THERMO 2000 COMBOMAX 23-8, Combomax 23, COMBOMAX 23-24, COMBOMAX 34-8, COMBOMAX 34-10 Use And Care Manual

...

MC

COMBOMAX

RÉSIDENTIAL

23

TO

64

Electric boiler with integrated instantaneous water heater

Capacity from 8 kW to 24 kW :

240 Volts ( single phase )

Use and Care Manual

With installation instructions for the contractor

Your COMBOMAX® electric boiler has been carefully assembled and factory tested to

provide years of trouble-free service. This manual contains instructions for the safe and

proper installation, operation and maintenance of the boiler, in order to ensure your full

satisfaction

It is imperative that all persons who are expected to install, operate or adjust this boiler read

the instructions carefully.

Any questions regarding the operation, maintenance, service or warranty of this water

heater should be directed to the dealer or distributor you purchased it from. When all

installation steps have been completed, replace this installation manual in its original

envelope, and keep in a safe place near the heater for future reference.

THERMO 2000 INC. revised : Oct. 2015

Printed in Canada

COMBOMAXMC Electric boiler Set-up, use and care guide

(revised Oct 2015)

, Page 2.

Section 1 : Technical specifications

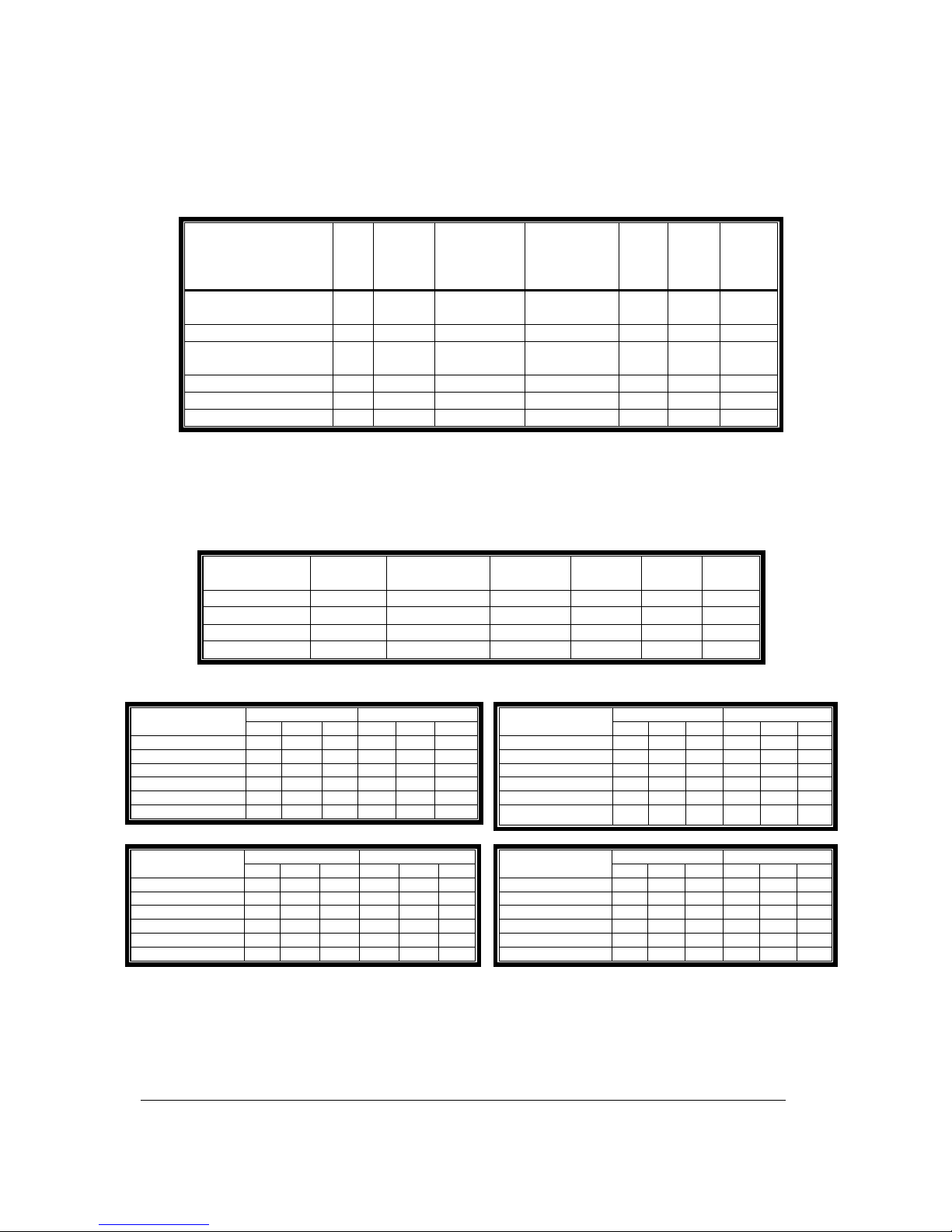

Table 1: Boiler specifications 240* Vac/1ph (3 wires L1/L2/N):

Modèle

Kw

À

240

V*

BTU/h

Amp.

