Thermocold MULTIFUNCTIONAL UNITS RLC Installation And Maintenance Manual

MULTIFUNCTIONAL UNITS RLC – Installation and maintenance manual

MUMRLCHEAT_REV01_1012_UK

Pag. 1 di 31

MANUALE DI INSTALLAZIONE E MANUTENZIONE MULTIFUNZIONE

RESIDENTIAL AND LIGHT COMMERCIAL

INSTALLATION AND MAINTENANCE MANUAL FOR MULTIFUNCTIONAL UNITS

RESIDENTIAL AND LIGHT COMMERCIAL

CODICE MANUALE

MANUAL CODE

MUMRLCHEAT_REV01_1012_UK

ANLEITUNGSKODEX

MULTIFUNCTIONAL UNITS RLC – Installation and maintenance manual

MUMRLCHEAT_REV01_1012_UK

Pag. 2 di 31

Dear customer,

Congratulation for purchasing a Thermocold product.

Thermocold operates in civil and industrial air conditioning for years to assure the best comfort with reliability, quality,

efficiency and total safety.

With this manual we try to offer you the best support from receiving, start up, use, maintenance to the most ecological

disposal.

Best regards,

Thermocold Costruzioni s.r.l.

MULTIFUNCTIONAL UNITS RLC – Installation and maintenance manual

MUMRLCHEAT_REV01_1012_UK

Pag. 3 di 31

Indice

1. Generalità ........................................................................................................................................................................ 4

2 Receiving the unit .......................................................................................................................................................... 4

3 Positioning .................................................................................................................................................................... 7

4 Safety regulations ....................................................................................................................................................... 7

5 INSTALLATION .......................................................................................................................................................... 12

6 Control of compressor fastening ............................................................................................................................. 14

7 Electrical Connections ............................................................................................................................................... 14

8 Water Connections .................................................................................................................................................... 15

9 Perdite di carico sugli scambiatori .......................................................................................................................... 24

10 Tabelle di correzione glicole etilenico ......................................................... Errore. Il segnalibro non è definito.

11 Tabelle di correzione fattore di incrostazione............................................ Errore. Il segnalibro non è definito.

12 Preparazione all’avviamento ................................................................................................................................ 26

13 Avviamento............................................................................................................................................................. 28

14 Manutenzione ......................................................................................................................................................... 29

15 Pezzi di ricambio consigliati ................................................................................................................................. 30

16 Usi impropri .................................................................................................... Errore. Il segnalibro non è definito.

17 Smaltimento ................................................................................................... Errore. Il segnalibro non è definito.

MULTIFUNCTIONAL UNITS RLC – Installation and maintenance manual

MUMRLCHEAT_REV01_1012_UK

Pag. 4 di 31

1. Generalità

1. OVERVIEW

1.1 Summary of guarantee regulations

A. The guarantee for Thermocold machines is 12 months from the date the machine is operated for the first time but no more than 18

months from the date of the invoice. The warranty is reduced to 6 months from the start up date for units running continuously, that is

more than 12 hours a day. The date the machine is operated for the first time means the date reported in the “1st start up form”

contained into the “machine log book”. This form should be filled in and sent, within 8 days from the start up, to Thermocold.

B. The guarantee is valid if all the installation regulations have been adhered to (both those which may have come from Thermocold and

those coming from current practice), if the “1st start up form” has been filled in and sent to the Thermocold after sales department.

C. The guarantee is subject to any faults or defects being reported within eight days from their discovery. The guarantee will only be

applied if and when the purchaser suspends use of the equipment as soon as a defect has been found.

C1. Replacement items are to be considered always ex THERMOCOLD factory. Labour costs to replace failed items either under warranty

or not, will be not of THERMOCOLD care.

D. The guarantee is valid if the first running of the machine is carried out by a Thermocold authorised assistance centre.

E. The guarantee is subject to regular maintenance of the unit which is appropriately indicated in the “machine log book” located inside

the electrical panel.

F. Warranty is automatically over in case of payments not fulfilled, non-performance of the contract and even if the units show tampering

without THERMOCOLD writing approvals.

G. Non observance of the above mentioned rules and of all the indications written on this manual, will cause the immediate loss of

warranty, getting free THERMOCOLD from any responsibility for the unit and any damages to persons or things.

