Page 1

APPLICATION NOTE

Blood banking applications using

the Thermo Scientific Sorvall

BP 8 and 16 and Cryofuge 8

and 16 Centrifuges

Author: Romana Hinz, Thermo Fisher

Scientific, Osterode am Harz, Germany

Key words: Blood processing, Blood bank protocols,

ACE integrator function, Centrifuge loading

Introduction

Blood banks collect, process, store and distribute blood

and blood products [1]. After collection, whole blood

(WB) is separated into its main components. Red blood

cells, plasma and platelets are used effectively for patient

purposes, while white blood cells are depleted [2]. Red

blood cells transport oxygen to body tissues, plasma has

specific proteins that allow proper regulation of coagulation

and healing, and platelets help the blood clot [3].

A key instrument in the blood banking workflow is a

centrifuge. Centrifuges separate whole blood into red blood

cells, plasma and platelets.

This note presents possible methods for the preparation

of blood components and illustrates general guidelines for

the different protocols in blood component production.

In addition, it provides a troubleshooting guide for the

improvement of blood product yields as well as gives

guidance on the correct use of centrifuge accessories and

explains the Thermo Scientific™ Accumulated Centrifugal

Effect (ACE™) integrator function.

Page 2

Blood processing

Blood component preparation is performed to separate

blood components from whole blood. Red blood cells

(RBCs) and plasma are produced by a single-step hard

spin centrifugation. Platelet concentrates (PLTs), RBCs and

plasma are prepared by a two-step centrifugation. The two

main procedures for preparing PLTs are the platelet-rich

plasma (PRP) method and the buffy-coat method [4].

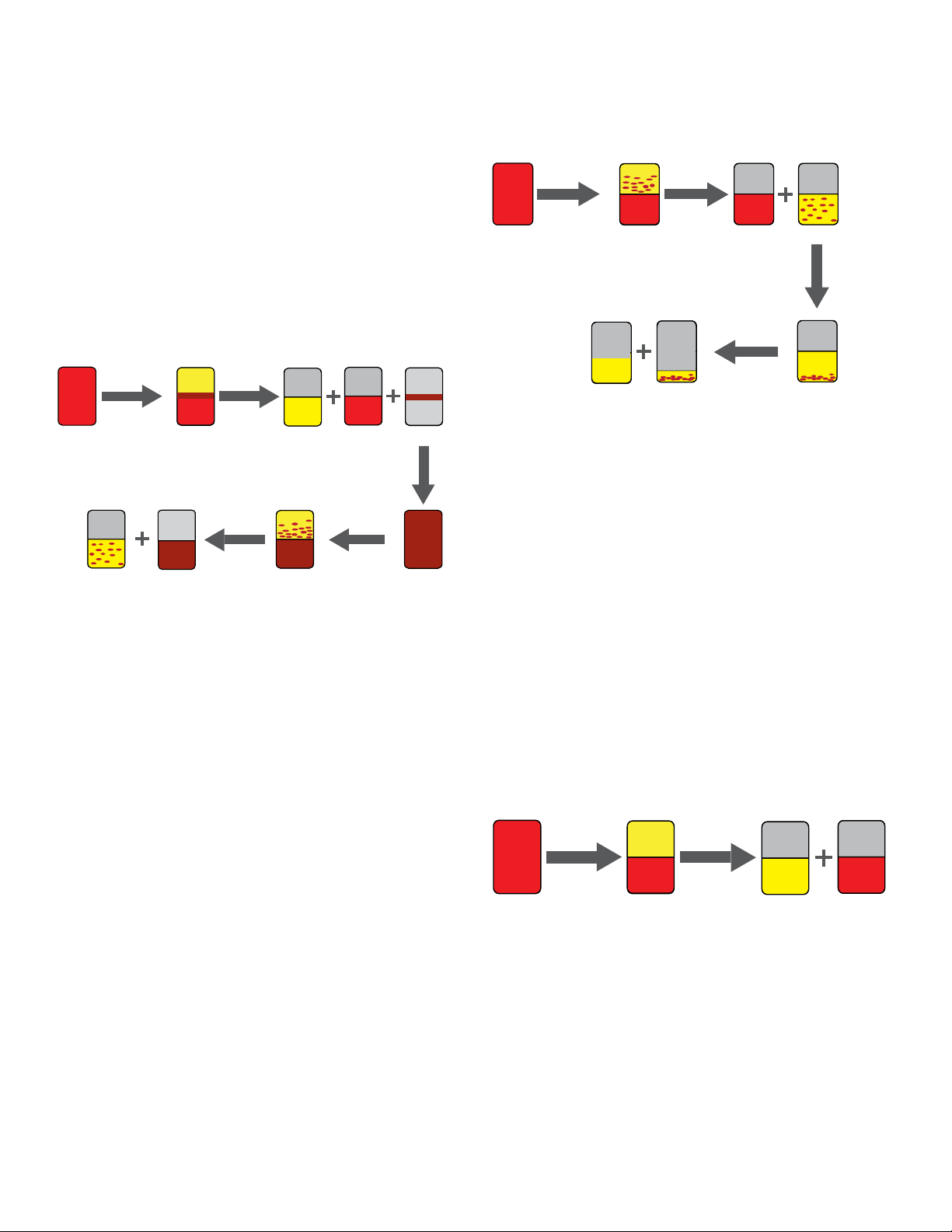

Platelets from whole blood (buffy-coat method)

