THERMO 2000 VOLTMAX 36, VOLTMAX 27, VOLTMAX 30, VOLTMAX 41, VOLTMAX 50 Installation And Operation Manual

...

1

VOLTMAX Electric Boiler

Your VOLTMAX Electric Boiler was carefully assembled and checked at the factory to ensure its proper

functioning for many years. The following information and safety measures are provided to enable

proper installation, operation, and maintenance of this product.

It is imperative that all persons who are expected to install, operate or adjust this boiler should read

these instructions carefully.

Any questions regarding the operation, maintenance, service or warranty of this electric boiler should be

directed to the installer or to a skilled technician.

When all installation steps have been completed, keep this installation manual in a safe place (near the

boiler) for future reference.

THERMO 2000 INC.

Printed in Canada Revised: August 2017

INSTALLATION AND OPERATION MANUAL

mo

TABLE OF CONTENTS

SECTION 1 : TECHNICAL SPECIFICATIONS ............................................................... 4

SECTION 2 : INTRODUCTION ....................................................................................... 9

2.1 LOCAL INSTALLATION REGULATIONS ............................................................................. 9

2.2 CORROSIVE ENVIRONMENT.............................................................................................. 9

2.3 INSPECTION UPON RECEPTION ....................................................................................... 9

2.4 TO BE CHECKED ................................................................................................................. 9

SECTION 3 : INSTALLATION ...................................................................................... 10

3.1 SAFETY MEASURES .......................................................................................................... 10

3.2 LOCATION........................................................................................................................... 10

3.3 CLEARANCES .................................................................................................................... 10

3.4 PIPING INSTALLATION ...................................................................................................... 10

3.4.1 Boiler piping connection ............................................................................................... 11

3.4.2 Auxiliary boiler piping connection ................................................................................. 11

3.4.3 Safety valve .................................................................................................................. 11

3.4.4 System pressure control and expansion tank .............................................................. 12

3.4.5 Water pressure makeup regulator ................................................................................ 12

3.4.6 Air bleeder .................................................................................................................... 12

3.4.7 Circulating pump .......................................................................................................... 12

3.4.8 Drain faucet .................................................................................................................. 13

3.4.9 Pressure loss ................................................................................................................ 14

3.5 ELECTRICAL CONNECTIONS ........................................................................................... 20

3.5.1 Main electrical supply ................................................................................................... 20

3.5.2 Pump supply ................................................................................................................. 20

3.5.3 Connection of external signals to the controller ........................................................... 20

SECTION 4 : CONTROLLER OPERATION ................................................................. 23

4.1 USER INTERFACE ............................................................................................................. 23

4.1.1 Symbol description ....................................................................................................... 23

4.1.2 Control panel ................................................................................................................ 24

4.1.3 Navigation and adjustements ....................................................................................... 24

4.1.4 Main menu navigation .................................................................................................. 25

4.1.5 Navigation in boiler setting ........................................................................................... 26

4.2 MAIN MENU ........................................................................................................................ 29

4.2.1 Boiler status .................................................................................................................. 29

4.2.2 Boiler configuration ....................................................................................................... 29

4.2.3 User setting .................................................................................................................. 29

4.2.4 Clock setting ................................................................................................................. 30

4.2.5 Consumption ................................................................................................................ 30

4.3 BOILER SETTINGS ............................................................................................................. 30

4.3.1 Heating mode W1 ......................................................................................................... 31

4.3.2 Heating mode W2/DHW ............................................................................................... 31

4.3.3 Pump setting................................................................................................................. 32

4.3.4 Capacity limiting ........................................................................................................... 32

4.3.5 Auxiliary boiler .............................................................................................................. 33

4.3.6 Limit setting .................................................................................................................. 34

4.3.7 Alarm ............................................................................................................................ 34

4.3.8 Communication............................................................................................................. 35

4.3.9 Occupation ................................................................................................................... 36

4.3.10 BOOST Mode ............................................................................................................. 36

4.3.11 Warm weather shutdown ............................................................................................ 37

4.3.12 Change password ...................................................................................................... 37

4.4 INTERNET ........................................................................................................................... 37

VOLTMAX ELECTRIC BOILER Installation and Operation Manual (Revised August 2017), Page 2.

4.4.1 Website ......................................................................................................................... 37

4.4.2 Email ............................................................................................................................. 37

4.5 BOILER STATUS DISPLAY SETTINGS ............................................................................. 39

4.6 HEATING MODE W1 SETTINGS ....................................................................................... 41

4.6.1 FIXED MODE ............................................................................................................... 41

4.6.2 OUTDOOR RESET MODE .......................................................................................... 42

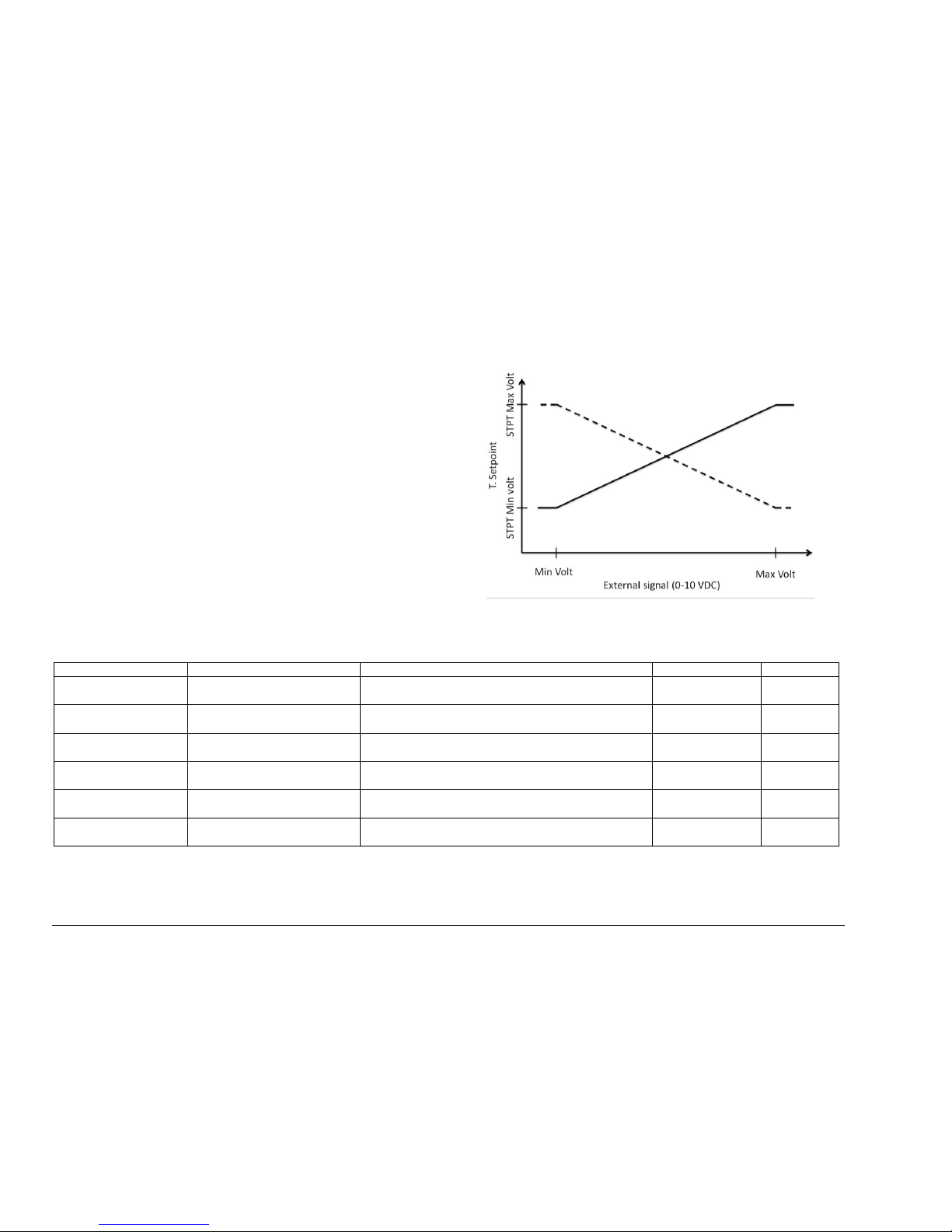

4.6.3 Mode : DDC 0-10VDC .................................................................................................. 43

4.7 W2 MODE SET-POINT TEMPERATURE SETTINGS ........................................................ 44

4.7.1 W2 MODE .................................................................................................................... 44

4.7.2 DHW MODE ................................................................................................................. 44

4.8 PUMP CONFIGURATION MENU SETTINGS .................................................................... 44

4.8.1 PUMP 1 ........................................................................................................................ 44

4.8.2 PUMP 2 ........................................................................................................................ 44

SPECIFIC PARAMETERS FOR THE CAPACITY LIMITING MENU .................................... 45

4.8.3 MANUAL MODE ........................................................................................................... 45

4.8.4 MODE: 0-10 VDC ......................................................................................................... 45

4.9 POWER LIMITATION MENU SETTINGS ........................................................................... 46

4.9.1 MANUAL MODE ........................................................................................................... 46

4.9.2 0-10 VDC MODE .......................................................................................................... 46

4.9.3 T. ext MODE ................................................................................................................. 47

4.9.4 Schedule MODE ........................................................................................................... 48

4.10 AUXILIARY BOILER SETTINGS ....................................................................................... 49

4.10.1 BACKUP MODE ......................................................................................................... 49

4.10.2 EXTERNAL CONTACT MODE .................................................................................. 50

4.10.3 ManuAl MODE ........................................................................................................... 50

4.10.4 Bi-Energy MODE ........................................................................................................ 50

4.11 LIMIT CONFIGURATION MENU SETTINGS .................................................................... 51

4.12 CONFIG. ALARM MENU SETTINGS ................................................................................ 52

4.13 OCCUPATION MENU SETTINGS .................................................................................... 52

4.14 BOOST MENU SETTINGS................................................................................................ 53

4.15 WARM WEATHER SHUTDOWN MENU SETTINGS ....................................................... 53

SECTION 5 : BOILER START UP ................................................................................ 54

5.1 FILLING THE BOILER ......................................................................................................... 54

5.2 ADJUSTEMENT OF THE CONTROLLER OPERATING PARAMETERS .......................... 54

5.3 STARTUP PROCEDURE .................................................................................................... 54

SECTION 6 : TROUBLESHOOTING ............................................................................ 56

6.1 WARNING LIGHTS ............................................................................................................. 56

6.2 OPERATING PROBLEM IDENTIFICATION ....................................................................... 56

6.2.1 External HL / LWCO ............................................................................................... 56

6.2.2 Sensor ( SE ) .......................................................................................................... 56

6.2.3 Low limit ( LL ) ........................................................................................................ 56

6.2.4 Flow ( F ) ................................................................................................................ 56

6.2.5 Current ( A ) ............................................................................................................ 56

6.2.6 HL temperature ( HL ) ............................................................................................ 57

6.2.7 Low pressure ( P ) .................................................................................................. 57

6.2.8 High pressure ( P ) ................................................................................................. 57

6.2.9 Lock out .................................................................................................................. 57

SECTION 7 : MAINTENANCE ...................................................................................... 58

7.1 BOILER WATER PIPING .................................................................................................... 58

7.2 PRESSURE RELIEF VALVE ............................................................................................... 58

7.3 AIR PURGE ......................................................................................................................... 58

7.4 ELECTRICAL INSPECTION................................................................................................ 58

VOLTMAX ELECTRIC BOILER Installation and Operation Manual (Revised August 2017), Page 3.

