THERMO 2000 BTH ULTRA 12, BTH ULTRA 15, BTH ULTRA 20, BTH ULTRA 18, BTH ULTRA 24 Installation & Operation Manual

...

Electric Boilers

Models ranging from 12 kW to 36 kW 208/240 Volts (1 phase)

Your BTH ULTRA Electric Boiler has been carefully assembled and factory tested to provide

years of trouble-free service. The following information and safety measures are provided to

enable proper installation, operation, and maintenance of this product.

It is imperative that all persons who are expected to install, operate or adjust this boiler should

read these instructions carefully.

Any questions regarding the operation, maintenance, service or warranty of this electric boiler

should be directed to the supplier.

When all installation steps have been completed, keep this installation manual in a safe place

(close to the boiler) for future reference.

BTH ULTRA

INSTALLATION & OPERATION MANUAL

THERMO 2000 INC. Revision : June 2015

Printed In Canada

Table des matières

Section 1: Technical specifications ............................................................................................................... 4

Table 1: Technical data on boilers operating at 240 Vac /1ph1 : .................................................................. 4

Table 2 : Boiler connections and dimensions (12-24 KW) ............................................................................ 5

Table 3 : Boiler connections and dimensions (27-36 KW) ............................................................................ 5

Section 2: INTRODUCTION .......................................................................................................................... 6

2.1 LOCAL INSTALLATION REGULATIONS .......................................................................................... 6

2.2 CORROSIVE ENVIRONMENT........................................................................................................... 6

2.3 INSPECTION UPON RECEPTION .................................................................................................... 6

2.4 TO BE CHECKED .............................................................................................................................. 6

Section 3: INSTALLATION............................................................................................................................ 7

3.1 SAFETY MEASURES ......................................................................................................................... 7

3.2 LOCATION.......................................................................................................................................... 7

3.3 CLEARANCES ................................................................................................................................... 7

Table 4: Boiler Clearances ............................................................................................................................ 7

3.4 PIPING INSTALLATION ..................................................................................................................... 8

3.4.1 Type of installation ...................................................................................................................... 8

3.4.2 Boiler piping connection ............................................................................................................ 11

Local codes may dictate the type of pipe to be used for the connections.......................................... 11

Install isolating valves to facilitate maintenance ................................................................................. 11

3.4.3 Pressure relief valve .................................................................................................................. 11

3.4.4 Expansion tank .......................................................................................................................... 11

3.4.5 Water pressure regulator ........................................................................................................... 11

3.4.6 Air eliminator.............................................................................................................................. 11

3.4.7 Circulating pump ....................................................................................................................... 11

Table 5: Temperature rise vs flow rate (GPM) ............................................................................................ 11

3.4.8 Drain valve ................................................................................................................................. 11

3.4.9 Strainer ...................................................................................................................................... 11

3.4.10 Dual Energy piping .................................................................................................................. 12

3.5 ELECTRIC CONNECTIONS ............................................................................................................ 12

3.5.1 Main Electric supply .................................................................................................................. 12

3.5.2 Electrical supply of External accessories .................................................................................. 13

3.5.3 Outdoor temperature sensor ..................................................................................................... 13

3.5.4 Connecting the thermostat and pump. ...................................................................................... 13

3.5.4 Dual-energy connection with an auxiliary boiler. ....................................................................... 14

Section 4: ADJUSTMENT OF THE CONTROLLER ................................................................................... 16

4.1 INTRODUCTION .............................................................................................................................. 16

4.2 DISPLAYED INFORMATION ........................................................................................................... 16

4.3 OPERATION OF THE INTERFACE ................................................................................................. 17

4.4 OPERATION IN “FIXED BOILER TEMPERATURE SET POINT” ................................................... 17

4.5 OPERATION WITH “OUTDOOR RESET”: ...................................................................................... 17

4.6 PURGE DELAY OF THE PUMP ...................................................................................................... 18

4.7 AUTOMATIC HEATING SHUT DOWN ............................................................................................ 18

4.8 CONFIGURATION OF THE CONTROLLER .................................................................................... 18

4.9 ADJUSTMENTS OF THE TARGET TEMPERATURE BY THE USER: ........................................... 20

4.10 BOOST SYSTEM OPERATION ..................................................................................................... 20

4.11 OPERATION IN DUAL-ENERGY: .................................................................................................. 21

