Page 1

Page 1

OPERATING AND INSTALLATION INSTRUCTIONS

HI-FIRE COLLECTION

BASE UNIT

GREAT BRITTAN-GB

IRELAND-IE

Page 2

Page 2

TABLE OF CONTENTS

1. General Page 3

1.1 Contents of the packaging

2. Safety device Page 4

2.1 Safety

3. Remote control Page 5

3.1 General

3.2 Manual transmitter

3.3 Screen setup

3.4 Time setup

3.5 Setting the desired temperature

3.6 Setting the Timer

3.7 Changing the signal codes

3.8 Controls (AB)

3.9 Possible error messages

3.10 Setting the flame size/ Extinguishing the fire

3.11 Switching the unit off

3.12 Replacing the batteries

4. Manual control Page 8

5. Initial start-up Page 9

5.1 Daily maintenance

5.2 Important tips

6. Installation instructions Page 10

7. Concentric flue system Page 11

7.1 Components of the concentric flue system

7.2 Construct concentric flue system

7.3 Installation instructions regarding existing flues.

7.4 Parts.

7.5 Installation

7.6 Cleaning and maintenance

8. Instructions for the Mertik Maxitrol GV60 and the Remote Control: Page 16

9. Maintenance check-list Page 19

10. Maintenance Page 20

11. Installing the unit Page 21

11.1 Components of the round and flat shaped combustion chamber

11.2 Connection to the gas pipes

11.3 Installing the ceramic wood blocks

12. Options for connecting the concentric flue system Page 22

12.1 Direct exterior wall duct

12.2 Indirect exterior wall duct

12.3 Roof termination without slope

12.4 Roof termination with 45º slope

12.5 Roof termination with 90º slope

12.6 Connection to existing flue pipe

12.7 Installing the restriction plate (O) and (P)

13. Technical details Page 23

13.1 Gas-technical specifications

14. Problems and possible solutions Page 24

Illustrations Page 24 –30

ALL RIGHTS RESERVED.

(0/07012008)

Page 3

Page 3

We hope you really enjoy the warmth of your new gas fire Read these instructions carefully before

installing and using the gas fire. Keep these instructions in a safe place. Always provide the following

information if the gas fire breaks down: model and serial number, which can be found on the unit. Your

purchase invoice is your proof of warranty.

1. General

The entire unit is delivered to you with your choice of mantle and/or accessories. See the installation instructions

for the relevant mantle and/or accessories that are packaged separately from the unit. Check the unit immediately

after delivery to confirm that it has not been damaged during transport. If it is damaged in any way, please

inform your supplier immediately and provide as many details as possible. Your fire has been finished with

special paint that can withstand extremely high temperatures. Allow the fire to burn at the highest setting and

ventilate the room thoroughly during the first hours of use. As the paint is cured, this will cause a non-hazardous smell and/

or some smoke to be emitted

. Any deposit on the heat-resistant glass should be removed immediately using a

fireplace cleaner suitable for heat-resistant glass.

Attention

The unit must be installed, connected and checked by a qualified fitter based on national, regional, and local

standards and regulations. The fitter must inspect the unit for tightness in relation to gas and combustion

products and correct operation of the different components and functions. The flue tube system and the outlets in

the outer wall or roof face must also meet the requirements of the applicable regulations. The unit falls in the

closed unit category, in a set-up location without a fan and with a chimney loss that is greater than 17 % (noncondensing).

Warning

Gas fires become hot when in use. Therefore care should be taken, for example, by keeping children and those

requiring help away from the immediate vicinity of burning fires. Gas fires must not be placed on or against

flammable materials (curtains, etc.).

1.1 Package contents:

1 x Base unit

1 x Wood mixset

1 x Operating and installation instructions

1 x Remote control

1 x Restriction plate and Restriction plate ø 65

1 x Radiation plate

1 x 9 volt battery

4 x AA 1.5V batteries

1 x 45º Bend Ø100/150

Page 4

Page 4

2. SAFETY DEVICE

The unit is fully safeguarded by means of thermo-electric pilot light protection to prevent unforeseen discharge

of gas from the main burner

2.1 Safety

Do not place ceramic burner decoration material or logs against the pilot burner. Ensure the pilot light is able to

burn freely over the main burner. Good ignition of the main burner is only guaranteed if this is the case. Not

adhering to these instructions can lead to dangerous situations.

The unit, complete concentric flue system and flue terminal need to be cleaned and checked annually by a

recognised gas technician/fitter, so the unit continues to operate safely. For additional instructions, see

Chapter 3: Maintenance.

If, for whatever reason, the pilot light extinguishes, you must wait 5 minutes before igniting the pilot light

again.

The unit may not be operated without the glass panel being in place.

It is not permitted to place flammable materials on the ceramic wood inset.

The layout of the main burner with ceramic burner decoration material and wood inset may under no

circumstances be changed or added to.

Light flammable materials, such as nylon clothing or flammable liquids, may not be placed near the unit.

Ensure children and other persons unaware of the operation of a gas unit, are supervised at all times when

near the unit.

Use a fireguard to protect against burns and protection of the children and persons named above.

Page 5

Page 5

3. REMOTE CONTROL

3.1 General

∗ The unit is operated using a radio-controlled remote control. This consists of a manual transmitter and a

receiver. The receiver is connected to the gas control block.

* The receiver and gas control block are located at the bottom of the unit.

