Thermo-Dynamics Boiler TDE-10, TDE-15, TDE-20, TDE-25, TDE-30 Installation And Maintenance Manual

THERMO-DYNAMICS

Electric Boiler

A Compact, Versatile, Easy-to-Use

Heat Source for Forced Hot Water Systems

Installation and Maintenance Manual

Thermo-Dynamics Boiler Company

ROUTE 61 • P.O. BOX 325 • SCHUYLKILL HAVEN, PA 17972

(570) 385-0731 FAX (570) 385-5304

Thermo-Dynamics TDE Electric Boiler

he Thermo-Dynamics TDE Electric Boiler

T

is compact, clean, quite, and does not require

a storage facility or chimney allowing convenient

installation near the point of use. The TDE electric

boiler provides an energy efficient supply of warm

and comfortable heat, and is built to ThermoDynamics quality standards – the highest in the

heating industry.

This electric boiler is versatile and provides an

easy-to-use heat source for forced hot water

systems in:

• new homes

• replacement systems in existing homes

• back-up units for solar heating systems

• supplemental heating systems for the heat

pump.

CLEAN.

The TDE heating system eliminates the need for

fuel storage facilities and chimneys. There are

never any odors to permeate the home or combustion emissions to pollute our environment.

COMPACT.

The TDE electric boiler is extremely compact and

can be easily wall-mounted almost anywhere in the

home to provide heat for areas that are isolated

from the main heat supply. These areas include

garages, apartments, and utility rooms to name a

few.

QUIET.

Quiet operation is maintained because elements are

energized in steps, thus preventing power surge and

start-up vibration. Quality electrical componentry,

circulator and cabinet design also contribute to the

whisper-quiet operation of the TDE electric boiler.

A Word About Supplemental

Heat for the Heat Pump

f you live in the great northeast, or in a region

I

of the country where temperatures regularly

fall below 40°F in the winter, the heat pump will

run almost constantly to heat the home. When

the temperatures fall below 32°F, most heat

pumps literally shut down and the resistance heat

comes on to provide back-up.

To extend the life of the very expensive heat

pump unit, the electric boiler provides supplemental heat allowing the heat pump to “rest.”

When heat is called for when the temperature

drops below 32°F, the air in the heat pump system is below body temperature and therefore

feels cool. The electric boiler can provide a heat

source that is warm and comfortable to the touch.

ENERGY EFFICIENT.

With Thermo-Dynamic’s unique “flow control”

system, the TDE electric boiler delivers a steady

flow of healthful heat using a minimal amount of

electricity. Low watt density heating elements, low

voltage thermostat and thorough insulation for

minimum heat loss are just a few design features

built in to deliver more comfort for every energy

dollar.

SMALL BOILER.

BIG IDEAS.

When your projects call for the efficiency of hot

water heat and the convenience of electricity,

choose the TDE electric boiler. The TDE is small

enough to install almost anywhere (remember, all

you need is a wall), yet powerful to handle big hot

water heating jobs.

Designed for

Reliable Home

Heating Comfort

A Summary of Practical Applications

• Solar Heating Systems. Every active solar heating

system needs a reliable back-up heating unit that can

perform through long periods of adverse weather.

The TDE is UL listed as a central heating boiler, thus

providing the power needed for total solar security.

A Summary of Product Features

• Recreational Pools. Because the TDE heats water

fast and efficiently, it is an ideal way to warm

swimming pool water. Ideal for home, hotel, club

and spa pools, and popular with the hot tubs, too. Its

powerful circulator maintains steady flow to keep

water at uniform temperature.

• Therapeutic Pools. Sports and institutional

facilities need a precisely regulated hot water supply

for their hydrotherapy facilities. Of course, the TDE

is the safe choice, offering a high limit switch feature

that instantly de-energizes heating elements at a set

temperature while the circulator continues operation.

• Condominiums, Co-ops, Apartments. When each

living unit needs individual hot water heat, the TDE is

the cost-efficient answer. It features staged start-up

for quiet operation; can be easily piped into existing

hydronic systems; is great for new construction; and a

necessity for conversion projects.

• Five models: 10 kw to 30 kw.

• One-piece steel boiler shell.

• Easily accessible controls.

• Low voltage thermostat.

• Heats single or multi-zone systems.

• Heat process water used in a manufacturing

process.

• Boiler Cabinet easily removes before or after

piping unit to system.

• UL Listed as central heating boiler.

• Circulator piped and wired at factory.

• 10 Year, plus 10 years pro-rated at 5% per year,

limited warranty on boiler shell; full year limited

warranty on all other components.

• One-piece steel boiler shell, ASME-constructed.

• Built-in dip tube air elimination system.

