Page 1

OPERATING AND SERVICE MANUAL

AC-4000 CONTROLLER

WAREHOUSE APPLICATION

REC 3838 REV G 10/05

PART NO. 045848

Page 2

REVISION HISTORY

REVISION A DECEMBER 1993

REVISION B APRIL 1994

REVISION C AUGUST 1995

REVISION D NOVEMBER 1995

REVISION E APRIL 1999

REVISION F SEPTEMBER 2000

REVISION G OCTOBER 2005

COPYRIGHT 1993, 1994, 1995, 1999 BY THERMO ELECTRON, INC

THIS DOCUMENT IS CONFIDENTIAL AND IS THE PROPERTY OF THERMO ELECTRON IT

MAY NOT BE COPIED OR REPRODUCED IN ANY WAY WITHOUT THE EXPRESS WRITTEN

CONSENT OF THERMO. THIS DOCUMENT ALSO IS AN UNPUBLISHED WORK OF THERMO.

THERMO INTENDS TO AND IS MAINTAINING THE WORK AS CONFIDENTIAL INFORMATION.

THERMO ALSO MAY SEEK TO PROTECT THIS WORK AS AN UNPUBLISHED COPYRIGHT.

IN THE EVENT OF EITHER INADVERTENT OR DELIBERATE PUBLICATION, THERMO

INTENDS TO ENFORCE ITS RIGHTS TO THIS WORK UNDER THE COPYRIGHT LAWS AS A

PUBLISHED WORK. THOSE HAVING ACCESS TO THIS WORK MAY NOT COPY, USE OR

DISCLOSE THE INFORMATION IN THIS WORK UNLESS EXPRESSLY AUTHORIZED BY

THERMO.

PLEASE READ AND OBSERVE THE FOLLOWING SAFETY

PRECAUTIONS FOUND THROUGHOUT THIS MANUAL.

DANGER

FAILURE TO OBSERVE WILL CAUSE VERY SERIOUS PERSONAL INJURY OR DEATH.

WARNING

FAILURE TO OBSERVE COULD CAUSE SERIOUS PERSONAL INJURY.

CAUTION

FAILURE TO OBSERVE MAY CAUSE MINOR OR MODERATE PERSONAL INJURY

OR DAMAGE TO THE EQUIPMENT.

