Thermo Dynamics TDX-90, TDX-100, TDX-110, TDX-125 Installation And Operating Manual

TDX Series

Installation

Operation

Maintenance

Manual

Thermo-Dynamics Boiler Company

ROUTE 61 • P.O. BOX 325 • SCHUYLKILL HAVEN, PA 17972

(570) 385-0731 FAX (570) 385-5304

www.thermodynamicsboiler.com

Service Policy

Congratulations on the purchase of your boiler. Here at Thermo-Dynamics Boiler Com-

pany we pride ourselves on the design and construction of our product. Our intent is to furnish

you with a high quality appliance that will provide you and your family with years of trouble

free service.

In order to maintain peak performance of your boiler, it is recommended that the burn-

er/boiler be serviced annually, preferably prior to the onset of the winter heating season.

Servicing of your appliance must be performed by a qualified heating technician. You should

utilize a qualified heating technician familiar with your installation to manage your boiler and

perform periodic maintenance. Proper care and maintenance of your boiler will allow you to

enjoy the benefits of your new purchase as well as extend its long useful life.

In the event that your serviceman encounters difficulty with the boiler, he/she shall con-

tact the distributor from which the product was purchased. The distributor shall, in turn, contact

the Thermo-Dynamics sales representative for your area. By adhering to this protocol, Thermo-

Dynamics wishes to provide you with responsive and unparalleled service. We realize the

importance that our product means to you and your family and our goal is to get your boiler up

and running as quickly as possible.

Thank you for purchasing the Thermo-Dynamics boiler. Again, it is our intent to provide

you with a high quality trouble free product that will be part of your family for many years to

come. Please consider Thermo-Dynamics Boiler Company in the future for all of your home

heating needs.

TDX Series

Boiler Installation and Operating Manual

Contents

Subject Page

Read This First 2

Specifications 4

Installation 4

Operational Sequence 7

Start-Up 8

Appendices

Troubleshooting Guide A 14

Dimensions B 16

Piping Diagrams C 17

Wiring Diagrams D 18

Installer/Serviceman Labels E 20

Burner Service Set Up Records 22

Installation and Service Check List Back Cover

Read This First

1. Installer must be a trained, experienced technician and should read all instructions before installation.

2. Inspect the boiler, jacket and all components to be sure damage has not occurred

in shipment. If damage is evident a claim must be filed with the freight carrier who

transported the boiler from the factory to the distributor where it was purchased.

Do not install the boiler. Contact your distributor.

3. Disconnect power supply before connecting wiring.

4. Refer to local codes for oil burning equipment, for recommended installation practice. You will need to be familiar with NFPA International Standard 31, “Standard

for the Installation of Oil Burning Equipment”.

5. A complete heat loss calculation is necessary to choose the proper size unit to

install. The boiler should be sized to within 25% of the actual heat loss of the

structure. Over sizing will result in short cycling and inefficient operation.

6. When moving the boiler, do not push against the jacket or burner. Damage will

result.

7. If the boiler is vented to a chimney, be certain the chimney is clean and free of

obstructions. The chimney must be masonry with tile lining or metal insulated

with a stainless steel surface. The Chimney must be properly sized. Draft

requirements are essential for safe and proper operation of the boiler.

8. If the boiler is connected to a venting device, make sure that it is listed by a

recognized testing service. Follow the venting device manufacturer’s installation

instructions. Verify that the venting device installation complies with the recommendations of the manufacturer and local and state codes.

9. Conduct a thorough checkout when installation is complete. Check for indications

of leaks and make sure that no material is left adjacent to the boiler.

10. The use of low sulfur No. 2 heating oil is highly recommended.

11. The following definitions apply to potential hazards noted in this manual.

3

DANGER: Indicates a hazardous situation which if not avoided will result in death

or serious injury.

WARNING: Indicates a hazardous situation which if not avoided could result in

death or serious injury.

CAUTION: Indicates a hazardous situation which if not avoided, may result in a

minor injury. It may also warn against unsafe practices that may result in minor

njury or damage to equipment.

NOTICE: Indicates that special attention to information is required. Not related

to personal injury or property damage.

