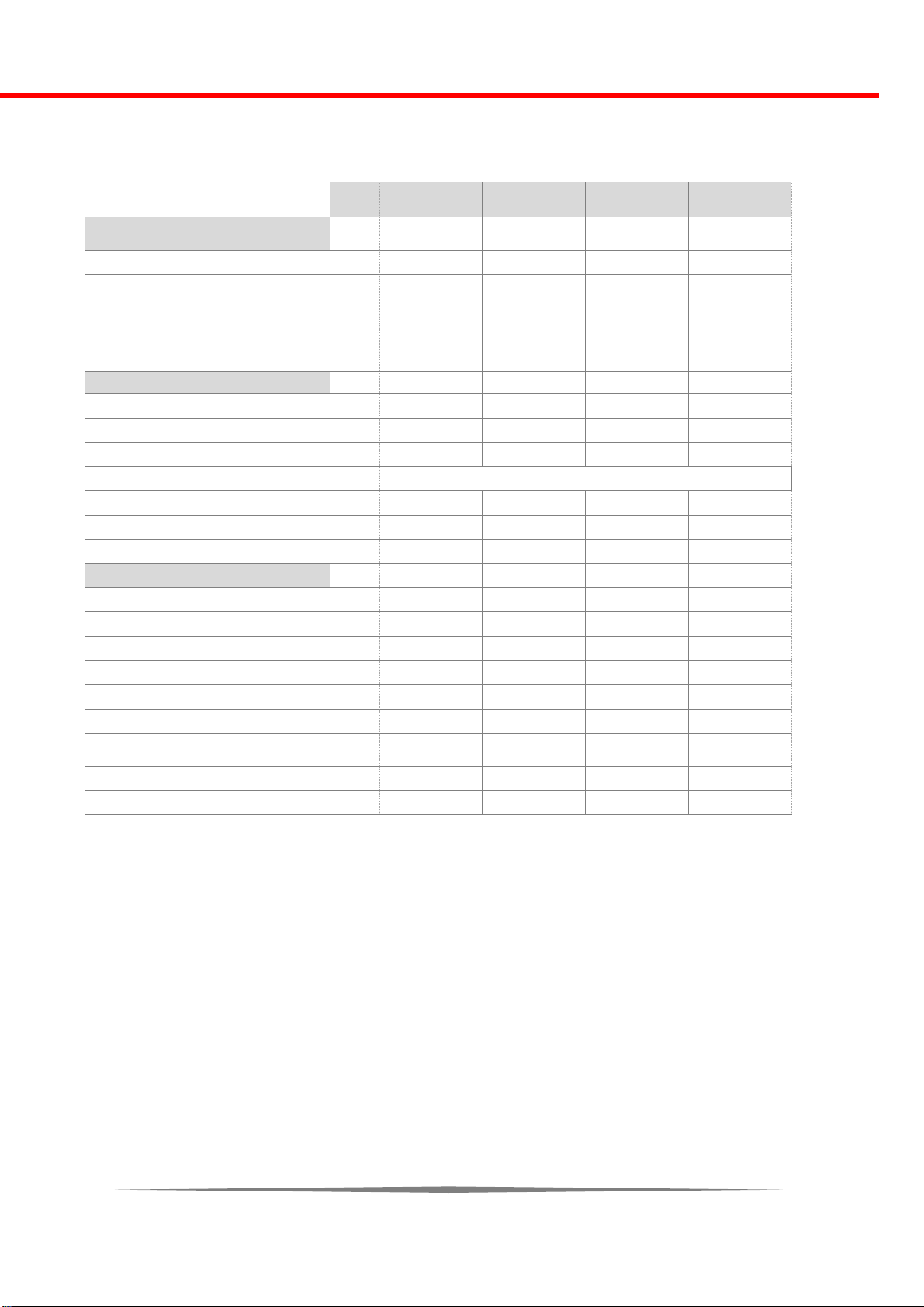

Technica l data

EcoLogic

25

EcoLogic

35

EcoLogic

44

EcoLogic

55

Performance (measured

according to EN 303-5: 2012)

