THERMO 2000 BTH ULTRA 12, BTH ULTRA 18, BTH ULTRA 10, BTH ULTRA 8, BTH ULTRA 15 Installation & Operation Manual

...

BTH ULTRA Electric Boilers

M

odels ranging from 6 kW to 33 kW :

120/240 Volts ( 1 phase )

INSTALLATION & OPERATION MANUAL

Your BTH ULTRA Electric Boiler has been carefully assembled and factory tested to provide

years of trouble-free service. The following information and safety measures are provided to

enable proper installation, operation, and maintenance of this product.

It is imperative that all persons who are expected to install, operate or adjust this boiler should

read these instructions carefully.

Any questions regarding the operation, maintenance, service or warranty of this electric boiler

should be directed to the supplier.

When all installation steps have been completed, insert this installation manual in its original

envelope, and keep in a safe place (close to the boiler) for future reference.

THERMO 2000 INC. revision : April 2011

Printed in Canada

Section 1: DIMENSIONS AND SPECIFICATIONS

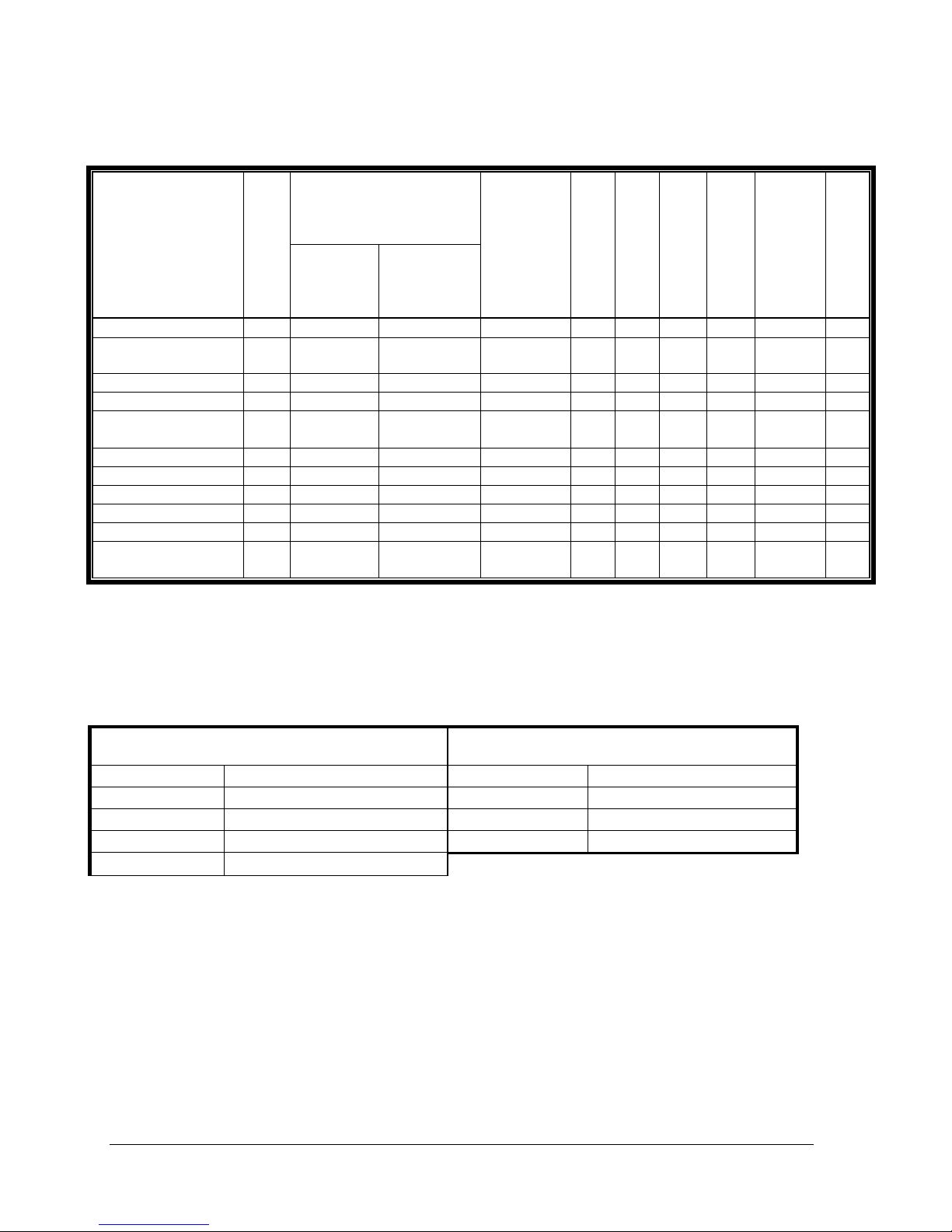

Table 1: Electric Ratings for 120/240 VAC (1 phase) Electric Boilers:

Current

Amp

Model

BTH ULTRA 6 6 25.0 30.0 2 X 3KW 2 1 1 2 8 40

BTH ULTRA 8 8 33.3 38.3

BTH ULTRA 10 10 41.6 46.6 2 X 5KW 2 1 1 2 6 60

