Page 1

Technol

o

gyMadeEas

y..

.

Instruction Manual

TN-100/T-100

Portable Turbidimeter

68X357701 Rev. 9 July 2013

Part of Thermo Fisher Scientific

Page 2

Page 3

Page 4

Preface

This manual functions in two ways: first as a step by step guide to help you operate the

waterproof TN-100/ T-100 turbidimeter; second, it serves as a handy reference guide.

It contains basic instructions that you must follow during the operation, care and

maintenance of the instrument. The safety protection provided by this equipment may

be impaired if it is used in a manner not described in this manual. It is recommended

that all operators should read this manual prior to working with this instrument.

Eutech Instruments/Oakton Instruments cannot accept any responsibility for damage or

malfunction to the meter caused by improper use of the instrument.

The information presented in this manual is subject to change without notice as

improvements are made, and does not represent a commitment on the part of Eutech

Instruments Pte Ltd/Oakton Instruments.

Note: Eutech Instruments Pte Ltd/ Oakton Instruments reserves the right to make

improvements in design, construction, and appearance of products without

notice.

Kimwipes

Copyright© 2012 All rights reserved.

®

is a registered trademark of Kimberly-Clark and its affiliates.

Eutech Instruments Pte Ltd

Oakton Instruments

Page 5

Table of Contents

1. Overview .............................................................................................. 1

1.1 Unpacking TN-100/ T-100 Meter and Accessories ............................................... 1

1.2 Display................................................................................................................... 2

1.3 Keys and Functions ............................................................................................... 3

1.4 Battery Installation ................................................................................................. 4

2. Turbidity Calibration ........................................................................... 5

2.1 Calibration Standards ............................................................................................ 5

2.2 Indexing ................................................................................................................. 5

2.3 Calibration Procedure ........................................................................................... 6

2.4 Restoring Factory Calibration ............................................................................... 8

3. Turbidity Measurement ..................................................................... 10

3.1 General Information ............................................................................................ 10

3.2 Turbidity Measurement Procedure ...................................................................... 10

3.3 Single-Shot or Continuous Measurement ........................................................... 13

4. Troubleshooting Guide ..................................................................... 15

5. Routine Maintenance ........................................................................ 16

5.1 Vials – Handling, Cleaning and Care .................................................................. 16

6. Accessories ....................................................................................... 17

7. Specifications .................................................................................... 18

8. Addendum 1: Turbidity ..................................................................... 19

8.1 Definition ............................................................................................................. 19

8.2 Why Is It Important? ............................................................................................ 19

8.3 Measurement Principle ....................................................................................... 19

8.4 Nephelometric Turbidity Units (NTU) .................................................................. 20

8.5 Indexing a Vial ..................................................................................................... 20

9. Addendum 2: Guide to Good Measurement Technique ................ 21

9.1 Maintain sample vials in good condition ............................................................. 21

9.2 Match Sample Vials ............................................................................................ 21

9.3 Degassing ........................................................................................................... 21

9.4 Timeliness of Sample .......................................................................................... 22

9.5 Other Important Sampling Techniques ............................................................... 22

9.6 Calibration ........................................................................................................... 22

9.7 Dilution .............................................................................................................. 222

10. Warranty ...................................................................................... 233

11. Return of Items .............................................................................. 24

Page 6

Instruction Manual TN-100/ T-100

1. Overview

Thank you for selecting the waterproof portable TN-100/ T-100 turbidimeter. The TN100/ T-100 allows you to measure turbidity of an aqueous sample in the field. This

instrument operates on the nephelometric principle of turbidity measurement and is

designed to meet the criteria specified in ISO 7027 and DIN 27027 standards (see

Measurement Principle on page 19).

1.1 Unpacking TN-100/ T-100 Meter and Accessories

The table below indicates the items that you should find in your turbidimeter shipment.

Item Quantity

1. Portable TN-100/ T-100 Turbidimeter with 4 “AAA” batteries 1

2. Instruction Manual 1

3. Instrument Carrying Case 1

4. Light Shield Cap 1

5. Calibration Set (0.02, 20.0,100, 800 NTU Standards, 60 ml each)

6. Empty Vials

7. Silicone Oil 1

8. Lint free cloth 1

1

7

Remove TN-100/ T-100 turbidimeter from the packing carton. Carefully inspect all

items to ensure that no visible damage has occurred during shipment. If the items you

received do not match your order, please contact your nearest distributor immediately.

WARNING: Extra care should be taken when unpacking, opening, and handling

the calibration standards and sample vials. Surface scratches or finger smudges

on the vial surface may cause measurement errors. Handle these items by their

caps only.

Batteries provided with the meter package are to be installed prior to use. See Section

1.4 - Battery Installation on page 4.