Heating

elements

Heating

elements

Stage

Cable

(cu)**

Fuse **

COMBOMAX XX-8 8 27 296 33.3

1 X 3KW

1 X 5KW

2 8 50

COMBOMAX XX-10 10 34 120 41.6 2 X 5KW 2 6 60

COMBOMAX XX-15 15 51 180 62.5

2 X 3KW

2 X 4.5KW

4 6 80

COMBOMAX XX-18 18 61 416 75.0 4 X 4.5KW 4 4 100

COMBOMAX XX-20 20 68 240 83.4 4 X 5KW 4 3 110

COMBOMAX XX-24 24 81 888 100.0 4 X 6KW 4 3 125

*Can be also connected on an electrical supply at 208V/1ph giving 75% of the nominal capacity at 240V.

**Add amperage of the pump when required (8amp./1/3hp max). Local Electrical codes may require

different cable gauge according to the type of installation.

Table 2 : Boiler and connection dimensions

Model Capacity Utility

connection

Boiler

connection

Height Diam. Ship.

weight

Combomax 23 30 Gal US 3/4 ’’ Sweat F 1’’ NPT F 49’’ 18’’ 265 lbs

Combomax 34 40 Gal US 3/4 ’’ Sweat F 1’’ NPT F 65’’ 18’’ 315 lbs

Combomax 44 52 Gal US 3/4 ’’ Sweat F 1’’ NPT F 55’’ 22’’ 345 lbs

Combomax 64 76 Gal US 3/4 ’’ Sweat F 1’’ NPT F 67’’ 24’’ 425 lbs

Table 3 : Domestic hot water production capacity in US gallons

1st hour Continuous Model

110F 140F 180F 110F 140F 180F

COMBOMAX 23-8 75 44 28 47 33 24

COMBOMAX 23-10 87 52 33 59 41 29

COMBOMAX 23-15 116 73 48 88 62 44

COMBOMAX 23-18 134 85 57 106 74 53

COMBOMAX 23-20 145 93 63 117 82 59

COMBOMAX 23-24 169 110 75 141 99 71

1st hour Continuous Model

110F 140F 180F 110F 140F 180F

COMBOMAX 34-8 85 48 29 47 33 24

COMBOMAX 34-10 97 56 34 59 41 29

COMBOMAX 34-15 126 77 49 88 62 44

COMBOMAX 34-18 144 89 58 106 74 53

COMBOMAX 34-20 155 97 64 117 82 59

COMBOMAX 34-24 179 114 76 141 99 71

1st hour Continuous Model

110F 140F 180F 110F 140F 180F

COMBOMAX 44-8 97 53 31 47 33 24

COMBOMAX 44-10 109 61 36 59 41 29

COMBOMAX 44-15 138 82 51 88 62 44

COMBOMAX 44-18 156 94 60 106 74 53

COMBOMAX 44-20 167 102 66 117 82 59

COMBOMAX 44-24 191 119 78 141 99 71

1st hour Continuous Model

110F 140F 180F 110F 140F 180F

COMBOMAX 64-8 121 63 34 47 33 24

COMBOMAX 64-10 133 71 39 59 41 29

COMBOMAX 64-15 162 92 54 88 62 44

COMBOMAX 64-18 180 104 63 106 74 53

COMBOMAX 64-20 191 112 69 117 82 59

COMBOMAX 64-24 215 129 81 141 99 71

With domestic cold water at 40

°F and heating water at 180°F

Operating temperature : from 50°F to 190°F; Maximum operating pressure: 30 psi

COMBOMAXMC Electric boiler Set-up, use and care guide

(revised Oct 2015)

, Page 3.

