Thermodyne 1600NDNL Installation Manual

ADD FLUID

INSTALLATION &

OPERATION MANUAL

ADD FLUID

MODELS

200NDNL

200CT

250PNDT

For additional information on Thermodyne Foodservice Products, Inc.,

or to locate an authorized parts and service provider in your area,

Thermodyne Foodservice Products, Inc.

4418 New Haven Avenue 011-260-428-2535

Fort Wayne, IN 46803 www.tdyne.com

300NDNL

300CT

300OC

visit our website at www.tdyne.com

700NDNL

700CT

950NDNL

1600NDNL

Rev. B (1-08)

IMPORTANT FOR YOUR SAFETY

WARNING

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN

CAUSE PROPERTY DAMAGE, INJURY OR DEATH.

READ THE INSTALLATION, OPERATING AND

MAINTENANCE INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING THIS

EQUIPMENT. SERVICE WORK SHOULD BE

PERFORMED BY A LICENSED PROFESSIONAL,

QUALIFIED TO SERVICE AND REPAIR ELECTRIC FOOD

SERVICE EQUIPMENT.

IN THE EVENT OF A POWER FAILURE,

DO NOT ATTEMPT TO OPERATE THIS DEVICE.

CAUTION

Models 200CT, 300CT, and 700CT have glass doors.

Remove carton carefully.

— 2 —

TABLE OF CONTENTS

IMPORTANT FOR YOUR SAFETY............................................................................................... 2

INTRODUCTION............................................................................................................................. 4

GENERAL .................................................................................................................................. 4

SPECIFICATIONS.....................................................................................................................4

UNPACKING ............................................................................................................................. 8

Thermodyne Damaged Goods Policy ................................................................................. 8

INSTALLATION CODES AND STANDARDS .........................................................................8

INSTALLATION ......................................................................................................................... 9

LOCATION .................................................................................................................................9

ELECTRICAL CONNECTION .................................................................................................. 9

OPERATION................................................................................................................................. 10

CONTROLS AND INDICATORS .......................................................................................... 10

STARTUP................................................................................................................................10

Setting Temperature ......................................................................................................... 10

Preheating ......................................................................................................................... 11

Extended Shutdown .......................................................................................................... 11

FLUID REPLENISHMENT ..................................................................................................... 11

PRODUCT PANS AND COVERS .............................................................................................. 12

GENERAL ............................................................................................................................... 12

Dry Pan Without Pan Screen ........................................................................................... 12

Dry Pan With Pan Screen ................................................................................................ 12

Wet Pan With Pan Screen ................................................................................................ 12

Pans With “V” Rack .......................................................................................................... 13

Removing Lids................................................................................................................... 13

CLEANING AND MAINTENANCE .............................................................................................. 14

WHEN TO CLEAN.................................................................................................................. 14

HOW TO CLEAN .................................................................................................................... 14

Cleaning Safeguards ........................................................................................................ 14

Sterilizing Stainless Steel ................................................................................................. 14

Cleaning Heat Transfer Plates ......................................................................................... 14

Stainless Steel Cabinet..................................................................................................... 15

Door Gasket ...................................................................................................................... 15

CHANGING FLUID................................................................................................................. 15

TROUBLESHOOTING ................................................................................................................. 17

SCHEMATIC DIAGRAMS ........................................................................................................... 18

WARRANTY...................................................................................................................................20

HEAT TRANSFER FLUID MSDS................................................................................................. 20

— 3 —

GENERAL

INTRODUCTION

Thermodyne cabinets are produced with quality

workmanship and materials. Proper installation,

operation and maintenance will result in many

years of satisfactory performance. It is

suggested that you thoroughly read this manual

in its entirety and carefully follow all of the

instructions provided.

The cabinets described in this manual are

programmable for the desired holding

temperature. The factory setting is 85°C unless

otherwise specified. Each shelf in the cabinet

maintains an exact temperature, allowing for

extended holding times without sacrificing

appearance or taste.