2 Receiving the unit

On receiving the unit it is up to the customer to check that there is no obvious damage or pieces missing. If this is so, an immediate

complaint must be made to the carrier for damage or for not-delivery and the Receiving Card to be found inside the unit electrical panel

must be filled in. Photographic evidence must be provided for macroscopic damage. The card must be sent to Thermocold within 8 days of

receiving the goods: if it is not sent back or delayed, the complaint will not be accepted.

The unit is identified by:

Packaging label: it contains the identification data of the product.

Thecnical label: it contains the technical and performance data of the unit.

In case of loss, ask for a copy to the After Sales department.

If the identification of the product is not sure because of the damaging, removal, lack of the identification labels, the installation and

mainteinance operations become difficult.

2.1 Preliminary notions

Operate in respect of the safety regulation.

About the dimensional data of the unit and the technical data, see the chapter “Technical information”.

For loading and unloading the unit use the necessary personal protective equipment .

2.2 Delivery checks

Before the delivery:

Check the packaging and the unit have not defect caused by carriage.

Check the delivered materials correspond to the good declared in the packing list.

MULTIFUNCTIONAL UNITS RLC – Installation and maintenance manual

MUMRLCHEAT_REV01_1012_UK

Pag. 5 di 31

2.3 Unit identification

2.3.1 Label

The unit is identified by the following label.

It contains the kind of the unit (serial and size), the serial number, the production year, the electric

data, the main technical data, logo anche manufacturer address.

In case of loss request for a duplicate to the after sale service.

Tampering and/or removing the label does not allow the identification of the product, and makes

difficult any installation and maintenance operation.

2.3.2 Serial number

The serial number identifies the unit unambigously, it permit to identify the specific characteristic of

the unit and the installed components. Without this code it is not possible identifies the specific

spare parts of the unit. In case of request for repair it is necessary the model and the serial

number.

2.4 Factory inspection

Thermocold units are inspected into the factory, in appropriate areas, in accordance with internal

procedures. Each performance test carried out on the unit is possible only if the same conditions

are reproduced and maintained (charge consistency, constant temperature and evaporation - condensation and recovery capacity, quality

and tolerance of the measuring instruments etc.) in the test rooms.

The inspection conditions are those indicated by the customer in the ordering phase: if not otherwise specified, reference should be made

to the nominal performance indicated in the technical bulletin in force at the date of the Confirmation of the Order.