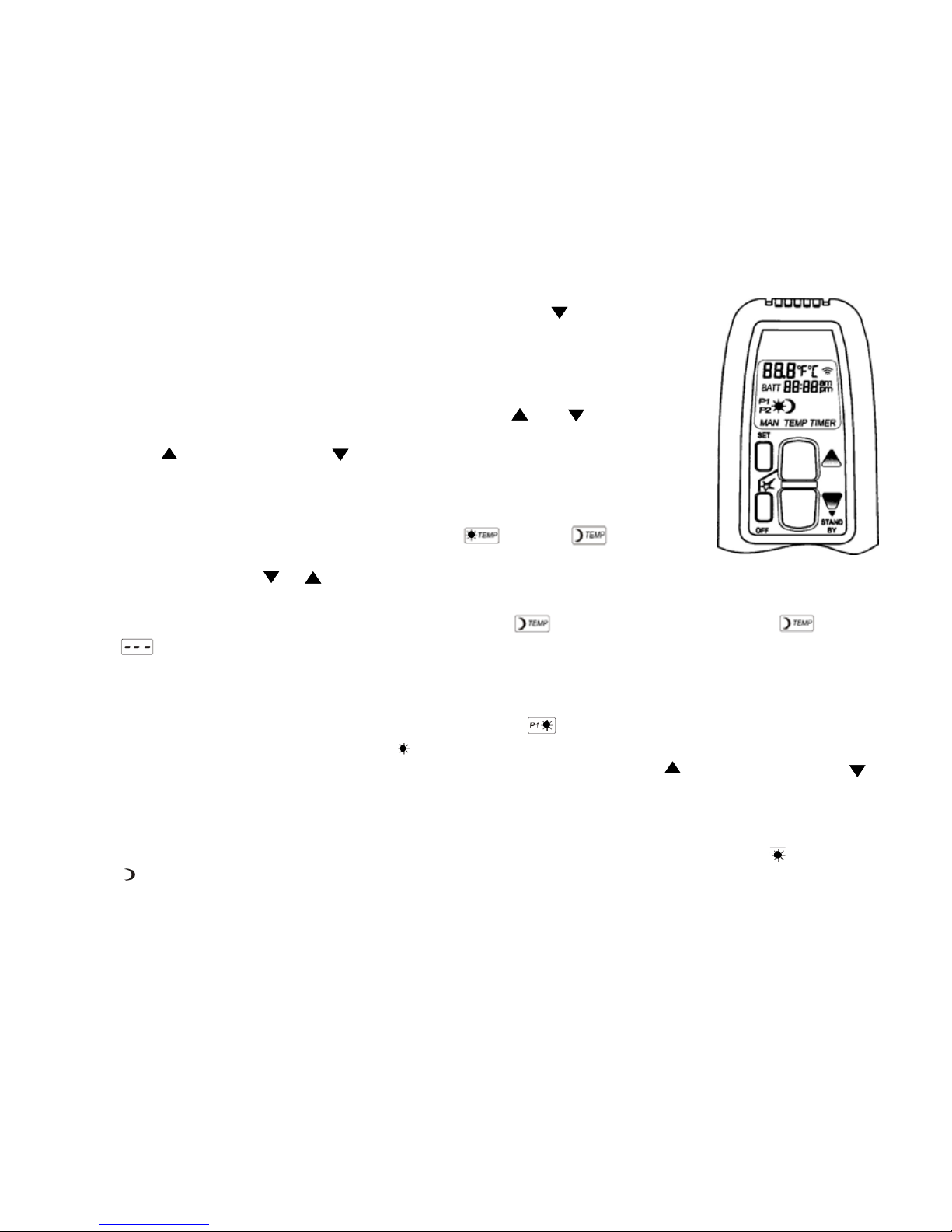

3.2 Manual transmitter

∗ The transmitter uses a radio-controlled signal. The signal code is set at the factory, but can be adjusted if

required. (See 3.7)

3.3 Screen setup

∗ After fitting the batteries, simultaneous pressing of OFF and

allows you to

change from °F (and 12-hour clock) to °C (and 24-hour clock), or vice versa.

∗ Wait a moment or press OFF to return to MAN mode.

3.4 Time setup

* For SET mode or program mode, simultaneously press

and

* The time can be set while the screen is flashing.

* Press to input the hour and to input the minutes.

* Wait a moment or press OFF to return to MAN mode.

3.5 Setting the desired temperature

∗ Press the SET -key briefly to select the required

mode or

∗ Keep the SET –key pressed in until the screen starts flashing.

∗ Subsequently press or to set the required temperature.

∗ Wait a moment or briefly press the OFF -key to select the MAN mode.

∗ If the temperature setting needs to be switched off with (low battery usage), then lower until

appears on the screen.

3.6 Setting the timer: P1 and P2

∗

Press briefly on the SET -key to select the required mode

∗ Keep the SET –key pressed in until P1

(heating period 1) flashes on the screen.

∗ Set the commencement time of the first (1

st

) heating period by pressing on to input the hour, and on

to input the minutes.

∗ Briefly press the SET -key; P1 now appears on the screen. Set the time the first (1

st

) heating period needs

to end.

∗ Press the SET -key again to set the beginning and end of the second (2

nd

) heating period P2 (ON) and

P2 (OFF).

∗ Wait a moment or press OFF to return to MAN mode.

Manual transmitter

Page 6

Page 6

3.7 Changing the signal code

It is possible that there are multiple units within the reach of one transmitter; the

transmitter can be customised for each unit if required. This can be performed by

changing the signal code in the transmitter.

∗ There are 15 other codes that can be set by adjusting the position of one or more

“DIP switches” in the transmitter.

∗ The “DIP switches” are accessible after opening the battery holder of the

transmitter.

∗ Simultaneously press the reset key on the receiver and the key on the

transmitter (approximately 20 seconds).

∗ When the receiver has read the new code, the gas block responds and is ready for use.

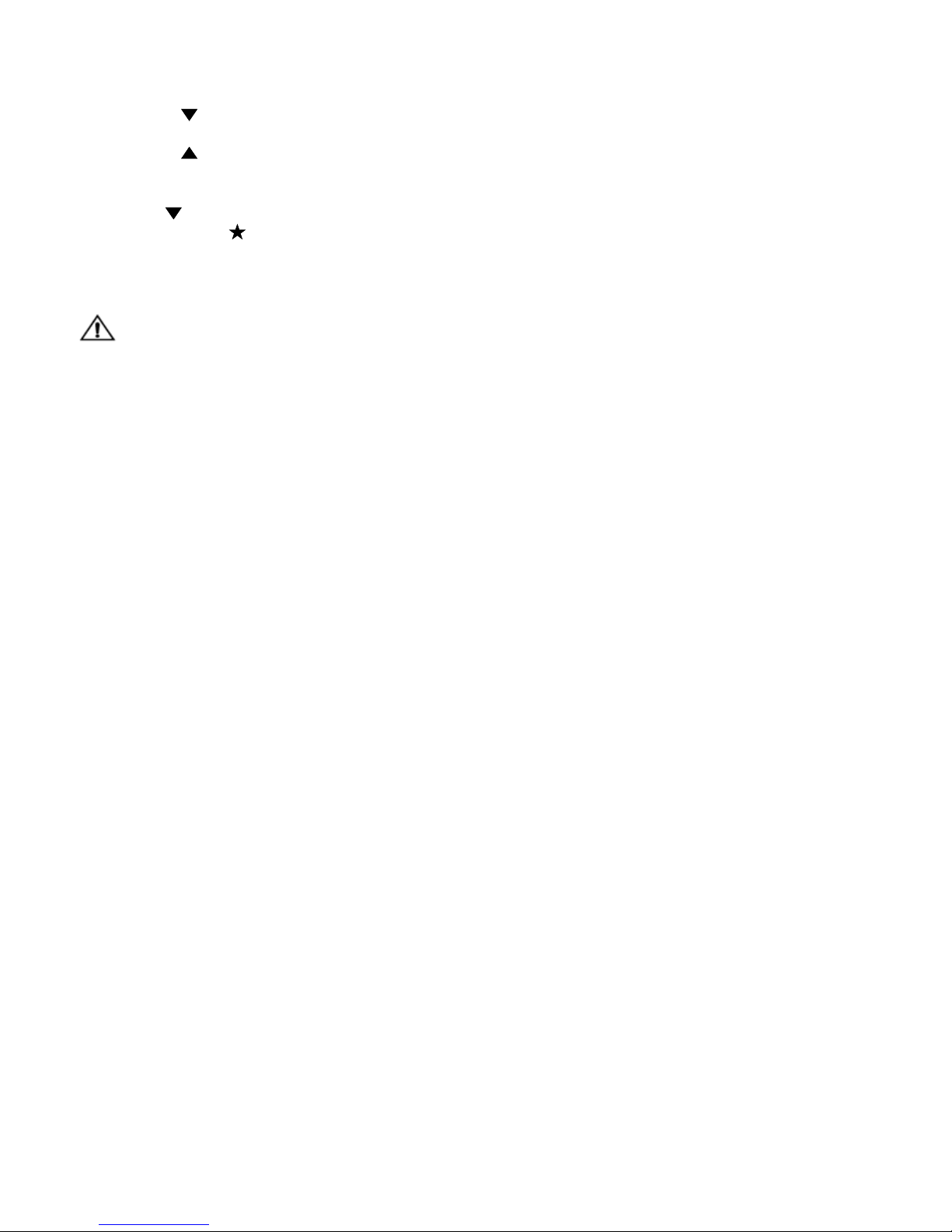

3.8 Controls (Remote Control)

Igniting the fire

∗ Open the gas shut-off cock that has been installed in the gas pipe to the unit.

