Thermo-Dynamics Boiler THERMOTRON OTF, THERMOTRON ITF Operation, Maintenance, And Installation Instructions

THERMOTRON

ROUTE 61 • P.O. BOX 325 • SCHUYLKILL HAVEN, PA 17972 • (570) 385-0731 • FAX (570) 385-5304

Operation

Thermo-Dynamics

www.thermodynami c s b o i ler.com

Maintenance

and

Installation

Instructions

Models OTF / ITF

Contents

Assembly Diagrams

General Information ......................................................................................................1

Service Policy ................................................................................................................1

Installation Instructions .................................................................................................2

Filling Instructions .........................................................................................................2

Winterizing .....................................................................................................................3

Start-Up and Operation ................................................................................................3

Piping/Connection Diagrams .......................................................................................4

......................................................................................................5

Trouble Shooting ..........................................................................................................6

Care and Maintenance .................................................................................................6

Pool Coil Diagram .........................................................................................................7

Wiring Diagrams ...........................................................................................................8

Parts List ........................................................................................................................9

Specifications ..........................................................................................................10

Home Owner Information .......................................................................................11

Set-Up and Service Records ..................................................................................12

Warranty Information ..............................................................................................12

1

General Information

nance. Proper care and maintenance of your pool heater will allow you to enjoy the benefits of your

with a high quality trouble free product that will be part of your family for many years to come.

1) Please read all instructions and review all diagrams prior to proceeding with installation.

2) Instructions and diagrams are intended only as guidelines.

3) Installations must conform with all applicable national, state and local codes.

4) Additional guidelines are available from National Fire Protection Association (NFPA), American

society of Mechanical Engineers (ASME) and Building Officials and Code Administrators

(BOCA).

Service Policy

Congratulations on the purchase of your new pool heater. Here at Thermo-Dynamics Boiler

Company we pride ourselves on the design and construction of our product. Our intent is to furnish

you with a high quality appliance that will provide you and your family with years of trouble free

service.

In order to maintain peak performance of your pool heater, it is recommended that the unit be winterized at the end of the season and that the burner/boiler be serviced annually. Servicing of your

appliance must be performed by a qualified heating technician. You should utilize a qualified heating technician familiar with your installation to manage your heater and perform periodic mainte-

new purchase as well as extend its long useful life.

In the event that your serviceman encounters difficulty with the pool heater, he/she shall contact

the distributor from which the product was purchased. The distributor shall, in turn, contact the

Thermo-Dynamics sales representative for your area. By adhering to this protocol, ThermoDynamics wishes to provide you with responsive and unparalleled service. We realize the importance that our product means to you and your family and our goal is to get your heater up and running as quickly as possible.

Thank you for purchasing the Thermo-Dynamics pool heater. Again, it is our intent to provide you

Please consider Thermo-Dynamics Boiler Company in the future for all of your home heating

needs.

2

Section I. Installation Instructions Control of combustion draft.

(1)

Locating The Heater:

pool circulation lines are at the back of

component to obtaining optimum

open take temperature readings for

(B)

ITF Series (Indoor Units)

two (2) feet higher than any portion of

pitched upward at least one-quarter

joint should be securely fastened with

effect the shortest possible run of

an indirect heater using primary water

water

Therefore the pool heater, or boiler

Before uncrating the unit prepare

the location. It should be placed upon

a good level concrete floor or pad.

Care should be taken to locate the

unit for easy accessibility. Please

maintain the following clearances to

combustible materials:

OTF

(Outdoor Pool Heaters)

Front 24 inches

Back 24 inches

Sides 12 inches

ITF

(Indoor Pool Heaters)

Front 24 inches

Back 12 inches

Sides 12 inches

In addition, the air openings in the

cabinet shall have adequate clearance

to allow for sufficient air intake to the

burner. Uncrate the unit as close to

its permanent location as possible to

prevent handling damage.

(2) Connections:

Do not run any piping along the

front access panel of heater as they

may interfere with servicing. The tappings for connecting the unit to the

the heater. These connections are 11/2" NPT. Connections should be

made as per the piping illustration on

page 4. Install unions at the heat

exchanger so it can be readily

removed for service. If plastic pipe is

used, make connection to the unit with

metal piping and run metal piping to

the floor line before joining to plastic

pipe. This will act as a “heat-trap” and

reduce possible damage to the plastic

pipes from overheating. Install positive check valve on inlet side. Install a

Tee joint at the coil where the PIPING

FROM the pool filter/pump ENTERS

the coil. Install the copper well provided into the piping Tee and insert the

remote sensing bulb from the L-4031

pool thermostat.

An adjustable by-pass around the

heat-exchanger is required. The bypass is an important and necessary

performance (see piping diagram on

page 4). In order to properly adjust

the flowrate through the system,

please adhere to the following steps:

By-Pass Set-Up

a) Use piping and full-size valve

to connect the “In” and “Out” streams

of the pool coil.

b) With the bypass valve wide

open take a pressure reading at the

gauge on the pool filter.

c) Pressure reading with bypass

valve full open is the baseline pressure.

d) Slowly close the bypass valve

so that the pressure increases.

e) Stop when pressure reaches 2

to 4 psi above the baseline at the filter.