Maximum power

kW

25

35

44

55

Minimum power

kW 8 11

13

17

Electrical conection

V,Hz

230 V, 50 Hz

230 V, 50 Hz

230 V, 50 Hz

230 V, 50 Hz

Electrical conection (current)

A

10

10

10

10

Boiler class

5 5 5

5

General information

Max. Permited presure

bar

2,5

2,5

2,5

2,5

Max. Permited temperature

°C

85

85

85

85

Min. permited return temperature

°C

55

55

55

55

Fuel

EN PLUS - UNI EN 14961 - 2 (UNI EN ISO 17225-2) Class A1 / A2

Pellet consumption min / max

kg

1,7 / 5,4

2,4 / 7,5

3 / 9,5

3,9 / 11,9

Pellet silo capacity

kg

170

170

170

200

Fresh air opening

cm

30x15

30x15

30x15

30x15

Technical data

Boiler width with pellet silo

mm

1050

1050

1050

1050

Height

mm

1270

1460

1460

1650

Depth

mm

1100

1100

1100

1100

Water content

l

55

68

90

115

Weight

kg

370

395

415

455

Height out / return

mm

1125 / 603

1315 / 603

1315 / 685

1505 / 685

Chimney underpresure

Pa /

mbar

5 / 0,05

5 / 0,05

5 / 0,05

5 / 0,05

Flue gas pipe height (direction UP)

mm

1250

1440

1440

1630

Flue gas pipe diameter

Ø

130

130

130

130

* minimal power - 30 % maximum

power

18

4. INSTALLATION

The commissioning of the system must be carried out by the personnel

authorized by ThermoFLUX d.o.o or the importer.

The warranty will not be valid if the boiler has not been commissioned

by an authorized servicer.

The first start-up includes the basic operation and maintenance of the boiler. The service

technician authorized for the first commissioning must check the functioning of the boile at

least during one complete work cycle. In some countries, it is obligatoy for first

commissioning to be controled and autorizied by chimney sweep or a person authorized

to control.

Risk of material and physical damage due to improper

commissioning. If the first start-up is done by an

unprofessional person, damage to the boiler and the

heating system may occur.