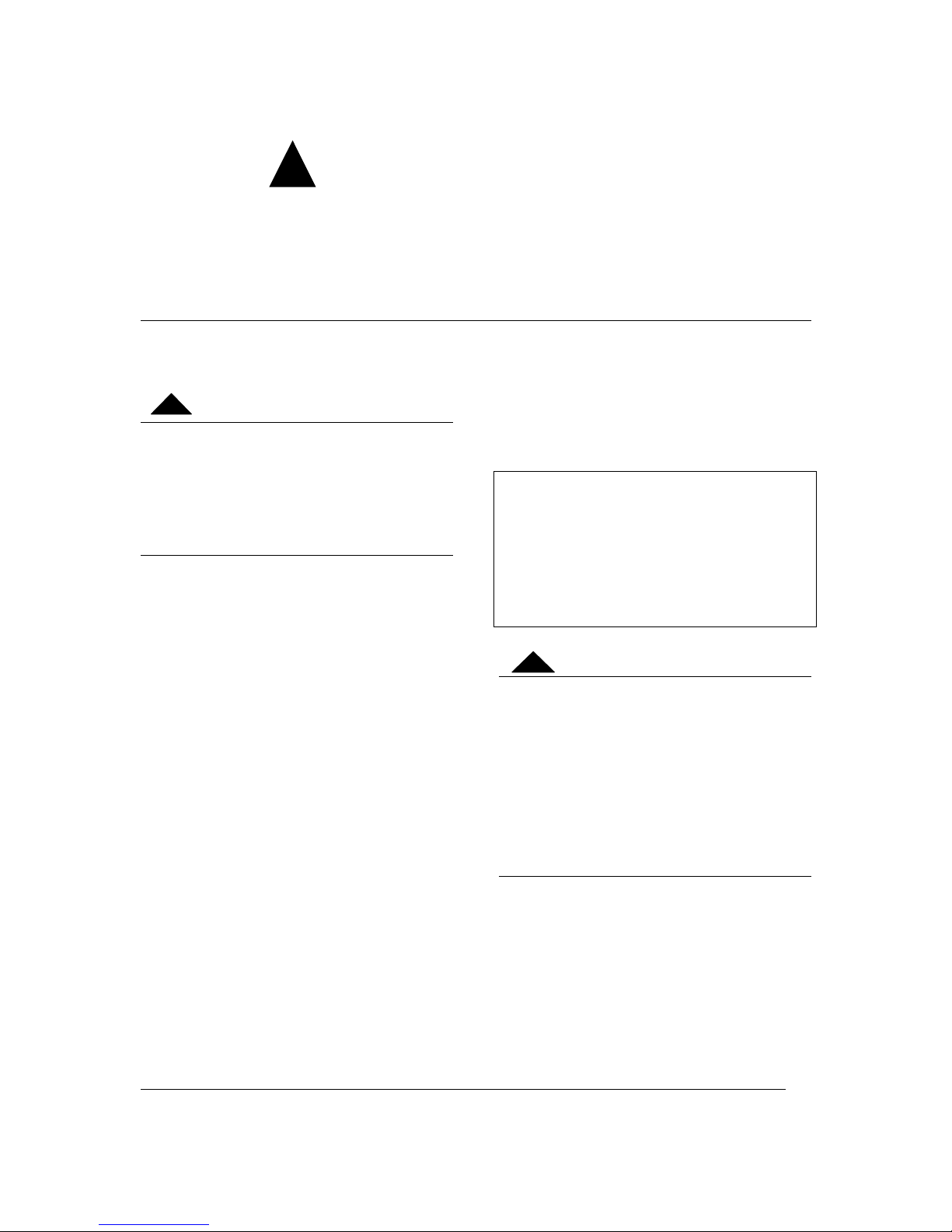

Figure 1 : Component diagram

COMBOMAXMC Electric boiler Set-up, use and care guide

(revised Oct 2015)

, Page 4.

General Safety Precautions

Be sure to read and understand the entire Use & Care Manual before attempting to

install or operate this water heater. Pay particular attention to the following General

Safety Precautions. Failure to follow these warnings could cause property damage,

bodily injury or death. Should you have any problems understanding the instructions in

this manual, STOP, and get help from a qualified installer or technician.

Section 2 : Introduction

The important safeguards and instructions

appearing in this manual are not meant to

cover all possible conditions and situations

that may occur. It should be understood that

common sense, caution and care are factors

which cannot be built into every product.

These factors must be supplied by the

person(s) caring for and operating the unit.

2.1 LOCAL INSTALLATION

REGULATIONS

This water heater must be installed in

accordance with these instructions and must

conform to local, or in the absence of local

codes, with the current edition of the National

Plumbing Code and the National Electric Code.

In any case where instructions in this manual

differ from local or national codes, the local or

national codes take precedence.

2.2 CORROSIVE ATMOSPHERE

The heater should not be located near an air

supply containing halogenated hydrocarbons or

high humidity. The limited warranty is voided

when failure of the water heater is due to a

corrosive atmosphere.

2.3 SHIPMENT INSPECTION

Inspect the water heater for possible shipping

damage. The manufacturer’s responsibility

ceases upon delivery of goods to the carrier in

good condition. Consignee must file any claims

for damage, shortage in shipments, or nondelivery immediately against carrier.

2.4 CHECKLIST

Please check the technical information plate to

ensure you have the right model.

The following items are shipped with the

unit :

• 30 PSI pressure relief valve.

• Drain cock.

• Thermo manometer (heat and

pressure indicator).

• Thermostatic mixing valve

The boiler should not be located in an area

where leakage from the tank or water

connections will result in damage to the

adjacent area or to lower floors of the

structure. When such areas cannot be

avoided, a suitable drain pan or nonflammable catch pan, adequately drained,

must be installed under the boiler. The pan

must be connected to a drain.

NOTE: Auxiliary catch pan MUST conform to

local codes.

!

WARNING

!

WARNING

!

COMBOMAXMC Electric boiler Set-up, use and care guide

(revised Oct 2015)

, Page 5.