• Low voltage thermostat.

• Uniform water temperature.

• Factory tested.

• Low voltage fuse protected control circuit.

A Summary of Product Benefits

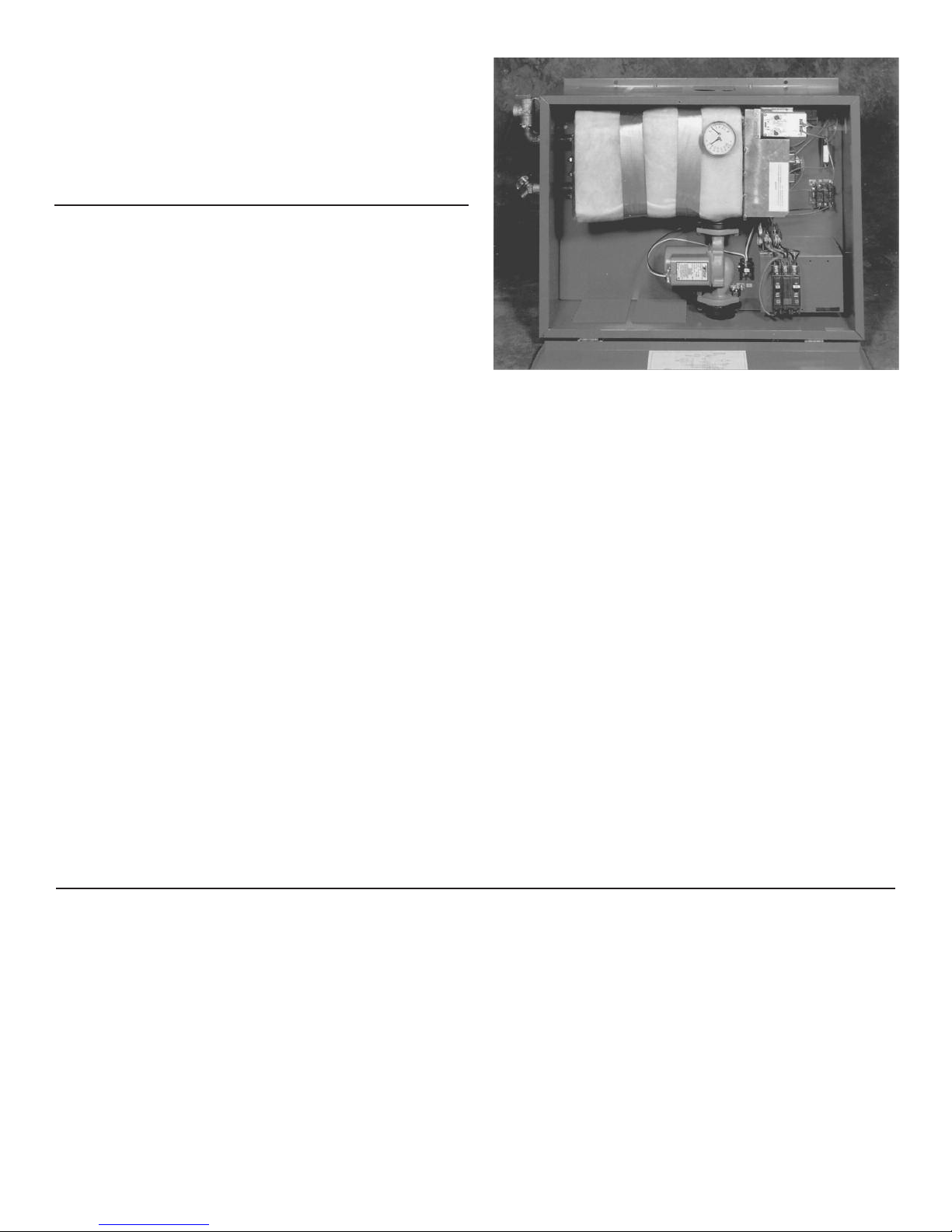

he Thermo-Dynamic TDE electric boiler features low watt density heating elements installed through the

T

sides of the boiler with ample access for service. The elements are energized in steps to prevent power

surge, prolonging heater element life and assuring quiet operation.

Standard controls are factory-wired on the control panel. All controls are easily accessible through the

removable cover.

Every TDE boiler is insulated with fiberglass insulation for minimum heat loss and housed in a rugged steel

cabinet finished in azure blue powder coat for extra durability.

Clean, compact, quiet, energy efficient, versatile, affordable, and backed by Thermo-Dynamics.

nergy efficiency is an important consideration when buying any heating system. But there are other factors you must consider too. Like manufacturer experience, reputation and service. The simple fact is, any

E

heating system is only as good as the company behind it.

