THERMO 2000 BTH 8, BTH 12, BTH 10, BTH 18, BTH 15 Use & Care Manual

...

BTH Electric Boilers

Models ranging from 8 kW to 36 kW :

240 Volts ( 1 phase ) & 600 Volts ( 3 phases ).

USE & CARE MANUAL

WITH INSTALLATION INSTRUCTIONS FOR THE CONTRACTOR

Your BTH Electric Boiler has been carefully assembled and factory tested to provide years

of trouble-free service. The following information and safety measures are provided to

enable proper installation, operation, and maintenance of this product.

It is imperative that all persons who are expected to install, operate or adjust this boiler

should read these instructions carefully.

Any questions regarding the operation, maintenance, service or warranty of this electric

boiler should be directed to the supplier.

When all installation steps have been completed, insert this installation manual in its original

envelope, and keep in a safe place (close to the boiler) for future reference.

THERMO 2000 INCORPORATED revision:August/06

Printed in Canada

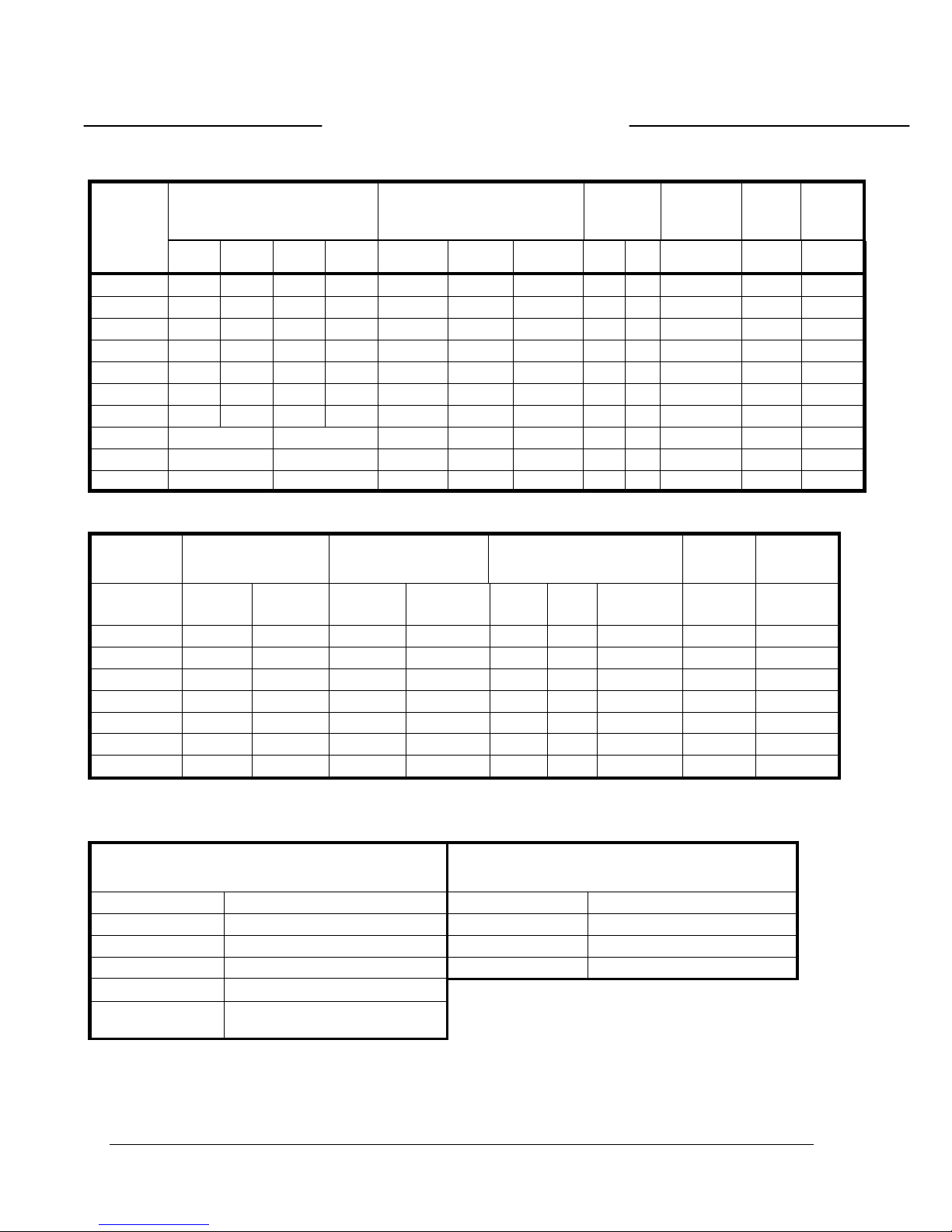

Ratings & Specifications

Electric Ratings for 240 VAC (1 phase) Electric Boilers:

Model

No.