Section 3 : INSTALLATION

The manufacturer’s warranty does not cover

any damage or defect caused by installation

or attachment or use of any special

attachment other than those authorized by

the manufacturer into, onto, or in

conjunction with the water heater. The use of

such unauthorized devices may shorten the

life of the water heater and may endanger life

and property. The manufacturer disclaims

any responsibility for such loss or injury

resulting from the use of such unauthorized

devices.

3.1 SAFETY MEASURES

All domestic and commercial installations will

include a pressure relief valve limiting the

operating pressure to 30 psi.

This COMBOMAXMC electric boiler is designed

for a maximum operating temperature of 190°F.

It is designed as a hot water heating system

only. When allowed by local regulation an

antifreeze water and propylene-glycol blend

(50% maximum concentration) may be used on

installations having a potable water supply

pressure above 240 kPa (35 psi).

3.2 LOCATION

The COMBOMAXMC water heater should be

installed in a clean, dry location. Long hot water

lines should be insulated to conserve water and

energy. The water heater and water lines should

be protected from exposure to freezing.

COMBOMAX

MC

water heaters must be installed

vertically. Use the adjustable feet to level the

unit.

The COMBOMAXMC water heater must be

located or protected so as not to be subject to

physical damage, for example, by moving

vehicles, area flooding, etc..

All models can be installed on combustible floors

and in alcoves. If the water heater is to be

installed in a restaurant or other location where

the floor is frequently cleaned, it must be

elevated to provide at least 6 inches of

clearance from the floor to comply with NSF

International recommendations.

The room temperature must not exceed 80°F or

27°C.

3.3 CLEARANCE

The minimum clearances required for proper

inspection and servicing are as follows:

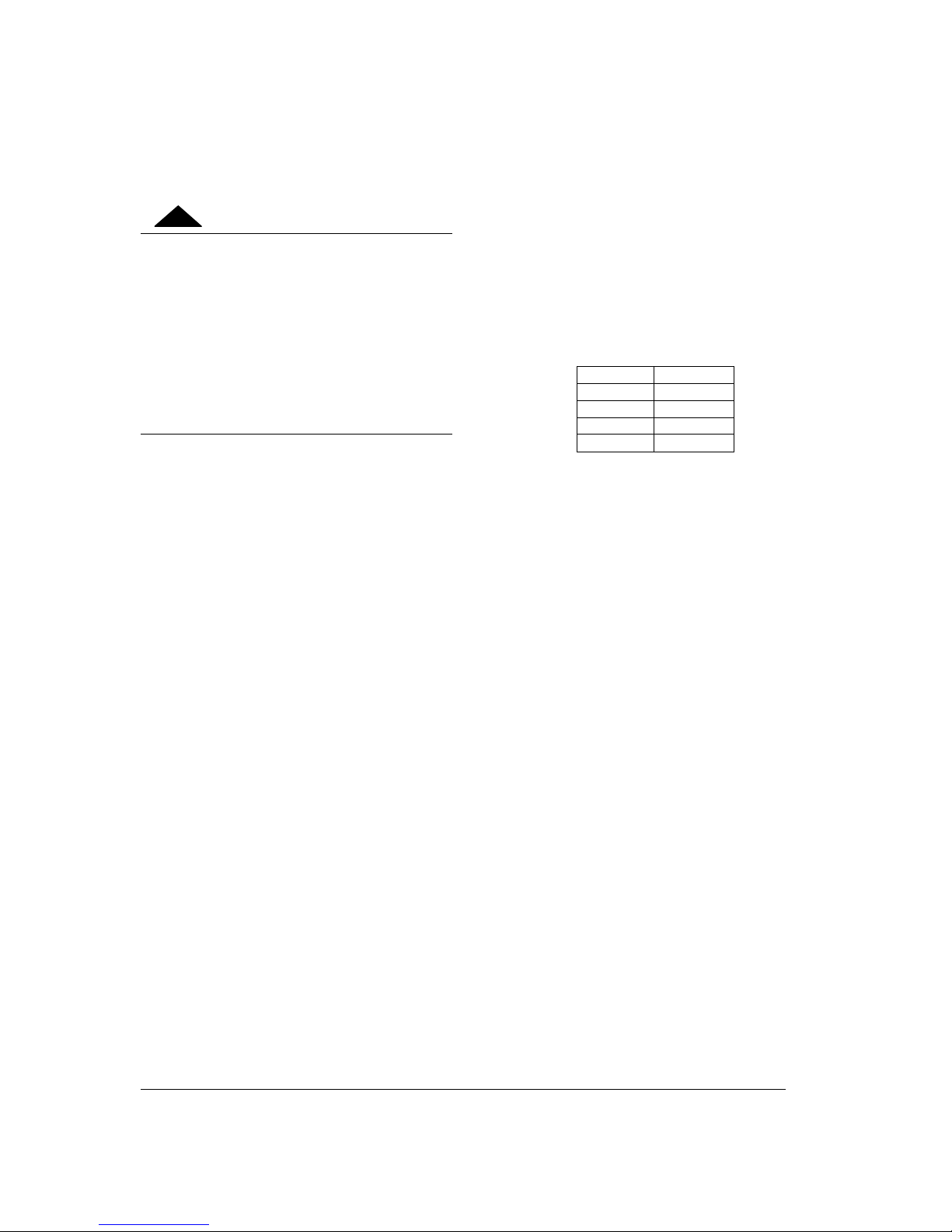

Table 4: Clearances

Left side 3 inches

Right side 3 inches

Top 6 inches

Front 24 inches

Back 3 inches

3.4 SYSTEM SETUP

Figures 2, 3 and 4 are general connection

diagrams including the circulator, the expansion

tank, the drain cock, the safety valve, the air

bleeder, the flow check valve and the thermo

manometer. Set-up details follow.

3.5 HEATING WATER CIRCUIT

3.5.1 Connecting the heating water

piping

The boiler may be set up alone or in parallel with

others. Parallel connections should be made

using the reverse-piping method to ensure equal

flow through each boiler.

The boiler water supply connector is located on

top of the boiler and the boiler water return

connector is located to the left of the three-way

valve. They are both threaded NPT female

connectors.

Unions are recommended on the hot and cold

water lines to disconnect the water heater easily

for servicing if necessary.

Dielectric (insulating) unions are required for

protection of the water heater if copper-steel

connections are made.

Use only clean copper or approved plastic pipe

for water connections. Local codes or

regulations shall govern the exact type of

material to be used.

WARNING

!

COMBOMAXMC Electric boiler Set-up, use and care guide

(revised Oct 2015)

, Page 6.

Insulate all pipes containing hot water,

especially in unheated areas.

Install shutoff (ball) valves for servicing

convenience. Install thermometers on the inlet

and outlet lines.

Never plug the pressure relief valve to avoid

creating a hazardous situation.

3.5.2 Flow-check valve

If the heating system uses a single circulator, a

flow-check valve must be installed to

minimize gravity flow and heat loss during nondraw periods.

3.5.3 Pressure relief valve

No boiler set-up is complete without a pressure

relief valve. Its pressure rating must not exceed

30 psi (207 kPa). It must conform to the « ASME

Boiler and Pressure Vessel Code» and limit the

boiler operating pressure. It is a safety device,

not a control device.

The BTU per hour rating of the relief valve must

equal or exceed the BTU per hour input of the

boiler(s) or heat source(s) as marked on the

boiler(s) rating plate.

Connect the outlet of the relief valve to a

suitable open drain, with the discharge at most

6” above the floor, far from any live electrical

parts. The discharge line must pitch downward

from the valve to allow complete draining and be

no smaller than the outlet of the valve. The end

of the discharge line should not be threaded or

concealed and should be protected from

freezing. No valve of any type, restriction or

reducer coupling should be installed in the

discharge line. Local codes shall govern the

installation of relief valves.

3.5.4 Operating pressure control :

Operating pressure control components ensure

minimum and maximum operating limits within

the design operating temperature range of the

heating system.

Expansion tank

The purpose of the expansion tank is to absorb

the water volume increase of the boiler and the

heating system related to the variation of its

water temperature during the heating season.

Consequently, the selection of the appropriate

expansion tank model must be made taking into

account both the maximum operating

temperature of the system and its water content.

Note that the water content of an heating system

with cast iron radiators is a lot more than a

system with hot water baseboard.

The important increase of heating water volume

brought with the addition of the Combomax will

also have to take into account.

Combomax 23 : 30usgal.

Combomax 34 : 40usgal

Combomax 44 : 52usgal

Combomax 64 : 76usgal

With these informations, these informations, the

installer with his distributor shall be in position to

make an appropriate selection.