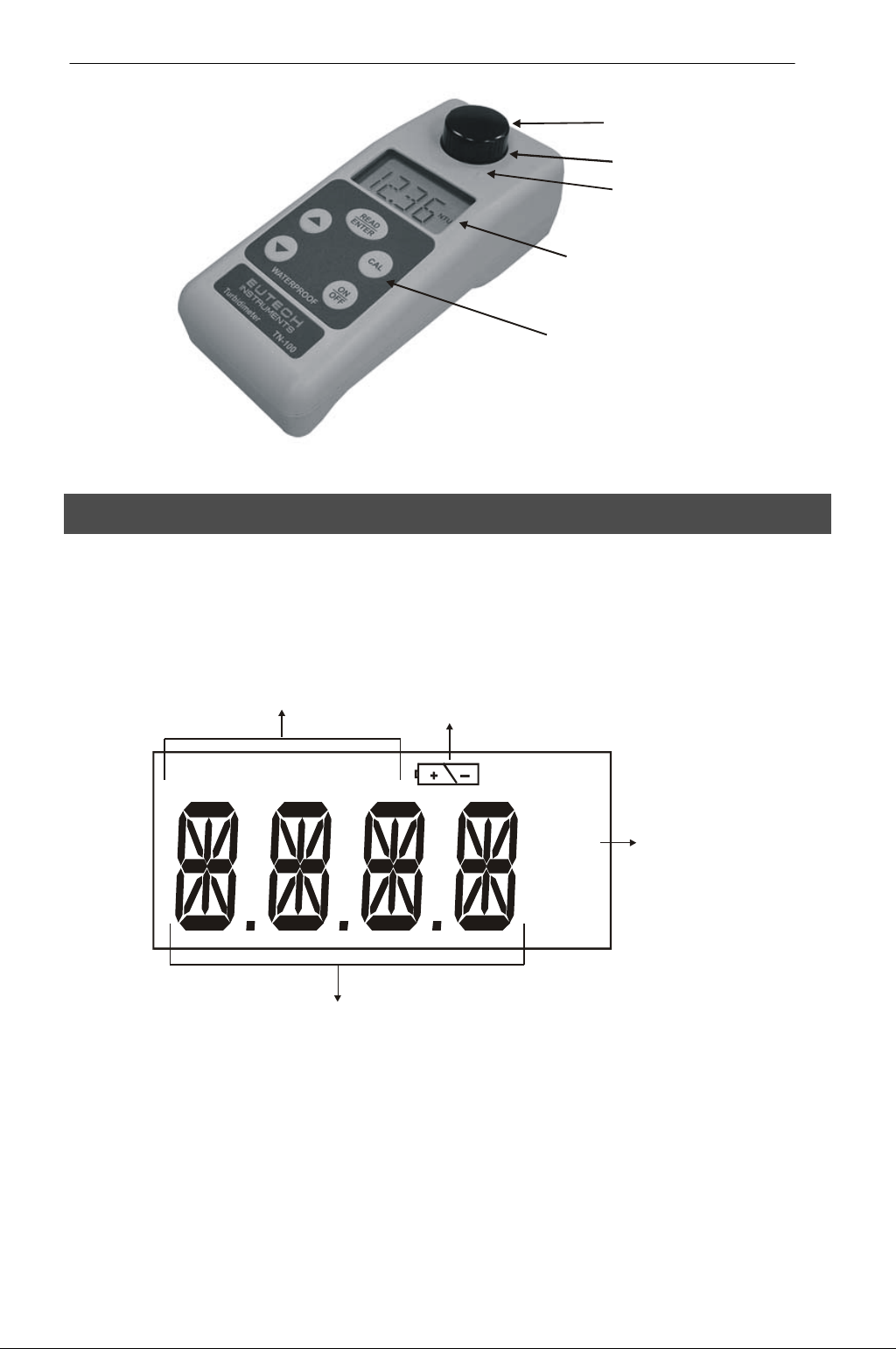

Figure 1 depicts the meter. The three main components of the instrument are the

sample well, the display, and the keypad. The following sections describe the

functionality of the display and the keypad. The proper use of the instrument and the

sample well are discussed in later sections.

1

Page 7

Instruction Manual TN-100/ T-100

Sample Vial

Sample Well

Index Mark

Liquid Crystal Display

Keypad

CAL 13 CAL 24

mg/l

NTU

ppm

%pH

TAvg

14-segment Liquid Crystal Display

Battery Indicator

Calibration

Standards

Units of

Measurement

Figure 1: Parts of TN-100/T-100 Turbidimeter

1.2 Display

All the LCD segments and annunciators that can appear on the display are shown in

Figure 2. The display is used for reporting the turbidity reading and to provide guidance

for the operation of the instrument. In addition, the display has several other

annunciators that are used to communicate error messages and provide user

guidance.

Figure 2: Customized LCD with all annunciators

2

Page 8

Instruction Manual TN-100/ T-100

Active only during calibration mode. These keys are used to select the

READ

ENTER

READ

ENTER

CAL

OFF

ON

WATERPROOF

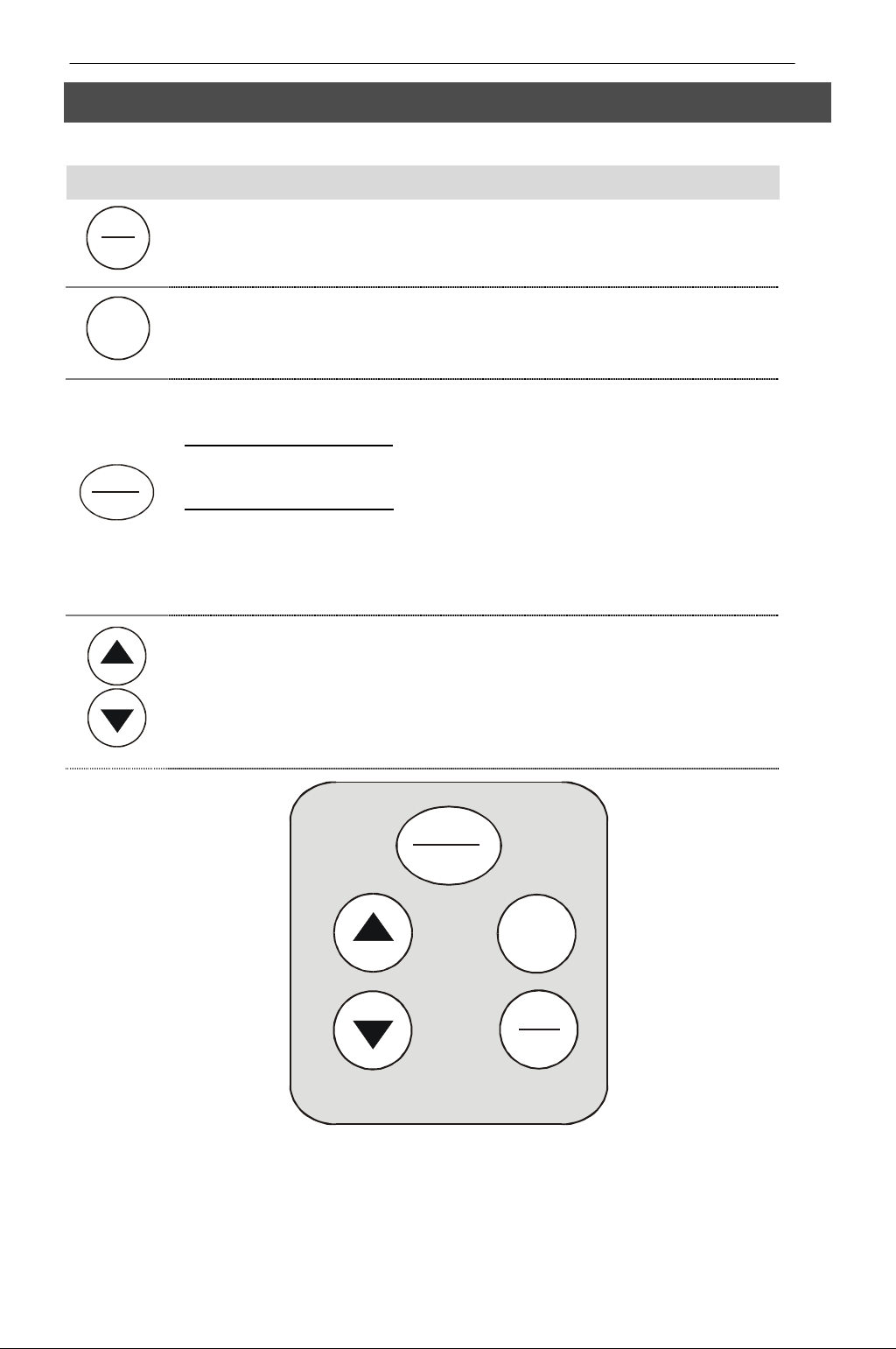

1.3 Keys and Functions

The keypad has five keys: ON/OFF, CAL, ▲, ▼, and READ/ENTER.