Alternatively, flowrate may be set

by comparing the temperature differ-

ence between the “In” and “Out”

streams of the pool coil.

a) Use full size piping and valve

to connect the “In” and “Out” streams

of the pool coil.

b) Allow the boiler to fire continuously for a period of ten (10) to fifteen (15) minutes.

c) With the bypass valve wide

the coil.

d) Note: surface temperature

readings taken on a cold day will vary

significantly from test data.

e) Slowly close the bypass valve

and continue to take temperature

readings.

f) Stop when the temperature

difference between the “In” and “Out”

streams reaches forty-five (45) to fifty

(50) degrees Fahrenheit.

g) Flowrate should correspond to

six (6) gallons per minute. (See chart

page 7).

(3) Flue Connections:

(A) OTF Series (Outdoor Units)

The OTF heaters are provided with

an outdoor vent cap to be installed

directly on top of the cabinet at the flue

outlet. This vent cap provides for a

waterproof unit as well as proper con-

(a) General:

Oil fired units must be connected

to a flue having sufficient draft at all

times to assure proper operation.

(b) Draft:

A draft regulator should be

installed in accordance with the man-

ufacturer’s instructions. Set the draft

to a negative –.01 to –.02 max. WC

over the fire.

(c) Roof Clearances:

The flue gas exit of the venting

system should be at least three (3)

feet above the outside point where it

passes through the roof and at least

a building within ten (10) feet of the

venting system.

(d) Chimney Connections:

The horizontal length of a chimney connector should not exceed ten

(10) feet unless a draft booster is

used. The connector should be

(1/4) inch to the foot. Use only high

quality lock seam smoke pipe. Each

sheet metal screws. Chimney connections should be positioned to

smoke pipe to the chimney.

(e) Vent Cap:

Install a UL listed vent cap where

the possibility of down draft exists.

Section II

Filling

Instructions

The Thermotron Pool Heater is

in the boiler shell to act as a heat

transfer medium to the pool

flowing through the separate all

copper/bronze heat exchanger coil.

section, MUST be filled with fresh city

water. DO NOT FILL WITH CHLORINATED OR WATER FROM THE

SWIMMING POOL.

3

(1) Do not turn on electrical

garden hose to the hose adapter of

Open the vent at the top of

When water flows out of

pipe systems as soon as the burner

also be caused by too high a “lift” or

the air band to allow just sufficient air

on the air shutter and closing the air

reading of

power to heater until boiler is properly

filled with water.

(2) * Connect the male end of a

the heater drain valve.

(3)

the boiler section location as shown

on page 4.

(4) Turn on water and open drain

valve, allow water to flow into boiler

section.

(5)

boiler vent, close vent and leave

heater drain valve open until pressure

gauge reads approximately 10 PSI.

(6) Close drain valve and disconnect hose.

(7) Pool temperature control

should be set at desired temperature.

(8) Burner can now be operated

as per specified instructions.

*You may choose to install permanent piping...filling instructions would be the same.

IMPORTANT NOTICE

Winterizing The Heater:

If the pool heater is installed in an

area known to have a freezing climate

it is necessary to COMPLETELY drain

both the primary boiler and indirect

heat exchanger (pool coil).

Connect a hose to the boiler drain

at the bottom of the boiler section.

Open the vent at the top of the boiler,

as well as the drain valve and drain

the boiler section completely.

Disconnect the unions and the piping

at the pool coil heat exchanger.

Remove the 1/8" pipe plugs in the bottom of the pool coil heat exchanger

header (to be completely certain that

all water is out of the indirect heat

exchanger, it may be advisable to

remove the pool coil completely or

force an anti-freeze solution into the

pool coil.)

Section III

Start Up and

Operation

A Start Up:

(1) Make sure the electrical

power is turned off.