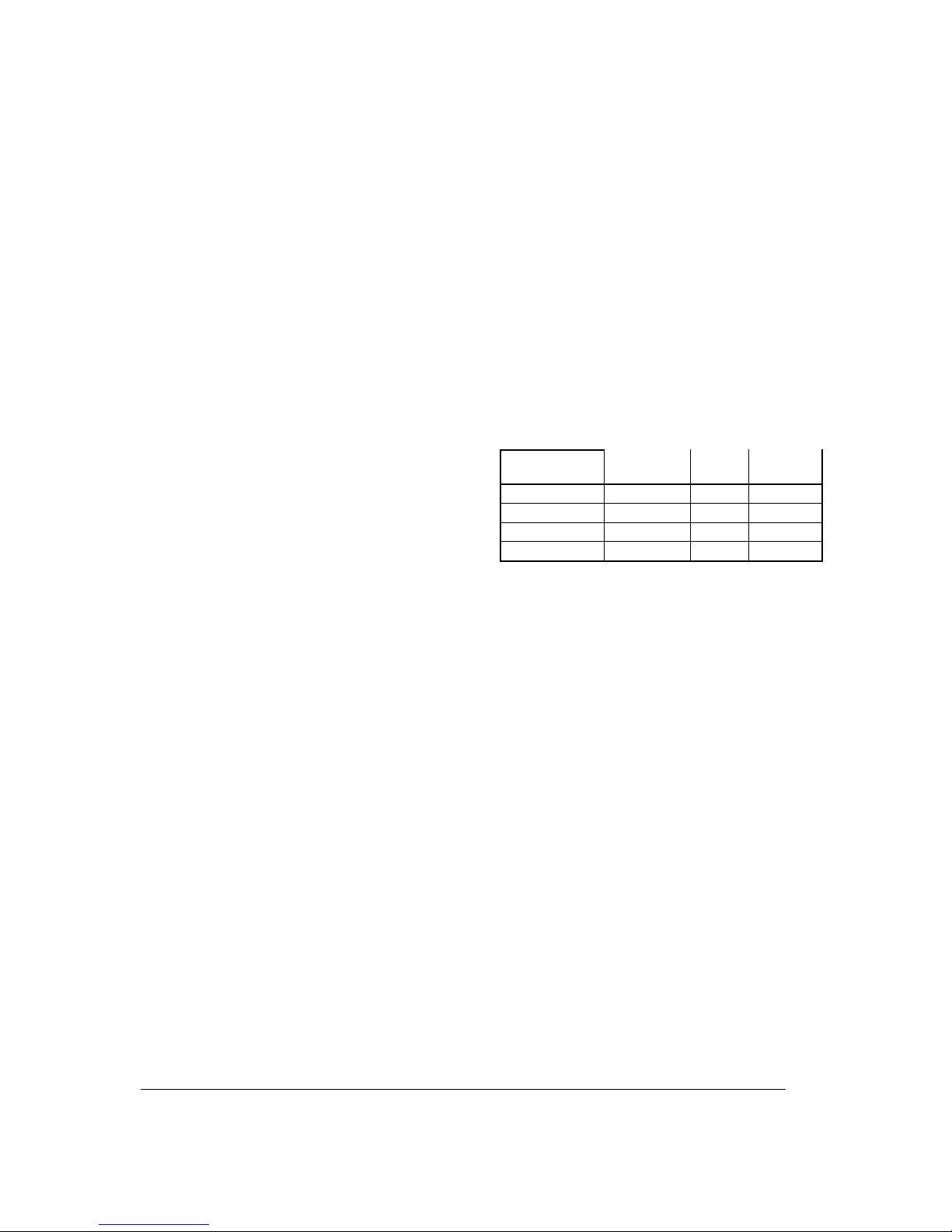

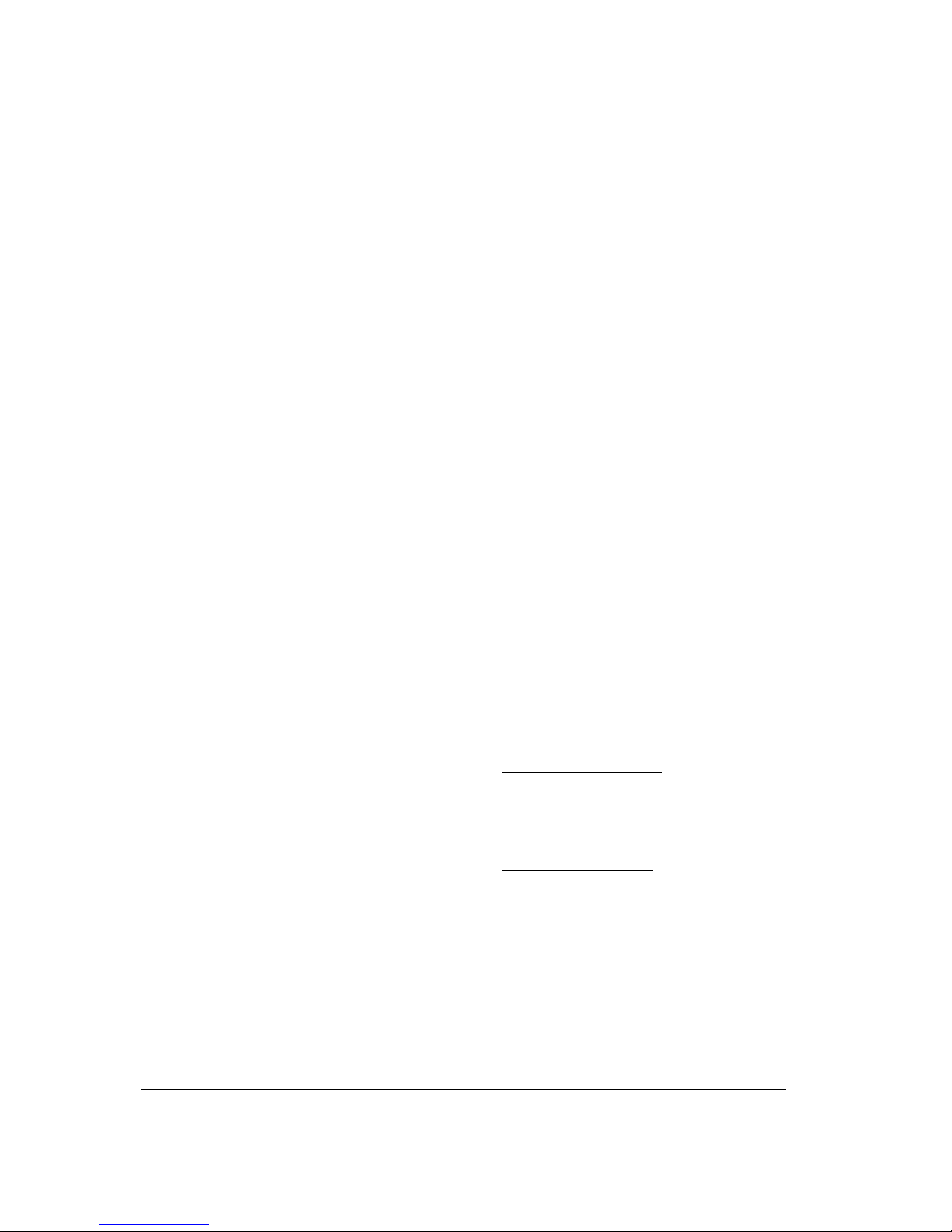

You will find below our recommendation on the

minimum size of tank in relation to the type of

heating system of the application.

Combomax #

Hot water

Baseboards

Radiant

floor

Cast iron

radiator

Combomax 23

#30 #30 #60

Combomax 34

#30 #30 #60

Combomax 44

#30 #30 #60

Combomax 64

#60 #60 #90

The expansion tank connection point must be

carefully chosen to prevent a situation where

closing a valve would isolate the tank from the

boiler or any part of the circuit.

3.5.5 Makeup valve

Connecting a makeup valve must be done

according to code. This valve must include a

flow-check valve to maintain the minimum

operating pressure by admitting fresh water from

the cold water supply line in case a leak occurs.

3.5.6 Air bleeder

There should be as little oxygen as possible in

the heating circuit to prevent corrosion. As

foreseen in section 3.5.4, this excludes the use

of air as a pressure regulator within the circuit.

Installing manual or automatic air bleeders

prevents air accumulation within the system.

The bleeders must be set at the highest points

of the system to purge any air accumulated

during system set-up and to check its air

tightness. Bleed the air regularly from the piping,

making sure the heating water causes no bodily

harm or material damage.

COMBOMAXMC Electric boiler Set-up, use and care guide

(revised Oct 2015)

, Page 7.

3.5.7 Circulator zoning

A flow-check valve must be installed in each

zone, preferably at the outlet of each circulator,

to prevent water flowing to zones where no heat

is currently required. (see figure 4).

3.5.8 Zone valve zoning

