Thermodyne 742HW Installation Manual

INSTALLATION &

OPERATION MANUAL

MODELS

742HW

744HW

For additional information on Thermodyne Foodservice Products, Inc.,

or to locate an authorized parts and service provider in your area,

visit our website at www.tdyne.com

Thermodyne Foodservice Products, Inc.

4418 New Haven Avenue 1-800-526-9182

Fort Wayne, IN 46803 www.tdyne.com

(07-09)

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL ELECTRICAL

EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD STARTUP AND ADJUSTMENTS OF

THE EQUIPMENT COVERED BY THIS MANUAL.

READ THIS MANUAL THOROUGHLY BEFORE OPERATING, INSTALLING OR PERFORMING

MAINTENANCE ON THE EQUIPMENT.

: Failure to follow all the instructions in this manual can cause property damage,

injury or death.

: Improper installation, adjustment, alteration, service or maintenance can cause

property damage, injury or death.

: Electrical connections should be performed only by a certified professional.

: Electrical and grounding connections must comply with the applicable portions

of the National Electric Code and/or all local electric codes. Failure to comply with this

procedure can cause property damage, injury or death.

: Before connecting the unit to the electrical supply, verify that the electrical and

grounding connections comply with the applicable portions of the National Electric Code and/or

other local electrical codes. Failure to comply with this procedure can cause property damage,

injury or death.

: Before connecting the unit to the electrical supply, verify that the electrical

connection agrees with the specifications on the data plate. Failure to comply with this

procedure can cause property damage, injury or death.

: UL73 grounding instructions: This appliance must be connected to a grounded,

metal, permanent wiring system. Or an equipment-grounding conductor must be run with the

circuit conductors and connected to the equipment-grounding terminal or lead on the appliance.

Failure to comply with this procedure can cause property damage, injury or death.

: Appliances equipped with a exible electric supply cord, are provided with

a three-prong grounding plug. It is imperative that this plug be connected into a properly

grounded three-prong receptacle. Failure to comply with this procedure can cause property

damage, injury or death.

: If the receptacle is not the proper grounding type, contact an electrician. Do not

remove the grounding prong from the plug. Failure to comply with this procedure can cause

property damage, injury or death.

: Before performing any service that involves electrical connection or

disconnection and/or exposure to electrical components, always perform the Electrical

LOCKOUT/TAGOUT Procedure. Disconnect all circuits. Failure to comply with this procedure

can cause property damage, injury or death.

— 2 —

: Before removing any sheet metal panels or servicing this equipment, always

perform the Electrical LOCKOUT/TAGOUT Procedure. Be sure all circuits are disconnected.

Failure to comply with this procedure can cause property damage, injury or death.

: Do not operate this equipment without properly placing and securing all covers

and access panels. Failure to comply with this procedure can cause property damage, injury or

death.

: Do not use or store gasoline or other ammable vapors or liquids in the vicinity

of this or any other appliance. Failure to comply can cause property damage, injury or death.

: In the event of a power failure, do not attempt to operate this appliance. Failure

to comply can cause property damage, injury or death.

CAUTION: These models have glass doors. Remove carton carefully.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE

VAPORS OR LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER

APPLIANCE. FAILURE TO COMPLY CAN CAUSE PROPERTY

DAMAGE, INJURY OR DEATH.

— 3 —

TABLE OF CONTENTS

IMPORTANT FOR YOUR SAFETY ................................................................................................... 2

INTRODUCTION .............................................................................................................................. 5

GENERAL .................................................................................................................................. 5

SPECIFICATIONS ...................................................................................................................... 5

UNPACKING ............................................................................................................................... 7

Thermodyne Damaged Goods Policy ................................................................................... 7

INSTALLATION CODES AND STANDARDS .............................................................................. 7

INSTALLATION ................................................................................................................................. 8

LOCATION .................................................................................................................................. 8

ELECTRICAL CONNECTION .................................................................................................... 8

ELECTRICAL SPECIFICATIONS ............................................................................................... 8

OPERATION ..................................................................................................................................... 9

CONTROLS AND INDICATORS................................................................................................. 9

STARTUP ................................................................................................................................... 9

Setting Temperature ............................................................................................................ 10

Preheating .......................................................................................................................... 10

FLUID REPLENISHMENT ........................................................................................................ 10

CLEANING AND MAINTENANCE ................................................................................................. 12

ELECTRICAL LOCKOUT/TAGOUT PROCEDURE .................................................................. 12

WHEN TO CLEAN .................................................................................................................... 12

STAINLESS STEEL CARE ....................................................................................................... 12

Cleaning .............................................................................................................................. 12

Preserving & Restoring ....................................................................................................... 12

Heat Tint ............................................................................................................................. 13

CLEANING HEAT TRANSFER PLATES................................................................................... 13

CLEANING DOOR GASKETS ................................................................................................. 13

CHANGING FLUID ................................................................................................................... 13

TROUBLESHOOTING .................................................................................................................... 16

SCHEMATIC WIRING DIAGRAM ................................................................................................... 17

WARRANTY ................................................................................................................................... 18

HEAT TRANSFER FLUID MSDS ................................................................................................... 18

— 4 —

INTRODUCTION

GENERAL

and carefully follow all of the instructions provided.