BTH 8 5 000 3 000 ------ ------ 8 000 33.3 27 296 8 6 50 50 41.3

BTH 10 5 000 5 000 ------ ------ 10 000 41.6 34 120 6 6 60 60 52

BTH 12 3 000 3 000 3 000 3 000 12 000 50 40 944 6 4 70 70 62.5

BTH 15 3 000 4 500 3000 4 500 15 000 62.5 51 180 4 3 100 80 78.2

BTH 18 4 500 4 500 4500 4 500 18 000 75 61 416 3 2 100 100 93.8

BTH 20 5 000 5 000 5000 5 000 20 000 83.4 68 240 3 1 125 110 104

BTH 24 6 000 6 000 6000 6 000 24 000 100 81 888 1 0 125 125 125

BTH 27 3 x 4 500 3 x 4 500 27 000 112.5 92 124 1 0 150 150 140

BTH 30 3 x 5 000 3 x 5 000 30 000 125 102 360 2/0 3/0 200 175 156

BTH 33 3 x 5 000 3 x 6 000 33 000 138 112 596 2/0 3/0 200 200 172

Electric Elements

(in Watts)

A B C D Watts Amp. BTU CU AL Amp. Amp. Amp.

Total Wires Breakers Fuse

Electric Ratings for 600 VAC (3 phases) Electric Boilers:

Model

No. Quantity Watts Quantity Watts kW Amp. BTU RW-90 HRC “D”

BTH 9 3 3 000 ------- ------ 9 8.7 30 708 14 15 A

BTH 13 3 4 500 ------- ------ 13.5 13 46 062 12 20 A

BTH 18 6 3 000 ------- ------- 18 17 61 416 10 30 A

BTH 22 3 3 000 3 4 500 22.5 22 76 770 10 30 A

BTH 27 6 4 500 ------- ------- 27 26 92 124 8 40 A

BTH 30 6 5 000 ------- ------- 30 29 102 360 8 40 A

BTH 36 6 6 000 ------- ------- 36 35 122 832 8 50 A

Electric Elements Electric Elements Total Wires Fuse

Note: 1 kW =3,412Btu

Connections sizes & overall dimensions

125%

Connections sizes Boiler overall dimensions

Boiler return 1 “ NPT M Height 12 inches

Boiler feed 1 “ NPT M Width 12 inches

Waterworks 1/2 “ NPT F Depth 34 inches

Safety valve 3/4 “ NPT F Shipping weight 99 lbs.

Drain valve 1/2 “ NPT F

Drain valve

(BTH 33,36)

3/4 “ NPT M

Operating temperature : from 50°F to 190°F. Maximum operating pressure: 30 p.s.i.

BTH Electric Boilers USE & CARE MANUAL (Revision August /06), Page 2.