MULTIFUNCTIONAL UNITS RLC – Installation and maintenance manual

MUMRLCHEAT_REV01_1012_UK

Pag. 6 di 31

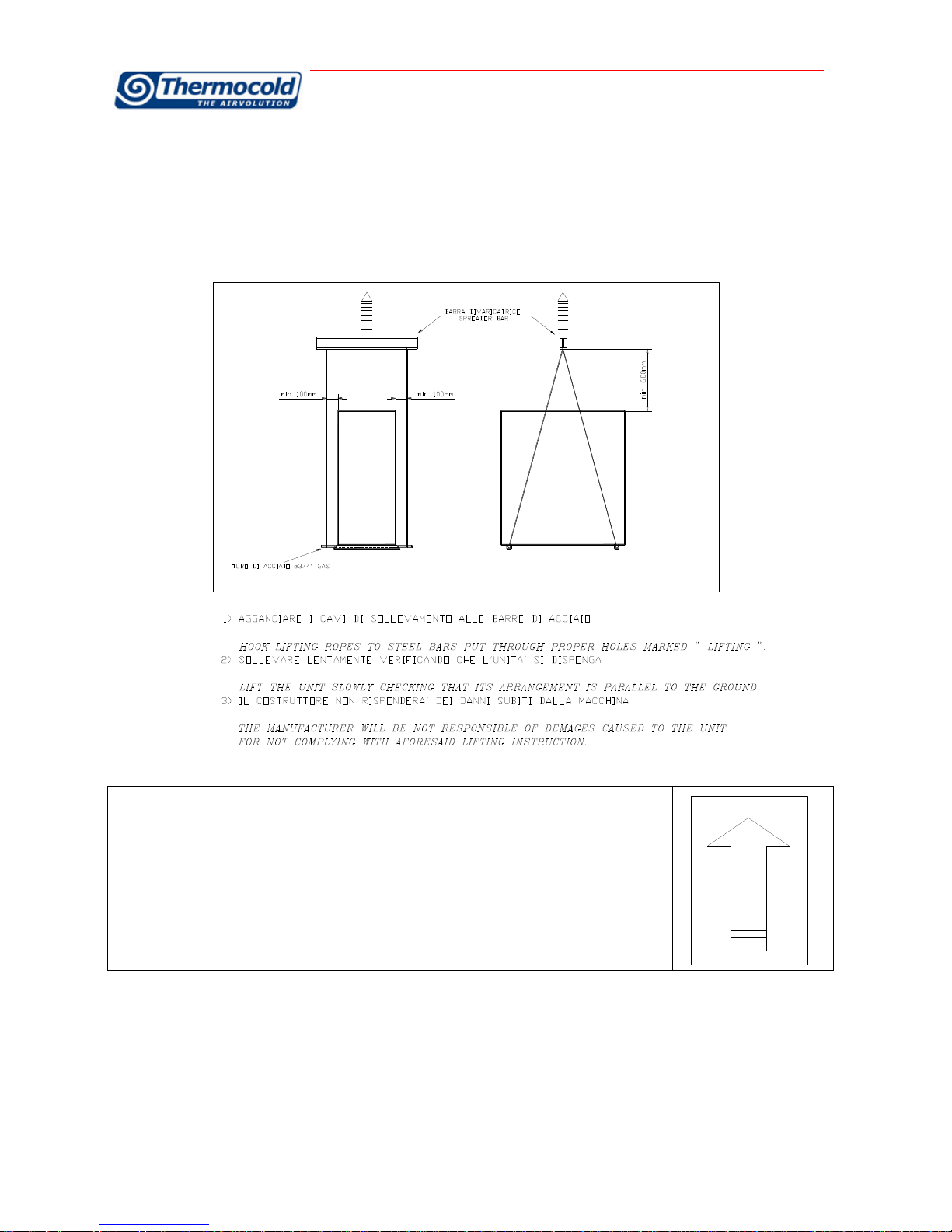

2.5 Handling

Verify the unit weight and the load capacity of the lifting mean. During the handling pay attention to obstacles along the route that could

damage the unit (disconnections, ramp, climb, etc.).

Verify the perfect stability during the handling operations of the unit. Do not perform dangerous operations that could damage the unit.

Make sure that the unit has the proper positioning during transportation. Placing horizontally the unit 'can

lead to irreversible damage to the compressors. Faultiness caused by uncorrect transport will not be under

warranty by the manufacturer. Immediately report an incorrect receipt. An arrow pointing straight up,

indicates the vertical positioning of the unit.

PER LA MANCATA OSSERV ANZA DEL LE ISTRUZIONI DI SOLLEV AMENTO SOPRAINDI CATE.

POSI ZI ONATE ATTRAV ERSO I FORI I NDI CATI " L I FTING " .

ORIZZONTALMENTE RISPETTO AL PIANO DI APPOGGIO.