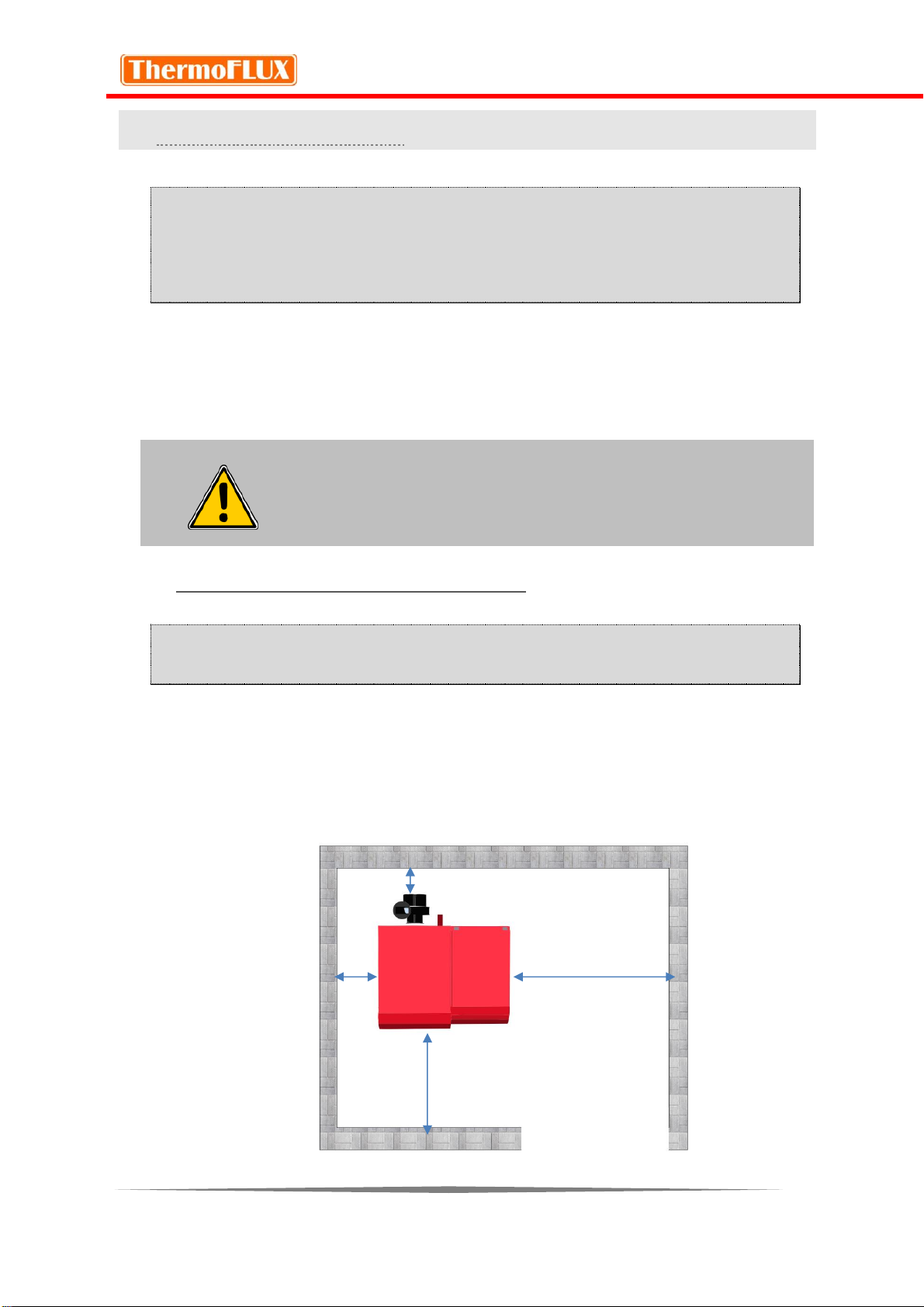

Conditions for installation

The following conditions must be completed before the system is

released.

The installation of the boiler must be done according to the regulations - with

a minimum distance of 50 cm from the side, ie 40 cm from the back of the

boiler measured from the flue gas fan. Distance in front of the boiler must be

at least 100 cm.