Section 5: START UP OPERATION ........................................................................................................... 22

5.1 PREPARATORY STEP .................................................................................................................... 22

5.2 STARTUP & INSPECTION ............................................................................................................... 22

5.3 COMPLEMENTARY CHECKS ON DUAL-ENERGY INSTALLATIONS .......................................... 22

BTH ULTRA Electric Boilers Installation & Operation manual (Revision: June 2015) 2

Section 6 MAINTENANCE .......................................................................................................................... 23

6.1 INTRODUCTION .............................................................................................................................. 23

6.2 AT ALL TIMES .................................................................................................................................. 23

6.3 TWICE A YEAR ................................................................................................................................ 23

6.4 ANNUALY ......................................................................................................................................... 23

Section 7- TROUBLE SHOOTING .............................................................................................................. 24

7.1 TROUBLE SHOOTING TABLE ........................................................................................................ 24

7.2 SPARE PARTS ................................................................................................................................. 26

BTH ULTRA LIMITED WARRANTY ............................................................................................................ 29

Figure 1 : Boiler dimensions (12-24 KW) ...................................................................................................... 5

Figure 2 : Boiler dimensions (27-36 KW) ...................................................................................................... 5

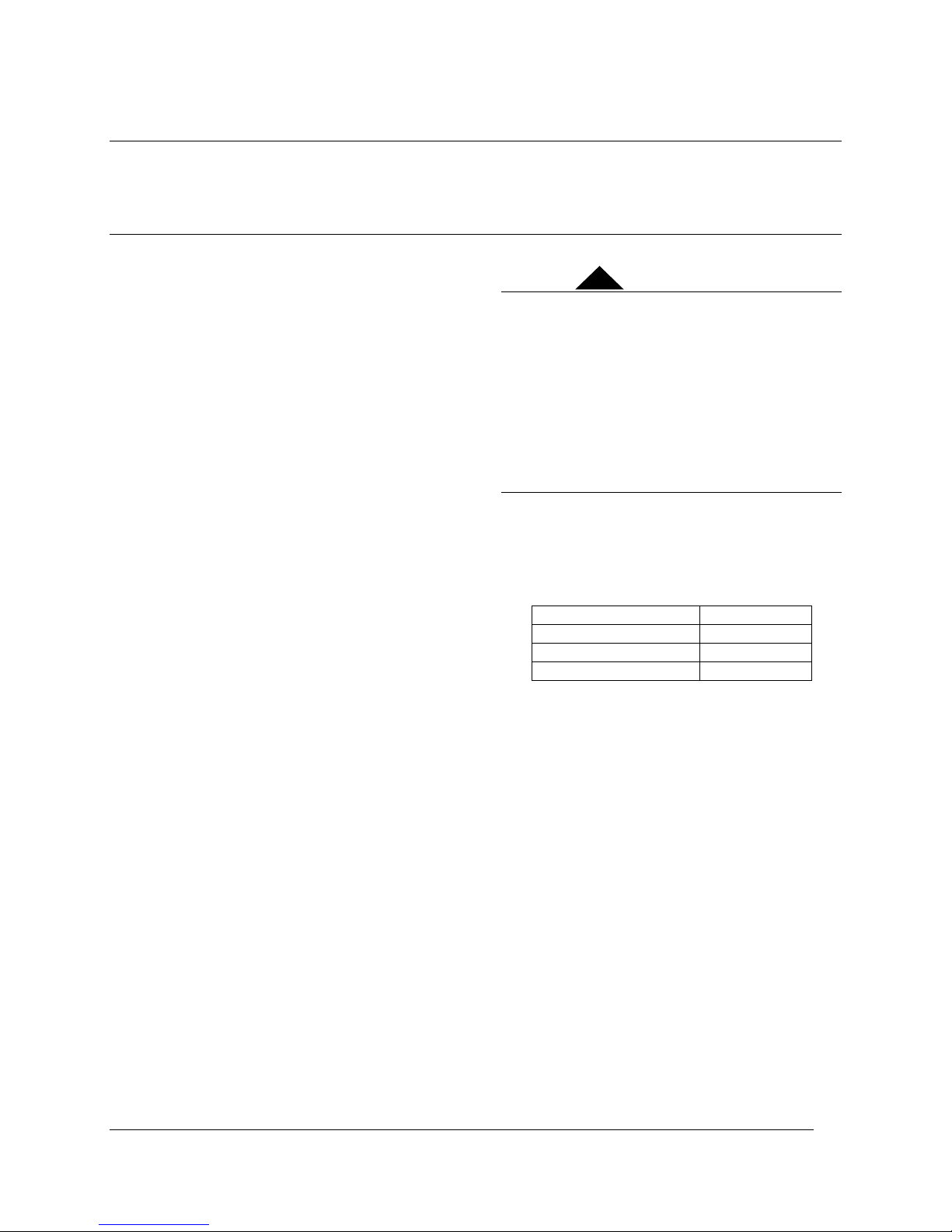

Figure 3 : Mounting positions ........................................................................................................................ 8

