Thermo Dynamics CWL GS, CWL GS DV, NCWL GS, NCWL GS DV Installation, Operation & Maintenance Manual

CWL-GS Series

Models CWL GS, CWL GS DV, NCWL GS, NCWL GS DV

Gas Fired Packaged Boiler

Installation

Operation

Maintenance

Manual

Thermo-Dynamics Boiler Company

ROUTE 61 • P.O. BOX 325 • SCHUYLKILL HAVEN, PA 17972

TEL (570) 385-0731 • FAX (570) 385-5304

WEB www.thermodynamicsboiler.com • EMAIL sales@thermodynamicsboiler.com

www.thermodynamicsboiler.com

FOR YOUR SAFETY READ BEFORE OPERATING

WARNING: If you do not follow these instructions exactly, a fire or explosion

may result causing property damage, personal injury or loss of life

A. This appliance does not have a pilot. It is

equipped with an ignition device which automatically lights the burner. Do not try to light

the burner by hand.

B. BEFORE OPERATING smell all around the

appliance area for gas. Be sure to smell next

to the floor because some gas is heavier than

air and will settle to the floor.

WHAT TO DO IF YOU SMELL GAS

*Do not try to light any appliance.

*Do not touch any electric switch; do not

use any phone in the building.

*Immediately call your gas supplier from a

neighbors phone. Follow the gas supplier’s

instructions.

OPERATING INSTRUCTIONS

*If you cannot reach your gas supplier, call the

fire department.

C. Use only your hand to push in or turn the

gas control knob. Never use tools. If the knob

will not push in or turn by hand, don’t try to

repair it, call a qualified service technician.

Force or attempted repair may result in a fire

or explosion.

D. Do not use this appliance if any part has

been under water. Immediately call a qualified

service technician to inspect the appliance

and to replace any part of the control system

and any gas control which has been under

water.

1

. STOP! Read the safety information above

on this label.

2. Set the thermostat to lowest setting.

3. Turn off all electric power to the appliance.

4. This device is equipped with an ignition

device which automatically lights the burner.

Do not try to light the burner by hand.

5. If the gas control knob is not in the “OFF”

position, turn the knob clockwise to ‘OFF”.

6. Wait five (5) minutes to clear out any gas.

Then smell for gas, including near the floor.

If you smell gas, STOP! Follow “B” in the

safety information above on this label. If

you do not smell gas, go to the next step.

7. Turn gas control knob counterclockwise

to “ON”.

8. Turn on all electric power to the appliance.

9. Set thermostat to the desired setting.

10. If the appliance will not operate, follow the

instructions “To Turn Off Gas To

Appliance” and call your service

technician or gas supplier.

TO TURN OFF GAS TO APPLIANCE

1. Set the thermostat to lowest setting

2. Turn off all electric power to the appliance if service is to be performed.

3. To turn off gas to appliance, turn the gas control knob clockwise to “OFF”.

i

Contents

Safety Instructions i

Service Policy 1

Component Arrangement 3

Installation 3

Operation 12

Maintenance 14

Trouble Shooting 16

Parts List 21

Product Features

• ASME Coded Boiler Registered with National Board

• Fully Insulated Heat Exchanger with Powder-Coated Cabinet

• Packaged with Standard Five Gallon per Minute Tankless Coil

For Domestic Hot Water (CWL Models Only)

• NCWL Model Available Without Tankless Coil

• Equipped with Triple Aquastat, Circulator, and Temperature/Altitude Gauge

(CWL Models Only)

• Equipped with Cold Start Aquastat, Circulator, and Temperature/Altitude

Gauge (NCWL Models Only)

• Additional Orifices Provided

• Lifetime Limited Warranty

• Available as Direct Vent

ii

Service Policy

Congratulations on the purchase of your boiler. At Thermo-Dynamics Boiler

Company we pride ourselves on the design and construction of our product. Our

intent is to furnish you with a high quality appliance that will provide you and your

family with years of trouble free service.