∗ Press the "O I” switch on the gas control block, into the “I” position.

∗ Turn the operating button on the gas control block, into the ON position.

∗ Simultaneously push the keys

OFF and

on the manual transmitter. A short sound signal will confirm

commencement. Short sound signals will then follow until the pilot flame and main burner are ignited.

After the main burner is ignited, the flame size will automatically move into the maximum setting.

3.9 Possible error messages

∗ Long sound signals during the ignition: Receiver batteries are almost empty. (After this signal occurs, the

unit can be switched on approximately another 10x).

∗ 5 seconds of continuous sound signal: Error message. For example: one of the cables is not connected, the

“

O I” switch is not in the “I” position.

∗ 5x short sound signal: Ignition of the pilot flame and main burner is unsuccessful.

Possible cause: air in the pilot pipes.

Important:

If the pilot light extinguishes, one should wait at least 5 minutes before repeating the aforementioned

steps.

“DIP switches” in the

transmitter battery holder

Piezo connector

(With manual

operation)

Control button

Motor button (in the

maximum setting)

Microswitch

“O I” switch

8-Pole cable receiver

connection

Gas control block (Operating button in ON-position

Page 7

Page 7

3.10 Setting the flame size / Extinguishing the fire

∗ After the burner is ignited, the flame size will automatically move into the maximum setting.

∗ Press to reduce the flame size and turn off the burner.

(Extinguishing the fire: “

STAND BY”). (Pressing the key for a short time gradually reduces the flame.)

∗ Press to increase the flame. (Pressing the key for a short time gradually increases the flame.)

3.11 Switching the unit off.

∗ Press

to reduce the flame size and turn the burner off (“

STAND BY”).

∗ Then press the OFF key to turn the entire unit off, including the pilot flame.

∗ If the unit is not used for an extended period of time, you can turn the "O I” switch, on the gas control

block, into the “

O” position, in order to save battery life.

∗ In this case, it is also recommended you close the gas shut-off cock in the supply line.

Important: If, for whatever reason, the pilot light extinguishes, you must wait 5 minutes before igniting

the pilot light again.

Malfunction

∗ If the signals from the manual transmitter are not received adequately by the receiver, this may be caused

by:

∗ Flat batteries: replace the batteries.

∗ An electronic problem: can be solved by pressing the "RESET” key on the receiver.

∗ Contact your fitter if the unit regularly turns off.

3.12 Replacing the batteries

∗ The batteries of the manual transmitter and receiver have a life span of approximately one year. The use of

alkaline batteries is recommended.

∗ The batteries need to be replaced when the following occur:

1. Manual transmitter: BATT appears on the display.

2. Receiver: long sound signals can be heard during the ignition.

1. Manual transmitter:

∗ Open the small lid on the back.

∗ Carefully remove the 9V block battery and loosen the battery from the contact holder. Do not pull the

wires!

∗ Connect the new battery and place it back into the transmitter. Close the lid.

2. Receiver:

∗ Carefully remove the entire receiver from the holder.

∗ Slide the small lid open.

∗ Remove the batteries from the battery holder.

∗ Place 4 new 1.5V batteries (type LR6 or AA) in the battery holder in the indicated manner. The spring

always needs to be against the minus (-) pole of the battery.

∗ Close the lid and place the receiver back into the holder.

Incorrect placing of the batteries can irreparably damage the electronics or power.

Only replace the batteries when the unit is completely turned off.

Page 8

Page 8

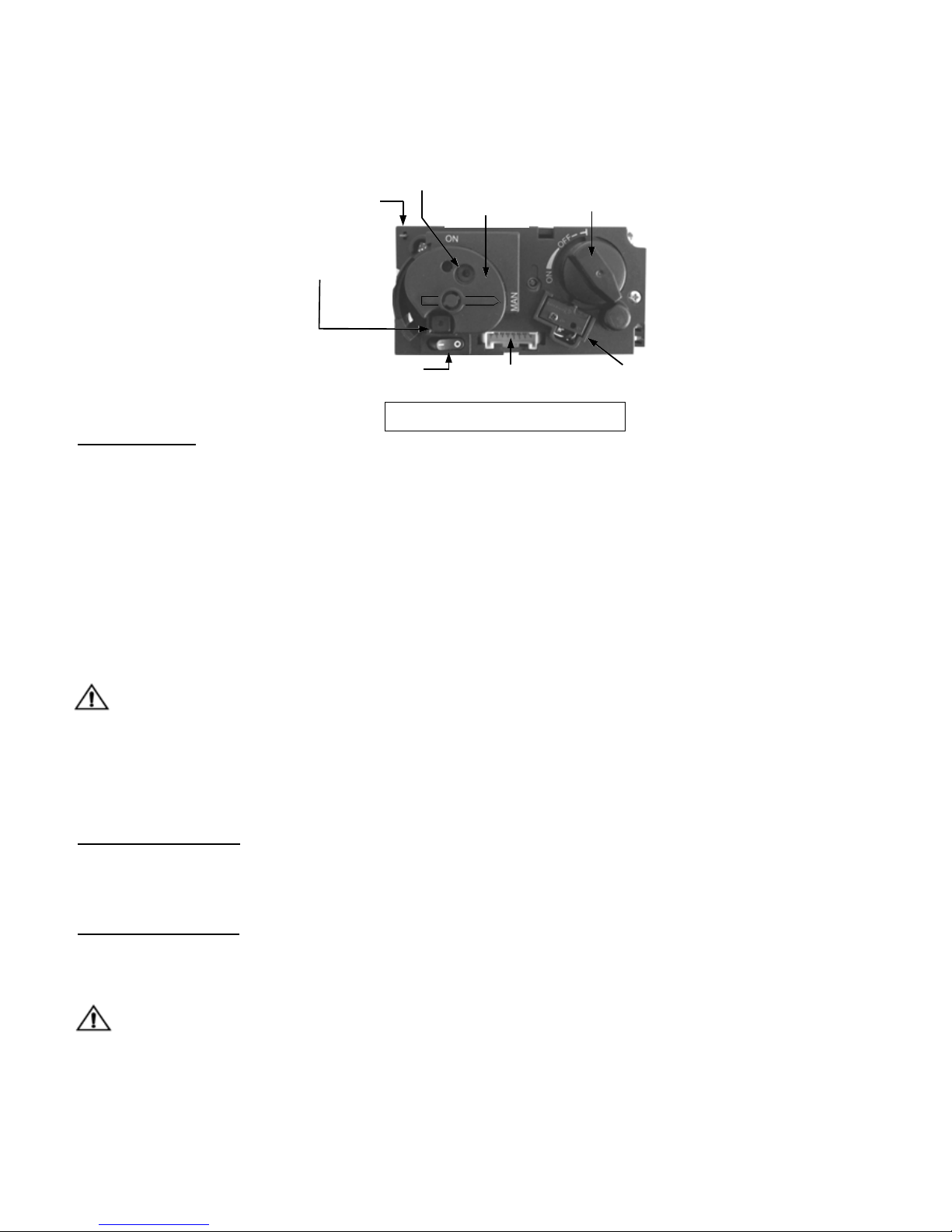

4.0 MANUAL CONTROL

The unit may be operated by hand if there is a defect in the remote control. To do so, the ignite (piezo)cable of

the receiver must first be removed and carefully slid into the piezo connector on the gas control block.

