Page 1

HyPerforma Single-Use Fermentor

(S.U.F.) User’s Guide

DOC0031 • Revision G

February 2021

Page 2

Contents

Warnings, safety, and warranty information 1

How to use this guide 7

Chapter 1 Single-Use Fermentor (S.U.F.) overview 10

1.1 Introduction 11

1.2 Hardware characteristics 14

1.2.1 System features 14

1.2.2 Agitation 14

1.2.3 Control system 14

1.2.4 Exhaust management system 14

1.2.5 Exhaust vent filter heater 14

1.2.6 Temperature 15

1.2.7 Heating performance 15

1.2.8 External control 15

1.2.9 Load cells 15

1.3 End user and third-party supplied components 16

1.3.1 pH and dissolved oxygen (DO) probes 16

1.3.2 Single-use probes 16

1.3.3 Controllers 17

1.4 BioProcess Container characteristics 18

1.4.1 Single-Use Fermentor BPC features 18

1.4.2 Operating pressure 18

1.4.3 Working volume 18

1.4.4 Draining and harvest 19

1.4.5 Aeration 19

1.4.6 Aseptic connections 19

1.4.7 Sampling 19

1.4.8 BPC features 20

1.5 Additional system components 22

1.5.1 Probe integration 22

1.5.2 Accessories 22

Page 3

Contents

Chapter 2 Installation and setup 24

2.1 Initial installation preparation 25

2.1.1 Hardware shipment and setup 25

2.2 Site preparation 25

2.2.1 Electrical connections for units with an electrical

control box 25

2.2.2 Outer support container preparation 26

2.2.3 Electrical preparation for systems with electrical

control boxes 26

2.2.4 Load cell preparation 27

2.3 Installation 28

2.3.1 Exhaust filter bracket setup 30

2.3.2 Condenser unit setup (when present) 31

2.3.3 TCU/chiller connection to condenser unit

(when present) 32

2.3.4 Exhaust filter pinch clamp setup (when present) 33

2.3.5 Optional cable management system setup 35

2.3.6 Air line preparation 35

2.3.7 Drilled hole sparger line(s) 35

Chapter 3 Operating information 36

3.1 General system operating information 37

3.1.1 BPC preparation and loading 37

3.1.2 BPC handling instructions 37

3.1.3 BPC operating information 37

3.1.4 Hardware operating information 39

3.2 BPC and drive shaft loading for 30 L units 43

3.2.1 Initial installation steps for 30 L units 43

3.2.2 Drive shaft insertion for 30 L units 51

3.2.3 Final installation steps for 30 L units 54

3.3 BPC and drive shaft loading for 300 L units 56

3.3.1 Initial installation steps for 300 L units 56

3.3.2 Drive shaft insertion for 300 L units 64

3.3.3 Final installation steps for 300 L units 69

3.4 Exhaust system 72

3.4.1 Exhaust system functional overview 72

3.4.2 When to use the condenser 73

3.4.3 Condensers and reserve vent filters 74

Page 4

Contents

3.4.4 Exhaust system setup 74

3.4.5 Exhaust system setup 75

3.5 Probe assembly 79

3.5.1 Preparation and sterilization 79

3.5.2 Making CPC AseptiQuik connections 80

3.5.3 Probe insertion 83

3.5.4 Probe calibration 85

3.5.5 Kleenpak connection instructions 85

3.6 Microbial cell culture operating instructions 95

3.6.1 Operating conditions for cell culture applications 95

3.6.2 Manual operation of drilled hole spargers 96

3.6.3 Checkpoints prior to media fill 97

3.6.4 Media fill 97

3.6.5 Agitation for units with electrical control boxes 98

3.6.6 Temperature control 99

3.6.7 pH probe calibration 100

3.6.8 DO probe calibration 100

3.6.9 Checkpoints prior to inoculation 100

3.6.10 Cell inoculation 100

3.6.11 In-process checkpoints 101

3.6.12 Dispense and harvest 101

3.6.13 S.U.F. shutdown and post-use BPC disposal 102

3.6.14 Preparation for the next run 103

3.7 BPC sampling 104

3.7.1 Aseptic sampling 104

3.7.2 Sampling with sterile manifold 105

3.8 Verification procedures 107

3.8.1 Mixer speed verification 107

3.8.2 Temperature controller verification 107

3.8.3 Pressure monitor verification (when present) 107

3.8.4 Load cell verification (when present) 107

Chapter 4 Specifications and parts information 108

4.1 Hardware features and dimensions 109

4.1.1 30 L S.U.F. design features 109

4.1.2 300 L S.U.F. design features 110

4.1.3 30 L S.U.F. dimensions and ordering information 111

4.1.4 300 L S.U.F. dimensions and ordering information 112

Page 5

Contents

4.2 30 L and 300 L S.U.F. hardware specifications 113

4.3 Configurable hardware options 115

4.4 BPC features and specifications 116

4.4.1 Standard 30 L S.U.F. BPC 116

4.4.2 Standard 300 L S.U.F. BPC 118

4.5 BPC options and packaging information 120

4.6 Accessories and options specifications 121

4.6.1 Load cells 121

4.6.2 Cable management system 124

4.6.3 Vent filter heaters 125

4.6.4 Exhaust system 126

4.6.5 Miscellaneous items 129

Chapter 5 Maintenance and troubleshooting 132

5.1 Maintenance 133

5.1.1 Routine maintenance 133

5.1.2 Preventive maintenance schedule 133

5.2 Troubleshooting and frequently asked questions 135

5.2.1 Hardware operation issues 135

5.2.2 Cell culture operation issues 137

5.2.3 Probe and connector issues 140

5.2.4 BPC and sparging issues 141

Chapter 6 General ordering information 142

6.1 Ordering instructions 143

6.2 Ordering/support contact information 143

6.3 Technical support 144

Appendices Appendix A—Installation of female electrical receptacle

for units with AC motors and electrical boxes 145

Appendix B—Mettler Toledo IND331 Display load cell

calibration instructions 148

Appendix C—Pre-fermentation run checklist 150

Page 6

Warnings, safety, and warranty information

Warnings, safety, and warranty

information

Thank you for purchasing the Thermo Scientific™ HyPerforma™

Single-Use Fermentor (S.U.F.). We have included safety information in

this guide, based on our knowledge and experience. It is important,

however, for you to work with your Safety Management personnel to

ensure that this equipment is integrated into your safety practices.

Please take some time to perform your own job safety analysis in order

to identify and control each potential hazard.

WARNING: Read and understand this user’s guide before

operating this equipment.

The Thermo Scientific HyPerforma Single-Use Fermentor (S.U.F.)

is designed to be operated under traditional microbial cell culture

conditions. A general understanding of Fermentor systems and their

operation is important prior to using the system for the first time. Read

and understand user’s guide before operating; failure to do so could

result in injury. Proper procedures for the disposal of Single-Use

BioProcess Containers (BPCs) should be followed, depending on

the culture in use. See the appropriate section of this guide.

WARNING: Tipping hazard. The vessel should only be moved by

pushing using the provided handles or at the mid-point of the

vessel.

If pulled or moved too quickly, the vessel can tip, potentially leading

to damage to equipment or injury to personnel. To reduce the risk

of tipping, the vessel should only be moved slowly over smooth, flat

surfaces by at least two qualified personnel. During movement, any

locking feet should be retracted, and casters should be in the unlocked

position. The vessel should not be moved by pulling of any kind.

WARNING: Hazardous voltage inside.

Electrical components are required for the proper function of the

S.U.F. The mixer motor, motor controller, and control panel all have

electrical components. There is a risk of electrical shock and injury.

Disconnect power before opening electrical components. Service

by trained personnel only. Thermo Fisher Scientific recommends

using standard lockout procedures when working on electrical

components. The main breaker on the electrical control panel may

be locked out.

HyPerforma Single-Use Fermentor User’s Guide | 1Thermo Scientific

Page 7

Warnings, safety, and warranty information

WARNING: Static electricity may build up in BPCs.

• BPCs may act as insulators for electrostatic charge. If electrostatic

• Where applicable, a product contact stainless steel coupler may be

WARNING: Rotating parts—entanglement hazard.

Rotating and moving parts can cause injury. Keep hands away from

moving parts.

• Do not operate this equipment unless the supplied guarding is in

• It is the responsibility of the end user to assess this equipment

charge is transferred to a BPC, the charge may be stored in

the BPC and/or the product inside. This phenomena varies by

product and use; therefore, it is the sole responsibility of the end

user to ensure a hazard assessment is conducted and the risk of

electrostatic shock is eliminated.

grounded to the frame to dissipate electrostatic build up from the

material within a BPC. It is good practice to dissipate electrostatic

build up by grounding all BPCs prior to coming in contact with

them. When working with BPCs, the use of nonconductive

materials, such as nonconductive gloves, is recommended.

place and properly functioning.

and ensure that equipment and safeguards are in good working

condition, and that all operators are trained and aware of

entanglement hazards and associated protective devices, such as

hazard signs and guarding.

WARNING: Use ladders and elevated platforms with caution.

A few operations, such as mounting the motor to the 300 L S.U.F.

during setup, may require the use of a ladder or platform. Before use,

ensure the ladder has been inspected and weight-rated for its user.

When using a ladder or platform, be sure it is stable, maintain three

points of contact and make sure the steps are clean.

WARNING: Follow lockout/tagout procedures.

To prevent injury, when servicing equipment, use your company’s

lockout/tagout procedures to isolate electrical, mechanical, pneumatic,

hydraulic, chemical, thermal, gravitational or any other potential energy

and protect workers from the release of hazardous energy.

WARNING: Use caution with hazardous chemicals or materials.

Personnel servicing equipment need to know the hazards of any

chemicals or materials that may be present on or in the equipment.

Use general hazard communication techniques such as Safety Data

Sheets, labels and pictograms to communicate any hazards.

HyPerforma Single-Use Fermentor User’s Guide | 2Thermo Scientific

Page 8

Warnings, safety, and warranty information

WARNING: Hot surface—do not touch.

The heating jacket is designed to heat the inner vessel wall. Normal

operating conditions generate heat and could create hot surfaces.

• Hot surface inside

• Contact with surfaces may cause burns

• Do not touch while in operation

WARNING: The Thermo Scientific HyPerforma S.U.F. may not

be installed in a potentially explosive atmosphere as set forth

in the applicable EU ATEX Directive.

WARNING: Burst hazard.

The S.U.F. BPC chamber is under slight pressure under normal

operating conditions. Normal passive venting prevents any excess of

pressure building up within the chamber. Chamber pressure and inlet

line pressure should be monitored for proper settings.