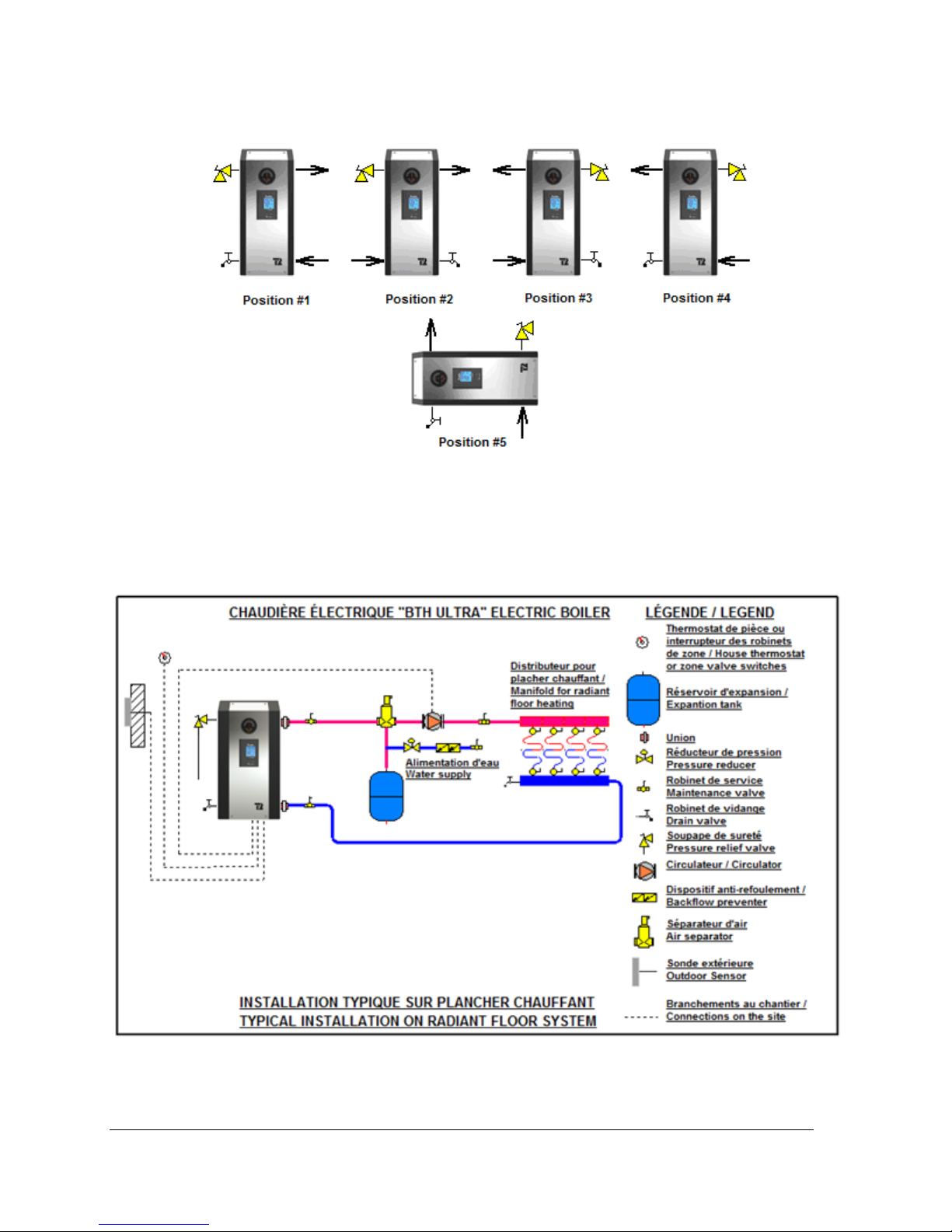

Figure 4 : Typical Installation on heating floor .............................................................................................. 8