In European countries, platelets preparation is done by the

buffy-coat (BC) method [5].

Platelets from platelet-rich plasma (PRP) method

Mainly in the United States, platelets are prepared from

whole blood with the PRP method [6].

Centrifugation

First spin

WB

Separation

RBC

Centrifugation

Second spin

Separation

PRP

Centrifugation

First spin

WB

PLTs Waste BC pool

Figure 1. Whole blood processing with the BC method.

Separation

Separation

Plasma RBC BC

Pooling of

4–6 units

Centrifugation

Second spin

The first centrifugation step (hard-spin) is used initially

to separate whole blood into three components: RBCs,

plasma and a BC layer. The components are extracted into

a “top-and-bottom” or a “top-top” blood bag collection set,

in which plasma and RBCs are transferred to storage bags

and the BC layer is left in the primary collection bag. This

BC contains PLTs, white blood cells (WBCs), plasma, and

some RBCs.

Subsequently, pools of 4–6 ABO-matched BCs are made

and either a plasma unit or a platelet additive solution

is added.

PLTsPPP

Figure 2. Whole blood processing with the PRP method.

PLTs

The first centrifugation step (soft spin) results in RBCs and

PRP. PRP is extracted with or without leukofiltration into a

so-called “satellite blood bag” and the RBCs are left in the

primary bag.

The PRP contains platelets, plasma and WBCs. The

secondary hard-spin centrifugation produces platelet-poor

plasma (PPP) and a platelet pellet. The PPP is extracted

into a satellite bag and the platelet pellet is re-suspended

in plasma.

Red blood cells/plasma separation

After a hard spin leukoreduced whole blood is separated

into its two main components: RBCs and plasma. Plasma

is extracted into a satellite bag while RBC is left in the

primary bag.

Centrifugation

First spin

WB

Separation

Plasma RBC

The second centrifugation step (soft step) is used

to produce PLTs which are then extracted with or

without leukofiltration.

Figure 3. Blood processing with RBC/plasma separation.

Page 3

Guidelines for blood component production

Blood separation is the partial separation of particles

from a liquid by gravity through sedimentation. The rate

of sedimentation is a function of liquid viscosity, particle

density and particle size, concentration of the solution

and the force of gravity. To speed up sedimentation, a

centrifuge is used.

Centrifugation conditions for blood component preparation

are shown in Tables 1, 2 and 3. These guidelines are based

on technical manuals and were validated in the Thermo

Scientific™ Sorvall™ BP 8 and 16 and Thermo Scientific™

Cryofuge™ 8 and 16 blood banking centrifuges [6], [7],

[8], [9]. Table 4 shows a troubleshooting guide to improve

blood component production. An adjustment in speed

by 200 rpm increments or time by 30 seconds should be

Since there is a relationship between the physical

properties of blood components and the physical principles

done. The protocol must be adjusted until the desired yield

of products is obtained.

of centrifugation that impact separation, the optimal

centrifugation for blood component production is achieved

by determination of the appropriate centrifuge parameters

such as time or ACE with a Thermo Scientific centrifuge,

speed and acceleration and deceleration profiles.

Table 1. Centrifuge conditions for whole blood processing with the buffy-coat method using the Sorvall BP 8 and 16 and Cryofuge 8 and 16

centrifuges and 500 mL blood bag systems.

Thermo Scientific

Method

Platelets

from WBC

(Buffy-coat

method)

Note: The given values are only a guideline; user should test different values to find optimized centrifuge conditions.

* At star t.

rotor Spin Speed (rpm)

HAEMAFlex™ 6

HAEMAFlex 8

HAEMAFlex 12

HAEMAFlex 16

1st spin: 3744 10:00 22 9 4

2nd spin: 1382 9:30 22 3 2

1st spin: 3393 10:00 22 9 4

2nd spin: 1294 9:30 22 3 2

1st spin: 3347 10:00 22 9 4

2nd spin: 1282 9:30 22 3 2

1st spin: 3201 10:00 22 9 4

2nd spin: 1242 9:30 22 3 2

Time*

(min:sec)

Temperature

(°C)

Acceleration

profile

Deceleration

profile

Table 2: Centrifuge conditions for whole blood processing with the PRP method using the Sorvall BP 8 and 16 and Cr yofuge 8 and 16

centrifuges and 500 mL blood bag systems.