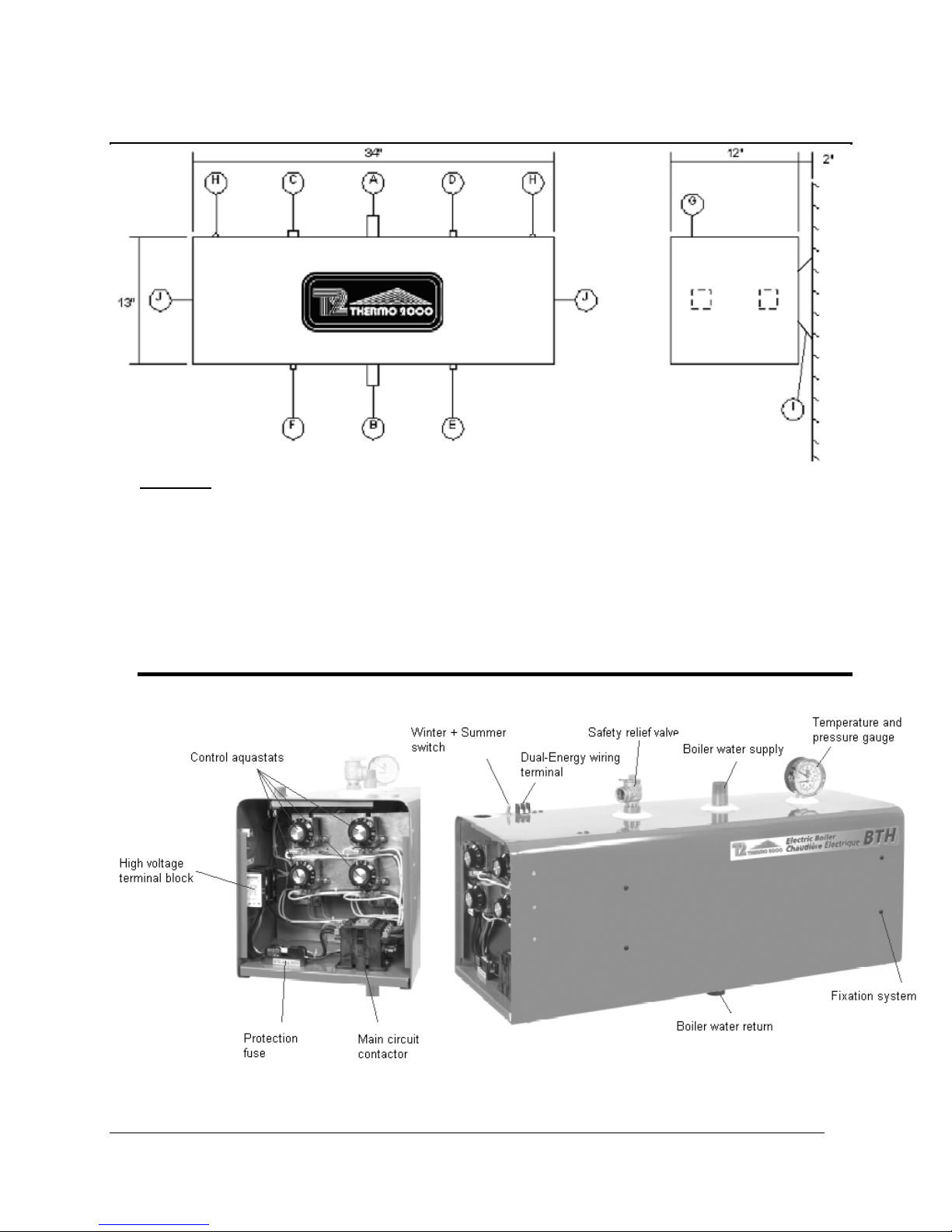

Unit description:

Legend :

A. Boiler Water Supply Connection ( 1 inch diameter, NPT male)

B. Boiler Water Return Connection ( 1 inch diameter, NPT male)

C. Safety Relief Valve ( ¾ inch NPT female )

D. Temperature & Pressure Gage (1/2 inch NPT female )

E. Drain Valve (1/2 inch NPT female )

F. Fill Water Connection (1/2 inch NPT female )

G. Electric Line Knock-Out ( 1 inch )

H. Pilot Light

I. Boiler Wall Hanging Brackets

J. Electrical Compartment

BTH Electric Boilers USE & CARE MANUAL (Revision August /06), Page 3.

General Safety Precautions

!

Be sure to read and understand the entire Use & Care Manual before attempting to install or to

operate this water heater. Pay particular attention to the following General Safety Precautions.

Failure to follow these warnings could cause property damage, bodily injury or death. Should

you have any problems understanding the instructions in this manual, STOP, and get help from

a qualified installer or technician.

Introduction

WARNING

!

These important safeguards and instruction

appearing in this manual are not meant to

cover all possible conditions and situations

that may occur. It should be understood that

common sense, caution and care are factors

which cannot be built into every product.

These factors must be supplied by the

person(s) caring for and operating the unit.

LOCAL INSTALLATION REGULATIONS

This electric boiler must be installed in

accordance with these instructions and in

conformity with local codes, or in the absence of

local codes, with the National Plumbing Code

and the National Electric Code, current edition.

In any case where instructions in this manual

differ from local or national codes, the local or

national codes take precedence.

SECURITY CONSIDERATIONS

Domestic and commercial installations have a

maximum design operating pressure limited to

30 psi by a safety relief valve.

Boiler maximum operating temperature is 190°F

by design. This boiler is designed to be used

only in a hot water heating system.

CAUTION

!

The heat transfer medium must be water or

other non-toxic fluid having a toxicity rating

or class of 1, as listed in clinical Toxicology

of Commercial products, 5

th

edition

LOCATION

The electric boiler should be installed in a clean,

dry location. Long hot water lines should be

insulated to conserve water and energy. The

electric boiler and water lines should be

protected from exposure to freezing

temperature.

The electric boiler must be installed horizontally

directly on the wall. Use the hanging brackets

for leveling the unit The electric boiler must be

located or protected so as not to be subject to

physical damage, for example, by moving

vehicles, area flooding, etc. All models can be

installed on combustible floors and in alcoves.