Key Functions

ON

OFF

CAL

Powers on and shuts off the meter. With the auto switch-off feature the

meter automatically shuts off 20 minutes after last key press.

Initiates the calibration mode of the meter. When pressed, the meter is set

to accept the first calibration standard.

It is also used to exit the calibration mode if the user does not want to

follow the complete calibration procedure.

When in measurement mode, the READ/ENTER key is used to perform a

measurement.

Single-shot measurements: When the key is pressed and released

immediately (a quick key stroke of less than 0.3 seconds), the display will

blink [-Rd-] for 10 times and then display the measured value.

Continuous measurements

the instrument will perform a continuous measurement during which the

display is updated every 2 seconds. This can be used for indexing vials.

(This function is not available in calibration mode).

After the READ/ENTER key is released, the instrument will automatically

perform a single-shot measurement.

: If the READ/ENTER key is pressed and held,

calibration point in an incremental/ decremental manner.

NOTE: This meter is fitted with an auto incrementing feature, i.e. after

the successful calibration of one point it auto selects the next calibration

point, or automatically exits the calibration mode after the fourth

calibration point.

Figure 3: Keypad

3

Page 9

Instruction Manual TN-100/ T-100

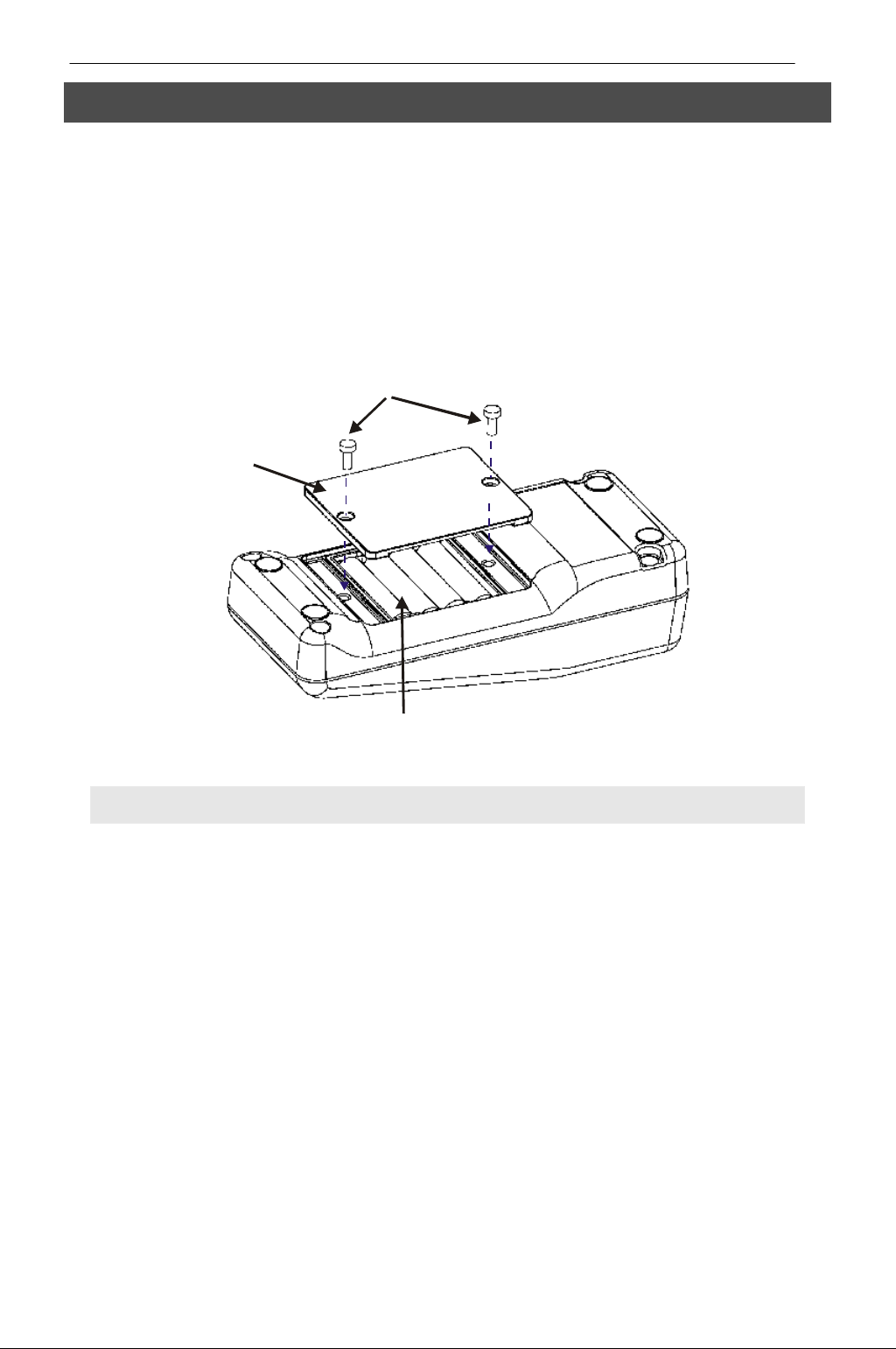

Philips Screws

Battery cover

Four 'AAA'-sized batteries

1.4 Battery Installation

Four AAA-sized batteries are included in the packaging:

1. Use a Philips screwdriver to remove the two screws holding the battery cover.

See Figure 4.

2. Remove the battery cover.

3. Insert the batteries. Follow the diagram inside the cover for correct polarity.

4. Replace the battery cover onto its original position using the two screws

removed earlier.