Thermo Scientific

Method

Platelets

from PRP

Note: The given values are only a guideline; user should test different values to find optimized centrifuge conditions.

rotor Spin Speed (rpm) ACE

HAEMAFlex 6

HAEMAFlex 8

HAEMAFlex 12

HAEMAFlex 16

1st spin: 3025 1.70E+07 22 9 7

2nd spin: 3832 5.5 E+07 22 9 7

1st spin: 2742 1.70E+07 22 9 7

2nd spin: 3474 5.5 E+07 22 9 7

1st spin: 2704 1.70E+07 22 9 7

2nd spin: 3427 5.5 E+07 22 9 7

1st spin: 2587 1.70E+07 22 9 7

2nd spin: 3278 5.5 E+07 22 9 7

Temperature

(°C)

Acceleration

profile

Deceleration

profile

Page 4

Table 3. Centrifuge conditions for whole blood processing with the PRP method using the Sorvall BP 8 and 16 and Cr yofuge 8 and 16

centrifuges and 500 mL blood bag systems.

Method

Red blood

cell/

plasma

separation

Thermo Scientific

rotor Spin Speed (rpm)

HAEMAFlex 6 1st spin: 3744 10:00 22 9 4

HAEMAFlex 8 1st spin: 3393 10:00 22 9 4

HAEMAFlex 12 1st spin: 3347 10:00 22 9 4

Time*

(min:sec)

Temperature

(°C)

Acceleration

profile

Deceleration

profile

HAEMAFlex 16 1st spin: 3201 10:00 22 9 4

Note: The given values are only a guideline; user should test different values to find optimized centrifuge conditions.

* At star t.

Table 4. Troubleshooting guide to improve blood product yields.

1st spin

Problem/observation

finding 1st spin action

Platelet pellet appears firm, well packed OK

Platelet concentrate has aggregates present OK

Platelet pellet appears soft, loosely packed OK

Plasma and red cell volume acceptable OK

Plasma volume high and

red cell volume low

Too hard Decrease time or speed OK Keep speed and time as is

Keep speed and time

as is

Keep speed and time

as is

Keep speed and time

as is

Keep speed and time

as is

2nd spin

finding 2nd spin action

OK Keep speed and time as is

Too hard Decrease time or speed

Too soft Increase time or speed

OK Keep speed and time as is

Plasma volume low Too soft Increase time or speed OK Keep speed and time as is

Platelet yield and plasma volume acceptable OK

Keep speed and time

as is

OK Keep speed and time as is

Platelet yield is low and pellet appears firm Too hard Decrease time or speed OK Keep speed and time as is

Platelet yield is low and pellet appears soft Too hard Decrease time or speed Too soft Increase time or speed

Platelet yield acceptable

and plasma volume low

No distinct red cell and plasma line.

‘Bloody interface’

Too soft Increase time or speed OK Keep speed and time as is

Too hard Decrease slow stop rate OK Keep slow stop rate same

Page 5

ACE integrator function

Results without the ACE integrator function

Obtaining a consistent product requires understanding

and controlling process variables. Variations in rotor load,

fluctuations in voltage or slight mechanical differences can

affect how quickly centrifuges reach set speed. The ACE

integrator function calculates the effect of speed in relation

to time and adjusts run duration to account for differences

in acceleration, thereby improving separation consistency

and run reproducibility—run after run, from centrifuge

to centrifuge [10].

2 bags

Speed

2,800 rpm

Figure 4. In a typical first centrifugation step, a two-bag rotor load

attains set speed faster than a six-bag load. Since both loads will time

out at the set time of 3:30 minutes, different total accumulated g-forces

are achieved during the run. By using the ACE integrator function, the time

for 2 bags would be changed to 3:00 minutes to obtain the same overall

accumulated g-force for both loads.

Results with the ACE integrator function

Run prole for 2 bags

Run prole for 6 bags

Speed

6 bags

3:30 min

Time out ACE value

Time out ACE value

Time out

Time

The ACE value is not a calculation as it depends on the

acceleration conditions and the deceleration rate. It can be

determined by using a stopwatch:

1. Determine the optimal time and speed for you application.

2. Choose a high ACE value.

3. Set your speed at the optimal speed.

4. Set your acceleration/deceleration setting.

5. Start the centrifuge.

6. As the stopwatch reaches the optimal run time, write down

the ACE value.

Guidelines for centrifuge loading

Blood bags that are not properly loaded could possibly

result in leakage or breakage of blood bag systems.

Leakage and/or breakage can cause contamination.