Min. 40 cm

Min. 50 cm

Min. 50 cm

Min. 100 cm

19

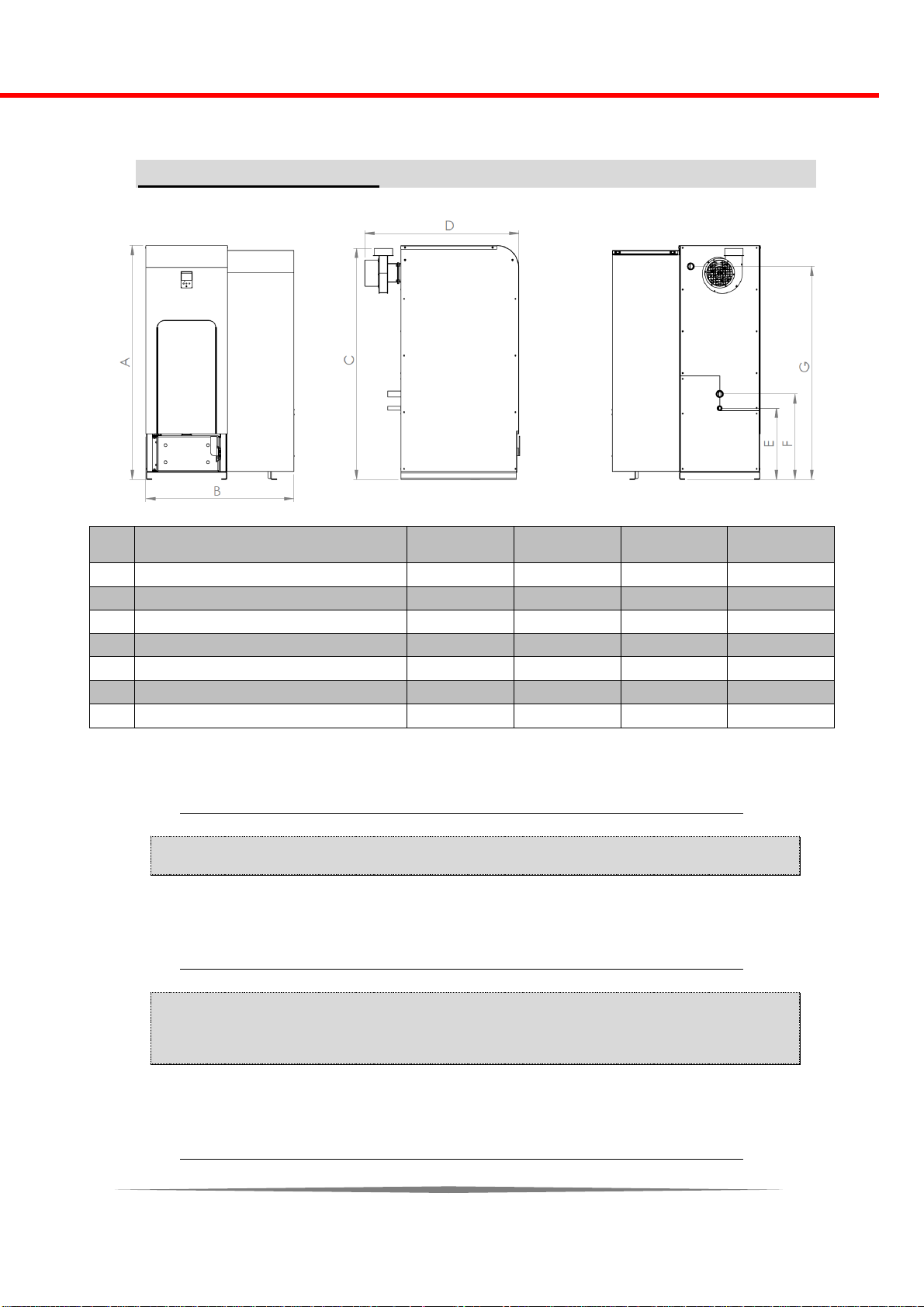

Boiler dimensions

EcoLogic

25

EcoLogic

35

EcoLogic

44

EcoLogic

55

A

Height

1270

1460

1460

1650

B

Width

1050

1050

1050

1050

C

Height of the flue outlet

1250

1440

1440

1630

D

Depth

1100

1100

1100

1100

E

Drain outlet

505

505

505

505

F

Return connection height

603

603

603

603

G

Output connection heght

1125

1315

1315

1505

Switch off main power supply

Be sure to turn off the main power before any work!

Check mechanical connections

• Check that all components are properly connected.

• Check that all mechanical components are securely attached.

20

Check hydraulic conections

Check that the circulation pump and the mixing valve are

properly connected.

Check that the safety equipment is properly connected

After completing the work, fill the system and wait an hour to

control all connections.

The boiler can be connected to an open or closed heating system.

With the connection to the open heating system, the open expansion vessel must be at a

height of 50 cm above the highest heating body and well insulated.

With the connection to the closed heating system, the safety valve and the membrane

expansion vessel must be installed as close as possible to the boiler and there can't be any

valves between them.

21

Hydraulic diagrams and connection mode s for individual system configu ration s

The boiler control supports the connection of three (3) circulation

pumps, mixing valve motor, buffer tank and sanitary water tank.

Only qualified service technicians have access to technical parameters

and settings, and can adjust the hydraulic connection.

The operation system will be adjusted according to the conducted

installation.

Electronic regulation supports connection to three heating circuit pumps, ie outputs: P1, P2

and P3.

P1 pump output can be used for the heating circuit 1 or by activating

the buffer for that circuit

P2 pump output can be used for the heating circuit 2 or by activating

the sanitary boiler for that circuit

The pump output P3 can be used for the remaining heating circuit 3.

Motor mixing valve output can be used only for one heating circuit

22

Hydraulic conection diagrams

Loading...

Loading...