5. The meter is now ready to operate.

Figure 4: Battery Installation

NOTE: Dispose used batteries in accordance with your local regulations.

4

Page 10

Instruction Manual TN-100/ T-100

2. Turbidity Calibration

Calibration Overview

The TN-100/T-100 turbidity meter was calibrated and tested prior to leaving the factory.

The meter kit now includes a set of prepared SDVB primary standards in plastic bottles

which are EPA-approved for meter calibration. This keeps the stock solutions for the

0.02, 20.0, 100 and 800 NTU standards ready to use and offers improved precision

and shelf life. A set of 4 empty vials for the standards are included in the meter kit.

Before using the meter for the first time, verify the meter calibration by reading back the

value for the prepared primary standard at the appropriate NTU value. This check is

recommended daily to check the meter prior to measuring a sample. When the

standard value drifts, retest with a vial of fresh standard solution. The 0.02 NTU

standard needs to read <0.1 NTU for acceptance.

A replacement set of the 4 standards in plastic bottles is available. These 60mL bottles

are identical to the bottles in the meter kit, so they can easily be carried in the case to

where the measurement needs to be taken. These standards are specifically made for

the TN-100/T-100 portable turbidity meters. The standards will not read to the stated

NTU value in other manufacturer’s turbidity meters.

2.1 Calibration Standards

We recommend that you use the following materials during calibration to achieve the

accuracy stated in this manual:

CAL 1: 800 NTU Calibration Standard

CAL 2: 100 NTU Calibration Standard

CAL 3: 20.0 NTU Calibration Standard

CAL 4: 0.02 NTU Calibration Standard

It is well known that diluted Formazin is unstable. If you choose to use Formazin to

calibrate the instrument, ensure that you are using a fresh stock suspension of

Formazin to achieve the accuracy quoted for the instrument. Calibration standards

offered are more stable than Formazin. For expiry date of calibration standard, please

refer to the expiration date indicated on the cap label.

It is important that the calibration standards are not violently shaken or agitated

because air entrapment in the fluid introduces an error factor during calibration

which subsequently will lead to an inaccurate measurement. Also, do not store in

freezing temperatures which causes irreversible shrinkage of the standards’

particles thus resulting to inaccurate calibration and measurement.

2.2 Indexing

Due to the high quality of the glass vials provided, indexing is not required. You only

need to align the mark on the vial with the mark on the meter. However, in order to

achieve a better accuracy of the measurement, you can proceed with indexing of the

vials. See Section 8.5 - Indexing a Vial on page 20 for more information.

5

Page 11

Instruction Manual TN-100/ T-100

2.3 Calibration Procedure

Preparing the Standard Vials

Each standard vial should be used with the same standard value (0.02, 20.0, 100, or

800 NTU) for the greatest accuracy. Follow the steps below at each change of solution.

1. Ensure there are no scratches or marks on the glass vial. If there are marks that

could affect the turbidity measurement, select another vial.

2. Slowly and gently invert the calibration standard plastic bottle five times but do

not shake the bottle as air bubbles can affect the reading.

3. Rinse a clean vial with 3-4 mLs of the calibration standard that will be used in

this vial. Invert the capped vial 5 times. Uncap and dispose of the rinsate.

4. Repeat the rinsing steps and dispose of the rinsate.

5. Fill the vial with the primary standard solution to the fill line and cap the vial.

6. Clean the exterior of the vial using a lint-free cloth to remove all traces of liquid,

dirt or fingerprints. Remove stubborn smudges with alcohol or a non-abrasive

glass cleaner, and silicone oil can be used to fill small external scratches on the

vial.

7. Repeat Steps 1-6 to prepare the other three standard solutions.

These standard vials can be used to check the meter calibration by reading back

the standard value daily and also be used for calibration when needed. When the

standard reading of 20.0, 100, or 800 NTU drifts more than 10% of the standard’s

NTU value, the solution should be replaced with another aliquot from the plastic

bottle following the Preparing the Standard Vials steps

read back value should be <0.1 NTU.

. The 0.02 NTU standard

6

Page 12

Instruction Manual TN-100/ T-100

CAL 1

800 NTU

NTU

CAL 1

NTU

NTU

CAL 3

CAL 3

NTU

CAL 2

NTU

CAL 2

READ

ENTER

NTU

CAL 1

CAL

Place the CAL 1

standard into the

sample well

Place the CAL 3

standard into the

sample well

Flashes about 5 time s

Flashes about 10 times

Flashes about 10 times

Flashes about 10 times

Flashes about 10 times

CAL 4

CAL 3

20.0 NTU

0.02 NTU

NTU

NTU

CAL 4

CAL 4

READ

ENTER

READ

ENTER

Place the CAL 2

standard into the

sample well

Place the CAL 4

standard into the

sample well

Measurement Mode

CAL 2

100 NTU

READ

ENTER

Measurement Mode

Figure 5: Calibration Sequence

7

Page 13

Instruction Manual TN-100/ T-100

2.4 Restoring Factory Calibration

The TN-100/ T-100 turbidimeter allows you to reset the meter back to the factory

default calibration values. This feature is extremely useful when there are errors in

calibration or when you have new calibration standards.

1. With the meter switched off, press and hold ▲ key.

2. Switch on the meter using ON/OFF. Release ▲ key when “URST” (User -Reset)

appears in the display.

3. The display shows “URST” for about 2 seconds and then shows “No”.

4. Use ▲ or ▼ key to select between “YES” or “No”.

YES = To restore meter back to factory calibration values

No = To retain last calibrated values

5. Press READ/ENTER key to confirm your selection. The meter performs the reset if

“YES” is selected.

6. The display flashes “--Rd—“about 10 times indicating that the meter goes to

measurement mode.

Figure 6 shows the sequence for restoring factory calibration values.

8

Page 14

Instruction Manual TN-100/ T-100

READ

ENTER

READ

ENTER

“-Rd-” flashes about 10 times

Select YES and

to restore factory

calibration

then

press

key

READ/ENTER

Select No

to retain last

calibration values

without retrieving

factory calibration

and then

press

key

READ/ENTER

OFF

ON

Instrument Off

Measurement Mode

Press & hold key and

switch on the meter u sing

keyON/OFF

Release key when you

see ‘URST’ in the display

Press or key to

select or YES No

Figure 6: Restoring Factory Calibration

9

Page 15

Instruction Manual TN-100/ T-100

CAL 13 CAL 24

mg/l

NTU

ppm

%pH

TAv g

NTU

OFF

ON

"-Rd-” flashes about 10

times indicating that the

meter goes to

measurement mode.