BTH ULTRA 12 12 50.0 55.0 4 X 3KW 4 1 1 4 6 70

BTH ULTRA 15 15 62.5 67.5

BTH ULTRA 18 18 75.0 80.0 4 X 4.5KW 4 1 1 4 3 100

BTH ULTRA 20 20 83.4 88.4 4 X 5KW 4 1 1 4 3 110

BTH ULTRA 24 24 100.0 105.0 4 X 6KW 4 1 1 4 2 150

BTH ULTRA 27 27 112.5 117.5 6 X 4.5KW 4 1 2 6 1 150

BTH ULTRA 30 30 125.0 130.0 6 X 5KW 4 1 2 6 1/0 175

BTH ULTRA 33 33 138.0 143.0

*Maximum current for circulator : 5 amps. (1/6 HP Max.)

**

Models 6 to 24kW are also certified for Aluminum cables of higher gauge.

Electrical local codes may require different cable gauge.

P

KW

Heating

Elements

Total

with

Circulator

Elements

1X 3KW

1 X 5KW

2 X 3KW

2 X 4.5KW

3 X 5KW

3 X 6KW

Stages

2 1 1 2 8 50

4 1 1 4 4 100

4 1 2 6 2/0 200

Control

Electronic

Power Relays

Table 2: Connections sizes & Boiler overall dimensions

Wire**

CU

90oC

Main Contactors

Fuse

A

Connections sizes Boiler overall dimensions

Boiler Inlet 1 “ NPT M Height 12 3/16 inches

Boiler Outlet 1 “ NPT M Width 16 7/16 inches

Waterworks 1/2 “ NPT F Depth 24 ½ inches

Safety valve 3/4 “ NPT F Shipping weight 99 lbs.

Drain valve 1/2 “ NPT F

Operating temperature : from 50°F to 190°F (10 to 90C)

Maximum operating pressure: 30 psi (207kPa)

BTH ULTRA Electric Boilers USE & CARE MANUAL

(Revision April 2011), Page

2.