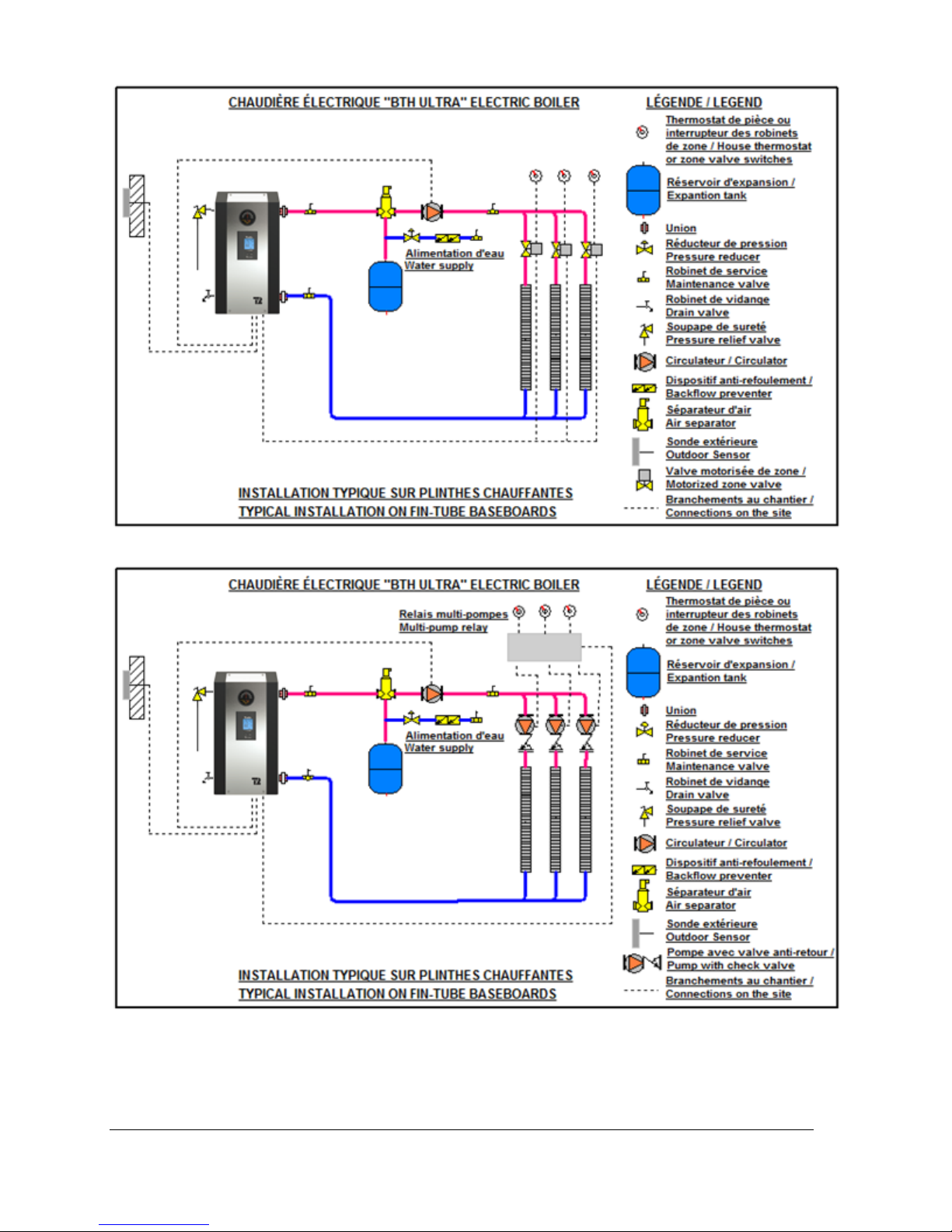

Figure 5 : Typical installation on fin-tube baseboards with zoning valves .................................................... 9

Figure 6 : Multi-pump zoning......................................................................................................................... 9

Figure 7 : Typical Installation in Dual-Energy Series .................................................................................. 10

Figure 8 : Typical installation with three way valve ..................................................................................... 10

Figure 9 : Zoning with Multiple pumps ........................................................................................................ 13

Figure 10 : Zoning with motorized valves ................................................................................................... 14