A reading is valid only if you have placed a

vial or any of the calibration standards

provided into the sample well.Otherwise

the reading has no meaning or an error

message "Err 8" appears.

Instrument Off

Place a sample vial or any of the

calibration standards provided into

the sample well of the meter, before

switch on.

X. x

“X.X” is software revision

number

3. Turbidity Measurement

3.1 General Information

The waterproof TN-100/ T-100 turbidimeter allows you to measure the turbidity of a

grab sample. The turbidity is reported in Nephelometric Turbidity Units (NTU).

Readings above 1000 NTU are outside the range of this instrument.

NOTE: Before switching on the TN-100/ T-100 turbidimeter, a sample vial MUST

be placed in the sample well. You can use any of the calibration standards for

this purpose.

The light shield cap provided could be used to cover the vial during

measurements.

When the ON/FF key is pressed to switch on the meter, it goes through the power-up

sequence as shown in Figure 7 below.

3.2 Turbidity Measurement Procedure

An accurate turbidity measurement depends on good measurement techniques.

Factors such as clean sample vials, positioning of vial in the sample well, covering the

vial with the light shield cap, meter calibration, handling of meter, and others, have to

be taken into consideration. Please see the following sections for more information.

Section 5.1: Vials – Handling, Cleaning and Care (page 16 )

Section 9: Addendum 2:

Guide to Good Measurement Technique (page 21)

Figure 7: Power-up Sequence

10

Page 16

Instruction Manual TN-100/ T-100

Preparation of Sample Vial

1. Obtain a clean and dry sample vial

2. Take care to handle the sample vial by the top.

3. Rinse the vial with approximately 10 ml of the sample

water, capping the vial with the black screw cap and

gently inverting it several times. Discard the used

sample and repeat the rinsing procedure two more

times.

4. Fill the rinsed vial with the remaining portion

(approximately 10 ml) of the grab sample up to the

mark indicated in the vial. Cap the vial with the

supplied black screw cap.

5. Wipe the vial with the soft, lint-free cloth supplied.

Figure 8: Sample Vial

Ensure that the outside of the vial is dry, clean and

free from smudges.

6. Apply a thin film of silicone oil (supplied) on the sample vial (see Figure 9).

7. Wipe with a soft cloth to obtain an even distribution over the entire vial’s surface.

NOTES:

1. The purpose of oiling the vial is to fill small scratches and to mask the

imperfection in the glass.

2. Do not apply large quantity of oil as this may collect dirt and dust

8. The sample vial is now ready to be inserted into the sample well of the meter for

measurement.

Figure 9: Apply a thin film of silicon oil

11

Page 17

Instruction Manual TN-100/ T-100

Align index mark on

the sample vial with

the index mark on

the TN-100/ T-100

turbidimeter and

push till it is fully

snapped in

IMPORTANT:

Place meter on a flat

and level surface.

DO NOT hold it on

hands while operating

the meter. It may lead to

inaccurate readings

Light shield cap for

covering the vial during

measurements

“-Rd-” flashes about

10 times

SAMPLE

Unknown

NTU

Place sample

vial into the

sample well

NTU

READ

ENTER

Measurement Mode

Measurement Procedure

1. Place TN-100/ T-100 turbidimeter on a flat and level surface.

2. Place the sample vial inside the sample well and align the vial’s index mark with the

meter’s index mark. See

Figure 10.

3. Push the vial until it is fully snapped in.

4. Cover the vial with the light shield cap.

5. Turn on the meter by pressing the

ON/OFF key.

6. After the power-up sequence, the meter

goes to measurement mode and the

display blinks “--Rd--“ for about 10 times.

See Figure 11.

7. The measured reading appears in the

display.

8. If necessary, place the second sample vial

into the sample well. Remember to align

the vial’s mark with the meter’s index

mark.

9. Press READ/ENTER key. The display

10. Repeat steps Error! Reference source

blinks “--Rd--“ for several times and

measured reading appears.

not found. through 9 for all of your

samples.

Figure 10: Align sample vial’s index mark with meter’s index mark

Reading Turbidity Value

Figure 11:

12

Page 18

Instruction Manual TN-100/ T-100

“-Rd-” flashes about

10 times

SAMPLE

Unknown

NTU

Place sample

vial into the

sample well

NTU

READ

ENTER

Measurement Mode

Press key and

release immediately

NOTES:

1. NEVER pour liquid directly into the sample well of the instrument. Always

use a vial. The instrument will only accurately measure the turbidity of a

sample when vials sealed with the black caps are used. The black cap

serves as both seal and a light shield.

2. NEVER attempt to clean the sample well. The optics may be damaged.

3. For battery conservation, the instrument automatically powers off 20

minutes after the last key pressed.

3.3 Single-Shot or Continuous Measurement

You can use TN-100/ T-100 turbidimeter to take a single reading or perform continuous

measurement. The latter is only used for indexing the vials. See Section 8.5 - Indexing

a Vial on page 20 for more information.

For Single-shot Measurement:

1. Make sure the meter is sitting on a flat and

2. Place sample vial in the sample well.

3. Cover the vial with the light shield cap.

4. Press READ/ENTER key and release

5. The display blinks “--Rd--“ for about 10

level surface and is in measurement

mode. The display shows the last

measured value or “STbY” after exiting

calibration mode.

immediately (<0.3 seconds). See Figure

12.

times and then display the measured

value.

Figure 12: Single-shot Measurement

13

Page 19

Instruction Manual TN-100/ T-100

Figure 13: Continuous Measurement

Reading flashes and

updates every 2 seconds

SAMPLE

Unknown

NTU

Place sample

vial into the

sample well

NTU

READ

ENTER

Measurement Mode

Press key and hold

For Continuous Measurement:

1. Make sure the meter is sitting on a flat and level surface and is in measurement

mode. The display shows the last measured value or “STbY”

2. Place the sample vial in the sample well.

3. Press READ/ENTER key and hold. See Figure 13

4. Wait for the reading to stabilize before rotating the sample vial.

NOTE: During continuous measurement, the display is updated every 2 seconds.

The displayed reading may not be the actual turbidity value. For accurate

measurement, use single-shot measurement.

You can rotate the sample vial for indexing purpose. See Section 8.5 - Indexing a Vial

on page 20 for more information.

