THERMO 2000 THERMO 2000, TURBOMAX 23, TURBOMAX 24, TURBOMAX 33, TURBOMAX 34 Use & Care Manual

...

®

TURBOMAX

Instantaneous Indirect Water Heater

USE & CARE MANUAL

WITH INSTALLATION INSTRUCTIONS FOR THE CONTRACTOR

Your TURBOMAX® Instantaneous Indirect Water Heater has been carefully assembled and

factory tested to provide years of trouble-free service. In order to insure the service

intended, the following information is provided to enable proper installation, operation, safety

precautions and maintenance of this product.

It is imperative that all persons who are expected to install, operate or adjust this water

heater read the instructions carefully so that they may understand how to do so.

Any questions regarding the operation, maintenance, service or warranty of this water

heater should be directed to the entity from whom it was purchased. If additional

information is required, refer to the section How to Obtain Service Assistance

When all installation steps have been completed, replace this installation manual in its

original envelope, and keep in a safe place for future reference.

Revision : December 2005

THERMO 2000 INCORPORATED

Specifications

The hot water heater for domestic hot water

purposes shall be a TURBOMAX

as manufactured by THERMO 2000 Inc. The hot

water heater shall have an all-copper domestic

waterways made of multiple helical copper tubes

operating in parallel with a 150 p.s.i. maximum

operating pressure rating. All copper components

shall meet the NSF 61 standard of NSF International

Standard Drinking Water Systems Components

Health Effects. All copper components shall be

joined at high temperature by a Sillfoss silver

brazing containing no lead. The hot water heater

shall have a patented steel injector through which

the boiler water or the primary circuit fluid enters the

top side of the tank and a steel collector through

which the boiler water or primary circuit fluid exits at

the bottom of the tank. The tank shall be made of

high carbon steel. All the steel joints must be

welded by the MIG/Argon gas process. The tank

shall be hydrostatically tested to a pressure of

300 p.s.i. and shall have a maximum operating

pressure of 150 p.s.i. The tank shall have a

fiberglass insulation jacket reducing the tank heat

loss to less than ½°F per hour. The outer steel

jacket shall be protected by baked epoxy. The hot

water heater shall have a temperature controller

(aquastat) that makes contact when the temperature

falls 9°F below the tank water temperature set point

and breaks contact when the temperature rises over

the set point. The tank shall have a drain (ball) valve

made of brass, which have a maximum working

pressure of 150 p.s.i. 3 adjustable feet support the

water heater for leveling. The hot water heater shall

be shipped from the factory with an ASME rated

pressure relief valve set at 30 p.s.i., a

thermometer/pressure gage (except #23, 33) and

an automatic air vent (except #23, #24, #33, #34).

The water heater is backed by a 10-year warranty (consult the

terms of the warranty shipped with the water heater).