12. Modifications, substitutions or removal of equipment supplied or specified may

result in property damage, personal injury or loss of life.

4

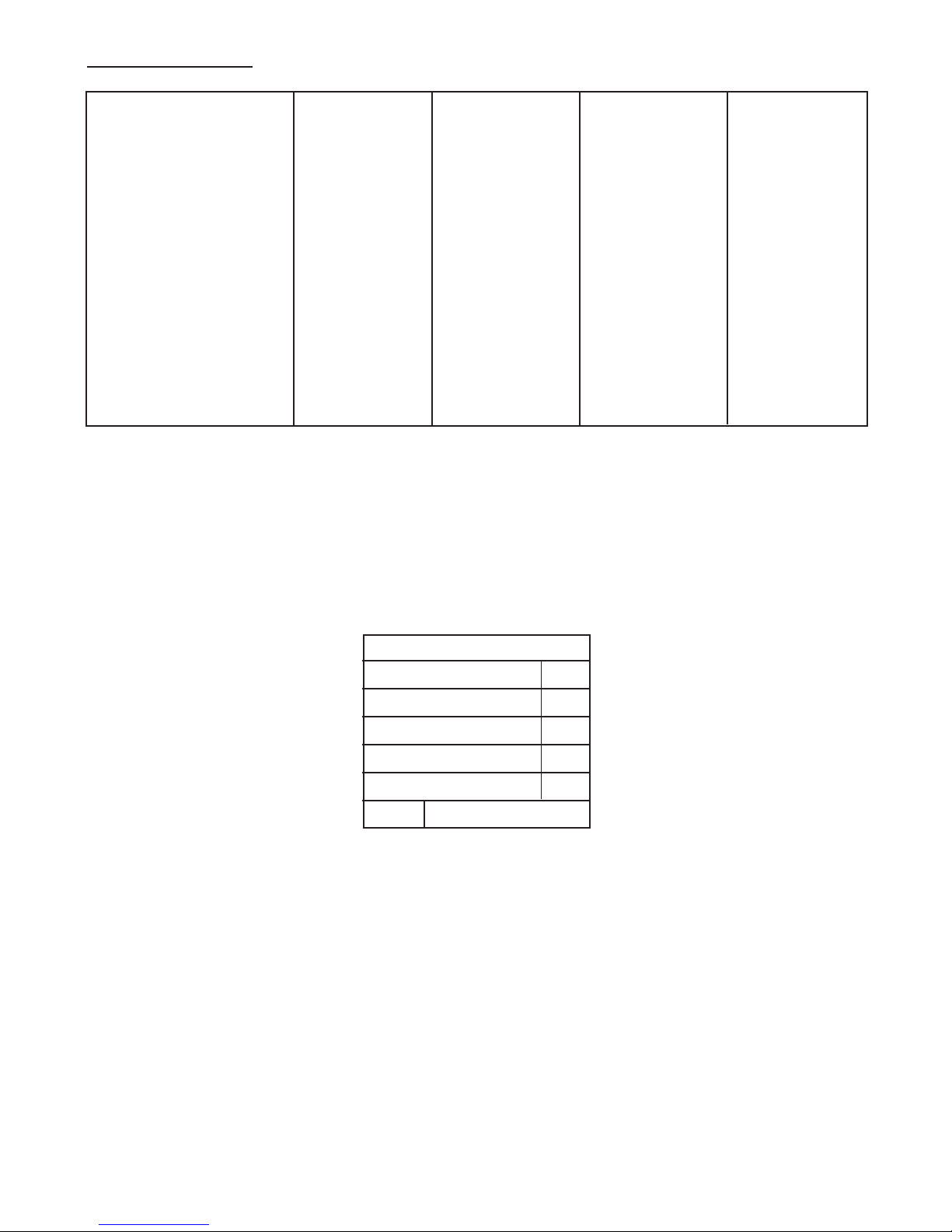

Specifications

___________________________________________________________________________________

Model TDX-90 TDX-100 TDX-110 TDX-125

___________________________________________________________________________________

Input BTU/HR 126,000 140,000 154,000 175,000

___________________________________________________________________________________

Heat Capacity BTU/HR 110,000 121,000 132,000 148,000

___________________________________________________________________________________

Net Output BTU/HR 95,000 105,000 115,000 129,000

___________________________________________________________________________________

Firing Rate GPH 0.90 1.00 1.10 1.25

___________________________________________________________________________________

Supply 1 1/4” 1 1/4” 1 1/4” 1 1/4”