5. Once you release READ/ENTER key, the meter automatically performs a singleshot measurement.

NOTES:

1. After a measurement is completed and the display is updated, a 4second recovery time occurs before the meter can perform another

function. If any key is pressed during the recovery time, the meter will

perform the corresponding action at the end of the recovery period.

2. When performing a measurement, if the meter detects stray light

exceeding the amount equivalent to 0.02 NTU in the low range, the

measurement is immediately aborted and an error message [ERR 8] is

displayed. Ensure the vial sits properly into the sample well. Press the

ENTER/READ key to re-do the measurement.

14

Page 20

Instruction Manual TN-100/ T-100

4. Troubleshooting Guide

The TN-100/ T-100 turbidimeter routinely performs self-diagnostics, and will

automatically generate messages to provide you with specific diagnostic information.

These messages are for your use and do not indicate a reduction in the performance of

the instrument or a failure of any component in the instrument, unless otherwise stated

in this list.

LCD

Message

Calibration Error. The meter is

ERR 1

ERR 2

ERR 3

ERR 4

ERR 5

ERR 6

ERR 7

ERR 8

ERR 9 Lamp Failure. Return unit.

Or

unable to recognize the 800 NTU

Calibration Standard.

Calibration Error. The meter is

unable to recognize the 100 NTU

Calibration Standard.

Calibration Error. The meter is

unable to recognize the 20.0 NTU

Calibration Standard.

Calibration Error. The meter is

unable to recognize the 0.02 NTU

Calibration Standard.

Calibration Error. There is not

sufficient signal to achieve the

appropriate resolution in the 01000NTU range.

General Calibration Failure. There

is not sufficient signal to achieve

the appropriate resolution in the 0100NTU range.

General Calibration Failure. There

is not sufficient signal to achieve

the appropriate resolution in the 020 NTU range.

Excessive stray light detected. Ensure the vial is fully snapped

Attempting a measurement when

low battery indicator is on.

When Turbidity value is above the

measurement range(>1000NTU)

Low battery indication. The

batteries need to be replaced.

Description Corrective Actions

Ensure to use the correct 800

NTU calibration standard. *

Ensure to use the correct 100

NTU calibration standard. *

Ensure to use the correct 20.0

NTU calibration standard. *

Ensure to use the correct 0.02

NTU calibration standard. *

Re-do calibration with all 4

standards provided. *

Re-do calibration with all 4

standards provided. *

Re-do calibration with all 4

standards provided. *

in the sample well. Use light

shield cover.

Replace batteries.

Dilute sample. See Section 9.7

on page 22.

Replace batteries.

* If an error message appears, take the appropriate

corrective action and re-do the desired procedure. If

the problem persists, contact Eutech Instruments or

your dealer. See Sections on Warranty and Return

of Items on page 24.

15

Page 21

Instruction Manual TN-100/ T-100

5. Routine Maintenance

The supplied carrying case is optimal for protecting the instrument. If you do not plan

on leaving the instrument in the supplied carrying case, when not in use, ensure that

the instrument has been turned off and that a clean sample vial fitted with a black cap

has been placed in the sample well. This will ensure that a minimal amount of dust

and/or debris will be able to settle on the optics of the instrument.

5.1 Vials – Handling, Cleaning and Care

Proper measurement of the turbidity of a sample requires the use of a vial that is free of

marks, smudges, scratches and any bacterial growth.

Therefore, sample vials must be handled with absolute care to avoid contamination or

damage, which might change the optical characteristics of the glass. Scratches,

fingerprints, and water droplets on the sample vial or inside the sample well can cause

stray light interference leading to inaccurate readings.

Cleaning the vial is accomplished by washing the interior and exterior of the vial in a

detergent solution. Once cleaned, the vial should be rinsed thoroughly 8 to 10 times

with clean distilled water to eliminate the possibility of detergent buildup and streaking.

Vials can also be acid washed periodically and coated with a special silicone oil to fill

small scratches and mask the imperfections in the glass. Since the silicone oil required

for this application should have the same refractive characteristics as glass, it is

recommended that the oil be obtained from us. Care should be taken not to apply

excessive oil that could attract dirt or contaminate the sample well of the meter. Once

the oil has been applied to the vial, the excess oil should be removed with a lint-free

cloth. The result should be a sample vial surface with a dry appearance, but with all

imperfections filled with oil.

Sample vials should always be handled from the top or by the cap to avoid fingerprints

or smudges. After a vial has been filled with a sample and capped, the outside surface

should be wiped with a clean, lint-free absorbent cloth until it is dry. Cleaned and dried

vials should be stored with the black caps on. The vials can be stored in the carrying

case. During normal operation you may use any typical glass cleaner along with a lint

free cloth or tissue (Kimwipes

Condensation may appear on the vial when your sample is very cold and the relative

air humidity is high. When this happens, the turbidity that you read may be higher than

the actual turbidity due to the light scattered by the condensate on the vial. If you find

yourself in this circumstance, you can alleviate the problem by either coating the vial

with an anti-fogging agent, or by running warm water over the vial for a short period of

time to warm the sample prior to measurement.

®

), to clean the outside of the vials.

16

Page 22

Instruction Manual TN-100/ T-100

&

6. Accessories

The items shown below are recommended accessories and replacement parts for the

instrument.

Eutech

Item Description

Instruments

Order Code

Waterproof TN100 portable turbidimeter with set

of 4 calibration standards (800, 100, 20.0 & 0.02

NTU), set of 7 sample vials, lint-free cloth, silicone

oil, batteries – all in a rugged carrying case.

Waterproof TN100 portable turbidimeter, set of 7

sample vials, lint-free cloth, silicone oil, batteries –

all in a rugged carrying case.

Calibration kit Set for TN100 (800, 100, 20.0,

0.02 NTU), 4 x 60 mL plastic bottles, with (4) vials

and labels for the vial caps.

Sample vials – pack of 3 vials ECTN100CUVKT

Sample vials – pack of 4 vials ECTN100CUVKIT4

Silicone oil – 10 mL

ECTN100IR

(01X357301)

N/A

TN100CALKIT

(01X621001)

(01X274902)

(01X638601)

ECSILICONEOIL

(01X358701)

Oakton

Instruments

Order Code

35635-00

35635-05

35635-52

35653-55

N/A

NCI# 00159II

To order any accessory or replacement part, please contact the nearest distributor or

Eutech Instruments/Oakton Instruments.