Only the finest materials and craftsmanship is used to manufacture our products.

Operation

On call for heat the circulator comes on immediately, and the elements are energized in steps — two elements

per step spaced at approximately 60 second intervals. When the thermostat is satisfied, all elements and circulator are de-energized at once. A high limit condition will instantly de-energize all elements and the circulator

will continue to run.

Ratings

Boiler

Size

TDE-10

TDE-15

TDE-20

TDE-25

TDE-30

KW

Rating

10

15

20

25

30

Input

34,000

51,000

68,000

85,000

102,000

BTU/Hour Amps

Gross

Output

34,000

51,000

68,000

85,000

102,000

*Net

Output

30,000

44,000

59,000

74,000

89,000

No. of 5KW

Heater

Elements

2

3

4

5

6

Total

43

64

85

106

127

Circuit

1

43

43

43

43

43

2

–

21

42

42

42

3

–

–

–

21

42

Watts

at

240V

10,000

15,000

20,000

25,000

30,000

Approx.

Shipping

Wgt. Lbs.

120

125

125

141

150

ELECTRICAL CHARACTERISTICS — 120/240 VOLTS A.C. 3 WIRE SINGLE PHASE 60 HZ

*Net ratings are based on installed radiation of sufficient quantity to serve the requirements of the building and nothing need be added for normal

piping and pick up. Net rating is based on a piping and pick up allowance of 13%.

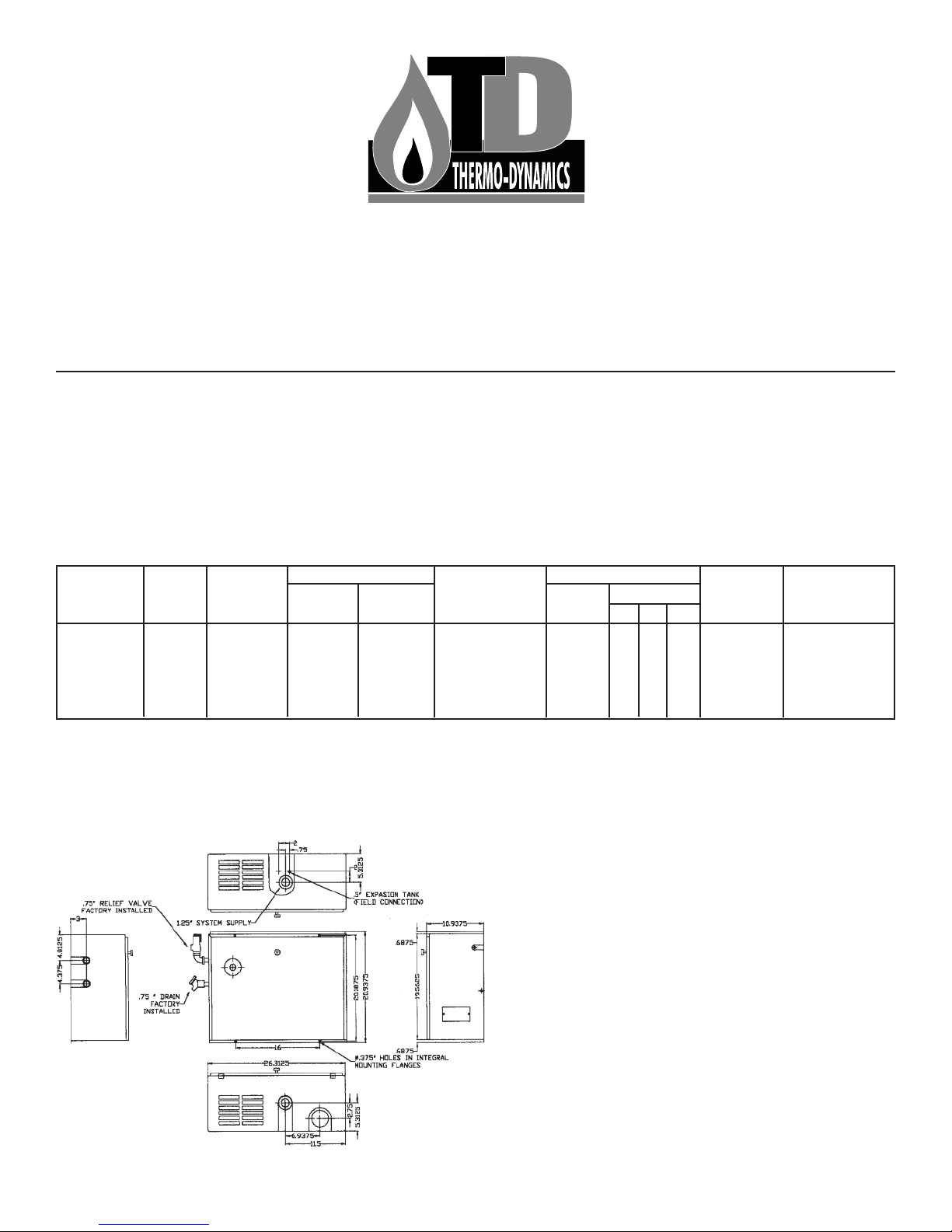

Dimensions Equipment

Steel boiler, jacket, insulation, controls and

circulator

Factory Installed – ASME relief valve,

temperature and pressure gauge, elements,

circulator, drain cock, completely wired.