In order to maintain peak performance of your boiler, it is recommended that

the burner/boiler be serviced annually, preferably prior to the onset of the winter

heating season. Servicing of your appliance must be performed by a qualified heating technician. You should utilize a qualified heating technician familiar with your

installation to manage your heater and perform periodic maintenance. Proper care

and maintenance of your boiler will allow you to enjoy the benefits of your new purchase as well as extend its long useful life.

In the event that your serviceman encounters difficulty with the boiler, he/she

shall contact the distributor from which the product was purchased. The distributor,

in turn, will contact the Thermo-Dynamics sales representative for your area. By

adhering to this protocol, Thermo-Dynamics will provide you with responsive and

unparalleled service. We realize the importance of what our product means to you

and your family and our goal is to get your unit up and running as quickly as possible.

Thank you for purchasing the Thermo-Dynamics boiler. Again, it is our intent

to provide you with a high quality trouble free product that will be part of your family for many years to come. Please consider Thermo-Dynamics Boiler Company in

the future for all of your home heating needs.

1

IMPORTANT

l

Read carefully and consult drawings before beginning work.

l

The CWL-GS is factory assembled and packaged. Check shipping list as the unit and accompanying cartons are unpacked. Report shortages or damage to the delivering carrier immediately.

l

Safe lighting and other performance criteria were met with the gas manifold and control

assembly provided on the boiler when the boiler underwent tests as specified in Gas Fired

Low-Pressure Steam and Hot Water Boilers ANSI Z21.13.

l

The instructions, drawings, and data included in this manual are only guidelines. The equipment shall be installed in accordance with the installation requirements of the authority having jurisdiction or in the absence of such requirements to the current edition of the National

Fuel Gas Code ANSI Z223.1. (Available from the American Gas Association, Pleasant Valley

Road, Cleveland, Ohio 44134)

l

When required by the authority having jurisdiction, the installation must conform to the

American Society of Mechanical Engineers Safety Code for Control and Safety Devices for

Automatically Fired Boilers, No. CSD-1.

l

This Instruction Manual shall be kept near the boiler for future reference.

! WARNING:

THIS PRODUCT MUST BE INSTALLED BY A LICENSED PLUMBER OR GAS FITTER WHEN

INSTALLED WITHIN THE COMMONWEALTH OF MASSACHUSETTS.

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE OF

THIS BOILER MAY CAUSE INJURY OR PROPERTY DAMAGE.

IF YOU SMELL GAS OR SUSPECT A GAS LEAK, TURN OFF GAS AT THE MANUAL SERVICE VALVE AND EVACUATE THE HOUSE. DO NOT TRY TO LIGHT ANY APPLIANCE. DO

NOT TOUCH ANY ELECTRICAL SWITCHES OR TELEPHONES IN THE BUILDING UNTIL

YOU ARE SURE NO GAS REMAINS IN THE AIR.

COMPLIANCE WITH ALL APPLICABLE CODES IS THE SOLE RESPONSIBILITY OF THE

INSTALLER.

2

Figure 1

Component Arrangement

Installation

I. GENERAL

CWL-GS Series hot water boilers are high quality, high efficiency gas fired vertical fire tube heating units.

The in stal la tion of the unit shall be in accordance with regulations of the authorities having jurisdiction.

Refer to Local installation Codes for Gas Burning Equipment, for recommended installation practice.

The CWL must be installed with the factory assembled jacket intact.

II. FREIGHT CLAIMS

All units should be inspected for damage upon arrival. Concealed damage claims should be filed

immediately against the carrier by the consignee. The carrier is responsible for taking prompt action on all

claims.

III. SIZING

A complete heat loss calculation of the structure is necessary to choose the proper size unit.

Oversizing will result in short cycling and inefficient operation. In order to insure proper sizing of the unit,

domestic hot water re quire ments and the structure heat load must be calculated.