• Do not exceed 0.03 bar (0.5 psi) pressure within the BPC

• Do not exceed 0.34 bar (5 psi) pressure in the section of BPC

• Make sure the vent filter is properly positioned and working

• Maintain a minimum gas flow of 0.1 vvm or 0.01 psi in the BPC

tubing between the inlet filter and the BPC

properly

while the impeller is spinning

Protective earth grounding

Protective earth grounding must be verified prior to plugging the

S.U.F. into any electrical outlet. Ensure the receptacle is properly earth

grounded.

Environmental conditions

• Operating: 17°C to 27°C; 20 to 80% relative humidity, noncondensing

• Storage: –25°C to 65°C

• Installation category II (over voltage) in accordance with IEC 664

• Altitude Limit: 2,000 meters

Water jacket vessel information

S.U.F. hardware unit with water jacket has been designed to be

operated with water as the heat transfer medium with temperatures not

exceeding 50°C (122°F) under 150 psig (1 MPa) operating pressure. For

the utmost safety it is recommended that the water jacketed S.U.F. be

operated at 75 psig or less.

HyPerforma Single-Use Fermentor User’s Guide | 3Thermo Scientific

Page 9

Warnings, safety, and warranty information

Note: The S.U.F. BPC operating limits for temperature are 5°C to 40°C.

The internal pressure should not exceed .003 bar (0.5 psi). The water

jacket is not required to be registered, inspected and stamped with the

Code U symbol per section U-1(c)2(f) of the ASME Boiler and Pressure

Vessel Code and/or European Pressure Equipment Directive (PED)

97/23/EC. Upon request, a Declaration of Conformity, PED Sound

Engineering Practices can be made available.

Electrical connections

Power should be supplied by a non-GFCI 15 amp circuit. Ground

faults occur when current is leaking somewhere, in effect, electricity is

escaping to the ground. Electrocution can occur when the human

body serves as the path for the leakage to the ground. A Ground

Fault Circuit Interrupter (GFCI) senses the current flowing to the ground

and switches off the power (trips the GFCI) in a fraction of a second at

currents well below those that are considered dangerous. Due to the

sensitivity of GFCIs to electrical leakage (a few mA), it is recommended

that the S.U.F. not be plugged into a GFCI outlet.

Warranty information

Any warranties, if applicable, covering this equipment exclude: (a)

normal wear and tear; (b) accident, disaster or event of force majeure;

(c) your misuse, fault or negligence; (d) use of the equipment in a

manner for which it was not designed; (e) causes external to the

equipment such as, but not limited to, external puncturing, power

failure or electrical power surges; (f) improper storage and handling of

the equipment; (g) use of the equipment in combination with equipment

or software that we did not supply; (h) equipment sold to you as ‘used’

products; (i) contact with improperly used or unapproved chemicals

or samples; (j) installation, removal, use, maintenance, storage, or

handling in an improper, inadequate, or unapproved manner, such as,

but not limited to, failure to follow the documentation or instructions in

the deliverables or related to the equipment, operation outside of stated

environmental or other operational specifications, or operation with

unapproved software, materials or other products; (k) manufacture in

accordance with requirements you gave us; (l) installation of software

or interfacing or use of the equipment in combination with software

or products we have not approved; (m) use of the deliverables

or any documentation to support regulatory approvals; (n) the

performance, efficacy or compatibility of specified components; and

(o) the performance of custom equipment or products or specified

components or achievement of any results from the equipment,

specified components or services within ranges desired by you

HyPerforma Single-Use Fermentor User’s Guide | 4Thermo Scientific

Page 10

Warnings, safety, and warranty information

even if those ranges are communicated to us and are described in

specifications, a quote, or a statement of work. ADDITIONALLY, ANY

INSTALLATION, MAINTENANCE, REPAIR, SERVICE, RELOCATION

OR ALTERATION TO OR OF, OR OTHER TAMPERING WITH, THE

EQUIPMENT PERFORMED BY ANY PERSON OR ENTITY OTHER

THAN US WITHOUT OUR PRIOR WRITTEN APPROVAL, OR ANY

USE OF REPLACEMENT PARTS WE HAVE NOT SUPPLIED, WILL

IMMEDIATELY VOID AND CANCEL ALL WARRANTIES WITH

RESPECT TO THE AFFECTED EQUIPMENT. IF THE EQUIPMENT

IS TO BE USED IN THE UNITED STATES, WE MAY VOID YOUR

WARRANTY IF YOU SHIP THE EQUIPMENT OUTSIDE OF THE

UNITED STATES.

Use restrictions

You must use this equipment in accordance with our documentation

and if applicable, with our other associated instructions, including

without limitation, a “research use only” product label or “limited use”

label license. This equipment is intended for research use or further

manufacturing in bioprocessing applications and not for diagnostic

use or direct administration into humans or animals, we do not submit

the equipment for regulatory review by any governmental body or

other organization, and we do not validate the equipment for clinical or

diagnostic use, for safety and effectiveness, or for any other specific

use or application.

HyPerforma Single-Use Fermentor User’s Guide | 5Thermo Scientific

Page 11

Warnings, safety, and warranty information

Seismic guidance

The buyer of the equipment is responsible for ensuring that countryspecific codes and seismic values are assessed for suitability of

equipment installation and safety at the designated site. In addition,

it is the buyer’s responsibility to assess the building structure for

the designated equipment to ensure correct seismic anchoring and

tethering designs for both the equipment and facility. It is highly

recommended that the buyer consult with a local, licensed third party

architecture and engineering firm to provide the buyer with correct

engineering analysis and stamped documentation prior to equipment

installation at the facility. In addition, the buyer will be responsible for

rigging and anchoring of the equipment to a specified, fixed location.

Upon request, Thermo Fisher Scientific can assist with establishing

compliant seismic anchoring and tethering designs for purchased

equipment based on building and country codes, at an agreed upon

fee.

It is also noted that movable equipment (i.e. non-fixed or caster mount)

is exempt from seismic design requirements according to ASCE

7-16, Chapter 13, section 1.4. Although these units are exempt from

the seismic design requirements of ASCE 7, it should be noted that

such equipment is susceptible to overturning during a seismic event.

Therefore, it is the responsibility of the buyer to address seismic safety

for movable equipment at the designated facility.

HyPerforma Single-Use Fermentor User’s Guide | 6Thermo Scientific

Page 12

How to use this guide

Rev. Date Section Change made Author

A.0 07/ 2 014 -- Initial release S. Jelus

A 11/ 2 0 16 -- Reformatted E. Hale

A 11/ 2 0 16 3.1.4, 4.2 Updated maximum temperature setpoint J. Brown/E. Hale

A 11/ 2 0 16 3.5.2 Added CPC AseptiQuik connection instructions E. Hale

A 11/ 2 0 16 3.5.5 Removed references to sterility E. Hale

A 11/ 2 0 16 4.2 Updated nominal tip speed E. Hale

A 11/ 2 0 16 Appendix D Added Appendix D (Pre-fermentation run checklist) J. Brown/E. Hale

B 04/2017 4.2

B 04/2017 4.2

B 04/2017 4.4.1

B 05/2017

B 05/2017 2.3, 4.1, 4.6

C 09/2017

C 09/2017 -- Changed values from “psi (bar)” to “bar (psi)” E. Hale

C 09/2017 -- Updated various aspects of formatting E. Hale

C 09/2017

C 09/2017 4.2 Added “Noise level” to specifications table E. Hale

C 11/ 2 0 17 Chapter 4 Removed hardware, BPC part numbers E. Hale

C 01/2018 -- Updated warning symbols E. Hale

How to use this guide

Scope of this publication

This user’s guide contains information about the standard Thermo

Scientific S.U.F. systems, including hardware, components, product

design verification methods, installation, operation, and specifications.

It is intended for use by people who may or may not have experience

with Thermo Scientific systems, but who have some knowledge of

bioproduction processes and large-scale mixing systems.

Document change information

Warnings and

Safety

Warnings, safety,

and warranty

information

How to use this

guide

Added Minimum Ceiling Height Requirement to 30 and 300

L specifications

Replaced “+/- 0.75% of full scale” with “+/- 5 rpm” in Motor

Speed specification field

Corrected part number for standard 30 L BPC with two 5 in.

exhaust filters

Added potentially explosive atmosphere (ATEX) warning E. Hale

Updated 30 L S.U.F. drawings to show the current motor

mount

Added warranty and usage information E. Hale

Added “Abbreviations/acronyms” section E. Hale

E. Hale

E. Hale

E. Hale

E. Hale

HyPerforma Single-Use Fermentor User’s Guide | 7Thermo Scientific

Page 13

How to use this guide

Rev. Date Section Change made Author

D 11/2 018

D 11/2 018

D 11/2 018 Various Removed references to metal probe clips E. Hale

D 11/2 018 2.2.3

D 11/2 018 3.6.5, 4.6.1 Updated Figures 3.104 and 4.12 E. Hale

D 11/2 018 Appendices Removed Appendix B (AC-Tech calibration) E. Hale

D 11/2 018

D 12 / 2018 3.1.3, 3.6.5 Edited sentence (3.1.3) and reworded step #2 (3.6.5) E. Hale

Warnings, safety,

and warranty

information

How to use this

guide

Warnings, safety,

and warranty

information

Added seismic guidance E. Hale

Changed “Input into Thermo Scientific publications” to

“Questions about this publication”

Updated Figure 2.1, showing the interior of S.U.F. E-Boxes,

and removed Figure 2.2

Added emphasis to “Electrical connections” section E. Hale

E. Hale

E. Hale

D 12 / 2018 4.2

E 10/ 2019 -- Minor revisions T. Golightly

E 10/ 2019 4.2 Updated cart length dimension on Table 4.2 T. Golightly

Warning, safety,

F 06/2020

G 11/2020 --

G 11/2020 4.1.3 Updated Figure 4.5 with new cart dimentions T. Golightly

G 11/2020 4.2

G 11/2020 1.3.1

and warranty

information

Added tolerance (± 5 rpm) to “Motor speed” in

specifications

Added Tipping hazard warning and symbol C. Jones

Minor updates to the document to meet current document

standards

Corrected the overall width, length, height and dry and wet

skid weights in Table 4.2

Updated the "Finesse pH and DO" sensors to "Hamilton pH

and DO" sensors in Table 1.1

E. Hale

T. Golightly

T. Golightly/E. Hale

T. Golightly

Questions about this publication

If you have any questions or concerns about the content of

this publication, please contact technicaldocumentation@

thermofisher.com and your Thermo Fisher Scientific sales team.

HyPerforma Single-Use Fermentor User’s Guide | 8Thermo Scientific

Page 14

How to use this guide

Related documents

If you are missing any of the related publications listed below, please

contact your local sales representative.