Included but not installed Air vent, thermostat.

Thermo-Dynamics

CAUTION: READ ME FIRST

Check the unit for shipping damage. If there is any evidence of damage,

including damage to the exterior jacket, you should contact your freight

company immediately and file a claim. Do not install the boiler.

Proper selection of the right size TDE, or any heating device, requires an

accurate heat balance performed by a qualified heating professional.

Consult the supplier of the indirect hot water heater or Thermo-Dynamics

for detailed instructions related to indirect hot water heater applications.

Follow the indirect hot water heater installation and piping instructions to

ensure proper performance.

These instructions include options for installation, including system components. Components are not provided, unless specifically noted otherwise. Suggested installation schemes are for the brand names specified. If

another brand is used, see the manufacturer’s instructions for installation.

Installation of the Thermo-Dynamics TDE electric boiler requires an experienced and trained service person. The TDE is similar to an oil or gas fired

boiler in many ways. The differences are important. Follow the installation

instructions carefully to avoid problems. Contact Thermo-Dynamics if you

have any questions or concerns.

Wiring, piping and construction must meet all local, state and federal

codes that may apply. In the event that no local electrical codes apply, the

National Electrical Code should be followed.

See the outline and dimension drawing on page 6 for location of all electrical and hydronic connections.

Before you start. You will need the following:

Four 3/16" lag screws or toggle bolts for mounting.

A low voltage, remote mounting thermostat.

Expansion tank: Check manufacturer’s instructions for sizing criteria.

Isolation valves, piping and zone devices as described in the installation diagrams.

1

INSTALLATION

1. Carefully remove unit from shipping

carton. Remove the boiler jacket by

removing the jacket assembly screws

around the perimeter of the jacket.

(The jacket can be reinstalled after

wiring and piping. The following

accessories are included and are

loose inside boiler jacket:

• Air Vent - mount in 1/8" pipe tap

hole at boiler top.

2. The Boiler must be wall mounted

only. The air vent provided must be

at the top of the boiler. The TDE is

provided with wall mounting

flanges integrally attached to the

boiler back sheet. There are two

holes 3/8" diameter on 16 inch centers in each flange. Securely mount

the boiler to the wall with 3/16" lag

screws or 3/16" toggle bolts. Be

sure the boiler is level before completing the boiler attachment to the

wall.

3. Allow 20" clearance in front of the

unit for removal of the jacket, for

making electrical connections and

servicing. The required side and top

clearance is 12". The required bottom and rear clearance is 0".

4. The only piping connections

required are the boiler water supply

and return, expansion tank, water

supply and drain line from the relief

valve. The circulator is factory

mounted. Flow should be UP,

toward the boiler vessel. An arrow

cast into the body of the circulator

indicates water flow direction.

5. An Expansion Tank (Not Provided)

must be matched to the system and

installed in accordance with the

manufacturer’s recommendations.

A conventional expansion type of

tank may be connected to the 1/2"

NPT fitting in the boiler top. If a

pressure type tank is used the 1/2"

opening must be plugged. See the

manufacturer’s instructions for sizing the expansion tank.

Do not under-size the expansion tank.

6. The home inlet water system shall

not exceed 60 psi. A pressure

reducer will be required if the system exceeds this pressure. An automatic feed valve (Not Provided)

should be installed in the water

inlet line to keep the entire system

(boiler and radiation) from falling

below the pressure setting of the

valve (12 psi).

7. The water supply and return lines

of the system must be connected

with shut off valves and purging

valves. Purging the system of air

prior to operation is critical to satisfactory operation. All connections

must be air tight and leak proof.

8. Required electrical power input is

three wire, 120/240 volt, single

phase, 60 hz. (The TDE-15 and TDE30 units may be wired using three

phase power, two or three branch

circuits. See wiring diagram.)

Caution

Wire the circuits as shown on the

diagram. The separate 120 volt circuit

for the circulator and control power

circuits is required to allow operation of

the circulator during the start-up

procedure, without energizing the

heater elements.

2

Loading...

Loading...