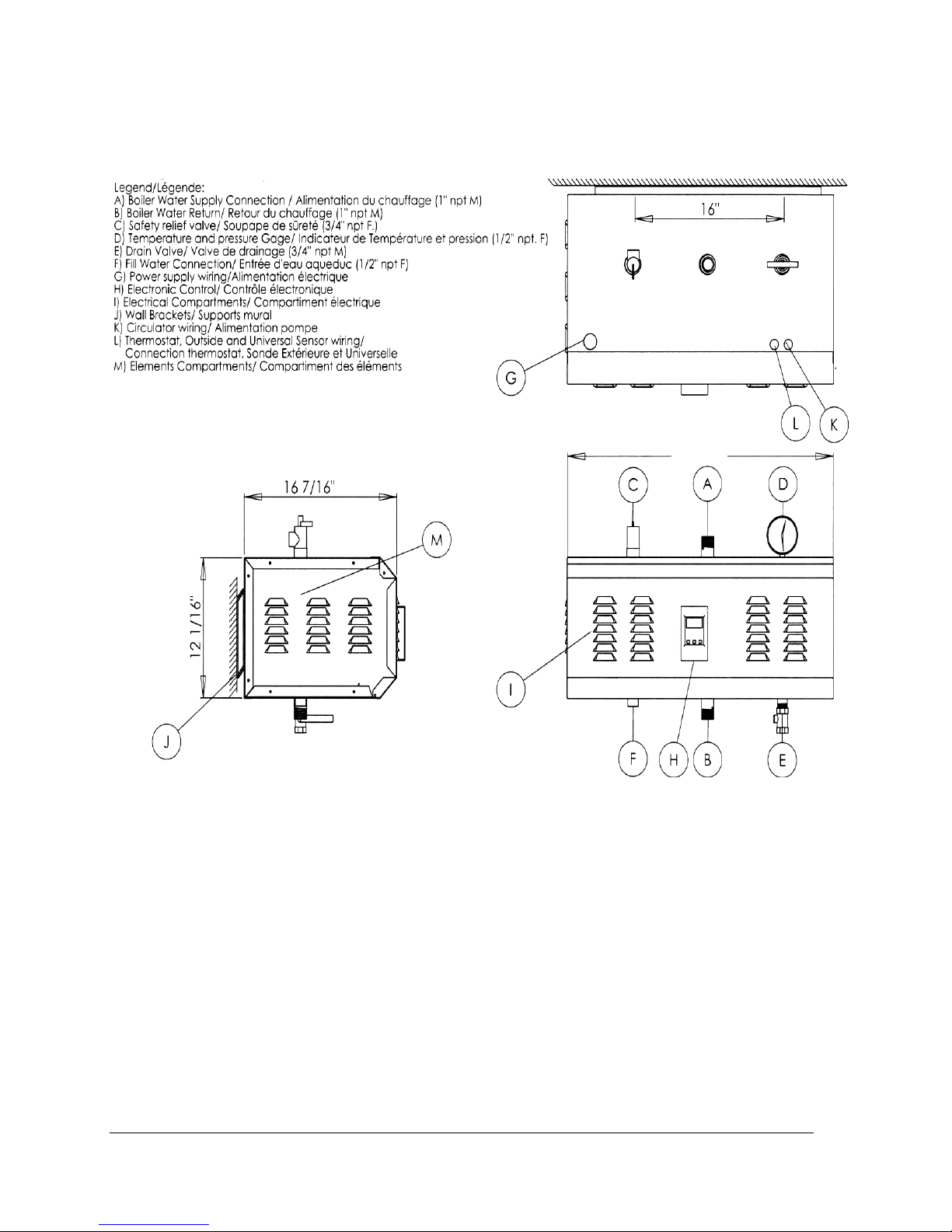

Figure 1 : Component identification

.

24 1/2"

BTH ULTRA Electric Boilers USE & CARE MANUAL

(Revision April 2011), Page

3.

General Safety Precautions

!

Be sure to read and understand the entire Use & Care Manual before attempting to install or to

operate this electric boiler. Pay particular attention to the following General Safety Precautions.

Failure to follow these warnings could cause property damage, bodily injury or death. Should

you have any problems understanding the instructions in this manual, ask for help from

a qualified installer or technician.

Section 2: INTRODUCTION

WARNING

!

The important safeguards and instructions

appearing in this manual are not meant to

cover all possible conditions and situations

that may occur. It should be understood that

common sense, caution and care are factors

which cannot be built into every product.

They are the responsibility of the person(s)

caring for and operating the unit.

2.1 LOCAL INSTALLATION

REGULATIONS

This electric boiler must be installed in

accordance with these instructions and in

conformity with local codes, or in the absence of

local codes, with the National Plumbing Code

and the National Electric Code current edition.

In any case where instructions in this manual

differ from local or national codes, the local or

national codes take precedence.

2.2 CORROSIVE ATMOSPHERE

The electric boiler should not be located near an

air vent containing a corrosive atmosphere or

high humidity. The limited warranty is void when

the failure of the electric boiler is due to a

corrosive atmosphere.

2.3 INSPECT SHIPMENT

Inspect the electric boiler for possible shipping

damage. The manufacturer’s responsibility

ceases upon delivery of goods to the carrier in

good condition. Consignee must file any claims

for damage, shortage in shipments, or nondelivery immediately against carrier.