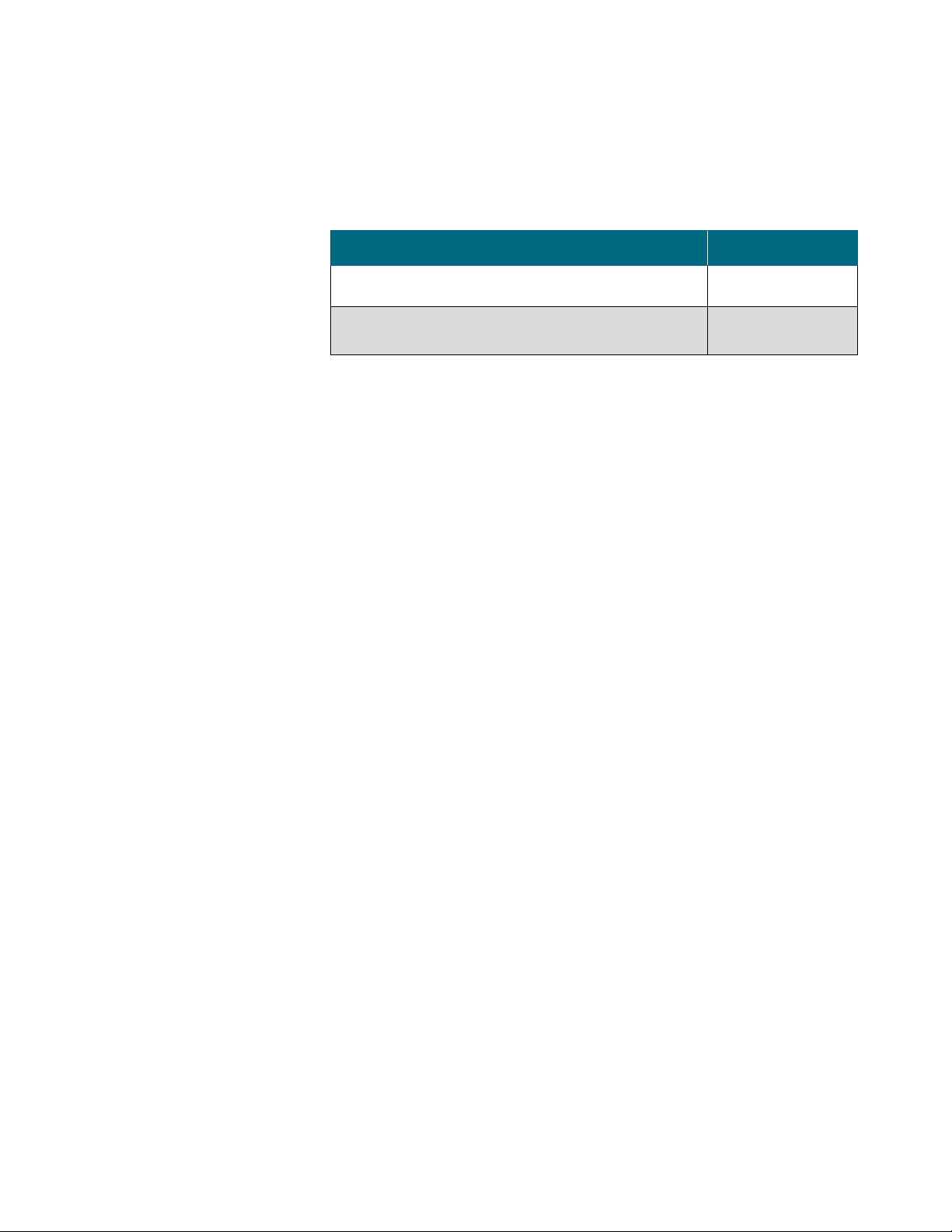

Document Document number

Thermo Scientific HyPerforma S.U.F. Validation Guide DOC0032

Thermo Scientific HyPerforma S.U.F. Packing and Unpacking

Instructions

DOC0052

Abbreviations/acronyms

Refer to the list below for definitions of the abbrieviations and acronyms

used in this publication.

BPC BioProcess Container

DO Dissolved oxygen

ETP Equipment Turnover Package

GFCI Ground fault circuit interrupter

ID Inner diameter

IEC International Electrical Code

OD Outer diameter

PED Pressure Equipment Directive

PID Proportional integral derivative

P/V Power input to volume

rpm Revolutions per minute

RTD Resistance temperature detector

slpm Standard liters per minute

STR Stirred tank reactor

S.U.F. Single-Use Fermentor

TCU Temperature control unit

VFD Variable frequency drive

HyPerforma Single-Use Fermentor User’s Guide | 9Thermo Scientific

Page 15

Chapter 1 | S.U.F. overview

1

Single-Use Fermentor

(S.U.F.) overview

Chapter contents

1.1 Introduction

1.2 Hardware characteristics

1.3 End user and third-party supplied components

1.4 BioProcess Container characteristics

1.5 Additional system components

HyPerforma Single-Use Fermentor User’s Guide | 10Thermo Scientific

Page 16

Chapter 1 | S.U.F. overview

1.1. Introduction

The Thermo Scientific Single-Use Fermentor (S.U.F.) has been designed

to be a single-use alternative to conventional stirred tank aerobic

fermentors currently utilized in microbial cell culture applications.

Based on years of accepted stirred tank reactor (STR) design, the

S.U.F. emulates STR scalability and operating parameters, yet it

has the unique advantage of being a single-use device. Ease of

setup with respect to system operation and integration into existing

facilities makes the S.U.F. an attractive alternative to its stainless steel

counterpart. Critical design parameters such as height to diameter

ratios, mixer design and location, and typical control system interfaces

are consistent with traditional fermentation platforms. S.U.F. BioProcess

Containers (BPCs) are supplied sterilized by irradiation and therefore

do not require any facility hook-ups for sterilization or cleaning. A key

element in the single-use design is the plastic (polyethylene) impeller

with a bearing/seal assembly linking to an external mixer drive. Quick

setup and changeover allows for faster turnover in microbial cell culture

runs over traditional reusable systems.

S.U.F. systems consist of the following primary components:

• Outer support container with standard water jacket heating

system

• S.U.F. BioProcess Container (BPC)

• Electrical control panel (E-Box) for agitation

• Direct drive agitation mixing assembly with an AC motor, drive

shaft, and impeller

HyPerforma Single-Use Fermentor User’s Guide | 11Thermo Scientific

Page 17

Chapter 1 | S.U.F. overview

Figure 1.1. 300 L S.U.F. with electrical

control panel, condenser, cable

management system, and bottle

management system.

The Thermo Scientific S.U.F. utilizes an open architecture design for

the control system, allowing for integration with customer systems

or with third-party controllers for feed pumps, mass flow controls,

and HMI (human-machine interface) screens. Controls for agitation

are integrated into the S.U.F., with temperature, pH/DO probes and

controls being supplied by the user or a third-party integrator. Water

jacketed systems require a temperature control unit (TCU) selected and

supplied by the end user or by Thermo Scientific.

The stainless steel outer support container is engineered and

fabricated to fully support each S.U.F. BPC and allow easy access

for operation. The outer support container is mounted to a portable

cart base and includes the mixing drive, water jacket for heating

and cooling, and optional controllers for mixing. The drive shaft is

detachable and reusable and is inserted into the BPC through the

motor assembly and into the bearing port. Load cells are offered as an

option.

HyPerforma Single-Use Fermentor User’s Guide | 12Thermo Scientific

Page 18

Chapter 1 | S.U.F. overview

The BPC includes the impeller assembly, sparger, vent filter inlet/outlet

ports, probe integration ports and filling, dispensing, and sampling

ports. The materials are fully qualified for biological product contact

per USP Class VI plastics. Each assembly is manufactured under

cGMP and is supported by qualification and validation information. No

reuse cleaning or sterilization validations are required as the BPC is

provided gamma irradiated. Innovative, proprietary technology allows

for the integration of the mixing shaft, pH and dissolved oxygen (DO)

probes, and the resistance temperature detector (RTD). The probe and

temperature interfaces are comparable to traditional systems with the

design allowing for simple, aseptic connections. Integrated spargers

are built into the S.U.F. BPC through universal ports.

This user’s guide covers the setup, operation, maintenance, and

troubleshooting of 30 and 300 L S.U.F. systems.

HyPerforma Single-Use Fermentor User’s Guide | 13Thermo Scientific

Page 19

Chapter 1 | S.U.F. overview

1.2. Hardware characteristics

1.2.1. System features

The S.U.F. is designed for system mobility and easy integration while

utilizing a straightforward operator interface. Hardware drawings and

specification tables specific to volume can be found in Chapter 4 of

this guide. The following topics include general descriptions of the

hardware components of the S.U.F.

1.2.2. Agitation

If your system uses a Thermo Scientific electrical control panel (E-Box),

the stirring speed is adjusted by using the keypad interface on the

control panel. The agitation control interface utilizes a digital display

to indicate stirring speed in units of revolution per minute (rpm). Power

is supplied to the motor by a two-position power switch. The up and

down arrows on the agitation keypad adjust the stirring speed. Your

system may also be integrated and managed by a third-party controller.

1.2.3. Control system

The S.U.F. is designed to integrate with existing control systems in

their many configurations. The S.U.F. control system supplied with the

Thermo Scientific E-Box enclosure manages the agitation process

and monitors the pressure inside the BPC. Parameters of pH and DO,

gas management, feed addition, and base addition control must be

managed by an external controller supplied by the end user or a thirdparty integrator.

1.2.4. Exhaust management system

A condenser system is recommended and is available as optional

hardware. It cools exhaust gases and re-circulates the condensate into

the fermentor.

1.2.5. Exhaust vent filter heater

An optional exhaust vent filter heater is available for increased longevity

of the exhaust filter on the S.U.F. BPC. Heating the filter sufficiently

to eliminate the formation of condensation is an effective means of

reducing the risk of fouling of the filter membrane. The heater is factory

preset to operate between 40–55°C, ± 3 degrees. Temperature

settings above 60°C are not recommended.

HyPerforma Single-Use Fermentor User’s Guide | 14Thermo Scientific

Page 20

Chapter 1 | S.U.F. overview

1.2.6. Temperature

The S.U.F. can be operated within the temperature range from 5–55°C.

The process temperature is measured by means of a supplied RTD

(pt-100) that is inserted into the thermowell of the S.U.F. BPC. Water

jacketed system temperature control is maintained through the TCU or

a third-party controller.

1. 2 .7. Heating performance

Heating times for S.U.F. systems vary based on operating liquid

volume and temperature, ambient or heating fluid temperature, sparge

rate, and mixing rate. Users should adjust process liquid staging

and seeding strategies to the unique aspects of the S.U.F. Process

controllers are designed to provide optimum heat transfer and to

minimize heat up times, while maintaining the material integrity of the

polymer film construction of the S.U.F. BPC. Refer to section 3.1.4 for

expected heating times.