Replacement boilers should not be sized from the firing rate of the old boiler. A DOE sponsored

study indicates 65% of the heating units in U.S. homes are substantially oversized.

3

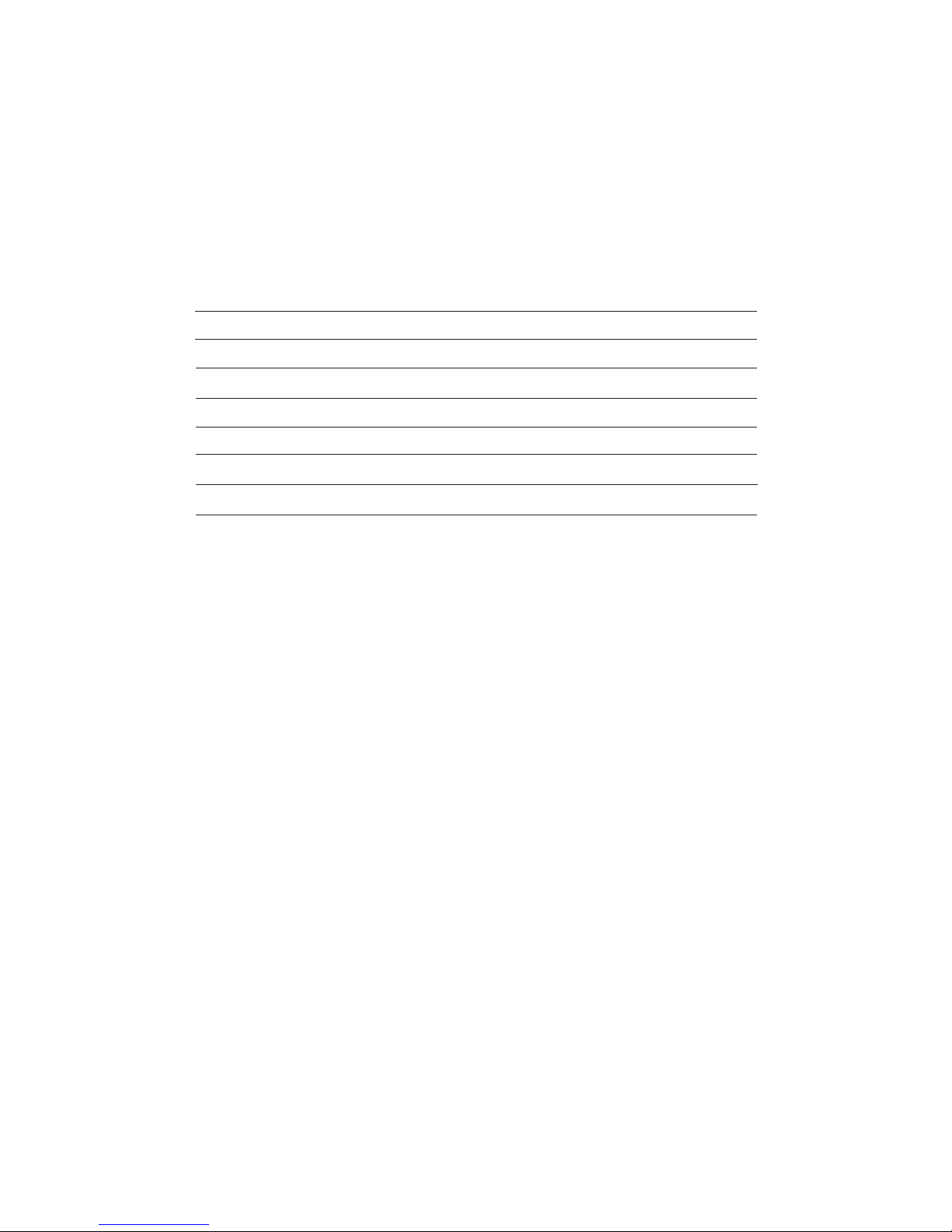

TABLE 1 – SPECIFICATIONS

Model: 120 140 160

Boiler Specifications

Firing Rate CFM 1.95 2.28 2.60

Input BTU/HR 120,000 140,000 160,000

DOE Capacity BTU/HR 100,000 115,000 130,000

Net Rate BTU/HR 87,000 100,000 113,000

Val. Cap. Lbs/HR 160 160 160

Max. W.P. PSI 30 30 30

AFUE 82.6 81.1 80.5

Boiler Dimensions

Water Content 15 Gal. 15 Gal. 15 Gal.