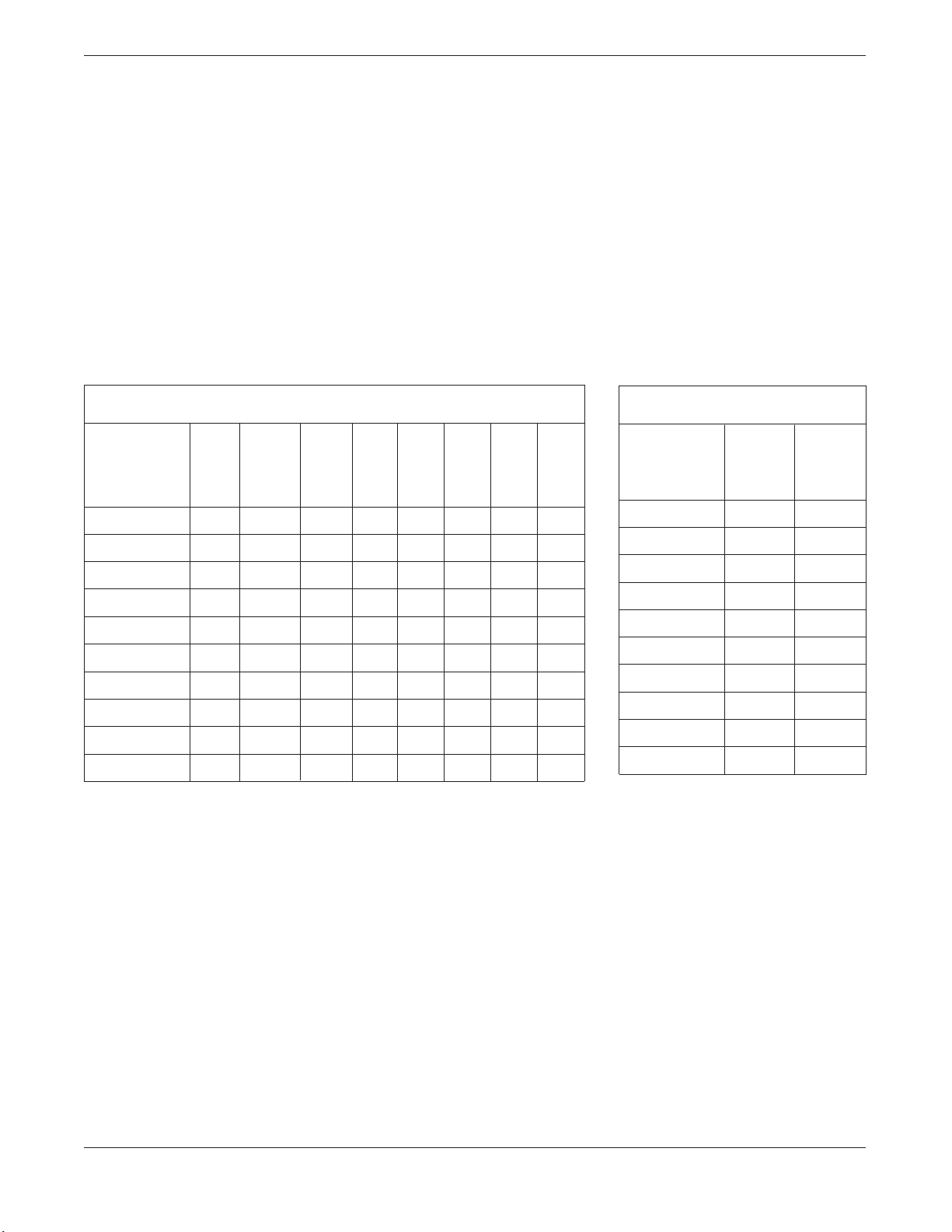

DIMENSIONS AND MAXIMUM TEMPERATURE

Ext. Ext. Ext. Int. Int. Int. Max Max

Width Depth Height Width Depth Height Oper. Oper.