REC 3838 II

Page 3

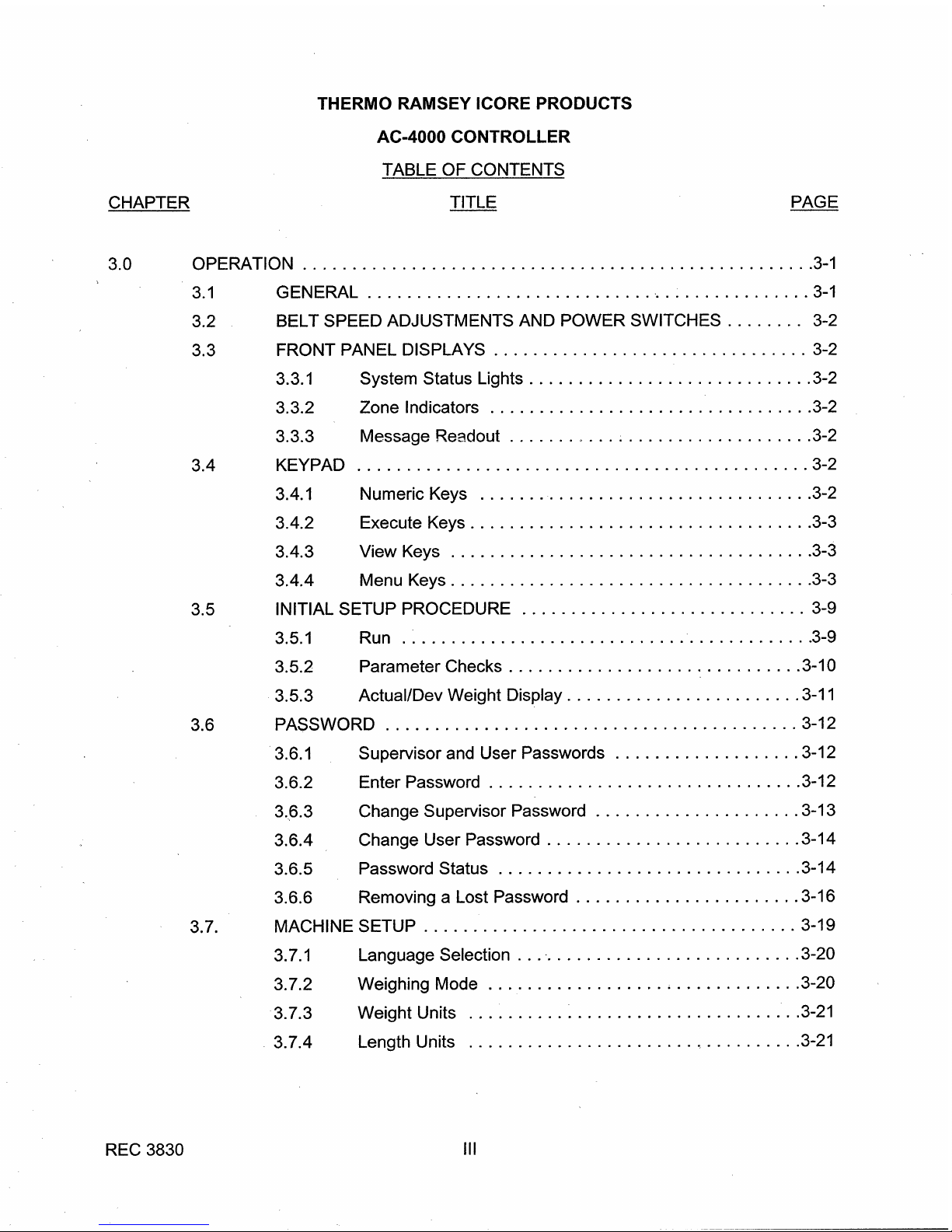

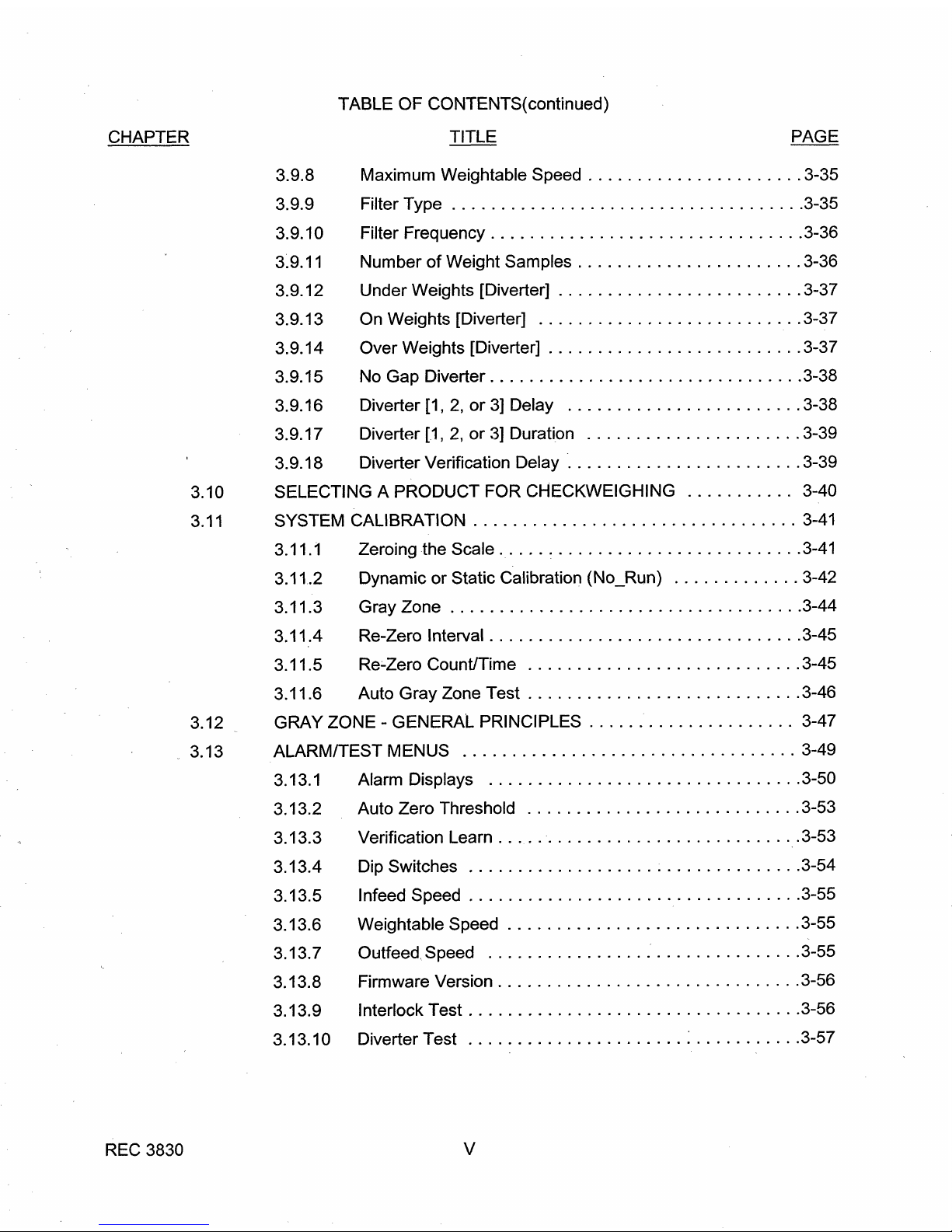

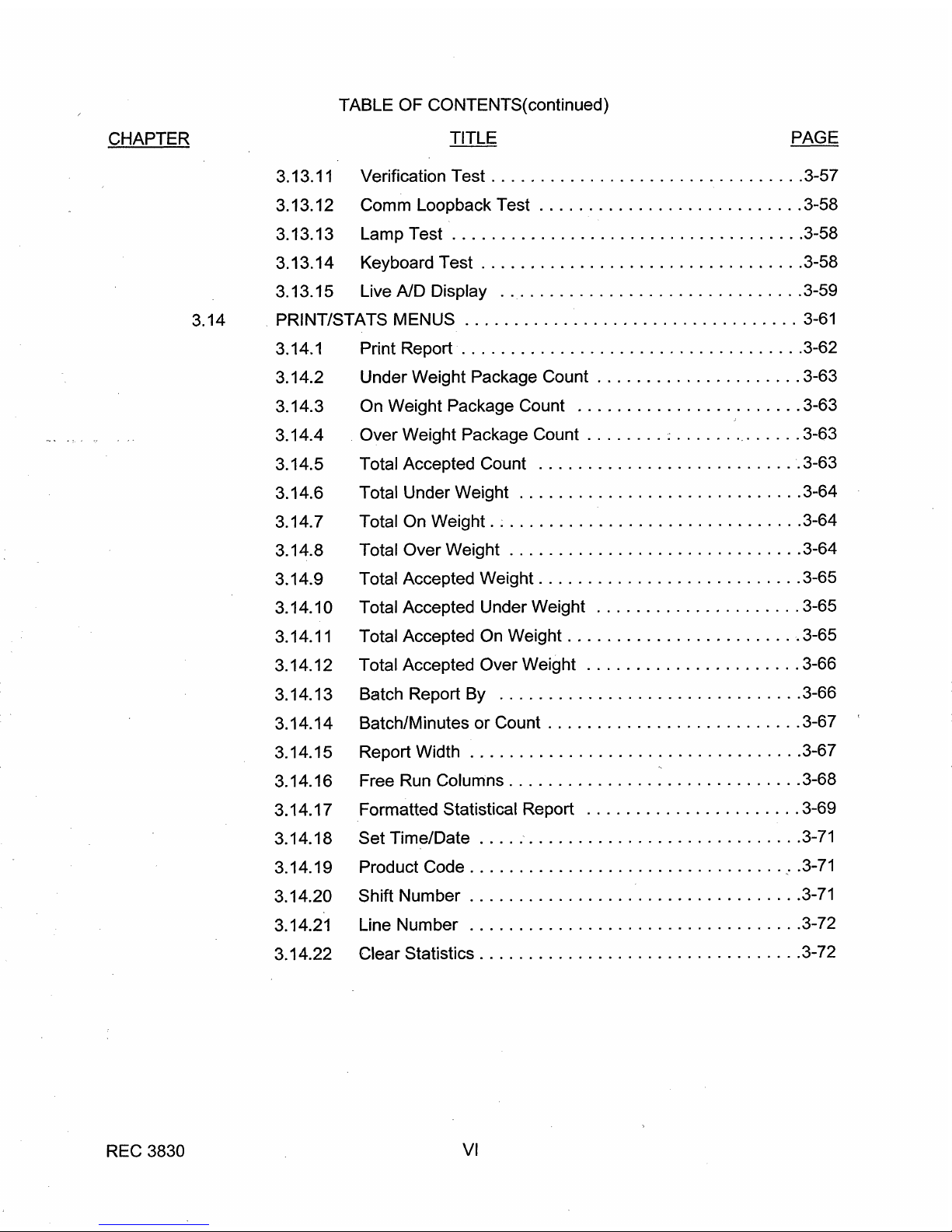

ICORE PRODUCTS

AC-4000 ELECTRONICS

TABLE OF CONTENTS

CHAPTER TITLE PAGE

1.0 INTRODUCTION ................................................. 1-1

1.1 GENERAL DESCRIPTION ................................ 1-1

1.1.1 Applications ....................................1-1

1.1.2 System Description ..............................1-1

1.1.3 Operation......................................1-1

1 . 1 . 4 F e a ture s ......................................1-3

1.2 OPTIONS ............................................. 1-3

1.2.1 15 Programmable Product Set-Ups . . . . . . . . . . . . . . . . . . 1-3

1.2.2 Communications (COM) ..........................1-3

1.3 WARRANTY .................. .. ....................... 1-6

2 . 0 I N S T ALLATI O N .................................................. 2-1

2.1 GENERAL ............................................. 2-1

2.2 SAFETY PRECAUTIONS ................................. 2-1

2.2.1 Occupational Safety and Health Act (OSHA) . . . . . . . . . . . 2-2

2.3 STORAGE............................................. 2-2

2.4 UNCRATING & INSPECTION .............................. 2-2

2.5 EQUIPMENT LOCATION ................................. 2-3

2.6 INSTALLATION .......................... ............... 2-4

2.6.1 Initial Power On .................................2-4

3.0 OPERATION .............. ...................................... 3-1

4 . 0 M A I N T E NA NCE.................................................. 4-1

4.1 GENERAL ............................................. 4-1

4.2 SERVICE & REPAIR ..................................... 4-1

4.3 COMPONENT REPLACEMENT PROCEDURES (ELECTRICAL) . . . 4-1

4.3.1 Display Board Assembly Replacement . . . . . . . . . . . . . . . 4-1

4.3.2 Display Module Replacement . . . . . . . . . . . . . . . . . . . . . . 4-2

REC 3838 III

Page 4

TABLE OF CONTENTS

(continued)

CHAPTER TITLE PAGE

4.3.3 Communications Board Replacement . . . . . . . . . . . . . . . . 4-4

4.3.4 CPU Board Replacement..........................4-4

4.3.5 Analog Board Replacement . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.3.6 Distribution Board Replacement . . . . . . . . . . . . . . . . . . . . 4-7

4.3.7 Front Panel Replacement . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4.3.8 Motor Speed Control Module Replacement . . . . . . . . . . . 4-11