1.2.8. External control

Users can choose to bypass the mixing speed control and display

pressure systems provided with the S.U.F. and utilize existing

controllers. Refer to section 3.6 for more details.

1.2.9. Load cells

Load cells, used to determine the weight of the contents of a S.U.F., are

optional. Load cell kits can be installed at the factory or can be added

later by a certified service technician. The load cell kit comes with three

load cells, summing block, wiring, and display with a choice of several

data interfaces.

Load cells arrive uncalibrated. It is recommended that the load cell

manufacturer or a qualified technician calibrate these systems on site.

HyPerforma Single-Use Fermentor User’s Guide | 15Thermo Scientific

Page 21

Chapter 1 | S.U.F. overview

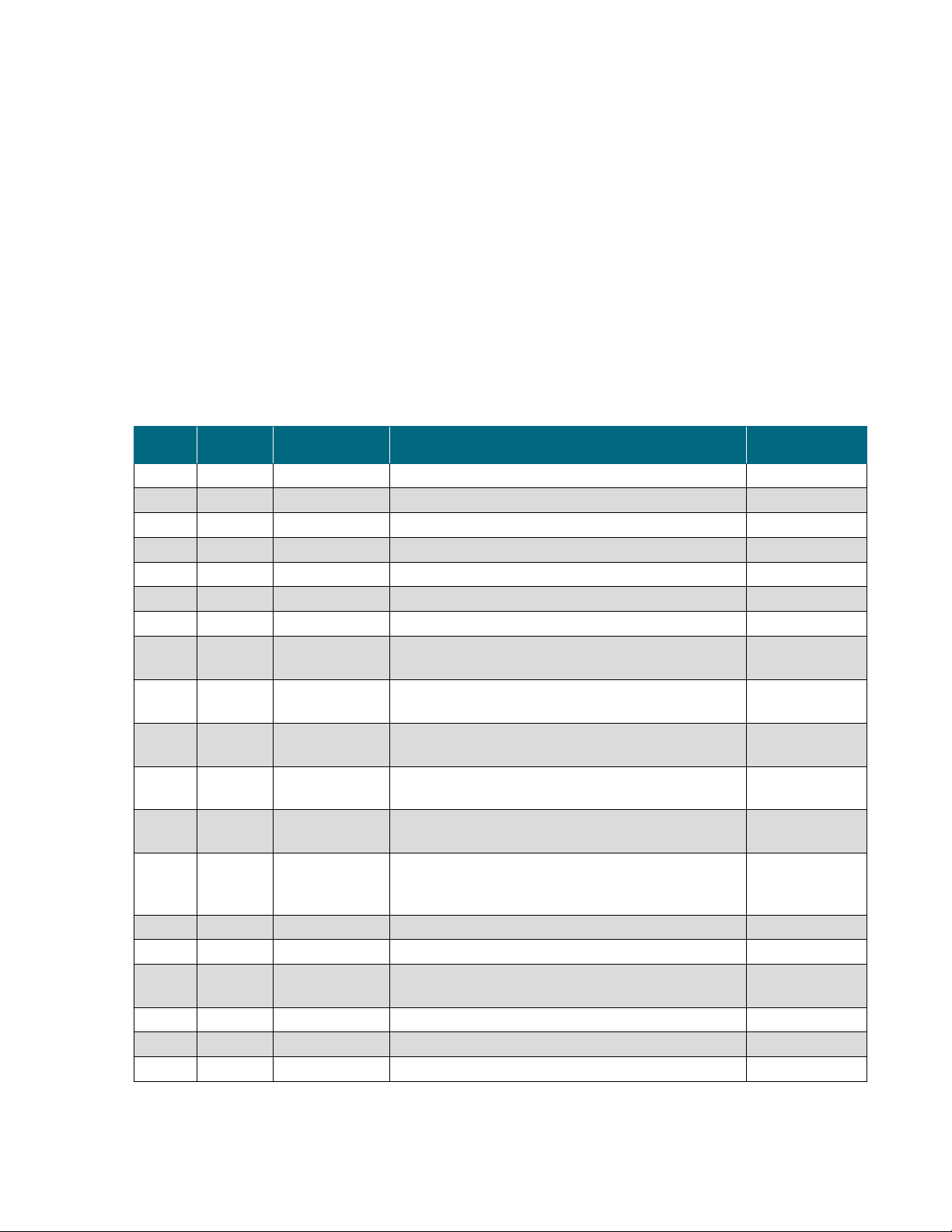

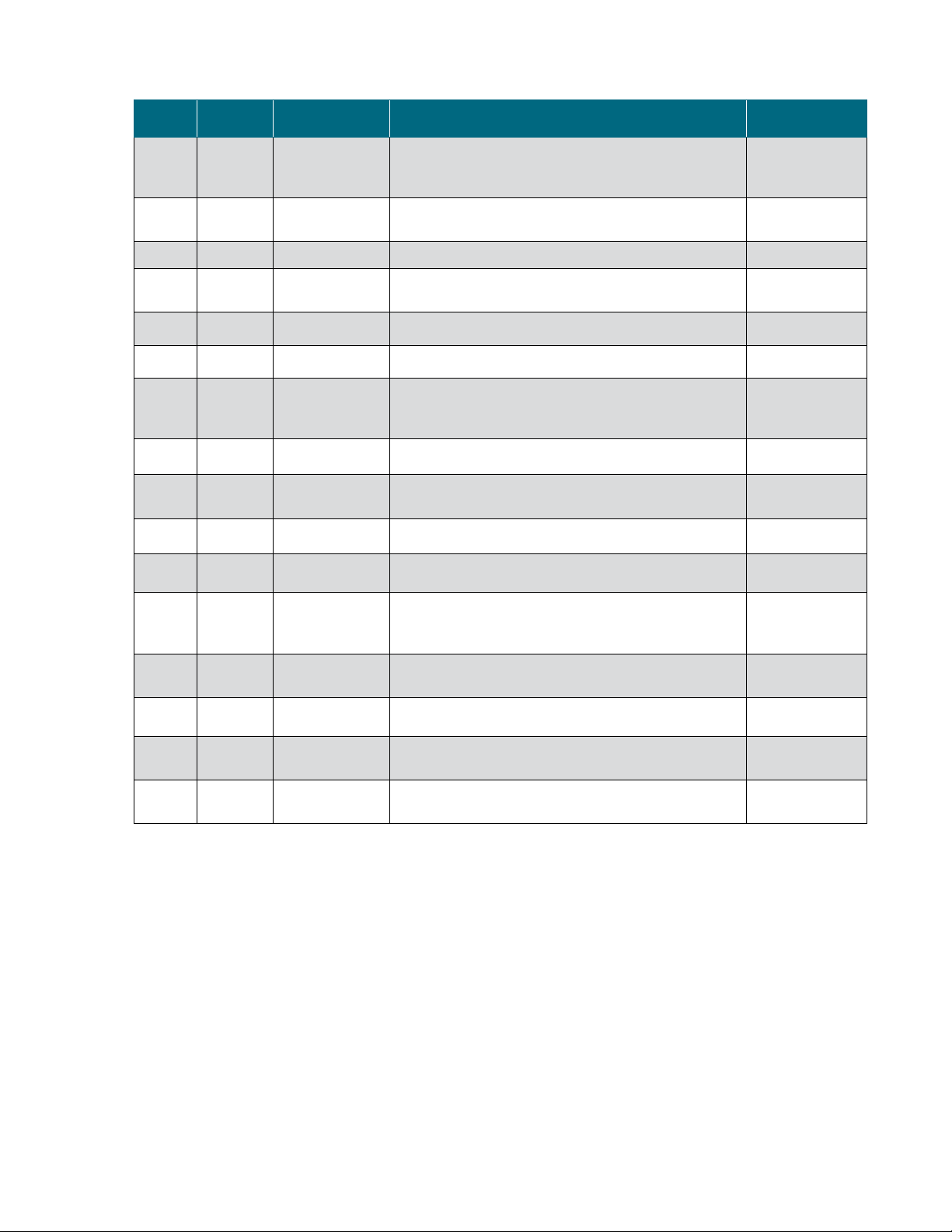

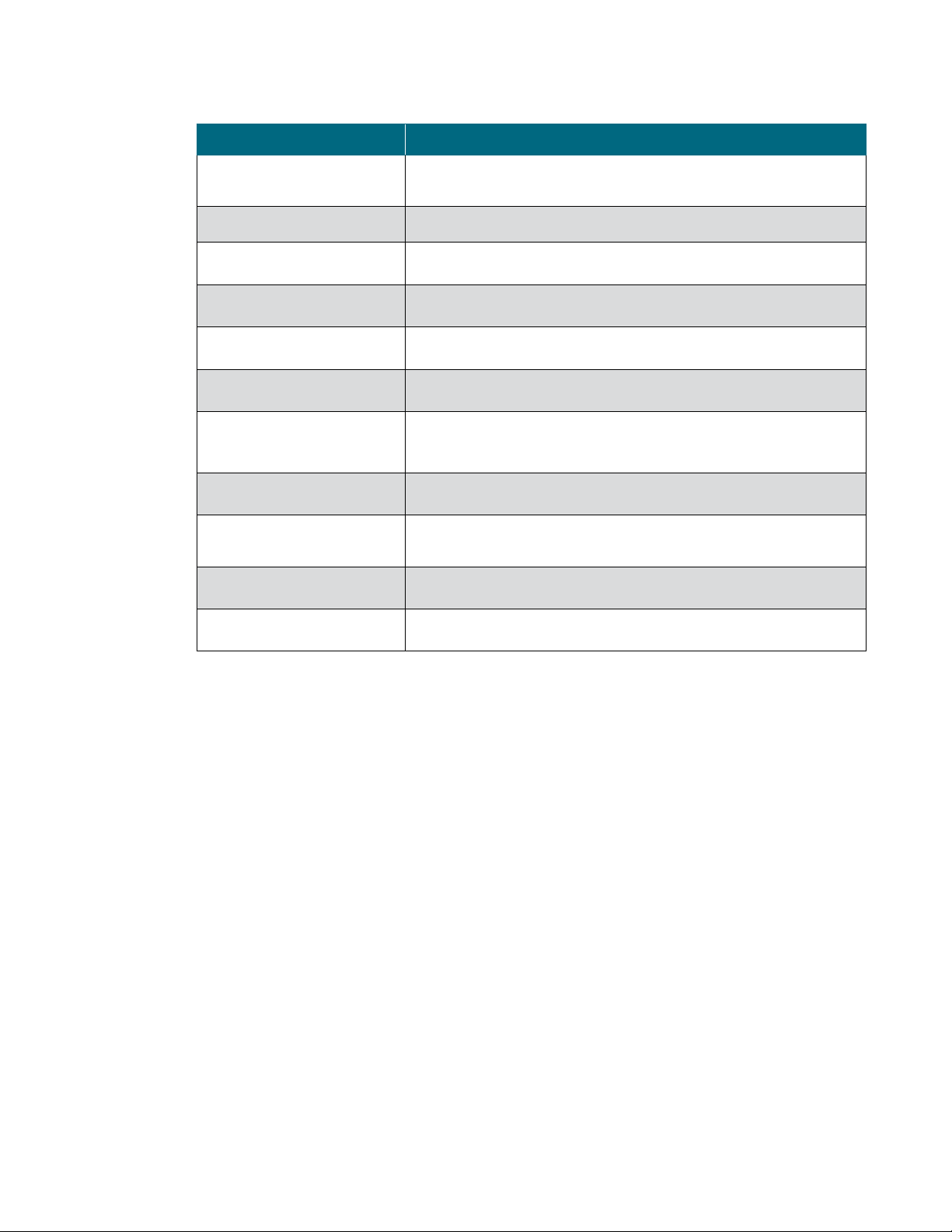

Table 1.1. Manufacturers and models of compatible pH/DO probes.