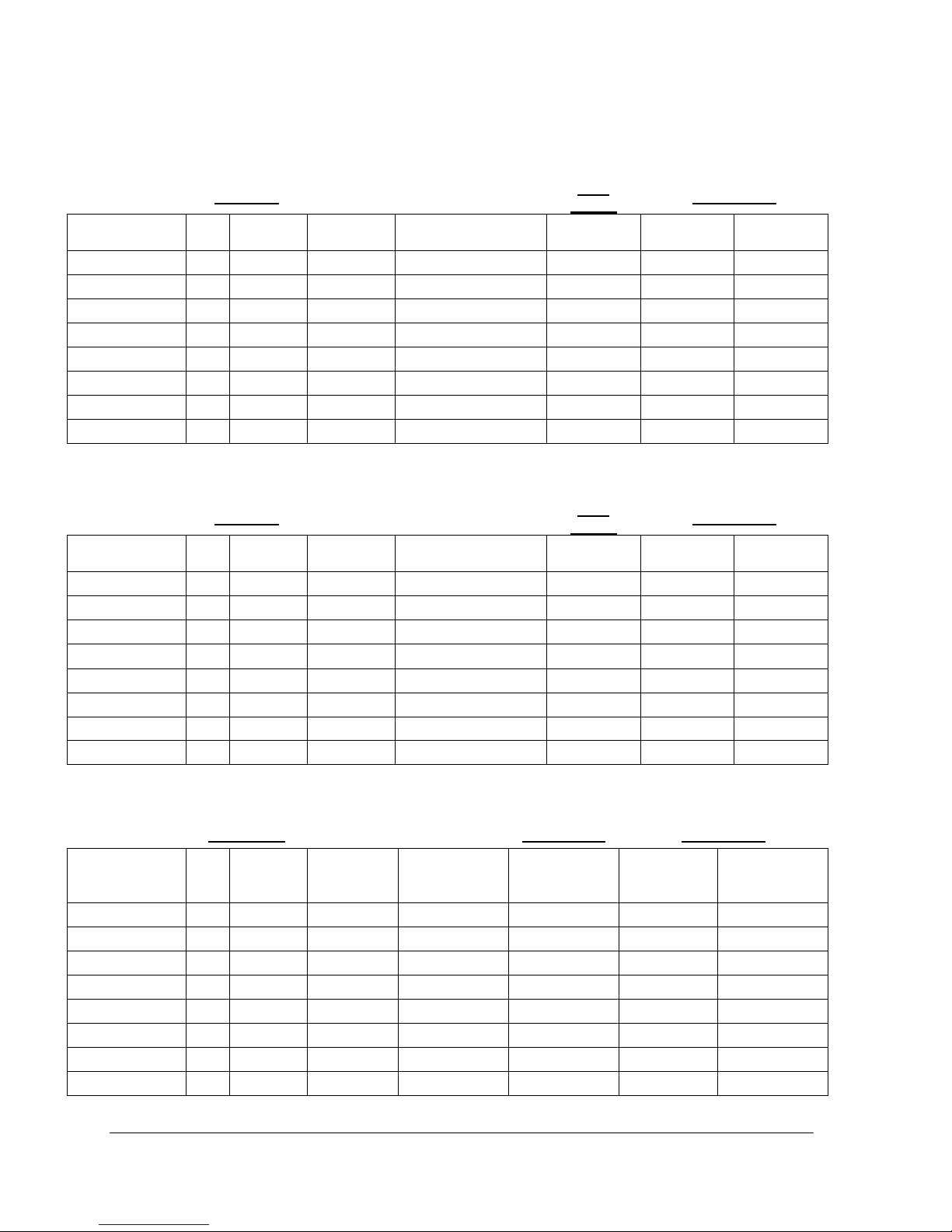

Capacity

STG

Series

SCR Series

Model

kW

BTU/h

Amps

Electrical

element(s) 240 V

Stage

Relay

Stage

Relay

SCR

Stage

VOLTMAX 23

22,5

76 770

108,4

6 x 5 kW

3 x 7,5 kW

2 x 7,5 kW

1 x 7,5 kW

VOLTMAX 27

27

92 124

130,1

6 x 6 kW

3 x 9 kW

2 x 9 kW

1 x 9 kW

VOLTMAX 30

30

102 360

144,5

8 x 5 kW

4 x 7,5 kW

3 x 7,5 kW

1 x 7,5 kW

VOLTMAX 36

36

122 832

173,4

8 x 6 kW

4 x 9 kW

3 x 9 kW

1 x 9 kW

VOLTMAX 41

41

139 892

198,7

5 x 5 kW + 5 x 6 kW

5 x 8,25 kW

4 x 8,25 kW

1 x 8,25 kW

VOLTMAX 45

45

153 540

216,8

10 x 6 kW

5 x 9 kW

4 x 9 kW

1 x 9 kW

VOLTMAX 50

49,5

168 894

238,4

6 x 5 kW + 6 x 6 kW

6 x 8,25 kW

5 x 8,25 kW

1 x 8,25 kW

VOLTMAX 54

54

184 248

260,1

12 x 6 kW

6 x 9 kW

5 x 9 kW

1 x 9 kW

Capacity

STG

Series

SCR Series

Model

kW

BTU/h

Amps

Electrical

element(s) 240 V

Stage

Relay

Stage

Relay

SCR

Stage

VOLTMAX 30

30

102 360

125

6 x 5 kW

3 x 10 kW

2 x 10 kW

1 x 10 kW

VOLTMAX 36

36

122 832

150

6 x 6 kW

3 x 12 kW

2 x 12 kW

1 x 12 kW

VOLTMAX 40

40

136 480

166,7

8 x 5 kW

4 x 10 kW

3 x 10 kW

1 x 10 kW

VOLTMAX 48

48

163 776

200

8 x 6 kW

4 x 12 kW

3 x 12 kW

1 x 12 kW

VOLTMAX 55

55

187 660

229,2

5 x 5 kW + 5 x 6 kW

5 x 11 kW

4 x 11 kW

1 x 11 kW

VOLTMAX 60

60

204 720

250

10 x 6 kW

5 x 12 kW

4 x 12 kW

1 x 12 kW

VOLTMAX 66

66

225 192

275

6 x 5 kW + 6 x 6 kW

6 x 11 kW

5 x 11 kW

1 x 11 kW

VOLTMAX 72

72

245 664

300

12 x 6 kW

6 x 12 kW

5 x 12 kW

1 x 12 kW

Puissance

STG Series

SCR Series

Model

kW

BTU/h

Amps

Electrical

element(s)

240 V

Stage Relay

Stage

Relay

SCR Stage

VOLTMAX 23

22,5

76 770

62,6

6 x 5 kW

2 x 11,25 kW

1 x 11,25 kW

1 x 11,25 kW

VOLTMAX 27

27

92 124

75,1

6 x 6 kW

2 x 13,5 kW

1 x 13,5 kW

1 x 13,5 kW

VOLTMAX 34

34

116 008

93,9

9 x 5 kW

3 x 11,25 kW

2 x 11,25 kW

1 x 11,25 kW

VOLTMAX 41

40,5

138 186

112,6

9 x 6 kW

3 x 13,5 kW

2 x 13,5 kW

1 x 13,5 kW

VOLTMAX 45

45

153 540

125,1

12 x 5 kW

4 x 11,25 kW

3 x 11,25 kW

1 x 11,25 kW

VOLTMAX 54

54

184 248

150,2

12 x 6 kW

4 x 13,5 kW

3 x 13,5 kW

1 x 13,5 kW

VOLTMAX 56

56

191 072

156,4

15 x 5 kW

5 x 11,25 kW

4 x 11,25 kW

1 x 11,25 kW

VOLTMAX 68

67,5

230 310

187,7

15 x 6 kW

5 x 13,5 kW

4 x 13,5 kW

1 x 13,5 kW

SECTION 1 : TECHNICAL SPECIFICATIONS

Table 1: VOLTMAX 208 VAC / 60 Hz / Single-Phase1

1

Electrical supply 208 V - 1 phase (L1-L2) with 2 conductors 90°C with a ground.

Table 2: VOLTMAX 240 VAC / 60 Hz / 1 Phase1

1

Electrical supply 240 V - 1 phase (L1-L2) with 2 conductors 90°C with a ground.

Table 3 : VOLTMAX 208 VAC / 60 Hz / 3 Phase1

1

Electrical supply 208 V - 1 phase (L1-L2) with 2 conductors 90°C with a ground.

VOLTMAX ELECTRIC BOILER Installation and Operation Manual (Revised August 2017), Page 4.

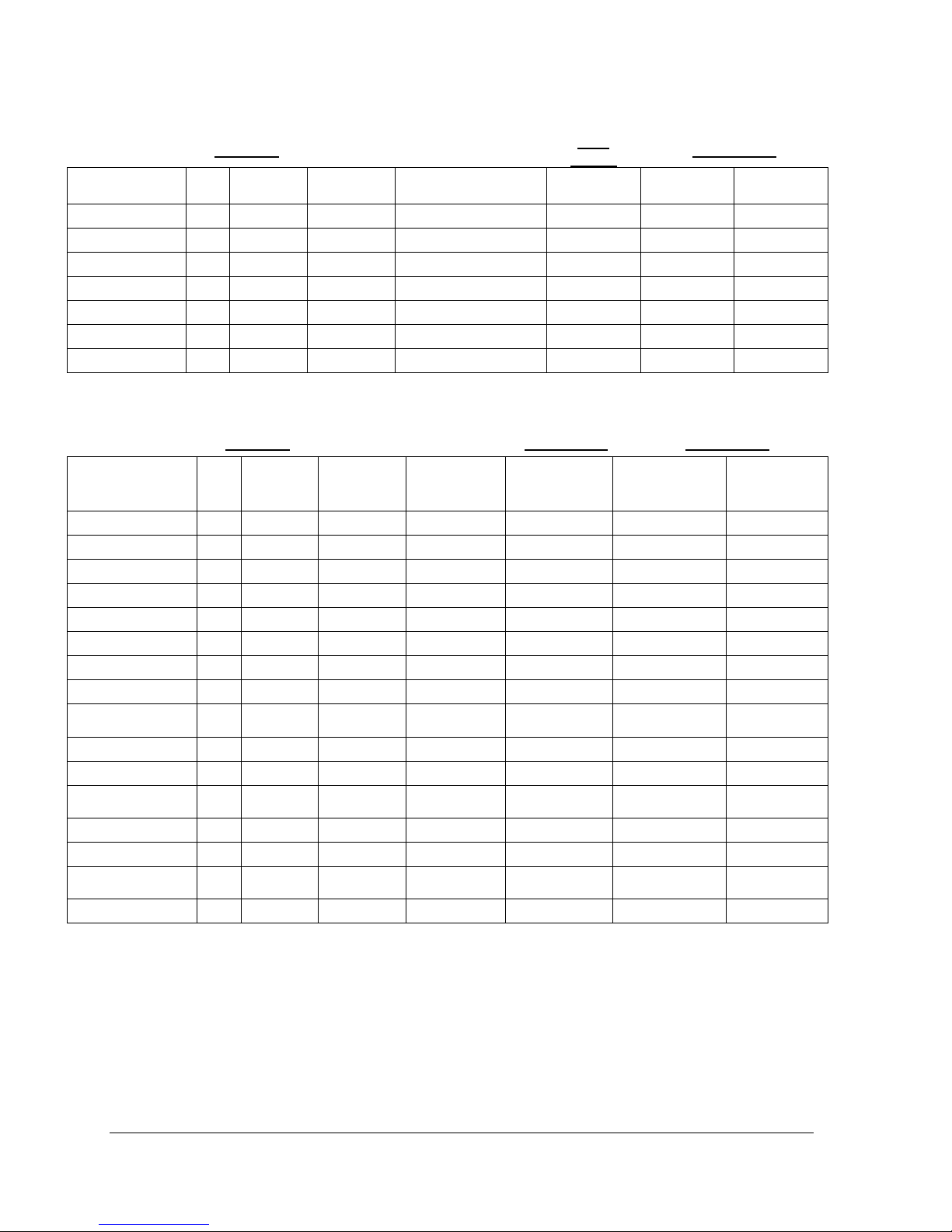

Capacity

STG

Series

SCR Series

Model

kW

BTU/h

Amps

Electrical

element(s) 240 V

Stage

Relay

Model

kW

VOLTMAX 30

30

102 360

72

6 x 5 kW

2 x 15 kW

1 x 15 kW

1 x 15 kW

VOLTMAX 36

36

122 832

86,6

6 x 6 kW

2 x 18 kW

1 x 18 kW

1 x 18 kW

VOLTMAX 45

45

153 540

108,3

9 x 5 kW

3 x 15 kW

2 x 15 kW

1 x 15 kW

VOLTMAX 54

54

184 248

129,9

9 x 6 kW

3 x 18 kW

2 x 18 kW

1 x 18 kW

VOLTMAX 60

60

204 720

144,3

12 x 5 kW

4 x 15 kW

3 x 15 kW

1 x 15 kW

VOLTMAX 72

72

245 664

173,2

12 x 6 kW

4 x 18 kW

3 x 18 kW

1 x 18 kW

VOLTMAX 75

75

255 900

180,4

15 x 5 kW

5 x 15 kW

4 x 15 kW

1 x 15 kW

Capacity

STG Series

SCR Series

Model

kW

BTU/h

Amps

Electrical

element(s)

240 V

Stage Relay

Model

kW

VOLTMAX 30

30

102 360

36,1

6 x 5 kW

2 x 15 kW

1 x 15 kW

1 x 15 kW

VOLTMAX 36

36

122 832

43,3

6 x 6 kW

2 x 18 kW

1 x 18 kW

1 x 18 kW

VOLTMAX 45

45

153 540

54,1

9 x 5 kW

3 x 15 kW

2 x 15 kW

1 x 15 kW

VOLTMAX 54

54

184 248

65

9 x 6 kW

3 x 18 kW

2 x 18 kW

1 x 18 kW

VOLTMAX 60

60

204 720

72,2

12 x 5 kW

4 x 15 kW

3 x 15 kW

1 x 18 kW

VOLTMAX 72

72

245 664

86,6

12 x 6 kW

4 x 18 kW

3 x 18 kW

1 x 18 kW

VOLTMAX 75

75

255 900

90,2

15 x 5 kW

5 x 15 kW

4 x 15 kW

1 x 15 kW

VOLTMAX 90

90

307 80

108,3

15 x 6 kW

5 x 18 kW

4 x 18 kW

1 x 18 kW

VOLTMAX 99

99

337 788

119,1

9 x 5 kW +

9 x 6 kW

3 x 33 kW

2 x 33 kW

1 x 33 kW

VOLTMAX 108

108

368 496

129,9

18 x 6 kW

3 x 36 kW

2 x 36 kW

1 x 36 kW

VOLTMAX 120

120

409 440

144,3

24 x 5 kW

4 x 30 kW

3 x 30 kW

1 x 30 kW

VOLTMAX 132

132

450 384

158,8

12 x 5 kW +

12 x 6 kW

4 x 33 kW

3 x 33 kW

1 x 33 kW

VOLTMAX 144

144

491 328

173,2

24 x 6 kW

4 x 36 kW

3 x 36 kW

1 x 36 kW

VOLTMAX 150

150

511 800

180,4

30 x 5 kW

5 x 30 kW

4 x 30 kW

1 x 30 kW

VOLTMAX 165

165

562 980

198,5

15 x 5 kW +

15 x 6 kW

5 x 33 kW

4 x 33 kW

1 x 33 kW

VOLTMAX 180

180

614 160

216,5

30 x 6 kW

5 x 36 kW

4 x 36 kW

1 x 36 kW

Table 4 : VOLTMAX 240 VAC / 60 Hz / 3 Phases1

1

Electrical supply 240 V - 1 phase (L1-L2) with 2 conductors 90°C with a ground.