Coil Capacity* 5 Gal. 5 Gal. 5 Gal.

A) Jacket Height 29-1/2 29-1/2 29-1/2

B) Jacket Width 21 21 21

C) Coil Supply Height 22 22 22

D) Supply Height (Hydronic) 27-1/2 27-1/2 27-1/2

E) Burner Height 7-7/8 7-7/8 7-7/8

F) Hydronic Return Height 15-1/2 15-1/2 15-1/2

G) Flue Pipe Dia. 555

H) Washout (Alt. Return Height) 3-1/2 3-1/2 3-1/2

I) Jacket Depth (Inc. Flange) 22 22 22

Depth Front to Rear w/Burner 34-1/2" 34-1/2" 34-1/2"

Hydronic Supply Size 1-1/4 1-1/4 1-1/4

Hydronic Return Size 1-1/4 1-1/4 1-1/4

Washout Size (Alt. Return) 1-1/4 (2) 1-1/4 (2) 1-1/4 (2)

* Intermittent draw: 5 minute draw and 5 minute waiting period

4

IV. LOCATION

Place the boiler on a level floor, preferably raised and as near to the chimney or venting device as

possible. Allow clearances as follows in accordance with local codes and NFPA-54. (For clearances less

than the listed values, consult NFPA-54 Table 6.2.3(B).

MINIMUM CLEARANCE TO COMBUSTIBLE MATERIALS

Sides - 0”

Rear - 0”

Front - 12”

Chimney Connector - 18”

Top - 18” for cleaning

The CWL-GS zero clearance rating is attributed

to its “Wet-Leg” Design. The boiler features a wall of

water on all four sides as well as the area directly above

the combustion chamber, thereby eliminating hazardous

chamber burn-through conditions and can be placed on

combustible flooring in accordance with U.L. 726.

V. AIR FOR COMBUSTION AND VENTILATION

The unit must be installed where provisions exist for combustion and ventilation air. Ordinarily, provi-

sions may be furnished by the following methods.

A. Utility Room or Closet

In buildings of tight construction, including most modern homes, you should provide an opening,

con nect ing to a well ventilated attic, crawl space or directly with the outdoors. The opening should have a

minimum free area of 1 square inch per 1,000 Btu per hour of total input for all appliances in the enclosure

and should terminate below the burner level. Boilers installed in a confined area or closet must have two

ventilation openings in the closet door. Each opening should have a free area of not less than 1 square inch

per 1,000 Btu of the total input for all appliances in the enclosure. One opening located near the top of the

enclosure and one near the bottom.

B. Basement

1. Where a boiler is installed in a full basement, infiltration is normally adequate to provide air for

combustion.

2. Buildings of tight construction where the basement windows are weather stripped, one opening

com mu ni cat ing with a well ventilated attic or with the outdoors should be provided. The opening should

have a minimum free area of 1 square inch per 1,000 Btu per hour of total input for all appliances in the

inclosure.

C. Special Conditions

Where a boiler is located in an area where the operation of exhaust fans, kitchen ventilation sys-

tems, clothes dryers, or fire places may create conditions of unsatisfactory combustion or venting, special provisions should be made for additional air for combustion, as specified by local authority.

VI. BOILER PIPING

The CWL-GS Series of boilers is equipped with a built in Air Scoop. This feature allows quiet air free

operation of your hot water system by assuring the removal of air pockets without the use of Air Scoops

(see Figure 2) to trap noisy air.

5

Loading...

Loading...