2.4 CHECK LIST

Please check the identification tag on the unit to

make sure you have the right model.

List of components shipped with the unit :

· Pressure relief valve set at 30 PSI.

· Drain valve.

· Outdoor temperature sensor

· Tridicator (temperature & pressure

gauge).

CAUTION !

The electric boiler should not be located in

an area where leakage of the tank or water

connections will result in damage to the

adjacent area or to lower floors of the

structure. When such areas cannot be

avoided, a suitable drain pan or nonflammable catch pan, adequately drained,

must be installed under the boiler.

The pan must be connected to a drain.

NOTE: Auxiliary catch pan MUST conform to

local codes.

BTH ULTRA Electric Boilers USE & CARE MANUAL

(Revision April 2011), Page

4.

Section 3: INSTALLATION

WARNING

!

The manufacturer’s warranty does not cover

any damage or defect caused by installation,

or attachment, or use of any special

attachment other than those authorized by

the manufacturer into, onto, or in

conjunction with the boiler. The use of such

unauthorized devices may shorten the life of

the boiler and may endanger life and

property. The manufacturer disclaims any

responsibility for such loss or injury

resulting from the use of such unauthorized

devices

3.1 SECURITY CONSIDERATIONS

Domestic and commercial installations have a

maximum design operating pressure limited to

30 psi (207 kPa) by a safety relief valve.

This boiler is designed to operate on a closed

circuit system operating between 50 to 190°F.

This boiler is designed to be used only in a hot

water heating system.

The hi-limit control of the unit is fixed and set at

212F (100C). If the heating distribution system

on which the boiler is installed requires a hi limit

controller set at a lower temperature, this

controller will have to be added to the system

and connected in series with the hi-limit installed

at the factory.

!

The heat transfer medium must be water or

other non-toxic fluid having a toxicity rating

or class of 1, as listed in clinical Toxicology

of Commercial products, 5th edition

3.2 LOCATION

The electric boiler should be installed in a clean,

dry location. Long hot water lines should be

insulated to conserve water and energy. The

electric boiler and water lines should be

protected from exposure to freezing

temperatures.

The electric boiler must be installed horizontally,

directly on the wall or on an adequate ground

support. On wall hung applications, use the

supplied wall mounting brackets. It is held on the

wall by four 5/16’’ lag screws. The openings are

located at 16’’ intervals (i.e. standard stud

spacing). When the first bracket is installed you

can hang the boiler on the wall (see figure 1).

The lag screws must be suitably anchored to

safely support the weight of the boiler including

water content, piping and wiring.

The electric boiler must be located or protected

so as not to be subject to physical damage, for

example, by moving vehicles, area flooding, etc.

All models can be installed on combustible floors

and in alcoves. Ambient temperature must not

exceed 90°F or 32°C.