The cabinets described in this manual are

Thermodyne cabinets are produced with quality

workmanship and materials. Proper installation,

operation and maintenance will result in many

years of satisfactory performance. It is suggested

that you thoroughly read this manual in its entirety

programmable for the desired holding temperature.

The factory setting is 185° F unless otherwise

specified. Each shelf in the cabinet maintains an

exact temperature, allowing for extended holding

times without sacrificing appearance or taste.

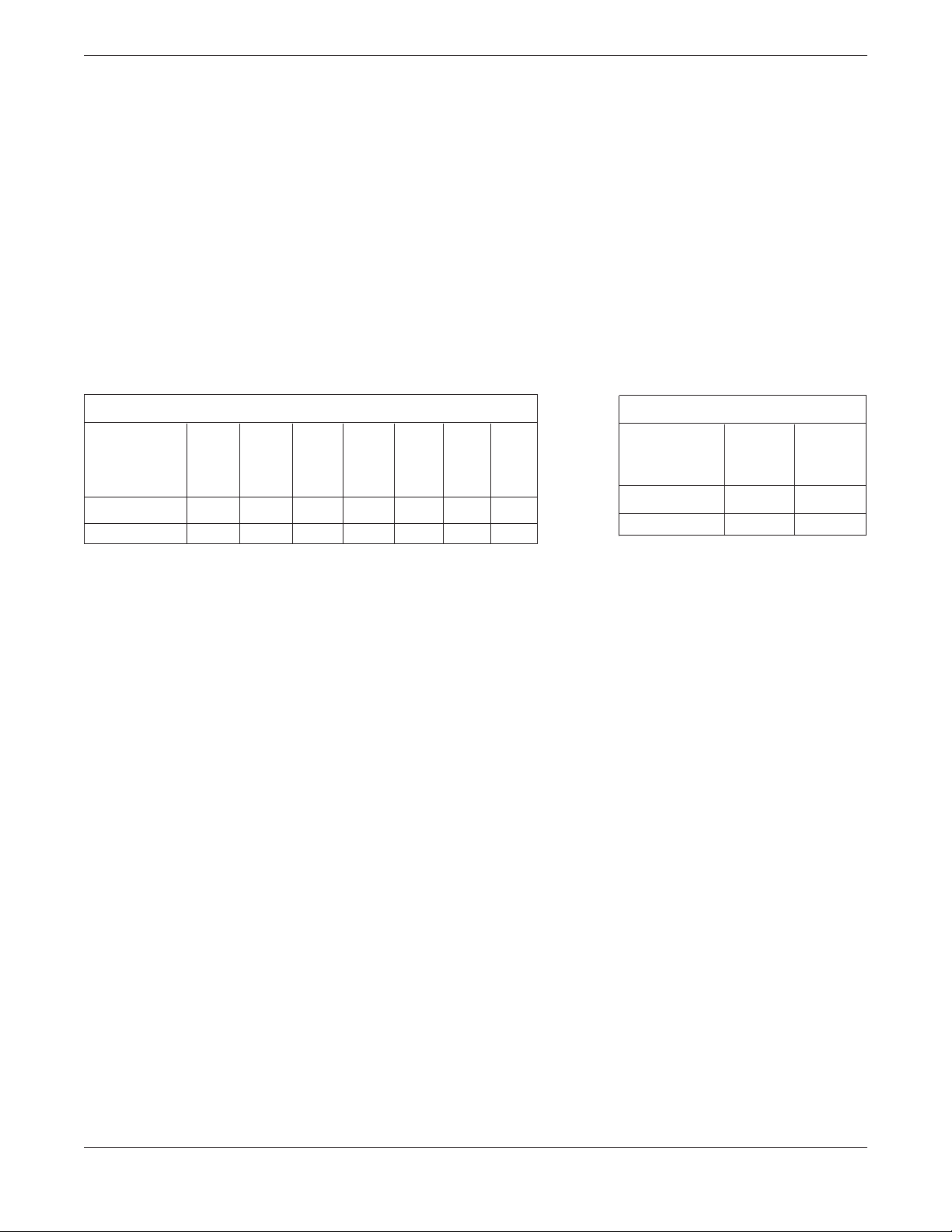

SPECIFICATIONS

DIMENSIONS AND MAXIMUM TEMPERATURE

Width Depth Height Width Depth Height Oper.