4.3.9 Cold Start Procedure ............................4-11

4.4 TROUBLESHOOTING .................................. 4-13

5.0 REPLACEMENT PARTS ........................................... 5-1

5.1 GENERAL .......................... ................... 5-1

5.2 ORDER INFORMATION .................................. 5-1

5.3 PARTS LIST INDEX ..................................... 5-2

5.3.1 Return Material Authorization . . . . . . . . . . . . . . . . . . . . . . . 5-3

6.0 AC-4000 OPTIONS ............................................... 6-1

6.1 VARIABLE SPEED ...................................... 6-1

6.1.1 Installation ........................ .............6-1

6.2 COMMUNICATIONS .................................... 6-2

6.2.1 Installation .....................................6-2

6.2.2 External Communication Cabling . . . . . . . . . . . . . . . . . . . . 6-4

6.2.3 Interconnect Information . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6.3 MULTIPLE PRODUCT.................................... 6-7

6.3.1 Installation ........................ .............6-7

6.4 MOTOR INHIBIT ........................................ 6-8

REC 3838 IV

Page 5

LIST OF ILLUSTRATIONS

FIGURE NO. TITLE PAGE

1-1 AC-4000 Electronics ............................................. 1-0

1-2 System Block Diagram ........................................... 1-2

2-1 Input Power Connections.......................................... 2-4

2-2 Analog Board................................................... 2-5

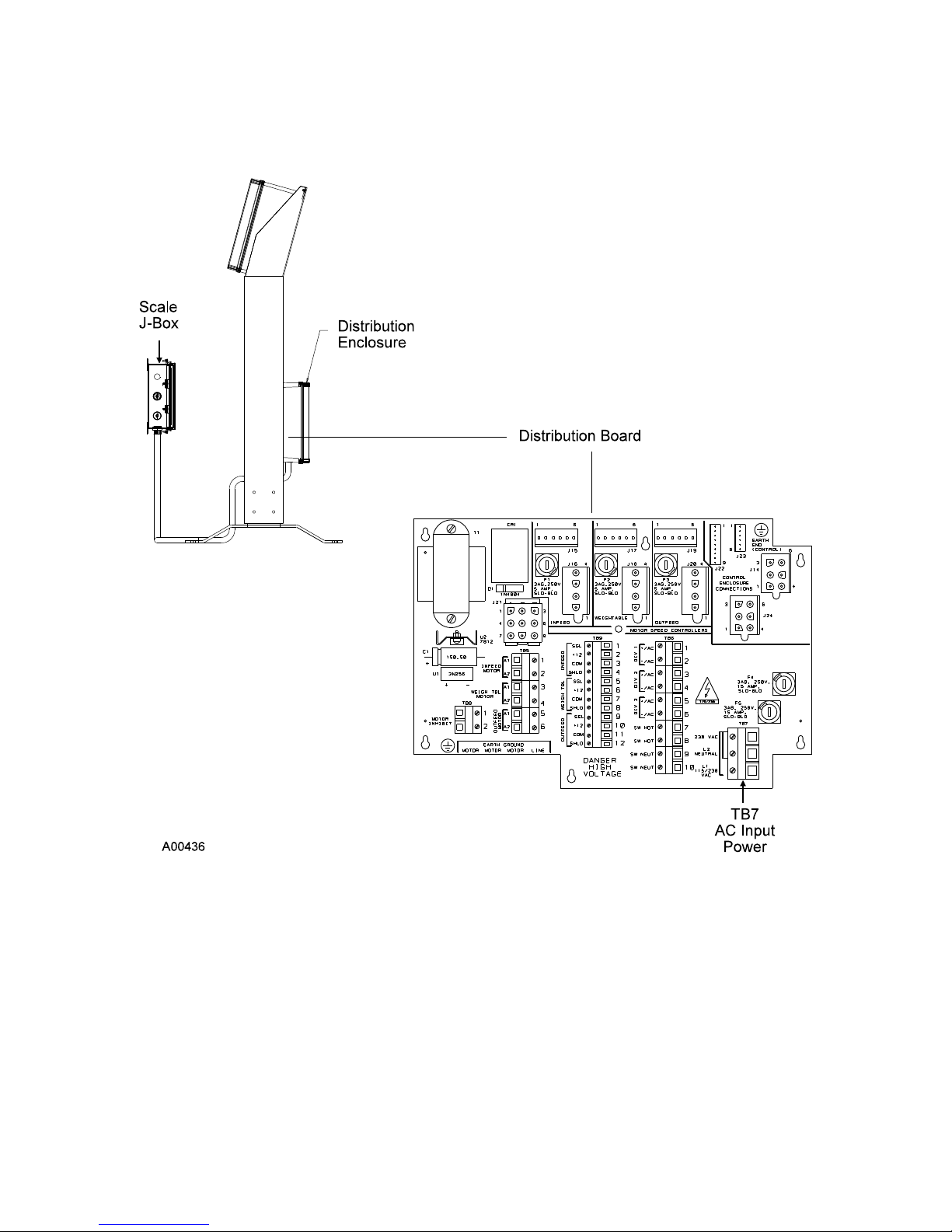

2-3 Distribution Board ............................................... 2-6

4-1 Display Board Assembly/Module Replacement . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4-2 Communications, CPU and Analog Board Replacement . . . . . . . . . . . . . . . . . . 4-6

4-3 Distribution Board Replacement .................................... 4-8

4-4 Distribution Board with Options ..................................... 4-8

4-5 Front Panel Replacement ......................................... 4-10

6-1 Communications Board Dip Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6-2 RS-232 Connections ............................................. 6-4

6-3 RS-485 Connections ............................................. 6-5

LIST OF TABLES

TABLE NO. TITLE PAGE

1-1 Technical Specifications .......................................... 1-4

4-1 Troubleshooting Procedures ....................................... 4-13

4-2 Power Troubleshooting Procedure................................... 4-18

5-1 AC-4000 Electronics (Remote or Local) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

6-1 Variable Speed Option............................................ 6-1

6-2 Communications Option .......................................... 6-3

6-3 Interconnect Terminations ......................................... 6-6

6-4 Multiple Project Option............................................ 6-7

REC 3838 V

Page 6

APPENDIX

NO. TITLE DRAWING NO.