®

model _______,

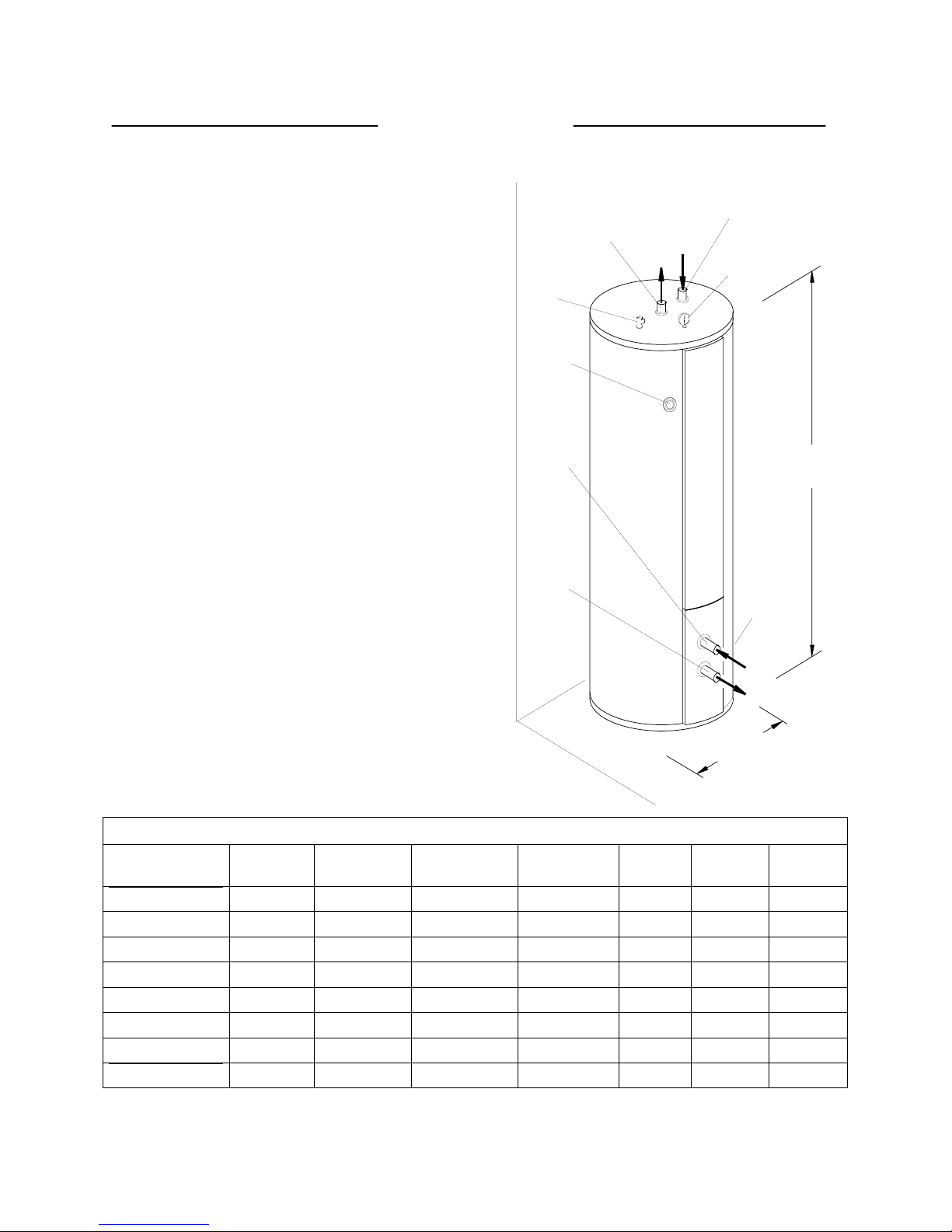

Connection

Domestic

Hot Water

Outlet

Safety

valve set

at 30 psi

Aquastat

Connection

Cold

Domestic

Water

Inlet

Connection

Boiler

Water

Return

Outlet

Specifications:

Model Tank

Volume

TURBOMAX® 109

TURBOMAX® 65

TURBOMAX® 45

TURBOMAX® 44

TURBOMAX® 34

TURBOMAX® 33

TURBOMAX® 24

TURBOMAX® 23

Note: Copyright 2005. Thermo 2000 Inc. All rights reserved. Turbomax® is a registered trademark of Thermo 2000 Inc. Thermo 2000 reserves the

right to modify at any time and without notice colors, components, materials, specifications or model described in or shown in this document.

119 US gal. 58.9 ft² 2’’ Sweat M 2’’ NPT M 74’’ 29’’ 555 lbs

72 US gal. 32.7 ft² 1-1/2’ Sweat M 1-1/2’’ NPT M 67’’ 24’’ 250 lbs

48 US gal. 32.7 ft² 1-1/2’’ Sweat M 1-1/4’’ NPT M 55’’ 22’’ 235 lbs

48 US gal. 26.2 ft² 1-1/2’’ Sweat M 1-1/4’’ NPT M 55’’ 22’’ 210 lbs

36 US gal. 26.2 ft² 1-1/2’’ Sweat M 1-1/4’’ NPT M 65“ 18“ 195 lbs

36 US gal. 19.6 ft² 1-1/4’’ Sweat M 1-1/4’’ NPT M 65“ 18“ 170 lbs

26 US gal. 26.2 ft² 1-1/2’’ Sweat M 1-1/4’’ NPT M 49’’ 18’’ 175 lbs

26 US gal. 19.6 ft² 1-1/4’’ Sweat M 1-1/4’’ NPT M 49’’ 18’’ 150 lbs

Heat transfer

area (sq. ft.)

Utility

connection

Boiler

connection

Height

Connection

Boiler Water

Supply

Inlet

Manometer/

thermometer

Height

Drain

Valve

(right

side)

r

e

t

e

m

ia

D

Diameter Shipping

weight

TURBOMAX Use and Care Manual with Installation Instructions (December 2005) Page 2

R

!

General Safety Precautions

Be sure to read and understand the entire Use & Care Manual before attempting to install

or operate this water heater. Pay particular attention to the following General Safety

Precautions. Failure to follow these warnings could cause property damage, bodily injury or

death. Should you have any problems understanding the instructions in this manual, STOP,

and get help from a qualified installer or technician.