Table 5 : VOLTMAX 480 VAC / 60 Hz / 3 Phases1

1

Electrical supply 480 V - 1 phase (L1-L2-L3) with 3 conductors 90°C with a ground.

VOLTMAX ELECTRIC BOILER Installation and Operation Manual (Revised August 2017), Page 5.

Capacity

STG Series

SCR Series

Model

kW

BTU/h

Amps

Electrical

element(s)

240 V

Stage Relay

Model

kW

VOLTMAX 30

30

102 360

28,9

6 x 5 kW

2 x 15 kW

1 x 15 kW

1 x 15 kW

VOLTMAX 36

36

122 832

34,6

6 x 6 kW

2 x 18 kW

1 x 18 kW

1 x 18 kW

VOLTMAX 45

45

153 540

43,3

9 x 5 kW

3 x 15 kW

2 x 15 kW

1 x 15 kW

VOLTMAX 54

54

184 248

52

9 x 6 kW

3 x 18 kW

2 x 18 kW

1 x 18 kW

VOLTMAX 60

60

204 720

57,7

12 x 5 kW

4 x 15 kW

3 x 15 kW

1 x 18 kW

VOLTMAX 72

72

245 664

69,3

12 x 6 kW

4 x 18 kW

3 x 18 kW

1 x 18 kW

VOLTMAX 75

75

255 900

72,2

15 x 5 kW

5 x 15 kW

4 x 15 kW

1 x 15 kW

VOLTMAX 90

90

307 80

86,6

15 x 6 kW

5 x 18 kW

4 x 18 kW

1 x 18 kW

VOLTMAX 99

99

337 788

95,3

9 x 5 kW +

9 x 6 kW

3 x 33 kW

2 x 33 kW

1 x 33 kW

VOLTMAX 108

108

368 496

103,9

18 x 6 kW

3 x 36 kW

2 x 36 kW

1 x 36 kW

VOLTMAX 120

120

409 440

115,5

24 x 5 kW

4 x 30 kW

3 x 30 kW

1 x 30 kW

VOLTMAX 132

132

450 384

127

12 x 5 kW +

12 x 6 kW

4 x 33 kW

3 x 33 kW

1 x 33 kW

VOLTMAX 144

144

491 328

138,6

24 x 6 kW

4 x 36 kW

3 x 36 kW

1 x 36 kW

VOLTMAX 150

150

511 800

144,3

30 x 5 kW

5 x 30 kW

4 x 30 kW

1 x 30 kW

VOLTMAX 165

165

562 980

158,8

15 x 5 kW +

15 x 6 kW

5 x 33 kW

4 x 33 kW

1 x 33 kW

VOLTMAX 180

180

614 160

173,2

30 x 6 kW

5 x 36 kW

4 x 36 kW

1 x 36 kW

VOLTMAX

90 kW and less

More than 90 kW

Maximum operating pressure

30 PSI

60 PSI

Optional maximum operating pressure

70 PSI*

125 PSI

Table 6 : VOLTMAX 600 VAC / 60 Hz / 3 Phases1

1

Electrical supply 600 V - 1 phase (L1-L2-L3) with 3 conductors 90°C with a ground.

Tableau 7 : Maximal service pressure

* Model from 23 to 90 kW are available at a maximum operating pressure of 125 PSI, but size of the unit will be the

same as model of more than 90 kW.

VOLTMAX ELECTRIC BOILER Installation and Operation Manual (Revised August 2017), Page 6.

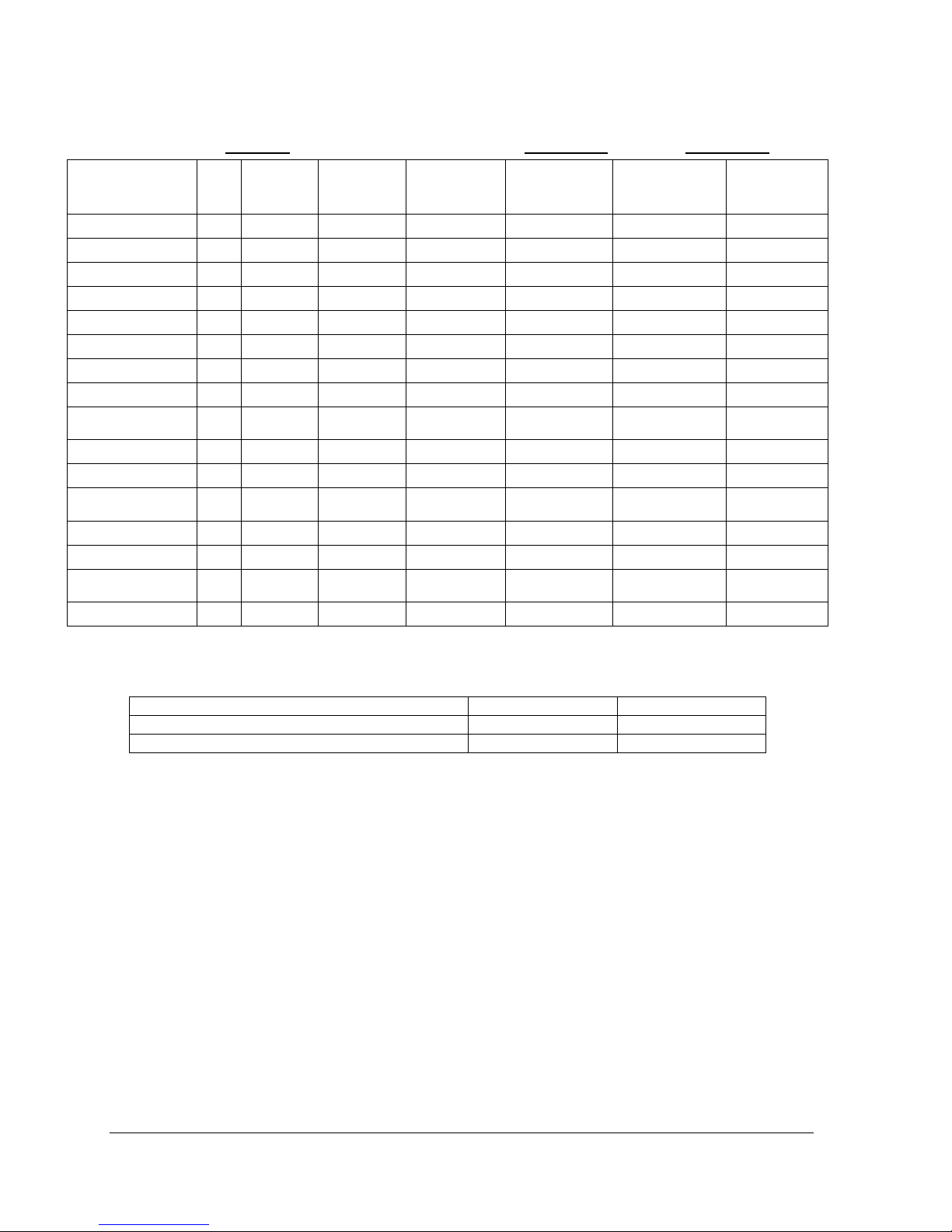

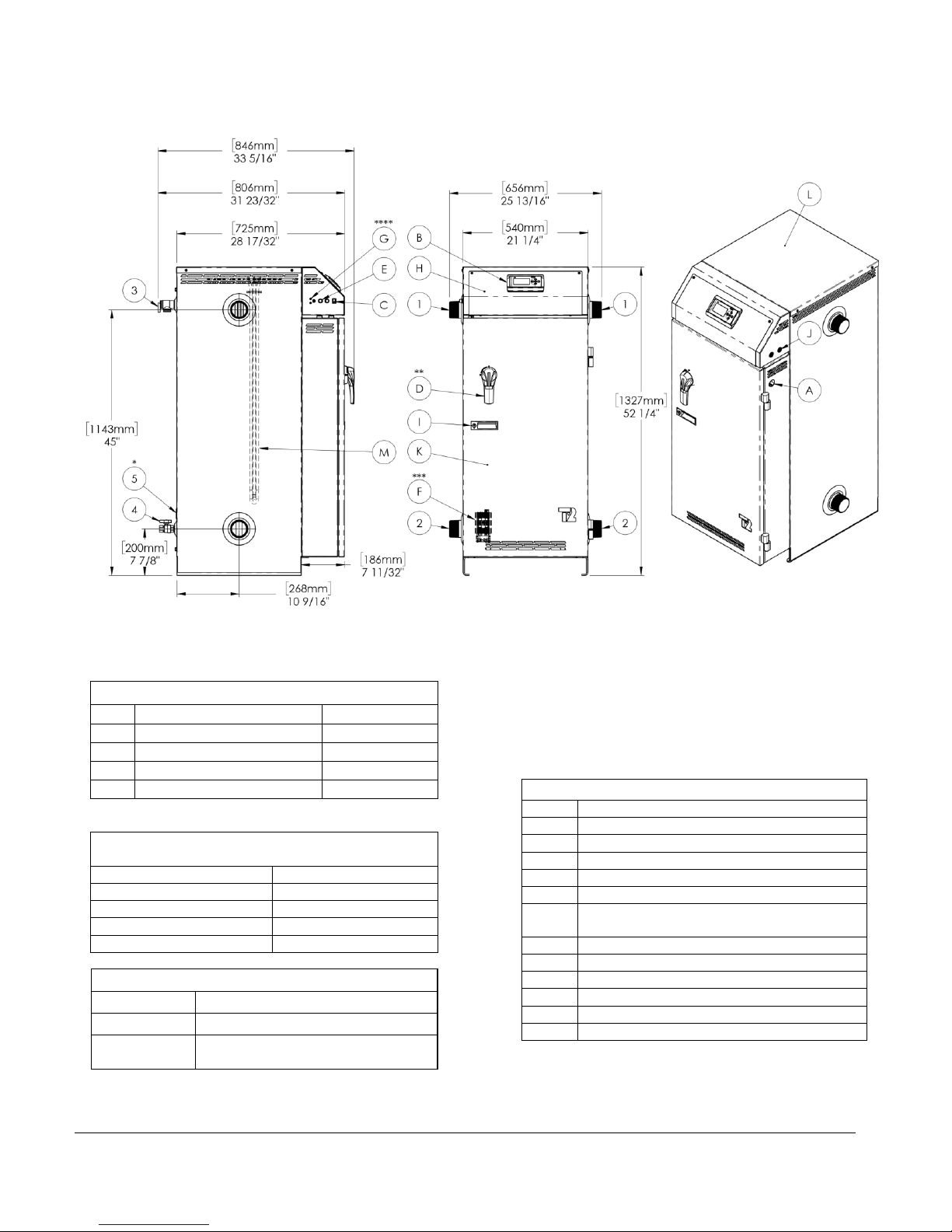

BOILER CONNECTIONS

1

Boiler outlet

1 1/2" NPT M

2

Boiler inlet

1 1/2" NPT M

3

Pressure relief valve

3/4" NPT F

4

Drain valve

3/4" NPT F

5*

Access to the return sensor

1/2" NPT F

MIN. CLEARANCES FOR INSTALLATION &

MAINTENANCE

Left and Right sides

3"/ 76mm

Rear

3"/ 76mm

Front

24" / 610mm

Bottom

0" / 0mm

Top

32" / 813mm

GENERAL INFORMATIONS

Weight

310lbs / 141kg

Water Volume

11 Us gal. / 41.6 liters

Max. operating

pressure

STANDARD: 30psi

OPTION: 70 PSI *

COMPONENTS IDENTIFICATION

A

Electrical main supply

B

Boiler controller

C

"On/Off" switch

D**

Disconnect switch & rotary handle

E

Fuses for controls

F***

Solid state SCR relay

G****

Low water cut-off, test button and indicator

lights

H

Electrical control access door

I

Door handle for electric access with lock

J

Electrical control wires access holes

K

Access door power circuit

L

Access cover to Heating elements

M

Heating elements

BOILER DIMENSIONS AND CHARACTERISTIC: MODELS 90KW OR LESS

* Return sensor available with the " SCR SERIES " configuration.

** Optional disconnect switch available on " THREE-PHASE " models.

*** Solid state SCR relay available with the " SCR SERIES " configuration.

**** Low water cut-off is optional.

*Available at 125PSI (See Shop Drawing 99-180KW)

VOLTMAX ELECTRIC BOILER Installation and Operation Manual (Revised August 2017), Page 7.