Figure 11 Connexions without three way valve ......................................................................................... 14

Figure 12 : Connexions with three way valve ............................................................................................. 14

Figure 13 : Wiring diagram (12-24 KW) ...................................................................................................... 15

Figure 14 : Wiring diagram (27-36 KW) ...................................................................................................... 15

Figure 15 : UltraSmart Controller Display ................................................................................................... 16

Figure 16 : UltraSmart Control Module ....................................................................................................... 17

Figure 17 : Back of the controller ................................................................................................................ 19

Figure 18 : Spare parts (front, 12-24 KW) ................................................................................................... 26

Figure 19 : Spare parts (top, 12-24 KW) ..................................................................................................... 26

Figure 20 : Spare parts (front, 27-29 KW) ................................................................................................... 27

Figure 21 : Spare parts (top, 27-36 KW) ..................................................................................................... 27

Figure 22 : Spare parts (front, 33-36 KW) ................................................................................................... 28

BTH ULTRA Electric Boilers Installation & Operation manual (Revision: June 2015) 3

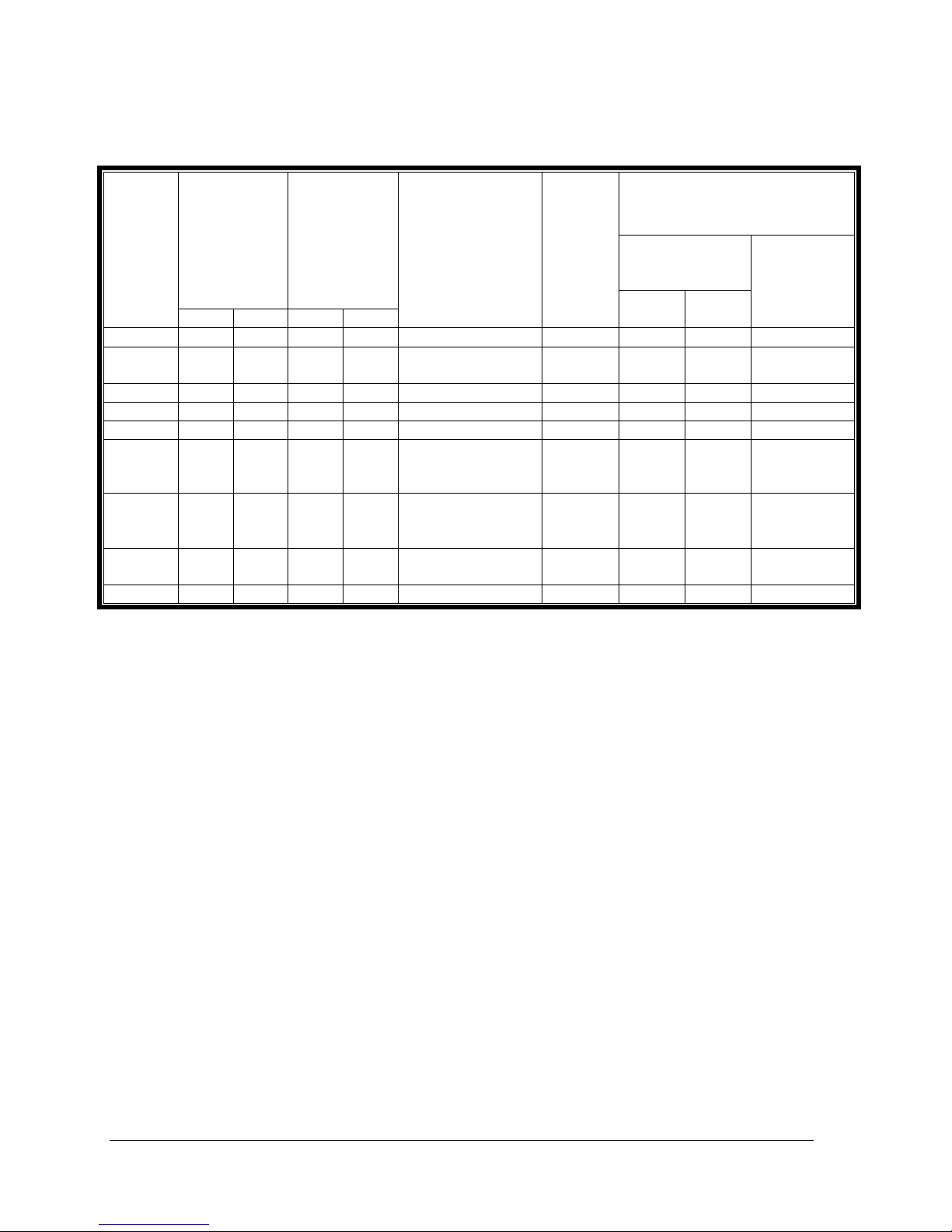

Section 1: Technical specifications

BTH

ULTRA

Capacity

(KW)

Amps2

Heating

Elements (240 V)

Stages

Suggested size at 240V/1ph.