mm mm mm mm mm mm Temp Temp

Model °

F

200NDNL 445 584 473 343 559 330 230 110

300NDNL 445 584 657 343 559 514 230 110

700NDNL 775 584 692 673 559 514 230 110

950NDNL 1143 584 508 1041 559 330 230 110

1600NDNL 445 838 1568 343 559 1260 230 110

200CT 445 629 508 343 559 330 230 110

300CT 445 629 692 343 559 514 230 110

700CT 775 629 692 673 559 514 230 110

300OC 1499 343 372 1397 318 229 230 110

250PNDT 540 508 845 438 483 702 230 110

WEIGHT

Net Shipping

Weight Weight

°

C

Model

200NDNL 46.27

300NDNL

700NDNL

950NDNL

Kg Kg

70.31

55.79 83.91

78.47 105.69

77.11 140.61

1600NDNL 109.35 183.76

200CT

300CT

700CT

300 OC

46.72 72.54

57.15 86.18

85.73 120.20

72.57 106.59

250 PNDT 76.20 92.08

— 4 —

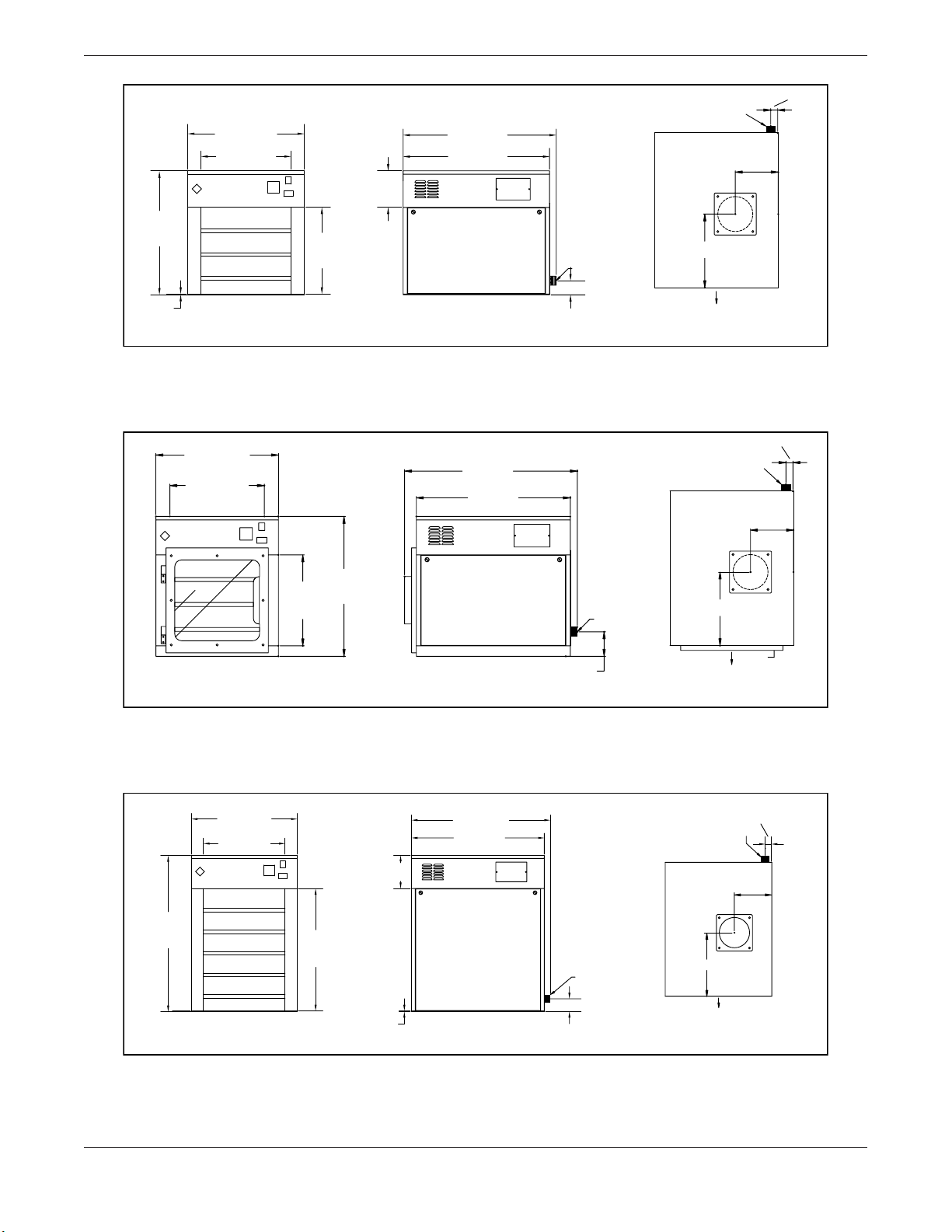

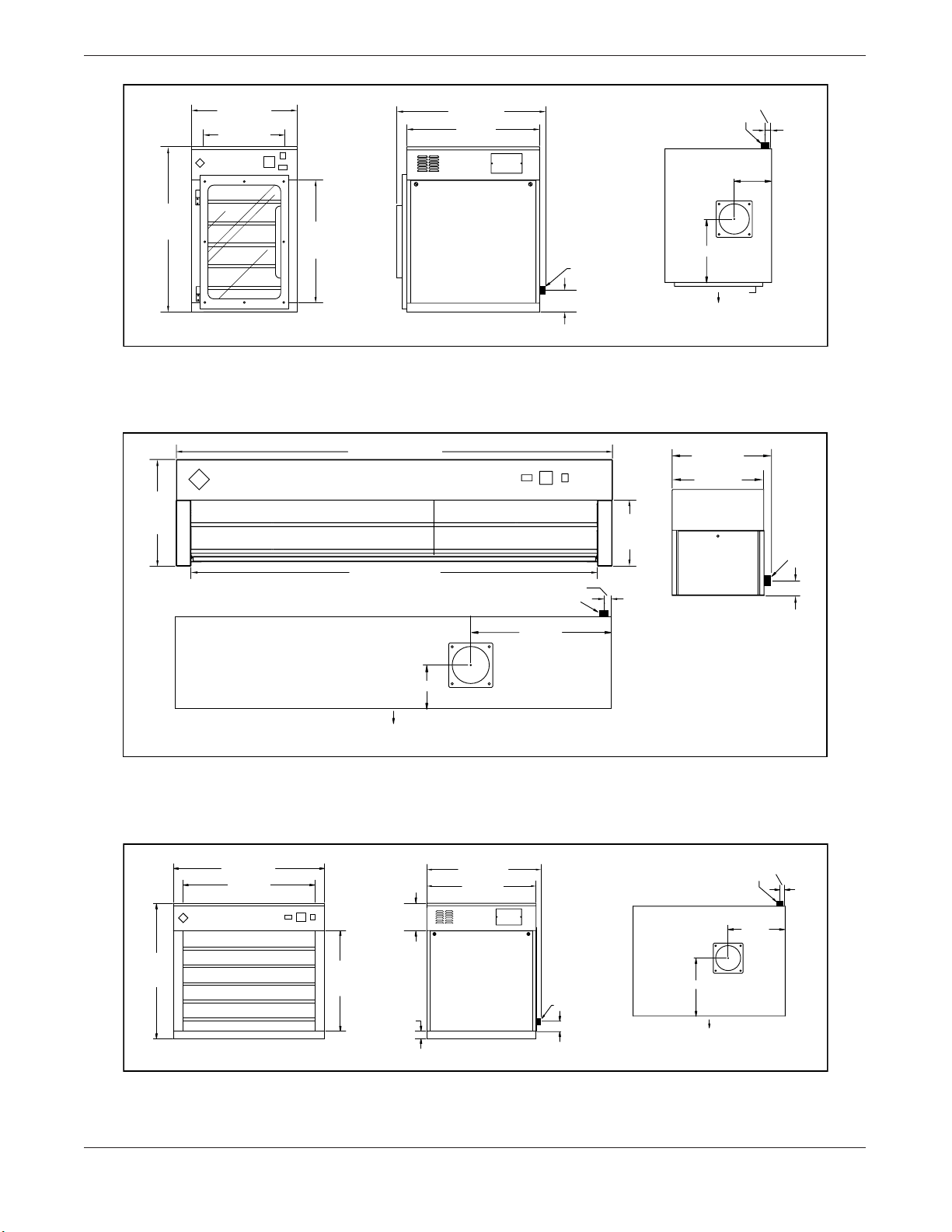

473 mm

Ext.

Height

3,2 mm

Base

445mm

Ext. Width

343 mm

Int. Width

Thermodyne

FRONT VIEW

584 mm

Ext. Depth

559 mm

Int. Depth

140 mm

P.H.

330 mm

Int.

Height

Electrical

55 mm

SIDE VIEW

Figure 1. Outline Dimensional Drawing, 200NDNL

25 mm

Cord & Plug

156 mm

267 mm

Front

PLAN VIEW

445mm

Ext. Width

343 mm

Int. Width

Thermodyne

FRONT VIEW

Thermodyne

445 mm

Ext. Width

343 mm

Int. Width

629 mm

Ext Depth

559 mm

Int. Depth

508 mm

Int.

Ext.

Height

