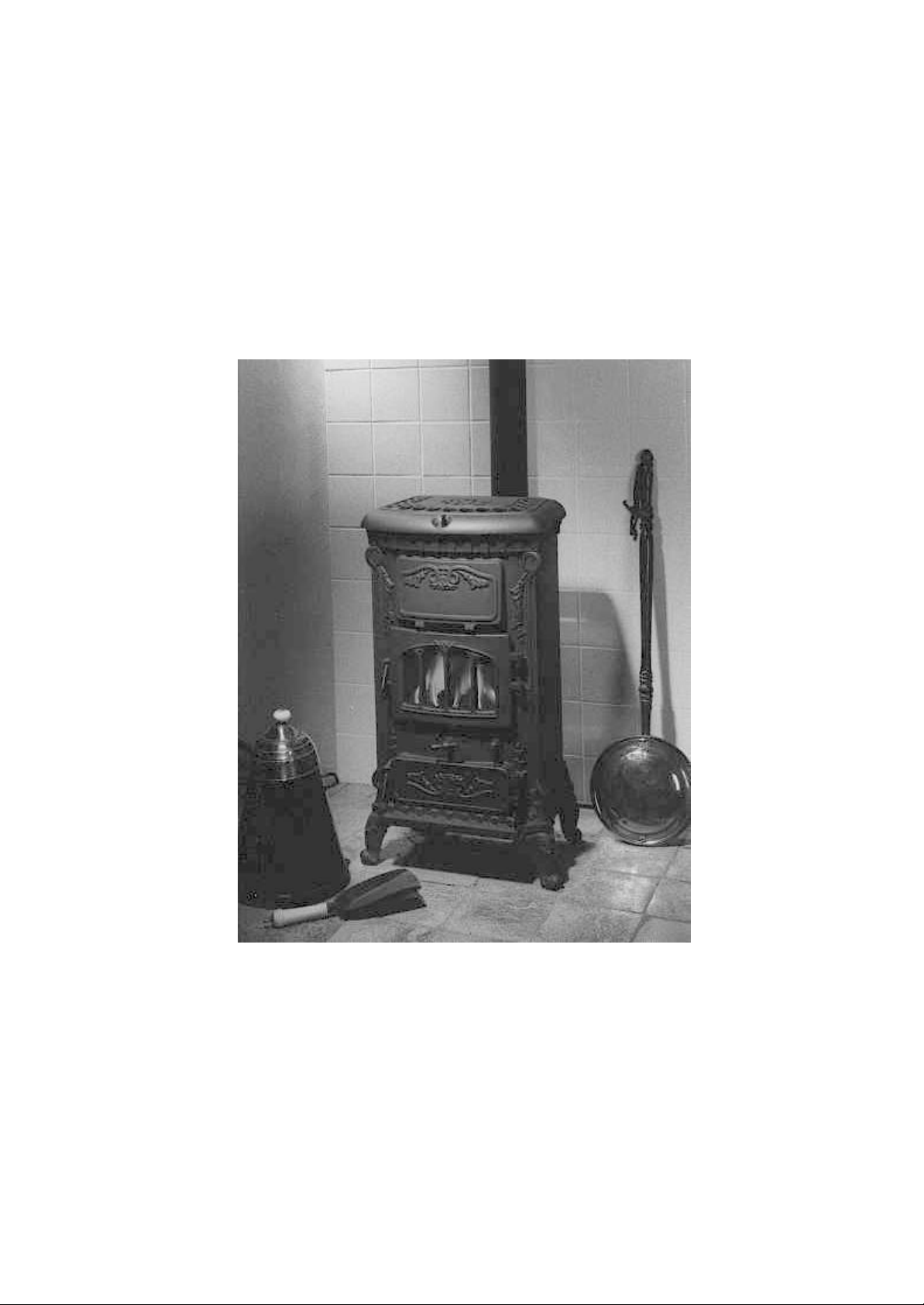

Thermocet Rose 6 NAT, Rose 6, ROSE Classic Series, Rose 9, Rose 9 NAT Operating And Installation Instructions

Page 1

Page .1

Operating and installation instructions

ROSE Classic

Page 2

Contents

1. General Page 3

1.1. Lighting the stove for the first time

1.2. Guarantee

1.3. Contents of the package

2. Operating instructions

2.1. Lighting

2.2. Thermostatic burner Page 4

2.3. Handcontrolled burner

2.4. Turning off the stove

2.5. Maintenance

3. Downdraught cutout

4. Installation instructions Page 5

4.1. General

4.2. Preparations for installing the stove

4.3. Installing the stove

4.4. Fitting the decorative coal effect Page 6

4.5 Thermostat probe

5. Technical data Page 7

6. Illustrations Page 8 till 10

Page .2

Subject to alterations

(0/20022006)

Page 3

Page .3

Congratulations on your purchase of this stove which will give you many years of excellent service. Read these instructions carefully before installing and commissioning the stove. Keep

these instructions in a safe place. In the event of a fault, please state the type and serial number.