3

Cable

Breaker

(Amp.)

Cu

Al

208V

240V

208V

240V

12

9,0

12

43.5

50

4 x 3 KW

4 6 4

70

15

11.2

15

54.3

62.5

2 x 3 KW +

2 x 4.5 KW

4 6 4

80

18

13.5

18

65.2

75

4 x 4.5 KW

4 4 2

100

20

15

20

72.5

83.3

4 x 5 KW

4 3 2

110

24

18

24

87

100

4 x 6 KW

4 2 0

125

27

20.2

27

97.9

112.5

6 x 4.5 KW

6

1 x 1

or

2 x 6

4

1 x 00

or

2 x 44

2 x 80

or

150

29

21.7

29

104

120

4 x 5 KW +

2 x 4.5 KW

6

1 x 1

or

2 x 64

1 x 00

or

2 x 44

2 x 80

or

175

33

25

33

119.6

137.5

3 x 5 KW +

3 x 6 KW

6

2 x 4

5

2 x 25 2 x 100

36

27

36

130.5

150

6 x 6 KW

6

2 x 45

2 x 25

2 x 100

Table 1: Technical data on boilers operating at 240 Vac /1ph1 :

1

Electrical supply 120/240V or 120/208V – 1ph (L1-N-L2) with three conductors and a ground or a supply

with two conductors 240V or 208V – 1ph (L1-L2) with a ground if the application does not require a 120V

electrical supply for external accessories such as a pump, etc

2

Add the amperage of the circulating pump and other external accessories if they are connected to the

boiler (max. 5A).

3

A higher cable size could be required. In all cases the local electrical code has priority. The electrician has

the responsibility to select the appropriate size.

4

Two main terminal blocks that could be converted to one on the job site.

5

Two double pole breakers

1 kW = 3412 Btu

BTH ULTRA Electric Boilers Installation & Operation manual (Revision: June 2015) 4