Electrical

89 mm

330 mm

Height

SIDE VIEW

Figure 2. Outline Dimensional Drawing, 200CT

584 mm

Ext. Depth

559 mm

Int. Depth

140 mm

P.H.

25 mm

Cord & Plug

156 mm

267 mm

Front

PLAN VIEW

25 mm

Cord & Plug.

156 mm

657 mm

Ext.

Height

FRONT VIEW

514 mm

Int.

Height

Electrical

3,2 mm

Base

SIDE VIEW

55 mm

Figure 3. Outline Dimensional Drawing, 300NDNL

— 5 —

267 mm

Front

PLAN VIEW

692 mm

Ext.

Height

445 mm

Ext. Width

343 mm

Int. Width

Thermodyne

514 mm

Int.

Height

629 mm

Ext. Depth

559 mm

Int. Depth

Cord & Plug.

25 mm

156 mm

267 mm

Electrical

372 mm

Ext.

Height

FRONT VIEW

Figure 4. Outline Dimensional Drawing, 300CT

Thermodyne

1499 mm Ext. Width

1397 mm Int. Width

FRONT VIEW

152 mm

Front

PLAN VIEW

SIDE VIEW

89 mm

25 mm

Cord & Plug

483 mm

229 mm

Int.

Height

Front

PLAN VIEW

343 mm

Ext. Depth

318 mm

Int. Depth

SIDE VIEW

Electrical

55 mm

692 mm

Ext.

Height

Ext. Width

Int. Width

Thermodyne

FRONT VIEW

Figure 5. Outline Dimensional Drawing, 300OC

775 mm

673 mm

514 mm

Int.

Height

140 mm

P.H.

38 mm

Base

564 mm

Ext. Depth

559 mm

Int. Depth

SIDE VIEW

Electrical

55 mm

Figure 6. Outline Dimensional Drawing, 700NDNL

— 6 —

Cord & Plug.

295 mm

Front

PLAN VIEW

25 mm

292 mm

Loading...

Loading...