17

Page 23

Instruction Manual TN-100/ T-100

7. Specifications

Parameter Specification

Measurement Method ISO 7027 compliant nephelometric method (90°)

Measurement Range 0 to 1000 NTU

Automatic Range Selection 0.01 – 19.99 NTU

20.0 – 99.9 NTU

100 – 1000 NTU

Resolution 0.01 NTU (0 – 19.99 NTU)

0.1 NTU (20 – 99.9 NTU)

1 NTU (100 – 1000 NU)

Accuracy <0.1 NTU for 0.02 NTU Standard

±2% of reading ± 1 LSD for 0.1 to 500 NTU;

±3% of reading ± 1 LSD for 501 to 1000 NTU.

Repeatability ± 0.01 NTU or ± 1% of reading, whichever is greater with

gel samples

Response Time < 6 seconds for full step change

Calibration Standards 0.02 NTU; 20 NTU; 100 NTU; 800 NTU

Standardization EPA-approved polymer-based primary standards

Light Source Infrared-emitting diode (850 nm wavelength)

Light Source Life > 1,000,000 tests

Detector Silicon photovoltaic

Stray Light < 0.02 NTU

Display 4-digit 14-segments customized liquid crystal display with

annunciators

Sample Cells (Vials) Borosilicate glass with screw caps, fill line and indexing

mark.

51 (H) x 25 (Dia) mm ( 2 x 1 in)

Sample Volume Required 10 ml (0.33 oz)

Operating Temperature

Range

Sample Temperature Range 0°C to 50°C (32°F to 122°F)

Operating Humidity Range 0-90% RH, non-condensing at 30°C (86°F)

Power Supply 4 x “AAA” Alkaline Batteries

Battery Life > 1200 readings

Enclosure Type & Rating: ABS Plastic / IP67 rated

Insulation Rating Pollution Degree 2

Weight: Meter: 200 g (7 oz)

Dimensions Meter: 6.8 (W) x 15.5 (L) x 4.6 (H) cm;

0°C to 50°C (32°F to 122°F)

Meter with case: 1.25 kg (2.75 lb)

(2.7 x 6.1 x 1.8 in)

Meter with Case: 16 (W) x 35 (L) x 12 (H) cm;

(6.3 x 13.8 x 4.7 in)

18

Page 24

Instruction Manual TN-100/ T-100

8. Addendum 1: Turbidity

8.1 Definition

Turbidity is defined as an “expression of the optical property that causes light to be

scattered and absorbed rather than transmitted in straight lines through the sample.”

That is, turbidity is the measure of relative sample clarity, not colour.

Water with cloudy or opaque appearance will have high turbidity, while water that is

clear or translucent will have low turbidity. High turbidity value is caused by particles

such as slit, clay, microorganisms, and organic matter. By definition, turbidity is not a

direct measure of these particles but rather a measure of how these particles scatter

light.

1

8.2 Why Is It Important?

For drinking water application, a turbidity value may give an indication of presence of

bacteria, pathogens, or particles that can shelter harmful organisms from disinfection

process. Therefore, turbidity measurement is particularly useful for water treatment

plants to ensure cleanliness.

In industrial processes, turbidity can be part of quality control measure to ensure

efficiency in treatment or manufacturing process.

8.3 Measurement Principle

There are two internationally accepted standard specifications for turbidity

measurement. These are the international standard ISO 7027 and the US EPA method

180.1.

Basically the ISO 7027 is a more stringent standard and requires the use of a

monochromatic light source. It also governs the design of a turbidimeter in the following

areas: (1) Light source’s wavelength; (2) Light sources’ spectral bandwidth; (3)

Measuring angle; (4) Aperture angle in water sample; (5) Distance traversed by

incident light and scattered light within the sample; (6) Calibration standard.

The TN-100/ T-100 turbidimeter follows the ISO 7027 standard whose specification

allows for greater reproducibility of the measured values and greater agreement

between other measuring instruments.

1

Provided by “Standard Methods for the Examination of Water and Wastewater, APHA, AWWA and

WPCF, 16

th

Edition, 1985.

19

Page 25

Instruction Manual TN-100/ T-100

90°

Lens

Glass Sample Vial

Transmitted

Light

Scattered Light

Lamp

Figure 14 shows the waterproof TN-100/ T-100 turbidimeter basic optical system. It

includes a light source and a detector to monitor the light scattered at 90° with respect

to the incident beam.

Figure 14: Basic Nephelometric arrangement for turbidity measurement

8.4 Nephelometric Turbidity Units (NTU)

Nephelometric Turbidity Units (NTU): Unit of measure used when relating the light

scattered by a liquid media to the light scattered by a known concentration of a

standard solution. This unit of measure is recognized as a measure of the optical clarity

of an aqueous sample. NTU is the accepted unit of measurement for turbidity.

Another unit commonly used to measure turbidity is Formazin Turbidity Unit (FTU). The

two units of measure of turbidity are equivalent: 1 NTU = 1 FTU.

8.5 Indexing a Vial

The United States Environmental Protection Agency (US EPA) recommends that vials

used for turbidimeter calibration or sample measurement be indexed.

To index a sample vial, slowly rotate the vial throughout one complete revolution

(360°). While rotating the sample vial, observe the display and locate the position that

the vial is in which provides the lowest turbidity reading. This position is the indexed

position of the vial.

Mark this position on the vial (not on the cap) against the mark on the meter.

After indexing a vial, make sure the vial will always be placed inside the sample well in

the indexed position.

20

Page 26

Instruction Manual TN-100/ T-100

9. Addendum 2: Guide to Good Measurement Technique

Turbidity is a very complex analytical measurement which can be affected by many

factors. Some are inherent in the instrument’s design such as angle of detection, light

beam aperture, incident beam wavelength and color sensitivity of the photocell.

However, there are other factors such as stray light, air bubbles and care of vial, which

can be prevented through proper care of equipment and accessories, and in the

operating procedure for measurement. Here are some points you may want to note:

9.1 Maintain sample vials in good condition

Sample vials must be meticulously clean and free from significant scratches. It should

be treated on the outside with a thin coat of silicone oil. This is to mask minor

imperfections and scratches that may contribute to stray light. Sample vials should be

handled only by the top to avoid dirt accumulation (or deposits) and fingerprints that

might interfere with the light path.

More information is found in Section 5.1 - Vials – Handling, Cleaning and Care on page

16.

9.2 Match Sample Vials

Best accuracy and repeatability of turbidity measurement are achieved using a single,

indexed vial. However, for more convenience, different vials can be used for

measurement provided their readings with the same solution are matched. That is, the

meter gives identical readings or within the specified repeatability and accuracy of the

meter.