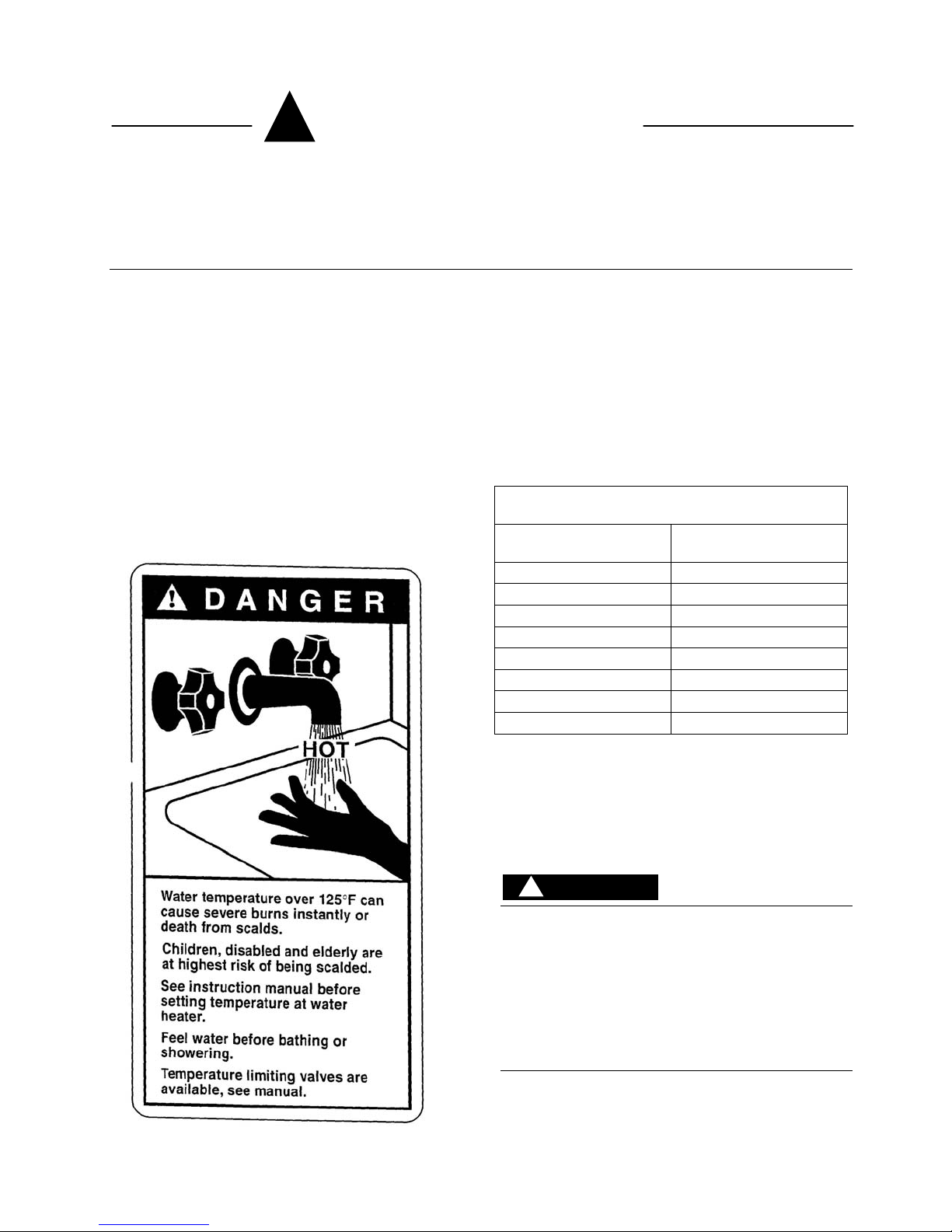

To meet commercial water use needs, the

aquastat on this water heater is adjustable up to

190°F. However water temperatures over 125°F

can cause severe burns instantly or death from

scalds. 125°F is the preferred starting point for

setting the control to supply general-purpose hot

water.

Safety and energy conservation are factors to be

considered when setting the water temperature

on the aquastat. The most energy efficient

operation will result when the temperature

setting is the lowest that satisfied the needs

consistent with the application.

Maximum water temperature occurs just after

burner or the energy source has shut off. To find

hot water temperature being delivered, turn on a

hot water faucet and place a thermometer in the

hot water stream and read the thermometer.

The following chart details the relationship of

water temperature and time with regard to scald

injury and may be used as a guide in determining

the safest water temperature for your applications.

TIME VS TEMPERATURE

RELATIONSHIPS IN SCALDS

Temperature

120°F More than 5 minutes

125°F 1-1/2 to 2 minutes

130°F About 30 seconds

135°F About 10 Seconds

140°F Less than 5 seconds

145°F Less than 3 seconds

150°F About 1-1/2 seconds

155°F About 1 second

Table courtesy of Shriners Burn Institute

The temperature of the water in the heater can be

regulated by setting the temperature dial in front of

the aquastat. To comply with safety regulations

the aquastat was set at its lowest setting before

water heater was shipped from the factory.

There is a Hot Water Scald Potential if the

aquastat is set too high. When this water

heater is supplying general purpose hot water

requirements for use by individuals, a

thermostatically controlled mixing valve for

reducing point-of-use water temperature is

recommended to reduce the risk of scald

injury. Contact a licensed plumber or local

plumbing authority for further information.

!

DANGE

Time to Produce Serious

Burn

TURBOMAX Use and Care Manual with Installation Instructions (December 2005) Page 3

Introduction

WARNING

!

The important safeguards and instructions

appearing in this manual are not meant to

cover all possible conditions and situations

that may occur. It should be understood that

common sense, caution and care are factors,

which cannot be built into every product.

These factors must be supplied by the

person(s) caring for and operating the unit.

LOCAL INSTALLATION REGULATIONS

This water heater must be installed in

accordance with these instructions and must

conform to local, or in the absence of local

codes, with the current edition of the National

Plumbing Code and the National Electric Code.

In any case where instructions in this manual

differ from local or national codes, the local or

national codes take precedence.

DECISIONS REQUIRED BEFORE

INSTALLATION

In some jusrisdictions the boiler’s operating

pressure must be limited to 30 psi (200 kPa) by

a safety relief valve. When a higher operating

pressure level is needed, select a boiler which is

certified to operate at the required pressure.

The boiler’s output rating must be within the

heater’s recommended sizing guide

specifications. Too low an output rating may

cause excessive condensation in the boiler. Too

high an output rating may cause a boiler short

cycling condition. Either of these conditions

could be detrimental to the life and performance

of the system.

Where the boiler’s output is used to supply

space heating and domestic water heating, two

options are available when wiring the controls.

The first option uses a priority relay. When the

aquastat of the water heater calls for heat, the

relay shuts off the space heating zones, giving

priority to producing domestic hot water. Any

demand for space heating is postponed until the

water heater has reached a preset level. This

delay in supplying the space heating zones is

usually not noticed by those occupying the living

space. The water heater gets adequate hot

water flow from the boiler to maintain the full

rated delivery of domestic hot water.

In the second option, the water heater will be

supplied as just another heating zone. This

means that if all space heating zones call for hot

boiler water at the same time, the water heater

may not be supplied with enough hot boiler

water to “recover” adequately. The delivery of

domestic hot water will be diminished. This is

not a problem when the boiler output is sized

adequately for both loads.

The flow of hot boiler water to the water heater

can be controlled with either a pump or a

motorized valve. If a zone valve is to be used,

the space heating system circulator must have

an adequate flow rate to allow proper heat

transfer of BTUs from the hot boiler water stored

in the tank to the domestic water flowing inside

the water heater’s heat exchanger. Be sure the

space heating zone valve chosen has maximum

pressure drop to insure proper boiler water flow

to the heater. The recommended way to provide

adequate boiler water flow through the water

heater is to use a separate dedicated circulator.

This option may be used even though the

heating system utilizes zone valves.

CAUTION

!