1. General

On delivery, check the unit carefully for damage during transport. If the unit is damaged in any way, please

inform your supplier immediately, giving full details.

1.1. Lighting the stove for the first time

Your stove is finished with a special coating which is resistant to very high temperatures. When using the

stove for the first time, run in at full output for an hour or two, ensuring that the room is well ventilated. As

the heat-resistant finish burns in, you may notice a smell or vapour. This is completely harmless.

Any deposits on the glass can be removed with a proprietary glass cleaner.

1.2. Guarantee

Fill in your guarantee card and return it within eight days o f purchase. Failure to do so will invalidate your

guarantee.

The type and serial number of the stove are given on the dataplate on the back side of the stove.

1.3. Contents of package

1 x Fully assembled appliance

2 x front leg nr. 62

2 x rear leg nr. 63

1 x Operating and Installation instructions

1 x Guarantee card

2. Operation instructions Rose ( See page 9 )

The Rose has two burners. The rear burner is controlled by the thermostat – you select the setting and the

modulating thermostatic control maintains the correct temperature. The front burner is controlled manually – you select the setting and the burner continues to operate at that setting until you reset the control.

The control panel is located at the bottom of the appliance behind the “ash” pan cover.

A: Gascontrole

B: Manual valve

C: Thermostat knob

D: Ignition knob

2.1. Lighting

• Turn on the tap in the gas pipe feeding the appliance.

• Pull out the manual control and turn it fully clockwise (closed) to check that the front burner is

turned off.

• Turn the thermostat control to PILOT, depress the control and keep it pushed in.

• Operate the ignition button until you hear the click of the spark ignition.

• Check through the glass panel that the pilot is burning. If necessary, click the ignition button again

until the pilot lights.

• Once the pilot is lit, keep the thermostat control pushed in for a further 30 seconds and release.

• If the pilot goes out, wait 5 minutes and repeat the procedure.

• The rear burner is ignited by turning the thermostat control to the desired position (1 = lowest setting,

6 = highest setting).

• The front burner is lit by pulling out the manual control and turning it to the left to the desired flame

height.

Page 4

Page .4

Note

At a room temperature of 10°C or above, the “1” position on the thermostat control is the standby position.

However, if the room temperature falls below 10°C, the rear burner will operate even with the thermostat

set at the “1” position until the room temperature reaches 10°C.

Warning

If the pilot goes out, wait at least 5 minutes before relighting it.

2.2. Thermostatic burner

The modulating thermostatic control system ensures that the temperature set on the thermostat control is

accurately maintained. When the thermostat control is adjusted, the burner will operate at maximum output

for a time while seeking the optimum level. If the room temperature drops, the burner output will increase

until the correct temperature is achieved. This is controlled automatically by the thermostat.

2.3. Handcontrolled burner

The front burner is operated by the manual control. To turn on the burner, pull out the control and turn it to

the left. Turn off the burner by turning the control to the right, pulling it out and releasing. Then check that

the front burner is out.

2.4. Turning off the stove

• To turn off the stove completely, turn the thermostat control to the OFF position and depress the con-

trol. This extinguishes the pilot.

• If the stove is unlikely to be used for some time, we advise to turn off the tap in the gas supply to the

appliance as well.

2.5. Maintenance

• The stove may be dusted with a soft moisted cloth. If a liquid is spilt on the stove it should be turned off

immediately and, once it has cooled down, any marks should be removed with a mild soap solution.

Abrasive cleaners must not be used!!!

• It is advisable to have the stove and flue checked and cleaned by a qualified installer before each heat-

ing season. If the special glass panel is broken or cracked, have it replaced before you use the stove

again. Do not operate the stove if the glass is broken or cracked.

Warning

The stove can reach very high operating temperatures. DO NOT TOUCH. Adequate precautions must be

taken to ensure that children, invalids etc. cannot come into contact with the stove when it is in operation.

Stoves must no be installed against or near flammable materials.

3. Downdraught cutout

The appliance is fitted with a temperature-activated downdraught cutout which turns off the pilot (and

therefore the main burner) in the event of leakage of combustion products from the draught stabilizer. This

safety device must not be disabled.