___________________________________________________________________________________

Return 1 1/4” 1 1/4” 1 1/4” 1 1/4”

___________________________________________________________________________________

Coil Capacity (WC Model) 5 GPM 5 GPM 5 GPM 5 GPM

___________________________________________________________________________________

Steady State 87.0 86.5 86.0 85.5

___________________________________________________________________________________

AFUE 87.0 86.5 86.0 85.5

___________________________________________________________________________________

Burner Model Carlin EZ-1 PRO Carlin EZ-1 PRO Carlin EZ-1 PRO Carlin EZ-1 PRO

___________________________________________________________________________________

Burner Model Beckett NX Beckett NX Beckett NX Beckett NX

A. Installation Instructions

1) Place the boiler on a level floor, preferably raised and as close to the chimney as possible.

Refer to the installers label to determine if the boiler may be installed on combustible flooring or

if non-combustible flooring is required. The minimum clearances for installation are shown

below. Reduced clearance installations must follow NFPA-31 guidelines. If the boiler is a Knock

Down (not packaged for ease of installation), install the jacket in accordance with the directions

provided in the jacket package, prior to piping.

Standard Clearances

Front 24”

Sides 6”

Rear 12”

Top 18”

Chimney Connector 18”

Floor Non-Combustible

2) Install the boiler piping. For location of piping refer to the Installation Drawing.

DANGER: Boilers with tankless coils must be piped in accordance with the piping diagram

including installation of a tempering or mixing valve. Domestic hot water temperatures exceeding 125°F will cause severe burns instantly or death by scalding.

WARNING: Relief valve discharges and drain valve piping must be piped to a safe place of

discharge.

NOTICE: TDX Series Boilers are provided with a built-in air scoop feature. This feature allows

quiet, air free operation of the hot water system by eliminating air pockets without installation of

air scoops. The supply line tapping in the top of the boiler extends approximately 1 inch below

the top of the boiler, allowing only air-free water to enter the heating system supply. Any air

trapped in the top of the boiler is purged through the 3/4” vent tapping. The 3/4" vent tapping

should be connected to an automatic float vent, a manual vent or piped to a conventional

expansion tank.

5

3) Packaged boilers are shipped with the burner, aquastat and circulator installed and wired

at the factory. See the Basic Wiring Diagram for wiring schematic. See component manufacturer’s manual for wiring instructions.

4) An expansion tank, not provided, must be matched to the system and installed in accordance with the manufacturer’s instructions. Do not undersize the expansion tank. An

automatic feed and pressure reducing valve, not provided, should be installed in the

water inlet line to keep the entire system from falling below the pressure setting of the

valve ( about 12 psi) See the feed valve suppliers instructions for maximum allowed

water supply pressure and requirements for pressure reducers. For piping and wiring of

other system components see the manufacturer’s installation manuals.

5 The tank-less water heater may be piped as shown in the Installation Drawing. A mixing

valve (tempering valve), not supplied, must be used to reduce the water temperature at

kitchen or bathroom taps. High temperature water for a dishwasher may be obtained by

piping as shown in the Installation Drawing. The nuts that secure the tank-less coil

flange should be tightened before the boiler is filled with water, after initial firing and once

a year during the annual maintenance.

CAUTION: Deterioration due to coil gasket leaks will void the warranty.