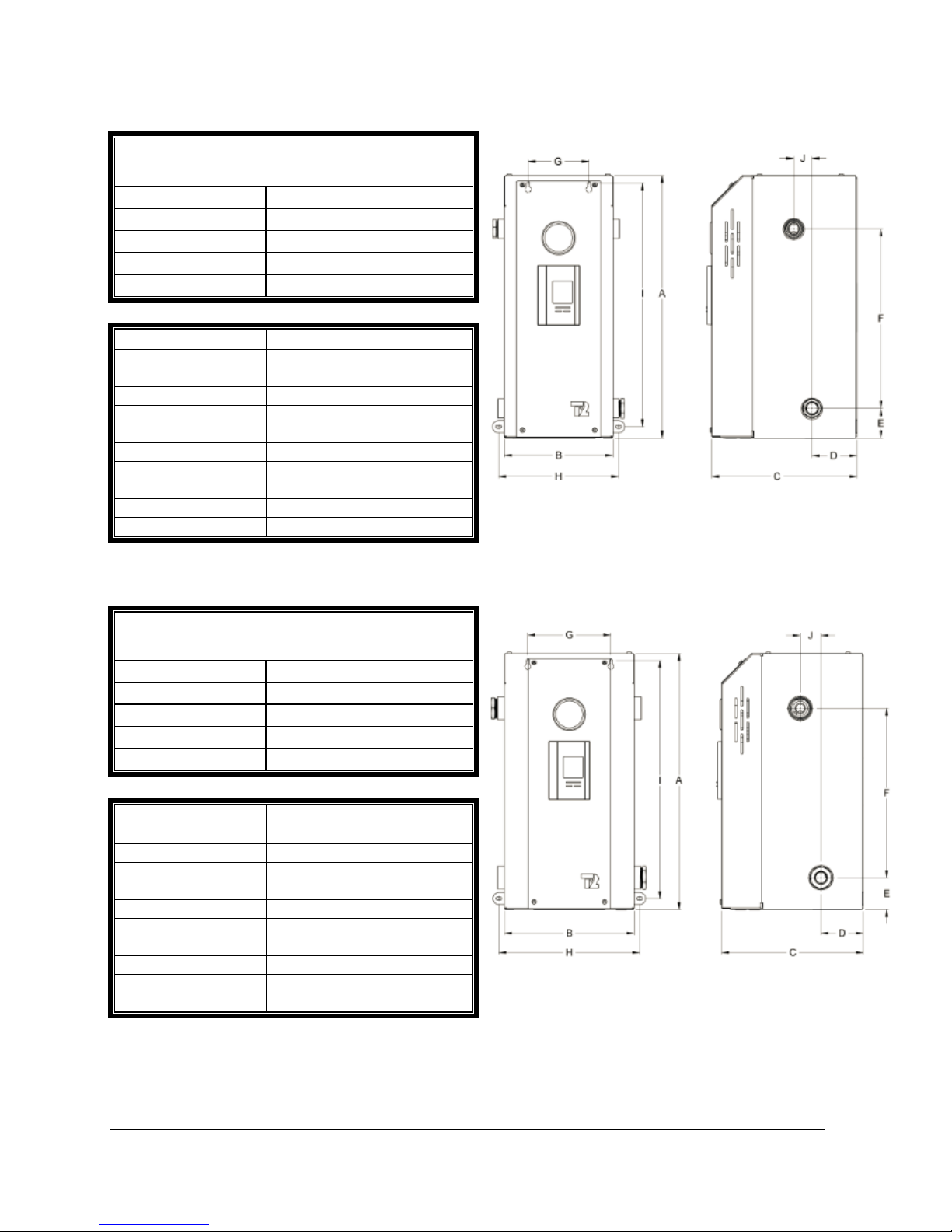

Table 2 : Boiler connections and dimensions (12-24 KW)

Connections

Inlet (return)

1 “ NPT Fem

Outlet (supply)

1 “ NPT Fem

Safety valve

1“reduced to 3/4 “ NPT Fem

Draining valve

1“reduced to 3/4 “ NPT Fem

Shipping weight

63 lbs

Item

Dimension (inches)

A

21-1/2 B 9 C 11-3/4

D

3-5/8

E

2-3/8

F

14-3/4 G 5 H 9-3/4

I

20 J 1-1/2

Connections

Inlet (return)

1 ¼ “ NPT Fem

Outlet (supply)

1 ¼ “ NPT Fem

Pressure relief valve

1 ¼“reduced to 3/4 NPTFem

Drain valve

1 ¼“reduced to 3/4NPT Fem

Shipping weight

75 lbs

Item

Dimension (inches)

A

21-1/2

B

11

C

11-3/4

D

3-1/2

E

2-3/4

F

14-1/4 G 7 H 11-5/8

I

20 J 1-3/4

Figure 1 : Boiler dimensions (12-24 KW)

Figure 2 : Boiler dimensions (27-36 KW)

Table 3 : Boiler connections and dimensions (27-36 KW)

BTH ULTRA Electric Boilers Installation & Operation manual (Revision: June 2015) 5

General Safety Precautions

List of components shipped with the unit :

Pressure relief valve set at 30 PSI.

Drain valve.

Two reducer fittings

Temperature & pressure indicator

Outdoor temperature sensor

Installation and operating manual

!

WARNING

!

Be sure to read and understand the entire Installation & operation manual before attempting to

install or to operate this water heater. Pay particular attention to the following General Safety

Precautions. Failure to follow these warnings could cause property damage, bodily injury or

death. Should you have any problems understanding the instructions in this manual, STOP,

and get help from a qualified installer or technician

Section 2: INTRODUCTION

These important safeguards and instruction appearing in this manual are not meant to cover all

possible conditions and situations that may occur. It should be understood that common sense,

caution and care are factors which cannot be built into every product. These factors must be

supplied by the person(s) caring for and operating the unit.

2.1 LOCAL INSTALLATION

REGULATIONS

This electric boiler must be installed in

accordance with these instructions and in

conformity with local codes, or in the absence of

local codes, with the National Plumbing Code

and the National Electric Code, current edition.