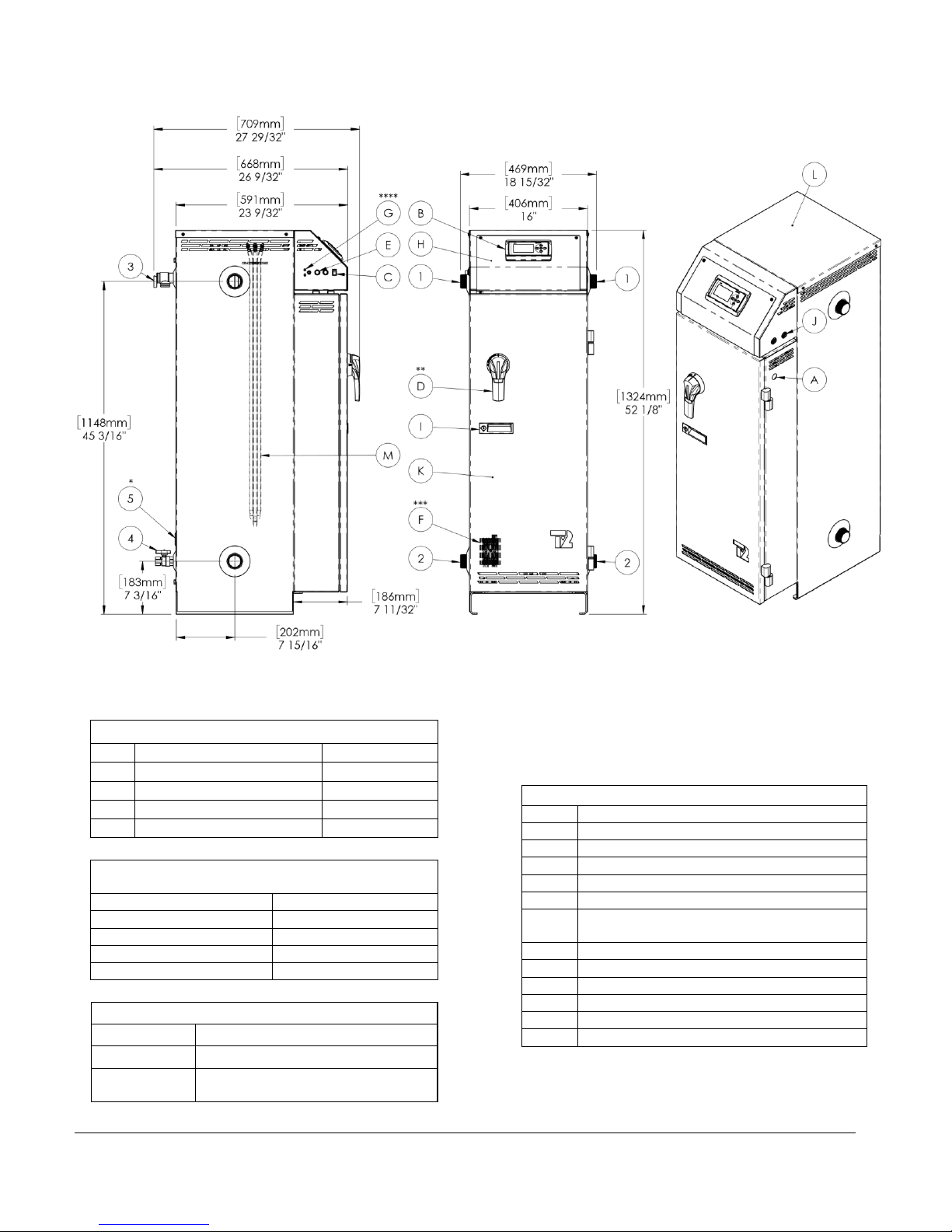

BOILER CONNECTIONS

1

Boiler outlet

1 1/2" NPT M

2

Boiler inlet

1 1/2" NPT M

3

Pressure relief valve

3/4" NPT F

4

Drain valve

3/4" NPT F

5*

Access to the return sensor

1/2" NPT F

MIN. CLEARANCES FOR INSTALLATION &

MAINTENANCE

Left and Right sides

3"/ 76mm

Rear

3"/ 76mm

Front

24" / 610mm

Bottom

0" / 0mm

Top

32" / 813mm

GENERAL INFORMATIONS

Weight

550lbs / 250kg

Water Volume

30 gal. Us/ 113.5 liters

Max. operating

pressure

STANDARD: 60psi

OPTION: 125 PSI

COMPONENTS IDENTIFICATION

A

Electrical main supply

B

Boiler controller

C

"On/Off" switch

D**

Disconnect switch & rotary handle

E

Fuses for controls

F***

Solid state SCR relay

G****

Low water cut-off, test button and indicator

lights

H

Electrical control access door

I

Door handle for electric access with lock

J

Electrical control wires access holes

K

Access door power circuit

L

Access cover to Heating elements

M

Heating elements

BOILER DIMENSIONS AND CHARACTERISTIC: MODELS 90KW TO 180KW

* Return sensor available with the " SCR Series " configuration.

** Optional disconnect switch

*** Solid state SCR relay available with the " SCR Series " configuration.

**** Low water cut-off is standard for models 120 kW and more.

VOLTMAX ELECTRIC BOILER Installation and Operation Manual (Revised August 2017), Page 8.

List of components shipped with the unit:

• Pressure relief valve

• Drain valve

• Outdoor temperature sensor ¸

(Located inside the control panel of the

unit)

!

AVERTISSEMENT

!

WARNING

!

General Safety Precautions

Be sure to read and understand the entire Installation & operation manual before attempting to install or to operate this water

heater. Pay attention to the following General Safety Precautions. Failure to follow these warnings could cause property damage,

bodily injury or death. Should you have any problems understanding the instructions in this manual, STOP, and get help from a

qualified installer or technician

SECTION 2 : INTRODUCTION

These important safeguards and instruction appearing in this manual are not meant to cover all

possible conditions and situations that may occur. Common sense,

caution and care are factors that cannot be built into every product. These factors must be

supplied by the person(s) caring for and operating the unit.

2.1 LOCAL INSTALLATION

REGULATIONS

This electric boiler must be installed in

accordance with these instructions and in

conformity with local codes, or in the absence of

local codes, with the National Plumbing Code

and the National Electric Code, current edition.

In any case where instructions in this manual

differ from local or national codes, the local or

national codes take precedence.

2.2 CORROSIVE ENVIRONMENT

The electric boiler must not be installed near an

air duct supplying corrosive atmosphere or with

high humidity content. When a boiler defect is

caused by such conditions, the warranty will not

apply.

2.3 INSPECTION UPON RECEPTION

Inspect the electric boiler for possible shipping

damage. The manufacturer’s responsibility

ceases upon delivery of goods to the carrier in

good condition. The Consignee must file any

claims for damage, shortage in shipments, or

non-delivery immediately against the carrier.

2.4 TO BE CHECKED

Please refer to the rating plate on the unit to

ensure that you have the correct model and

voltage in hand.

The electric boiler should not be installed where it may damage the adjacent structures or lower

floors in the event of leakage of the tank or connections. If this cannot be avoided, install a nonflammable tray or bowl under the boiler to collect and drain water from leaks.

NOTE: Any tray or cuvette MUST conform to local codes.

VOLTMAX ELECTRIC BOILER Installation and Operation Manual (Revised August 2017), Page 9.

Sides**

3 inches / 76 mm

Bottom

0 inches / 0 mm

Top*

32 inches / 813 mm

Front

24 inches / 610 mm

Back

3 inches / 76 mm

MISE EN GARDE

!

SECTION 3 : INSTALLATION

The manufacturer’s warranty does not cover any damage or defect caused by installation, or

attachment, or use of any special attachment other than those authorized by the manufacturer

into, onto, or in conjunction with the water heater. The use of such unauthorized devices may

shorten the life of the boiler and may endanger life and property. The manufacturer disclaims any

responsibility for such loss or injury resulting from the use of such unauthorized devices

3.1 SAFETY MEASURES

Any commercial installation will be equipped with

a safety valve that limits the maximum working

pressure to the maximum design pressure of the

tank. The maximum operating pressure of the

VOLTMAX Boiler with a power of 90kW and less

is 30 psi or 70 psi, depending on the options

chosen. The maximum operating pressure of the

VOLTMAX boiler with a power of more than

90kW is 60 psi or 125 psi, depending on the

options selected. See boiler data sheet for

maximum operating pressure.

The boiler is equipped with an automatic high

limit temperature control set at 210°F (99°C) and

a second manual high limit temperature settable.

This electric boiler is designed to operate at a

maximum operating temperature of 200 ° F (93 °

C). The boiler is designed for use in a hot water

heating system only.

The heat transfer fluid must be water or an

antifreeze water / propylene glycol solution or

an antifreeze water / ethylene glycol solution

specially designed for heating systems. The

maximum concentration of solution must be a

maximum of 50%.

3.2 LOCATION

The electric boiler should be installed in a clean,

dry location. Long hot water lines should be

insulated to conserve water and energy. The

electric boiler and water lines should be protected

from exposure to freezing temperature.

The boiler can be mounted vertically or

horizontally directly on a solid surface.

The electric boiler must be located or protected

to avoid risk of physical damage, such as from

moving vehicles, flooding, etc.

The location must have sufficient ventilation to

maintain an ambient temperature not exceeding

80°F (27°C).

To prevent condensation on the boiler walls,

boiler temperature should not be maintained

below the condensation temperature (dewpoint temperature) of the ambient. The

operating temperature of the boiler must not

be lower than the condensation temperature

(dew temperature) relative to the ambient

humidity content.

3.3 CLEARANCES

For adequate inspection and servicing the

following minimum clearance is necessary:

Table 8 : Boiler Clearances

* A minimum clearance of 32 inches. For units

equipped with 18 kW elements (25 in. For 15 kW

elements) is required for possible replacement of

heating elements.

** The left side of the control panel, where the

boiler ON / OFF switch is located, must

remain visible after installation. Otherwise, a

label indicating its location must be affixed to

the control panel indicating its position.

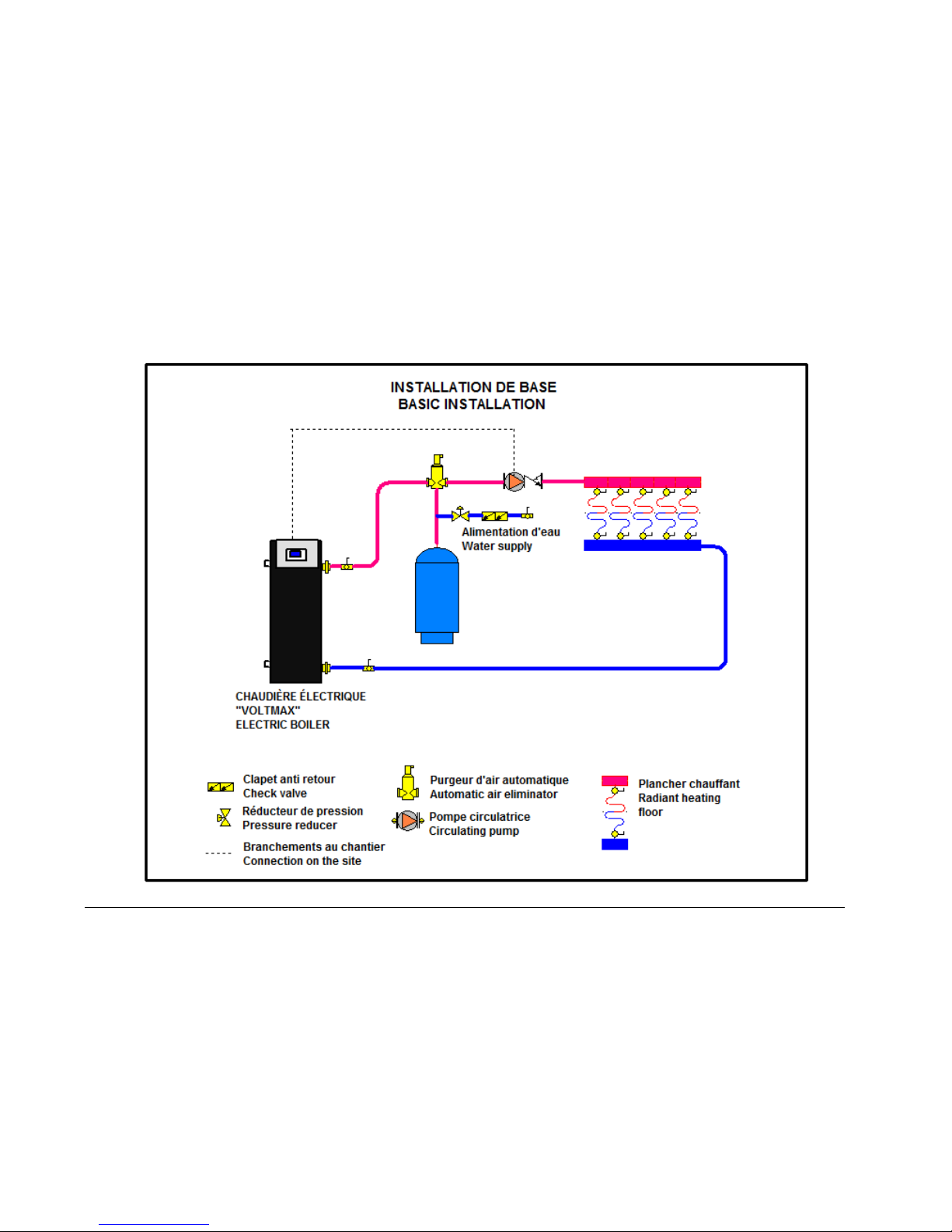

3.4 PIPING INSTALLATION

The location of the inlet and outlet piping shall

conform to the various configurations shown in

Figure 1. You will find typical connection

diagrams to the Figure 3, Figure 4 and Figure 5.