Probe lengths (from O-ring to tip) must not exceed 235 mm (9.25 in.)

1.3. End user and third-party supplied

components

1.3.1. pH and DO probes

The following table shows the length and diameter requirements for

traditional sensors (probes) that can be integrated into the S.U.F. These

requirements are based on the necessary insertion depth of the probe

when used with the probe ports. Note: The presence of a properly

positioned O-ring on the probe is critical for use with the S.U.F.

O-ring to probe tip

Sensor Inserted

Probe Part number Diameter

AppliSens DO Z010023525 12 mm (0.47 in.) 13.5 PG

AppliSens pH Z001023551 12 mm (0.47 in.) 13.5 PG

Mettler Toledo DO

Mettler Toledo pH

Broadley-James DO D140-B220-PT-D9 12 mm (0.47 in.) 13.5 PG

Broadley-James pH F-635-B225-DH 12 mm (0.47 in.) 13.5 PG

Hamilton DO 237542 12 mm (0.47 in.) 13.5 PG

Hamilton pH 238633-2543 12 mm (0.47 in.) 13.5 PG

NOTE: Consult probe manufacturer’s website for appropriate probe cable connection and part number.

InPRO 6800/12/220,

PN 52200966

405-DPAS-SCK8S/225, PN

104054481IG

12 mm (0.47 in.) 13.5 PG

12 mm (0.47 in.) 13.5 PG

Thread

type

Length Length

235 mm

(9.25 in.)

235 mm

(9.25 in.)

215 mm

(8.46 in.)

195 mm

( 7.6 7 in. )

215 mm

(8.46 in.)

225 mm

(8.85 in.)

225 mm

(8.85 in.)

225 mm

(8.85 in.)

235 mm

(9.25 in.)

235 mm

(9.25 in.)

215 mm

(8.46 in.)

219 mm

(8.62 in.)

214 mm

(8.42 in.)

219 mm

(8.62 in.)

220 mm

(8.66 in.)

220 mm

(8.66 in.)

1.3.2. Single-use probes

Mettler Toledo single-use pH and DO sensors are supported, and

BPCs may be ordered with single-use sensors as fully integrated

components.

HyPerforma Single-Use Fermentor User’s Guide | 16Thermo Scientific

Page 22

Chapter 1 | S.U.F. overview

1.3.3. Controllers

Thermo Scientific operates with an open architecture approach to the

integration of controls. Our industry-leading S.U.F. can be integrated

with most controllers on the market, allowing customers to choose

the control system they want, or to reduce expense by integrating

with a controller that is already onsite. In order to facilitate integration,

electrical schematics are provided in the Equipment Turnover Package

(ETP) supplied with the Thermo Scientific S.U.F.

S.U.F. units may be provided with integrated controls, pump towers, a

control monitor, and advanced features, such as data logging, multiple

S.U.F. connections, and optional 21CFR part 11 compliance for cGMP

manufacturing. A variety of single-use sensors are available for pH,

DO, and pressure control. Thermo Scientific can provide complete,

integrated solutions with the Thermo Scientific OEM Controller, or using

the manufacturers listed below.

• Applikon SUB-Controller

• Legacy Finesse PC Controller

• Emerson Delta V

• Allen-Bradley

• Siemens

Contact your local sales representative for more information.

Note: The S.U.F. will work well with any of the various control system

platforms, such as PLC, PC, DCS, or proprietary operating system

based controllers.

HyPerforma Single-Use Fermentor User’s Guide | 17Thermo Scientific

Page 23

Chapter 1 | S.U.F. overview

1.4. BPC characteristics

1.4.1. S.U.F. BPC features

The microbial culture itself is contained inside the S.U.F. BPC

(Figures 1.2 and 1.3). The chamber is manufactured from single-web,

multi-layer film, which is a co-extruded structure specifically designed

for biopharmaceutical process usage. All materials are qualified for

a broad range of physical, mechanical, biological, and chemical

compatibility requirements (refer to data in our BPC Catalog, which is

available from your sales representative). The BPC is presterilized using

validated gamma irradiation processes.

1.4.2. Operating pressure

The S.U.F. BPC does not operate as a closed system, as it has both

inlet and exhaust filters that are utilized to maintain an environment for

cells to grow without concern for contamination. However, conditions

can be encountered when gas inlet flow rate may exceed exhaust

flow rate. This may be encountered in the unlikely event of a pressure

regulator failure on a gas feed, or when excessive foaming creates

conditions of vent blockage. The S.U.F. BPC is not rated as a pressure

vessel (gas pressure should not exceed 0.03 bar (0.5 psi) within the

BPC). Custom BPCs can be ordered with an optional single-use

pressure transducer for monitoring the pressure within the S.U.F.

1.4.3. Working volume

Each S.U.F. is designed for a working volume range. The minimum

working volume and the rated working volume are listed in the

specification tables provided in Chapter 4. The total volume listed

includes the head space needed for proper aeration and gas

management. Actual working volumes should not exceed the indicated

rated working volumes. In addition, working volumes less than the

minimums listed can result in damage to the BPC and S.U.F. hardware

malfunction.

HyPerforma Single-Use Fermentor User’s Guide | 18Thermo Scientific

Page 24

Chapter 1 | S.U.F. overview

1.4.4. Draining and harvest

The S.U.F. is equipped with a bottom drain line that allows for liquid

harvest, typically with a peristaltic pump. Connection of the bottom

drain line can be accomplished by use of a tubing welder or the aseptic

connection of quick connect or fitting that is provided. Manipulation of

the BPC as the last few liters of media are removed can minimize liquid

hold-up within the S.U.F.

1.4.5. Aeration

Gas to liquid mass transfer in microbial culture fermentors is controlled

by the solubility of the gas in the liquid, its distribution, and the

temperature and pressure. Direct air sparging is a way of providing

for the oxygen requirements of cell cultures. The standard S.U.F. BPC

incorporates a unique rind-like film sparger design that allows for

optimal aeration of the culture process.

1.4.6. Aseptic connections

Multiple aseptic connection options exist for S.U.F. users. The

standard BPCs include tubing welder sections, quick connects, CPC

™

AseptiQuik,

or Pall™ Kleenpak™ aseptic connections. The S.U.F.

BPC is designed with various lengths and dimensions of thermoplastic

tubing for the purpose of addition to and dispensing from the S.U.F.

BPC. Refer to ordering information in Chapter 4 for custom end

treatment options.

™

1.4.7. Sampling

The S.U.F. is equipped with a small volume sample port that is adjacent

to the BPC thermowell. This small diameter silicone dip tube of 152.4

mm length (6 in.) allows low void volume samples to be taken for

cell viability and density, as well as analyte analysis. This dip tube is

supplied with an aseptic luer lock connector (SmartSite

for direct sampling or attachment of various sampling manifolds by

use of standard luer lock connection. Alternatively, manifolds can be

™

welded onto the C-Flex

sample line by tubing welder.

™

) that allows

Detailed BPC drawings and standard configuration tables specific to

volume can be found in Chapter 4 of this guide.

HyPerforma Single-Use Fermentor User’s Guide | 19Thermo Scientific

Page 25

Chapter 1 | S.U.F. overview

1.4.8. BPC features

Figures 1.2 and 1.3 illustrate the components of standard 30 L and

300 L S.U.F. BPCs. See Table 1.2 on the following page for more

information.

1

4

6

11

Figure 1.2. 30 L S.U.F. BPC.

2

3

5

7

9

10

1

2

8

3

6

11

4

5

8

9

7

10

Figure 1.3. 300 L S.U.F. BPC.

HyPerforma Single-Use Fermentor User’s Guide | 20Thermo Scientific

Page 26

Chapter 1 | S.U.F. overview

Table 1.2. BPC information for Figures 1.2 and 1.3.

1. Exhaust vent filter Single-use capsule filter for exhaust gas exchange (two types available)

2. Condenser bag (optional) Optional single-use condenser bag

Component Description

3. Foam sensor (optional)

4. Seal/bearing assembly

Built-in single-use sensor may be used with a controller to automatically trigger

addition of an anti-foaming agent when excessive foam is present

Links with mixer motor and allows impeller to turn while retaining integrity of

the S.U.F. BPC

5. Feed ports Feed port for addition of media and other liquids

6. Impeller

Injection molded plastic; linked to seal/bearing assembly by C-Flex tubing

contact material of the shaft

7. Ports with single-use sensors

or standard Pall Kleenpak*

Ports with single-use sensors or standard Pall Kleenpak* connectors

connectors

8. Spare sterile connect port Spare port

9. Temperature RTD/ small volume

sampling port

10. Gas sparge line(s)

For integration of temperature probe while retaining integrity of the S.U.F. BPC,

and for needleless sampling or connection to sampling manifold

Drilled hole sparger integrated into the chamber and protected by gas filters

and a check valve (check valve is provided on 30 L units only)

11. Drain port Used when draining the S.U.F.

*CPC AseptiQuik aseptic connectors are also available on S.U.F. BPCs.