The following are instructions for properly preparing blood

collection systems for centrifugation:

1. Attach all buckets to the rotor and ensure all buckets move

freely. All buckets must be in place before run. Choose a

centrifugation setting that will achieve the optimal yield for

your procedure; See Tables 1–4.

2. When possible, use the ACE integrator function to

standardize centrifugation from run to run for better

reproducibility and consistency; See section IV.

3. Gently mix the blood bag by inversion.

4. Blood bag systems should be packed following the

blood bag manufacturer´s instructions [11], [12], [13].

2,800 rpm

Time out ACE value

at 0 rpm

Time (in ACE mode)

Figure 5. With an ACE value and speed set at the start of a run, times

were adjusted to achieve the same overall g-force regardless of the

rotor load.

5. Blood bag systems must be placed into liners. Thermo

Scientific liners and liner stands are used for simplifying

the liner loading and unloading process. It enables

easier transportation and stabilization of blood bags in

an effort to improve the quality of the blood separation.

Spacers should be used to compensate for low volume

blood bags.

6. Counterbalance all liners and use weights as necessary.

7. Place liners into buckets.

Page 6

8. Make sure all tubing is secured inside the centrifuge

Tubing outside of the liner

Syphoning of blood.

Risk of centrifuge cycle failure

Low volume, bags

without compensation

Red cell traps

Blood bag systems only in one cavity

bucket. During loading, the tubing must be put between

the bags with the bag tabs remaining upright to prevent

them from becoming tangled around the rotor body

during centrifugation.

Correct loading. No need for spacers or balance bags

Figure 6. Incorrect loading of tubing not properly secured.

9. Blood bags with a low volume must be compensated by

using spacers or balance bags. Without compensation,

low volume blood bags could result in red cell traps.

As balancing bags could easily break after several

centrifugation runs, select spacers for use over a longer

time period.

Figure 7. Incorrect loading of bags without compensation.

Correct loading. Low volume blood bag systems, spacers

Figure 8. Correct loading.

or balance bags are needed

10. Prior to centrifugation all liners should be loaded with

blood bag systems. Never run empty liners. If there is

only one blood bag system left, then the empty cavity of

the liner should be filled with water filled bags.

Incorrect loading.

Correct loading.

Blood bag systems in each cavity

Running empty liners

is not permitted

Correct loading.

Water filled bag is used instead

Figure 9. Incorrect loading of only one cavity loaded and correct

loading of full liners.

Page 7

Summary

This application note presented possible methods for the

preparation of blood components and showed general

guidelines for different protocols for blood component

production. In addition, it provided a troubleshooting

guide for the improvement of blood product yields. It

also provided guidance on the correct use of centrifuge

accessories and explains the ACE integrator function.

References

1. American Red Cross [online] (2016). http://www.redcross.org/blood.

2. Higgins, Vl, Leukocyte-reduced blood components: patient benefits and practical

applications, May; 23 (4); 659 – 67 (1996).

3. Rodney A. Rhoades, David R. Bell Medical Physiology, Principles for Clinical Medicine,

4th edition, (2013).

4. Hans Gulliksson, Platelets from platelet-rich-plasma versus buffy-coat-derived platelets:

what is the difference?; Rev Bras Hematol Hemoter, 34 (2); 76 – 77 (2012).

5. Christopher D. Hillyer, Blood Banking and Transfusion Medicine: Basic Principles &

Practice, 2nd edition, (2007).

6. AABB. [Online] (21.01.2016). https://www.aabb.org/tm/coi/Documents/coi1113.pdf.

7. Guide to the preparation, use and quality assurance of blood components, European

committee (partial agreement) on blood transfusion, 16th Edition (2010).

8. Thermo Scientific Sorvall BP 8/16 and Cryofuge blood banking centrifuges, brochure,

14.02.2016.

9. Validation was done at Bonfils Blood Center, 717 Yosemite Street, Denver, CO 80230.

10. Smart Note: How can blood banks eliminate potential variables to ensure consistent

product yield and reproducibility?, Thermo Fisher Scientific, brochure 01.02.2017.

11. Fresenius. [Online] (21.01.2016). https://www.fresenius.de/689.htm.

12. Haemonetics. [Online] (21.01.2016). http://wbt.haemonetics.com/en/Products.aspx.

13. Macopharma. [Online] (21.01.2016).

http://www.macopharma.com/category/transfusion/blood-processing/blood-bags/.

Find out more at

thermofisher.com/bloodbankcentrifuges

This product is intended for General Laboratory Use. It is the customer’s responsibility to ensure that the performance of

the product is suitable for customer s specific use or application. © 2017, 2020 Thermo Fisher Scienti fic Inc. All rights reserved. All

trademarks are the property of Thermo Fisher Scientific and its subsidiaries unless otherwise specified. ANCFGBLOODBANK 0420

Loading...

Loading...