The VOLTMAX boiler is designed to be

operated on a closed circuit piping system.

Therefore, it should not be used to heat open

air tanks

VOLTMAX ELECTRIC BOILER Installation and Operation Manual (Revised August 2017), Page 10.

Figure 1 : Possible pipe flow configurations

3.4.1 BOILER PIPING CONNECTION

The boiler is equipped with two fittings on each

side of the unit. One of the bottom connections

must be used for the heating return (inlet) and

one of the top connections must be used for

supplying the heating system (outlet).

The outlet and inlet size are 1½ "NPTM threaded

steel pipes, for the VOLTMAX with a power of

90kW and less and 2½ "NPTM threaded steel

pipes for the VOLTMAX with a power of More

than 90kW.

Installation of plugs on the inlet and exhaust

ducts is required to facilitate the disconnection

and maintenance of the boiler.

When connecting different types of pipes

(galvanized steel and copper), use dielectric

joints (insulation) to protect the boiler and piping.

Use only new and clean pipes as piping

connection to the boiler. Local codes or

regulations may dictate the exact type of material

to be used.

Insulate all piping containing hot water, especially

in an unheated environment.

Install faucets for easy maintenance.

Install a thermometer on the inlet and outlet

duct(s).

Close the unused openings on the boiler. Do not

block the safety valve, this may cause loss,

damage or injury.

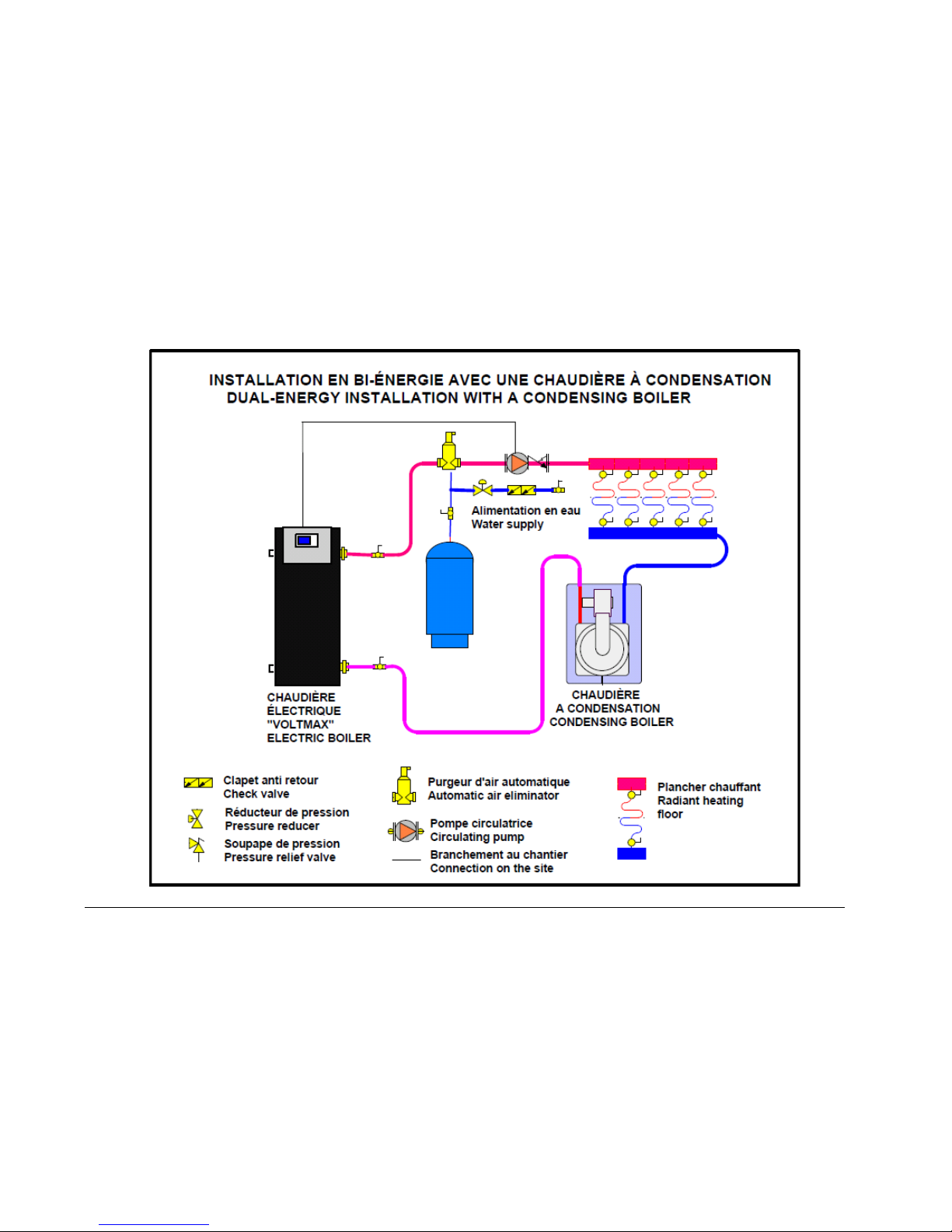

3.4.2 AUXILIARY BOILER PIPING

CONNECTION

When an auxiliary boiler used as back up is

twinned to the VOLTMAX boiler to act as a backup controlled by the VOTLMAX, the auxiliary

boiler shall be installed downstream of the

electric boiler as shown on Figure 5 and 7.

3.4.3 SAFETY VALVE

The installation of a safety valve is an integral

part of the boiler’s installation. The trigger point of

the valve must not exceed the design pressure of

the boiler as indicated on its registration and

identification plate. The valve must comply with

the ASME Boiler and Pressure Vessel Code and

limit the boiler maximum operating pressure. The

safety valve is a security component, not a

control component.

The capacity of the safety valve expressed in

BTU / hour must equal or exceed the rating on

the nameplate of the boiler (s).

A safety valve adjusted to the maximum design

pressure of the boiler has been installed at the

factory. The latter can be replaced by a valve with

a lower trigger pressure, but its BTU / hour

capacity must not be lower than the maximum

boiler power.

Connect the exhaust of the safety valve to a drain

line. The lower end of this conduit shall be at

least 6" (15 cm) from the floor drain away from

any electrical component. The drain line must be

directed downwards from the exhaust of the

safety valve to ensure complete drainage by

gravity. The diameter of the drainpipe must not

be less than that of the exhaust of the valve. The

end of the conduit must not be threaded or

hidden and must be protected from freezing. No

VOLTMAX ELECTRIC BOILER Installation and Operation Manual (Revised August 2017), Page 11.

valves, valves or valves shall be installed on the

pipe. The installation of the safety valves is

governed by the local code.

3.4.4 SYSTEM PRESSURE CONTROL

AND EXPANSION TANK

Pressure control devices within the system

ensure that each component operates within

minimum and maximum allowable pressures and

maintain minimum pressure for all normal

operating temperatures. They also allow air

bleeding, prevent cavitation at the pump inlet and

prevent water from boiling within the system; all

this is accomplished with minimal addition of new

water.

The increase in boiler water volume resulting

from higher temperature is stored in the

expansion tank during periods of high operating

temperature and is returned to the system when

the temperature decreases.

The expansion tank must be able to store the

required volume of boiler water during maximum

design operating temperature without exceeding

the maximum allowable operating pressure, and

to maintain the required minimum pressure when

the system is cold. Contact your installing

contractor, plumbing supply house, or local

plumbing inspector for assistance. The point

where the expansion tank is connected should be

carefully selected to avoid the possibility that

normal operation of automatic check or manual

valves will isolate the tank from a hot boiler or

any part of the system.

The expansion tank should preferably be located

on the suction or intake side of the pump.

3.4.5 WATER PRESSURE MAKEUP

REGULATOR

Make-up systems must be employed as required

by codes. An automatic fill valve (automatic

pressure regulator) must be used with a backflow

preventer as required, to maintain minimum

system pressure by supplying water to make up

for leakage.

A minimum pressure of 5psi (34kPa) must be

maintained at all times.

A backflow prevention device that complies with

local standards must be installed upstream of the

pressure regulator.

3.4.6 AIR BLEEDER

The air contained in the heated water must be

removed from the system to allow the proper

functioning of the heating system and the boiler.

Installation of manual or automatic air vents is

required to eliminate all air from the boiler and the

heating distribution system.

The main air eliminator must be installed near the

outlet of the boiler on the highest point of the

main supply piping. It is imperative to ensure that

all air possibly located in the boiler be eliminated

at all time.

Regularly purge air from the pipes and beware

that the heated water does not cause injury or

damage.

If the boiler is located at a location higher than

the heat distribution system such as a heated

floor, an automatic air eliminator should be

installed close to the boiler outlet.

3.4.7 CIRCULATING PUMP

The pump capacity required is determined in

relation to the capacity of the boiler installed and

the type of heating distribution system on which it

will be connected.

They are generally designed for an operation at a

differential of temperature (Delta T0) of 10 to 20F

between the supplies and return temperature to

the boiler.

Use the following equation to determine the

required water flow.

Pump flow rate = Boiler power ÷ Delta T ÷ 500

Pump flow rate is expressed in US gallons

per minute or GPM.

The Boiler output (in net BTU per hour) is the

maximum amount of heat to be transferred

through the heating loop to meet the heating

load.

Delta T: The boiler water temperature drop

For example, an electric boiler rated at 180KW

has an output capacity of 614 160 BTU per hour.

The system is designed for a temperature drop of

20°F.

Required pump flow rate = 614,160 20 500 =

61,4 GPM

VOLTMAX ELECTRIC BOILER Installation and Operation Manual (Revised August 2017), Page 12.

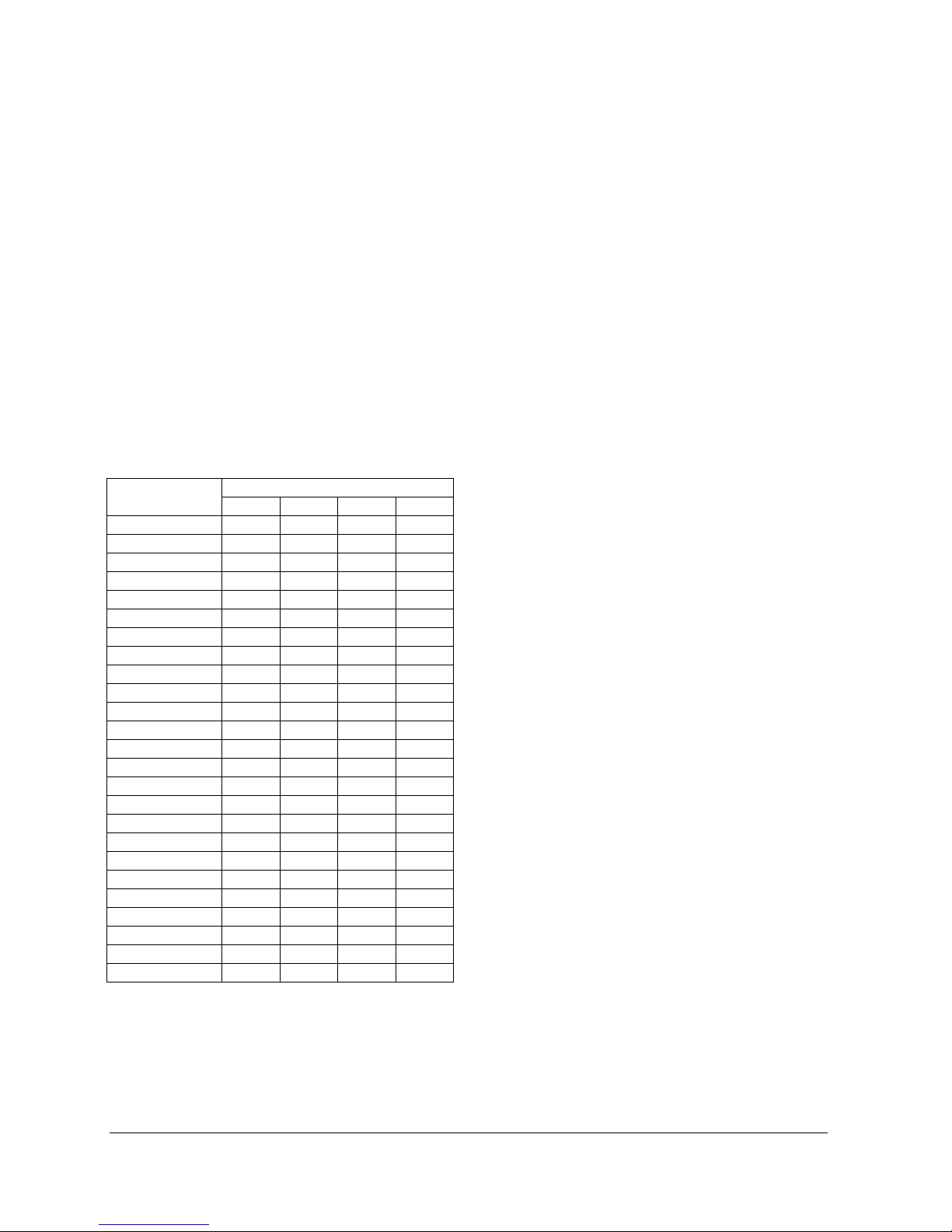

MODEL

DELTA T0

10oF

20oF

30oF

40oF

VOLTMAX 23

15.7

7.8

5.2

3.9

VOLTMAX 27

18.4

9.2

6.1

4.6

VOLTMAX 30

20.5

10.2

6.8

5.1

VOLTMAX 36

24.6

12.3

8.2

6.1

VOLTMAX 40

27.3

13.6

9.1

6.8

VOLTMAX 41

28.0

14.0

9.3

7.0

VOLTMAX 45

30.7

15.4

10.2

7.7

VOLTMAX 48

32.8

16.4

10.9

8.2

VOLTMAX 50

34.1

17.1

11.4

8.5

VOLTMAX 54

36.8

18.4

12.3

9.2

VOLTMAX 55

37.5

18.8

12.5

9.4

VOLTMAX 60

40.9

20.5

13.6

10.2

VOLTMAX 66

46.4

23.2

15.5

11.6

VOLTMAX 68

45.0

22.5

15.0

11.3

VOLTMAX 72

49.1

24.6

16.4

12.3

VOLTMAX 75

51.2

25.6

17.1

12.8

VOLTMAX 90

61.7

30.8

20.6

15.4

VOLTMAX 99

67.8

33.9

22.6

17.0

VOLTMAX 108

73.7

36.8

24.6

18.4

VOLTMAX 120

82.2

41.1

27.4

16.1

VOLTMAX 132

90.5

45.2

30.2

22.6

VOLTMAX 144

98.7

49.3

32.9

24.7

VOLTMAX 150

102.4

51.2

34.1

25.6

VOLTMAX 165

112.6

56.3

37.5

28.1

VOLTMAX 180

122.8

61.4

40.9

30.7

For example, an 180kW electric boiler has a

power of 614,160 BTU/h. The system is designed

for a drop-in temperature (Delta T) of 20°F.