The heat transfer medium must be water or

other non-toxic fluid having a toxicity rating

or class of 1, as listed in Clinical Toxicology

of Commercial Products, 5

th

edition

LOCATION

The water heater should be installed in a clean,

dry location as close as practical to the boiler or

the heat source. Long hot water lines should be

insulated to conserve water and energy. The

water heater and water lines should be protected

from exposure to freezing temperatures.

TURBOMAX

vertically. Use the adjustable feet to level the

unit.

The water heater must be located or protected

so it is not subject to physical damage, for

example, by moving vehicles, area flooding, etc.

®

water heaters must be installed

TURBOMAX Use and Care Manual with Installation Instructions (December 2005) Page 4

All models can be installed on combustible floors

and in alcoves. Minimum clearance from

combustible construction is 0 inches on all sides.

A minimum 3 inch clearance on both sides and

in the rear and a minimum 24 inch clearance in

front and on top should be available for

adequate inspection and servicing.

CAUTION

!

The water heater should not be located in an

area where leakage from the tank or water

connections will result in damage to the

adjacent area or to lower floors of the

structure. When such areas cannot be

avoided, a suitable drain pan or nonflammable catch pan, adequately drained,

must be installed under the water heater.

The pan must be connected to a drain.

NOTE: Auxiliary catch pan MUST conform to

local codes.

Catch pan or drain pan kits made of metal are

available in 16”, 19”, 22”, 24” and 26-1/2”

diameters from the distributor or store where the

water heater was purchased.

RESTAURANTS

If the water heater is to be installed in a

restaurant or other location where the floor is

frequently cleaned, it must be elevated to

provide at least 6 inches of clearance from the

floor to comply with NSF International

recommendations. A factory-designed leg

extension kit is available for this purpose from

the distributor or store where the water heater

was purchased.

CORROSIVE ATMOSPHERES

The heater should not be located near an air

supply containing halogenated hydrocarbons or

high humidity. For example, The air in beauty

salons, dry cleaning establishments, photo

processing labs and storage areas for liquid and

powder bleaches or swimming pool chemicals

often contains such hydrocarbons.

The limited warranty is voided when failure of

the water heater is due to a corrosive

atmosphere. TURBOMAX

designed for corrosive atmospheres are

available from the distributor or store where the

water heater was purchased.

®

water heaters

Check List of Mechanical Components for Proper Installation

NON-PRIORITY SYSTEM

A) If separate circulator for each zone

• 1 circulator per zone

• 1 flow check per zone

B) If only one circulator used by the

heating system

• 1 zone valve per zone

C) Common Components:

• 4 x unions

• 4 x ball valves minimum

• 1 x vacuum breaker (if required)

• 1 x temperature & pressure relief valve

with probe of sufficient length.

• 1 x thermostatic mixing valve

• copper pipe & copper pipe fittings

• steel pipe & steel pipe fittings

PRIORITY SYSTEM

A) If separate circulator for each zone

• 1 circulator per zone

• 1 flow check

B) If only one circulator used by the

heating system

• 1 – 3 way zone valve

• 1 x potable water expansion tank if

necessary. See the “Domestic water

connections” section.

• 1 x pressure reducing valve (boiler

water)

• 1 x pneumatic expansion tank

• 2 x automatic air vents at least.

• Switching relays or zone controller

• And any other necessary components.

TURBOMAX Use and Care Manual with Installation Instructions (December 2005) Page 5

Installation

WARNING

!

The manufacturer’s warranty does not cover

any damage or defect caused by installation

or attachment or use of any special

attachment other than those authorized by

the manufacturer into, onto, or in

conjunction with the water heater. The use

of such unauthorized devices may shorten

the life of the water heater and may endanger

life and property. The manufacturer

disclaims any responsibility for such loss or

injury resulting from the use of such

unauthorized devices

INSPECT SHIPMENT

Inspect the water heater for possible shipping

damage. The manufacturer’s responsibility

ceases upon delivery of goods to the carrier in

good condition. Consignee must file any claims

for damage, shortage in shipments, or nondelivery immediately against carrier.

DOMESTIC WATER CONNECTIONS

This water heater may be connected individually,

in multiples with others, or with an external hot

water storage tank. If two TURBOMAX

are installed, the piping method to be used to

connect the TURBOMAX

“reverse-return piping”, so domestic water flow

rate through each TURBOMAX

®

in parallel should be

®

is equal.

The HOT WATER OUTLET and the COLD

WATER INLET connections are clearly marked.

Inlet water connections (COLD WATER INLET)

are to be made to the copper pipe (sweat

connection) at the bottom of the heater. Outlet

water connections (HOT WATER OUTLET) are

to be made to the copper pipe (sweat

connection) at the top of the heater.

The installation of copper unions or copper alloy

unions is recommended on the HOT and COLD

water lines, so that the water heater may be

easily disconnected for servicing if necessary.

Dielectric unions are required for protection of

the water heater if dissimilar pipe material like

galvanized pipe is used.

Install shutoff (ball) valves for servicing

convenience.

®

or more

Use only clean copper or approved plastic pipe

for water connections. Local codes or

regulations shall govern the exact type of

material to be used.

To minimize heat loss during non-draw periods,

a heat trap formed from piping can be used.

Insulate all pipes containing hot water, especially

in unheated areas.

Cap or plug unused connections. If the water

heater is replacing a tankless coil in the boiler,

do not cap tube outlets in the tankless coil after

disconnecting from plumbing.

Thermometer(s) should be installed to indicate

the temperature of the water at or near the outlet

of the water heater and storage tank(s), if

provided.

EXPANSION TANK FOR POTABLE

WATER

Determine if there is a check valve, a back flow

preventer, a pressure-reducing valve, a water

meter or a water softener in the cold water

supply line.

A check valve creates a closed system and

prevents the water, as it is being heated, from

expanding back into the cold water supply line.

Pressure can build up within the water heater,

causing the relief valve to operate during a

heating cycle. This excessive operation can

cause premature failure of the relief valve and

possibly of the water heater itself.