HyPerforma Single-Use Fermentor User’s Guide | 21Thermo Scientific

Page 27

Chapter 1 | S.U.F. overview

1.5. Additional system components

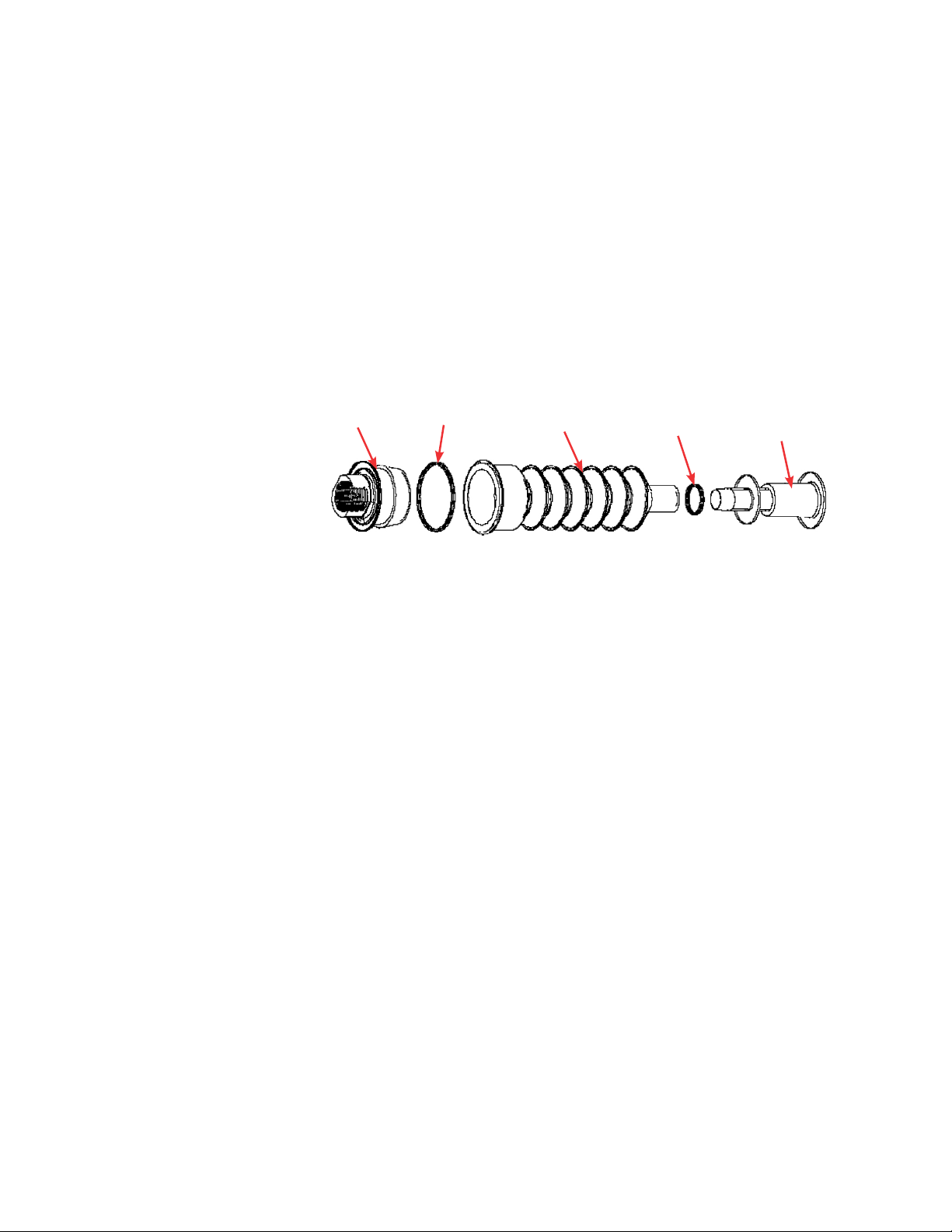

1.5.1. Probe integration

The probe assembly is an innovative design to package user-supplied

pH and DO probes for sterilization and to aseptically connect them to

the S.U.F. BPC. The probe assembly (Figure 1.4) includes the following

components:

1. Molded bellows cover

2. Threaded probe adapter

3. Pall Kleenpak connector (KPCHT series—high temperature)

4. Cable ties

2

Figure 1.4. Probe assembly.

Note: Figure 1.4 shows a Pall Kleenpak connector. CPC AseptiQuik

connectors are also available for S.U.F. systems.

4

1

4

3

1.5.2. Accessories

To assist in the operation of the S.U.F., additional accessories are

available (see accessories below).

Required

• Heavy-duty tubing clamps

Recommended

• Exhaust management system with condenser and vent filters.

Optional

• E-Box

• Sampling manifold with luer lock

• Temperature sample port (for RTD calibration/validation)

• Vent filter heater system—for users who require additional

protection for the exhaust vent filter on the standard S.U.F. BPC;

includes filter heater, controller, and power cord.

HyPerforma Single-Use Fermentor User’s Guide | 22Thermo Scientific

Page 28

Chapter 1 | S.U.F. overview

• Load cells—Load cell packages include three load cells, summing

block, wiring, and an optional display screen with your choice of

several data interfaces

• Cable management system

• Bottle management system

• Feed bag management hook

See Chapter 4 of this guide for accessory ordering information.

HyPerforma Single-Use Fermentor User’s Guide | 23Thermo Scientific

Page 29

Chapter 2 | Installation and setup

2

Installation and setup

Chapter contents

2.1 Initial installation preparation

2.2 Installation

HyPerforma Single-Use Fermentor User’s Guide | 24Thermo Scientific

Page 30

Chapter 2 | Installation and setup

2.1. Initial installation preparation

The Single-Use Fermentor (S.U.F.) hardware will arrive crated. For

unpacking instructions and detailed contents of the crate, please refer

to the S.U.F. Packing and Unpacking Guide (DOC0052).

There will be detailed instructions for crating, uncrating, and assembly

of 30 L and 300 L S.U.F. units. Be sure to follow the instructions

provided and retain all packaging materials. After uncrating, contact

your sales representative immediately if you find that any damage has

occurred in shipping.

2.1.1. Hardware shipment and setup

The S.U.F. hardware will arrive with the following items:

• Outer support container (platform, tank, and control panel)

• Drive shaft, resistance temperature detector (RTD), four probe

brackets, and standard tool set (spanner wrench and torque

wrench)

• Equipment Turnover Package (ETP) provided on a USB drive,

shipped separately

2.2. Site preparation

2.2.1. Electrical connections for units with an electrical

control panel

S.U.F. hardware with AC motors cannot be used on circuits equipped

with GFCI circuit protection due to the potential for nuisance tripping.

The electrical plug on the S.U.F. is a connector that offers a secure

ground. These connectors meet the electrical safety codes for portable

equipment and are International Electrical Code (IEC) rated (meet IEC

standard 60309). This plug serves to provide electrical ground prior

to power connection. The supplied electrical receptacle should be

hard-wired into the facility by a qualified electrical technician; for US

installations the receptacle will require the use of an adapter mounting

plate (supplied) which will fit into a two gang box. For additional

information on the adapter mounting plate, please see the ETP.

Alternatively, the system can be hard-wired directly into the facility.

Note: The yellow plug and receptacle are for 120 VAC and the blue are

for 240 VAC S.U.F.s.

HyPerforma Single-Use Fermentor User’s Guide | 25Thermo Scientific

Page 31

Chapter 2 | Installation and setup

2.2.2. Outer support container preparation

Each outer support container is shipped from the manufacturer and

arrives with various safety mechanisms in place. Please follow the

guidelines below to set up the S.U.F. upon arrival.

WARNING: Any procedures that require the electrical control panel

(E-Box) to be opened should be performed with the main electrical

disconnect in the locked out position, and all power sources removed.

For operator safety, secure the location of the S.U.F. unit by disabling

the swivel casters before servicing.

2.2.3. Electrical preparation for systems with electrical

control panels

1. Before beginning, refer to electrical schematics included with the

ETP, which is shipped on a USB drive.

2. Make sure the unit is disconnected from any power source, and

use standard lockout safety procedures.

3. Open the E-Box using a flat-head screwdriver. Verify that the

three-way motor controller switch is in the middle position

(Figure 2.1).

Motor controller

breaker

Main breaker

Motor controller

Figure 2.1. Internal view of typical S.U.F. E-Box.

HyPerforma Single-Use Fermentor User’s Guide | 26Thermo Scientific

Motor controller

switch (3-way)

Page 32

A

Chapter 2 | Installation and setup

4. Fermentor units are shipped with the main electrical breaker in the

off position. Turn the main breaker on.

5. Close the E-Box and lock the panel.

2.2.4. Load cell preparation

1. For S.U.F. units purchased with factory-installed load cells, the load

cells are shipped in the locked position (threaded up) for equipment

protection. To unlock the load cells, remove and discard the delrin

slip ring if it is present (Figure 2.2). Remove the tri-clamp. Loosen

the lockout nut, using the small end of the supplied tool (Figure 2.3),

until the nut is tight against the base or leg of the tank. Repeat this

process for each load cell until all lockout nuts are disengaged from

the lockout posts. Do not reinstall the tri-clamp.

Lockout nut

38.1 mm (1.5 in.)

tri-clamp

Lockout post

Delrin slip ring

Drive shaft

cap end

Figure 2.2. Load cells.

Load cell

lockout end

Figure 2.3. Supplied wrench.

HyPerforma Single-Use Fermentor User’s Guide | 27Thermo Scientific

Page 33

Chapter 2 | Installation and setup

2. At this point, the S.U.F. hardware is ready to prepare for a cell

culture run. CAUTION: Do not move unit, especially when filled,

while load cells are unlocked, as this can damage the load cells.

3. For systems with load cell display screens, refer to Appendix C for

information about how to calibrate the tools.

4. To lock load cells that have been unlocked, hand-tighten the

lockout nut onto the post. Use the supplied tool to turn the nut an

extra 1/4 turn.

WARNING: To avoid damaging the load cells, do not over-tighten the

nut. Assemble a standard stainless 38.1 mm (1.5 in.) tri-clamp around

the flanges. Complete this process for all load cells.

2.3. Installation

300 L S.U.F. systems are shipped with motors detached. Depending

on doorway height, you may need to wait to install the motor until the

S.U.F. is in place. See the specifications for the outer support container

in Chapter 4 and the S.U.F. Packing and Unpacking Guide for more

information.

All manual movements of mobile S.U.F. hardware should be over

smooth surfaces, with the S.U.F. empty and disconnected from all

power and gas/feed sources. All load cells must be fully locked down

in order to move a S.U.F. Refer to the previous subsection of this guide

for illustrations.

WARNING: Tipping hazard. The vessel should only be moved by

pushing using the provided handles or at the mid-point of the

vessel.

If pulled or moved too quickly, the vessel can tip, potentially leading

to damage to equipment or injury to personnel. To reduce the risk

of tipping, the vessel should only be moved slowly over smooth, flat

surfaces by at least two qualified personnel. During movement, any

locking feet should be retracted, and casters should be in the unlocked

position. The vessel should not be moved by pulling of any kind.

1. Verify that the facility electrical supplies are sufficient to support the

power requirements of the S.U.F. and ancillary components such as

controllers or pumps.