Flow required = 614,160 20 500 = 61.4 GPM

N.B. To achieve proper operation, a minimum

flow must be present when a heating request is

applied and the heating elements are in

operation. See the table below for the

recommended minimum flow depending on the

boiler output. Installation of a flow switch is not

mandatory

The following table lists the required pump flow

rate in relation to the boiler capacity and Delta T.

Table 9 : Temperature rise vs flow rate

(GPM)

3.4.8 DRAIN FAUCET

A drain valve is installed behind the unit. It allows

the boiler to be emptied, to make possible the

replacement of defective components.

VOLTMAX ELECTRIC BOILER Installation and Operation Manual (Revised August 2017), Page 13.

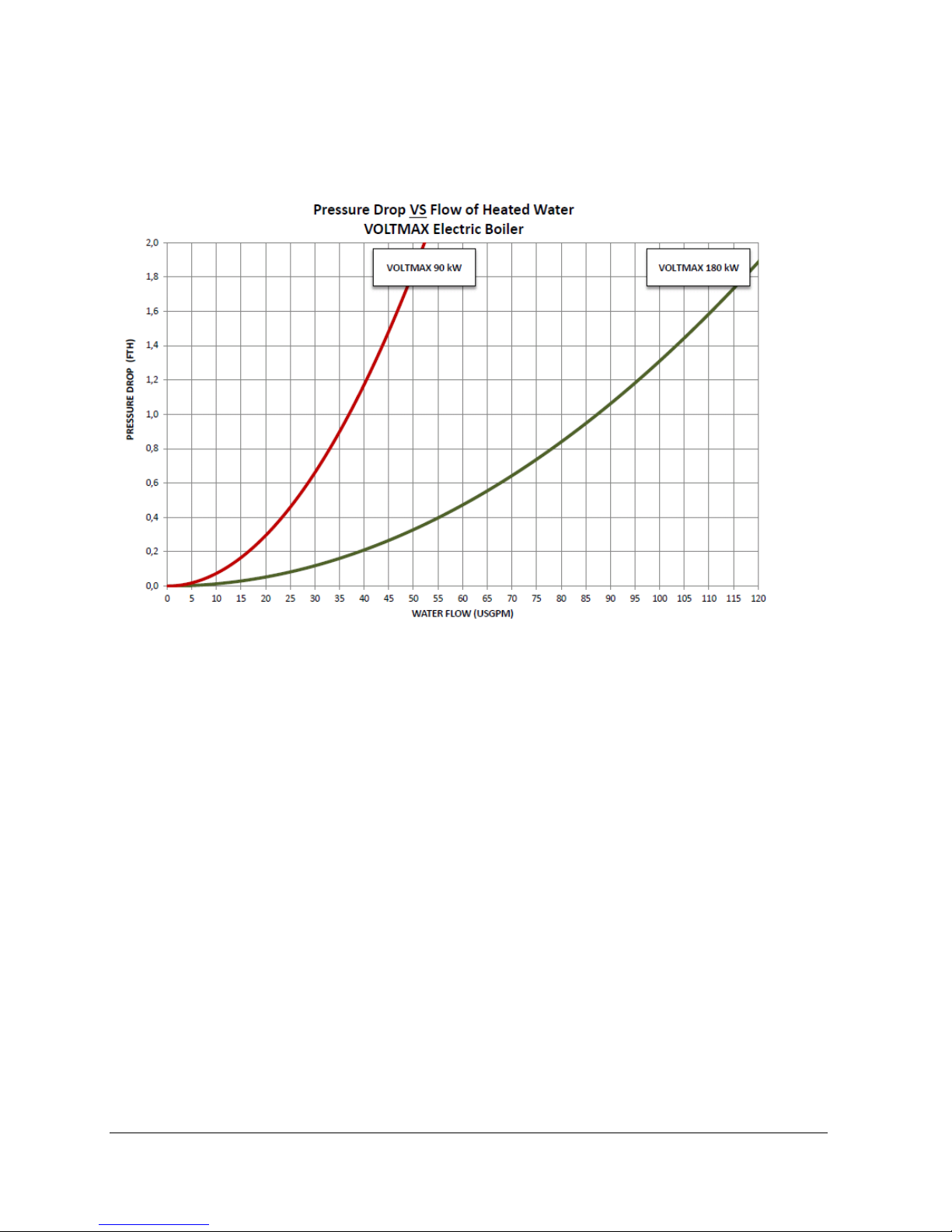

3.4.9 PRESSURE LOSS

The graph of pressure loss due to flow of water inside the VOLTMAX boiler is shown in the following figure.

Figure 2 : Pressure loss (FTH) as a function of the flow rate of heated water (GPM)

VOLTMAX ELECTRIC BOILER Installation and Operation Manual (Revised August 2017), Page 14.

VOLTMAX ELECTRIC BOILER Installation and Operation Manual (Revised August 2017), Page 15.

Figure 3 : Basic installation

VOLTMAX ELECTRIC BOILER Installation and Operation Manual (Revised August 2017), Page 16.

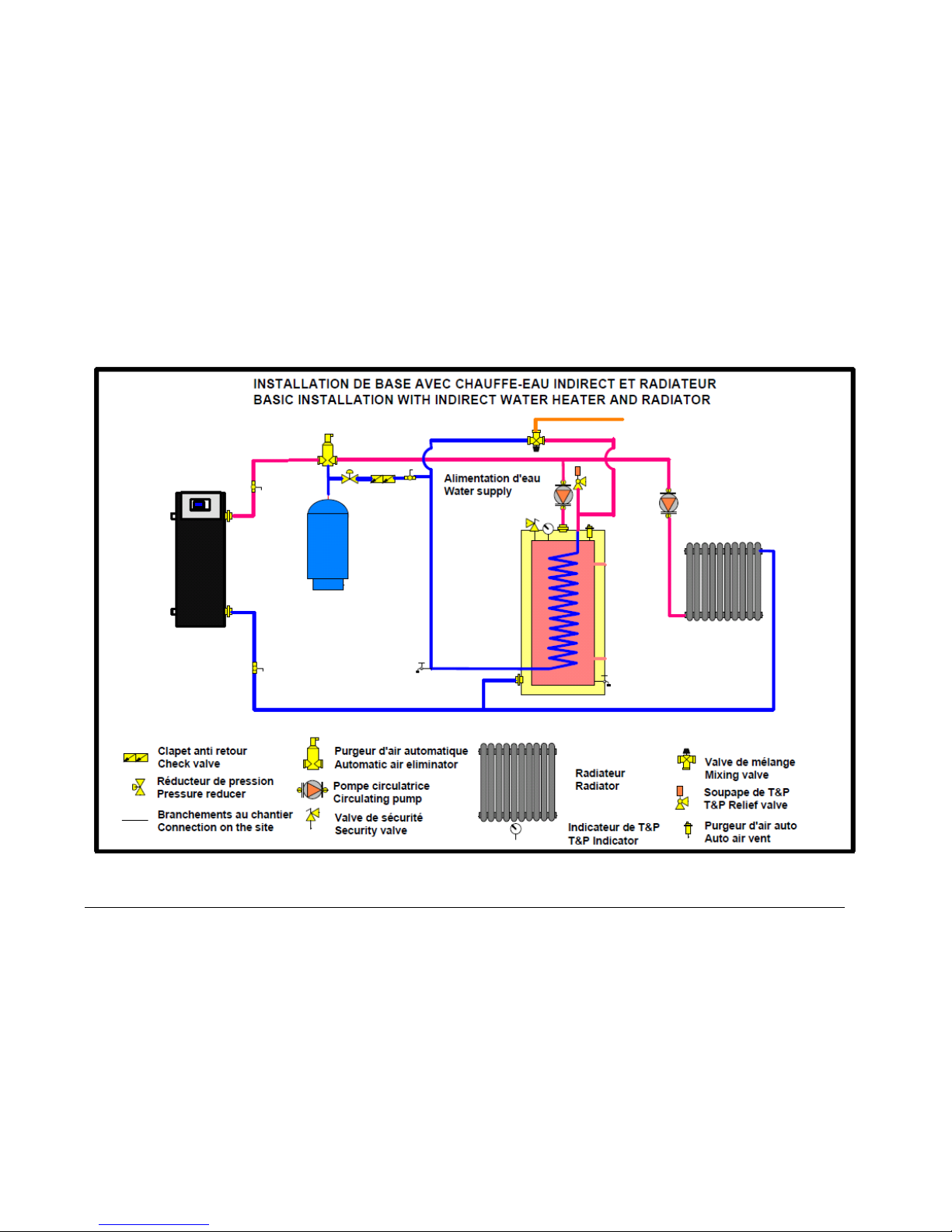

Figure 4 : Basic installation with indirect water heater and radiator

VOLTMAX ELECTRIC BOILER Installation and Operation Manual (Revised August 2017), Page 17.

Figure 5 : Dual-Energy installation with a condensing boiler

VOLTMAX ELECTRIC BOILER Installation and Operation Manual (Revised August 2017), Page 18.

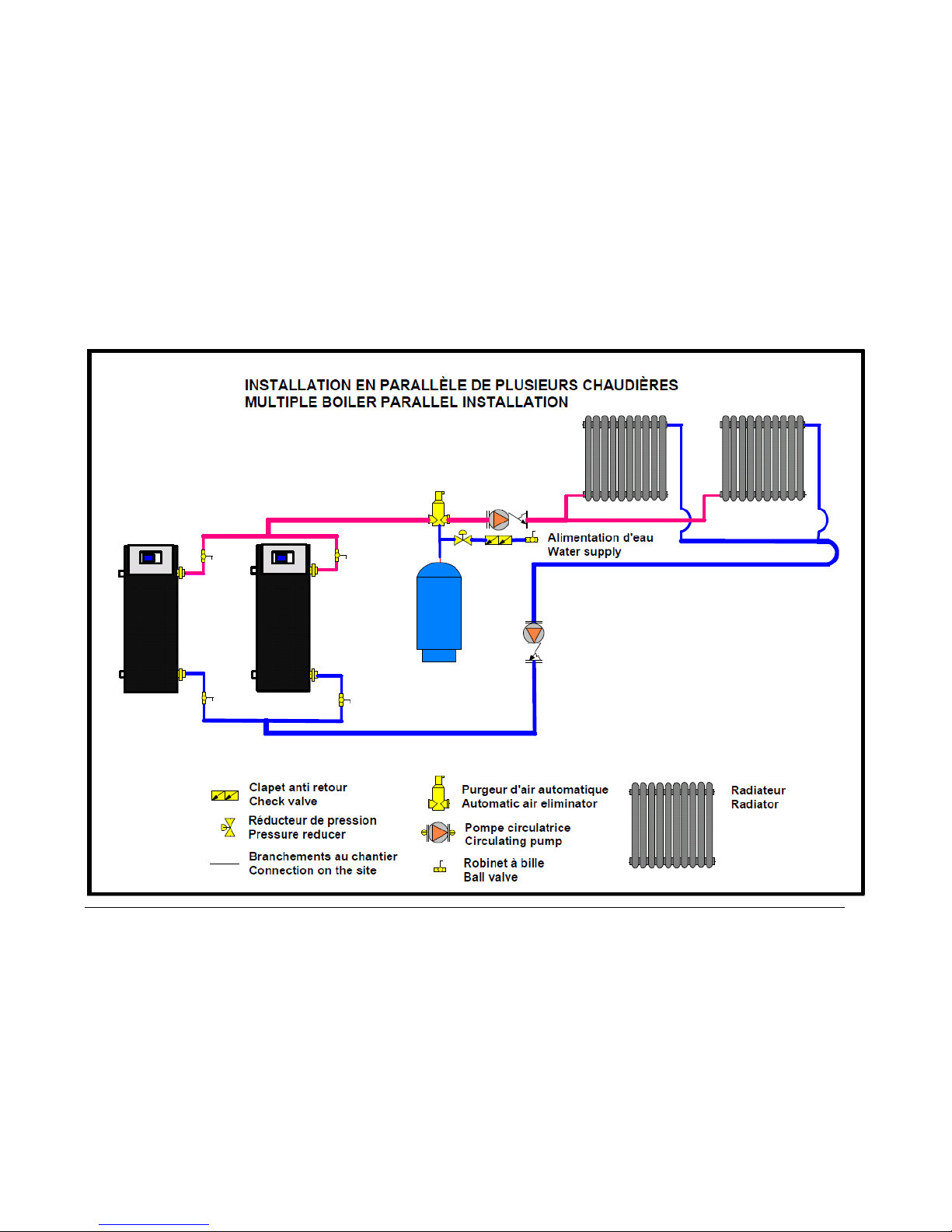

Figure 6 : Multiple boiler parallel installation

VOLTMAX ELECTRIC BOILER Installation and Operation Manual (Revised August 2017), Page 19.