Igniting the fire

∗ Open the gas shut-off cock that has been installed in the gas pipe to the unit.

∗ Press the "O I” switch, on the gas control block, in the “I” position.

∗ Turn the motor button, on the gas control block, completely to the right. The button will make a "click”

sound.

∗ Turn the operating button on the gas control block, into the “MAN” position. A metal circle in the

operating button will become visible.

∗ Push the metal circle inwards. For example, with a pen. Gas will now flow to the pilot flame.

∗ While keeping the metal circle pressed down, press the (square) piezo button (along the “O I” switch)

several times to ignite the pilot flame. You will be able to see whether the pilot flame is burning through

the glass window.

∗ If the pilot flame is alight, keep the metal circle pressed down for another 10 seconds and then let go.

Important: If the pilot light extinguishes, one should wait at least 5 minutes before repeating the

aforementioned steps.

∗ Turn the operating button to the ON position. The burner may or may not ignite, depending on the position

of the motor button.

∗ By turning the motor button to the required setting to the left, the burner will ignite and the flame size can

be adjusted.

Extinguishing the fire

Turn the motor button, on the gas control block, completely to the right. The button will make a "click” sound.

The burner will turn off. The pilot flame continues to burn.

Switching the unit off

Press the "O I” switch, on the gas control block, in the “O” position. The pilot flame will extinguish.

If the fireplace is not used for an extended period of time, we recommend closing the gas shut-off cock in the

supply line.

Important: If, for whatever reason, the pilot light extinguishes, you must wait 5 minutes before

igniting the pilot light again.

Piezo Button

Piezo connector (With

manual operation)

Operating

button

Motor button (in the

maximum setting)

Microswitch

“O I” switch

8-Pole cable receiv er

connection

Small metal circle for

manual operation of the

ignition

(Control button in Manual position)

Page 9

Page 9

5. INITIAL START-UP

The unit has a layer of heat-resistant varnish that resists very high temperatures. An unpleasant smell may

develop in the first hours after starting the unit due to burning in of the varnish; however, this is not dangerous.

To accelerate this process, allow the unit to burn at the highest setting for several hours and ventilate the area

well. After the first time the unit is turned on, a light deposit may form on the inside of the window. This is due

to the varnish hardening. After the fireplace has cooled down, this deposit can be removed using a fireplace

glass cleaner or ceramic hotplate cleaner.

5.1 Daily maintenance

∗ Avoid having a lot of dust and cigarette smoke, candle and oil lamp particles in the air of your home.

Heating of these particles through the convection system of the unit, can lead to discolouring of walls and

ceilings. It is therefore advisable to ensure the area containing the unit is always sufficiently ventilated.

Regularly remove any dust that has settled behind the operating lid with a vacuum cleaner.

If the glass is broken or cracked, it should be replaced immediately by a recognised fitter before the

unit is used again.

∗ The unit must be switched off immediately if something is spilt on it. It should only be cleaned once the

unit has cooled down. Never use abrasive, aggressive cleaning products or fireplace cleaner; only use a dry

cloth that does not give off fluff.

∗ Your local specialised dealer will be able to provide you with spray cans containing heat-resistant varnish,

so that small stains or damages may be touched-up during annual maintenance.

5.2 Important tips for gas heating or wood fuelled units and fireplaces.

Prevent discolouration of walls and ceilings!

There are always particles in the air in each living area even if the area is vacuum cleaned regularly!

These particles are easily visible when the sun streams in. This issue will not arise if the amount of

particles in the air is limited. If these particles are present in greater quantities and particularly if the air is

contaminated by soot and tar particles, for example, through the burning of candles or oil lamps and

cigarette or cigar smoke, then we can speak of a poor inner climate! Cooled air slowly flows over the floor

to the heater in a heated living area. This air is heated in the convection system of the fireplace or heater,

resulting in a quickly rising column of air that subsequently spreads through the room again. This means

there is always dust and other polluting particles depositing on cold and often damp surfaces. This issue

occurs especially in a new building (building damp) that is not yet dry. An undesirable consequence of this

phenomenon could be discolouration of walls and or ceiling!

How can this problem be avoided?

∗ With a newly built fireplace or following renovation, wait at least 6 weeks before firing up.

∗ The building damp must have disappeared completely from the walls, floor and ceiling.

∗ The room where the unit is located must be well ventilated.

∗ The required air ventilation must be in line with local building regulations.

∗ Limit the use of candles and oil lamps and keep the taper as short as possible.

∗ These two atmosphere creators create considerable quantities of polluting and unhealthy soot particles in

your home.

∗ Among other things, cigarettes and cigars contain tar that will precipitate on cold and damp walls during

heating.

∗ This may occur above radiators and light fittings and with ventilation grilles (if there is a poor internal

climate), although to a lesser degree.

Page 10

Page 10

6. INSTALLATION INSTRUCTIONS

Important

The installation may only be performed

by an authorized person

General instructions

∗ The gas fireplace must be installed, connected and inspected as a closed unit by a qualified fitter, according

to national, regional, and local standards and regulations.

∗ The flue tube system and the outlets in the outer wall or roof face must also meet the requirements outlined

in the applicable standards and regulations.

∗ The temperature of the walls and shelves near the side and back of the unit may not be more than 80°C

higher than the temperature of the environment.

∗ The unit has been approved in combination with the Metaloterm US system number: 0063-CPD-6308 con-

centric flue system Ø100 mm - Ø150 mm, in accordance with European CE standards for gas units, and

may therefore only be applied with this system.

∗ The unit needs to be inspected by the fitter for local gas distribution (gas type and gas pressure) as indicated

on the identification plate.

∗ The instructions are only applicable if the relevant country code is stated on the unit. If this is not the case,

the gas technical information for the relevant country needs to be consulted and modifications discussed

with the manufacturer.

∗ There will be air in the gas pipes when the unit is first used. The gas pipes therefore need to be vented first.

∗ Ignite the heater according to operating instructions and check whether the burner flame is uniform. After

the unit has been used for the first time, you should remove any deposits resulting from convection-curing

of the unit, from the glass window using a glass cleaner for heaters.

Warning:

Never install the unit against or within a flammable wall!