Replacing the relief valve will not correct the

problem. One method of preventing pressure

build-up is to install an expansion tank for

potable water in the cold water supply line

between the heater and check valve. Contact

your installing contractor, water supplier, local

plumbing inspector or plumbing supply house for

assistance.

RECIRCULATION LINE (IF APPLICABLE)

If a recirculation line is installed, the return

connection should be made to a tee close to the

inlet connection on the water heater. A check

valve should always be installed in the

recirculation line to prevent cold water from

entering.

TURBOMAX Use and Care Manual with Installation Instructions (December 2005) Page 6

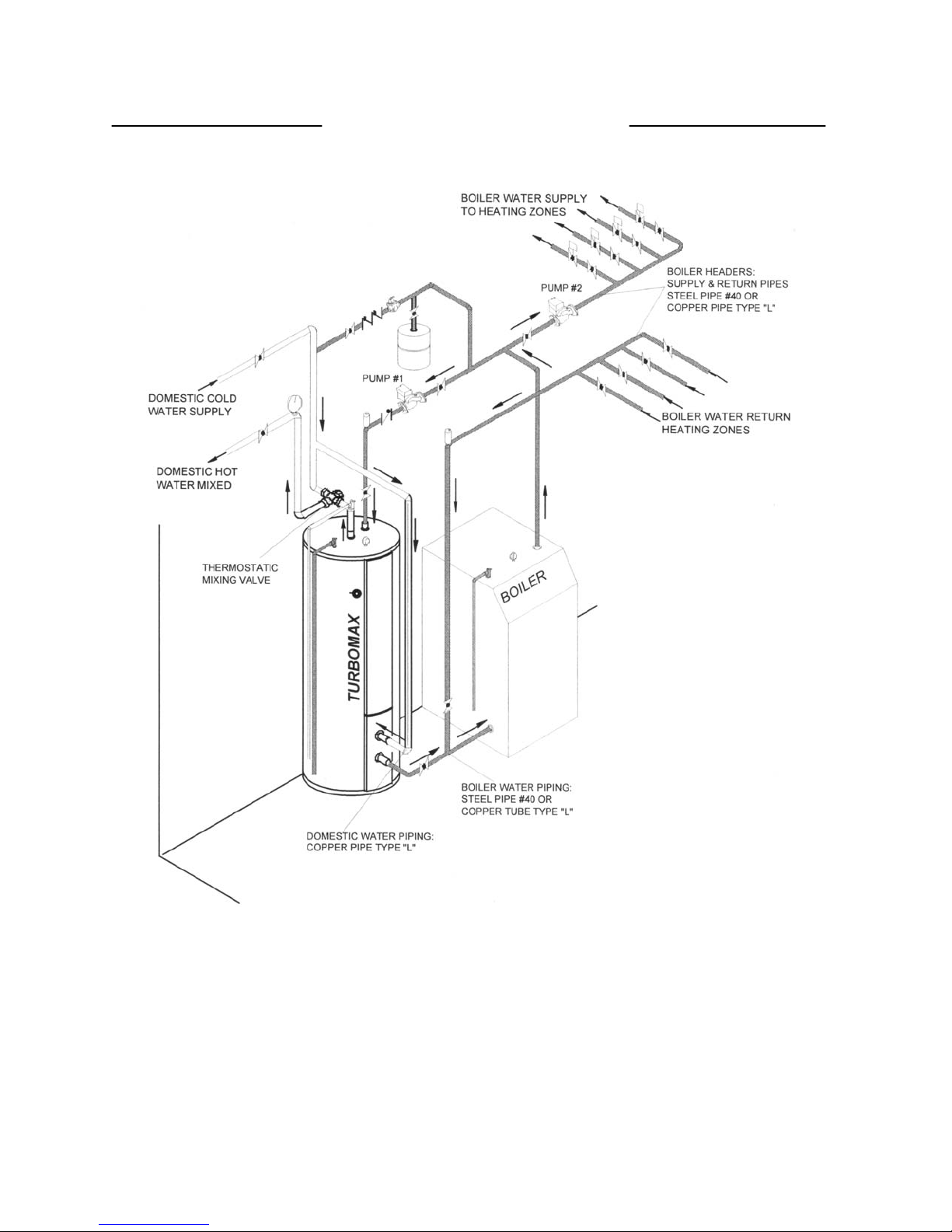

Basic Piping Schematic

Zone Valve Zoning

Requirements:

1. The installation must conform to local, state, provincial and national codes. In any case where instructions conflict

with the above, let those codes take precedence.

2. This is a basic piping schematic. Please consult the installation manual.

3. Install a safety valve (temperature & pressure) on the domestic hot water line, as near as possible to the hot water

heater connection and before any shut off valve.

4. Pipe all the safety valves and drain valves to the drain or accordingly to the code.

5. When a back flow preventer or water meter or a pressure reducing valve is used on the domestic cold water supply

line, then a thermal expansion tank must be installed between the water heater and this device.