A/1 Field Wiring Diagram .................................. Engineer

Selected

A/2 Interconnect Wiring Diagram ............................ D07226K-E079

A/3 CPU Board Schematic................................. D07226K-E004

A/4 Analog Board Schematic ............................... D07226K-E014

A/5 Display Board Schematic ............................... D07226K-E024

A/6 Communications Board Schematic . . . . . . . . . . . . . . . . . . . . . . . D07226K-E034

A/7 Distribution Board Schematic............................ C07226K-E054

SUPPLEMENTAL MANUALS

TITLE DOCUMENT NO.

Minarik Adjustable Speed Control, Model MM 2300 . . . . . . . . . . . MC-3

REC 3838 VI

Page 7

PREFACE

This manual contains information necessary to install, operate, and service the Thermo AC4000 Electronics (see Figure 1-1).

All persons concerned with the operation and servicing of the electronics should read the

contents of this manual carefully and thoroughly. Keep this manual in a convenient place and

refer to it often, as it is an important tool in performing proper service.

Information in this manual is presented as follows:

Chapter 1.0, INTRODUCTION, presents a brief description of the electronics' capabilities,

operation, features, options specifications and warranty.

Chapter 2.0, INSTALLATION, outlines site preparation operating requirements, and installation

instructions.

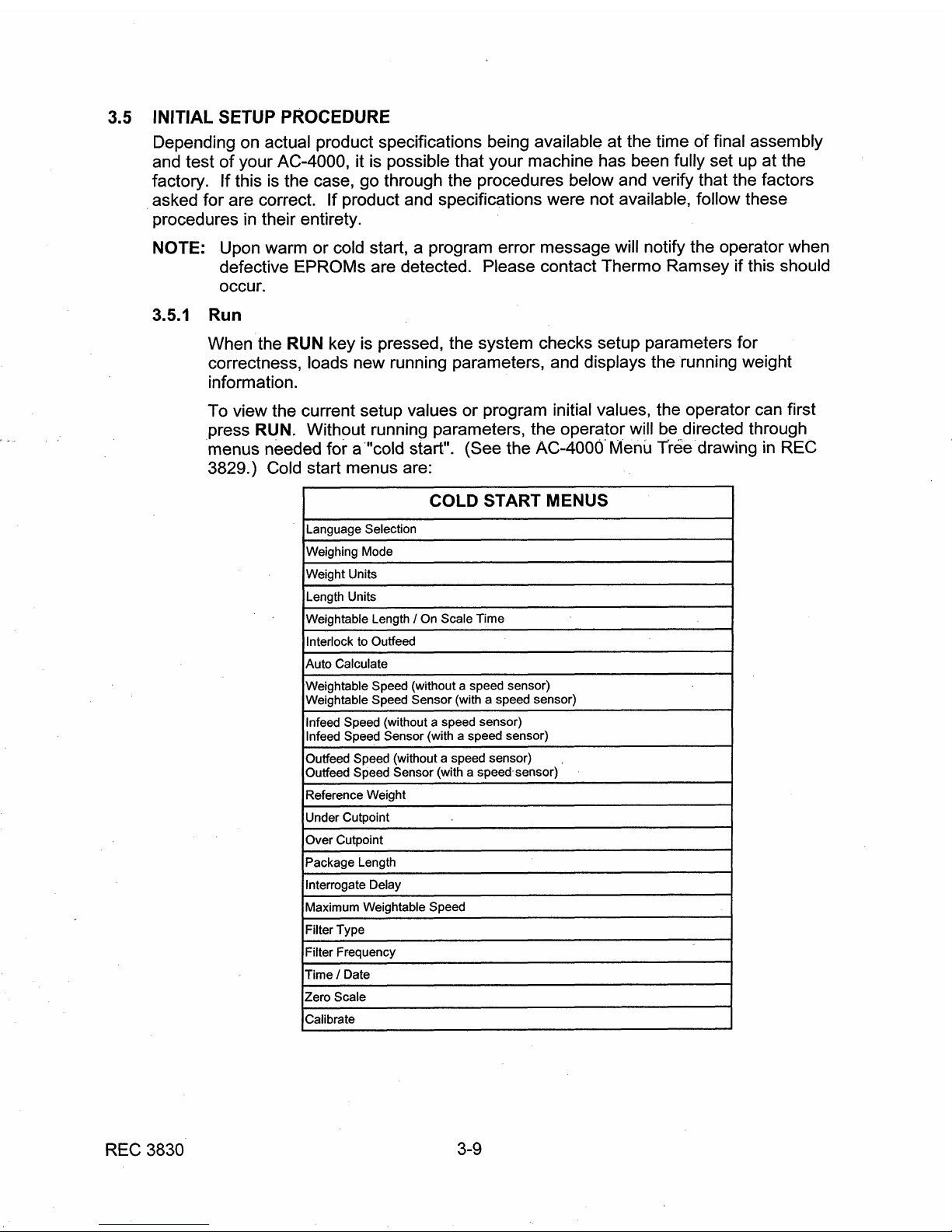

Chapter 3.0, OPERATION, explains the operating controls and procedures.