Figure 7 : Basic installation with auxiliary boiler for production of domestic hot water and heating

3.5 ELECTRICAL CONNECTIONS

Wiring must be conform to the National Electrical

Code and to state or local code requirements.

The electric boiler must be electrically grounded

in accordance with local codes, or, in the

absence of local codes, with the National

Electrical Code.

3.5.1 MAIN ELECTRICAL SUPPLY

The power supply must be a 208 or 240-volt

circuit (single-phase or three-phase, 60Hz), 480

volts (three-phase, 60 Hz) or 600 volts (threephase, 60 Hz) protected by an appropriately

sized breaker.

Refer to the boiler rating plate to select the

breaker capacity and wiring rating

3.5.2 PUMP SUPPLY

The VOLTMAX Electric boiler (SCR models) can

control 1 or 2 pumps of the distribution system.

According to the VOLTMAX configuration, the

contact of the pump will function differently.

During a heat demand on W1 or W2, the contact

between Pc and P1 or Pc and P2 will be used to

start an external pump relay (maximum of 3

amps.). Depending on the configurations selected

in the controller, the pump P2 can have priority

over the pump P1.

N.B. The VOLTMAX boiler is not designed to

heat without a water circulation in its tank.

Therefore, if external pump controls are used,

they must be interlocked with the operating

authorization on W1or W2 of the controller.

3.5.3 CONNECTION OF EXTERNAL

SIGNALS TO THE CONTROLLER

The connection of all external signals is made

directly on the boiler controller on terminals

located on top of it. See the connection diagram

on

Figure 8 and Figure 9.

Cables used for the connections shall resist

temperature up to 90 °C.

3.5.3.1 Connecting the building heat demand

signal

Upon reception of a closed contact connected to

terminals 24V+ and W1 or W2, the corresponding

circulating pump P1 or P2 will start and the boiler

will be allowed to operate.

If external controllers control the heating system

pumps, they must provide the operating

authorization signal. The boiler must not receive

a heat demand without the circulation pumps

running.

On heating systems when water circulation is

continuous, the heat demand control can be

connected to the 24V+ and W1 terminals. The

heating elements will then be active and available

only when there is a request (dry contact).

If the heating system is designed to keep water

warm with continuous circulation, a jumper

(jumper) must be installed on the 24V+ and W1

terminals to maintain the boiler in demand. The

boiler will then attempt to maintain the water

temperature at the set-point.

Operation with an upper fixed set-point W2 can

be established by connecting the auxiliary

heating demand signal (Dry contact) of a

thermostat to the 24V+ and W2 of the terminal

block.

In all operating modes of the controller, a heat

demand on W1 and W2/DHW (close contact)

must be present to DI1 or DI2 to allow the

operation of the boiler. The only exception is in

domestic hot water mode (DHW) with an indirect

water heater where the minimum boiler

temperature shall be maintained.

3.5.3.2 Connecting au auxiliary boiler

(Available only on SCR models)

The boiler controller is designed to allow the

operation of a second boiler or an auxiliary boiler

according to two different mode of operation

“Auxiliary Backup” or Dual-Energy”.

To do so, connect the TT terminals of the

auxiliary boiler to terminals AUX of the

VOLTMAX. The maximum capacity of this

contact is 3A/120Vac.

See section 3.4.5 for details.

VOLTMAX ELECTRIC BOILER Installation and Operation Manual (Revised August 2017), Page 20.

3.5.3.3 Connection of an “Unoccupied signal”

of the building.

This function allows dropping the boiler

temperature during periods where the building is

not used and this without having to lower all the

room thermostats of the building.

To do so, a signal (dry contact) will have to be

connected to terminal OCC. (SCR model only)

The contact shall be close during the periods of

temperature drop.

You can also manage the periods of temperature

drop by setting a schedule in the controller.

3.5.3.4 Connection of an indirect domestic

hot water heater

The VOLTMAX electric boiler can be used not

only to fill the heating requirements of the building

but also to fill its domestic hot water needs using

an indirect domestic hot water heater such as our

TURBOMAX series.

To do so, connect the signal (dry contact) of

indirect water heater temperature control to the

terminal 24V+ and W2/DHW (SCR model only.

This will activate the circulating pump supplying

the water heater (if properly installed).

On STG models, the pumps can be controlled by

an external pump controller with the same

characteristics

3.5.3.5 Connection of a dual-energy signal

(SCR model only)

The VOLTMAX can be operated in a dual-energy

mode with an auxiliary boiler.

To do so, connect the normally close contact of

the dual energy controller to terminals 24V+ & BI-

E to operate with the electric boiler. See section

4.3.4.5 for more details on the sequence of

operation in dual energy.

3.5.3.6 Connection of an outdoor temperature

sensor

If you wish to modulate the boiler water

temperature according to the outdoor

temperature (Outdoor Reset, ORST) and also

wish to stop the operation of the boiler when the

outdoor temp. reaches a selected value, then the

outdoor sensor supplied with the unit or a

corresponding signal coming from the network

system shall be connected with a cable of

minimum gauge 20 (max 100pi) to terminals S.

Ext. of the controller.

This probe does not need to be connected during

an operation with a fixed setpoint temperature

unless you want to use the Warm weather

Shutdown function.

N.B. Do not install a jumper if the outside sensor

is not used.

Outdoor sensor location

o Outside the building at a location that best

represents the heat demand of the building (a

wall facing north for most of the buildings and

on a south one on buildings with large

windows facing south).

o It should not be exposed to external heat

sources (dryer outlet, window openings, noninsulated walls).

o It should not be installed in a location where it

could be covered with snow.

3.5.3.7 Remote controller used to determine

the target boiler temperature (SCR model

only)

An external controller (such as a central building

energy management system) can be used to

determine the boiler target temperature required

for the building. To do so, the external controller

shall give a 0 to 10VDC signal connected to

terminals 0-10Vdc G & 0-10Vdc T° of the

controller.

3.5.3.8 Limit Capacity 0-10VDC (SCR model

only)

An external controller providing a 0-10Vdc signal

could be used to manage the capacity (kW) of the

boiler.

Example: An application where the main

electrical service supply of the building is limited

or when the electricity rate is billed according to

the maximum peak loads of the building. To do

so, the external controller shall be connected to

terminals 0-10Vdc G & 0-10V cap. The capacity

of the boiler could be manually limited by

adjusting some of the controller parameters. See

section 4.3.4 for more details.

3.5.3.9 External alarm contact (SCR model

only)

An alarm signal (dry contact) is available on the

boiler to advise the user of an alarm situation.

The capacity of the contact is 3A resistive/1A

inductive on terminal AL/AL.

An internal audible alarm inside the controller is

available on all models. Just activate it in the

settings.

VOLTMAX ELECTRIC BOILER Installation and Operation Manual (Revised August 2017), Page 21.

VOLTMAX ELECTRIC BOILER Installation and Operation Manual (Revised August 2017), Page 22.

Figure 8 : ELECTRICAL CONNECTIONS OF THE INPUT AND OUTPUT SIGNALS TO THE CONTROLLER (SCR MODEL)

Figure 9 : ELECTRICAL CONNECTIONS OF THE INPUT AND OUTPUT SIGNALS TO THE CONTROLLER (STG MODEL)

W1

Heating request 1 : On

W2

Heating request 2 : On

P1

Pump 1 : On

P2

Pump 2 : On

BIE

Boiler in Bi-Energy mode

VOLTMAX Boiler : On

Auxiliary boiler : On

Boost mode : On

Warm Weather Shut Down : On

An alarm is active

The boiler is in lock out mode

HL

High temperature limit condition at

the boiler outlet

LL

Low temperature limit conditions

(lack of capacity)

P

Alarm due to a pressure problem

A

Alarm due to an electrical problem

F

Alarm due to a flow problem

Se

Alarm due to a sensor problem

T° SETPOINT

Actual set-point temperature

T° BOILER

Water temperature at the

outlet of the boiler

CAP (%)

Percentage of power used

according to boiler rated

power

T° EXT

Outdoor temperature

measured using the outdoor

sensor

KW ACT

Actual power calculated by

the boiler

PRESS.

Pressure inside the boiler

STAGE

Status of active stage

SECTION 4 : CONTROLLER OPERATION

4.1 USER INTERFACE

The control of the boiler is ensured by a

controller TM171PFE03 of the company

Schneider Electric. The LCD display of the

controller provides an interface for configuring

and displaying the boiler parameters.

A communication module also allows you to

integrate the controller with an intelligent building

management system (BACnet protocol). It is

also equipped with an Ethernet connection.

Allowing the connection to the Internet network

of the building allowing to read and modify

locally or remotely the boiler setting. It can be

configured to send alarm messages via e-mail.

Icons will also display to indicate the boiler’s

current operating status. Temperature can be

displayed in Celsius or Fahrenheit and text can

be set to either English or French.

The controller has a backlight function. It is also

equipped with three indicator lights (Green /

Yellow / Red). The green light indicates normal

operation of the unit; the yellow light indicates

that the controller has diagnosed and anomaly

which requires verification by a technician. The

red light indicates that the unit is currently in a

critical state (high temperature alarm) or in lock

out mode. More detail is provided in Section 6:

Troubleshooting. The controller can also be

configured to activate an internal buzzer and

activate an external alarm signal (SCR only)

when an alarm condition occurs causing the

boiler to fail.

Boiler operating mode

Alarm symbol

Operating state of the boiler

Figure 10 : Illustration of the display

4.1.1 SYMBOL DESCRIPTION

The main display shows most the boiler

operation status information. The explanation of

the main display is shown below.

VOLTMAX ELECTRIC BOILER Installation and Operation Manual (Revised August 2017), Page 23.

1

2 3 4

4.1.2 CONTROL PANEL

Figure 11 : Control panel

On the left side of the appliance, an on / off

switch (# 3) is used to operate the appliance and

to reset the boiler.

An indicator light showing the status of the low

water level cut off and a test button (# 1) is

standard for models 120 kW and above. The

control circuit fuses (# 2) are accessible from the

left side of the unit.

4.1.3 NAVIGATION AND

ADJUSTEMENTS

The navigation within the display is done with

the five pushbuttons on the right of the screen.

Navigation between the elements is done with

the up and down arrows. Use the right key to

change the page in the menus. The return key

will bring you to the previous menu. The return

key returns you to the main display when it is

pressed for 2 seconds or more.

The OK button confirms the selection and allows

you to edit a parameter. Only highlighted box

can be modified. To modify an option, select the

box to modify with the arrow keys and press OK.

The black box or one of its values will flash and

can be changed. Change the values using the

arrows and confirm the change by pressing OK.

VOLTMAX ELECTRIC BOILER Installation and Operation Manual (Revised August 2017), Page 24.

4.1.4 MAIN MENU NAVIGATION

Press one of the 5 buttons on the main display to access the main menu

VOLTMAX ELECTRIC BOILER Installation and Operation Manual (Revised August 2017), Page 25.

Figure 12 : Main menu navigation

4.1.5 NAVIGATION IN BOILER SETTING

Figure 13 : Navigation in boiler setting menu (1/3)

VOLTMAX ELECTRIC BOILER Installation and Operation Manual (Revised August 2017), Page 26.

You can switch from page by using the left or right arrow (Ex : 1/3 to 2/3 by using the

right arrow)

Figure 14 : Navigation in boiler setting menu (2/3)

VOLTMAX ELECTRIC BOILER Installation and Operation Manual (Revised August 2017), Page 27.

Figure 15 : Navigation in boiler setting menu (3/3)

VOLTMAX ELECTRIC BOILER Installation and Operation Manual (Revised August 2017), Page 28.

Menu

Contents

Boiler status

Detailed information on the

boiler condition

Boiler setting

Configuration of the boiler

operating mode and

parameters.

User setting

Configuration of the

controller display option

Clock setting

Configuration of the internal

clock

Consumption

Power consumption of the

boiler

Parameters

Description

Language

Select English or French

version

Temperature

unit

Select the temperature units,

either Celsius (C) or

Fahrenheit (F)

Flow unit

Select the flow unit, either US

gallons per minute (USgpm) or

liters per second (L / sec)

Backlight

Setting the backlight mode:

- Off

- 30 secondes

- Always On

Internal

buzzer

Setting of the internal buzzer

4.2 MAIN MENU

The main menu is accessible to the user, no

access code is required.