6) a. Chimney Vent Aplications. Connect boiler flue outlet to chimney using galvanized

smoke pipe. The flue pipe should be pitched upward at least 1/4” per foot of run. Refer

to the boiler specifications for proper size flue pipe for your model boiler. Use only

elbows and straight sections. Tees may be used in a straight section in conjunction with

a barometric draft regulator however they must not be used for a 90° turn. Each joint

should be securely fastened with sheet metal screws. The flue pipe must not be inserted

beyond the inside wall of the chimney. Install barometric draft regulator in the horizontal

or vertical section of the flue pipe. The draft regulator should be installed in accordance

with the manufacturer’s instructions. Set the draft to in the stack as specified in the boiler

specifications and on the Installer/Serviceman Label on the boiler jacket. The flue gas exit

of the venting system should be at designed with clearances in accordance with NFPA

31. A chimney must be at least 3 feet above the highest point where it passes through

the roof and at least 2 feet higher than any portion of a building within 10 feet of the venting system. The horizontal length of a chimney connector should not exceed 10 feet

unless a draft booster is used. Where the possibility of down drafts exist, install a listed

vent cap.

b. Direct Vent Applications. Follow the instructions provided with the Double Wall Direct

Vent Kit for installation, operation and maintenance.

CAUTION: External vent surfaces are hot.

NOTICE: Use only the venting system components supplied with the kit.

NOTICE: Surface discoloration of the building may occur due to improper burner/boiler

adjustmet. Thermo-Dynamics will not accept any liability for such discoloration.

7) The boiler room must be well ventilated to allow sufficient make-up air to support combustion. Lack of adequate combustion air may result in erratic operation of the burner,

noisy combustion or fuel odors. Remember your need for outside air will be greatly

6

increased if you have a vented dryer in the basement or other venting fans in the home.

Boilers located in confined spaces shall be provided with two permanent openings, one

near the top and one near the bottom of the enclosure. Each opening shall have a free

area of not less than one square inch per 1000 BTU per hour input rating of the boiler,

freely communicating with interior areas having adequate infiltration from the outside.

8) Fill boiler and system with water. Be sure entire system has been purged of air and the

desired pressure is obtained. Leak-check the boiler and piping system by turning off the

make-up water supply and observing the boiler pressure gage. A loss of pressure indicates a system leak that must be repaired prior to operating the boiler.

9) Remove the nozzle line assembly and check that the correct nozzle is installed for the

desired firing rate. Check that burner settings are correct for the nozzle that is installed.

See the Installer/Serviceman Label.

10) Connect burner to fuel supply. Refer to fuel unit manufacturer literature for piping, connections, lift and tank installation. If such information is unavailable use the following guide lines.

FUEL UNITS/FUEL LINES

Fuel supply “level with” or “above” burner: A single stage fuel unit connected to the fuel

supply with a single supply line is the most common type of installation for these conditions.

Manual venting of the fuel unit is usually required on initial start-up. Failure to vent air could

result in an air lock/oil starvation condition. (One pipe)

Fuel supply below the level of burner:

Use a single stage fuel unit in lift conditions of up to

10 ft., and a two stage fuel unit when the lift exceeds 10 ft. Both conditions require the use of

a return line which purges the fuel unit of air returning it to the fuel tank. The “by-pass” plug

must be inserted into the fuel unit when installing a return line. (Two pipe)

Fuel line installation:

Continuous lengths of heavy wall copper tubing are recommended

and should be installed under the floor when possible. Always use flare fittings. Always install

fittings in accessible locations. Never use teflon tape on any fuel fitting. Use of teflon will void

any warranty. Fuel lines should not run against the appliance or the ceiling joists.

Fuel line valve and filter:

Install two high quality shutoff valves in accessible locations on

the oil supply line. Locate one close to the tank and the other close to the burner ahead of the

filter. Some filters come with built-in shutoff valves. Install a generous capacity filter inside the

building between the fuel tank shutoff valve and the burner locating both the filter and the

valve close to the burner for ease of servicing.

CAUTION: All oil feed lines to burners must be air tight. Use only flare fittings when assembling oil lines since the slightest air leak, caused by loose fittings, bad gaskets or any other

reason, can cause a foaming oil stream which will cause any of the following conditions:

a) Intermittent firing, causing safety shutdown

b) Poor starts

c) Smokey starts

d) Continual sooting of boiler and burner parts including the cad cell

e) Reduced firing rate, inefficient operation and erratic fire pattern

f) A dangerous combustion condition, allowing the firebox to fill with a lean mixture (too

much air in the oil stream) which could cause a delay in ignition of the fuel mixture until

the danger point has been reached.

7

Loading...

Loading...