Distance to flammable materials:

∗ With respect to the front, side and top of the unit, a distance of 1000 mm needs to be kept between the unit

and: curtains, floor covering, upholstery and fabrics, and/or other flammable material unless stated otherwise in these instructions.

Distance to non-flammable materials:

∗ The unit needs to be placed a minimum distance of 50 mm from the wall unless stated otherwise in these

instructions.

Important

∗ Construction material for fireplaces and mantles etc., or for an assembly must be made of non-flammable

material. This also applies to floors and ceilings. Never use flammable materials near the unit in compliance with the abovementioned instructions.

Note: Please contact your supplier if you are unsure.

Page 11

Page 11

7. CONCENTRIC FLUE SYSTEM CC

The concentric flue system consists of a 100 mm Ø inner flue concentric with a 150 mm Ø outer flue. These flues

have been set up concentrically; the combustion gases are exhausted through the internal flue while the fresh

combustion air is supplied between the internal and external flues.

7.1 Components of the concentric flue system. ( See Page 27 )

Different connections are possible using the concentric flue system. These are:

Through the roof face and through the exterior wall.

There are various options for mounting the pathway for this system,

however, there are a few important requirements/conditions:

∗ The total vertical duct length allowed may not exceed 12 metres (the sum of the duct length and calculation

lengths for the bends).

∗ The horizontal duct length at the roof outlet should not exceed 5 metres between bends.

∗ 90° bends have a 2-metre horizontal calculation length.

∗ 45° bends have a 1-metre horizontal calculation length.

∗ The outlet can be installed at any point on the roof face or exterior wall (supply and discharge in an

identical pressure area), but must meet applicable regulations.

∗ Duct pathways may not be insulated

Important:

∗ Ensure the restriction plate is mounted in the correct manner, as indicated in these instructions.

∗ The correct restriction plate will provide the unit with the most optimal efficiency, flame image and

combustion.

∗ Mounting an incorrectly placed restriction plate may cause malfunction of the unit.

CC KANAAL SYSTEEM ARTIKEL NR’S

DESCRIPTION MEASURE ( mm ) CODE NR. STAINLES STEEL

A) CONCENTRIC PIPE 1000

500

250

401410100000

401410050000

401410025000

B) CONCENTRIC BEND 45° SET 401420045002

C) WALL BRACKET 401430110000

D) CONCENTRIC BEND 90° 401420090000

E) WALL BAND ADJUSTABLE 401430120000

F) ADJUSTABLE LENGHT 250 401412025000

G) FLAT ROOF PLATE 401450150000

H) LOCKING BAND 401430100000

I) ADJUSTABLE ROOF PLATES (SET) 401450130000

J) FLAT ROOF FLASHING ALUMIN. 401472000000

K) STORM COLLAR / ROSETTE 401470100000

L) HORIZONTAL TERMINAL EXC 401450160000

M) SLOPE ROOF FLASHING 20-45° 401476020000

N) ROOFOUTLET 401450180000

O) SLOOP ROOF FLASHING 5-30° 401474005000

Page 12

Page 12

7.2 Construction of concentric flue system CC

Assembly instructions are provided below:

Direct connection.

∗ The unit can be connected directly to an exterior wall using the exterior wall duct set, taking any hindrance

to the surrounding area into consideration, according to national, regional, local standards and regulations.

Ensure wind pressure on the flue terminal is not too extreme, such as a balcony, flat roof, corners and in

small alleys etc., as this may negatively influence the unit efficiency.

∗ Provide a recess in the exterior wall of around 155 mm (in a flammable wall ensure there is 50mm of extra

space around the outer pipe) and fix the wall duct with the wall plate to the inner side of the wall.

∗ The wall plate of the exterior wall duct must be sealed adequately against the wall on the outside, to avoid

potential moisture and/or flue gas leaks into the living space.

∗ The flue should be cased if necessary. Sufficient fireproof measures must also be taken when the flue is be-

ing mounted along flammable materials.

∗ Determine the position of the unit and the outlet and begin construction of the flue with the connection on

the unit, paying attention to the direction of installation. The inner flue must be installed for draining purposes. Connect the elements by using clamping strips.

Indirect wall connection.

∗ The outlet may also be installed above the exhaust in the wall, taking any hindrance to the surrounding area

into consideration, according to national, regional, local standards and regulations. Ensure wind pressure on

the flue terminal is not too extreme, such as a balcony, flat roof, corners and in small alleys etc., as this may

negatively influence the unit efficiency.

∗ Provide a recess in the exterior wall of around 155 mm (in a flammable wall ensure there is 50mm of extra

space around the outer pipe) and fix the wall duct with the wall plate to the inner side of the wall. The wall

plate of the exterior wall duct must be sealed sufficiently against the wall on the outside, to avoid moisture

and/or flue gas leaks into the living space.

∗ The flue should be cased if necessary. Sufficient fireproof measures must also be taken when the flue is be-

ing mounted along flammable materials.

∗ Determine the position of the unit and outlet and begin construction of the flue with the connection on the

unit, paying attention to the direction of installation and connecting the elements by means of clamp strips.

∗ Mount a 90° bend directly on the wall pass-through and connect with the elements on the unit. Ensure that

all connections are gastight.

∗ The fitted pipe can be used between the bends or when connecting to the unit.

L= 50 - 250 mm. If necessary, use wall brackets to support the flue.

Comments:

The outlet vent may need to be mounted close to the wall in some situations. In this case, the 90° bend cannot be

easily placed. Note that at the location of the 90° bend where the bend has the smallest radius, an oval hole needs

to be created in the wall to ensure good passage.

Page 13

Page 13

Mounting using the roof pass-through option

∗ The flue terminal can be located at any random place on the roof face (supply and exhaust in identical

pressure areas) and must meet the applicable rules and regulations.

∗ A roofing sheet for a flat roof or a roofing sheet lead for sloping tiled roofs can be used for a watertight

duct. Use various bends for the slope, if required. The recess in the roof decking should be 5 cm larger all

around, to ensure sufficient fire resistance.

∗ One needs to take into account the regulation regarding fire resistance between rooms (See national,

regional, local standards and regulations). A casing made of fireproof material (e.g. 12 mm Promatect fire

resistant plate) must be used at 25mm from the outside duct.

∗ Determine the posi tion of the unit and outlet and begin construction of the flue with the connection on the

unit (always 1 metre vertical first), paying attention to the direction of installation! The inner flue must be

installed for draining purposes. Connect the elements by using clamping strips. Ensure the gas tightness of

all connections is correct.

∗ A fitted pipe can be used between the bends or when making the connection to the unit and/or the roof

pass-through. Use 2 wall brackets to support the flue on each floor

G

L

D

A

A

F

K

M

I

C

B

N

K

H

A

N

K

J

G

E

A

H

F

Page 14

Page 14

7.3 Installation instructions regarding existing flues.

Attention.! This flue system must be installed, connected and inspected as a closed unit by a qualified fit-

ter, according to national, regional, and local standards and regulations such as written in this instruction.

for instance : Consider the inner diameter of the chimney as a Concentric Flue system with a outside diameter

ore square of 150 mm with a maximum of 200 mm witch in be placed a flexible tube of Ø1 00 mm.