MULTIFUNCTIONAL UNITS RLC – Installation and maintenance manual

MUMRLCHEAT_REV01_1012_UK

Pag. 7 di 31

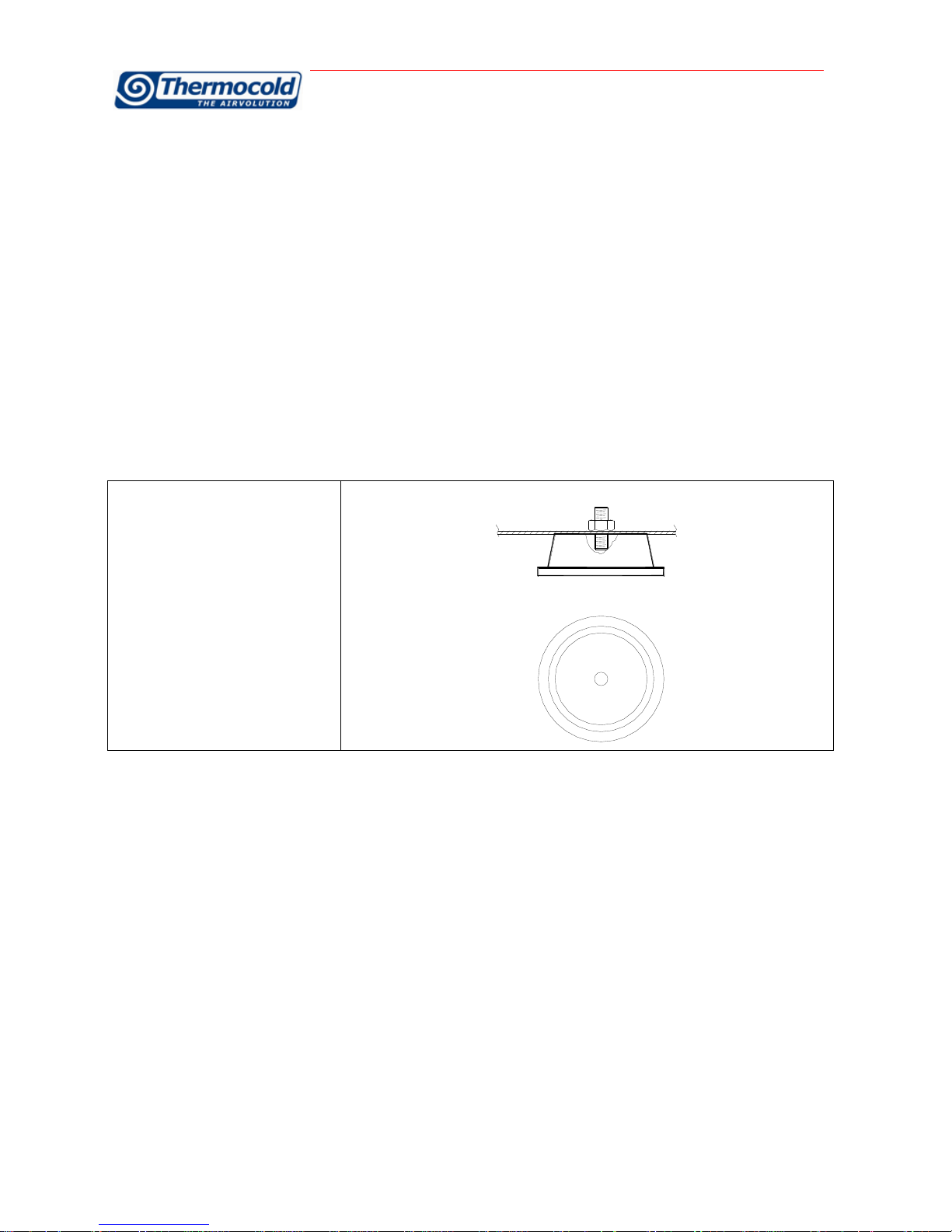

3 Positioning

3.1

Installation servicing space

Respect the instructions in the dimensional drawing provided on board. Narrow installations spaces may cause:

Noise level increase

Not correct heat exchange and unit ventilation.

Maintenance difficulties or impossibility.

3.2 Condensate

The unit in order to easily discharge the condensate caused by the heat pump operation, especially during the defrosting cycle. Avoid the

condensate drain in location where people transit.

3.3 Anti-vibrantion

L’unità esterna va ancorata su antivibranti in gomma o a molla che vanno fissati nel seguente modo:

Firmly fasten the anti-vibration bottom

part to the support base plate of the unit.

Screw the fastening nut and the lock nut

to adjust the correct inclination of the unit.

The incorrect positioning of the unit can

cause damage of the compressor because

of the incorrect oil leveling.

4 Safety regulations

4.1 Preamble

All Thermocold units are designed, built and inspected in compliance with the European Community Directives n° 98/37/CE (three phase

power supply), EN 60335 Part 1 and 2 , low voltage directive 73/23CEE, electromagnetic compatibility directive EMC 89/336CEE, Pressure

Equipment Directive 97/23/CEE. Before using the machine read carefully the recommendations reported in the following manual.

MULTIFUNCTIONAL UNITS RLC – Installation and maintenance manual

MUMRLCHEAT_REV01_1012_UK

Pag. 8 di 31

4.2 Definitions

4.2.1 Owner:

The legal representative of the company, body or natural person who owns the plant in which the Thermocold unit is installed: he or she is

responsible for the control and respect of all the safety regulations indicated in this manual as well as the national ones in force.

4.2.2 Installer:

The legal representative of the company appointed by the owner to position and hydraulically, electrically etc. connect the Thermocold unit

to the plant: he or she is responsible for moving and the correct installation of the unit in accordance with the indications in this manual

and with the national regulations in force.

4.2.3 Operator:

A person authorised by the owner to carry out all the operations of regulation and control on the Thermocold unit which are specifically

mentioned in this manual. He or she should keep to actions described in the manual and limit his or her action to what is explicitly allowed.