Select a few vials. After the sample vials are cleaned, fill them with ultra-low turbidity

water. Allow the sample vials to stand and for air bubbles to rise. Polish sample vials

with silicone oil and take turbidity measurement at several points while rotating it in the

sample well. Find the position where turbidity reading is the lowest and index it for each

vial. Whenever these sample vials are used, use the indexed mark to position each vial

into the sample well. Choose those vials that match the readings.

NOTE: Not all vials can be matched because of some manufacturing variations.

9.3 Degassing

Air or other trapped gases should be removed before measurement. Degassing is

recommended even if no bubbles are visible. There are three methods commonly used

for degassing:

Addition of a surfactant: This involves adding a surfactant to the water

samples to lower the surface tension of the water, thereby releasing trapped

gasses.

Application of a partial vacuum: Partial vacuum can be created by using

simple syringe or vacuum pump. (This is only recommended for ultra-low

turbidity measurement).

21

Page 27

Instruction Manual TN-100/ T-100

Use of an ultrasonic bath: This may be effective in severe conditions or in

viscous samples, but not recommended for ultra-low measurements.

Each of the method above has its own advantages and disadvantages. For instance,

under certain sample conditions, the use of vacuum pump or ultrasonic bath may

actually increase the presence of gas bubbles.

9.4 Timeliness of Sample

Samples should be measured immediately to prevent changes in particle

characteristics due to temperature and settling. Temperature can affect particles by

changing their behavior or creating new particles if precipitates are formed. Dilution

water may dissolve particles or change their characteristics. It is recommended to take

samples only when the turbidimeter is ready to be operated. Samples should not be

drawn and allowed to sit while the instrument warms up or is being readied.

9.5 Other Important Sampling Techniques

1. Samples should not be violently shaken or agitated as particles can be broken

apart or air may be entrapped into the fluid. Gentle agitation such as swirling the

sample vial is advisable to reduce particle settling.

2. Sample vials should be used only with the instruments for which they were

intended. Do not mix and match.

3. Perform a visual observation of the sample vial every time a measurement is made.

Ensure that there are no visible bubbles in the sample and the vial is clean and free

of scratches.

4. Samples entering the turbidimeter should be at the same temperature as the

process flow samples. Changes in temperature can cause precipitation of soluble

compounds and affect readings.

5. Sample vials should be evaluated with a low turbidity water (after cleaning) to

determine if cells remain matched. If the evaluation determines that a cell is

corrupted, discard the vial. It is recommended to conduct this evaluation weekly.

6. When in doubt or question about whether a sample vial is too scratched or stained,

throw it away.

9.6 Calibration

1. Do not open the vials with calibration standards.

2. Check that the standards have not expired.

3. Make sure the calibration vials are free of dust, smudges and scratches before use.

4. Conduct the calibration in the same manner each time. Variations in how calibration

is performed could yield inaccurate measurements.

5. It is very important that the user(s) who perform calibration have been trained to do

so. Creating a Standard Operating Procedure (SOP) for the user(s) to read, learn,

and practice may help to ensure accuracy.

9.7 Dilution

This dilution procedure is necessary only when your turbidity measurement is above

1000 NTU.

1. To measure the turbidity above 1000 NTU, dilute the sample with turbidity-free

water.

22

Page 28

Instruction Manual TN-100/ T-100

2. Turbidity-free water can be obtained by filtering deionized water through a < 0.2μm

filter membrane with precision-sized pores.

3. Measure the volume of the sample before dilution and record the value in ml (Vs).

4. Take a known volume (Vd) of dilution water and add it to the sample.

5. Pour 10 ml of the diluted sample in a clean vial and measure the turbidity of the

diluted sample. Record this value in NTU (Td).

6. Calculate the true turbidity (T) of the original sample - in NTU - using the following

formula:

T = Td * (Vs + Vd) / Vs

Example:

Dilute 20 ml of the original sample (whose turbidity is above 1000NTU)

with 50 ml of dilution water.

Measure the turbidity of the diluted sample.

If the reading is 300 NTU, the turbidity of the original sample is 1050

NTU. (In this case: Td=300NTU, Vs=20ml, Vd=50ml, so T = 300 *

(20+50) / 20 = 300*70/20 = 21000/20 = 1050)

10. Warranty

The TN-100/ T-100 meter is supplied with a 2-year warranty from manufacturing

defects and calibration standards for 6 months.

If repair or adjustment is necessary and has not been the result of abuse or misuse

within the designated period, please return – freight pre-paid – and correction will be

made without charge. Eutech Instruments/ Oakton Instruments will determine if the

product problem is due to deviations or customer misuse.

Out of warranty products will be repaired on a charged basis.

Exclusions

The warranty on your instrument shall not apply to defects resulting from:

• Improper or inadequate maintenance by customer

• Unauthorized modification or misuse

• Operation outside of the environment specifications of the products

Waterproof Seal: Opening the instrument enclosure (excluding the battery

compartment) may void the warranty.

23

Page 29

Instruction Manual TN-100/ T-100

11. Return of Items

Authorization must be obtained from our Customer Service Department or authorized

distributor before returning items for any reason. A “Return Materials Authorization”

(RMA) form is available through our Authorized Distributor. Please include data

regarding the reason the items are to be returned. For your protection, items must be

carefully packed to prevent damage in shipment and insured against possible damage

or loss. Eutech Instruments/ Oakton Instruments will not be responsible for damage

resulting from careless or insufficient packing. A restocking charge will be made on all

unauthorized returns.

NOTE: Eutech Instruments Pte Ltd/ Oakton Instruments reserve the right to

make improvements in design, construction, and appearance of products without

notice.

24

Page 30

Page 31

For more information on Eutech Instruments/ Oakton Instruments’ products, contact your

nearest distributor or visit our website listed below:

Oakton Instruments

P.O Box 5136,

Vernon Hills, IL60061, USA

Tel: (1) 888-462-5866

Fax: (1) 847-247-2984

E-mail:

Web-site:

www.4oakton.com

info@4oakton.com

Eutech Instruments Pte Ltd

Blk 55, Ayer Rajah Crescent,

#04-16/24 Singapore 139949

Tel: (65) 6778 6876

Fax: (65) 6773 0836

E-mail:

eutech@thermofisher.com

Web-site: www.eutechinst.com

Distributed by:

Loading...

Loading...