Chapter 4.0, MAINTENANCE, includes troubleshooting, electronic checkout, and maintenance

procedures.

Chapter 5.0, REPLACEMENT PARTS, provides ordering information and replaceable parts list.

Chapter 6.0, OPTIONS, contains information about optional equipment.

The APPENDIX contains assembly, installation, and wiring drawings.

IMPORTANT

Do not turn the equipment on or attempt to operate the electronics until you have read and

understood Chapter's 2.0 and 3.0. Improper operation of the electronics may result in damage

to the machine.

REC 3838 VII

Page 8

REC 3838 1-0

AC-4000 ELECTRONICS

FIGURE 1-1

Page 9

CHAPTER 1.0

INTRODUCTION

1.1 GENERAL DESCRIPTION

The AC-4000 Electronics System is a high accuracy machine. When combined with a

weighing frame, it performs weight inspection of individual product packages in a

production process or package line. The AC-4000 and a weighing frame perform these

functions without interrupting product flow.

1.1.1 Applications

Typical applications for the AC-4000 Electronics System are the in-motion

weighing of:

Frozen food, bakery, confectionery, meat, and any canned or packaged goods.

Detergents, chemicals, pharmaceutical, and any bottled liquid products.

Manufactured products such as rubber, plastic, metal parts, multi-component parts

packages, and count-by-weight packages.

1.1.2 System Description

The AC-4000 Electronics System consists of:

A microprocessor-based electronic system with filtering and amplification circuitry

to interpret the signal from a loadcell. The electronics enclosure houses the CPU,

A/D and display boards.

A front panel keypad and vacuum fluorescent display. The digital keypad is used

to enter set-up parameters. The display presents weight.

1.1.3 Operation

Upon installation, certain data must be entered into the AC-4000 electronics. The

AC-4000's front panel is designed to simplify set-up and operation of a machine.

All data is entered digitally, using the keyboard buttons on the front panel. The

operator is assisted in set-up by the fluorescent displays that show what data to

enter.

During operation, the package is transported by a conveying medium (such as

chains or belts) across a weightable. The loadcell supporting a weightable

produces an electronic signal proportional to the package weight. As the package

interrupts a beam from a photocell sensor (interlock), the gross weight of the

package is computed by the AC-4000 electronics.

The AC-4000 displays the weight of the package in grams, kilograms, ounces or

pounds.

REC 3838 1-1

Page 10

REC 3838 1-2

SYSTEM BLOCK DIAGRAM

FIGURE 1-2

Page 11

1.1.4 Features

The AC-4000 Electronics System has the following standard features:

1. Auto Zero and Manual Zero

The electronics automatically compensate for minor buildup on the weightable

by rezeroing the weightable between packages. Manual zero allows the

rezeroing of the weightable at the operator's discretion.

2. Automatic Self-Diagnostics

This feature continually monitors system operation and assures that

everything is operating properly.

3. Digital Filter

During set-up, filter parameters are selected for individual products using the

front panel keyboard. This exclusive feature improves the weighing accuracy

by providing the best filter setting for each product.

4. Password Protection

This feature provides protection against an unauthorized change in set-up

parameters and access to certain data.

5. Permanent Data Storage

An EEPROM retains set-up information and stores accumulated data.

6. 32-Bit Microprocessor

This large memory capacity increases the flexibility of the AC-4000 and allows

it to handle a broader range of applications.

7. Corrosion Resistant Finish

All exposed metal parts on the AC-4000 Electronics System are either

stainless steel or painted mild steel.

8. 20 bit analog to digital converter (A/D) for loadcell signal.

1.2 OPTIONS

Electronics can be remote or local, and numerous options are available to transform the

AC-4000 from a low-cost, basic electronics into a sophisticated tool for monitoring

productivity and packaging line performance. These options include the following:

1.2.1 15 Programmable Product Set-Ups

The set-up parameters for 15 products can be preset into the electronics. The

AC-4000 can then be switched from one product to another in a matter of

seconds.

1.2.2 Communications (COM)

Provides for communication of weight or statistical information from the AC-4000

to a printer, CRT, or host computer.

REC 3838 1-3

Page 12

TABLE 1-1

TECHNICAL SPECIFICATIONS - AC-4000 ELECTRONICS

Package Rate To 350 PPM

Accuracy:

Displayed Resolution ±1, ±0.1, or ±0.01 Units

Zeroing Automatic self zeroing between packages.

REZERO light turns on if an autozero cannot occur

within two minutes.

Environment:

Electrostatic Discharge

Temperature

Humidity

5000 V

14° to 122°F (-10° to +50°C)

0% to 95%

Electrical:

Standard

100-130/200-250 VAC, 50/60 Hz, 300 VA

Neutral to Ground

Maximum Voltage

140 Volt AC

REC 3838 1-4

Page 13

TABLE 1-1

TECHNICAL SPECIFICATIONS - (Continued)

REC 3838 1-5

Page 14

1.3 WARRANTY

Thermo Electron

WARRANTY

The seller agrees, represents, and warrants that the equipment delivered hereunder shall be free

from defects in material and workmanship. Such warranty shall not apply to accessories, parts,

or material purchased by the seller unless they are manufactured pursuant to seller's design, but

shall apply to the workmanship incorporated in the installation of such items in the complete

equipment. To the extent purchased parts or accessories are covered by the manufacturer's

warranty, seller shall extend such warranty to buyer.