Zone valves with low pressure drop are

recommended. (see figure 3)

3.5.9 Circulator selection criteria

The COMBOMAXMC boiler includes a premounted circulator. The information below will

help you select additional units for multiple

circulator set-ups.

3.5.9.1 Pump flow rate calculation

The boiler output rating must correspond to the

calculated heating load. Use the equation below

to calculate the pump flow rate:

Pump flow rate = Boiler output ÷÷÷÷ BWTD ÷÷÷÷ 500

• Pump flow rate is expressed in U.S. gallons

per minute or GPM.

• The Boiler output ( in net BTU per hour) is

the maximum amount of heat to be

transferred through the heating circuit to

meet the hot water demand.

• BWTD is the boiler water temperature drop

through the heating circuit.

For example, a 24 Kw COMBOMAXMC boiler has

a rated output of 81,964 BTU/hour. The system

is designed for a boiler water temperature drop

(BWTD) of 20°F.

Pump flow rate = 81,964 ÷ 20 ÷ 500 = 8,2 GPM.

The following table shows the required flow rate

as a function of boiler water temperature drop

(BWTD) and rated power output.

Table 5 : BWTD vs. flow (GPM)

BWTD

Model Kw

10

o

F

20

o

F

30

o

F

40

o

F

COMBOMAX XX-8 8 5,5 2,7 1,8 1,4

COMBOMAX XX-10 10 6,8 3,4 2,3 1,7

COMBOMAX XX-15 15 10,2 5,1 3,4 2,6

COMBOMAX XX-18 18 12,3 6,1 4,1 3,1

COMBOMAX XX-20 20 13,7 6,8 4,6 3,4

COMBOMAX XX-24 24 16,4 8,2 5,5 4,1

3.5.9.2 Selecting a circulator

Consult the manufacturer’s operating

characteristic curves to select the proper model.

These curves plot flow versus pressure, together

with other information such as efficiency and

power. Ask your pump dealer or HVAC

wholesaler to recommend the circulator which

best fits your needs.