TURBOMAX Use and Care Manual with Installation Instructions (December 2005) Page 7

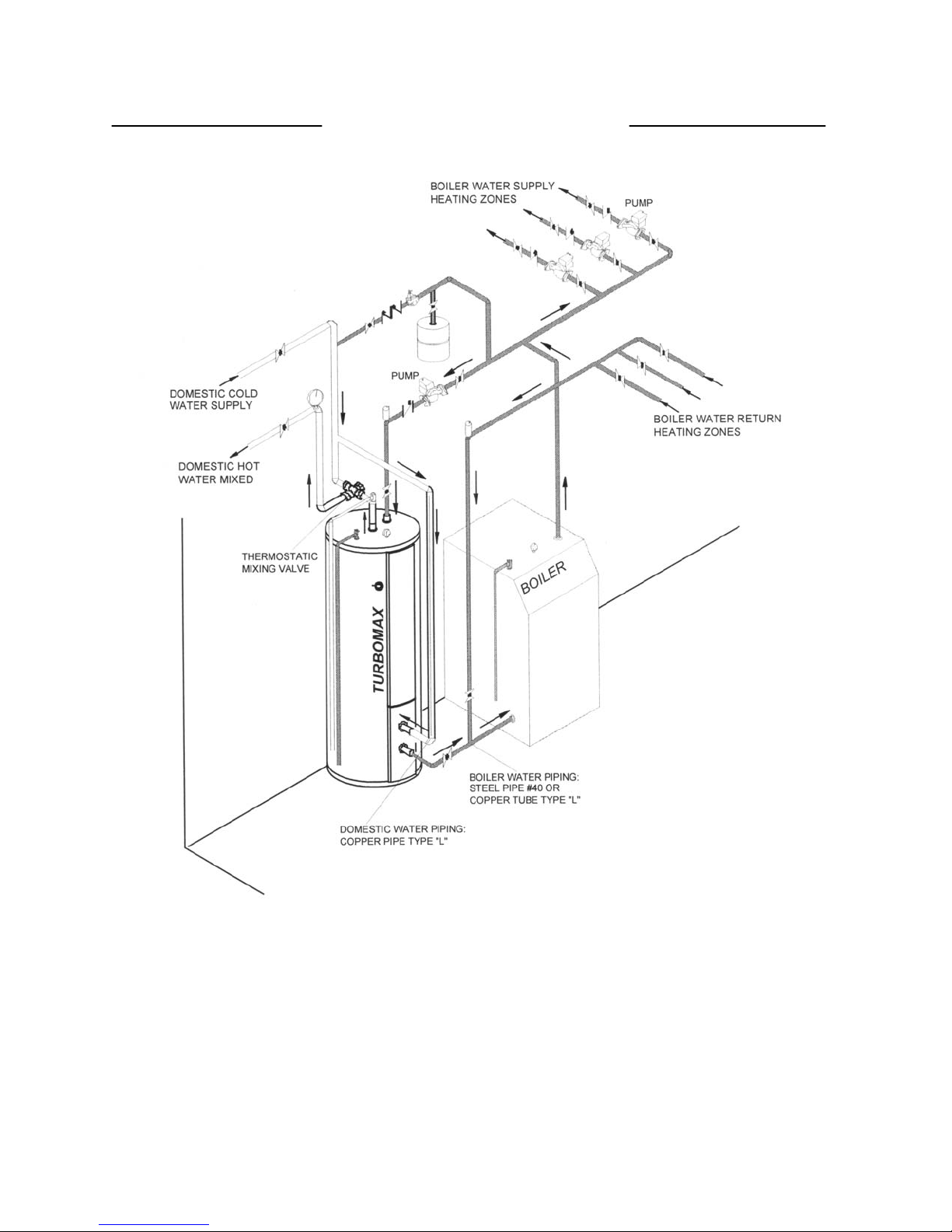

Basic Piping Schematic

Circulator Zoning

Requirements:

1. The installation must conform to local, state, provincial and national codes. In any case where instructions conflict

with the above, let those codes take precedence.

2. This is a basic piping schematic. Please consult the installation manual.

3. Install a safety valve (temperature & pressure) on the domestic hot water line, as near as possible to the hot water

heater connection and before any shut off valve.

4. Pipe all the safety valves and drain valves to the drain or accordingly to the code.

5. When a back flow preventer or water meter or a pressure reducing valve is used on the domestic cold water supply

line, then a thermal expansion tank must be installed between the water heater and this device.

TURBOMAX Use and Care Manual with Installation Instructions (December 2005) Page 8

DOMESTIC HOT WATER TEMPERATURE

& PRESSURE RELIEF VALVE

An automatic temperature & pressure relief valve

with a temperature probe of sufficient length must

be installed at the time of the installation. No valve

of any type should be placed between the T&P

relief valve and the water heater. Use a tee to

install the relief valve onto the hot water outlet.

The pressure rating of the relief valve must not

exceed 150 psi.

The BTU per hour rating of the relief valve must

equal or exceed the BTU per hour input of the

boiler(s) or heat source(s) as marked on the

boiler(s) rating plate.

For a circulating tank installation, the separate

storage tank(s) must have similar protection.

Connect the outlet of the relief valve to a suitable

open drain, so discharge can exit only 6” above

the structural floor; and cannot contact any live

electrical parts. The discharge line must pitch

downward from the valve to allow complete

draining (by gravity) of the relief valve and

discharge line, and be no smaller than the outlet

of the valve. The end of the discharge line should

not be threaded or concealed and should be

protected from freezing. No valve of any type,

restriction or reducer coupling should be installed

in the discharge line. Local codes shall govern

the installation of relief valves.

THERMOSTATIC MIXING VALVE

When this water heater is supplying generalpurpose hot water requirements for use by

individuals, a thermostatically controlled mixing

valve is recommended to reduce the risk of scald

injury. Contact a licensed plumber or the local

plumbing authority for further information.

Keep temperature control of the mixing valve at

the lowest setting which is satisfactory.

When installing a mixing valve, locate it at the

bottom of anti-thermosiphon loop at least 24” high

to prevent excessive hot water from entering

mixed water supply.

VACUUM BREAKER (IF REQUIRED)

Install a vacuum breaker (or vacuum relief valve)

for water heater protection. Prevents siphoning of

the water from the system and collapse of the

water heater.

BOILER WATER CONNECTIONS

This water heater may be connected individually,

in multiples with others, or with an external

storage tank containing boiler water. If two

TURBOMAX

method to be used to connect the TURBOMAX

parallel should be “reverse-return piping”, so boiler

water flow rate through each TURBOMAX

®

or more are installed, the piping

®

is

®

in

equal.