Model

742HW 30.50 30.94 40.50 26.50 22.50 20.00 230

744HW 60.00 30.94 40.50 56.00 22.50 20.00 230

Ext. Ext. Ext. Int. Int. Int. Max

inches inches inches inches inches inches Temp

WEIGHT

Weight Weight

Model

°

F

lbs lbs

742HW 265 340

744HW 470 560

Net Shipping

— 5 —

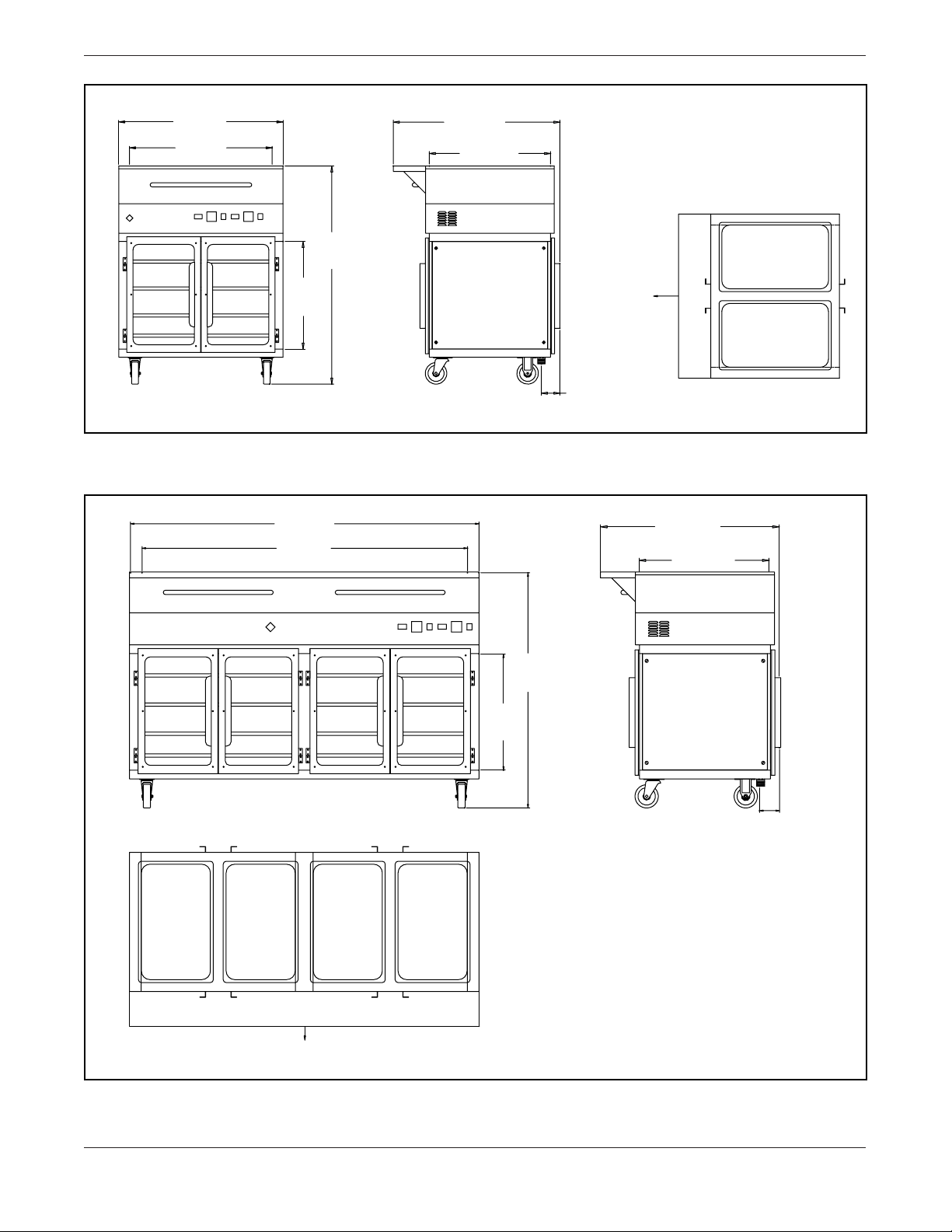

"

FRONT VIEW

SIDE VIEW

PLAN VIEW

30 1/2"

Ext. Width

26 1/2"

Int. Width

20"

Int.

Height

40 1/2"

Ext.

Height

30 15/16"

Ext. Depth

22 1/2"

Int. Depth

3 7/16"

Cord & Plug

Front

Thermodyne

Figure 1: Outline Dimensional Drawing, 742HW

60"

Ext. Width

56"

Int. Width

FRONT VIEW

SIDE VIEW

PLAN VIEW

Thermodyne

20"

Int.

Height

40 1/2"

Ext.

Height

3 3/8"

Cord & Plug

Front

30 15/16"

Ext. Depth

22 1/2"

Int. Depth

Figure 2: Outline Dimensional Drawing, 744HW

— 6 —

Loading...

Loading...