The main menu is accessed by pressing one of

the 5 pushbuttons. Navigation between menu is

done with the arrows (up, down, left and right).

4.2.2 BOILER CONFIGURATION

Configuration of the boiler operating mode

This menu is accessible only to the installer or to

an authorized person.

The options in the Boiler setting menu are

detailed in Section 4.3.

The Manufacturer access code gives access to

advanced operating parameters that are not

accessible to the installer and the user.

4.2.3 USER SETTING

Configuration of the controller display option

This menu allows the modification of different

display parameters.

4.2.1 BOILER STATUS

Detailed information on the boiler condition

This menu allows the display of data not

included in the main display. The boiler status

menu display the measurements of temperature,

pressure, flow, alarm summary, version of the

programme and the status of the heating

element.

The set of variables presented in this menu are

presented in Section 4.5

VOLTMAX ELECTRIC BOILER Installation and Operation Manual (Revised August 2017), Page 29.

HEATING

MODE W1

Boiler heating mode W1

configuration according to

the type of application

HEATING

MODE

W2/DHW

Boiler heating mode W2 or

DHW configuration according

to the type of application

PUMP

SETTING

Pump contact configurations

CAPACITY

LIMITING

Capacity limiting mode

configuration

AUXILIARY

BOILER

Auxiliary boiler mode

configuration (if needed)

4.2.4 CLOCK SETTING

Internal clock configuration

Use this menu to adjust the controller’s internal

clock. To set the clock correctly, you must adjust

the time, minutes, and date.

This adjustment is necessary in order for these

modes to function properly:

- The boiler’s power consumption

- Limiting the boiler’s power capacity according

to a schedule

- The boiler’s occupation mode

Battery life for the clock is at least 1 year when

the controller is unpowered (at 25°C).

N.B. The date and day of the week must be set

correctly to ensure the controller automatically

changes to daylight savings time.

4.2.5 CONSUMPTION

Boiler consumption cycle report

N.B. For the STG model, the calculation of

power consumption is based on a theoretical

approach, there may be differences between the

actual consumption of the boiler and the

consumption displayed on the screen.

N.B The consumption values are approximate

and should not be used as a comparison with

actual consumption data charged by the

electricity distributor.

4.3 BOILER SETTINGS

In order to be able to configure the boiler, it is

necessary to authenticate yourself with an

installer or manufacturer code.

The default "Installer" access code is

1111 and can be changed in the

Change password menu.

This menu allows visualization of the boiler

power consumption report. First, you must

activate the beginning of the consumption cycle

with the Start key. The consumption report can

be saved using the Save key. And all saved

report is available on the History tab. The

beginning of the consumption cycles can be

reset using the Reset button.

The controller records up to 30 consumption

report.

VOLTMAX ELECTRIC BOILER Installation and Operation Manual (Revised August 2017), Page 30.

LIMIT SETTING

Configuration of the

boiler operating limits

ALARM

Configuration of the

alarms

COMMUNICATION

Configuration of the

boiler communication

parameter (Web, Email,

Bacnet)

OCCUPATION

Configuration of the

occupation parameter

mode

MODE BOOST

Enable Boost mode

WARM WEATHER

SHUTD.

Enable warm weather

shut-down function

CHANGE

PASSWORD

Changing the Installer

password

FIXED

Fixed boiler set-point

DDC 010 VDC

Modulation of the boiler set-point

using a 0-10VDC signal

OUTD

RESET

Modulation of the boiler set-point

using the outdoor temperature

STOP

No heating demand on W1

4.3.1 HEATING MODE W1

Selection of the operating mode

In this menu you must select an operating mode

for selecting the desired setpoint temperature

depending on the application. A heat demand or

a demand must be present on W1 and/or

W2/DHW so that the boiler can heat up.

During a heat demand, the boiler activates

(depending on a PID curve) the number of

stages required in sequence so that the boiler

output temperature is maintained at the

approximate set-point temperature.

Here is the list of W1 heating modes:

4.3.1.1 Fixe

This mode is used for an installation where it is

desired to have a fixed set-point temperature.

If the boiler is thermostat-controlled with a heat

demand signal on W1, the boiler uses the

corresponding set-point (T. Set-point W1) as

the supply temperature.

4.3.1.2 DDC 0-10 VDC

(Available only on SCR model)

This operating mode allows modulating the

boiler set-point temperature according to a 010VDC signal applied the terminal 0-10VDC and

bornier 0-10Vdc G et 0-10Vdc T, produced by

an external controller (Ex: Building Energy

Management Controller).

The details of the parameters in this mode are

presented in Section 4.6.3.

4.3.1.3 Outdoor reset

This operating mode makes it possible to

modulate the boiler output set-point temperature

as a function of the outdoor temperature.

The outdoor temperature signal comes from the

temperature sensor supplied with the boiler,

which will be connected to the boiler controller.

The details of the parameters are presented in

Section 4.6.2 .

4.3.1.4 Stop

Select this mode to stop the boiler. The heating

elements will not operate on a W1 demand.

4.3.2 HEATING MODE W2/DHW

This mode allows you to configure a second

heating demand (W2) or a demand from an

indirect domestic water heater (DHW).

Select none if none of these functions are used.

These modes are presented in detail in Section

4.7.

W2

This mode allows the W2-DHW input to be used

to receive a signal (dry contact) from a 2nd

stage of heating.

When the contact on W2-DHW closes, the setpoint temperature changes to the set value (T.

Set-point W2), even if there is no demand on

W1.

DHW

This mode allows you to configure the demand

for an indirect domestic water heater. When the

DHW mode is selected, the boiler is kept at a

minimum temperature (T. Min Boiler) and when

contact W2 closes (Dry contact) the set-point

rises to T. DHW Set-point. In addition, the PID

curve is more aggressive.

VOLTMAX ELECTRIC BOILER Installation and Operation Manual (Revised August 2017), Page 31.

On W1 Dem.

Contact of pump 1 is activated

only when there is a demand

on W1.

On W2 Dem.

Contact of pump 2 is activated

only when there is a demand

in W2.

Priority over

P1

When there is a request on

W2, contact of pump 2 is

activated and contact of pump

1 is deactivated.

Always On

The selected pump is always

on (contact is always on).

Stop

The selected pump is always

deactivated (contact is always

off).

Off Delay

The delay in seconds before

the contact of the pump is

deactivated.

4.3.3 PUMP SETTING

Configuring pump contact activation

(Available only on SCR model)

The system allows the control of up to two

pumps. Each of these pumps can be activated

using a contact. Each pump can be activated

according to different modes.

If the amperage of each of the pumps exceeds

3A, external pump relays must be used.

Pump Configuration Options

N.B. External pump relays can also be used as

an alternative to the boiler pump controller. If this

alternative is used, a dry contact of this

controller must be connected to W1 or / and W2

to allow the boiler to operate only when there is

a flow of water present.

4.3.4 CAPACITY LIMITING

Adjusting the maximum authorized power

This menu allows you to configure the boiler

output limit. The selection of the limit mode can

be selected in the Capacity limiting menu

o None

o Manual

o DDC 0-10 VDC

o T. Ext

o Schedule

Details of each of these options are presented in

Section 4.9 .

N.B: It is not recommended to disconnect one of

the power relays inside the VOLTMAX boiler to

accomplish this function.

N.B: On the STG models, the maximum power

chosen must correspond to the power of the

stages of the boiler since there is no power

modulation relay on these models.

4.3.4.1 NONE

The boiler is not limited in power, the maximum

power it can deliver is equivalent to its maximum

rated power.

4.3.4.2 MANUAL

The maximum capacity permitted of the boiler is

configured in a fixed mode.

Details of the variables in this mode are

presented in Section 4.9.1

4.3.4.3 DCC 0-10 VDC

(Available only on SCR model)

A 0-10 VDC signal from a building management

system can be used. The signal is treated as a

function in order to limit the maximum power.

In order to configure this mode, you must

connect the 0-10 VDC signal to the terminal

block 0-10Vdc Cap. and 0-10Vdc G.

Details of the variables in this mode are

presented in Section 4.9.2

VOLTMAX ELECTRIC BOILER Installation and Operation Manual (Revised August 2017), Page 32.

None

No auxiliary boiler is present

Backup

Aux.

This mode allows the adjustment of a

second boiler to play a Backup role

Ext

Contact

Select the heating source using

electrical contact to the BI-E terminal.

BiE (BI-

Energy)

Select the heating source using

electrical contact to the BI-E terminal

with the possibility of support

mode of the auxiliary boiler.

Manual

Manually select the system operation

mode (Electrical or Auxiliary).

4.3.4.4 T. EXT

The maximum permitted power can be adjusted

according to the outside temperature sensor.

The outdoor temperature is used in order to limit

the maximum authorized power.

Details of the variables in this mode are

presented in Section 4.9.3 .

This mode of operation is particularly

advantageous in applications where the

boiler is connected to an electrical network

taking account of demand peaks in order to

determine the cost of use (demand meter).

Since the boiler will thus be limited to a

maximum power which will have to be

established as a function of the heating

requirements of the building and the outside

temperature, it will thus be possible to avoid

peaks of power not required to satisfy the

heating needs in periods of cold weather.

4.3.4.5 Schedule

The maximum authorized boiler power can be

programmed according to a schedule. See

section 4.9.4 for an explanation of how to

modify a schedule.

4.3.5 AUXILIARY BOILER

(Available only on SCR model)

The controller program has been designed to

allow the operation of a second boiler or

auxiliary boilier.

4.3.5.1 Select setpoint source for Auxiliary

Boiler

The source of the set-point temperature control

can be configured by selecting STPT source

Aux. consequently.

In the Internal mode, the terminal contact Aux

closes when there is a request for W1 or

W2/DHW and the VOLTMAX output temperature

is below the setpoint temperature. In addition,

the Aux contact is opened when the output

temperature is higher than the setpoint

temperature.

In External mode, the Aux contact closes when

there is a request on W1 or W2 / DHW

regardless of the boiler output temperature

VOLTMAX. The VOLTMAX boiler thus has no

set temperature and is only used to activate the

auxiliary boiler relay.The various configurations

of the Aux boiler mode are the following:

N.B. The auxiliary boiler can only be switched on

when a heat demand is present on W1 or / and

W2 / DHW.

4.3.5.2 None

This mode must be active when there is no

auxiliary boiler on the hydronic heating system.

4.3.5.3 Backup Aux.

The boiler will be activated according to the

configuration of the lack of capacity of the

VOLTMAX boiler.

In the event of a lack of capacity, the boiler is

started to compensate.

The lack of capacity is defined by the fact that

the boiler output temperature is less than X

degrees (Delta T. Start Aux.) relative to the setpoint for duration of X min. (Auxiliary Start

Delay). The auxiliary boiler will be deactivated

when the temperature differential between the

water outlet temperature and the set-point

temperature is lower than Delta T. Off Aux. The

calculation of the delay begins only when the

electric boiler reaches its maximum power (or

maximum power allowed).

The value of "Delta T." should be a negative

value.

Details of the variables in this mode are

presented in Section 4.10.1

VOLTMAX ELECTRIC BOILER Installation and Operation Manual (Revised August 2017), Page 33.

An alarm is active

The boiler is in lock mode

HL

The high limit temperature has been

reached

LL

Low limit (Lack of capacity)

P

Pressure problem alarm

A

Electrical problem alarm

F

Flow problem alarm

Se

Sensor problem alarm

4.3.5.4 Contact Ext.

This configuration mode makes it possible to

operate the electric boiler or the auxiliary boiler

according to a contact. During a close contact at

the BI-E terminals, the electric boiler ( ) is

activated. When the contact is open, the

auxiliary boiler ( ) will be on. The auxiliary

boiler will not be allowed to operate if the electric

boiler lacks capacity.

Details of the variables in this mode are

presented in Section 0

4.3.5.5 BiE (BI-Energy)

The Bi-Energy mode allows the auxiliary boiler

to operate when there is a lack of capacity.

Upon receipt of an electrical signal (contact

closed at Bi-E) and a request at the terminal of

W1 or W2, the contact at the terminal of AUX

will be opened and thus the electric boiler ( ) is

allowed to operate and the auxiliary boiler is

deactivated.

When an electrical signal is absent (contact

open at Bi-E) and a request is present at the

terminals of W1 or W2, the contact will close at

the terminal of AUX, in order to operate the

boiler Auxiliary ( ) and not the electric boiler.

Details of the variables in this mode are

presented in Section 0.

4.3.5.6 Manual

Manual mode is used to manually select the

operating mode of the system (Electrical or

Auxiliary).

Details of the variables in this mode are

presented in Section 4.10.3

4.3.6 LIMIT SETTING

Configuring the boiler operating limits

Use this menu to adjust the permissible

operating boiler limits for various parameters.

This menu’s configuration options are presented

in detail in Section 4.11.

4.3.7 ALARM

Alarm Mode Configuration

When an alarm is active, it will be displayed on

the main display as a symbol.

Ex: If P and Se are displayed at the same time,

this indicates a pressure sensor problem

A summary of active alarms is also available in

the Boiler status menu.

An alarm report is available under the Alarm log

menu. Information about date, time and alarm

code is available in this menu. The internal clock

must be adjusted beforehand so that the alarm

registers correctly. Section 6 -

Troubleshooting details alarm codes and

settings specific to this menu.

Details about this menu’s operation are available

in Section 4.12

VOLTMAX ELECTRIC BOILER Installation and Operation Manual (Revised August 2017), Page 34.

Address IP

10.0.0.100