The BOILER WATER SUPPLY and BOILER

WATER RETURN connections are clearly

marked. Boiler water supply connections are to

be made to the steel pipe (threaded connection) at

the top of the heater. Boiler water return

connections are to be made to the steel pipe

(threaded connection) at the bottom of the heater.

The installation of unions is recommended on the

BOILER WATER SUPPLY and BOILER WATER

RETURN lines, so that the water heater may be

easily disconnected for servicing if necessary.

Dielectric unions are required for protection of the

water heater and the pipes, if dissimilar pipe

material like galvanized pipe, copper and steel is

used.

Use only clean pipe for boiler water lines. Local

codes or regulations shall govern the exact type of

material to be used. Install shutoff (ball) valves for

servicing convenience. Thermometer(s) should be

installed to indicate the temperature of the boiler

water supply and return lines.

Circulator zoning recommendations

The preferred location of the circulator pumps for

each zone is on the boiler supply, with an

expansion tank between the boiler and the

circulators.

A flow check valve must be installed on each

zone, preferably at the outlet side of each

circulator pump, to prevent water flow to other

zones when they are not demanding flow

Zone valve zoning recommandations

The preferred location of the circulator pump is on

the boiler supply, with the expansion tank between

the boiler and the circulator.

Use zone valves with low pressure drop

specifications, particularly on the water heater

zone.

TURBOMAX Use and Care Manual with Installation Instructions (December 2005) Page 9

PUMP & PIPE SIZING

Boiler water temperature drop (TD) through

the water heater

Simplified design methods based on a 20°F

temperature drop (TD) of boiler water going

through the water heater to heat up domestic

water are commonly used. Although such

methods are widely used and generate

satisfactory system performance when applied

properly, they do not determine the system

operating point. The pipe size is often

uneconomically large, and the actual system

flow rate is likely to be much higher than

intended. Such design methods seldom

consider temperature drops higher than 20°F,

which results in over-design.

Another method by which the boiler water

temperature drop (TD) could be calculated is to

assume a constant supply boiler water

temperature minus the domestic water final

temperature. For example a domestic water

heater might have a final temperature of 140 °F.

Assuming a constant supply boiler temperature

of 180 °F, the TD would be 40 °F

( = 180 °F – 140 °F). Second example: If the

domestic water heater has a final temperature of

180 °F and the boiler supply is at 200 °F, then

temperature drop is 20 °F (= 200 °F – 180 °F).

Precautions should be taken so that the boiler

return is above the boiler manufacturer’s lowest

recommended temperature. Most hot water

heating systems use standard, non-condensing

boilers (cast iron or steel), which must be

operated above 140°F in order to prevent the

corrosion that is associated with flue gas

condensation.

Alternatively, when the boiler surfaces are hot

due to previous loads such as domestic hot

water generation, the large temperature

difference between the boiler and its return

water can cause the boiler to become thermally

shocked.

An experienced designer could work with other

values than those proposed by looking into the

TURBOMAX performance tables and use the

guidelines stated above to design a state of the

art system.

The following chart proposes a temperature drop

(TD) that should be used to calculate the pump

flow rate.

Proposed boiler water temperature drop

through the water heater (TD)

Boiler water

supply

temperature

200 °F 180 °F 20 °F

200 °F 160 °F 40 °F

180 °F 160 °F 20 °F

180 °F 140 °F 20 °F to 40 °F

180 °F 125 °F 20 °F to 40 °F

180 °F 110 °F 20 °F to 40 °F

160 °F 140 °F 20 °F

160 °F 125 °F 20 °F

160 °F 110 °F 20 °F

NOTE: The boiler water in TURBOMAX

Domestic water

final

temperature

TD

®

constitutes a store of heat energy ready to heat

fresh domestic water. The volume of boiler

water stored in TURBOMAX

®

tank provides

enough heat to keep your domestic hot water

hot while the boiler heats up. In fact, it acts as a

buffer, which prevents domestic hot water, or

boiler water temperature swings.

Pump flow rate calculation

The boiler’s output rating must be within the

heater’s the heat loads calculation or the sizing

guide recommendations. Use the equation

below to calculate the pump flow rate.

Pump flow rate = Boiler output ÷ TD ÷ 500

• Pump flow rate is express in U.S. gallons

per minute or GPM.

• The Boiler output ( in net BTU per hour) is

the maximum heat to be transferred through

the water heater to meet the hot water

demand.

• TD is the boiler water temperature drop

through the TURBOMAX®.

For example, a cast iron boiler has an output

rated at 90,000 BTU per hour. The system is

designed for a temperature drop (TD) of 20°F.

Pump flow rate = 90,000 ÷ 20 ÷ 500 = 9 GPM.

TURBOMAX Use and Care Manual with Installation Instructions (December 2005) Page 10

Pipe sizing criteria

Proper selection of pipe size is important to

efficient system operation. A large pipe size

results in lower friction losses and may allow the

selection of smaller, more economical pump.

The larger pipe, however, costs more initially

and must be balanced against the cost savings

realized by a smaller pump. Likewise, small

pipe costs less initially but must be balanced

against the increased operating cost of pumping

water through a system with high friction losses.

An economical balance should be reached

between pump size, operating costs, and pipe

diameter.

The ASHRAE fundamentals handbook states

the general range of pipe friction loss used for

the design of hydronic systems and upper limits

of water velocity in piping.

A variety of upper limits of water velocity and/or

pressure drop in piping and piping systems are

used. One recommendation places a velocity

limit of 4 feet per second for 2 inch pipe and

smaller, and a pressure drop limit of 4 feet of

water per hundred feet for piping over 2 inches.