Operation:

The sensor is a thermostat which breaks an electrical contact when a set temperature is exceeded. This

breaks the thermocouple circuit, causing the control unit to cut off the gas supply to the main burner and

pilot. The pilot can be reignited after waiting 5 minutes for the sensor to cool. If the downdraught cutout

trips again, have the flue (chimney) checked by a qualified installer. The system will not operate correctly

if the downdraught cutout is disabled or modified in any way. Only original ThermoCet spares should be

used to replace defective components. This also applies to fixings and wiring.

Page 5

Page .5

Tripping of the downdraught cutout may be due to:

• A poor joint between the stove and the flue.

• Complete or partial blockage of the flue by bricks etc.

• Inadequate flue draught.

• In open-plan layouts, the effect of a high -power kitchen extractor fan.

If in doubt, consult your installer!

4. Installation instructions

4.1 General

The appliance should only be installed and connected by a qualified installer in accordance with the current

gas regulations and local and National Building standards.

This stove operates at high temperature and suitable heat-resistant installation materials only must be used.

The stove must not be installed in or against a wall made of flammable material. If the stove is connected

to a flue which has previously been used for burning wood, coal or oil, the flue must be thoroughly inspected and cleaned.

A flue draught of approximately 0,5 mm w.g. (measured at full output) should be adequate. If the flue

draught exceeds 2 mm w.g., provision should be made for reducing the draught. If the room is effectively

draughtproofed or is fitted with an extractor fan, suitable apertures must be provided to equalise the pressure between inside and outside, so that the operation of the flue is not affected by low pressure in the

room.

When installing gasstoves we advise in general to connect the stove to a full stainless steel or aluminium

chimney liner ∅ 100 mm. This to avoid possible problems with the downdraught cutoutsystem.

4.2. Preparations for installing the stove

Assembly of the legs of the stove

The stove is placed on a pallet without the assembled rear and front legs.

The legs have to be fitted on the inside of the lower cast iron mounting plate. For assembly carefully place

the stove horizontal. The necessary M6-bolts are already in place. Legs with nr. 63 should be mounted on

the backside, nr. 62 on the frontside of the stove.

4.3. Installing the stove

• Place the stove as close as possible to the chimney; connect the stove to the chimney with a short non -

corrosive connection. Following the current Gas and Building Regulations.

• The gas pipework can now be fitted. Make sure that the gas connection is not under stre ss, which might

damage the gas control system.

Check for leaks

Use soapy water or a leak detector to check the gas connection to the control unit.

Page 6

Page .6

4.4 Fitting the decorative coal effect ( see page 7 )

• Loosen the two screws on the leftside of the door knob.

• Open the door and take out the packed ceramic coal set, carefully unpack the coal sets.

• Place the ceramic coal sets with care. Mount on the front lugs and gentle lean backwards on to the rear

mounting plate; which is about 8 cm above the burner unit.

• Close the door and fix the two screws. Important: always take care that the door is fixed tight before op-

erating the stove.

• Now light the stove according to the Operating Instructions.

4.5 Thermostat probe

The stove is supplied with a remote mounting thermostat capaillary probe. The probe should be placed in a

position which will allow it to operate from the temperature of the room not the appliance.

Happy heating!

Page 7

5. TECHNICAL DATA

1. Screws

2. Doorknob

3. Glass door

4. Lower “ash” pan door

Page .7

1

2

3

4

Situation of ceramic coal sets

Page 8

Page .8

GASCONNECTION

Page 9

Page .9

Page 10

Page .10

Rose 6 NAT

GAS I2H

Rose 6

LPG I3+

Rose 9 NAT

GAS I2H

Rose 9

LPG I3+

ROSE Classic

Pre -pressure

Burner pressure

Nominal input

Nominal output

Flue connection

Gas connection 3/8”G 3/8”G 3/8”G 3/8”G

Mbar

Mbar

Kw Hi

kW

φ mm

20 37 20 37

6,3 26,0 10,6 26,0

7,5 8,3 10,9 8,3

6,2 7,1 9,2 7,2

100 100 100 100

Page 11

Important tips for heating with gas -fired or wood-fired stoves and fireplaces.

Prevent discolouration of walls and ceilings!

There are always dust particles in the air in every living space, even if it is regularly vacuumed! These particles are clearly visible in

rays of sunlight and they will not bother you as long as the concentration of particles in the air remains low. The indoor climate can only

be described as bad if these particles are floating through the room in larger quantities for any reason whatsoever and, above all, if the

air is additionally polluted by soot and tar particles caused by the burning of candles or oil lamps for example, and by smoking cigarettes or cigars! In a heated living space, cooled air slowly streams across the floor to the combustion appliance. This air is heated in the

convection system of the stove or fire, causing a fast -rising column of warm air to develop, which then spreads throughout the room

again. As a consequence, this air always contains dust and other pollutant particles that will leave deposits on cold and often damp surfaces. This is potentially a particular problem in new buildings that are not yet dry (construction moisture). An unwelcome result of this

phenomenon could be discolouration of walls and/or ceilings!