3.6 DOMESTIC HOT WATER CIRCUIT

3.6.1 Connecting the domestic hot water

piping

The COMBOMAX

MC

domestic hot water coil may

be set up alone or in parallel combination with

other COMBOMAXMC units or storage tanks.

Parallel connections should be made using the

reverse-piping method to ensure equal flow

through each boiler.

The HOT WATER OUTLET and the COLD

WATER INLET connections are clearly marked.

Inlet water connections (COLD WATER INLET)

are to be made to the copper pipe (sweat

connection) at the bottom of the heater. Outlet

water connections (HOT WATER OUTLET) are

to be made to the three-way thermostatically

controlled valve (sweat connection) at the top of

the heater.

The installation of copper unions or copper alloy

unions is recommended on the HOT and COLD

water lines, so that the water heater may be

easily disconnected for servicing if necessary.

These unions must be dielectric (insulating) if

you are making steel-copper connections.

A shutoff (ball) valve is present on the

COMBOMAXMC domestic hot water outlet for

servicing convenience.

Use only clean copper or approved plastic pipe

for water connections. Local codes or

regulations shall govern the exact type of

material to be used.

Insulate all pipes containing hot water,

especially in unheated areas.

Thermometer(s) should be installed to indicate

the temperature of the water at or near the outlet

of the water heater and storage tank(s), if

provided.

COMBOMAXMC Electric boiler Set-up, use and care guide

(revised Oct 2015)

, Page 8.

3.6.2 Expansion tank on the cold water

supply line

Determine if a flow check valve, a back flow

preventer, a pressure-reducing valve, a water

meter or a water softener is present on the cold

water supply line.

A flow check valve creates a closed system and

prevents the water, as it is being heated, from

expanding back into the cold water supply line.

Pressure can build up within the water heater,

causing the pressure relief valve to operate

during a heating cycle. This excessive operation

can cause premature failure of the relief valve

and possibly of the water heater itself.

Replacing the relief valve will not correct the

problem. One method of preventing pressure

build-up is to install an expansion tank on the

cold water supply line between the

COMBOMAXMC unit and flow check valve.

Contact your installing contractor, water

supplier, local plumbing inspector or plumbing

supply house for assistance.

3.6.3 Recirculation line (if applicable)

If a recirculation line is installed, the return

connection should be made to a tee close to the

inlet connection on the water heater. A check

valve should always be installed in the

recirculation line to prevent cold water from

entering.

3.6.4 Domestic hot water pressure relief

valve

An automatic pressure relief valve must be

installed on a tee installed on the domestic hot

water pipe coming out of the water heater. No

valve of any type should be placed between the

safety relief valve and the water heater. The

pressure rating of the relief valve must not

exceed 150 psi.

The BTU per hour rating of the relief valve must

equal or exceed the BTU per hour input of the

boiler(s) or heat source(s) as recorded on the

boiler(s) rating plate.

Connect the outlet of the relief valve to a

suitable open drain, with the discharge at most

6” above the floor, far from any live electrical

parts. The discharge line must pitch downward

from the valve to allow complete draining and be

no smaller than the outlet of the valve. The end

of the discharge line should not be threaded or

concealed and should be protected from

freezing. No valve of any type, restriction or

reducer coupling should be installed in the

discharge line. Local codes shall govern the

installation of relief valves.

3.6.5 Thermostatically controlled mixing

valve (included)

For general-purpose hot water requirements in a

domestic environment, a thermostatically

controlled mixing valve is recommended to

reduce the risk of scald injury. Contact a

licensed plumber or the local plumbing authority

for further information. Adjust the mixing valve to

the lowest required temperature setting.

3.7 BOILER WIRING

The boiler cabling and grounding must conform

to local codes or, in their absence, to the

National Electrical Code.

Power must be provided by a 120/240 volt

(single phase, 60 Hz) circuit, appropriately fused

and with 3-wire plus ground cabling of sufficient

gage. The fuse and cabling gauge may be

determined from the boiler rating plate.

3.8 CIRCULATOR WIRING

The COMBOMAXMC heating pump (120 Vac,

1/25 Hp) is connected to the C&C terminals on

the boiler electrical panel. The control circuit is

designed to start the pump upon receiving a

heating signal from the thermostat or priority

aquastat.

3.9 CONNECTING THE THERMOSTAT

3.9.1 Single heating zone

Connect the low-voltage thermostat to the T&T

terminals on the COMBOMAXMC electrical panel

(DO NOT apply current to these terminals).

(see figure 2&3).

3.9.2 Zone valve zoning

Connect the low-voltage thermostat to the zone

valve. The components must wired such that,

upon a heating signal from a thermostat, only

the corresponding zone valve will be actuated

and will in turn activate the COMBOMAXMC

circulator relay. Connect the zone valve switch

to the T&T terminals on the COMBOMAXMC

electrical panel (DO NOT apply current to

these terminals). See figures 8.

Loading...

Loading...