The inner tube of the chimney itself must not be provided with a grate ore ells what influence the flue. Inner diameter ore square bigger than 200 mm can be provided with a flexible tube Ø 150 mm and a flexible tube of

Ø 100 mm within the flexible tube Ø 150 mm (combination). Other situations in consultation with your supplier

ore manufacturer

.

Instructions

The flue gas exhaust system must be built in accordance with national rules and regulations and the instructions

of the manufacturer as specified in the documentation and installation instructions. This documentation will be

supplied free of charge on request.

7.4 Parts

Check all parts for damage before commencing the installation. You will require the following parts for converting a brickwork duct to a concentric duct connecting to a CC duct system (see page 15, figure A):

1. Gas-fired fireplace with a maximum nominal power of 10 kW

2. Concentric duct

3. Mounting plate inside, square 300

4. Single-wall and round slider 97

5. Parkers (4 units)

6. Flexible hose, stainless steel 316 L, single-wall and round 100 /107

7. Hose bracket, stainless steel, ranging from approx. 90 to 165

8. Existing brickwork duct

9. Mounting plate on the roof, square 300

10. Clamping strip (supplied with 11)

11. Roof pass-through

Note: The renovation/sanitation set consists of parts 3, 4, 5, 7, and 9.

7.5 Installation (See page 15, figure B)

•

Guide the flexible hose (6) through the existing duct (8).

• Attach the slider (4) to the bottom of the flexible hose and secure this in place using two parkers (5).

• Keep the bottom of the slider at the same height as the bottom of the duct or ceiling. Shorten the flexible

hose to approximately 100 mm above the chimney coping.

• Attach the mounting plate to the flexible hose on the roof (9), clamp it with a hose bracket (7) and secure it

in place using a parker (5).

• Attach the mounting plate to the chimney coping watertight on the roof (9) using silicone sealant and

stainless steel screws.

• Install the roof pass-through (11) and secure it in place using the supplied clamping strip (10).

• The slider (4) will protrude approximately 100 mm underneath the duct or ceiling after installation.

• Attach the mounting plate inside (3) gastight against the bottom of the structural duct or against the bottom

of the concrete floor using silicone sealant and screws.

• Position the unit (1) in accordance with the instructions of the unit manufacturer.

• Install a minimum of 1 metre of concentric duct type US (2).

• Extend the concentric duct using sections (2) up to a minimum of 100 mm in the structural duct. Finally,

turn the clamping strip by hand in the mounting plate inside (3).

7.6. Cleaning and maintenance.

The unit must be cleaned and checked every year by your dealer. The Concentric flue system must be cleaned

every 2 years.

Check the following:

1 The seal of the gas combustion products and combustion air supply circuit.

2 Correct operation of the gas control block and ignition of the burner.

Page 15

Page 15

A

B

Page 16

Page 16

8. Instructions for the Mertik Maxitrol GV60 and the Remote Control:

Ensure that the fuel supplied to the unit is clean and free from particles and moisture.

Before a gas supply pipe (new or existing) is connected to the main gas pipe at the gas meter and to the gas

control block of the unit, clean and dry compressed air needs to have been blown through it. Cut copper

pipes as well as aluminium pilot pipes must be debarred and blown clean before they are connected. The

dust filter at the connection to the gas control block will only filter out the coarsest dirt from the system.

Fine particles are still able to reach the inside and may damage and/or adversely affect regulation in the gas

control block.

Heat, moisture and dust are a threat to all electronic components

Protect the electronic gas control until all construction, plastering and paintwork has been completed. If

such work cannot be avoided, then protect the control against dirt and moisture penetration by using, for

example, plastic film.

Warning

Electronic components will become permanently faulty when exposed to temperatures higher than 60°C.

Standard AA batteries will crack open at temperatures >54°C and the battery contents will damage the

electronic switches located underneath. Batteries last longest at <25°C. At >50°C the life span is around 23

weeks, this makes the use of the gas fire unnecessarily expensive.

Only install the gas control block and receiver as pre-installed at the factory

Remember that components may have to be replaced or that repairs may have to be performed at a later

date. This may be more difficult if the control is installed using a method that is different from the

instructions provided here.

Please note:

Only place the batteries after wiring to the receiver, gas control block and pilot set is connected.

Premature connection to the energy source may damage the control’s CPU (central processor).

Ensure that the ignition cable is not near the antenna wire and that they do not cross each other.

The high voltage released at ignition may damage the sensitive receiver circuit. This may mean that the

unit becomes less responsive or not responsive at all to handset commands. (See photograph 1 on page 22)

Loosen the antenna wire from the terminals on the receiver box

Direct the antenna wire away from the ignition cable and in the direction of the control box door.

Ensure there is no contact with metal components. Ensure there is no damage to the connection to

electronic components or to the wire itself. (See photograph 1 on page 22)

Connect the wires correctly to the contact breaker behind the gas control block.

The shortest wire runs immediately back to the 1/0 switch and can be found nearest to the back of the gas

control block. The longest wire runs to one of the two connections on the receiver box and only fits on one

of the screws.

Do not tighten the contact breaker and the thermocouple connection too tightly on the gas control

block or to each other.

It is sufficient to tighten by hand and add a half a turn with an open-end spanner. Tightening too much will

break the connection to the magnetic coil below and/or the insulation around the aluminium contact pin in

the contact breaker. This may lead to the magnetic coil not opening the gas supply to the pilot and the unit

not working.

Page 17

Page 17

Do not extend the thermocouple supplied to the pilot set

Extending the thermocouple beyond its limit will lead to a reduction in voltage. This may, in turn, lead to

the magnetic coil not being activated.

Prevent leakage of the ignition spark to parts of the installation other than the ignition rod at the pi-

lot.

Ensure the ignition cable is not in contact with the shell or other metal parts. If a cable extension is used,

ensure that connections are additionally insulated using silicone.

The receiver and the control units on the gas control block should be switched on to ensure automatic

start-up via the manual transmitter.

The oval disk on the gas control block should be turned to the ON position. The 1/0 switch should be set to

1. See photograph 2. The ignition cable should be connected to the SPARK connection point on the receiver box. See photograph 1.

The manual transmitter has to communicate via the receiver. This has to be ‘learnt’.

Press the RESET button using a blunt object. (See photograph 3.) Continue to press this button until you

hear a short beeping sound, followed immediately by a long beeping signal. Release the button. Direct the

manual transmitter towards the receiver and press the arrow down until you hear a long beeping sound. The

gas control button will now move for a short period. The manual transmitter has now learned the setting

with regard to the receiver and the unit can now be ignited using the remote control.

The manual transmitter contains the system’s thermostat sensor

The manual transmitter operates best at a distance of 2 or 3 metres from the unit. Although communication

occurs via short wave radio signals, it is recommended to place the manual transmitter in view of the gas

unit in a place where the user wishes to experience a pleasant temperature. Do

not place the manual trans-

mitter in direct sunlight or other warm location. The thermostat measures the temperature and regulates the

flame size of the gas unit accordingly.

Only remove batteries using non-metallic tools

Removing batteries with a metal object may damage the electronic control permanently.

Photo 2

Photo 3

Photo 1

40 mm

Page 18

Page 18

Page 19

Page 19

Name

Address

Unit serial number

Date of purchase

Installation date

Comments

9.0 MAINTENANCE CHECK-UP LIJST.

Fitter details:

Service date Performed by Work activities performed

Service and maintenance log book:

Page 20

Page 20

10. Maintenance activities.

Please note: turn off the gas supply and power supply as much as possible during maintenance activities. Maintenance

activities should be performed by a qualified fitter. Close the gas valve while maintenance activities are being performed

Inspect

Work activities OK

1 General inspection a The main burner should ignite smoothly (within several seconds) and not give a bang sound due to

delayed ignition. Go to number 7 if there appears to be delayed ignition.

b Check the flame image. No flames against the glass. The flame image should be stable (See page 22

item 12.7). The flame should be yellow after appro xima tel y 15 minutes; go to number 7 if the flame

image is blue.

c Check for excessive formation of soot on the inside of the glass/combustion chamber and on decorative

parts. Go to number 7 if there is excessive for mation of soot.

2 Door/front a c heck for obstructions in the convection air openings

3 Glass window, seal. a check the glass window for cracks etc. Replace if damaged, cracked, or broken.

b check the seal of the glass window; this needs to join the unit and glass window. Replace if required.

c c heck any hinges, seals, quadrants etc.

d clean the glass. Check there is an even (not too large) load on the glass window. Prevent point load.

4 Gas control compart-

ment and convection

part of the unit

a clean these areas with a vacuum cleaner. Do so carefully. Remove parts that do not belong here.

b check if the convection airflow is free. .

5

Decorative parts (logs/

pebbles etc.)

and

(pilot)burner

a remove decorative parts and clean the burner (be careful with ceramic burners!) with a vacuum cleaner.

b inspect decorative parts for damage/cracks/discolouration and clean with a soft brush if required

c check if the burner cover is intact and free of corrosion. Replace the burner if required.

d after completing the inspection: replace decorative parts, exactly as stipulated by th e manufacturer.

Ensure the pilot burner is kept free!

e c heck if the pilot flame protection is intact (if applicable).

f check the piezo for sufficient spark power, and ensure the ignition cable is free from metal parts/

electrical parts.

6 Combustion chamber a check the condition of the finishing, such as varnish and enamel. Check for corrosion. Repair if

required.

b

replace the unit if there are holes. Close the unit for further use.

c c heck overpressure hatches or overpressure construction for sealing and su fficient mo vement/deposits.

7 Ignition and operation

of the main burner

a remove the burner from the unit and check whether the main injector is dirt-free.

b check if the primary ventilation opening in the main burner is dirt-free.

c mount the burner and check if the burner is in a good position in relation to the pilot burner.

d check if the burner is fixed and cannot move.

e check if the pilot burner burns well, with a blue flame (blue only)

f check if the burner ignites uniformly across the entire surface and without significant delay.

g check if the flame image is uniform and stable (manufacturer’s description).

h check the initial and burner pressure. Do not forget to close the pressure measuring points.

i check if gas control parts are intact, and that plastic parts have not melted, for example.

j check electrical wiring for damage and ensure they are away from hot parts of the unit.

8 Installation a check if convection grates are dust-free and dirt-free

b check if there is sufficient distance between the unit and flammable furniture

9 Flue tube/air suppl y a where possible, inspect the general state of the exhaust/supply system and check for blockages / leaks /

corrosion.

b check the outlet, which should be free from dirt and blockages.

c specifically check for leaking of cement borders etc.

10 Remote control a check for correct functioning of the remote control.

11 Ventilators (if present) a c lean the convection ventilators and check for correct functioning.

Page 21

Page 21

11. PLACING THE UNIT (first read “General instructions”)

Please note: Before placing the unit, we recommend you first read Chapter 7 “Concentric flue system” on

page 11.

11.1 Round and level unit components (See page 25 )

A. Combustion chamber J. Remote control

B. Burner plate K. Decoration plate

C. Gas control block L. Gas clamps

D. Receiver M. Window

E. Burner N. Wall plate/radiation plate

F. Ceramic wall at the back O. Restriction plate

G. Ceramic wall at the top P. Restriction plate Ø 65

H. Ceramic wall on the left Q. pilot flame cover

I. Ceramic wall on the right

11.2 Connection to the gas pipes

You can determine where the gas pipes will be placed, dependent on the layout. Ensure control equipment is not

twisted during installation and there is no excessive tension. Accessibility of various connection points in relation

to components need to be maintained. After installation, check the connections for tightness in relation to gas.

Use a 1/2“ gas tap with connection. Ensure the gas pipes are dirt-free and sand-free, and gas and combustion

products from various parts and functioning is correct. The gas connection should only be undertaken when the

electricity supply is disconnected. This prevents any damage occurring to the gas control equipment.

11.3 Placing ceramic wood blocks (See page 28 )

Please note!

You need to check if a restriction plate needs to be mounted before the wood blocks are placed. (See

page 22)

• Remove the gas clamps (hold the window back) to the left, right and at the top of the unit. Screw the

bottom clamp(s) a little looser so the window is still supported and the window can be easily removed from

the unit. Place the window somewhere safe.

• After the window has been removed, the log inset can be placed. To this end, please see the photo’s on page

28 outlining the order in which items are placed.

• Firstly, mix the Lava stones and the so-called ‘wokkels’ (worm-shaped ceramic burner decoration material)

and distribute these over the burner and decoration plate. Ensure the ventilation slot around the burner and

pilot burner are taken into account, as these need to be kept free from decoration material.

Warning!

Do not place ceramic burner decoration material or logs against the pilot burner.

• Carefully place the log inset. Different positions may have a significant influence on the flame image or

cause poor functioning of the burning process.

• For maintenance activities (to the burner, pilot flame or thermocouple), the window can be removed by

dismantling the gas clamps as described above. Remove the ceramic logs one log at a time and replace

these once maintenance has been performed as described above.

• Replace the window and carefully fasten the gas clamps.

Page 22

Page 22

12. POSSIBILITIES FOR CONNECTING THE CONCENTRIC FLUE SYSTEM

12.1 Direct exterior wall duct (see page: 26, figure 1.2).

Determine the position of the unit and close the exterior wall duct. When placing directly against the exterior wall

(e.g. cavity wall) ensure the exterior wall duct (Y Max) is shortened, but only if required. In all installation situations, take into account the possible application of the radiation plate delivered with the unit.

12.2 Indirect exterior wall duct (see page: 26, figure 1.3 and 1.4).

Always fit a length of X=1 metre vertical on the unit, followed directly by a bend of 90° with a length of X=1

metre and the wall terminal. The horizontal part can be extended to 4 metres plus wall duct (Y maximum) if required. From 1 metres to 4 metres the restriction plate (O) should be mounted.

12.3 Roof pass-through without slope (see page: 26, figure 1.5).

You can use a direct pipe layout without a slope for a maximum length of X=12 metres (excluding the roof terminal) measured from the connection on the unit. The minimum length is 3 metres. You can have a flue terminal at

every position on the roof face (both flat and sloping); the flue exit and combustion air supply are located in the

same pressure area. Between 2 and 5 meters restrictor plate (O) should be mounted. . From 5 metres and above

the restriction plate (O) and restriction plate (P) should be mounted.