Ambient temperature must not exceed 80°F.

CLEARANCE

For adequate inspection and servicing the

following minimum clearance is necessary:

Right side 2 inches

Left side 14 inches

Top & Bottom of the boiler 6 inches

Front side of the boiler 24 inches

Back side of the boiler 1 inch

CAUTION

!

The electric boiler should not be located in

an area where leakage of the tank or water

connections will result in damage to the

adjacent area or to lower floors of the

structure. When such areas cannot be

avoided, a suitable drain pan or nonflammable catch pan, adequately drained,

and must be installed under the boiler.

The pan must be connected to a drain.

NOTE: Auxiliary catch pan MUST conform to

local codes.

BTH Electric Boilers USE & CARE MANUAL (Revision August /06), Page 4.

CORROSIVE ATMOSPHERE

The electric boiler should not be located near an

air vent blowing a corrosive atmosphere or high

humidity. The limited warranty is void when the

failure of the electric boiler is due to a corrosive

atmosphere.

CHECK LIST

Please check the identification tag on the unit to

make sure you have the right model.

List of components shipped with the unit :

• Pressure relief valve set at 30 PSI.

• Drain valve.

• Tridicator (temperature & pressure

gage).

SHIPMENT INSPECTION

Inspect the electric boiler for possible shipping

damage. The manufacturer’s responsibility

ceases upon delivery of goods to the carrier in

good condition. Consignee must file any claims

for damage, shortage in shipments, or nondelivery immediately against carrier.

BTH Electric Boilers USE & CARE MANUAL (Revision August /06), Page 5.

Installation

The manufacturer’s warranty does not cover

any damage or defect caused by installation,

or attachment, or use of any special

attachment other than those authorized by the

manufacturer into, onto, or in conjunction with

the water heater. The use of such

unauthorized devices may shorten the life of

the boiler may endanger life and property. The

manufacturer disclaims any responsibility for

such loss or injury resulting from the use of

such unauthorized devices

WIRING

Wiring must conform to the National Electrical

Code and to state or local code requirements.

The electric boiler must be electrically grounded in

accordance with local codes, or, in the absence of

local codes, with the National Electrical Code.

240Vac models

Wiring must be from a 240 Volt (single phase, 60

Hz) circuit protected by a properly sized breaker.

Wire gage (3 wires, ground) must be properly

sized. Consult the boiler rating plate to select the

proper breaker and wire gage.

600Vac models

Line wiring must be from a 600 Volt ( 3 phase, 60

Hz) circuit protected by a properly sized breaker.

Wire gage (3 wires, ground) must be properly

sized. Consult the boiler rating plate to select the

proper breaker and wire gage.

Circulator zoning wiring

Components must be wired to ensure that only the

circulator corresponding to the zone calling for

heat is actuated.

Zone valve zoning wiring

Connect the low voltage thermostat to the zone

valve. Components must be wired to ensure that

only the zone valve corresponding to the zone

calling for heat is actuated and that the circulator

is powered on a demand from any zone. The

transformer used to power the zone valves must

be sized for the load represented by all zone

valves in the heating system.

WARNING

!

BOILER WATER CONNECTIONS

This electric boiler may be connected individually

or in parallel with other boilers. If two or more

boilers are connected, the “reverse-return piping”

method (whereby the boiler with the first return

inlet also has the last supply outlet and so forth

until the last return inlet corresponds to the first

supply outlet) should be used to connect the

boilers in parallel, to ensure an equal water flow

rate through each boiler.

The boiler water supply, located on the top side,

and the boiler water return, located on the bottom

side of the boiler are steel pipes (male NPT

threaded connection) where supply and return line

connections are to be made.

Installing a union is recommended on the boiler

water supply and return lines to facilitate boiler

disconnection for servicing.

Dielectric unions are required for protection of the

boiler and piping if dissimilar pipe material such as

galvanized steel and copper are present.

Use only clean, new piping for boiler water lines.

Local codes or regulations shall govern the exact

type of material to be used.

Insulate all pipes containing hot water, especially

in unheated areas.

Install shutoff (ball) valves for servicing

convenience. Thermometer(s) should be installed

on the boiler water supply and return lines.

Cap or plug unused connections on the boiler. Do

not cap the pressure relief valve on the boiler

since it will damage and shorten the life of the

boiler and may endanger life and property.

Flow check valve

If the heating system includes a single pump, then

to minimize flow by gravity and heat loss during

non-draw periods, a flow check valve must

installed.

be

Pressure relief valve

An automatic pressure relief valve must be

installed during boiler setup. The pressure rating

of the relief valve must not exceed 30 psi. The

safety relief valve must meet the requirements of

BTH Electric Boilers USE & CARE MANUAL (Revision August /06), Page 6.

the ASME Boiler and Pressure Vessel Code and

limit the maximum operating boiler pressure. It is

a safety device, not an operating control.