These limitations are imposed either to control

the levels of pipe and valve noise, erosion and

water hammer pressure or for economic

reasons.

Please note that in the smaller pipe sizes, this

velocity limit allows the use of friction loss rates

higher than 4 feet per 100 feet.

Fluid velocity should be above 1-1/2 to 2 feet per

second in order to carry entrained air along with

the flowing water to the point of air separation

where the air can then be separated from the

water and purged.

Velocities greater than 4 feet per second are

often used on piping larger than 2 inches.

It is generally accepted that if proper air control

is provided to eliminate air and turbulence in the

system, the maximum flow rate can be

established by the piping friction loss rate at 4

feet of water per 100 feet. This allows the use of

velocities higher than 4 feet per second in pipe

sized 2 inches and larger.

Tables 1 and 2 provide friction loss values for

new pipe. It should be taken into consideration

that as the pumping system ages, friction losses

increase. It is recommended that for most

TURBOMAX Use and Care Manual with Installation Instructions (December 2005) Page 11

commercial design purposes a safety factor of

10 to 15 % be added to the values in the tables.

What is a “foot of water”? A mass of water at

60°F standing inside a vertical column or a

vertical pipe 5 feet tall creates a constant

pressure of “5 feet of water” at the bottom of the

column or pipe. If the water column is 2.31 feet

tall, the mass of water creates a constant

pressure (head) of one (1) p.s.i. (pound per

square inch). Pressure losses are expressed

either in “feet of water” or in p.s.i.. Usually,

pump manufacturers use feet of water units.

Pressure loss from water flow in pipes

To get the proper boiler water flow through the

water heater tank, the pump must overcome the

pressure loss from water flow in pipes, valves,

fittings and components in the piping circuit.

Friction is a resistance to flow.

Pressure loss (or pressure drop) from friction in

straight pipe, in Tables 1 and 2, are in feet of

water per 100 feet of pipe length.

Example 1: What is the pressure drop caused by

water flowing at a rate of 25 GPM (gallons per

minute) through a 1-1/2 inch diameter copper

tube which has a length of 100 feet?

Answer: by looking at the data in Table 1, you

notice that the pressure loss is 5.46 feet of water

for a tube of 100 feet.

Example 2: What if the pipe has a length of 40

feet for the same flow rate?

Answer: the pressure loss is 40% (= 40 feet /

100 feet) of 5.46 feet of water per 100 feet. The

calculated pressure loss is 2.18 feet of water (=

40% X 5.46 ft water).

Pressure loss from water flow in pipe fittings

and valves

In addition to the pressure loss in straight pipe,

there will be pressure losses from turbulence

and change of direction through fittings and

valves. These pressure losses are shown in

Table 3.

The pressure losses are expressed in Table 3

in a way that is called the “equivalent length”.

The listings for a particular fitting of a given size

show the “equivalent length” (E.L.) of straight

pipe that would have the same pressure drop.

After finding the “equivalent length” (E.L.) from

Table 3, the appropriate friction loss table (Table

1 or Table 2) is used to find the actual pressure

drop through the fitting.

Example 3: What is the pressure loss through a

1-1/2 inch 90° copper standard elbow in a piping

system through which 25 GPM of water is

flowing.

Answer: from Table 3 find the equivalent length

of the fitting = 4.5 feet. From Table 1 find the

pressure loss for a 1-1/2 inch copper tube,

through which 25 GPM of water is flowing

= 5.46 feet of water per 100 feet. The pressure

loss through the fitting is 4.5% (= 4.5 feet E.L./

100 feet) of a straight 1-1/2 inch diameter copper

tube. The calculated result is 0.25 feet of water

(= 4.5% of 5.46 feet of water)

Pressure loss from water flow in TURBOMAX

tank.

There will be pressure losses from turbulence

and change of direction through TURBOMAX

tank. These pressure losses are shown in

Table 4. The pressure losses through the boiler

water’s side (or tank‘s side) are expressed in

feet of water. The pressure losses, through the

domestic water’s side (or copper coil system’s

side) are expressed in p.s.i..

Example 4: What is the pressure loss of boiler

water flowing through a TURBOMAX

®

#109 at 60

GPM? Answer: the pressure loss is 2 feet of

water.

Pressure loss from boiler or other equipment

Information on pressure drops (losses) through a

boiler or other equipment is obtained from the

manufacturer.

Piping system pressure drop calculation.

The pressure loss from friction in a closed piping

system is required to determine the required

pump head. The system pressure drop is simply

the sum of the losses through each item in one

circuit from pump discharge to pump suction,

including piping, fittings, valves, TURBOMAX

®

tank, boiler and other equipment.

To find the system pressure drop, therefore:

First inspect the piping layout.

Second, note all the elements through which

pressure loss occurs in the circuit from pump

discharge to pump suction. Write down the size

of the fitting.

Third, measure pipe length and note the pipe

diameter and material of the circuit.

Fourth, calculate for each element (pipes,

fittings, valves, TURBOMAX tank, boiler and

other equipment) the pressure loss at the boiler

water flow rate calculated earlier.

It should be taken into consideration that, as the

piping system ages, friction losses increase. It is

recommended that for most commercial design

purposes a safety factor of 15 to 20 % be added

to the values in Tables 1 and 2.

Fifth, sum all the pressure losses of each item in

the circuit

Pump or circulator selection

Consult pump manufacturer’s pump curves to

select the proper pump model. Performance

characteristics of centrifugal pumps are

described by pump curves, which plot flow

versus head or pressure together with other

information such as efficiency and power.

To select the proper pump that fits your needs,

ask your pump dealer or your HVAC wholesaler

for a recommendation.

TURBOMAX Use and Care Manual with Installation Instructions (December 2005) Page 12

Loading...

Loading...