HyPerforma Single-Use Fermentor User’s Guide | 28Thermo Scientific

Page 34

Chapter 2 | Installation and setup

2. Locate the outer support container in the area for the cell culture

run.

3. If monitoring the volume, the unit may be located on a scale if load

cells are not utilized. Other applications may measure all liquids

going in and coming out.

4. Level the platform by disabling the swivel casters on the bottom of

the outer support container. This is accomplished by threading the

leveling

feet (at the center of each caster) to the floor.

5. Verify the location of the pH/DO controllers and ensure cable/tubing

lengths are satisfactory.

WARNING: Electrical shock is possible.

6. Verify that the main power is off and the emergency stop is pulled

out.

Note: The emergency stop disconnects all power to the system. An

alarm buzzer will sound when the emergency stop is activated.

7. Verify that the main motor power switch is in the off position.

8. Connect all electrical plugs to facility power.

Note: 120 VAC S.U.F. should be connected to a dedicated 10 A

circuit. Refer to hardware/electrical labels and schematics to ensure

proper electrical voltage is connected to the S.U.F. The main power

switch can now be turned on.

9. Connect the water inlet and outlet lines from the temperature

control unit (TCU) to the S.U.F. (Figure 2.4). The inlet is typically on

the left side when you are facing the

connectors

. The inlet and

outlet ports on the S.U.F. water jacket are labeled.

HyPerforma Single-Use Fermentor User’s Guide | 29Thermo Scientific

Page 35

Chapter 2 | Installation and setup

Figure 2.4. Attaching a TCU hose to the water

jacket port.

2. 3.1. Exhaust filter bracket setup

To install the exhaust filter bracket, clamp it onto the rim of the S.U.F.

tank. Push the red handles down to lock it into place (Figure 2.5). The

exhaust filter post will slide into the hole in the bracket. The center red

handle locks the post in place. This may need to be adjusted during

initial BPC loading. Note: The pinch clamp for 30 L systems must be

installed onto the exhaust filter post before it is mounted to the tank.

See section 2.3.4 for instructions.

Figure 2.5. Clamping the exhaust filter bracket to

30 L S.U.F. tank.

HyPerforma Single-Use Fermentor User’s Guide | 30Thermo Scientific

Page 36

Chapter 2 | Installation and setup

30 L condenser

attached

to pole

2.3.2. Condenser unit setup (when present)

If your system includes an optional condenser, the assembled

condenser will need to be installed. Condensers for 30 L units are

clamped onto the exhaust filter pole (Figure 2.6). Condensers for 300 L

units are bolted onto the exhaust filter bracket (Figure 2.7).

300 L

condenser

attached to rim

mount

Figure 2.6. Condenser installed on a 30 L system.

Figure 2.7. Condenser installed on a 300 L system.

HyPerforma Single-Use Fermentor User’s Guide | 31Thermo Scientific

Page 37

Chapter 2 | Installation and setup

2.3.3. TCU/chiller connection to condenser unit (optional)

Use the following steps to connect a TCU or chiller to the S.U.F.

condenser unit, if present.

1. Connect inlet and outlet hoses to the TCU (Figure 2.10). You may need

to attach the valves to the TCU, if necessary.

a. Use the clear supplied washers and tri-clamps to attach the fitting

and then the hoses to both the inlet and the outlet port on the TCU

(Figures 2.8 and 2.9).

Figure 2.8. Attaching line to a TCU unit. Figure 2.9. Attaching a clamp to a line.

Process outlet

port on TCU

Process inlet port

on TCU

Figure 2.10. TCU ports with lines

connected for S.U.F. condenser.

2. Connect the remaining end(s) to inlet port(s) on the condenser.

closer

On 300 L systems the inlet ports are the ports

(shown in Figure 2.11)—On 30 L systems the inlet port is the

to the tank

upper

port on the condenser (can be seen in Figure 2.6).

HyPerforma Single-Use Fermentor User’s Guide | 32Thermo Scientific

Page 38

Chapter 2 | Installation and setup

3. Connect the remaining end(s) to outlet port(s) on the condenser. On

300 L systems the outlet ports are the ports

farther from

(shown in Figure 2.11)—On 30 L systems the outlet port is the

to the tank

lower

port on the condenser (can be seen in Figure 2.6).

Note: The inlet and outlet hoses for 300 L systems include a

Y-splitter to make the connections on the condenser plates.

Outlet ports

on 300 L

condenser

Figure 2.11. Attaching TCU lines to a

condenser on a 300 L S.U.F. unit.

Inlet ports

on 300 L

condenser

4. Fill the TCU and prepare it for operation as specified in the user’s

guide provided with the TCU.

2.3.4. Exhaust filter pinch clamp setup (when present)

Some systems include an exhaust filter pinch clamp (Figure 2.12), which

is used to temporarily keep exhaust from flowing through redundant

exhaust filters.

Pinching

surface

Figure 2.12. Exhaust filter pinch clamp.

HyPerforma Single-Use Fermentor User’s Guide | 33Thermo Scientific

Release button

(

blue

light

indicates unit is

receiving power)

Locking pin

Page 39

Chapter 2 | Installation and setup

Use the following steps to install the exhaust filter pinch clamp.

1. Mount the pinch clamp to the exhaust filter post (Figure 2.13) using

the supplied C bracket. If the exhaust filter post is not already

installed on the system, mount it onto the exhaust system bracket.

WARNING: Pinch hazard. Keep hands away from the pinching

surface. Close and use locking pin when pinch clamp is not in use.

Pinch clamp installed

onto exhaust system

post with C-bracket

Figure 2.13. Pinch clamp installed on a 300 L S.U.F.

2. Lift the center red handle of the exhaust bracket. Slide the exhaust

filter holder post into the bracket and lock the center handle down.

3. Plug the wire attached to the pinch clamp unit into the controller.

A blue light on the pinch clamp’s release button indicates that unit

is receiving power and the unit is ready for manual initiation of the

clamp.

Refer to the BPC loading instructions in section 3.2 for more

information about how to use the pinch clamp with the BPC.

HyPerforma Single-Use Fermentor User’s Guide | 34Thermo Scientific

Page 40

Chapter 2 | Installation and setup

2.3.5. Optional cable management system setup

If your system includes the optional cable management system, the

arm of the cable management system may be removed for shipping.

Use an allen wrench to attach the arm as shown in Figure 2.14.

Refer to the BPC loading instructions in section 3.1 for more

information on how to use the cable management system.

Figure 2.14. Attaching arm to cable management system.

2.3.6. Air line preparation

See Tables 3.2 and 3.3 (page 96) for recommended air flow rates.

The operating pressures at the level of the S.U.F. are of primary

importance and these values must be adhered to. Please note that flow

rates in the graphics include both half and full volume applications.

WARNING: The S.U.F. BPC is not rated as a pressure vessel. The BPC

should not be allowed to become tight during inflation or operation.

Gas pressure in the BPC should not exceed 0.03 bar (0.5 psi) at

any time. Conditions of over pressure may result in BPC damage or

personal injury. For reference the BPC will appear to be tight at 0.007

bar (0.1 psi). The tubing after the inlet filter should be easy to compress

with two fingers. When testing, be sure NOT to pinch off the air inlet

line completely.

2. 3 .7. Drilled hole sparger line(s)

Manually orient the sparge line vertically for maximum effectiveness.

HyPerforma Single-Use Fermentor User’s Guide | 35Thermo Scientific

Page 41

Chapter 3 | Operating information

3

Operating information

Chapter contents

3.1 General system operating information

3.2 BPC and drive shaft loading instructions for 30 L units

3.3 BPC and drive shaft loading instructions for 300 L units

3.4 Exhaust system

3.5 Probe assembly

3.6 Microbial cell culture operating instructions

3.7 BPC sampling

3.8 Verification procedures

HyPerforma Single-Use Fermentor User’s Guide | 36Thermo Scientific

Page 42

Chapter 3 | Operating information

3.1. General system operating information

3.1.1. BPC preparation and loading

Each outer support container is designed for a specific S.U.F.

BPC. Confirm that the correct volume BPC is being used for the

corresponding volume outer support container. This section outlines

the installation and setup of the different volume S.U.F. BPCs. Please

follow these instructions in the order in which they are presented.

3.1. 2. BPC handling instructions

Use caution when using sharp objects to open outer polybags, in order

to avoid causing damage to the BPC. Do not drag containers over

corners or sharp objects. Do not lift the container by the corners or top

seams. Carefully coil tubing on top of the BPC to prevent puncturing

the container with cable ties or clamps. Use cushioning between tubing

and container in storage and transport.

3.1.3. BPC operating information

Aseptic line connection

The most commonly recommended process for making connections to

the tubing lines is with an aseptic tubing fuser. Note: Other connection

options are available as a custom BPC assembly.

Following the recommended tubing welder operating instructions,

successful connections can be obtained for filling, supplementing,

sampling, or dispensing from the BPC as needed.

Working volume

Each S.U.F. is designed for a working volume range. The minimum

working volume and the rated working volume are listed in the

specifications tables in Chapter 4. The total volume listed includes the

headspace needed for proper aeration and gas management.

Note: Actual working volumes should not exceed the indicated

rated working volumes by more than 10%. In addition, working

volumes less than 20% of the rated volume can result in damage

to the BPC and hardware.

Exhaust system

The exhaust vent filter(s) and condenser used on the 30 L and

300 L S.U.F.s include ZenPure

filters. Condensate must be managed by use of the condenser system

or vent filter heater(s).

™

polyethylene or Meissner™ PVDF

HyPerforma Single-Use Fermentor User’s Guide | 37Thermo Scientific

Page 43

Chapter 3 | Operating information

Sampling

The S.U.F. is equipped with a small volume sample port that is

part of the BPC thermowell. This small diameter (1.59 x 4.76 mm

(1/16 x 3/16 in.)) silicone dip tube of 152.4 mm (6 in.) length allows low

void volume samples to be taken for cell viability and density, as well

as analyte analysis. This dip tube is supplied with an aseptic luer lock

™

connector (SmartSite

) that allows for direct sampling or attachment

of various sampling manifolds by use of standard luer lock connection.

Alternatively, manifolds can be welded onto the C-Flex sample line (3.18

x 6.35 mm (1/8 x 1/4 in.)) by tubing welder. For recommended systems

for fluid transfer, contact your sales representative.

Operating pressure

The BPC is not rated as a pressure vessel. All gas supplied to

the fermentor controller must be regulated to a pressure not to

exceed manufacturer’s recommendations, typically 1.034–4.137 bar

(15–60 psi), depending on vessel scale and use. Gas pressure in the

BPC headspace should not exceed 0.03 bar (0.5 psi) at any time.

WARNING: Conditions of overpressure may result in BPC damage or

personal injury. The maximum pressure in the tubing after the inlet filter

should be about 0.344 bar (5 psi). The section of tubing after the inlet

filter should be easy to compress with two fingers.