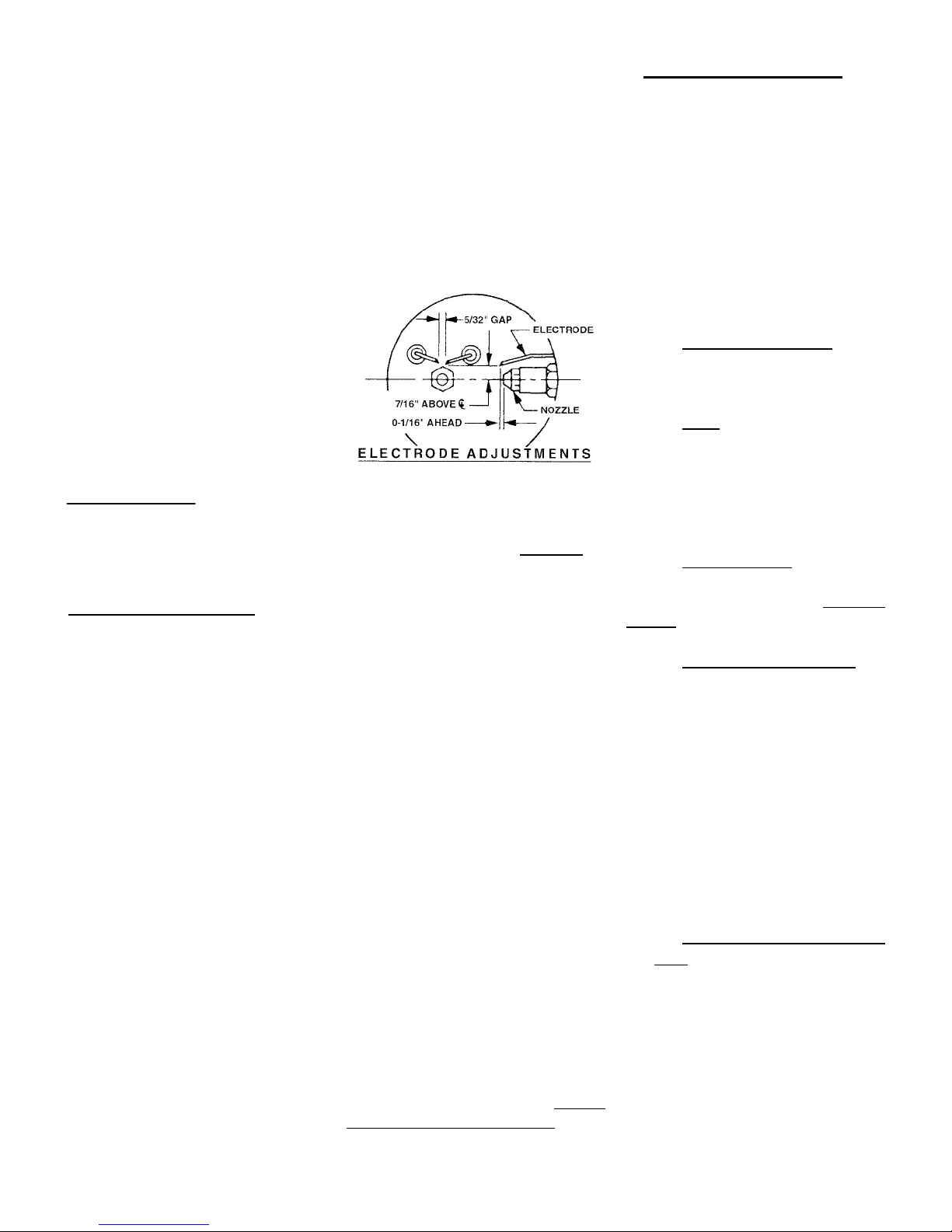

(2) Check the Oil Burner ignition

electrodes carefully and adjust if necessary.

(3) Check to be certain oil tank is

full.

(4) Be certain unit is filled with

water as per filling instructions.

(5) Turn on pool filter pump.

(6) Set limit control at 180°.

(7) Install pressure gauge in the

nozzle port of the fuel pump. Do not

take reading at the bleed port. The

pressure gauge should have a minimum range of 100 PSI. Consult Fuel

Pump specification sheet (shipped

with Oil Burner).

(8) Turn on burner power switch.

(9) Push the safety reset button

on the primary control and release.

(10)Bleed the fuel unit on one-

motor starts. To bleed, attach a piece

of 1/4" OD clear plastic tubing to the

end of the bleed port. Loosen same

and purge oil of air for at least 15 seconds after oil appears to be clear. If oil

stream does not become clear and

free of air bubbles or foam, check all

fittings, filter and valve connections.

Foam can also be caused by kinks in

the oil line, causing an oil vacuum

condition. High vacuum readings can

too small diameter tubing. Consult

Fuel Pump specification sheet.

B Equipment Adjustments:

Equipment Required:

(1) CO2Analyzer (absorption

type)

(2) Draft Gauge

(3) Fuel Pressure

Gauge/Vacuum Gauge

(4) Stack Thermometer

(5) Smoke Tester (Bacharach

Type)

Allow the burner to operate continuously for at least 15 minutes and

then make adjustments:

(a) Combustion Samples:

Should be taken through the

observation port above the burner,

directly over the fire.

(b) Draft:

Take a draft reading over the fire

(OTF outdoor equipment will range

from “0” to –.01 negative minimum).

(ITF indoor equipment should be

adjusted to a –.01 draft minimum to a

–.02 max.)

(c) Pump Pressure:

Adjust the pump discharge pressure to 100 PSI. Vacuum must not

exceed 6" on one pipe and 10" on a

two-pipe system.

(d) Combustion Settings/CO

2

Reduce the air supply by closing

for clean combustion. This is accomplished by loosening the lock screws

shutter until a TRACE of smoke is

recorded. Take a CO2sample, which

should be approximately 12%. Open

the air shutter and lower CO2reading

approximately by 1-1/2 to 2% from the

above reading. A “0” smoke reading

should result with a CO

2

approximately 10%.

(e) Stack Temperature: (ITF

only)

Check to see that the stack temperature is approximately 500° above

the ambient temperature.

(f) Turn LIMIT CONTROL to the

lowest setting; burner should shut

down. Turn back to the desired setting, (normally 180°) burner should

operate.

(g) Turn POOL TEMPERATURE

CONTROL down to lowest setting;

Loading...

Loading...