Seller's obligation under said warranty is conditioned upon the return of the defective equipment,

transportation charges prepaid, to the seller's factory in Minneapolis, Minnesota, and the

submission of reasonable proof to seller prior to return of the equipment that the defect is due to

a matter embraced within seller's warranty hereunder. Any such defect in material and

workmanship shall be presented to seller as soon as such alleged errors or defects are discovered

by purchaser and seller is given opportunity to investigate and correct alleged errors or defects and

in all cases, buyer must have notified seller thereof within one (1) year after delivery, or one (1)

year after installation if the installation was accomplished by the seller.

Said warranty shall not apply if the equipment shall not have been operated and maintained in

accordance with seller's written instructions applicable to such equipment, or if such equipment

shall have been repaired or altered or modified without seller's approval; provided, however, that

the foregoing limitation of warranty insofar as it relates to repairs, alterations, or modifications, shall

not be applicable to routine preventive and corrective maintenance which normally occur in the

operation of the equipment.

"EXCEPT FOR THOSE WARRANTIES SPECIFICALLY CONTAINED HEREIN, SELLER

DISCLAIMS ANY AND ALL WARRANTIES WITH RESPECT TO THE EQUIPMENT DELIVERED

HEREUNDER, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR USE. THE SOLE LIABILITY OF SELLER ARISING OUT OF THE WARRANTY

CONTAINED HEREIN SHALL BE EXCLUSIVELY LIMITED TO BREACH OF THOSE

WARRANTIES. THE SOLE AND EXCLUSIVE REMEDY FOR BREACH OF THE WARRANTIES

SET OUT ABOVE SHALL BE LIMITED TO THE REPAIR OR REPLACEMENT OF ANY

DEFECTIVE ACCESSORY, PART OR MATERIAL WITH A SIMILAR ITEM FREE FROM DEFECT,

AND THE CORRECTION OF ANY DEFECT IN WORKMANSHIP. IN NO EVENT SHALL SELLER

BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES."

FIELD SERVICE

Purchaser agrees to underwrite the cost of any labor required for replacement; including time,

travel, and living expenses of Thermo Field Service Engineer at closest factory base.

Thermo Electron

501 90th Avenue N.W.

Minneapolis, MN 55433

Phone: (612) 783-2500

Fax: (612) 783-2525

REC 3838 1-6

Page 15

CHAPTER 2.0

INSTALLATION

2.1 GENERAL

The customer is responsible for initial inspection of the equipment and site preparation. It

is essential that the equipment be placed on the production line in accordance with the

guidelines set forth in this section. The customer must ensure that qualified personnel are

available to make interconnections with other production equipment and perform work at

the installation site. An Thermo Products Customer Service representative is available to

supervise installation and verify operation as well as train personnel assigned to operate

and maintain the equipment.

2.2 SAFETY PRECAUTIONS

IMPORTANT

Do not install, operate, or perform any maintenance procedures until you have read the

safety precautions presented below.

1. Do not connect power to the machine or turn on the unit until you have read and

understood this entire manual. The precautions and procedures presented in this

manual must be followed carefully in order to prevent equipment damage and

protect the operator from possible injury.

2. CAUTION! Hands and clothing must be kept away from all moving or rotating

parts.

3. WARNING! Covers over the electronics, or rotating parts should always remain in

place during operation. They should be removed only for maintenance procedures

with the machine's power OFF. Be sure to replace all covers before resuming

operation.

4. WARNING! All switches (control, motor, power, etc., as applicable) must be OFF

when checking input AC electrical connections, removing or inserting printed circuit

boards, or attaching voltmeters to the system.

5. Incoming voltages must be checked with a voltmeter before being connected to the

machine. Pay special attention to the red tag attached to the machine that

stipulates the correct input voltage for your particular unit.

6. WARNING! Extreme caution must be used in testing in, on, or around the

electronics cabinet, PC boards, or modules. There are voltages in excess of 115 V,

230 V, or 440 V in these areas. Avoid high voltage and static electricity around the

printed circuit board.

7. CAUTION! Do not leave insulating material over the machine for any length of time

or the machine will overheat. The specified maximum ambient temperature is not to

be exceeded for more than 5 minutes.

8. Maintenance procedures should be performed only by qualified personnel and in

accordance with procedures/instructions given in this manual.

9. During maintenance, a safety tag (not supplied by Thermo) should be displayed in

the ON/OFF switch areas as a precaution instructing others not to operate the unit

(ANSI:B157.1).

REC 3838 2-1

Page 16

10. Only qualified electricians should be allowed to open and work in the electronics

cabinets, power supply cabinets, control cabinets, or switch boxes.

11. Objects of any kind should never be placed or stored on the machine.

12. This equipment should not be operated at more than the specified production rate

nor utilized in applications other than those stated in the original order. (To adapt

production rates or applications, consult Thermo Products Customer Service for

recommendations.)

13. All panels and doors covering the electronics must be in place and tight before

conducting washdown. Damage to the electronics could result from water,

moisture, or contamination in the electronics housing.

14. Harsh chemicals, caustics, disinfectants, etc., should never be added to washdown

solutions.

15. Infeed and outfeed conveyors and transfer assemblies should be mounted and/or

positioned so clearance is maintained between moving parts. Check to ensure

weighing or infeed/outfeed conveyor(s) are clear of debris before turning the drive

motor ON.