The BPC is not operated as a closed system. It has both inlet and

exhaust filters that are utilized to maintain a sterile environment for

cells to grow without concern for contamination. However, conditions

can be encountered when gas inlet flow rate may exceed exhaust

flow rate. This may be encountered in the unlikely event of the failure

of a pressure regulator on a gas feed, or when excessive foam within

the S.U.F. creates conditions of vent blockage. The S.U.F. BPC is not

rated as a pressure vessel. All gas supplied to the fermentor controller

must be regulated to a pressure not to exceed manufacturer’s

recommendations, typically 2.06–4.13 bar (30–60 psi). Gas pressure in

the BPC headspace should not exceed 0.03 bar (0.5 psi) at any time.

• Demanding applications may warrant an optional exhaust vent

heater.

• If foaming is excessive in your cell culture process, use a foam

sensor.

• Single-use pressure transducers are available with the S.U.F. This

technology combined with high-level control systems common with

industrial applications can regulate gas pressure within the confines

of the S.U.F.

HyPerforma Single-Use Fermentor User’s Guide | 38Thermo Scientific

Page 44

Chapter 3 | Operating information

Extensive testing has not found an occurrence of overpressure

sufficient to create a containment breach. Development testing of the

BPC system has shown that in conditions of excessive pressure the

polymer container will fail at the upper regions of the chamber where it

is unsupported by the outer support container, minimizing the likelihood

of the loss of bulk liquid.

Agitation

The agitator should not be operated at volumes less than the stated

minimum volume. Stirring speed may be adjusted by using the keypad

interface on the controller. At low volumes, the chamber should be

inflated to prevent the film of the BPC from contacting the agitators.

Agitation control interface for units with electrical control

panels

The agitation control interface utilizes an LED digital display to indicate

stirring speed in units of revolution per minute (rpm). Power is supplied

to the motor by a two position power switch that is illuminated in green

when turned to the “on” position (right position). The up and down

arrows on the agitation keypad adjust the stirring speed. Due to the

auto-restart capabilities of the S.U.F., the green start button on the

keypad has been disabled; however, the red stop button on the keypad

is active. If the red stop button has been used to stop the motor, the

controller can be reset and agitation restarted by using the main motor

toggle switch on the left side of the E-Box.

Dispense and harvest

The S.U.F. is equipped with a bottom drain line that allows for liquid

harvest by means of peristaltic pump. Connection of the bottom drain

line can be accomplished by use of a tubing welder or the aseptic

connection of 6.35–9.53 mm (1/4–3/8 in.) quick connect that is

provided. Manipulation of the S.U.F. BPC as the last few liters of media

drain will minimize liquid hold-up within the S.U.F.

3.1.4. Hardware operating information

Temperature

Temperature setpoints can be adjusted via the temperature control

unit (TCU). These setpoints should be between 5 and 55°C. The

process temperature is measured by means of a supplied resistance

temperature detector (RTD) (pt-100) that is inserted into the thermowell

of the S.U.F. BPC. The temperature measured by the RTD is not

displayed, but is passed through the 16-pin cable as a raw PT100

signal.

HyPerforma Single-Use Fermentor User’s Guide | 39Thermo Scientific

Page 45

Chapter 3 | Operating information

Heating performance

Heating times for the S.U.F. system vary based upon liquid volume and

temperature, ambient or heating liquid temperature, sparge rate, and

mixing rate. Users should adjust process liquid staging and seeding

strategies to the unique aspects of the S.U.F. Process controllers and

heaters are designed to provide optimum heat transfer and minimize

heat up times, while maintaining the material integrity of the polymer

film construction of the BPC (Table 3.1).

Do not operate the heater if the BPC is not at minimum liquid, 5:1 (20%)

volume or greater. Care must be taken not to melt or damage the

container or other components. Heaters should not be used to warm

liquid above 45°C. The main power disconnect should be in the off

position unless the S.U.F. hardware system is in active use.

Table 3.1. Heating times for S.U.F. systems (Ambient temperature of

25°C).

System

Liquid batch volume

(half/full)

Initial

liquid

Liquid

target

Time (half/

full)

30 L 15 /30 L 5°C 37°C 1 hr/1.16 hr

300 L 150 /300 L 5°C 37°C 1.3 hr/1.8 hr

General temperature mapping has been performed for S.U.F. systems

by tracking thermal profiles within the liquid confines of the fermentor.

Testing conditions were analyzed using chilled media and low agitation

rates. Gradients within the liquid did not exceed 0.5°C during heat-up.

Testing has also shown that temperature measurements in the S.U.F.

when using the standard silicone thermowell with 3.18 mm (1/8 in.)

diameter temperature probes properly represent fermentor content

temperatures. Users desiring exact temperature calibrations can order

a S.U.F. temperature/sample port. Using this port will allow users to

simulate the temperatures seen by the RTD when used with the BPC.

HyPerforma Single-Use Fermentor User’s Guide | 40Thermo Scientific

Page 46

Chapter 3 | Operating information

Protective earth grounding

Protective earth grounding for the S.U.F. hardware system and the

controller is provided through the ground terminal of the power plug.

Source power to the controller must provide protective earth grounding

to this terminal in order to minimize the hazard of a possible shock

in the occurrence of a fault condition. Please refer to Appendix A for

information about electrical receptacles. A ground wire is provided

underneath the tank, and must be tied to the controller before

operation.

Resettable breakers

Electrical components of the S.U.F. are equipped with circuit protection.

The variable frequency drive (VFD) used to power the mixer motor is

protected by the use of resettable breakers. In the case of an electrical

fault condition, these safety devices are designed to protect the user

from electrical shock, and prevent electrical system components from

being damaged. The breakers can be reset once the fault condition is

resolved.

Breaker notes:

• The normal “on” setting for these breakers is in the up position.

• A tripped breaker will be in the mid-position.

• “Off” is in the fully down position.

• To reset a tripped breaker, it must first be moved from the tripped

or mid position to the “off” or fully down position before moving it

the fully up or “on” position.

Scales and weighing systems

Monitoring liquid volume within the S.U.F. during operation can be

critical in fermentation applications that involve nutrient media feeds.

This can also be a useful method for increasing the scalability of the

S.U.F. by starting the process run at minimum operating volume. The

ability to track operating volume by use of load cells or weigh scales

allows the user the ability to control liquid volume and cell density as

the fermentor is increased to rated working volume during the process

run.

A load cell kit for weight/volume measurement is available as an

option. Load cell kits can be installed at the factory or can be added

later by a certified service technician. The load cell kit comes with

three load cells, summing block, wiring, and display with a choice of

several interfaces. For more information, refer to the Specifications and

parts information in Chapter 4 of this guide. Refer to section 2.1 for

information about unlocking the load cells, and Appendix B for load

cell display calibration instructions. Note: Ensure that load cells are

locked down before moving the S.U.F. unit.

HyPerforma Single-Use Fermentor User’s Guide | 41Thermo Scientific

Page 47

Chapter 3 | Operating information

Use the following steps to lock the load cells before transporting a

S.U.F. (refer to Figures 2.3 and 2.4 in section 2.2.4 (page 27).

1. Hand-tighten the load cell lockout nut onto the load cell lockout

post. You may need to use the small end of the supplied wrench to

loosen the load cell lockout nut from the bottom of the base.

2. After you hand-tighten the nut against the post, use the

small end of the supplied wrench to turn it an extra 1/4 turn.

CAUTION: To avoid damaging the load cell, do not over-tighten

the nut.

3. Assemble a standard stainless 28.6 mm (1.5 in.) tri-clamp around

the flanges.

4. Repeat these steps each load cell attached to the tank.

External data logging and control

Optional digital display weighing scales can be sourced from

manufacturers such as Mettler Toledo. Bench top scales are commonly

used to measure the amount of bulk source media stored in a smaller

volume BPC as it is transferred by peristaltic pump into the S.U.F.,

floor scales can be used to measure the fluid content within the S.U.F.

This is accomplished by rolling the S.U.F. onto the scale platform and

leveling the S.U.F. skid once it is in position.

S.U.F. hardware systems are designed to allow advanced users to

control all aspects of the operation of the fermentor. Contact technical

support for Thermo Scientific products for general integration

guidance.

HyPerforma Single-Use Fermentor User’s Guide | 42Thermo Scientific

Page 48

Chapter 3 | Operating information

3.2. BPC and drive shaft loading for 30 L units

3.2.1. Initial installation steps for 30 L units

Each outer support container is designed for a specific S.U.F.

BPC. Confirm that the correct volume BPC is being used for the

corresponding volume outer support container. The following section

outlines the installation and setup of the BPC.

Before beginning to load the BPC, verify that the S.U.F. hardware is

stationary, with the casters locked into place.

1. Remove the irradiated BPC from the protective double polybags.

Open the S.U.F. door and load the BPC into the stainless steel

outer support container (Figures 3.1 and 3.2).

Figure 3.1. Opening the S.U.F. door latch.

Figure 3.2. Interior of the outer

support container.

HyPerforma Single-Use Fermentor User’s Guide | 43Thermo Scientific

Page 49

Chapter 3 | Operating information

2. Orient the BPC with the bearing port up and toward the motor

drive, with the connector probe ports facing the bottom access

cutout.

3. Remove the cap on the BPC bearing port, and place the bearing

port into the bearing port receiver (Figure 3.3). Close the door and

the clamp.

Figure 3.3. Inserting the bearing port.

4. Route the bottom ports through the opening in the bottom of the

outer support container (Figure 3.4).

Figure 3.4. Routing the bottom

ports through the bottom of the

outer support container.

HyPerforma Single-Use Fermentor User’s Guide | 44Thermo Scientific

Page 50

Chapter 3 | Operating information

5. Route the sparge line and bottom drain line through the bottom

access opening (Figure 3.5).

Figure 3.5. Routing the sparge and bottom drain

lines.

6. Open the door of the condenser unit, if present, and feed the

condenser portion of the bag through the condenser.

7. Insert the vent filter(s) into the filter bracket (Figure 3.6).

Figure 3.6. Inserting a vent filter

into the filter bracket.

HyPerforma Single-Use Fermentor User’s Guide | 45Thermo Scientific

Page 51

Chapter 3 | Operating information

8. If present, straighten and smooth the condenser bag in the

condenser unit and close and latch the door of the condenser

(Figure 3.7). Ensure that the condenser BPC is not too tight or too

loose in the condenser hardware unit.

Figure 3.7. Loading of an optional

condenser bag.

9. Secure filter heater(s) on the filter(s) (Figure 3.8). Connect the heater

to the controller, and verify that it is plugged into an appropriate 120

or 240 VAC outlet. Then connect the power cord to the controller or

the E-Box.

Filter notes: