/i

A

B

C

E

D

F

G

H

THERMOBILE

Type.......................................................

Cap Max. Mj/h........................................

Cap Max. kW.........................................

3

/h...........................................

Airflow m

Volt/Hz/Amp...........................................

Prod. code.............................................

Fabr.year 0000

Made by THERMOBILE Ind. B.V. Breda, Holland

- 1 - - 2 -

A B

C DE

AT-400

000

00

0

000/00/0,00

00.000.000

Serial nr: 00.0000

F

A

G H I

B

C

D

A

B

J

C

R Q P NO M L K J

S

- 3 - - 4 -

AB

AT400

AT500

D

E

F

G

H

I

A B C D

- 5 - - 6 -

2 40.020.943 - rev. 04 - 2011 AT 400 - 500-US series

/i

B

A

C

D

A

- 7 - - 8 -

ABCDEF

B

C

- 9 - - 10 -

A

- 11 - - 12 -

AT 400 - 500-US series 40.020.943 - rev. 04 - 2011 3

B A

D

C

C

B

A

B

English.........................................................5

Français.....................................................19

Español......................................................35

4 40.020.943 - rev. 04 - 2011 AT 400 - 500-US series

English

English

Contents

Safety instructions....................................... 5

Introduction................................................. 7

Preparations................................................ 8

Use............................................................ 10

Maintenance ..............................................11

Faults........................................................ 14

Spare parts................................................ 17

Technical information ................................ 17

Installing accessories................................ 17

Standards and guidelines.......................... 18

Preface

This manual contains instructions for use of

the stationary used oil fired heaters as shown

on the cover. The information in this manual

is important for the correct and safe use of

the heater.

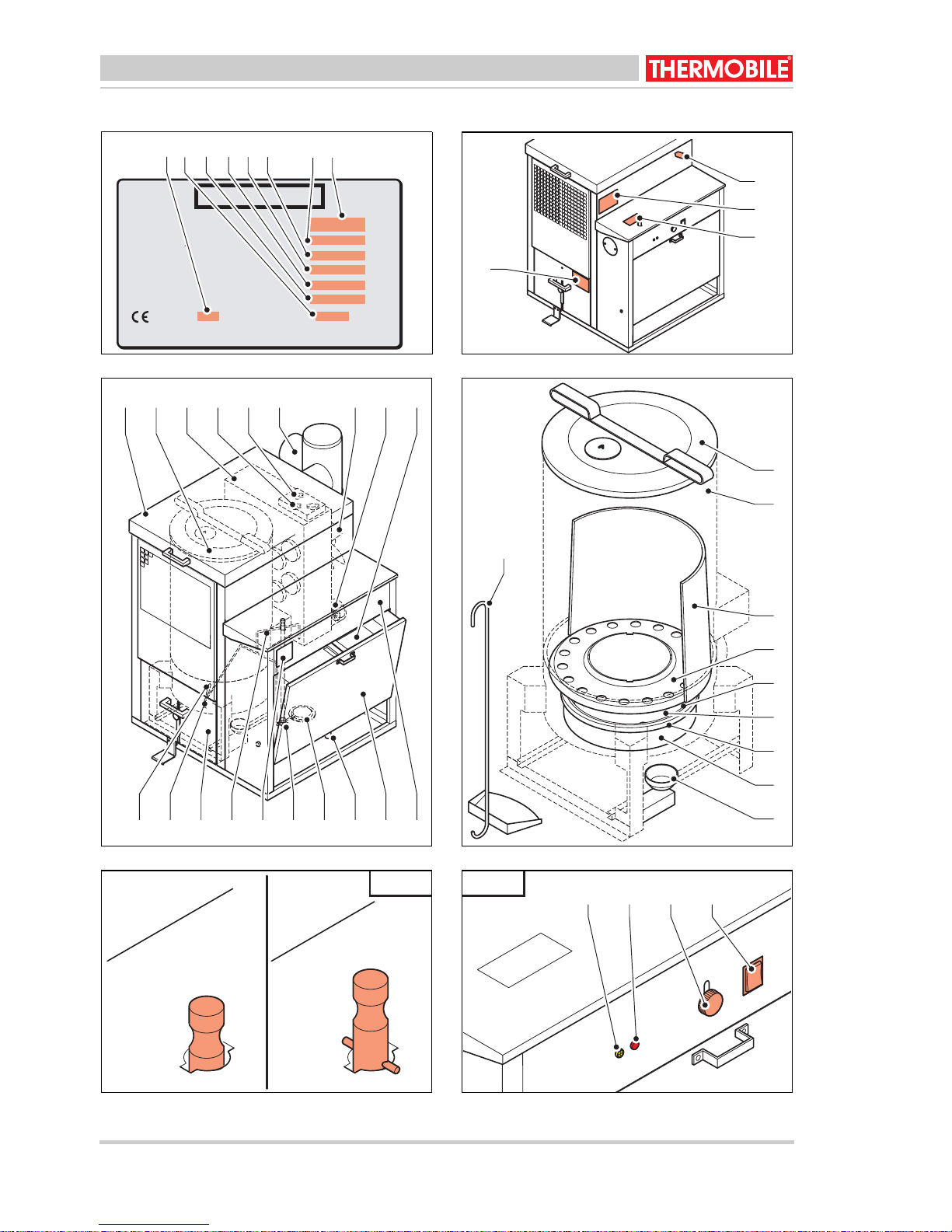

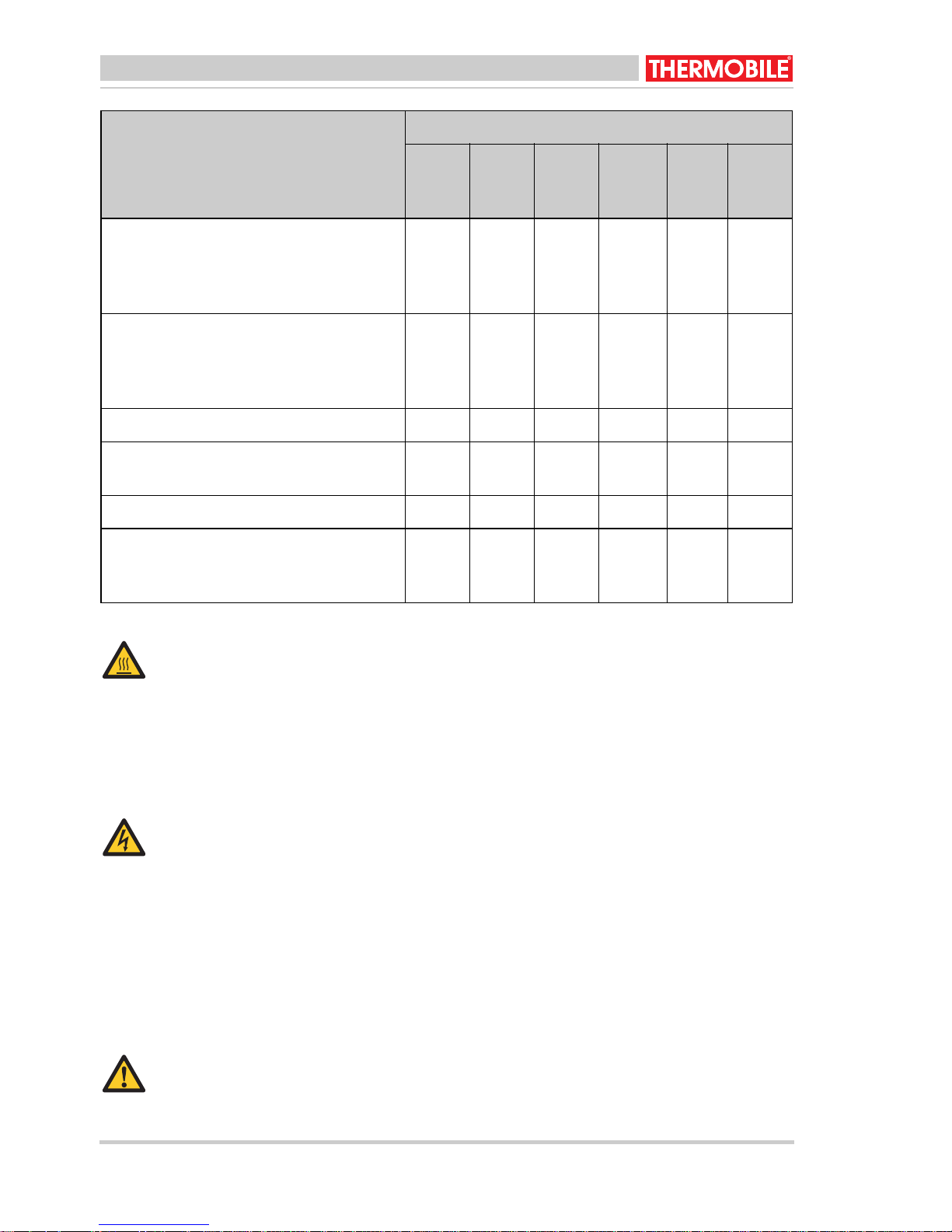

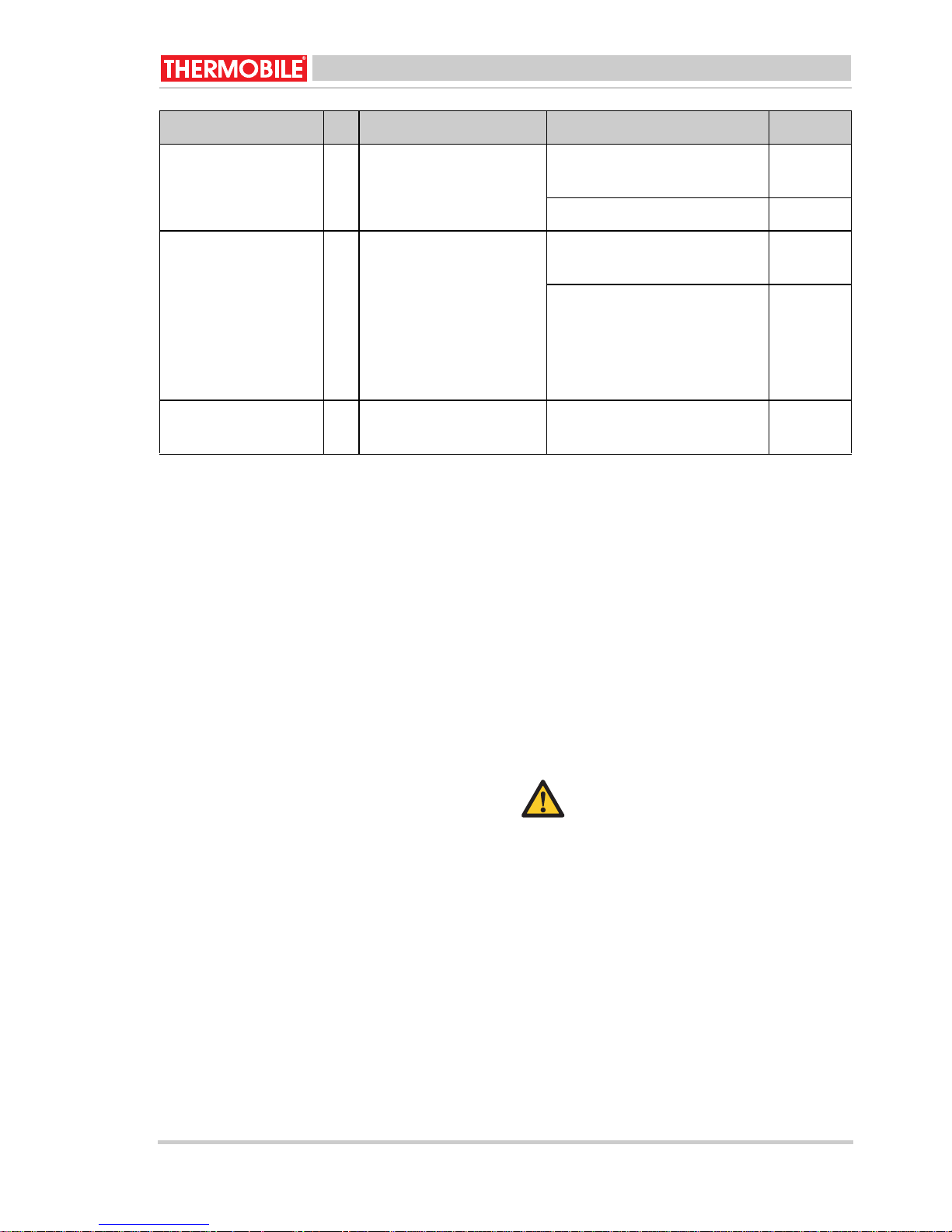

Identification of the product (fig. 1)

The identification plate is attached to the side

of the heater. The identification plate contains

the following data:

A Year of manufacture

B Serial number

C Production code

D Voltage data

E Air displacement

F Capacity max (kW)

G Capacity max (MJ/h)

H Type of machine

Service and technical support

Please contact your dealer or the

manufacturer for information about the

heater. Make sure you have the following

data at hand: type and serial number of the

stationary used oil fired heater.

Warranty and liability

For warranty and liability, see general

warranty regulations.

Environment

Note

The heater is made of various metals

and synthetic materials. The heater

also contains electronic parts, which

must be treated as electronic waste.

Please contact your dealer for further

information.

1 SAFETY INSTRUCTIONS

1.1 Pictograms in this manual

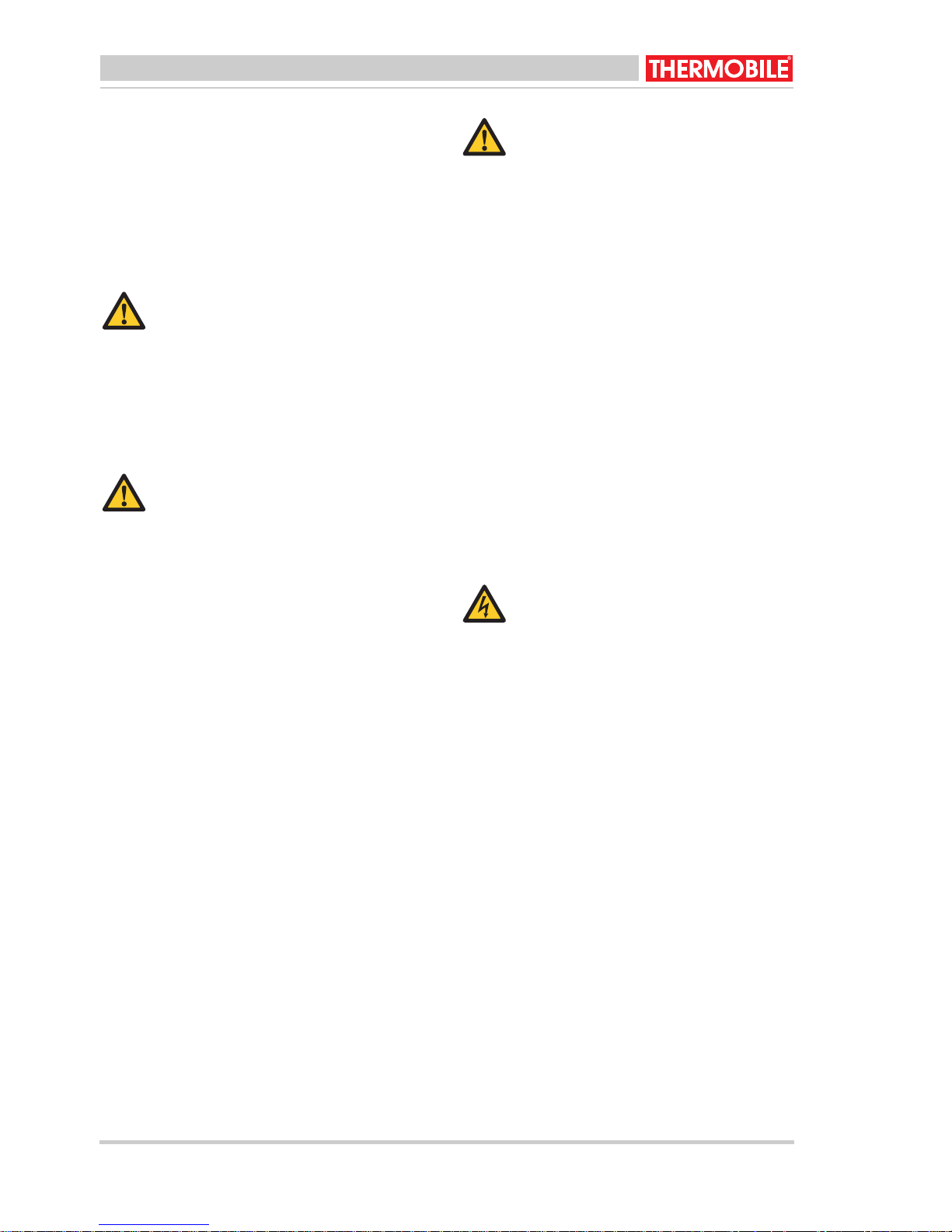

Caution

Indicates risk of damage to the

appliance.

Warning

Indicates a dangerous situation, that

can lead to death or serious injuries.

Warning

Always switch off power when

performing maintenance or repairs on

the hot air heater!

Hot

Some surfaces may be hot! Wait until

these parts have sufficiently cooled

down before performing

maintenance.

Suggestions and tips to simplify the

carrying out of the specified tasks or

actions.

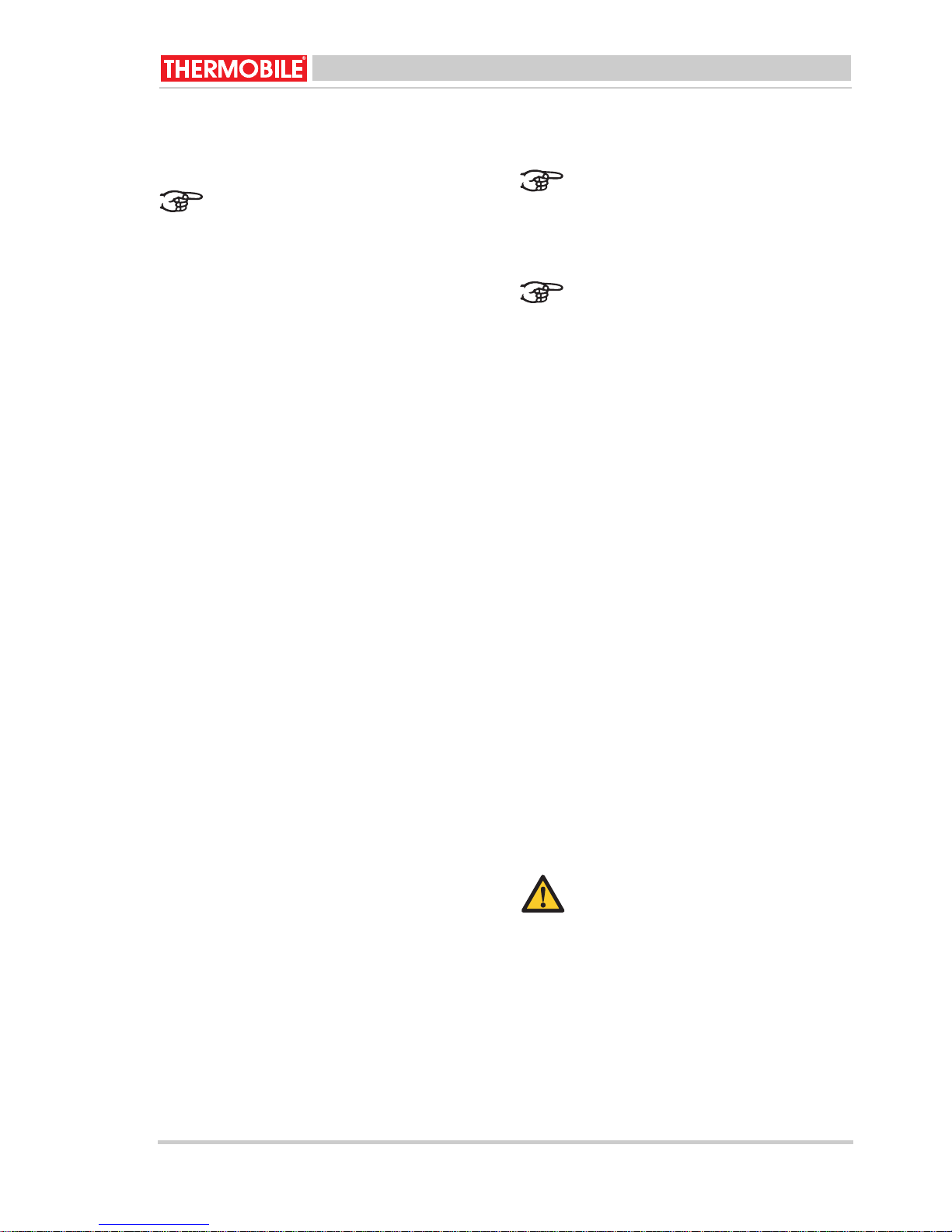

1.2 Pictograms on the stationary used

oil fired heater (fig. 2)

A Warning for quantity of oil to be used

Instruction not to put the burner dish on a

cold surface

B Overheating thermostat

C Instruction for re-ignition.

D Positions of the burner: low and high.

AT 400 - 500-US series 40.020.943 - rev. 04 - 2011 5

English

1.3 Use this product for its intended

use

The stationary used oil fired hot air heater

has been designed for heating of workshops

at mechanization companies, heating and

frost protection of halls, transit sheds and

warehouses and heating of garage

workshops.

Caution

If the heater will be installed indoors,

make sure that there is proper

ventilation in the room. Make sure the

flue gas can only flow to an outside

source separate from the room.

1.4 General instructions

Warning

• Make sure that the heater is

properly installed, adjusted and

maintained.

• For all service and adjustments

contact qualified, competent and

authorized persons.

• Do not make any modifications to

the heater without the prior

written consent of the

manufacturer.

• Make sure to always follow the

local standards and guidelines as

well as the local requirements,

concerning environmental

quality, fuel, fire and electrical

safety.

• Read this manual carefully

before using the heater.

• Keep this document with the

heater.

• Follow the described procedures.

• Never lean against the heater.

Warning

• Do not create a fire hazard by

storing or using highly

inflammable materials near the

heater. Keep these materials at

adequate distance from the

heater:

- top and sides 6 inch (150

mm)

- front 35 inch (890 mm)

- back and flue 18 inch (460

mm)

• Make sure there is enough air for

proper combustion.

• Make sure that the convector

heater has cooled down

sufficiently and that the plug has

been removed from the socket

before carrying out any repair or

maintenance work.

1.5 Additional safety

Warning

• Connect the heater only to a

120 V / 60 Hz power supply.

• Replace fuses only with identical

spares.

• The heater must be grounded.

6 40.020.943 - rev. 04 - 2011 AT 400 - 500-US series

English

Warning

• Use only the following types of

fuel:

• Automatic transmission oil

• Crankcase oil

•Diesel oil

• Hydraulic oil

• Domestic fuel oil

• Do not add the following

materials to the used oil:

• Anti-freeze

• Carburettor cleaner

• Paint thinner

• Parts washer solvents

• Gasoline

• Transformer oil

• Oil additives

• Any other inappropriate or

hazardous material

• Do not fill the tank while the

heater operates.

2 INTRODUCTION

2.1 Purpose

These stationary used oil fired heaters are

direct fired heaters with thermal protection,

heat exchanger, combustion air fan, flue

stack connection with T-piece and draught

regulator and hot air fan.

The A T 500 is equipped with a connection for

a room thermostat

The hot air heaters have been tested at sea

level at a temperature of 68 °F.

2.2 Working principle

The stationary used oil fired heater is

equipped with three electric motors.

The first electric motor drives a fuel pump,

which extracts fuel from the fuel tank.

The second electric motor drives the

combustion air ventilator, which blows the

combustion air into the combustion chamber.

The third electic motor drives the hot air fan,

which draws the surrounding air around the

combustion chamber and heat exchanger.

The hot air is blown into the space to be

heated.

Diesel oil is poured manually on a burner

dish, which is ignited with a burning paper

pellet. As soon as the burner dish is at the

right temperature, the pump thermostat

activates the fuel pump; the control light

flashes on. The fuel pump pumps the used oil

onto the burner dish. The used oil evaporates

due to the temperature of the burner dish.

The gas vapour burns. A thermostat switches

on the hot air fan motor to blow hot air into

the space to be heated.

The pump thermostat switches off the fuel

pump when a failure causes the heater to

overheat.

The fuel pump is switched off when the

heater is switched off.

The hot air ventilator runs until the

combustion air thermostat switches off the

ventilator: this allows the heater to cool down.

The maximum thermostat switches off the

heater when the temperature gets too high.

The fuel supply has an overflow that ensures

that the used oil flows back into the fuel tank

when the fuel pipe is blocked.

The overflow protection switches off the fuel

pump when the burner dish overflows.

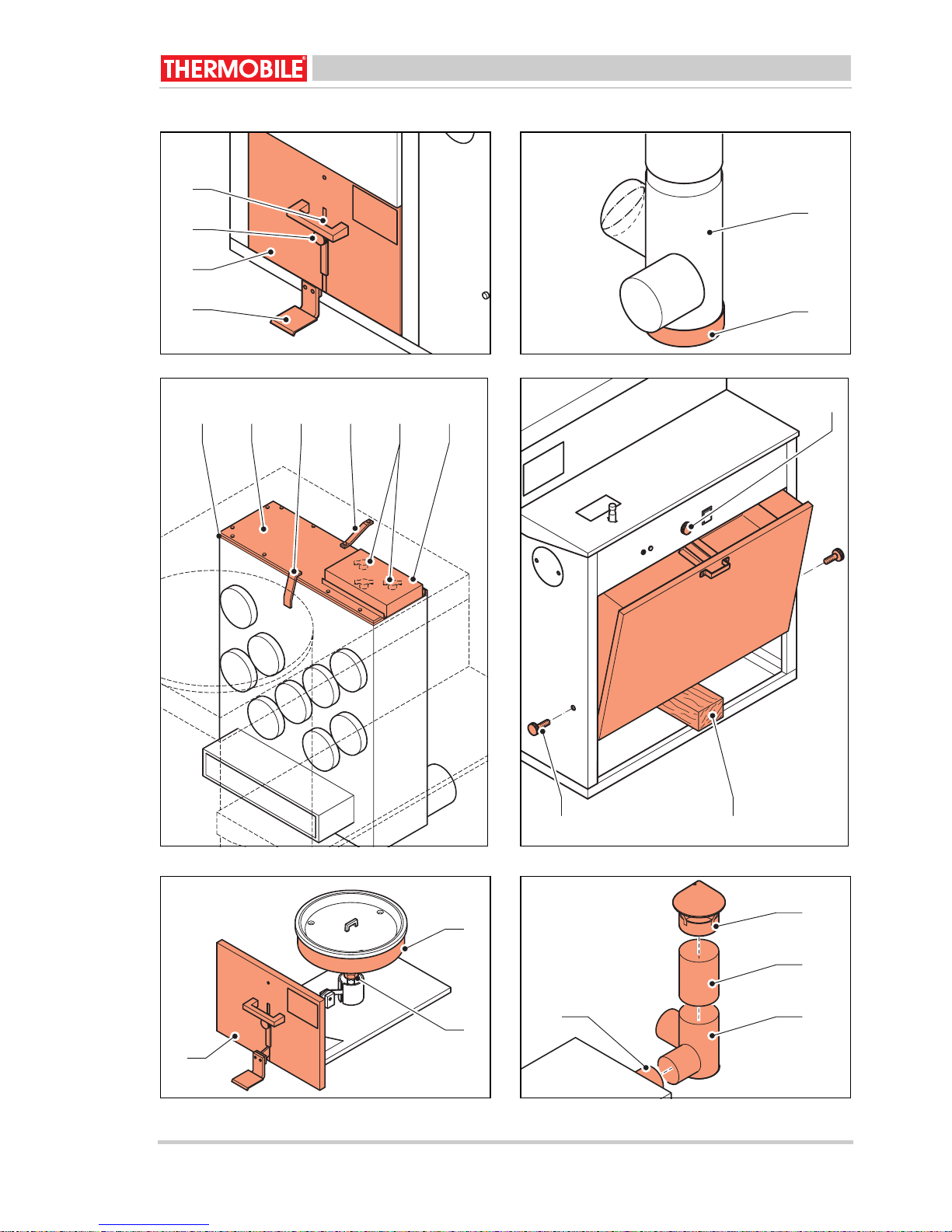

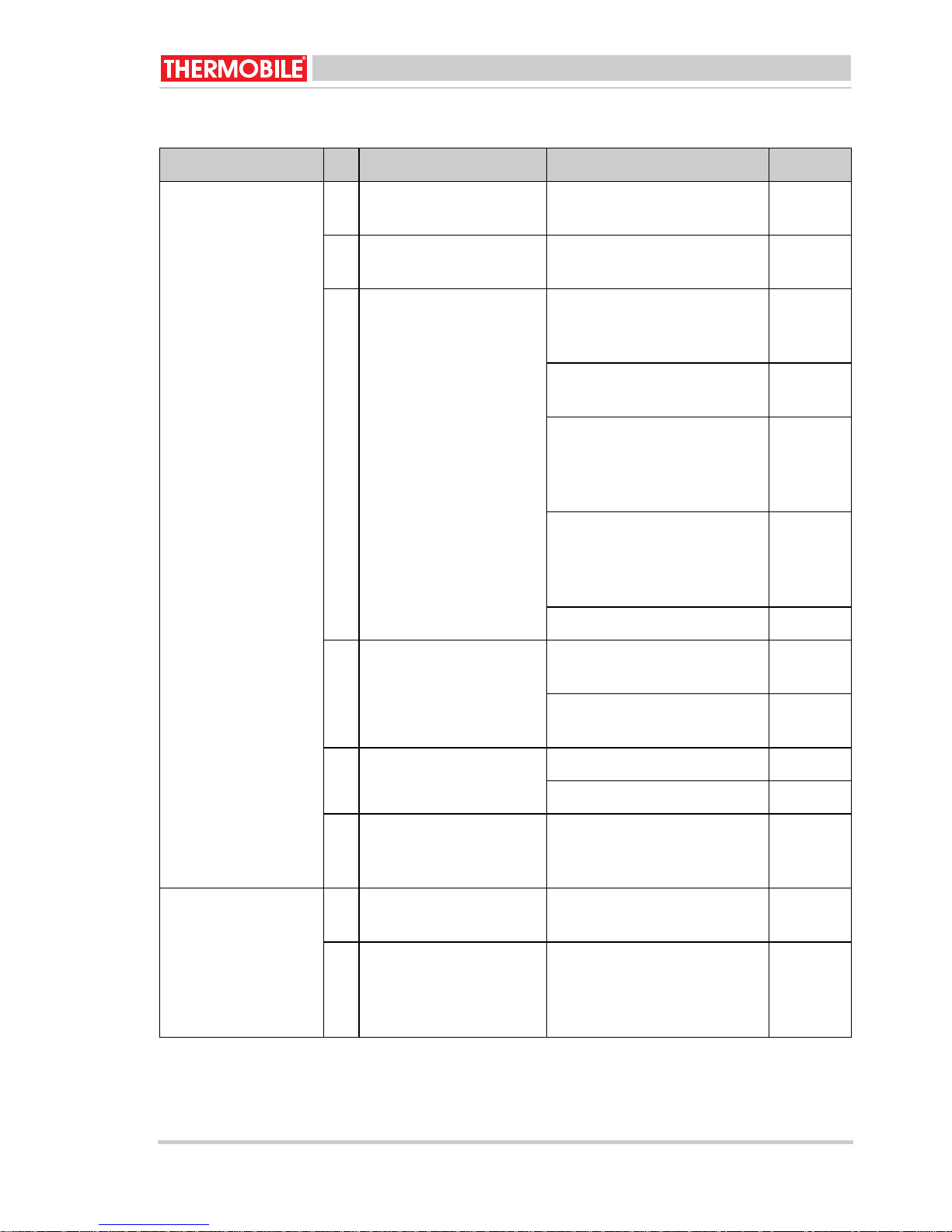

2.3 Main components of the stationary

used oil fired heater (fig. 3)

ACover

B Combustion chamber

C Heat exchanger

D Maximum thermostat

E Thermostats

F T-piece with draught regulator

G Hot air fan

H Combustion air ventilator

I Fill filter

J Control panel

K Fuel tank

LDrain cock

M Fuel filter

N Fuel pump

O Identification plate

P Return line

QDrawer

R Fuel pipe

S Fuel supply pipe

AT 400 - 500-US series 40.020.943 - rev. 04 - 2011 7

English

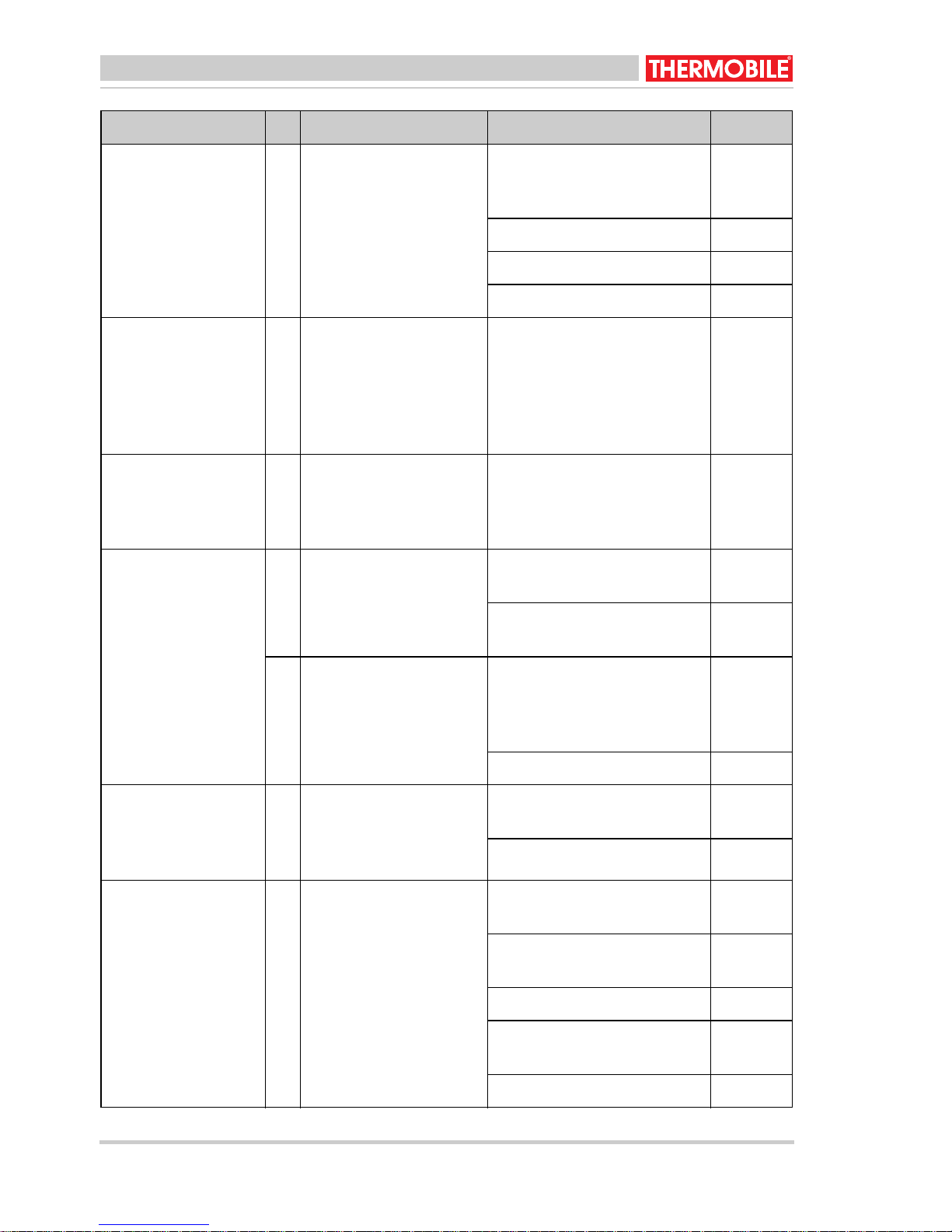

2.4 Main components of the burner

(fig. 4)

A Cover combustion chamber

B Combustion chamber

C Flame trap

D Burner ring

ESeal cord

F Burner dish

G Vaporiser

H Bottom combustion chamber

I Overflow protection

JShovel

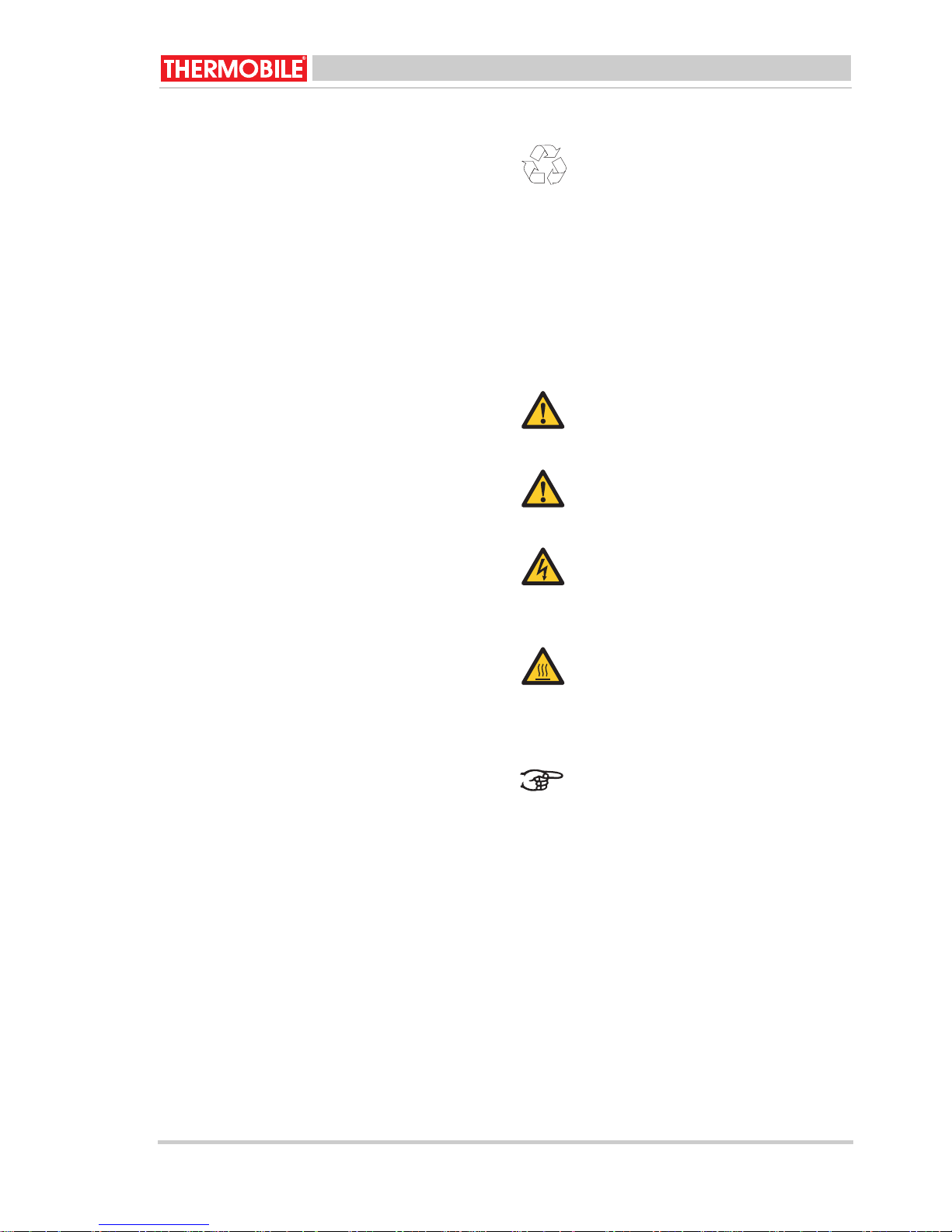

2.5 Control panel (fig. 6)

A Indicator light, yellow

B Indicator light, red

C Bolt fuel tank

D Rocker switch:

- 0: The pump is switched off

- 1: The pump is in operation

- 2: High pump speed (only for AT 500)

2.6 Thermostat

The heater has the following thermostats:

• Pump thermostat

When the burner dish is sufficiently preheated, the fuel pump starts up.

• Hot air thermostat:

The thermostat starts the hot air fan

when the heater reaches a certain

temperature.

• Maximum thermostat

The thermostat stops the fuel pump when

the hot air temperature gets too high.

2.7 Accessories

•Flue with rain cap

3 PREPARATIONS

3.1 Removing the packaging

1. Remove packaging from the hot air

heater

2. Remove packaging from the loose parts

in the combustion chamber.

3.2 Installation

1. Ensure that the heater is positioned

horizontally.

2. Correctly attach the parts of the

combustion chamber, see fig. 4.

3. Attach the various handles to the cover

and the drawer, see fig. 3.

4. Push the tank bolt up, see fig. 5 (D).

5. Pull the fuel tank forward.

6. Fill the fuel tank through the tank filter

with used oil, until the level of used oil is

1 inch below the top of the tank.

Caution

Only the following oil types may be

used in the stationary used oil fired

heaters:

• Automatic transmission oil

•Diesel oil

• Hydraulic oil

• Oil for household use

Note

• Install the equipment in the US

according to the following

publications of the National Fire

Protection Association:

• NFPA #30: Flammable and

Combustible

• Liquids Code

• NFPA #31: Oil Burning

Equipment

• NFPA #88A: Parking

Structures

• NFPA #88B: Repair Garages

• NFPA #211: Chimneys,

Fireplaces and Vents

• Local codes may require that the

heater is mounted at a minimum

of 8 feet (2.4 m) off the ground.

This is especially the case when

there are possible combustible or

flamable fumes in the room.

Refer to NFPA #88B.

• Install the equipment in Canada

according to the following

standard: CSA B139, installation

Code for Oil Burning Equipment.

8 40.020.943 - rev. 04 - 2011 AT 400 - 500-US series

English

Place the heater on a location with

respect to the following:

• Possibility of unobstructed, even

heat distribution.

• Safe and easy access for

servicing.

• Unobstructed passage for shop

vehicles and equipment.

• Proper clearances for

combustibles. Refer to the safety

section.

• Adequate combustion air per

local codes. The room must be

ventilated to provide sufficient

combustion-air. The maximum air

consumption is 12 USG/h (46 m

h)

• Proper installation of the stack.

• The structure in which the heater

is located requires the following

minimum dimensions:

• height from the point of

location of the heater: 15 feet

(4.5 m).

• length and width: 20 feet

(6 m).

• floor area: 400 square feet

2

(36 m

)

• Possibility to place the heater on

a combustible flooring.

• If the heater is installed at an

elevation, a permanent platform,

including stairs and railings, must

be provided to facilitate regular

maintenance.

7. Close the fuel tank: Ensure that it is

locked.

8. Ensure that the hot air can flow out freely.

9. Ensure that inflammable materials are at

a sufficient distance from the heater, see

1.4.

10. Ensure there is sufficient ventilation: the

maximum air consumption is 2650 ft

3

/

hour.

11. Check the floor surface: this needs to be

at least 645 ft

2

.

12. Install the flue (18 ft and a rain cap).

13. Make sure the rocker switch is positioned

at 0.

14. Check the supply voltage: see

identification plate.

15. Place the plug in the socket.

3.3 Preparing for start-up

1. Switch the rocker switch to "0".

2. Only for the AT 400:

Switch control (A) of the fuel pump to

"low", see (fig. 5).

3. Drain possible water of condensation

from the fuel tank, see fig. 3 (L).

4. Open the drawer: Push pedal (A) down

and keep it down, lift safety (B) up, turn

3

/

control (C) left or right and let go of the

pedal, see fig. 7. Pull drawer (D) forward.

5. Check whether the burner dish and the

floor of the combustion chamber are

clean and cold.

6. Clean the burner dish and the floor of the

combustion chamber if necessary.

7. Pour 0.3 litre of diesel oil onto the burner

dish, see fig. 4 (F).

Warning

Never pour diesel oil onto a hot

burner dish.

The burner dish must be cool!

8. Form a paper pellet and light it.

9. Drop the burning pellet on the burner

dish.

10. Close the drawer.

1 1. Check through the upper cover that there

is no flame around the seal cord and

between the bottom and the combustion

chamber, see fig. 4.

AT 400 - 500-US series 40.020.943 - rev. 04 - 2011 9

English

3.4 Starting up

Warning

• Never pour diesel oil onto a hot

burner dish. The burner dish

must be cool and clean!

• Do not start the heater if the fan

still runs. The heater is cooling

down.

• Do not start the heater if excess

oil has accumulated in or near

the heater.

Caution

Do not switch on the convector

heater if there is no fuel, or if the

connected fuel tank is empty.

Caution

Only the following oil types may be

used in the stationary used oil fired

heaters:

• Automatic transmission oil

• Crankcase oil

• Diesel oil

• Hydraulic oil

• Domestic fuel oil

1. Switch the rocker switch to "2", see fig. 6

(D).

When the burner dish has reached the

right temperature, the fuel pump starts

running and the control light is on.

2. During the first 20 - 30 minutes the fuel

pump should have a low capacity.

For AT 400:

Position the rocker switch to "low", see

fig. 5 (A).

For AT 500:

The yellow control light is on, see fig. 6

(A).

3. Set the pump regulator to high capacity if

maximum capacity is desired.

For AT 400:

Switch the rocker switch to "high", see

fig. 5 (B).

For AT 500:

Switch the rocker switch to "2", see fig. 6

(D).The red control light is on, see

fig.6(B).

4USE

4.1 During operation

Caution

• Do not operate the heater in hot

weather to burn oil.

• Do not burn used oils other than

generated on the premiss of the

owner, unless written

authorization is obtained from the

regulatory authority.

Hot

Do not touch the flue stack or blower

outlet! The flue stack and blower

outlet get hot during operation!

4.2 Switching off

Switch off heating:

1. Switch the rocker switch to "0".

The fuel pump stops running.

The control light turns off.

Caution

After switching off the heater it will

run for several minutes, until the fuel

on the burner dish is used up. In the

meantime the hot air fan and the

distributor fan keep running. These

fans cool the heater until it has

sufficiently cooled down (after 10 to

30 minutes).

Both fans will stop around the same

time.

10 40.020.943 - rev. 04 - 2011 AT 400 - 500-US series

5 MAINTENANCE

English

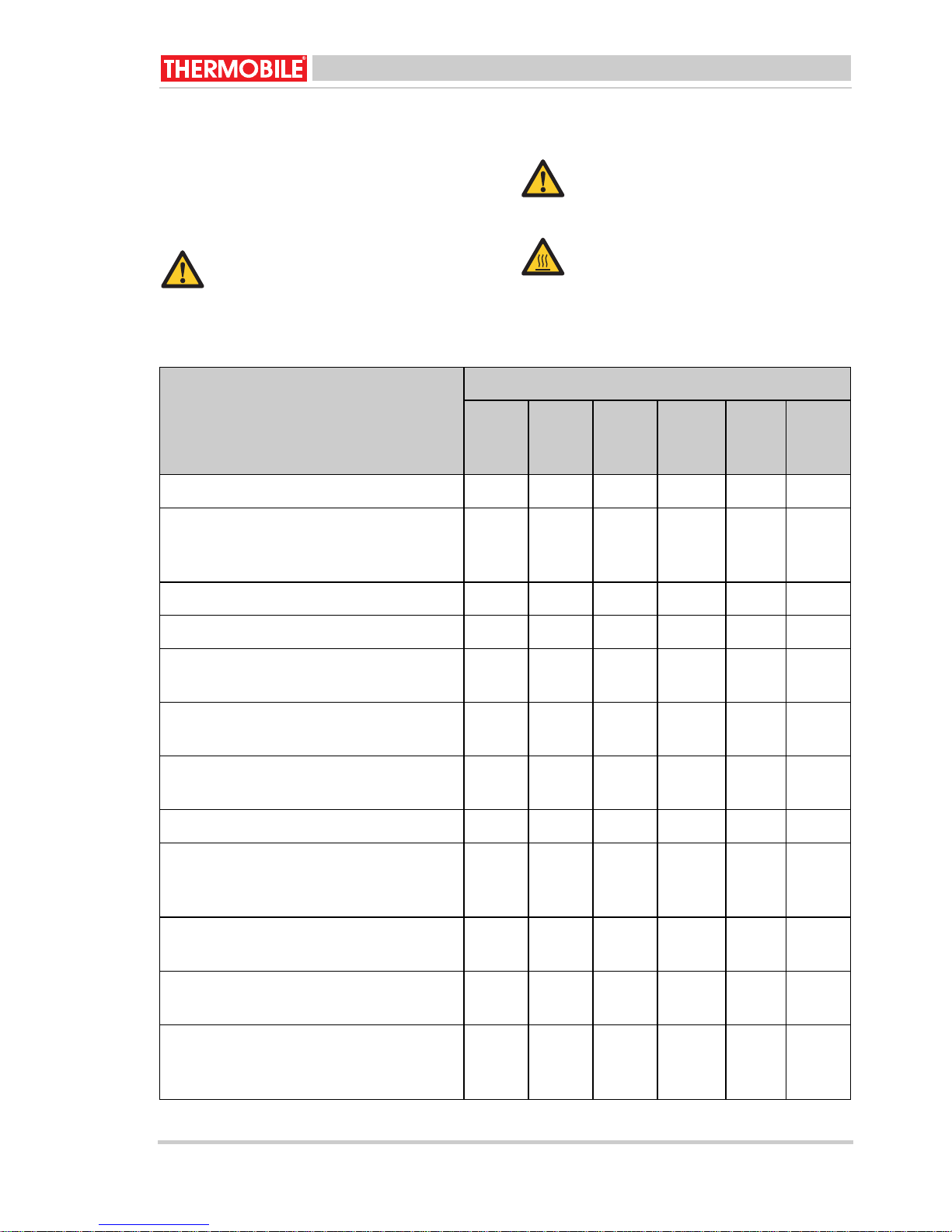

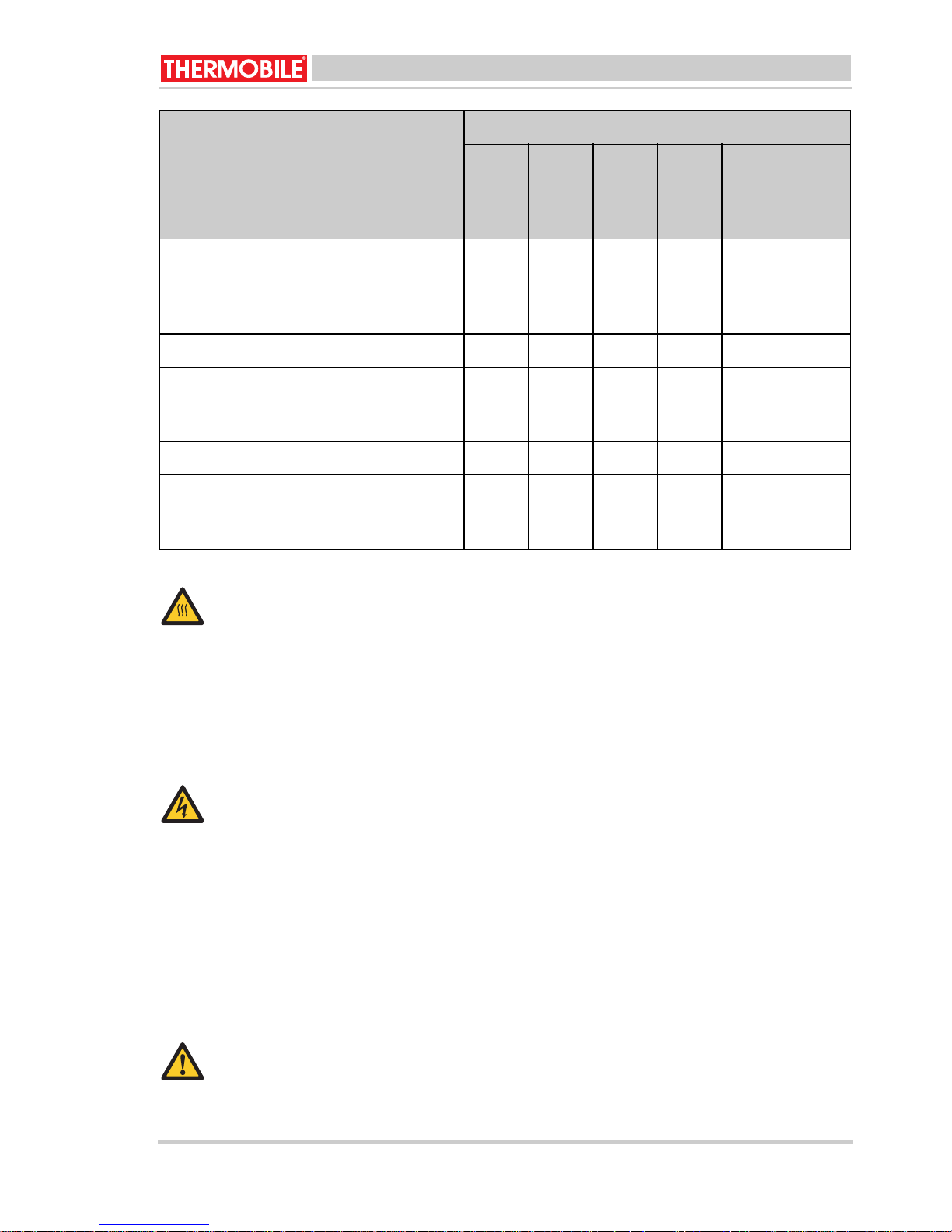

5.1 Maintenance table

Use the table in this booklet to record

performed maintenance after each winter

season.

Warning

For all service and adjustments

contact qualified, competent and

authorized persons.

Description Period

Every

12

hours

Clean the burner dish. X

Drain (water of) condensation from the

fuel tank, when the waste oil contains

water.

Clean the combustion chamber. X

Warning

Always clean the combustion

chamber before starting the heater.

Hot

Do not touch the flue and air outlet!

Wait until the flue and the air outlet

have cooled down sufficiently before

carrying out any maintenance.

/i

Week-lyMonth-lyEvery

six

months

X

Annually

Every

two

years

Clean the burner ring. X

Clean the combustion chamber and the

X

vaporiser with a steel brush.

Clean the combustion chamber and the

X

vaporiser with a steel brush.

Clean the overflow pipe in the floor of

X

the combustion chamber. See fig. 4(I).

Check the oil pipes for leakage. X

Clean the fuel tank, the supply filter and

the fuel filter.

The fuel tank can easily be removed.

Check the combustion air fan and clean

if necessary.

Check the hot air fan and clean if necessary.

Clean the flue stack valve in the T-piece,

Dealer

see fig. 8 (A).

The recommended draught is 2 mmwk.

X

X

X

AT 400 - 500-US series 40.020.943 - rev. 04 - 2011 11

English

Description Period

Every

12

hours

Check the seal between the bottom and

Week-lyMonth-lyEvery

six

months

X

the vaporiser for leakage.

Adjust the pressure on the seal cord, or

replace the seal.

Replace the seal cord in the bottom.

X

Check the seal ring for leakage.

Adjust the pressure on the seal cord in

case of a leakage.

Clean the heat exchanger. X

Clean the flue stack T-piece, see "clean-

ing the flue stack valve".

Check the heater's wiring. X

Clean the heat exchanger.

Take the heat exchanger apart for a

good cleaning.

Annually

X

X

Every

two

years

Hot

Do not touch the flue stack or

combustion chamber!

Do not perform maintenance until the

flue and combustion chamber have

cooled down.

5.2 General

Warning

Switch off the power supply before

carrying out any repairs!

When the heater is stored long-term:

1. Switch off the heater.

2. Disconnect the power plug.

3. Clean the heater.

4. Use an oily cloth to clean the combustion

chamber, to protect the combustion

chamber against corrosion.

Warning

Do not operate the heater in hot

weather to burn oil.

5.3 Cleaning the combustion

chamber(fig. 4)

1. Open the cover of the heater, see fig. 4

(A).

2. Remove the burner ring (D) with the hook

of the shovel (J).

3. Clean the burner ring with a steel brush.

4. Remove the burner dish (F) with the hook

of the shovel.

5. Clean the burner dish with a scraper.

12 40.020.943 - rev. 04 - 2011 AT 400 - 500-US series

English

6. Clean the inner side of the combustion

chamber (B) and the vaporiser (G) with

the front of the shovel.

Note

• Used oils can contain heavy

metallic compounds and foreign

materials. These materials stay

as a residu when burned.

Therefore it is necessary to take

care when using, cleaning and

maintaining the heater.

• Wear protective gear when

cleaning the inside of the heater:

• Respirator for fine particles

• Rubber gloves

• Safety goggles

• Protective clothing

• Ensure that the holes in the

combustion chamber wall remain

open for combustion air supply.

7. Remove any soot pieces from the floor of

the combustion chamber.

8. Clean the inside of the pipe in the

vaporiser with a small brush (diameter 4

mm).

9. Clean the fuel supply line (N) with a

brush (inner diameter 0.33 in), see fig. 3.

10. Install all parts in reversed order.

5.4 Cleaning the heat exchanger (fig.

9)

1. Disconnect the power connection from

the heater.

2. Open the cover, see fig. 3 (A).

3. Unscrew the thermostat clamp (A).

4. Take the wiring off both thermostats (B).

5. Remove safety strip (C).

6. Remove safety strip (D).

7. Remove cover (E) from the heat

exchanger.

8. Clean the inner side of the heat

exchanger with a brush and vacuum

cleaner.

9. Re-install the cover of the heat

exchanger.

Always attach a new gasket (F)

between the cover and the heat

exchanger.

Install all parts in reversed order.

Apply the wiring of the thermostats

according to the electrical circuit

diagram. The thermostats are equal.

5.5 Taking t he heat exchanger apart

(fig. 9)

1. Disconnect the power connection from

the heater.

2. Remove the T-piece (A) from the flue,

see fig. 3 (F).

3. Remove the grate, see fig. 3 (A).

4. Unscrew the thermostat clamp (A).

5. Take the wiring off both thermostats (B).

6. Remove safety strip (C).

7. Remove safety strip (D).

8. Remove the fuel supply pipe, see fig. 3

(S).

9. Unscrew the overflow cup support and

put the overflow protection on the floor of

the heater.

10. Remove the combustion air fan (H) with

motor support, see fig. 3.

11. Unscrew the back panel from the heater

and turn it 180° to the fuel tank.

Temporarily support the back panel in

this position.

12. Remove the casing of the combustion air

fan.

Warning

Do not change the position of the

valve in the casing.

13. Unscrew the frame of the combustion

chamber from the groundplate of the

heater.

AT 400 - 500-US series 40.020.943 - rev. 04 - 2011 13

English

14. Lift the combustion chamber with heat

exchanger from the heater.

Do this with another person.

15. Unscrew the connection of the

combustion chamber and the heat

exchanger.

16. Remove the strip between the

combustion chamber and the heat

exchanger.

17. Pull the heat exchanger from the

combustion chamber.

18. Remove upper and lower cover of the

heat exchanger.

19. Clean the heat exchanger internally with

a brush and remove dirt with a vacuum

cleaner.

20. Re-install the upper and lower cover of

the heat exchanger.

Always apply new gaskets between

the upper and lower cover and the

heat exchanger.

Re-install the heater in reversed order.

Apply the wiring of the thermostats

according to the electrical circuit

diagram. The thermostats are equal.

Reposition the bottom cover.

5.7 Removing the fuel tank (fig. 10)

1. Drain the fuel tank through the drain

cock, see fig. 3 (L).

2. Push the tank bolt up, see fig. 10 (C).

3. Support the fuel tank with a woo den reel

(A).

4. Remove the black knurled bolt (B) on the

left and right side of the fuel tank.

5. Remove the fuel tank using both hands

by grasping the bottom of the tank.

6. Remove the wooden reel.

7. Gently lower the fuel tank and take the

fuel tank from the heater.

Remove the fuel tank with care: the

fuel system is installed in the fuel

tank.

Install the fuel tank in reversed order.

5.8 Adjusting the pressure of the seal

cord (fig. 11)

1. Open the control panel (A), see 3.3.

2. Unscrew nut (B).

3. Turn the bottom (C) of the vaporiser

slightly up or down (depending on the

situation).

4. Unscrew nut (B).

5. Push the control panel in the heater.

5.6 Cleaning the flue (fig. 8)

1. Remove the bottom cover (B) of the T-

Check whether the seal cord seals

properly when the heater is running.

piece (A).

2. Clean the flue from top to bottom with a

flue brush.

3. Check the connections for leakage.

4. Check the flue parts for rust.

Caution

Rust formation indicates that chlorine

6 FAULTS

Warning

For all service and adjustments

contact qualified, competent and

authorized persons.

containing materials have been

burnt.

Chlorine containing materials

seriously damage the heater. This

may void your warranty.

Contact your dealer for instructions

on how to test waste oil for chlorine.

Warning

Switch off the power supply before

carrying out any repairs!

Ensure that the power is switched on,

and the fuel tank is full, before you

start troubleshooting.

14 40.020.943 - rev. 04 - 2011 AT 400 - 500-US series

English

6.1 Troubleshooting table

/i

Fault Cause Solution Action

The flame is extinguished immediately

after ignition; the

control light is off.

1 The heater has no volt-

age.

2 The fuel pump is not

switched on.

3 The motor and pump

are not functioning.

Check the electric connec-

User

tion.

Position the switch to "1", see

User

fig. 5 (A).

Dilute the waste oil with die-

User

sel oil when the waste oil is

too viscous.

Check the pump thermostat

Dealer

and replace if necessary.

Check the overflow protec-

User

tion switch by moving the

overflow basin a few times

from left to right.

Check whether the pump

User

axis can be turned manually.

Clean the pump if this is not

possible.

Check the pump motor. Dealer

The flame is extinguished immediately

after ignition; the

control light is on.

4 The pump thermostat

has not reached the

right temperature yet.

5 The maximum thermo-

stat is defective.

6 The overflow protection

is full of waste oil.

7 There is water or sedi-

ment in the fuel tank.

8 The fuel supply pipe is

blocked: The fuel flows

back into the fuel tank

through the return pipe.

Let the heater cool down.

User

Restart the heater.

Replace the pump thermo-

Dealer

stat.

Reset the thermostat. User

Replace the thermostat. User

Clean the overflow basin,

User

burner dish and the bottom of

the vaporiser.

Clean the fuel tank and the

User

fuel filter, see fig. 3.

Clean the fuel supply pipe or

User

replace if necessary.

AT 400 - 500-US series 40.020.943 - rev. 04 - 2011 15

English

Fault Cause Solution Action

The flame is extinguished immediately

after ignition; the

control light is on.

The air combustion

fan keeps running,

while the hot air fan

has stopped and the

heater has cooled

down.

There is soot formation in the combustion chamber and in

the flue.

There is soot formation in the combustion chamber and in

the flue.

9 There is no proper flue

draught.

10 The combustion thermo-

stat is defective.

11 The combustion air fan

is not functioning.

12 There is insufficient sup-

ply of combustion air

Check whether the flue is fit-

User

ted according to the description, see "flue".

Check the flue for leakage. User

Clean the flue if necessary. User

See faults: 3 and 4.

Replace the combustion

User

thermostat.

Check the motor and replace

Dealer

if necessary.

Clean the holes in the vapor-

User

iser.

Check the functioning of the

User

combustion air fan.

There is leakage

between the bottom

of the control panel

and the vaporiser.

The flame goes out

directly after ignition.

13 The flue draught is too

high or irregular.

14 There is leakage

between the bottom of

the control panel and

the vaporiser.

15 The flue draught is too

low.

Position a flue stack valve,

Dealer

see "flue".

Adjust the flue to the right

pressure, see § 5.3.

See faults: 9, 12, and 13.

Adjust the pressure on the

User

seal cord.

Replace the seal cord. User

Check all connections in the

User

flue.

Check whether the draught

User

regulator is off.

Check the flue for blockage. User

Reduce the number of

User

bends.

Heighten the flue. User

16 40.020.943 - rev. 04 - 2011 AT 400 - 500-US series

English

Fault Cause Solution Action

The flame goes out

directly after ignition.

The heater makes a

humming sound.

The flue draught is too

low.

16 There is too much diesel

oil at start up.

There is unburnt fuel

on the burner dish.

Record the maintenance details in table A in

the appendix of this manual.

7 SPARE PARTS

Before use we advise you to have spare parts

in store, see table B in the appendix of this

manual.

Isolate the flue outside the

User

building.

Check the flue, see "flue". User

Reduce the amount of diesel

User

oil.

Low temperatures for single

User

walled flue, for instance in

case of frost.

The sound will stop when the

temperature rises.

See faults: 2, 11, 12, 13 and

14.

8 TECHNICAL INFORMATION

• See for technical specifications table C in

the appendix of this manual.

9 INSTALLING ACCESSORIES

9.1 Flue (fig. 12)

The heater has a flue stack connection.

1. Push a T-piece (A) directly over the

connection (B).

2. Push the flue pipe (C) on the T-piece.

3. Use three screws to screw the flue pipe

to the T-piece.

AT 400 - 500-US series 40.020.943 - rev. 04 - 2011 17

Caution

The flue must meet the following

requirements.

• The flue must be pointed upwards.

• The flue (or any part of it) may not be

positioned horizontally. A 45° angle is

acceptable.

• It is not allowed to lenghten the flue

connection horizontally.

• When a pipe is used under 45°, pipe

pieces of at least 3.2 ft must be fitted in

front of and at the back of the slanting

pipe.

English

• The flue must stick out at least 1.6 ft

above the apex of the building.

• Keep the vertical part at the back of the

heater as long as possible before leading

it outside through the wall.

4. Fit the following pipe pieces.

5. Place a cap (D) at the end of the flue.

9.2 Diameter flue

/i

AT 400 AT 500

6 inch 8 inch

10 STANDARDS AND GUIDELINES

For the standards and guidelines, go to

www.thermobile.nl.

18 40.020.943 - rev. 04 - 2011 AT 400 - 500-US series

Français

Français

Table des matières

Consignes de sécurité .............................. 19

Introduction............................................... 21

Préparations.............................................. 22

Emploi....................................................... 25

Entretien.................................................... 25

Erreurs...................................................... 30

Pièces détachées...................................... 34

Caractéristiques techniques...................... 34

Installation accessoires............................. 34

Normes et directives................................. 34

Avant-propos

Ce manuel contient les instructions

d'utilisation des générateurs alimentés à

l'huile à utilisation fixe présentés en

couverture. Pour une utilisation correcte et

sans risque du générateur, veuillez lire

attentivement les informations de ce manuel.

Identification du produit (fig. 1)

La plaque signalétique est fixée sur le côté

du générateur. Elle indique les données

suivantes :

A Année de fabrication

B Numéro de série

C Code de production

D Données de tension

E Déplacement d'air

F Capacité max (kW)

G Capacité max (MJ/h)

H Type de machine

Environnement

Remarque

Le générateur se compose de

plusieurs métaux et matériaux

synthétiques. Le générateur contient

également des pièces électroniques

qui doivent être traitées comme des

déchets électroniques. Veuillez

contacter votre revendeur pour en

savoir plus.

1 CONSIGNES DE SÉCURITÉ

1.1 Pictogrammes de ce manuel

Précaution

Indique le risque de dommages à la

machine.

Avertissement

Indique une situation dangereuse,

qui peut provoquer la mort ou des

blessures graves.

Avertissement

Toujours couper l'alimentation avant

tout entretien ou réparation sur le

générateur!

Chaud

Certaines surfaces peuvent être

chaudes ! Faire refroidir

suffisamment ces pièces avant tout

action d'entretien.

Maintenance et support technique

Pour obtenir des informations sur le

générateur, veuillez contacter le revendeur

ou le fabricant. Assurez-vous de disposer

des informations suivantes : type et numéro

de série du générateur alimenté à l'huile à

utilisation fixe.

Garantie et responsabilité

Pour des conditions de garantie, voir les

conditions générales de garantie.

AT 400 - 500-US series 40.020.943 - rev. 04 - 2011 19

Suggestions et conseils pour

effectuer plus aisément les tâches ou

activités en question.

1.2 Pictogrammes sur le générateur à

l'huile à utilisation fixe (fig. 2)

A Avertissement de quantité d'huile à

utiliser

Instruction pour ne pas placer le plateau

brûleur sur une surface froide

B Thermostat de surchauffe

C Instructions de rallumage.

D Positions du brûleur : bas et haut.

Français

1.3 Utilisez ce produit pour son usage

prévu

Le générateur d'air chaud alimenté à l'huile

pour utilisation fixe a été conçu pour le

chauffage des ateliers des sociétés

d'usinage, le chauffage et la protection contre

le gel des halls, zones de transit et entrepôts

et le chauffage des ateliers automobiles.

Précaution

Si le générateur est installé à

l'intérieur, assurez-vous que la pièce

est correctement ventilée. Assurezvous que les gaz de refoulement

peuvent uniquement passer dans une

source externe à la pièce.

1.4 Consignes générales

Avertissement

• Assurez-vous de l'installation, du

réglage et de l'entretien corrects

du générateur.

• Pour tout entretien ou réglage,

contactez des personnes

qualifiées, compétentes et

agréées.

• N'apportez aucune modification

au générateur sans l'accord écrit

préalable du fabricant.

• Assurez-vous de toujours

respecter les normes et

directives locales ainsi que les

obligations locales relatives à

l'environnement, la qualité, les

carburants, les incendies et la

sécurité électrique.

• Lisez attentivement ce manuel

avant d'utiliser le générateur.

• Conservez ce document près du

générateur pour toute utilisation

ultérieure.

• Suivez les procédures décrites.

• Ne vous appuyez jamais contre

le générateur.

Avertissement

• Ne créez aucun risque d'incendie

en stockant ou en utilisant des

matériaux hautement

inflammables à proximité du

générateur. Conservez ces

matériaux à une distance

adéquate du générateur :

- haut et côtés 6 pouce (150

mm)

- avant 35 pouce (890 mm)

- arrière et tuyau de cheminée

8 pouce (460 mm)

• Veillez à ce qu’il y ait assez d’air

frais pour que la combustion soit

satisfaisante.

• Assurez-vous que le générateur

a refroidi suffisamment et que le

bouchon a été retiré de la douille

avant tout entretien ou

réparation.

1.5 Sécurité additionnelle

Avertissement

• Connectez le générateur

uniquement à une alimentation

120 V / 60 Hz.

• Remplacez les fusibles

uniquement à l'identique.

• Le générateur doit être mis à la

terre.

20 40.020.943 - rev. 04 - 2011 AT 400 - 500-US series

Français

Avertissement

• Utilisez uniquement les types de

combustibles suivants :

• Huile transmission

automatique

• Huile de carter

•Diesel

• Huile hydraulique

• Fioul domestique

• N'ajoutez pas les matières

suivantes à l'huile utilisée :

• Antigel

• Nettoyant de carburateur

• Diluant pour peinture

• Solvants de nettoyage de

pièces

• Essence

• Huile de transformation

• Additifs d'huile

• Toute autre matière

dangereuse ou inappropriée

• Ne remplissez p as le rés ervoi r si

le générateur marche.

2 INTRODUCTION

2.1 But

Ces générateurs alimentés à l'huile à

utilisation fixe sont des générateurs à

alimentation directe avec protection

thermique, échangeur de chaleur, ventilateur

d'air de combustion, connexion de tuyau de

cheminée avec raccord en T et régulateur de

tirage et ventilateur d'air chaud.

L'AT 500 est équipé d'une connexion pour

thermostat d'ambiance

Les générateurs d'air chaud ont été testés au

niveau de la mer et à une température de

68 °F.

Le second moteur électrique entraîne le

ventilateur d'air de combustion qui souffle l'air

de combustion dans la chambre de

combustion.

Le troisième moteur électrique entraîne le

ventilateur d'air chaud qui tire l'air de la partie

autour de la chambre de combustion et de

l'échangeur de chaleur. L'air chaud est

soufflé dans l'espace à chauffer.

Le diesel est versé manuellement dans un

plateau brûleur qui est allumé par une

boulette de papier brûlante. Dès que le

plateau brûleur est à la bonne température,

le thermostat de la pompe active la pompe à

combustible. Le témoin de contrôle s'allume.

La pompe de carburant pompe l'huile utilisée

dans le plateau brûleur. L'huile utilisée

s'évapore en raison de la température du

plateau brûleur. Les vapeurs gazeuses

brûlent. Un thermostat enclenche le moteur

du ventilateur d'air chaud pour souffler l'air

chaud dans l'espace à chauffer.

Le thermostat de la pompe coupe la pompe à

combustible en cas de panne provoquant

une surchauffe du générateur.

La pompe à combustible est coupée lorsque

le générateur est coupé.

Le ventilateur d'air chaud fonctionne jusqu'à

ce que le thermostat d'air de combustion

l'arrête : le générateur peut ainsi refroidir.

Le thermostat maximum coupe le générateur

lorsque la température est trop élevée.

L'alimentation en combustible présente un

trop plein qui garantit que l'huile utilisée

retourne dans le réservoir de combustible

lorsque le tuyau de combustible est bouché.

La protection de trop plein coupe la pompe à

combustible lorsque le plateau brûleur

déborde.

2.2 Principe de fonctionnement

Les générateurs alimentés à l'huile à

utilisation fixe sont équipés de trois moteurs

électriques.

Le premier moteur électrique entraîne une

pompe à combustible qui extrait le

combustible du réservoir de combustible.

AT 400 - 500-US series 40.020.943 - rev. 04 - 2011 21

Français

2.3 Principaux composants des

générateurs alimentés à l'huile à

utilisation fixe (fig. 3)

A Cache

B Chambre de combustion

C Échangeur de chaleur

D Thermo stat maximum

E Thermostats

F Raccord en T avec régulateur de tirage

G Ventilateur d'air chaud

H Ventilateur d'air de combustion

I Filtre de remplissage

J Panneau de commande

K Réservoir de combustible

L R obinet de purge

M Filtre à combustible

N Pompe à combustible

O Plaque signalétique

P Conduite de retour

QTiroir

R Tuyau de combustible

S Tuyau d'alimentation en combustible

2.4 Principaux composants du brûleur

(fig. 4)

A Cache chambre de combustion

B Chambre de combustion

C Pare-flamme

D Bague de brûleur

E Bourrelet de joint

F Plateau brûleur

G Vaporisateur

H Fond de chambre de combustion

I Protection de trop plein

J Pelle

2.5 Panneau de commande (fig. 6)

A Témoin jaune

B Témoin rouge

C Bou lon réservoir de combustible

D Interrupteur à bascule :

- 0: La pompe est arrêtée

- 1: La pompe fonctionne

- 2: Vitesse pompe élevée

(uniquement pour AT 500)

2.6 Thermostat

Le générateur comporte les thermostats

suivants :

• Thermostat de pompe

Lorsque le plateau brûleur est

suffisamment préchauffé, la pompe à

combustible se met en marche.

• Thermostat d'air chaud :

Le thermostat lance le ventilateur d'air

chaud lorsque le générateur atteint une

certaine température.

•Thermostat maximum

Le thermostat coupe la pompe à

combustible lorsque la température de

l'air chaud est trop élevée.

2.7 Accessoires

• Tuyau de cheminée avec capuchon antipluie

3 PRÉPARATIONS

3.1 Retrait de l’emballage

1. Enlevez l’emballage du générateur d'air

chaud.

2. Retirez l'emballage des pièces libres de

la chambre de combustion.

3. Retirez l'emballage des pièces libres de

la chambre de combustion.

3.2 Installation

1. Vérifiez que le générateur est à

l'horizontale.

2. Fixez correctement les pièces de la

chambre de combustion, voir fig. 4.

3. Fixez les diverses poignées au cache et

au tiroir, voir fig. 3.

4. Poussez le boulon du réservoir vers le

haut, voir fig. 5 (D).

5. Tirez le réservoir de combustible vers le

haut.

22 40.020.943 - rev. 04 - 2011 AT 400 - 500-US series

Français

6. Remplissez le réservoir de combustible

avec l'huile utilisée pour que le niveau

soit 1 pouce sous le haut du réservoir.

Précaution

Seuls les types de combustibles

suivants peuvent être utilisés avec

les générateurs alimentés à l'huile à

utilisation fixe :

• Huile transmission automatique

•Diesel

• Huile hydraulique

• Huile à usage domestique

Remarque

• Installez l'équipement aux ÉtatsUnis selon les publications

suivantes de la National Fire

Protection Association :

• NFPA #30: Flammable and

Combustible Liquids Code

• NFPA #31: Oil Burning

Equipment

• NFPA #88A: Parking

Structures

• NFPA #88B: Repair Garages

• NFPA #211: Chimneys,

Fireplaces and Vents

• Les codes locaux peuvent exiger

le montage du générateur à un

minimum de 8 pied (2.4 m) m du

sol. C'est spécialement le cas si

la pièce peut contenir des

fumées combustibles ou

inflammables. Voir NFPA #88B.

• Installez l'équipement au Canada

selon les normes suivantes :

CAN B139, Code d'installation

pour équipement de combustion

d'huile.

Placez le générateur dans un endroit

respectant les conditions suivantes :

• Possibilité d'une distribution

uniforme et libre de la chaleur.

• Accès sécurisé et facile pour

l'entretien.

• Passage libre pour les véhicules

et équipement d'atelier.

• Distance adaptée des

combustibles. Voir la section

Sécurité.

• Air de combustion adéquat selon

les codes locaux. La pièce doit

être ventilée afin de fournir

suffisamment d'air de

combustion. La consommation

maximum d'air est de 12 USG/h

3

(46 m

/h.

• Installation correcte du tuyau.

• La structure dans laquelle le

générateur se trouve doit

présenter les dimensions

minimum suivantes :

• hauteur depuis le point

d'emplacement du

générateur : 15 pied (4.5 m).

• longueur et largeur : 20 pied

(6 m).

• surface au sol : 400 pied

carré (36 m

2

).

• Possibilité de placer le

générateur sur un sol

combustible.

• Si le générateur est installé en

hauteur, une plate-forme

permanente, incluant des

escaliers ou des rampes, doit

être prévue pour faciliter

l'entretien régulier.

AT 400 - 500-US series 40.020.943 - rev. 04 - 2011 23

7. Fermez le réservoir de combustible :

vérifiez qu'il est verrouillé.

8. Veillez également à ce que le flux d’air

réchauffé ne soit pas obstrué.

9. Assurez-vous que les matériaux

inflammable sont suffisamment éloignés

du générateur, voir 1.4.

Français

10. Assurez-vous que la ventilation soit

suffisante : la consommation maximum

d'air est de 2650 ft

3

/h.

11. Vérifiez la surface au sol : elle doit

mesurer au moins 645 ft

2

.

12. Installez le tuyau de cheminée (18 ft de

long et un capuchon anti-pluie)

13. Assurez-vous que l'interrupteur à bascule

est sur 0.

14. Vérifiez la tension d’alimentation : pour

cela, consulter la plaque signalétique.

15. Branchez la prise électrique.

3.3 Préparation à démarrage

1. Positionnez l'interrupteur à bascule sur

"0".

2. Uniquement pour l'AT 400 :

Positionnez l'interrupteur (A) de la pompe

à combustible sur "bas", voir (fig. 5).

3. Purgez le condensat potentiel du

réservoir de combustible, voir fig. 3 (L).

4. Ouvrez le tiroir : enfoncez la pédale (A)

sans la relâcher , soulevez la sécurité (B),

tournez la commande (C) à droite ou à

gauche et lâchez la pédale, voir fig. 7.

Tirez le tiroir (D) en avant.

5. Vérifiez si le plateau brûleur et le fond de

la chambre de combustion sont propres

et froids.

6. Nettoyez le plateau brûleur et le fond de

la chambre de combustion, si nécessaire.

7. Versez 0,3 litre de diesel sur le plateau

brûleur, voir fig. 4 (F).

Avertissement

Ne versez jamais le diesel sur un

plateau brûleur chaud.

Le plateau brûleur doit être froid !

8. Formez une boulette de papier et

allumez-la.

9. Jetez la boulette de p apier brûlante sur le

plateau brûleur.

10. Fermez le tiroir.

11. Vérifiez à travers le cache supérieur

qu'aucune flamme ne se trouve autour du

bourrelet de joint et entre le fond et la

chambre de combustion, voir fig. 4.

3.4 Démarrage

Avertissement

• Ne versez jamais le diesel sur un

plateau brûleur chaud. Le

plateau brûleur doit être froid et

propre !

• Ne démarrez pas le générateur

si le ventilateur tourne encore. Le

générateur refroidit.

• Ne démarrez pas le générateur

si l'huile s'est excessivement

accumulée dans le générateur

ou à proximité.

Précaution

Ne mettez pas le générateur en

marche en l'absence de combustible

ou si le réservoir de combustible

connecté est vide.

Précaution

Seuls les types de combustibles

suivants peuvent être utilisés avec

les générateurs alimentés à l'huile à

utilisation fixe :

• Huile transmission automatique

• Huile de carter

•Diesel

• Huile hydraulique

• Fioul domestique

1. Positionnez l'interrupteur à bascule sur

"2", voir fig. 6 (D).

Lorsque le plateau brûleur a atteint la

bonne température, la pompe à

combustible se met en marche et le

témoin de contrôle s'allume.

2. Pendant les 20 à 30 premières minutes,

la pompe à combustible devrait avoir une

faible capacité.

Pour AT 400 :

Positionnez l'interrupteur à bascule sur

"bas", voir fig. 5 (A).

Pour AT 500 :

24 40.020.943 - rev. 04 - 2011 AT 400 - 500-US series

Français

Le témoin jaune est allumé, voir fig. 6 (A).

3. Réglez le régulateur de pompe sur haute

capacité si la capacité maximum est

nécessaire.

Pour AT 400 :

Positionnez l'interrupteur à bascule sur

"haut", voir fig. 5 (B).

Pour AT 500 :

Positionnez l'interrupteur à bascule sur

"2", voir fig. 6 (D). Le témoin rouge est

allumé, voir fig. 6 (B).

4EMPLOI

4.1 Au cours du fonctionnement

Précaution

• N'utilisez pas le générateur par

temps chaud pour brûler de

l'huile.

• Ne brûlez aucune huile usée

exceptée celle générée sur le

site du propriétaire, sauf

autorisation écrite de l'autorité

régulatoire.

Chaud

Ne touchez pas au tuyau de

cheminée ni à la sortie d'air ! Le

tuyau de cheminée et la sortie d'air

deviennent chauds pendant le

fonctionnement!

4.2 Arrêt

Arrêt du chauffage:

1. Positionnez l'interrupteur à bascule sur

"0".

La pompe à combustible s'arrête.

Le témoin de contrôle s'éteint.

Précaution

Une fois le générateur arrêté, il

continue de tourner plusieurs

minutes pour consommer tout le

combustible du plateau brûleur.

Pendant ce temps, le ventilateur d'air

chaud et le ventilateur de diffusion

continuent de tourner. Ces

ventilateurs refroidissent le

générateur jusqu'à ce qu'il soit

suffisamment froid (après 10 à 30

minutes).

Les deux ventilateurs s'arrêtent à

peu près au même moment.

5ENTRETIEN

5.1 Tableau d’entretien

Utilisez le tableau dans ce manuel pour

enregistrer l'entretien effectué après chaque

saison d'hiver.

Avertissement

Pour tout entretien ou réglage,

contactez des personnes qualifiées,

compétentes et agréées.

AT 400 - 500-US series 40.020.943 - rev. 04 - 2011 25

Avertissement

Nettoyez toujours la chambre de

combustion avant de démarrer le

générateur.

Chaud

Ne touchez ni au tuyau de cheminée

ni à la sortie d’air !

Attendez que le tuyau de cheminée

et la sortie d'air aient suffisamment

refroidi avant d'effectuer tout

entretien.

Français

/i

Description Fréquence

Nettoyez le plateau brûleur. X

Purgez la condensation (l'eau) du réser-

voir de combustible si le déchet d'huile

contient de l'eau.

Nettoyez la chambre de combustion. X

Nettoyez la bague du brûleur. X

Nettoyez la chambre de combustion et

le vaporisateur avec une brosse à dents.

Nettoyez la chambre de combustion et

le vaporisateur avec une brosse à dents.

Nettoyez le tuyau de trop plein au fond

de la chambre de combustion. Voir fig. 4

(I).

Vérifiez si les tuyaux d'huile présentent

une fuite.

Toutes les

12

heures

X

X

Hebdomadaire

X

Mensuel

X

Tous

les six

mois

X

Annuel Tous

les

deux

ans

Nettoyez le réservoir de combustible, le

filtre d'alimentation et le filtre à combustible.

Le réservoir à combustible est facilement amovible.

Contrôlez le ventilateur d'air de combustion et nettoyez-le au besoin.

Contrôlez le ventilateur d'air chaud et

nettoyez-le au besoin.

Nettoyez la vanne de tuyau de cheminée dans la pièce en T, voir fig. 8 (A).

Le tirage recommandé est de 2 mmce.

Vérifiez les traces de fuite au niveau du

joint entre le fond et le vaporisateur.

Réglez la pression sur le bourrelet de

joint ou remplacez le joint.

X

X

X

Revendeur

X

26 40.020.943 - rev. 04 - 2011 AT 400 - 500-US series

Description Fréquence

Français

Toutes les

12

Hebdomadaire

Mensuel

Tous

les six

mois

heures

Remplacez le bourrelet de joint au fond.

X

Vérifiez si la bague de joint fuit.

Réglez la pression sur le bourrelet de

joint en cas de fuite.

Nettoyez l’échangeur de chaleur. X

Nettoyez la pièce en T du tuyau de che-

minée, voir "nettoyage de la vanne de

tuyau de cheminée".

Vérifiez le câblage du générateur. X

Nettoyez l’échangeur de chaleur.

Retirez l'échangeur de chaleur pour le

nettoyer correctement.

Chaud

Ne touchez pas au tuyau de

cheminée ni à la chambre de

combustion !

N'effectuez aucun entretien tant que

le tuyau de cheminée et la chambre

de combustion n'ont pas refroidi.

5.3 Nettoyage de la chambre de

combustion(fig. 4)

1. Ouvrez le cache du générateur, voir fig. 4

(A).

2. Retirez la bague du brûleur (D) avec le

crochet de la pelle (J).

3. Nettoyez la bague du brûleur avec une

brosse d'acier.

5.2 Général

Avertissement

Coupez l'alimentation électrique

avant toute réparation !

4. Retirez le plateau brûleur (F) avec le

crochet de la pelle.

5. Nettoyez le plateau brûleur avec un

grattoir.

Annuel Tous

les

deux

ans

X

X

Si le générateur est stocké pendant une

période prolongée :

1. Éteignez le générateur.

2. Débranchez la prise d'alimentation.

3. Nettoyez le générateur.

4. Utilisez un chiffon huileux pour nettoyer

la chambre de combustion afin de la

protéger de la corrosion.

Avertissement

N'utilisez pas le générateur par

temps chaud pour brûler de l'huile.

AT 400 - 500-US series 40.020.943 - rev. 04 - 2011 27

Français

6. Nettoyez l'intérieur de la chambre de

combustion (B) et du vaporisateur (G)

avec l'avant de la pelle.

Remarque

• Les huiles utilisées peuvent

contenir des composés

métalliques et des substances

étrangères. Ces matières restent

sous forme de résidus une fois

brûlées. Il est donc nécessaire de

faire attention en utilisant, en

nettoyant et en entretenant le

générateur.

• Portez un équipement de

protection pour nettoyer

l'intérieur du générateur :

• Respirateur pour particules

fines

• Gants en caoutchouc

• Lunettes de sécurité

• Vêtements de protection

• Assurez-vous que tous les

orifices de la chambre de

combustion restent ouverts pour

alimenter la combustion en air.

7. Retirez toute trace de suie du fond de la

chambre de combustion.

8. Nettoyez l'intérieur du tuyau du

vaporisateur avec une petite brosse

(diamètre 4 mm).

9. Nettoyez la conduite alimentation en

combustible (N) avec une brosse

(diamètre intérieur de 8,38 mm), voir fig.

3.

10. Installez les pièces en ordre inverse.

5.4 Nettoyage de l’échangeur de

chaleur (fig. 9)

1. Déconnectez l'alimentation électrique du

générateur.

2. Ouvrez le cache, voir fig. 3 (A).

3. Dévissez la fixation du thermostat (A).

4. Retirez le câblage des deux thermostats

(B).

5. Ôtez la barrette de sécurité (C).

6. Ôtez la barrette de sécurité (D).

7. Retirez le cache (E) de l'échangeur de

chaleur.

8. Nettoyez l'intérieur de l'échangeur de

chaleur avec une brosse et un aspirateur.

9. Installez à nouveau le cache de

l'échangeur de chaleur.

Prévoyez toujours un joint (F) neuf

entre le cache et l'échangeur de

chaleur.

Installez les pièces en ordre inverse.

Replacez le câblage des thermostats

selon le diagramme de circuit

électrique. Les thermostats sont

identiques.

5.5 Retrait de l'échangeur de chaleur

(fig. 9)

1. Déconnectez l'alimentation électrique du

générateur.

2. Retirez le raccord en T (A) du tuyau de

cheminée, voir fig. 3 (F).

3. Retirez la grille, voir fig. 3 (A).

4. Dévissez la fixation du thermostat (A).

5. Retirez le câblage des deux thermostats

(B).

6. Ôtez la barrette de sécurité (C).

7. Ôtez la barrette de sécurité (D).

8. Retirez le tuyau d'alimentation en

combustible, voir fig. 3 (S).

9. Dévissez le support de cuvette de trop

plein et placez la protection de trop plein

sur le fond du générateur.

10. Retirez le ventilateur d'air de combustion

(H) avec le support de moteur, voir fig. 3.

11. Dévissez le panneau arrière du

générateur et tournez-le à 180° vers le

réservoir de combustible.

Soutenez temporairement le panneau

arrière dans cette position.

12. Retirez le carter du ventilateur d'air de

combustion.

Avertissement

Ne modifiez pas la position de la

vanne dans le carter.

28 40.020.943 - rev. 04 - 2011 AT 400 - 500-US series

Français

13. Dévissez le cadre de la chambre de

combustion de la plaque de fond du

générateur.

14. Levez la chambre de combustion avec

l'échangeur de chaleur hors du

générateur.

Demandez de l'aide à une autre

personne.

15. Dévissez la connexion de la chambre de

combustion et de l'échangeur de chaleur.

16. Retirez la barrette entre la chambre de

combustion et l'échangeur de chaleur.

17. Retirez l'échangeur de chaleur de la

chambre de combustion.

18. Retirez les caches supérieur et inférieur

de l'échangeur de chaleur.

19. Nettoyez l'intérieur de l'échangeur de

chaleur avec une brosse et retirez les

salissures avec un aspirateur.

20. Installez à nouveau les caches supérieur

et inférieur de l'échangeur de chaleur.

Appliquez toujours des joints neufs

entre les caches supérieur et

inférieur et l'échangeur de chaleur.

Installez le générateur dans l'ordre inverse.

Replacez le câblage des thermostats

selon le diagramme de circuit

électrique. Les thermostats sont

identiques.

5.6 Nettoyage du tuyau de cheminée

(fig. 8)

1. Retirez le cache du fond (B) de la pièce

en T (A).

2. Nettoyez le tuyau de cheminée du fond

avec un hérisson.

3. Vérifiez si les connexions fuient.

4. Vérifiez si les pièces du tuyau de

cheminée présentent des traces de

rouille.

Précaution

La formation de rouille indique que

des matériaux contenant du chlore

ont été brûlés.

Les matériaux contenant du chlore

peuvent endommager gravement le

générateur. Votre garantie peut être

annulée.

Contactez votre revendeur pour en

savoir plus sur le moyen de tester la

présence de chlore dans l'huile de

rebut.

Repositionnez le cache du fond.

5.7 Retirez le réservoir de

combustible (fig. 10)

1. Purgez le réservoir à combustible via le

robinet de purge, voir fig. 3 (L).

2. Poussez le boulon du réservoir vers le

haut, voir fig. 10 (C).

3. Soutenez le réservoir de combustible

avec une pièce de bois (A).

4. Retirez la molette noire (B) à gauche et à

droite du réservoir de combustible.

5. Retirez le réservoir de combustible avec

les deux mains en tenant le fond du

réservoir.

6. Retirez la pièce de bois.

7. Abaissez doucement le réservoir de

combustible et retirez-le du générateur.

Retirez le réservoir de combustible

avec un soin extrême : le circuit de

combustible est installé dans le

réservoir de combustible.

Installez le réservoir à combustible en ordre

inverse.

AT 400 - 500-US series 40.020.943 - rev. 04 - 2011 29

5.8 Réglage de la pression du

bourrelet de joint (fig. 11)

1. Ouvrez le panneau de commande (A),

voir 3.3.

2. Desserrez l'écrou (B).

Français

3. Tournez légèrement le fond (C) du

vaporisateur à gauche ou à droite (selon

la situation).

4. Desserrez l'écrou (B).

5. Poussez le p anneau de commande dans

le générateur.

Vérifiez si le bourrelet de joint scelle

correctement lorsque le générateur

marche.

6 ERREURS

Avertissement

Pour tout entretien ou réglage,

contactez des personnes qualifiées,

compétentes et agréées.

Avertissement

Coupez l'alimentation électrique

avant toute réparation !

Assurez-vous que l'alimentation

électrique est activée et que le

réservoir à combustible est plein

avant de commencer le dépannage.

30 40.020.943 - rev. 04 - 2011 AT 400 - 500-US series

Français

6.1 Tableau de dépannage

/i

Défaillance Cause Solution Action

La flamme est

éteinte immédiatement après l'allumage. Le témoin

s'éteint.

1 Le générateur n'est pas

sous tension.

2 La pompe à combustible

n'est pas allumée.

3 Le moteur et la pompe

ne fonctionnent pas.

Vérifier le branchement élec-

Utilisateur

trique.

Positionnez l'interrupteur sur

Utilisateur

"1", voir fig. 5 (A).

Diluez l'huile de rebut avec

Utilisateur

du diesel lorsqu'elle est trop

visqueuse.

Vérifiez le thermostat de

pompe et remplacez-le au

Reven-

deur

besoin.

Contrôlez l'interrupteur de

Utilisateur

protection de trop plein en

remuant la cuvette de trop

plein à droite et à gauche.

Vérifiez si l'arbre de pompe

Utilisateur

tourne manuellement. Nettoyez la pompe dans le cas

contraire.

Vérifiez le moteur de pompe. Reven-

deur

La flamme est

éteinte immédiatement après l'allumage. Le témoin

s'éteint.

4 Le thermostat de pompe

n'a pas encore atteint la

bonne température.

5 Le thermostat maxi-

mum est défectueux.

6 La protection de trop

plein est pleine d'huile

de rebut.

Laissez le générateur refroi-

Utilisateur

dir.

Redémarrez le générateur.

Remplacez le thermostat de

pompe.

Reven-

deur

Réinitialisez le thermostat. Utilisateur

Remplacez le thermostat. Utilisateur

Nettoyez la cuvette de trop

Utilisateur

plein, le plateau brûleur et le

fond du vaporisateur.

AT 400 - 500-US series 40.020.943 - rev. 04 - 2011 31

Français

Défaillance Cause Solution Action

La flamme est

éteinte immédiatement après l'allumage. Le témoin

brûle.

Le ventilateur d'air

de combustion continue de tourner alors

que celui d'air chaud

est arrêté et le générateur a refroidi.

7 Présence d'eau ou de

sédiment dans le réservoir à combustible.

8 Le tuyau d'alimentation

en combustible est bouché : le combustible

retourne dans son

réservoir via le tuyau de

retour.

9 Le tirage du tuyau de

cheminée n'est pas bon.

10 Le thermostat de com-

bustion est défectueux.

Nettoyez le réservoir et le filtre à combustible, voir fig. 3.

Nettoyez ou remplacez le

tuyau d'alimentation de combustible, au besoin.

Vérifiez si le tuyau de cheminée est raccordé selon la

description, voir "tuyau de

cheminée".

Vérifiez si le tuyau de cheminée fuit.

Nettoyez le tuyau de cheminée au besoin.

Voir défaillances : 3 et 4.

Remplacez le thermostat de

combustion.

Utilisateur

Utilisateur

Utilisateur

Utilisateur

Utilisateur

Utilisateur

De la suie se forme

dans la chambre de

combustion et le

tuyau de cheminée.

11 Le ventilateur d'air de

combustion ne fonctionne pas.

12 L'alimentation d'air de

combustion est insuffisante.

Vérifiez et remplacez le

moteur si nécessaire.

Nettoyez les orifices du

vaporisateur.

Vérifiez le fonctionnement du

Revendeur

Utilisateur

Utilisateur

ventilateur d'air de combustion.

32 40.020.943 - rev. 04 - 2011 AT 400 - 500-US series

Français

Défaillance Cause Solution Action

De la suie se forme

dans la chambre de

combustion et le

tuyau de cheminée.

Il y a une fuite entre

le fond du panneau

de commande et le

vaporisateur.

La flamme s'éteint

directement après

l'allumage.

13 Le tuyau de cheminée

est trop haut ou irrégulier.

14 Il y a une fuite entre le

fond du panneau de

commande et le vaporisateur.

15 Le tirage du tuyau de

cheminée est trop faible.

Positionnez une vanne de

tuyau de cheminée, voir

"tuyau de cheminée".

Réglez le tuyau de cheminée

à la pression correcte, voir §

5.3.

Voir défaillances : 9, 12 et

13.

Réglez la pression du bour-

relet de joint

Remplacez le bourrelet de

joint.

Vérifiez toutes les con-

nexions du tuyau de cheminée.

Vérifiez si le régulateur de

tirage est coupé.

Vérifiez si le tuyau de cheminée est obstrué.

Revendeur

Utilisateur

Utilisateur

Utilisateur

Utilisateur

Utilisateur

Le générateur émet

un bourdonnement.

16 Il y a trop de diesel au

démarrage.

Réduisez le nombre de coudes.

Relevez le tuyau de cheminée.

Isolez le tuyau de cheminée

à l'extérieur du bâtiment.

Vérifiez le tuyau de cheminée, voir "tuyau de cheminée".

Réduisez la quantité de diesel.

Températures basses pour

les tuyau de cheminée à

paroi unique, par exemple en

cas de gel.

Le son cesse dès que la température s'élève.

Utilisateur

Utilisateur

Utilisateur

Utilisateur

Utilisateur

Utilisateur

AT 400 - 500-US series 40.020.943 - rev. 04 - 2011 33

Français

Défaillance Cause Solution Action

Le plateau brûleur

contient du combustible non brûlé.

Conserver les informations d’entretien dans

le tableau A qui se trouve en annexe de ce

manuel.

7 PIÈCES DÉTACHÉES

Il est recommandé de toujours disposer de

pièces détachées en stock: voir tableau B en

annexe de ce manuel.

8 CARACTÉRISTIQUES

TECHNIQUES

• Pour des spécifications techniques, voir

le tableau C dans l'annexe de ce manuel.

9 INSTALLATION ACCESSOIRES

9.1 Tuyau de cheminée (fig. 12)

Le générateur comporte une connexion pour

le tuyau de cheminée.

1. Poussez une pièce en T (A) directement

sur la connexion (B).

2. Poussez le tuyau de cheminée (C) sur la

pièce en T.

3. Utilisez trois vis pour fixer le tuyau de

cheminée sur la pièce en T.

Voir défaillances : 2, 11, 12,

13 et 14.

• Si un tuyau est utilisé à 45°, les pièces de

tuyau d'au moins 1 m doivent être

montées à l'avant et à l'arrière du tuyau

incliné.

• Le tuyau de cheminée doit dépasser d'au

moins 0,5 m au dessus du bâtiment.

• Maintenez la partie verticale à l'arrière du

générateur aussi longue que possible

avant de la faire passer à l'extérieur dans

le mur.

4. Fixez les pièces de tuyau suivantes.

5. Placez un capuchon (D) à l’extrémité du

tuyau.

9.2 Diamètre tuyau cheminée

/i

AT 400 AT 500

6 pouce 8 pouce

10 NORMES ET DIRECTIVES

Pour les normes et directives, rendez-vous

sur le site www.thermobile.nl.

Précaution

Le tuyau de cheminée doit respecter

les impératifs suivants.

• Le tuyau de cheminée doit être dirigé

vers le haut.

• Le tuyau de cheminée (ou une de ses

parties) ne peut être positionné à

l'horizontale. Un angle de 45° est

acceptable.

• Il n'est pas permis d'allonger le raccord

de tuyau de cheminée à l'horizontale.

34 40.020.943 - rev. 04 - 2011 AT 400 - 500-US series

Español

Español

Índice

Instrucciones de seguridad.......................35

Introducción .............................................. 38

Preparaciones........................................... 39

Uso............................................................ 42

Mantenimiento .......................................... 43

Fallos ........................................................ 47

Piezas de repuesto................................... 51

Información técnica................................... 51

Instalación de accesorios.......................... 51

Normas y directivas ..................... ............. 51

Prólogo

Este manual contiene las instrucciones de

uso de los generadores de uso estacionario

que utilizan aceite que se muestran en la

portada. La información de este manual es

importante para el uso correcto y seguro del

generador.

Identificación del producto (fig. 1)

La placa de identificación está fijada en el

lateral del generador. En la placa de

identificación figuran los siguientes datos:

A Año de fabricación

B Número de serie

C Código de fabricación

D Datos sobre tensión

E Desplazamiento de aire

F Capacidad máx. (kW)

G Capacidad máx. (MJ/h)

H Modelo de máquina

Servicio y asistencia técnica

Póngase en contacto con su distribuidor o

con el fabricante para obtener información

sobre el generador de aire caliente.

Asegúrese de tener a mano los siguientes

datos: el modelo y el número de serie del

generador de uso estacionario que utiliza

aceite.

Medio ambiente

Nota

El generador de aire caliente está

fabricado de diversos materiales

metálicos y sintéticos. El generador

también contiene componentes

electrónicos, que tienen que tratarse

como desechos electrónicos.

Póngase en contacto con su

distribuidor para obtener más

información.

1 INSTRUCCIONES DE SEGURIDAD

1.1 Símbolos utilizados en este

manual

Precaución

Indica un riesgo de daños en el

aparato.

Advertencia

Indica una situación peligrosa, que

puede provocar la muerte o lesiones

graves.

Advertencia

¡Desconecte siempre la alimentación

eléctrica cuando realice trabajos de

mantenimiento o reparaciones en el

generador de aire caliente!

Caliente

¡Algunas superficies pueden estar

calientes! Espere hasta que estos

componentes se hayan enfriado lo

suficiente antes de realizar el

mantenimiento.

Sugerencias y consejos para

simplificar la realización de las tareas

o acciones especificadas.

Garantía y responsabilidad

Consulte los términos de garantía y

responsabilidad en las reglas generales de

garantía.

AT 400 - 500-US series 40.020.943 - rev. 04 - 2011 35

Español

1.2 Símbolos en el generador de uso

estacionario que utiliza aceite (fig.

2)

A Advertencia sobre la cantidad de aceite

que debe emplearse

Instrucción sobre no colocar el plato

quemador en una superficie fría

B Termostato de sobrecalentamiento

C Instrucciones de reencendido.

D Posiciones del quemador: baja y alta.

1.3 Utilice este producto para su uso

previsto

El generador de aire caliente de uso

estacionario que utiliza aceite se ha diseñado

para el calentamiento de talleres en

empresas de mecanizado, el calentamiento y

protección antihielo de salas, naves de

tránsito y almacenes y para el calentamiento

de talleres mecánicos.

Precaución

Si va a instalar el generador de aire

caliente por convección en el interior,

asegúrese de que haya la suficiente

ventilación en el recinto. Asegúrese

de que los gases de la chimenea

puedan salir únicamente a una fuente

exterior independiente del recinto.

36 40.020.943 - rev. 04 - 2011 AT 400 - 500-US series

Español

1.4 Instrucciones generales

Advertencia

• Asegúrese de que el generador

esté correctamente instalado,

ajustado y mantenido.

• Para todos los ajustes y tareas

de mantenimiento, póngase en

contacto con personal con la

debida formación, competencia y

autorización.

• No realice modificaciones al

generador sin el previo

consentimiento por escrito del

fabricante.

Advertencia

• Asegúrese de seguir siempre las

normativas y directivas locales,

así como los requisitos relativos

a la calidad medioambiental y a

la seguridad eléctrica,

antiincendios y de combustible.

• Lea este manual detenidamente

antes de utilizar el generador.

• Mantenga este documento con el

generador.

• Siga los procedimientos

descritos.

• No se apoye nunca en el

generador.

• No provoque un riesgo de

incendio almacenando o

utilizando materiales altamente

inflamables cerca del generador.

Mantenga estos materiales a una

distancia adecuada del

generador:

- parte superior y laterales 6

pulgada (150 mm)

- parte delantera 35 pulgada

(890 mm)

- parte posterior y chimenea

18 pulgada (460 mm)

• Asegúrese de que haya

suficiente aire fresco para

garantizar una correcta

combustión.

• Asegúrese de que el generador

de aire caliente por convección

se haya enfriado lo suficiente y

de que se haya quitado el

enchufe de la toma de corriente

antes de realizar trabajos de

reparación o mantenimiento.

AT 400 - 500-US series 40.020.943 - rev. 04 - 2011 37

Español

1.5 Seguridad adicional

Advertencia

• Conecte el generador

únicamente a un suministro de

alimentación de 120 V / 60 Hz.

• Sustituya los fusibles por

repuestos idénticos.

• El generador debe conectarse a

tierra.

Advertencia

• Utilice únicamente los siguientes

tipos de combustible:

• Aceite para transmisión

automática

• Aceite para el cárter del

cigüeñal

• Gasóleo

• Aceite hidráulico

• Fuel-oil doméstico

• No añada los siguientes

materiales al aceite usado:

• Anticongelante

• Limpiador de carburador

• Diluyente de pinturas

• Disolventes de limpieza de

componentes

• Gasolina

• Aceite para transformador