2.2.1 Occupational Safety and Health Act (OSHA)

The Occupational Safety and Health Act clearly places the burden of compliance

on the user of the equipment and the act is generalized to the extent that

determination of compliance is a judgement decision on the part of the local

inspection. Hence Thermo Electron will not be responsible for meeting the full

requirements of OSHA in respect to the equipment supplied or for any penalty

assessed for failure to meet the requirements, in respect to the equipment

supplied, of the Occupational Safety and Health Act, as interpreted by an

authorized inspector. Thermo Electron will use their best efforts to remedy such

violation at a reasonable cost to the buyer.

2.3 STORAGE

If you are not going to install the electronics system now, it can be safely stored at

temperatures from -40° F (-40° C) to +158° F (+70° C). All components should be

protected against moisture.

2.4 UNCRATING & INSPECTION

The electronics system has been properly packaged for shipment. Inspect all packages

for damage before opening as often times the carrier may be responsible for shipping

damage.

1. Inspect the electronics for shipping damage.

2. Remove the poly covering from the electronics.

3. Cut the nylon shipping bands securing the electronics to pallet.

4. Lift the electronics and pedestal off the pallet.

REC 3838 2-2

Page 17

2.5 EQUIPMENT LOCATION

Careful consideration should be given to the location of the electronics, as system

performance is affected by its location. The following requirements must be followed.

1. The electronics should be located so maintenance personnel can easily perform

cleaning and adjustment procedures, and so both the control panel and electronics

enclosure rear doors are easily accessible. This requires clear space behind and in

front of the machine.

2. There should be a minimum of vibration in the area. Vibrations can be conducted to

a loadcell and affect weighing accuracy.

3. The electronics system is designed to operate in an environment where the

temperature ranges no lower than -14° F (-10° C) nor higher than 122° F (50° C).

4. The electronics will operate in an environment where the humidity (non-condensing)

ranges from 0% to 95%.

REC 3838 2-3

Page 18

2.6 INSTALLATION

The procedures given below provide for installing the electronics in your production line.

2.6.1 Initial Power On

The initial power on procedures describe the checks to be performed before the

initial system setup procedures are performed.

1. Verify that the fuses on the Analog Board (Figure 2-2) and Distribution Board

(Figure 2-3) inside the controller enclosure are correct for the AC input

voltage. The following lists define the correct fuses.

REC 3838 2-4

INPUT POWER CONNECTIONS

FIGURE 2-1

Page 19

ANALOG BOARD

FUSE 115VAC 220VAC

F1 (for electronics) 3/8A, 3AG, SB 3/16A, 3AG, SB

F2 (for line [L2]) 10A, 3AB, SB 10A, 3AB, SB

REC 3838 2-5

ANALOG BOARD

FIGURE 2-2

Page 20

DISTRIBUTION BOARD

FUSE 115VAC/220VAC

F1 (for infeed motor) 5A, 3AG, SB

F2 (for weightable motor) 5A, 3AG, SB

F3 (for outfeed motor) 5A, 3AG, SB

F4 (for line [L1]) 15A, 3AB, SB

F5 (for line [L2]) 15A, 3AB, SB

REC 3838 2-6

DISTRIBUTION BOARD

FIGURE 2-3

Page 21

2. Verify that switch SW-2 on the Analog Board is set to the correct AC input

voltage.

3. Verify that the dip switches on the Analog Board are correct for your

configuration. The following list defines the standard switch settings for the

Analog Board, if the specific options noted are installed. (For options see

Chapter 6.0.)

ANALOG BOARD DIP SWITCHES

SWITCH POSITION DESCRIPTION

SW1-1 OFF/OPEN

ON/CLOSED*

SW1-2 OFF/OPEN

ON/CLOSED*

SW1-3 OFF/OPEN*

ON/CLOSED

SW1-8 ON/CLOSED*

OFF/OPEN

Reserved.

Switch must be in this position.

Standard weightable speed sensor.

No weightable speed sensor.

Optional infeed with speed sensor.

No infeed speed sensor.

Normal Run position.

Remove forgotten password.

Others OFF/OPEN Not Used

*Default position.

4. Turn the front panel CONVEYOR POWER switch ON and verify that the belt

(chains) are running.

5. Turn the ELECTRONICS POWER switch ON and let the electronics warm up.

REC 3838 2-7

Page 22

This page intentionally left blank

Page 23

Page 24

This page intentionally left blank

Page 25

Page 26

This page intentionally left blank

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

This page intentionally left blank

Page 33

Page 34

Page 35

Page 36

Page 37

Page 38

Page 39

Page 40

Page 41

Page 42

Page 43

Page 44

Page 45

Page 46

Page 47

Page 48

Page 49

Page 50

Page 51

Page 52

Page 53

Page 54

Page 55

Page 56

Page 57

Page 58

Page 59

Page 60

Page 61

Page 62

Page 63

Page 64

Page 65

Page 66

Page 67

Page 68

Page 69

Page 70

Page 71

Page 72

Page 73

Page 74

Page 75

Page 76

Page 77

Page 78

Page 79

Page 80

Page 81

Page 82

Page 83

Page 84

Page 85

Page 86

Page 87

Page 88

Page 89

Page 90

Page 91

Page 92

Page 93

Page 94

Page 95

Page 96

Page 97

Page 98

Page 99

Page 100

Loading...

Loading...