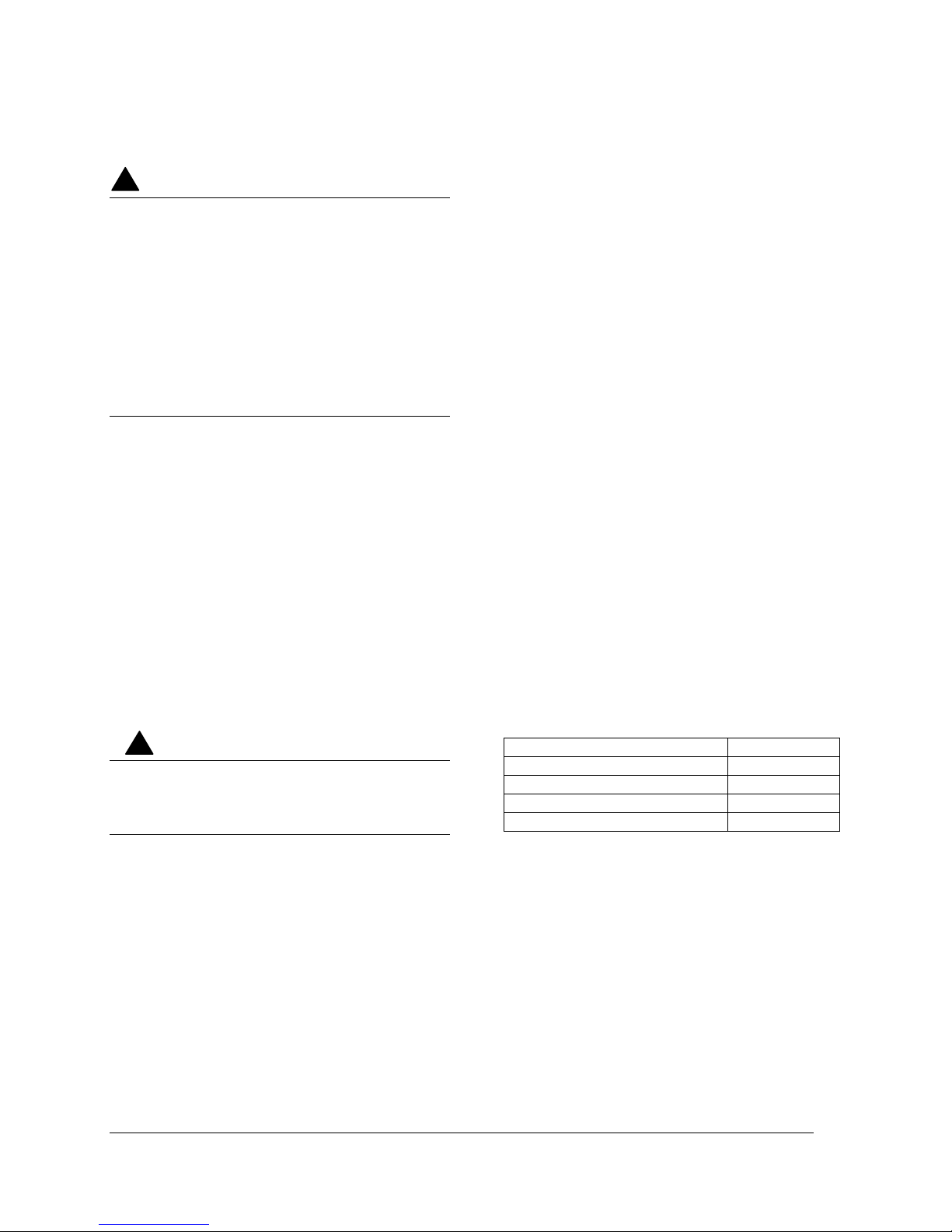

3.3 CLEARANCE

Minimum clearances for adequate inspection

and servicing are listed in the following table:

Table 3: Boiler clearance

Top & Bottom of the boiler

Front side of the boiler 24 inches

Back side of the boiler

Left side 16 inches

Right side

6 inches

6 inches

0 inch

BTH ULTRA Electric Boilers USE & CARE MANUAL

(Revision April 2011), Page

5.