4.2.4 Technician:

A person who is directly authorised by Thermocold or, secondarily, for all EU countries except for Italy, by the distributor of the

Thermocold product, under their own responsibility, to carry out all ordinary or extraordinary maintenance operations, as well as

regulations, controls, repairs and parts replacement which may be necessary during the lifetime of the unit.

4.3 Access to dangerous areas

The access to the unit dangerous areas is usually obstructed through protection panels, which are removable, by using a tool. Axial fans

are protected with accident prevention grilles. Centrifugal fans are not protected on the discharge, as they have to be connected to ducts.

In case they have to run without ducts, it is the installer duty to provide protection grilles.

Finned coil, for units not equipped with coil protection grilles, is completely accessible with danger for cuts and abrasions. In these cases

technicians and operators must be aware about this risk.

For all the units which allow access to the cooling piping or to the packaged condensing coils with fins, without security gratings (optional)

or closing panelling, the following precautions must be taken:

-mark the areas with contact risks.

-apply warning signs.

The danger zone must be of a suitable size to avoid any contact, even accidental contact.

In the presence of safety valves without relevant remote controls, the operating area must be of a size which considers a range of action

of the discharge flow of 3 metres.

Thermocold declines any responsibility for damage to things and unauthorised personnel in case of absence of clear and static limiting

systems of the risk areas and of the relevant warning and danger signs.

4.4 General precautions

The operator must only intervene on the unit commands; he or she must not open any panels except for the one which gives access to the

command module.

The installer must only intervene on the connections between the plant and the machine; he or she must not open any machine panels nor

carry out any commands.

The following precautions should be made when approaching or working on the unit:

• do not wear jewellery, baggy clothes or any other accessory which can get caught up.

• Use appropriate protection (gloves, glasses etc.) when using an open flame (welding) or compressed air.

• If the unit is located in a closed environment, wear hearing protection.

• before disconnecting, removing tubes, filters, joints or other line parts intercept the connection tubes, empty them until the pressure

reaches that of the atmosphere.

• do not use your hands to check for possible pressure losses.

• always use tools which are in good condition; make sure the instructions have been fully understood before using them.

• make sure that any tools, electrical cables or other loose objects have been removed before closing the unit and starting it up again.

MULTIFUNCTIONAL UNITS RLC – Installation and maintenance manual

MUMRLCHEAT_REV01_1012_UK

Pag. 9 di 31

4.5 Precautions against risks due to the refrigerant

Safety data

R 410 a

Toxicity

Not important

Risks for skin touching

Splashes or sprinkles can cause chill burns. The risk of absorptions through the skin is not

relevant.

Those refrigerants could take some lightly irritating effects and in lliquid stage they have a

strong skinning effect. In this case it is necessary to rinse with fresh water the

contaminated parts of the skin

The refrigerant in liquid stage in contact with wet fabries cause freezing and adherence to

the skin. In this case it is necessary to put off the contaminated clothes to avoid freezing.

Please contact a doctor in case of irritation of the contaminated parts.

Risks for contact with the eyes

Vapors don’t take any effect. Splashes or sprinklers can cause chill burns. In those cases it

is necessary to rinse the eyes with water or with solution for ocular washings for 10

minutes. The intervention of a doctor is needed.

Risks for ingestion

Should it happen, it causes chill burns. It does not cause vomiting. The person must be

kept awake. It is needed to rinse the mouth with fresch water and to drink almosto 0,25

liters. The intervent of a doctor is needed.

Risks for inhalation

High concentration of vapours in air can lead to anaesthetic effects up to a loss of

conscience. Long exposures could give rise to cardiac arrhythmia and sometimes even to

death.

High concentrations can create a reduction of oxygen in air, with consequent possibility of

suffocation. Should it happen the person must be taken to the open air and let him to take

a rest.

Administer oxigen if needed. In case the breathing has interrupted or become irregular, it

is necessary to apply the artificial breathing. In case of cardiac arrest a heart massage

must be applied. Contact a doctor immediately.

Conditions to avoid

Use in presence of exposed flames, and of elevates levels of humidity.

Dangerous reactions

Possibility of violent reactions with the sodio, the potassio, the barium and with other

alkaline substances, incompatible materials and all the alloys containing more than 2% of

magnesium.

Protection wearing

Wear protection apparel and self respirators. Insulate the source of the loss, if this

operation can be done in safety conditions.