In any case where instructions in this manual

differ from local or national codes, the local or

national codes take precedence

2.2 CORROSIVE ENVIRONMENT

The electric boiler must not be installed near an

air duct supplying corrosive atmosphere or with

high humidity content.

When a boiler defect is caused by such

conditions, the warranty will not apply

2.3 INSPECTION UPON RECEPTION

Inspect the electric boiler for possible shipping

damage. The manufacturer’s responsibility

ceases upon delivery of goods to the carrier in

good condition. Consignee must file any claims

for damage, shortage in shipments, or nondelivery immediately against carrier.

2.4 TO BE CHECKED

Please check the identification tag on the unit to

make sure you have the right model (Capacity in

kilowatt, voltage, number of phase and ASME

construction or not ASME).

BTH ULTRA Electric Boilers Installation & Operation manual (Revision: June 2015) 6

Section 3: INSTALLATION

Sides

3 inches

Electric elements side

14 inches

Front side of the boiler

3 inches*

Back

0 inches

CAUTION

!

The manufacturer’s warranty does not cover any damage or defect caused by installation, or

attachment, or use of any special attachment other than those authorized by the manufacturer

into, onto, or in conjunction with the water heater. The use of such unauthorized devices may

shorten the life of the boiler and may endanger life and property. The manufacturer disclaims any

responsibility for such loss or injury resulting from the use of such unauthorized devices

3.1 SAFETY MEASURES

All installation will include the supplied pressure

relief valve which limits the maximum operating

pressure to 30 psi (207 kPa).

This electric boiler is designed to be installed on

a circuit operated between 50°F to 190°F (10°C

to 90°C) and at a maximum operating pressure

of 30 psi (207 kPa).

The unit in designed solely to be used on a

close loop hydronic heating system. The heat

transfer solution must be a solution of water or if

a freeze protection is required, a mix solution

Water/propylene glycol specially made for

hydronic heating systems and having a

maximum concentration of 50% (do not use

plumbing or automobile glycol).

The boiler is equipped with an automatic high

limit temperature control set at 210°F 99°C) and

some models have a second limit device

manually re-settable set at 227F (108C). If the

heating distribution system on which the boiler is

installed requires a high limit controller having a

lower setting, this controller will be added to the

system and connected in series with the factory

installed limit control.

3.2 LOCATION

The electric boiler should be installed in a clean,

dry location. Long hot water lines should be

insulated to conserve water and energy. The

electric boiler and water lines should be

protected from exposure to freezing

temperature.

The boiler can be mounted vertically or

horizontally directly on a solid surface with 4

adequate screws inserted in the provided boiler

openings. Make sure it is properly leveled

The electric boiler must be located or protected

so as not to be subject to physical damage, for

example, by moving vehicles, area flooding, etc.

All models can be installed directly on a

combustible wall and into an alcove. The

location must have sufficient ventilation to

maintain an ambient temperature not exceeding

90°F (32°C).

The electric boiler should not be located in

an area where leakage of the tank or water

connections will result in damage to the

adjacent area or to lower floors of the

structure. When such areas cannot be

avoided, a suitable drain pan or nonflammable catch pan, adequately drained

must be installed under the boiler.

The pan must be connected to a drain.

NOTE: Auxiliary catch pan MUST conform to

local codes.

3.3 CLEARANCES

For adequate inspection and servicing the

following minimum clearance is necessary:

Table 4: Boiler Clearances

*If the boiler is installed in a closed

compartment, allow an access service opening

and adequate ventilation to maintain an ambient

temperature lower than 90°F/32°C.

BTH ULTRA Electric Boilers Installation & Operation manual (Revision: June 2015) 7

3.4 PIPING INSTALLATION

The inlet and outlet piping of the boiler must be in conformity with the different configurations shown

below. Make sure that the fluid flows is in the proper direction.

Figure 3 : Mounting positions

3.4.1 Type of installation

You will find below on figures 4 to 8 the typical piping arrangement for the two main types of installation.

The first being as a self-operating unit and the others being connected to an auxiliary boiler in dualenergy.

Figure 4 : Typical Installation on heating floor

BTH ULTRA Electric Boilers Installation & Operation manual (Revision: June 2015) 8

Figure 5 : Typical installation on fin-tube baseboards with zoning valves

BTH ULTRA Electric Boilers Installation & Operation manual (Revision: June 2015) 9

Figure 6 : Multi-pump zoning

Loading...

Loading...