The BTU per hour rating of the relief valve must

equal or exceed the BTU per hour input of the

boiler(s) or heat source(s) as marked on the

boiler(s) rating plate.

Connect the outlet of the relief valve to a

discharge line with its lower tip at most 6” above a

floor drain, well clear of any live electrical parts.

The discharge line must pitch downward from the

valve to allow complete draining by gravity of the

relief valve and discharge line, and be of a

diameter no smaller than that of the valve outlet.

The tip of the discharge line should not be

threaded or concealed and should be protected

from freezing. No valve of any type, restriction or

reducer coupling should be installed on the

discharge line. Local codes shall govern the

installation of relief valves.

SYSTEM PRESSURE CONTROL

Expansion tank

Pressure control devices within the system ensure

that each component operates within minimum

and maximum allowable pressures and maintain

minimum pressure for all normal operating

temperatures. They also allow air bleeding,

prevent cavitation at the pump inlet and prevent

water from boiling within the system; all this is

accomplished with minimal addition of new water.

The increase in boiler water volume resulting from

higher temperature is stored in the expansion tank

during periods of high operating temperature and

is returned to the system when the temperature

decreases.

The expansion tank must be able to store the

required volume of boiler water during maximum

design operating temperature without exceeding

the maximum allowable operating pressure, and

to maintain the required minimum pressure when

the system is cold. Contact your installing

contractor, plumbing supply house, or local

plumbing inspector for assistance.

The point where the expansion tank is connected

should be carefully selected to avoid the

possibility that normal operation of automatic

check or manual valves will isolate the tank from a

hot boiler or any part of the system. Pre-charged

diaphragm expansion tanks are preferable to air

control.

These tanks incorporate a balloon-like bladder or

diaphragm. It is inflated, prior to filling the system,

to a pressure equal to the setting of the water

pressure makeup regulator.

The expansion tank should be located on the

suction or intake side of the pump. The pump can

be located either just upstream or just

downstream from the boiler.

BTH Electric Boilers USE & CARE MANUAL (Revision August /06), Page 7.

Water pressure makeup regulator

Make-up systems must be employed as required

by codes. An automatic fill valve must be used

with a backflow preventer as required, to maintain

minimum system pressure by supplying water to

make up for leakage.

Air bleeder

Oxygen should be excluded from the system to

prevent corrosion. As mentioned in the expansion

tank paragraph above, this precludes the use of

air in direct contact with the boiler water as a

pressurization means.

Installation of manual or automatic air vent

devices prevents air from accumulating in the

system. Air vents should be installed at all high

points to remove trapped air during initial setup

and to ensure that the system is tight. Regularly

purge the air out of the system while taking care to

avoid personal injuries or property damage

caused by hot boiler water spray.

Circulator zoning recommendations

The preferred location of the circulator pump for

each zone is on the boiler supply side, with the

expansion tank between the boiler and the pump.

A flow check valve must be installed in each zone,

preferably on the outlet side of each circulator

pump, to prevent water flow to other zones where

no heat is required.

Zone valve zoning recommendations

The preferred location of the circulator pump is on

the boiler supply side, with the expansion tank

between the boiler and the circulator. Use zone

valves with low pressure drop.

Dual energy installation

In order to obtain a special rate from your electric

utility for residential use, your BTH boiler can be

hooked-up to an existing oil heater. Contact your

electric utility to find out if your property is eligible

for such rates and how to register for them.

The CBE-EM dual-energy control (an available

option, three-way, motorized valve (1’’ NPT F

standard) included) is specially designed to

electric utility standards. The CBE-EM control

selects the least expensive energy source based

on outside temperature, user choice or a signal

from your utility.

The CBE-EM dual-energy control will start up the

oil burner upon receiving the appropriate signal,

even if the thermostat in the house is not calling

for heat. It will shut off when the temperature in

the boiler reaches its target on the Limit Control. It

is for this reason that the piping requires an antigravity valve (flow check valve) or motorized zone

valves.

A three-way, motorized valve (1’’ NPT F standard)

will direct the water flow either to the oil-fired

heater or to your DTH electric boiler, depending

on the signal received. This way, your oil heater

will cool down and eliminate any energy loss,

either through the chimney or by way of

conduction in the boiler room.

BTH Electric Boilers USE & CARE MANUAL (Revision August /06), Page 8.

Loading...

Loading...