How can you prevent these problems?

If the gas-fired or wood-fired appliance is fitted with insulated covering, one of the following materials should only be used:

§ Loose white insul ation wool (heat resistant to 1000°C)

§ Rocktherm 180.012 insulation wool (700°C) from Rockwool, or the equivalent

§ Other min eral insulation wool without binding agents (synthetic resins) or water-repellent substances (mineral oils).

Wait at least 6 weeks before firing a newly-bricked chimney or after renovations, since the construction moisture must have disappeared

completely from walls, floor and ceiling. The room where the appliance is located must be well-ventilated and the required ventilation

must be in compliance with the stipulations of the local Buildings Decree. Use candles and oil lamps as little as possible and keep the

wicks as short as possible. These two “atmospherics” provide considerable quantities of pollutant and unhealthy soot particles in your

home. Smoke from cigarettes and cigars contains tarry substances which will also leave deposits on colder and damp walls when heated.

If the interior climate is bad, this phenomenon may also occur above radiators and lighting fixtures and at ventilation grilles, although to

a lesser degree.

This section to be kept by the customer This section to be returned by the customer (see reverse)

GUARANTEE CERTIFICATE

Type of fireplace/heating appliance

Model

Serial number

Design

Name of customer

Street

Postcode, town/city

Telephone

Date of purchase

Name of supplier/installer

Street

Postcode, town/city

Signature and stamp Supplier/Installer

REGISTRATION CARD

Type of fireplace/heating appliance

Model

Serial number

Design

Name of customer

Street

Postcode, town/city

Telephone

Date of purchase

Name of supplier/installer

Street

Postcode, town/city

Signature and stamp Supplier/Installer

Page 12

GUARANTEE CONDITIONS

1. All appliances are supplied under a guarantee against material and manufacturing errors. The guarante e is limited to a maximum of the supply of a replacement com ponent and only applies if the instructions for installation and use enclosed with the appliance have been followed, and if the product is being used under normal con ditions in the dealer’s assessment.

2. There is a five year guarantee on fire refractory clay, with effect from the date of purchase. Shrinkage cracks and discolouration after heating are not covered by the

guarantee.

3. There is a five-year guarantee on cast iron fires, cast iron stoves and cast iron recessed fires. A two-year guarantee is given on components of these appliances, such

as ceramic sealants, nuts, bolts, screws, washers, mastic, knob springs, bearings, fans, fireguards and sheet metal parts.

4. There is a two-year guarantee on gas appliances, with the exception of thermocouples and fuses. The appliance must have been installed by a registered installer in

compliance with current standards.

5. The guarantee conditions only apply if the attached guarantee card is completely filled in on the date of purchase and returned to the importer within 10 days. This is

also the date of inception of the guarantee.

6. The guarantee lapses if changes have been made to the appliance without the advance knowledge and written permission of BosNed, and when an appliance has been

shipped without sound packaging and transport protection.

7. The following are not covered by the guarantee:

- Defects caused by inexpert assembly and/or treatment.

- Costs of transport, assembly and dismantling.

- Glazing, fire gratings, refractory stones, flue gas baffle plates, heat shields and controllers.

- Paint discolouration which may develop after heating.

- Overheated parts due to faulty installation and/or fitting.

8. In view of the tremendous variations in the possible options for building a chimney, we are unable to give any guarantee regarding the draught of a chimney that

might lead to complaints about smoke. The chimney must be built by a professional and this establishes the guarantee for the proper functioning of this appliance.

9. The dealer/importer will supply a new component free of charge for every component that becomes defective during the guarantee period. The dealer must return the

defective component to the importer, stating date of purchase, type of appliance and serial number.

10. Renewal or replacement of components that fall under the guarantee cannot prolong the total length of the guarantee. The guarantee provides no right whatsoever to

indemnification in the event it is not possible to use the fire.

11. Liability can never be accepted for loss in any form whatsoever sustained by the customer, third parties or their property and caused directly or indirectly by the

product.

12. Complaints will only be dealt with if the customer has met all his obligations, including his obligation to pay.

13. For further provisions, please refer to our Metaalunie and Orgalime conditions, which are filed at the office of the Court in Rotterdam (the Netherlands).

Send the guarantee card to your dealer / importer in a

properly stamped envelope

G U A R A N T E E C A R D

Address;

Postcode ;

Town/city ;

Loading...

Loading...