3.4 PIPING INSTALLATION

3.4.1 Type of installation

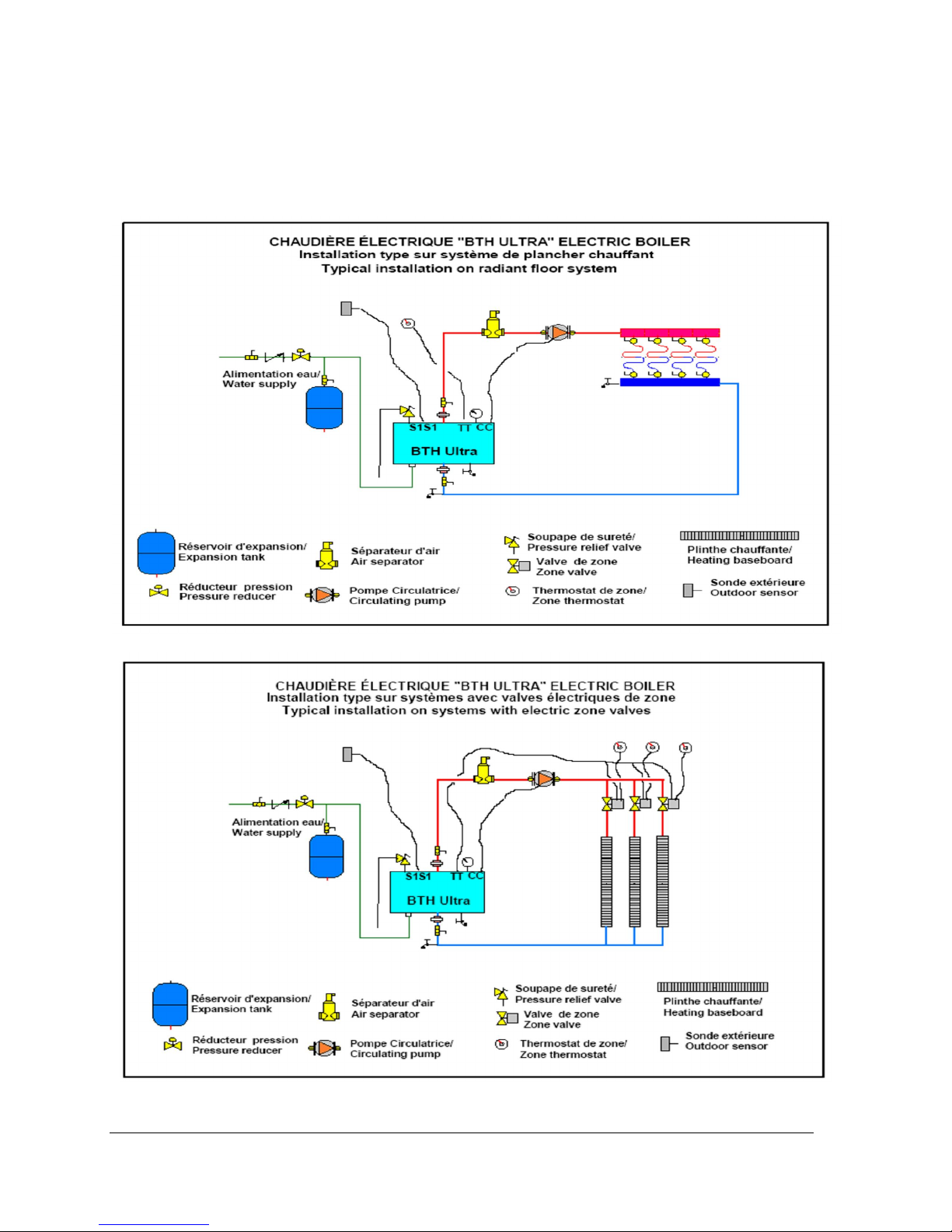

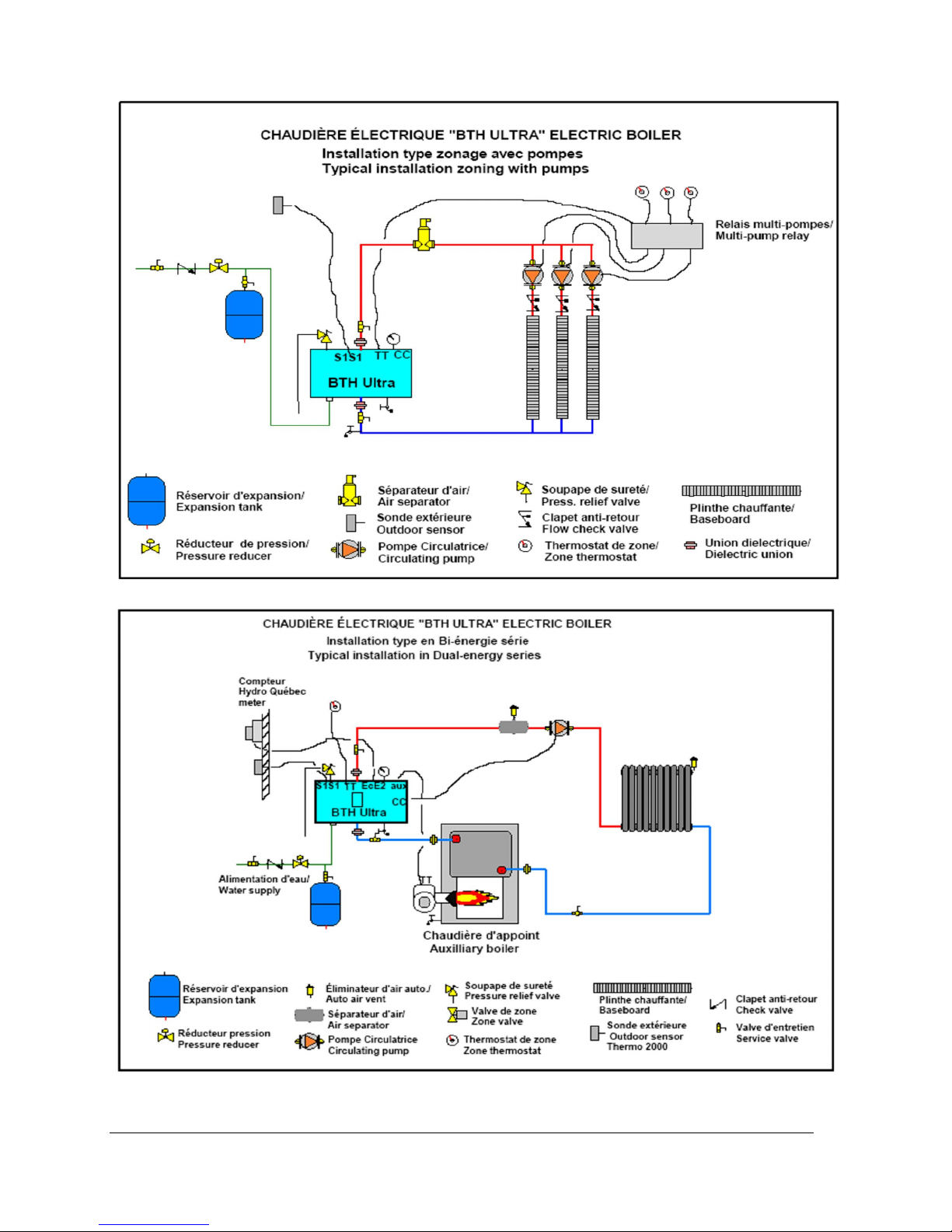

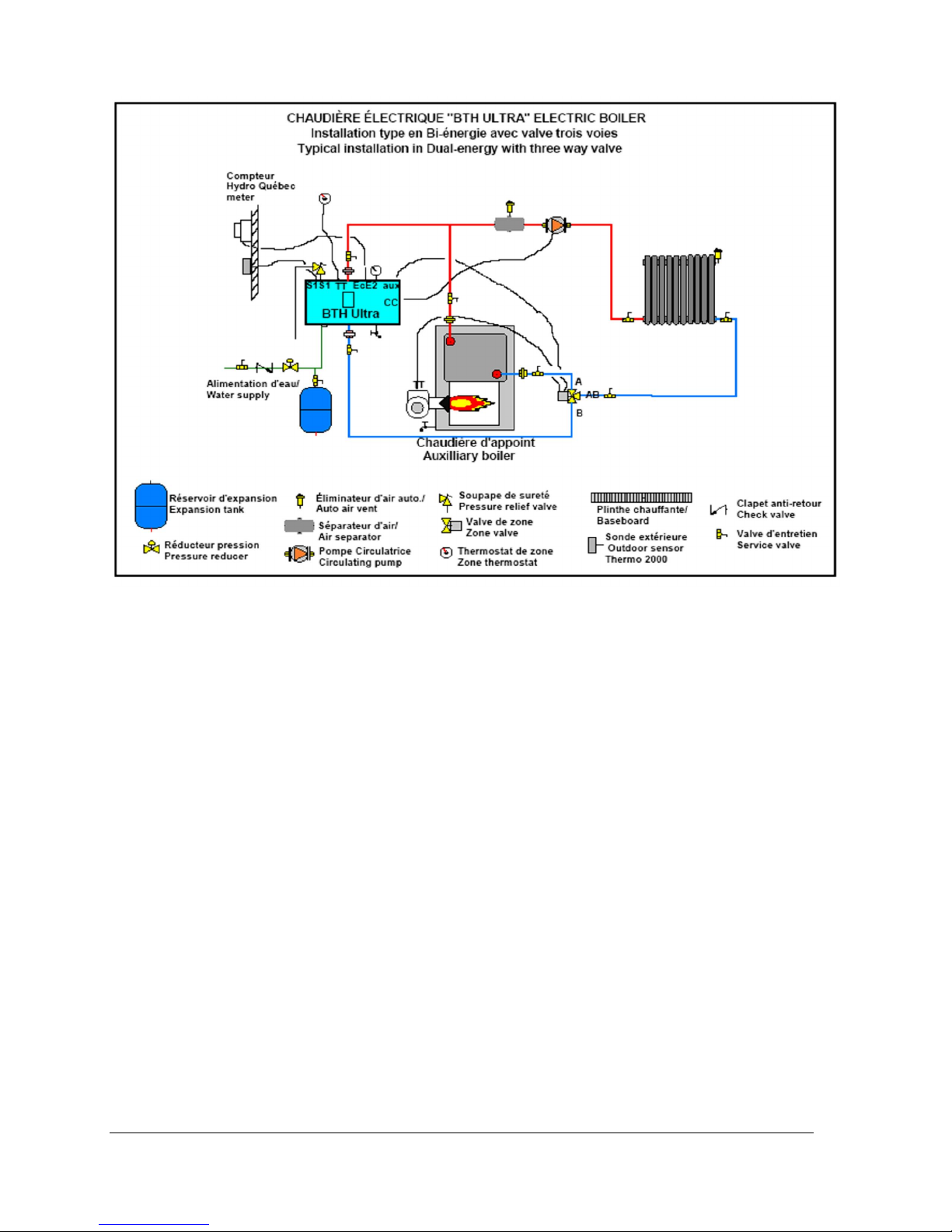

You will find below on figures 2 to 6 typical piping arrangement for the two main types of installation. The

first being as a self operating unit and the others being coonected to an auxiliary boiler in dual-energy.

Figure 2

Figure 3

BTH ULTRA Electric Boilers USE & CARE MANUAL

(Revision April 2011), Page

6.

Figure 4

Figure 5

BTH ULTRA Electric Boilers USE & CARE MANUAL

(Revision April 2011), Page

7.

.

Figure 6

3.4.2 Boiler piping

The outlet of the boiler is located on the top side,

and the inlet of the boiler is located on the bottom

side of the boiler. They are steel pipes (1”male

NPT threaded connection) where the connections

are to be made.

Installing a union is recommended on the boiler