Behavior in case of losses or escapes

Small quantitative of refrigerant escaped at liquid state can be allowed to evaporate only if

the room is well ventilated. In case of great losses ventilate the room immediately. Plug

the loss with sand, soil or other absorbent material; avoid that the liquid refrigerant can

enter in water-drainages or losing pools.

Dismantlement

The best procedure is the recovery and the recycle. If this is not possible the refrigerant

must be conferred to an accredited system for its destruction in order to neutralize acid

and toxic by-products.

MULTIFUNCTIONAL UNITS RLC – Installation and maintenance manual

MUMRLCHEAT_REV01_1012_UK

Pag. 10 di 31

4.6 Precautions against residual risks

Prevention from risks due to the command system

• make sure the instructions for use have been understood before carrying out any work on the control panel.

• always keep the instruction manual close at hand when working on the control panel.

• start up the unit only after having certified that it is correctly connected to the plant.

• inform the technician promptly of any alarms which appear on the unit.

• do not reset the alarms to manual restart without having first identified the cause and removed it.

4.7 Prevention against residual mechanical risks

• install the unit in accordance with the provisions of the following manual.

• carry out all the maintenance operations provided for by this manual regularly.

• wear a protective helmet before entering inside the unit.

• before opening a machine panel make sure that it is firmly connected by means of a hinge.

• do not touch the air condensation batteries without having first put on protective gloves.

• do not remove the protections to the moving parts while the unit is running.

• before restarting the unit make sure that the moving part protections are in the correct position

4.8 Prevention against residual electrical risks

• connect the unit to the mains in accordance with the provisions of this manual.

• carry out all maintenance operations regularly.

• before opening the control panel disconnect the unit from the mains by means of the external knife switch.

• check that the unit has been earthen correctly before starting it up.

• control all the electrical connections, the connection cables paying particular attention to the state of isolation; replace the cables which

are clearly worn or damaged.

• carry out periodic checks of the wiring inside the panel.

• do not use cables with an inappropriate section or flying connections not even for a limited period or in an emergency.

4.9 Prevention against residual risks of a different nature

• The residual risk due to pressure are mainly coming from non functioning of the safety devices. To prevent them it is necessary to follow

the checks and replacements as following indicated (§12.1 and 13)

• To protect from safety devices exhausting it is not allowed to remove the protections while the unit is in operation and to approach the

unit without wearing the right protections. In case of accidental contact with refrigerant due to the safety valves exhaust it is necessary to

follow the above indicated (§2.5)

• carry out the plant connections to the unit by following the indications reported on the following manual and on the panels of the unit

itself.

• if a part is disassembled, make sure that it is correctly reassembled before restarting the unit.

• do not touch the discharge line of the compressor, the compressor itself or any other tube or component which is inside the machine

without putting on protective gloves.

• keep a fire extinguisher which is able to put out fires on electrical equipment near the machine.

• on units installed inside, connect the refrigerant circuit shut off valve to a network of tubes which are able to lead the possible spillage of

refrigerating fluid outside.

• eliminate any fluid loss inside or outside the unit.

• collect the discharge liquid and clean up any possible oil leakage.

• periodically clean the compressor casing of the accumulated dirt deposits.

• do not keep inflammable liquids near the unit.

• do not dispose of the refrigerant fluid and the lubricating oil in the environment.

• welding should only be carried out on empty tubes; do not approach the tubes containing refrigerant fluid with flames or other sources

of heat.

• do not bend or strike tubes containing pressurised fluids.

4.10 Precautions to be observed during maintenance operations

Authorised technicians may only carry out maintenance operations.

Before carrying out any maintenance the following must be performed:

• isolate the unit from the mains electricity by using the external knife switch.

• place a notice on the external knife switch which says “do not use - maintenance in progress”.

• make sure that any possible on-off commands are disabled.

• use appropriate safety equipment (helmet, isolating gloves, protective glasses, safety shoes etc.).

If measurements or controls must be carried out which require the machine to be running the following observations must be followed:

• operate with the electrical panel open for as short a time as is possible.

• close the electrical panel as soon as the individual measurement or control has been carried out.

• for units which are located outside, do not carry out interventions in dangerous atmospheric conditions such as rain, snow, fog etc.

The following precautions should also be taken at all times:

• never dispose of fluids contained in the refrigerant circuit into the environment.

• when replacing an EPROM or electronic card always use appropriate equipment (extractor, anti static bracelet, etc.).

Loading...

Loading...