12.4 Roof pass-through with 45° slope (Refer to page: 26, figure 1.6).

Always fit a length of X=1 metre vertically on the unit. Next, continue building up the flue pipe using two 45°

bends (the calculation length for each bend is 1 metre) until you have reached the maximum pipe length of 12

metres (including bends, excluding roof pass-through). Between 2 and 5 metres the restrictor (O) should be

mounted. From 5 metres and above the restriction plate (O) and restriction plate (P) should be mounted.

12.5 Roof pass-through with 90° slope (see page: 26, figure 1.7).

Always fit a length of X=1 metre vertically on the unit. Next, continue building up the flue pipe using two 90°

bends (the calculation length for each bend is 2 metres) until you have reached the maximum pipe length of 12

metres (including bends excluding roof pass-through). Take into account a maximum horizontal layout of Y=4

metres (measured between bends) and also ensure sufficient gradient.

12.6 Connection to existing flue pipe.

See page 15 “INSTALLATION INSTRUCTIONS REGARDING EXISTING FLUES”

Use the special concentric connection pieces for existing ducts and keep strictly to the installation instructions.

12.7 Installing the restriction plate (O) and (P) duct (see page: 30)

∗ Hold the ceramic baffle plate (G) with one hand while you remove the decoration strip (1) with the other

hand.

∗ Slide the baffle plate a little forward so it comes out at the back from its fixture, after which it can be re-

moved from the unit.

∗ Carefully remove the ceramic side walls (H) and (I).

∗ Dismantle the baffle plate holder by loosening 2 bolts (3).

∗ Place the restriction plate (O) behind the bracket. (Only when instructed)

∗ Mount the restriction plate (P) to the restriction plate (O) with 2 parkers and place the entirety behind the

bracket. (Only when instructed)

Page 23

Page 23

13. TECHNICAL DETAILS GV60

Model : Hi-Fire

Gas block type : Mertik GV60

Ignition : Remote operation and Piezo ignition

Gas connectio : 3/8 “ (Internal)

Unit category : C11-C31-C91

Pilot flame: : SIT 3 flames

Combustion gas discharge

and Combustion air supply: Concentric : Ø100/ 150 mm (Metaloterm US system number:

0063-CPD-6308)

13.1 Gas technical specifications

Side view GV60

Back view GV60

GASTYPE G20 G25 G30/31 G30/31 G30/31 G31 G31 G31

COUNTRY NO/ES/PT/DE/IE/

GB/BE/FR/IT

NL ES/PT/DE/IE/

GB/BE/FR/IT

NL/NO DE ES/PT/DE/IE/

GB/BE/FR/IT

NL/DE NO

CATEGORY I2H/I2E/I2E+ I2L I3B/P I3B/P I3B/P I3P I3P I3P

PRIMAIRE AIR INLET 2 x Ø 6,5 2 x Ø 4,4 3 x Ø 13 3 x Ø 13 3 x Ø 13 2 x Ø 13

1 x Ø 5

2 x Ø 13

1 x Ø 5

2 x Ø 13

1 x Ø 5

PRE-PRESSURE mBAR 20 Mbar 25 Mbar 28-30 Mbar 30 Mbar 50 Mbar 37 Mbar 50Mbar 30Mbar

BURNER PRESSURE HIGH mBAR 11,3 16,5 26,5 26,5 26,5 24,7 24,7 24,7

BURNER PRESSURE LOW mBAR 5,5 7,8 13,4 13,4 13,4 11,6 11,6 11,6

BURNER INJECTOR Ø mm 2,00 2,00 1,20 1,20 1,20 1,30 1,30 1,30

PILOT BURNER INJECTOR CODE 41 41 25 25 25 25 25 25

LO SETTING BORE mm 1,70 1,70 1,20 1,20 1,20 1,20 1,20 1,20

LOAD Hi kW 5,50 5,50 5,60 5,60 5,60 5,60 5,60 5,60

LOAD Hs kW 6,11 6,10 6,06 6,06 6,06 6,06 6,06 6,06

CONSUMPTION M³/h 0,571 0,669

0,171

0,171 0,171 0,225 0,225 0,225

NOM.CAPACITY kW 4,30 4,20 4,13 4,13 4,13 4,13 4,13 4,13

Page 24

Page 24

14. PROBLEMS AND POSSIBLE SOLUTIONS

Please first check if all guidelines were followed before attempting to solve any problems with the unit.

Warning:

Solving problems with your unit, whether gas related or electrical, must always be performed by a qualified

technician.

SYMPTOM ACTION TO BE TAKEN

The pilot flame will not

light. After repeated ignition.

1. There is air in the pipes if you switch the unit on for the first time or after a service. It will take a little while until all the air has flowed out of the pipes and gas

flows through that can be ignited. Ignite the pilot flame several times in order to

allow the air to escape.

2. See whether the gas pipe to the unit is open and if there is sufficient gas pressure

to the unit.

3. Check whether there are sparks between the spark electrode and the pilot. If

there are no sparks:

a) Check whether the connection between the electrode and the ignition is bro-

ken or faulty.

b) Check whether the spark short circuits at another point or jumps.

c) Check whether the electrode is broken.

The pilot flame will not remain alight after ignition.

1. Check whether the pilot flame is large enough to burn around the thermocouple.

If the flame is too small, you need to check the gas feed pressure. If the size of

the pilot flame cannot be adjusted, there may be an obstruction in the pilot.

2. Check whether the thermocouple interrupter is connected to the gas valve properly.

3. Check that the gas valve is not faulty.

4. Check whether the restriction plate has been placed according to instructions

(See page 22)

The main burner goes out

when the unit is warm.

1. This can be a normal effect of the thermostat.

Check whether the pilot flame is able to heat the thermocouple adequately. If the

pilot flame is too small then the gas pipe or the pilot flame adjustment need to be

checked.

2. Check whether the restriction plate has been placed according to instructions

(See page 22)

Soot deposits on the glass. 1. Check whether the lava split is lying on the burner in the correct manner.

2. Check if the pilot burner is free from burner filling.

3. Check whether there is any blockage in the burner openings

4. Check if the flue tube is functioning correctly and if the flue tube is not hindered

or blocked.

5. Check the pipe pressure.

Sharp blue flames that are

released by the burner or a

pilot that burns too wildly.

1. Check whether the restriction plate has been used.

Weak (stifling) pilot flame. 1. Check the pilot burner pressure or duct pathway

Main burner will not burn

after the pilot burner is

functioning.

1. Check if the motor button turns and whether the batteries are empty.

2. Possible defect in the gas block

3. Check whether the pilot flame ignites the burner well.

4. Check that the burner opening is not blocked.

Page 25

Page 25

1

Page 26

Page 26

1.2

1.7

1.6

1.5

1.4

1.3

Page 27

Page 27

A

E

B C

D F

I H

G

K L

J

M

N

O

Page 28

Page 28

E

D

C

B

A

Page 29

Page 29

Page 30

Page 30

3

1

G

2

G

1

H

I

P

O

P

O

2

Page 31

Page 31

Page 32

Pag.32

TTI d.o.o.

Thermo Technology International

Loading...

Loading...