water outlet and inlet piping to facilitate boiler

disconnection for servicing.

Dielectric unions are required for protection of the

boiler and piping if dissimilar pipe material such as

galvanized steel and copper are present.

Use only clean pipe for boiler water lines. Local

codes or regulations shall govern the exact type of

material to be used.

Insulate all pipes containing hot water, especially

in unheated areas.

Install shutoff (ball) valves for servicing

convenience.

Cap or plug unused connections on the boiler. Do

not cap the pressure relief valve on the boiler

since it will damage and shorten the life of the

boiler and may endanger life and property.

3.4.3 Pressure relief valve

An automatic pressure relief valve must be

installed during boiler setup. The pressure rating

of the relief valve must not exceed 30 psi.

Connect the outlet of the relief valve to a

discharge line going to 6” above a floor drain,

away of any live electrical parts. The discharge

line must pitch downward from the valve to allow

complete draining by gravity of the relief valve and

discharge line, and be of a diameter no smaller

than that of the valve outlet. The tip of the

discharge line should not be threaded or

concealed and should be protected from freezing.

No valve of any type, restriction or reducer

coupling should be installed on the discharge line.

Local codes shall govern the installation of relief

valves.

3.4.4 Expansion tank

The increase in boiler water volume resulting from

higher temperature is stored in the expansion tank

during periods of high operating temperature and

is returned to the system when the temperature

decreases.

BTH ULTRA Electric Boilers USE & CARE MANUAL

(Revision April 2011), Page

8.

Loading...

Loading...